DIRECTOR: Mark A. Barker

INTERNATIONAL MEDIA DIRECTOR: Anthony Stewart anthony@senglobalcoms.com

EDITORIAL MANAGER: Beatriz Romao beatriz@senglobalcoms.com

DESIGN DIRECTOR: Jana Sukenikova www.fanahshapeless.com

FINANCE DEPARTMENT: Akash Sharma accounts@senglobal.co.uk

RESEARCH & CIRCULATION: Jessica Chapman jessica@senglobalcoms.com

COVER IMAGE: iStockphoto ©

PUBLISHED BY: Senglobal ltd. Unit 5.02, E1 Studios, 7 Whitechapel Road, E1 1DU, United Kingdom

Tel: +44 (0)20 4541 7569 Email: info@senglobalcoms.com www.international-biopharma.com

All rights reserved. No part of this publication may be reproduced, duplicated, stored in any retrieval system or transmitted in any form by any means without prior written permission of the Publishers.

The next issue of IBI will be published in Spring 2023.

ISSN No.International Biopharmaceutical Industry ISSN 1755-4578.

The opinions and views expressed by the authors in this journal are not necessarily those of the Editor or the Publisher. Please note that although care is taken in the preparation of this publication, the Editor and the Publisher are not responsible for opinions, views, and inaccuracies in the articles. Great care is taken concerning artwork supplied, but the Publisher cannot be held responsible for any loss or damage incurred. This publication is protected by copyright.

2022 Senglobal ltd.

Volume 5 Issue 4 – Winter 2022

www.international-biopharma.com

The lab at Riga East Clinical University Hospital provides clinical reporting of infectious diseases, pathology and oncology patient samples. Dr. Girts Skenders and Mr. Renis Zeltmatis shed light on how the COVID-19 pandemic brought significant changes to their hospital laboratory. Upgrading it in the midst of a global pandemic wasn’t ideal but a combination of shared insights and the right instruments helped open the door to success.

Success does not come about by coincidence. Success is an outcome of preparation. When it comes to successful U.S. Food and Drug Administration (FDA) inspection outcomes, preparation is at the foundation. Finding out that the Site is not in a position to meet the Agency’s requirements during the process of the Inspection is not a desirable position for any site. Unsuccessful FDA inspections can impose a lengthy time impact on a company’s strategic plan. Noelle Clifford at Pharmalex explains how to have a positive inspection.

Outsourcing all or part of the pharmacovigilance (PV) and patient safety services required during a project lifecycle is common practice in the current market. Ever evolving demands and increasing regulation presents additional challenges to determining the best solution for your PV and patient services needs. Karen Johnstone and Dr. Sabine Richter at ICON explore opportunities for outsourcing these services, potential models, and best practices for selecting a service provider and establishing a successful relationship.

RESEARCH / INNOVATION / DEVELOPMENT

The ideas behind integrated laboratory informatics are not new, but there are serious questions as to how many organisations are fully, or even partially, realising these benefits. Simon Wood at Autoscribe Informatics will re-emphasise the potential benefits and provide examples of successful digitalisation in the laboratory environment. It will also briefly explore factors that may prevent organisations realising the benefits of innovation.

The silkworm, Bombyx mori, has an interesting defense against bacterial and fungal invasion. This defense is found in the hemolymph and cuticle of the insect, as well as various other insect species as well. The defense mechanism involves a chemical cascade, the pro-phenol oxidase (proPO) cascade, that ultimately results in melanin formation around the foreign matter within the insect’s body. Timothy Francis at FUJIFILM Wako Chemicals outlines the use of SPL in the pharmaceutical industry

Promising broader patient access to critical medicines, biosimilars offer a more cost-effective alternative therapeutic option compared with originator products. With many patents for "blockbuster"

commercial biologics set to expire in the next few years, biopharma developers have become increasingly drawn to the biosimilars market. Understanding the benefits of having more readily available cutting-edge treatment options available for patients, a number of government and regulatory body-backed incentives are being introduced to streamline the biosimilar development process. In this article, Jim McNally and Lynn Kamen BioAgilytix Labs explore the incentives, regulations, and other trends pushing biopharma companies down the biosimilar development route.

The manufacturing and commercialisation of vaccines to tackle COVID-19 took place at an unprecedented speed and on a scale never before seen in the pharmaceutical industry. Billions of doses of effective mRNA vaccines have now been delivered to patients around the world, and Billions more continue to be manufactured. Jon Reed at Recipharm oulines how to the company addresses Product Finishing and Dispensing Challenges for Future Pandemics.

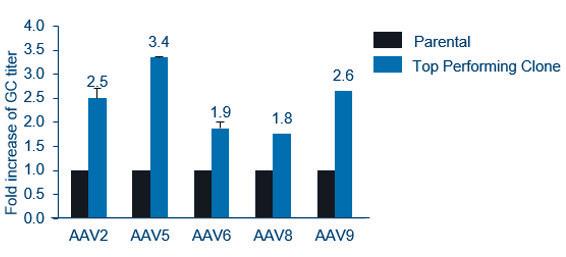

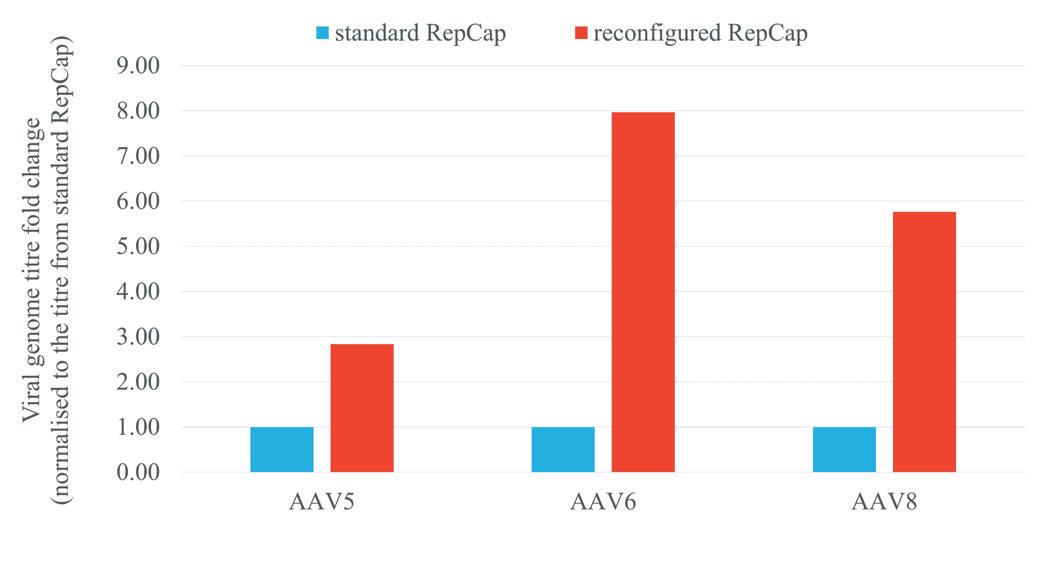

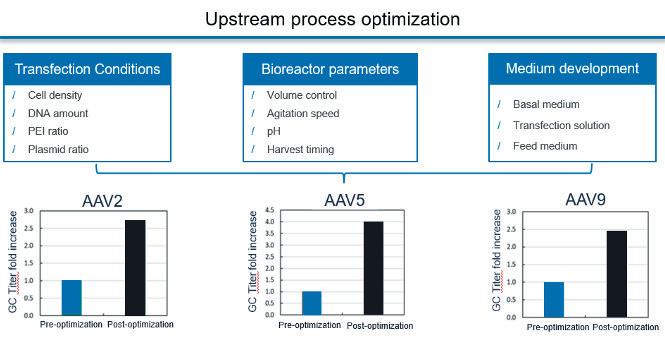

Gene therapy represents an expanding area of medicine with the potential to change the lives of people with life-limiting conditions. As the interest in gene therapies has increased over the years, so has the number of clinical trials, with 372 gene therapy trials active in the first half of 2022. Katie Roberts at OXGENE and Man-Shiow Jiang at WuXi Advanced Therapies explain how to build a AAV manufacturing platform.

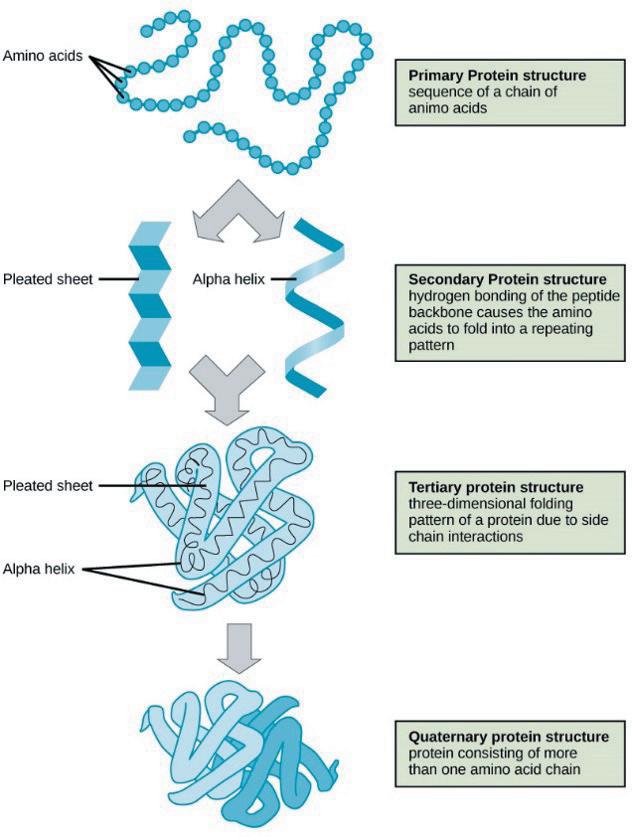

The availability of a wide range of therapeutic biologics has revolutionised modern medicine. Whilst the majority of pharmaceutical drug products remain conventional, small molecule medicines; the emergence of biotherapeutics has allowed for the treatment of many disease areas which were previously out of

reach. Ross Blezard and Mara van Haandel at DFE Pharma analyse some strategies to reduce cold chain burden in biopharmaceuticals.

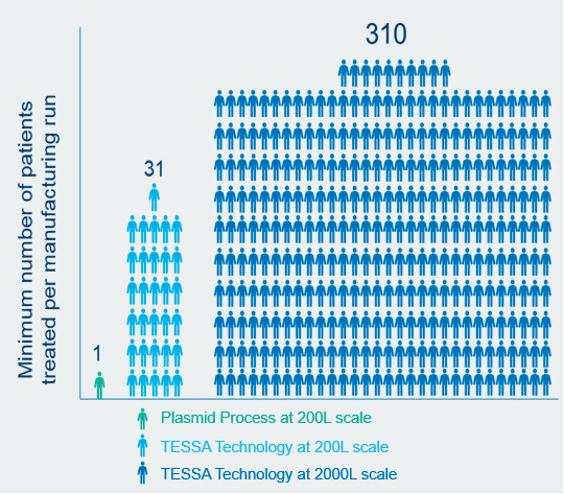

Plasmid-based methods have, for good reason, been a trusted method for the manufacture of adeno-associated viral (AAV) vectors for many years. As 2022 closes and we look towards 2023, plasmids will likely continue to be useful for gene therapies already in the pipeline. The refinement of robust plasmid-based manufacturing platforms, in particular, will further support drug developers as they prepare for the later stages of their therapeutic journey to commercialisation. Katie Roberts at OXGENE discusses the future for gene therapy manufacture.

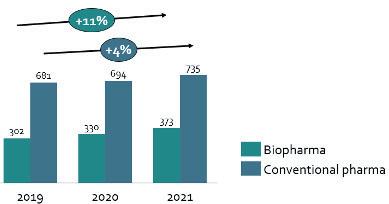

The biopharma industry requires digital transformations to improve efficiencies and deliver critical therapeutics to patients at an accelerated rate. Although great efforts have gone into implementing data-driven business models and processes, the industry has seen mixed results in return, with the digital evolution remaining in the early phases of development. In this article, James Choi at Samsung Biologics delves into the shared vision of biopharma’s leaders to drive a digital transformation in their organisations. He also emphasizes the need for the industry to prepare for the road ahead.

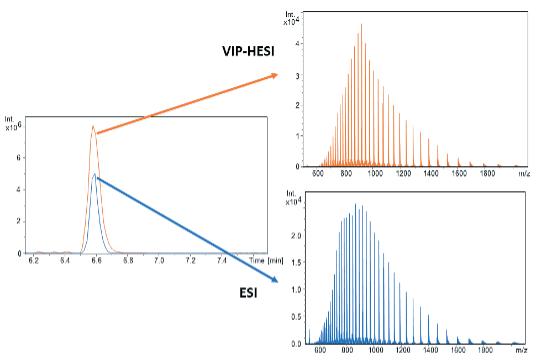

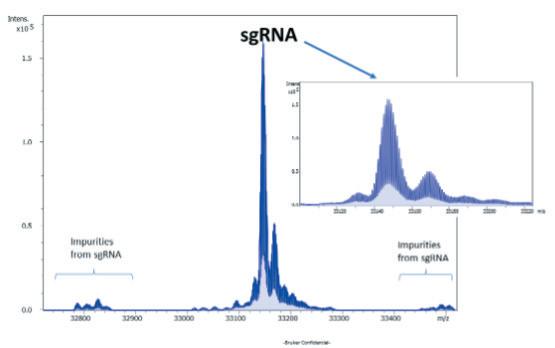

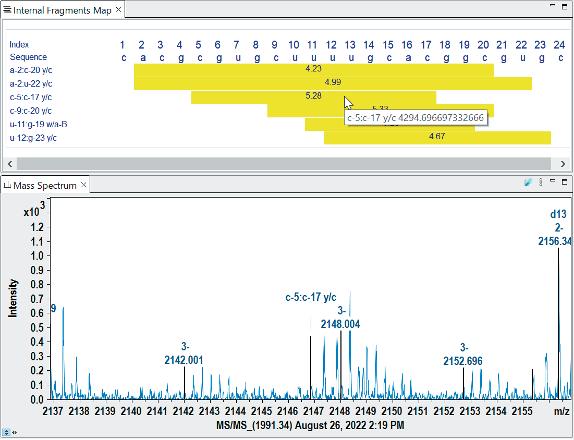

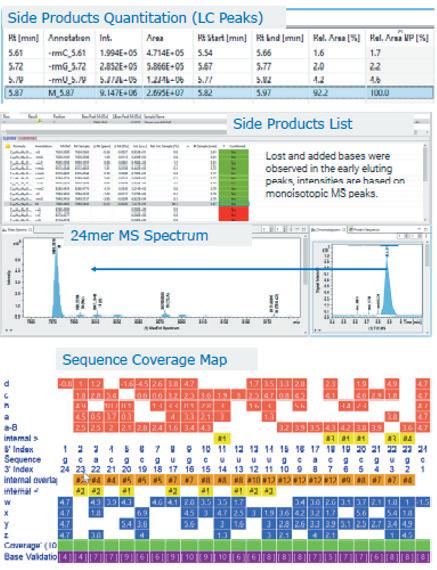

Advancements in gene therapy and the approval of mRNA vaccines have dramatically increased the demand for well-characterised RNA and oligonucleotides in the biopharmaceutical industry. To support this emerging need, researchers have developed new analytical tools to analyse nucleic acid sequences by mass spectrometry. Christian Albers, Detlev Suckau, Guillaume Tremintin and Stuart Pengelley talk about the technological advancements support RNA and oligonucleotide sequence confirmation.

This issue features an interesting lineup of articles dealing with the different aspects from production to analysis of so-called Advanced Therapeutic Medicinal Products (ATMP), a very exciting class of therapies.

Fast and reliable DNA sequencing helped to identify the COVID-virus and find targets for vaccine development. The technology behind DNA sequencing has developed at a remarkable pace. Dr. Girts Skenders and Mr. Renis Zeltmatis at the Riga East Clinical University Hospital explain how they have implemented Next Generation Sequencing (NGS) technologies and how they are putting this technology to use. NGS is also one of the technologies key to the development and QC strategy of ATMP.

Plasmid DNA is the basic intermediate of most ATMPs developed to date. Ensuring and controlling sequence fidelity, relevant isoforms and host-cell contaminants is no easy task. Katie Roberts at OXGENE will talk us through complex steps of pharmaceutical grade plasmid DNA production and what we can expect to see in future.

Plasmid DNA by bacterial fermentation, requires the control of host cell contaminant such as endotoxins and pyrogens, which at even low concentrations can cause severe immune responses in patients. Having assays in place to test for theses complex compounds is mandatory. Timothy Francis at FUJIFILM Wako Chemicals explains how Silkworm Larvae Plasma may be real a alternative to the established LAL testing.

QC-Methods to determine the sequence fidelity and purity of mRNAs derived from plasmids and synthetic oligonucleotides are currently being implemented to support development projects. Mass spectrometry is a versatile tool and can be used to determine the sequence and purity of polynucleotides. Christian Albers, Detlev Suckau, Guillaume Tremintin and Stuart Pengelley report on how advances in mass spectrometry aid sequencing of mRNAs and Oligonucleotides and the current limitation of the technology.

• Ashok K. Ghone, PhD, VP, Global Services MakroCare, USA

• Bakhyt Sarymsakova – Head of Department of International Cooperation, National Research Center of MCH, Astana, Kazakhstan

• Catherine Lund, Vice Chairman, OnQ Consulting

• Cellia K. Habita, President & CEO, Arianne Corporation

• Chris Tait, Life Science Account Manager, CHUBB Insurance Company of Europe

• Deborah A. Komlos, Senior Medical & Regulatory Writer, Clarivate Analytics

• Elizabeth Moench, President and CEO of Bioclinica – Patient Recruitment & Retention

• Francis Crawley, Executive Director of the Good Clinical Practice Alliance – Europe (GCPA) and a World Health Organization (WHO) Expert in ethics

• Hermann Schulz, MD, Founder, PresseKontext

• Jim James DeSantihas, Chief Executive Officer, PharmaVigilant

Nucleic acids and their ability to add or even correct defective genetic information in cells hold a great promise for some of the severest illnesses. Unfortunately, these molecules do not readily enter cells where they are effective nor are they very stable outside of cells. Therefore, means to protect nucleic acids and to facilitate their transport into target cells are developed. Viruses are naturally very good at this, and Adeno-Associated Viruses (AAV) are one of the widely used viral vectors to date. Katie Roberts at OXGENE and Man-Shiow Jiang at WuXi Advanced Therapies will give an insight into how to setup a AVV production platform.

I want to end the foreword of the last issue for this year on an optimistic note. Now, that most of the countries are coming out of the COVID-19 pandemic, it is time to look back at how the pharmaceutical industry in collaboration with heath agencies and legislators managed to respond to the global health crises with both, more conventional and novel vaccines. Although, all stakeholders were operating under high speed and unprecedented public scrutiny to deliver efficacious and safe vaccines for the globes entire population. For vaccines, being a preventative therapy, the safety aspects are probably more important than for any other treatment. As vaccines are administered to principally healthy individuals and to whole populations, to be effective on an epidemiological scale, a thorough risk-benefit evaluation must be made. The past two years with lockdowns, homeschooling and in some cases, the tragic loss of life, has left it´s marks on all of us. Looking back at all of this and to see that we as individual, societies and humanity can achieve, I cannot help but to feel optimistic for the pressing challenges that lie ahead!

Dr. Steven A. Watt, Head of Business Development at A&M STABTEST GmbH• Jeffrey W. Sherman, Chief Medical Officer and Senior Vice President, IDM Pharma.

• Lorna. M. Graham, BSc Hons, MSc, Director, Project Management, Worldwide Clinical Trials

• Mark Goldberg, Chief Operating Officer, PAREXEL International Corporation

• Maha Al-Farhan, Chair of the GCC Chapter of the ACRP

• Rick Turner, Senior Scientific Director, Quintiles Cardiac Safety Services & Affiliate Clinical Associate Professor, University of Florida College of Pharmacy

• Robert Reekie, Snr. Executive Vice President Operations, Europe, Asia-Pacific at PharmaNet Development Group

• Stanley Tam, General Manager, Eurofins MEDINET (Singapore, Shanghai)

• Stefan Astrom, Founder and CEO of Astrom Research International HB

• Steve Heath, Head of EMEA – Medidata Solutions, Inc

SGS Health Science enables the medical and health innovators to deliver life-changing solutions in the quickest, safest and most efficient way, helping improve the lives of many Contact us healthscience@sgs com sgs com/healthscience sgs com/healthcommunity

Dr. Ģirts Šķenders and Mr. Reinis Zeltmatis shed light on how the COVID-19 pandemic brought significant changes to their hospital laboratory. Upgrading it in the midst of a global pandemic wasn’t ideal but a combination of shared insights and the right instruments helped open the door to success.

To develop more agile digital laboratories, QC leaders whose systems have become disconnected will need to reimagine an approach that advances a connected quality ecosystem. This requires thinking beyond specific tools and problems to consider a holistic approach to modernising QC and how it will fit within the organisation's overall technology modernisation efforts.

The lab at Riga East Clinical University Hospital provides clinical reporting of infectious diseases, pathology and oncology patient samples. However, for Dr Ģirts Šķenders, the laboratory’s Development Project Manager, and Laboratory Specialist Reinis Zeltmatis, things became a lot more complicated during the pandemic when the facility upgraded from Sanger sequencingbased approaches to next-generation sequencing (NGS). Fortunately, the duo is accustomed to challenges and problem-

solving and were therefore ideally equipped to lead their team through a successful transition to a new workflow.

The laboratory was originally part of the infectious disease department of the city’s University Hospital. This changed when five hospitals were brought together under the umbrella of the Riga East Clinical University Hospital, now the biggest hospital group in Latvia. Included in this consolidation were several independent laboratories focusing on pathology, oncology and infectious disease.

Although the University Hospital’s lab had been performing Sanger sequencing for around ten years, it only started integrating NGS workflows two years ago. “The plan to begin NGS of oncology and infectious disease samples started back in 2018,” explained Dr. Šķenders. However, some logistical and administrative challenges delayed the delivery of sequencing instruments and reagents.

Fortunately, the hospital received an additional sequencing grant from the Latvian Center for Biomedicine Studies and Research in 2020, which helped accelerate things. “The state decided it needed more sequencing and European governments were concerned about the public impact of COVID-19, so some additional money was given with the aim of increasing essential sequencing capabilities for critical laboratories,” said Dr. Šķenders.

Now, almost two years later, the lab’s workload is still focused on SARS-CoV-2: it analyses nearly 200 samples of the virus and around 12 oncology specimens each week.

Finding the Right Tools for the Job Building NGS workflows into a lab required benchmarking and optimisation. Sample quality control (QC) is a critical part of optimising NGS workflows, especially for labs that analyse formalin-fixed, paraffin-embedded (FFPE) tissue samples. However, a sample QC method was only selected after an investigation into which solutions other clinical researchers found to be the most successful for their genomics labs.

“We checked the other users’ experiences with kits or instruments and tried to choose the ones that had the greatest customer reviews,” said Mr Zeltmatis. The lab eventually settled on the Agilent 4200 TapeStation system.

“The TapeStation system is faster, much easier to use and the precision is much higher than other alternatives, so we can really determine what our average library size is. Using the original platform, we could only guess but the TapeStation system really shows the definitive number.”

Considering the large volume of samples processed weekly, including the additional labour of nucleic acid extraction and sample prep, speed was also a clear benefit. “We are able to

obtain results within 10 to 15 minutes, maximum,” said Zeltmatis. “It’s also simple to learn the workflow. Mix a little buffer with the sample, vortex, and you’re ready to go.”

Although NGS is a recent addition, the team plans to replace all the lab’s current genotyping methods with whole genome sequencing within the next 12 months. There will also be a specific focus on liquid biopsies. “We currently send those samples to external service labs for analysis, but liquid biopsies are a very promising direction, especially for oncology,” explained Dr. Šķenders.

RNA sequencing for oncology, as well as for rare genetic diseases, is another priority. They both agreed that Cell-free DNA and RNA ScreenTape devices will be essential for the more challenging sample types used in RNA sequencing and liquid biopsies.

SARS-CoV-2 may have generated the headlines but the lab has other infectious diseases in its sights. “We are going to do more bacterial work, such as sequencing tuberculosis, which is still an issue in Latvia because of multidrug-resistant cases,” said Dr. Šķenders. “We will also focus on other bacterial isolates and look into the possibility of finding bacterial DNA in the primary samples.”

Dr. Šķenders and Mr Zeltmatis have brought the Riga East Clinical University Hospital a long way in a very short period of time. By using NGS workflows, in conjunction with robust sample QC, they are already starting to unlock valuable insights around disease control.

Ģirts has 15 years of experience of diagnosing tuberculosis and drug-resistant tuberculosis at a National TB reference laboratory. He has participated in in two EU FP7 Collaborative Projects – TB PAN-NET and FAST-XDR-DETECT, has acted as temporary advisor for WHO and ECDC for assessment and optimisation of TB laboratory services in several countries. Research interests: Improvement of tuberculosis diagnostics, tuberculosis epidemiology, TB diagnostics and new TB drug clinical trials.

Reinis Zeltmatis began his career in IT working with medical insurance companies which led to a renewed interest in biology and medicine. Moving into the field of plant genetics, he followed his passion for genetics and medicine into molecular diagnostics. Recent advances in technology led Reinis and a colleague to formed the Sequencing Department as part of the National Microbiology Reference Laboratory at the Latvian Centere of Infectious Diseases in 2018. Since then Reinis has been a part of every field of sequencing performed in the department – from microbiology and SARS-CoV-2 to oncology, with latter becoming his main field of work.

Success does not come about by coincidence. Success is an outcome of preparation. When it comes to successful U.S. Food and Drug Administration (FDA) inspection outcomes, preparation is at the foundation. Finding out that the Site is not in a position to meet the Agency’s requirements during the process of the Inspection is not a desirable position for any site. Unsuccessful FDA inspections can impose a lengthy time impact on a company’s strategic plan.

Those of us who have had the experience of FDA inspections are well aware that they can be challenging. However, the chances of having the inspection process run as smoothly as possible can be greatly improved by implementing the proper preparational tools. In the following article we will discuss a few simple but useful tools and offer guidance that you, and your team, can use to help you set up for success in your next FDA inspection.

First impressions are everything. You have worked hard as a team to get your Site to where it is, now take pride and show it off at its best. It is important that the areas the Inspectors are going to see are clean, tidy and in a state of control. This does not just include the inspection areas, all areas that the Inspectors are going to see need to be treated in the same manner. If your areas are well presented, clean, tidy, and organised this will build the Inspector’s confidence in the Site. Sites that are visually well maintained and well-presented speak to the Site attitude as a whole. Consider the implementation of a 5S program in your area. 5S helps to establish an orderly work environment in addition to improving efficiency. Some helpful tips on how to implement a 5S program can be found here.

This is a common pitfall during inspections. Many observations have been assigned to sites for lack of procedural accuracy. Always be clear and concise in your SOPs. Ensure that the overall requirements of your procedures are described in enough detail

to document the procedural activities. However, it is essential to have the appropriate balance in your level of detail. Do not be tempted to add too much granularity and get into minute detail as you will inevitably be caught out. Extensive detail in procedures opens you up to non-compliance when the Inspector reviews the process.

Be sure to keep on top of periodic review of your procedures. To keep procedures accurate, efficient and effective in terms of their intended use, it is important during this process to involve the people who use those procedures on a regular basis. They can provide valuable hands on experience and insight resulting in robust procedures.

It is important to understand the FDA’s inspection process and it is an expectation from the Inspectors that sites have an understanding of their inspection process. The FDA Website contains some useful guides which can be referred to such as What should I expect during an inspection?. The Site also contains a set of Inspection Guides which are useful in preparation for inspections as they contain reference material that the Inspectors will use during the inspection. These guides will provide information as to what the Inspectors will be looking for, specific to that inspection area.

A good tip is to put together a folder of documents in advance of the Inspection that you anticipate the Inspector may request. This way the documents will be quickly to hand should they need to be provided during the Inspection. For documents that may simply be too large to do this with, compile a categorised list including location, so you can easily find the document. Make sure that you, or the identified SME, are familiar with the documents and prepared for any potential queries that can be anticipated from the Inspectors.

An effective Self Inspection program is vital in preparing the Site for inspection success. Self-Inspections may seem an inconvenience at times, however they are a great opportunity to ensure your area is compliant in advance of inspections and remediate areas of concern. Discuss the Self Inspection in advance with the Self Inspection Team and request a review of any areas of concern within your department. Whilst this may be challenging, it is far more preferable to identify potential deficiencies and resolve them than to have them identified by an Inspector as an observation. An effective Self-Inspection process will help ensure a compliant state within your department and place it in a strong position of inspection readiness.

In recent times where COVID-19 has resulted in travel restrictions and therefore the requirement for virtual audits, inspection skills may not be as honed as they once were, and some personnel may have no direct inspection experience at

all. Self-Inspections are a great training opportunity where you can practice and develop your inspection approach, Use this time to role play, polish your inspection skill set and train in-experienced personnel.

The internal audit schedule needs to be at an appropriate frequency and needs to be effective. Senior management should empower the Self Inspection Team to be able to make effective changes. Rather than simply make recommendations, Internal Inspectors should have the required level of authority to hold functional areas accountable and ensure that they push actions through to completion in order to ensure compliance.

The internal audit program should also be assessed to ensure that the Self Inspections are not only performed on independent functional areas, but also laterally across departments, using a system based approach so that all the interconnected elements between processes are audited.

Each team should review their list of investigations/ discrepancies for their area identifying those they anticipate the Inspector may request to review, or the ones believed to be an area of concern. The person who is likely to discuss the issue with the Inspector should be well versed in all aspects of the investigation. Have all required supporting documentation readily available. Consider putting together a presentation to ‘tell the story’. This can provide clear context to the event should the Inspector take a deep dive into it. This strategy can be applied to not just investigations, but any area of concern. Try to identify other areas that review of an investigation, or similar document, may lead to. An FDA inspection can feel like threads being pulled, leading to larger and larger holes! To prevent this,

make sure that every question arising from the review of any issue, leads to a dead end, with documented information and if required, a documented position or strategy to prevent risk to the product.

Prepare your Team Area Subject Matter Experts (SMEs) should be identified in advance of the Audit. Ensure that they are confident in their abilities to engage with the Inspectors and are well prepared to discuss any areas of concern that may be identified.

Personnel should be appropriately equipped with the tools to interact with the Inspector. Inspection skills and behaviours should be part of an internal training programme and should be retrained upon appropriately . As part of this training try to include role play workshops where personnel present on their particular area of specialty, as they would in a real inspection situation. This can really help to build confidence and therefore result in stronger and more confident responses to the Inspectors queries.

Ensure that personnel are fully trained on the procedures required to complete their tasks and that training records are up to date, reviewed and readily available during the Inspection.

Promoting the correct mindset in this area is also very important. Remember why the FDA are inspecting your Site. They are there to ensure that the products being supplied are safe for the patient; you, your family and your friends. This is a necessary and positive process.

On the Front Line

When speaking with the Inspectors there are a few golden rules that need to be observed:

As the leading supplier of Recombinant Insulin for innovative biologics, we can help you keep development on track and production flowing.

Novo Nordisk Pharmatech A/S remains the best supplier of Insulin Human AF or cell culture processes by providing excellence at every step of the supply chain –beginning with the quality of our insulin sourced directly from Novo Nordisk, the world’s largest producer.

Manufacturing and quality control, precision delivery and a risk mitigation strategy that assures continuous availability are a few of the reasons why you should grow your cells with our insulin.

Learn more about our Insulin Human AF at novonordiskpharmatech.com

• Be prompt with a documentation request. Should the Inspector request a document, provide it as quickly as possible. If it is not available do not evade the Inspector’s request, admit this up front.

• Admit to, rather than hide known deficiencies, the plan for remediation should be prepared during inspection readiness and readily available. It is better to show you have identified issues and have a plan in place to remediate them, rather than hoping an Inspector doesn’t find an issue and give the impression the Site was unaware.

• Provide only the information directly related to answering the Inspector’s question, don’t offer any additional information.

• If you do not know the answer to a question, say so. Tell the Inspector that you will find the answer and come back to them as soon as possible.

• Do not use language like, ‘Sometimes’, ‘Occasionally’, ‘To be Honest’.

• You may find that there are pauses in conversation with the Inspector, do not be tempted to add more information in order to break an uncomfortable silence. Wait for the Inspector to re-initiate the discussion.

• Maintain a very high level of professionalism. Questions should be directed at the auditor in a polite and professional manner.

• Be courteous to the Inspector and do not get into an argument.

Inspectors can vary widely in terms of their inspection style or approach in order to obtain the required information and sometimes those approaches can be testing. If you are finding the interaction with the Inspector challenging, remember the tips above and try to keep in mind that they are just a person, like you, and you are simply interacting with them.

During the course of, and at the end of, the inspection the Inspectors may have a list of observations for the Site. Review these with the Inspector as they arise during the Inspection and attempt to remediate them immediately if this can be achieved. It will show the Inspector that the Site is committed to achieving and maintaining a compliant state. This helps to promote and build a positive relationship with the Agency. Fostering a good relationship with Inspection Agencies is important as it shows the Agency that the site is supportive of the process. This will stand to the site in future inspections.

Sites should strive to be in an audit ready state at all times. This approach not only promotes a constant state of control and continuous compliance but saves much energy and resources in the long run. It also saves your team a lot of pressure and stress by removing the possibility of ‘audit scramble’.

In a hectic inspection it is often easy to forget that not everyone is experienced in the inspection process, some team members may be new to the industry and unfamiliar with inspections. As discussed above, COVID-19 has resulted in the need for many inspections to be conducted virtually meaning that not everyone has had direct interaction with Inspectors. Be mindful of this and offer support/advice where necessary. Also, be

It is advisable, in advance of any upcoming inspections, that you perform some reconnaissance. Complete a review of publications and articles and see what the current trends are in terms of what areas or topics the Agency is frequently looking into during their inspections. Information on FDA observations given to sites, or 483s, can be found on the Agency’s website and can be reviewed according to the industry area and fiscal year. These findings should be communicated across the team so that all are aware of the current trends.

If you happen to have a network of sites within your company, it is in your mutual interest to maintain lines of communication and share your inspection experiences to aid in and support each other’s preparation. Often, when an Inspector discovers a discrepancy at one site they will look for the same at another site.

Noelle, Manager/Consultant in Pharmalex, is a qualified and experienced Microbiologist with a BSc (Hons) in Industrial Microbiology from UCD. She has worked within the pharmaceutical industry for over 15 years in Quality Control roles from ground level through to management. Noelle has worked for several multinational pharmaceutical companies gaining experience with Sterile Products, Dry Powder Inhalation Products, Oral Solid Dosage and Topical Products.

www.qualogy.co.uk

The primary focus of this one-day course is on the implementation of archive systems and procedures within an organisation and the operation of an archive in compliance with GLP. The principles of archiving covered in this course are also relevant for any research or scientific archive.

For further information on courses, dates and costs, please refer to our website: www.qualogy.co.uk/archive-training-courses/

Location Qualogy, in Rushden, Northamptonshire.

of the Archivist and the operation of a GLP archive

The primary focus of this one-day course is on the implementation of archive procedures for clinical trials conducted in accordance with GCP regulatory requirements.

The course provides guidance on the GCP regulations and the specific needs for archiving of Trial Master Files (TMF) and Investigator Site Files (ISF) in compliance with GCP.

For further information on courses, dates and costs, please refer to our website: www.qualogy.co.uk/archive-training-courses/

Location Qualogy, in Rushden, Northamptonshire.

Qualogy’s Regulatory Archive Service is a dedicated solely to the archiving of GxP regulated clients and their material.

Providing a high standard, secure archive facility. We offer a personal service for each client based upon knowledge of the requirements which are then geared to the needs of individual clients

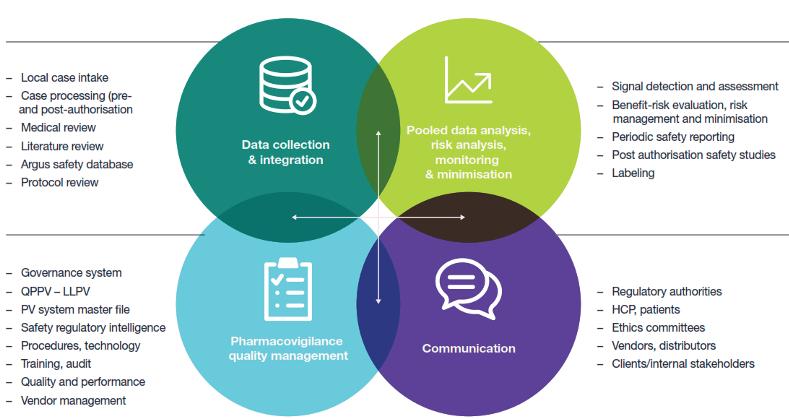

Outsourcing all or part of the pharmacovigilance (PV) and patient safety services required during a project lifecycle is common practice in the current market. Ever evolving demands and increasing regulation presents additional challenges to determining the best solution for your PV and patient services needs. We explore opportunities for outsourcing these services, potential models, and best practices for selecting a service provider and establishing a successful relationship.

Outsourcing pharmacovigilance and patient safety activities has become a standard business practice within a continuously expanding market segment. Innovations and rapid changes in technology and regulatory environments have created opportunities for sponsors to re-evaluate their requirements for successful outsourcing of their pharmacovigilance and patient safety obligations. While outsourcing provides access to unique expertise, specialised intellectual property, multidisciplinary knowledge and an unbiased view, there are certain challenges associated with the increasingly competitive market. These challenges include stricter regulatory environments with variations across the globe, a wider range of safety indicators and a higher demand for transparency that puts added pressure on biotech and pharmaceutical companies, especially within the pharmacovigilance and patient safety scopes.

Choosing a service provider that is a qualified to meet your needs is crucial to the success of your program. Outsourcing PV and patient safety can lower costs for staffing (based on reduced effort), recruitment, management and training. For organisations operating globally in the pre- and/or post-marketing setting, outsourcing PV can also provide improved access to important resources in non-traditional cost-effective regions. With the right service provider, the partnership can result in innovative solutions that maximise the value of the product portfolios while improving patients’ lives. In this article, we explore opportunities for outsourcing these services, potential models and best practices for selecting a service provider and establishing a successful relationship.

Small biotech, mid-size and large pharmaceutical organisations will have differing requirements for outsourcing their PV and patient safety services. At every phase of development, there are opportunities for outsourcing either as a full-service model from phase 1 through post-launch surveillance or as discrete, stand-alone services. Elements such as company size, pharmacovigilance and patient safety department size, in addition to existing license or development partnerships can impact these outsourcing decisions. Any of the services in the figure below can be outsourced individually, in a tailored combination of services or as part of a full-service contract:

Increasingly, pharma companies seek to establish a fit-topurpose, cost-effective operating model for the services they require. Traditional models for outsourcing are either resource-based or activity-based. Resource-based models operate on forecasted project workloads translated to full-time equivalent (FTE) per qualification/role requirements on programs and are cost-effective options for projects with predictable workloads. Activity-based models contain costs which are based on agreed unit pricing and allow for partially allocated resources to support the program. A blended model, leveraging aspects of both the resource- and activity-based models, can be tailored more specifically to the client’s needs. Blended models can provide a cost-effective FTE team to support an agreed baseline workload while more flexible, unitised services support the team during periods of higher volume.

A client’s needs may change over time and the established blended, resource or activity models may no longer fit the program as comfortably. In such situations, operating models require change or adjustment. ICON, for example, has implemented a transformational model with clients to convert them into the best-fit model while maintaining existing team knowledge and supporting business continuity. In any model,

the service provider must be flexible and agile enough to meet the dynamic needs of the client as scopes grow and evolve.

Outsourcing PV and patient safety can yield a mutually successful and positive outcome for the client if the right expectations for partnership are established. To achieve a beneficial partnership, this article provides guidance on:

• Selecting a provider that has the qualifications to perform the service

• Ensuring the contractual agreement and service models cover your needs

• Establishing collaborative partnerships with clear communication and well-defined responsibilities

In a highly competitive marketplace, there are various types of service providers available. The first step in a successful cooperative relationship is selecting a provider that is best suited to your current need as the required pharmacovigilance and patient safety activities can vary significantly. The typical range of service providers includes individual consultants,

specialty CROs, larger full-service CROs, or global service providers under the umbrella of business process outsourcing (BPO). To choose the best provider, we suggest first following these steps to inform your decision-making:

1. Set clear goals and objectives: establish a clear definition of the tasks to be contracted and assess the expertise and the resources required. Then evaluate the potential service providers against these objectives

2. Establish a realistic timeline: plan for enough time to conduct a thorough selection process with clearly defined scopes and appropriately determined outsourcing models

3. Conduct due diligence: we highly recommend checking references for past performance, confirming the provider’s regulatory compliance and comparing the tenure and technical expertise of the senior staff

4. Maintain flexibility: when timelines are tight or scopes are a moving target, communicate openly and stay flexible

Determining a service provider should also include an evaluation of potential business models for the services offered. Choosing a model will depend on factors including the services outsourced, complexity and variability, volume of work and duration of the project. Typical models can include a time and materials contract, fixed unit price or FTE. Time and materials contracts may include a budget cap and are often

good options for ad hoc services. Fixed price contracts serve well on projects that have well-defined scopes over a limited period. For projects with well-defined tasks but undefined or variable volumes of work, clients may opt for an FTE price. Large-scale projects with variability will benefit from a unit price model where the provider can ensure sufficient trained resources are available even when volumes fluctuate frequently and significantly.

Building a strong partnership with the selected service provider can benefit the project through improved communication, increased efficiency and opportunities for innovation. Establishing a collaborative relationship between sponsor and provider begins with clearly defined roles and responsibilities, definitive escalation procedures, a joint governance structure and contingency plans. With these key elements in place, both parties can enter the relationship with more trust and investment in the process.

From this foundation, we suggest investing time and resources into regular oversight committee meetings to deepen the collaboration, harmonise processes and value systems and leverage opportunities for innovation and process optimisation.

Delivering quality services and managing cost remain strong motivators for the common practice of outsourcing pharmacovigilance and patient safety tasks in today’s market. The increasing complexity of clinical studies, higher regulatory PV hurdles, wider range of safety indicators and a higher demand for transparency across the growing global footprint add challenges that push pharmaceutical and biotech companies to rely on outsourcing. With the right service provider, outsourcing provides smarter, leaner, more flexible solutions that contain costs without compromising quality. This article outlined some best practices for outsourcing PV and patient services, evaluating service models, selecting a service provider and establishing a successful relationship to support overall projects.

Karen Johnstone, Executive Director –Customised Solutions Safety and Risk Management, has been with ICON for 20 years with previous positions at GlaxoSmithKline (GSK) and Wyeth. She has held various pharmacovigilance leadership roles providing oversight for safety project management, operations, and project delivery.

Dr. Sabine Richter

Dr. Sabine Richter

Dr. Sabine Richter, Vice President, Pharmacovigilance & Patient Safety, has over 30 years of research experience in the pharmaceutical and CRO industries, and in academia. As Vice President, she is responsible for all aspects of ICON's pharmacovigilance and patient safety services.

• Prefer paper (5 responses – 8%)

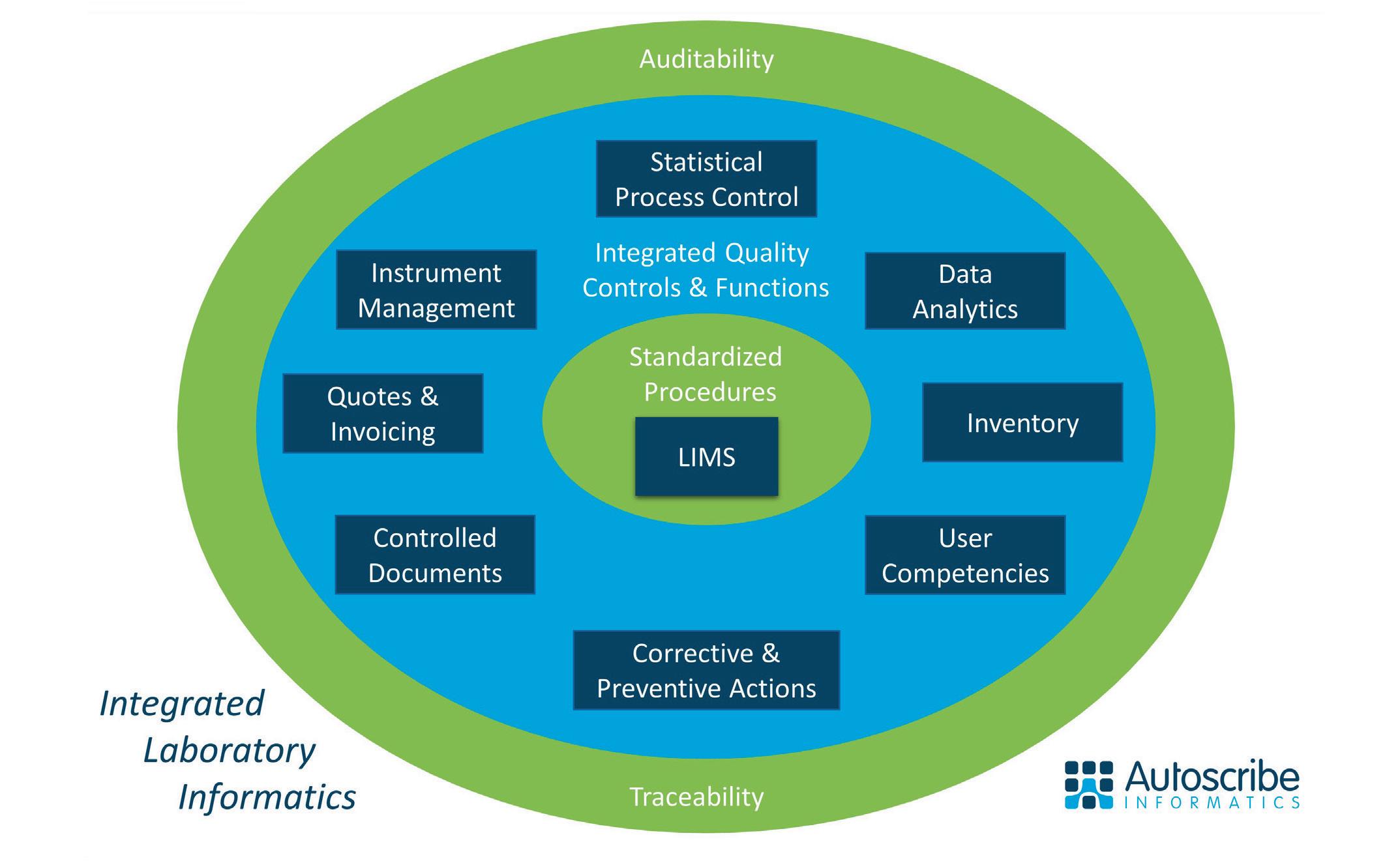

The ideas behind integrated laboratory informatics are not new, but there are serious questions as to how many organisations are fully, or even partially, realising these benefits. This article will both re-emphasise the potential benefits and provide examples of successful digitalisation in the laboratory environment. It will also briefly explore factors that may prevent organisations realising the benefits of innovation.

In the Winter 2021 edition of this magazine Autoscribe Informatics contributed an article titled ‘Digitisation versus Digitalisation – Understanding the Difference and the Role of LIMS in Achieving both’1. In this they described digitisation as the transformation of manual or paper-based operations to a digital format. While it was stated that digitalisation was more difficult to define it was described as the way that the digital environment, as enabled by the process of digitisation, can affect the way we work and do business.

Without doubt digitalisation is currently a hot topic with many articles, conference papers and webinars devoted to the subject. However, there is at least circumstantial evidence that it is a topic that may be more talked about than practiced. This article will outline why this statement has been made and reiterate the potential benefits of digitalisation. It will also identify some of the key barriers to implementing digitalisation in the laboratory that are often associated with an organisation’s resistance to change that can stifle innovation.

Autoscribe Informatics runs regular webinars on topics relevant to laboratory informatics. These are public events open to all. Two recent well attended events have been ‘Utilizing LIMS to Take Your Laboratory Paperless’ and ‘Incorporating ISO 17025 into your laboratory’. In these webinars polls are taken asking questions relevant to the topics, and the answers to these questions can be revealing.

To a question about what the attendees used to manage their lab data the following responses were received to the possible answers:

• We have a LIMS (12 responses – 13%)

• We have a LIMS but still need to use paper (40 responses – 43%)

• We use paper or spreadsheets (41 responses – 44%)

The question was then asked that if they were using paper why they were still using it:

• No funding to buy a LIMS at the moment (29 responses – 47%)

• Our LIMS does not meet our requirements (24 responses – 39%)

• We don’t believe a LIMS can meet our needs (4 responses – 6%)

Asked to select what the benefits of a LIMS might be the following responses were received:

• Automatic creation of Certificates of Analysis (6 responses– 7%)

• Compliance with regulatory requirements (20 responses – 23%)

• Free up laboratory staff time (21 responses – 24%)

• Keep all data in one place (40 responses – 46%)

In the second webinar the following questions were asked

How is your organisation currently managing controlled documents, employee training documentation and issue management or corrective action preventive actions (CAPA)

• Integrated in our LIMS (22 responses – 9%)

• Separate QMS electronic system (95 responses – 38%)

• Spreadsheets or paper based (121 responses – 49%)

• Not managing these (10 responses – 4%)

When asked to select what their organisation’s most significant challenge(s) for audits was, the following response were received (multiple options could be chosen)

• Too many places to look for records selected – chosen by 48% of 200 respondents

• Time required to compile records – chosen by 63% of 200 respondents

• Availability of staff to assist auditor in reviewing records –chosen by 41% of 200 respondents

• Lost/incomplete records – chosen by 34% of 200 respondents

As there were close to five hundred attendees at the first webinar and four hundred at the second it is clear that not everyone responded to the poll questions, however the answers still provide interesting observations on the state of digitalisation within the laboratory environment.

The use of paper records or spreadsheets, possibly in conjunction with an existing LIMS, is still highly prevalent. However, where a LIMS is in place it should be of concern to lab managers and executives that so many do not seem to meet their needs. It would also seem that even digitisation, the first step along the path to true digitalization, has some way to go as so many organisations are still using paper to a greater or lesser extent to manage their lab data and QMS. The need for better access to relevant data and information is clear, with attendees identifying time required to compile records for audit purposes as a significant challenge together with having too many places to look, and lack of resources to look in all these places.

However, the vast majority of respondents have records including controlled documents, training records and CAPA records either in a separate QMS or as a spreadsheet/paper-based system.

The state of true digitalisation would seem to be even worse with only 9% of respondents indicating that their LIMS and QMS were integrated into a single system. This is an area that has the potential to provide many benefits, for example linking training records to LIMS functions to check, in real time, that staff have the correct training to complete the task or linking CAPA directly to sample or batch records within LIMS.

The benefits of digitalisation have been outlined many times before, but what may be missing is evidence of these benefits. With a large installed base Autoscribe Informatics have a number of case studies to draw on. These can provide insights into the benefits that organisations can gain from digitalization of the laboratory environment, and some examples are outlined below. They come from a broad cross section of industries, but the lessons to be learnt are applicable to all organisations with a laboratory, testing or QA/QC function.

A lubricants company that, among other sample types, tests field samples provided by customers replaced a hybrid paper and electronic system and, each day, reduced the time it took a technician to register samples from 5-6 hours to one hour. By integrating their instruments with LIMS and introducing other automation to replace paper-based steps, the number of manual touch points for each sample was reduced from around 11 to 3-4, with an associated reduction in transcription errors and improvement in turn-around time. Finally, having electronic records makes it simple to compare original batch results against results from field samples to see if there has been significant degradation of the product.

Similarly, a rapidly growing UK based specialist testing company needed to replace an existing hybrid paper and Microsoft Access system. As well as improving the sample management workflow and recording of results, the previously manual and time-consuming processes of creating certificates of analysis, customer quotes and invoices as well as the transfer of those invoice to a finance system were automated. Having all the information in a single system also means that required data is instantly available for reporting and audit purposes.

In a specialty chemical company, whose products include pharmaceutical APIs, a paper-based result approval process took 2–3 hours to complete with reactors idle while it was completed. The approval process was digitised, and reactors now rarely stand idle waiting for result approval.

Other examples include a veterinary testing lab that saved 2-3 hours per employee per day during their peak season through improved digitalisation of the laboratory, and a manufacturing organisation where the time to create lot traceability reports in response to customer complaints was reduced from up to two days using the previous paper-based system to a matter of seconds using an integrated LIMS solution. Case studies are available on the Autoscribe Informatics web site.2

It is clear that digitalisation and integration of laboratory operations can bring major benefits to organisations of many different types, but it is also clear that adoption is far from universal and paper-based systems persist. Lack of funding and either a belief that a LIMS cannot meet the organizations needs, or an existing LIMS that doesn’t meet these needs, are reasons cited in our polls for the continued use of paper. However, all too often we see potential customers thinking of buying a LIMS who have not created a compelling business case for the purchase.

Therefore, there is a lack of understanding of why digitisation is needed and little sense of the value of digitalisation. A business case should be the basis to obtain funding and ensure you get a LIMS that meets your needs. However, other barriers may be more difficult to overcome at both an organisational and individual level, and these may include:

• Lack of leadership and support for innovation

• Belief in superiority of existing processes and procedures

• Reluctancy to accept new technology

• Distrust of new technology

• Lack of vision

• Previous negative experience of new technology

• Lack of communication especially of potential benefits

• Unrealistic expectations especially of time required to achieve benefits

These objections can be difficult to overcome but it is worth doing if the true value of digital innovation is to be realised.

Simon Wood PhD, Product Manager at Autoscribe Informatics, has over 30 years' experience in the commercial LIMS environment. He is an acknowledged expert in the field of scientific and laboratory informatics. With a degree in Plant Biology from Newcastle University and a PhD in Mycology from the University of Sheffield, Simon successfully moved into the field of laboratory informatics.

Email: swood@autoscribeinformatics.com

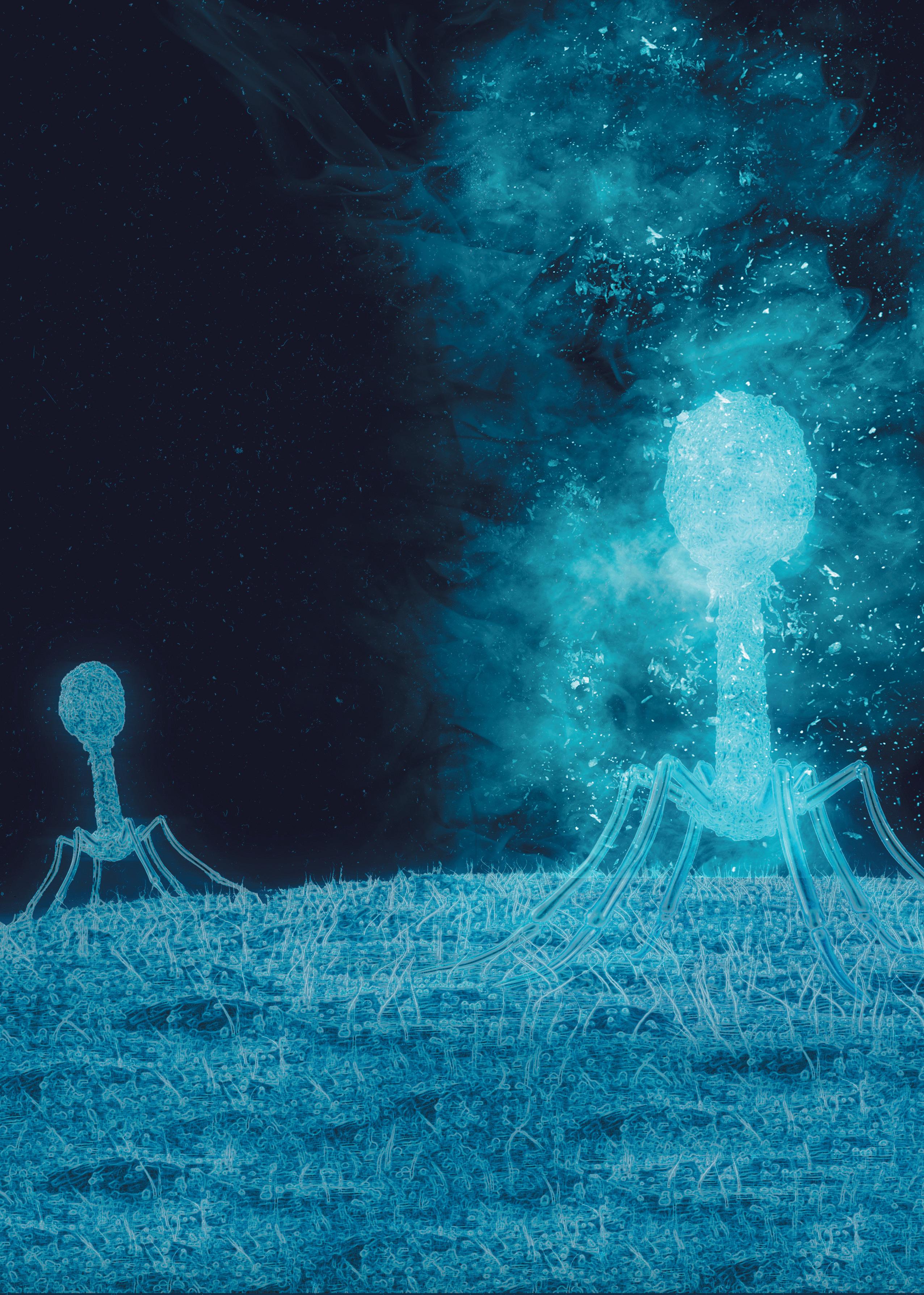

The silkworm, Bombyx mori, has an interesting defense against bacterial and fungal invasion. This defense is found in the hemolymph and cuticle of the insect, as well as various other insect species as well. The defense mechanism involves a chemical cascade, the pro-phenol oxidase (proPO) cascade, that ultimately results in melanin formation around the foreign matter within the insect’s body. When one thinks of melanin, the first thing that that comes to mind is the tanning process in basal skin cells in response to ultraviolet light from the sun. This response is not simply aesthetic – the formation of melanin in human cells is a protective mechanism guarding the cells’ DNA against the ionization dangers of the radiation. In a similar manner, melanin is formed in the insects’ bodies to contain foreign matter.1

Thre proPO cascade can be activated by one of two unique receptor proteins. One is activated by peptidoglycan (PG), and the other is activated by (1, 3)- β-D-glucans (BG). These two molecules have three unique aspects that will be highlighted. First, these molecules are each signature components of different microorganisms. PG is a component of bacterial cell walls, and BG is a component of fungal cell walls. As a result, the proPO cascade is a defense against a wide variety of microorganisms. Second, this defense mechanism is not specific to living organisms. Any piece of bacterial or fungal matter containing PG or BG activates the proPO cascade. Third, these molecules themselves are pyrogens, fever producing substances. These three principles result in a means of detecting the presence of bacteria and fungi rapidly with no need of live cultures or the detection of an immune assay. Collection and formulation of the SLP has resulted in a rapid BG and PG detection method.1

By definition, a pyrogen is any substance that initiates a human immune febrile response. Exogenous pyrogens are therefore foreign substances that initiate a febrile response in the human body. By far, the most problematic pyrogen is bacterial endotoxin – the LPS molecule of the outer membrane of gram-negative bacteria. This pyrogen’s potency as well as resilience to sterilization techniques has prompted the pharmacopeial standard that all parenteral substances need be tested for bacterial endotoxin (USP 85). However, endotoxin is not the only form of pyrogen produced by microorganisms.2

PG and BG are both exogenous pyrogens. BG is easily detected long before the level of pyrogenicity is reached by the LAL assay – the same test method used to detect bacterial endotoxin. PG, however, is not detected by any pharmacopeial test. Problems with PG have arisen. Most notably, PG contamination of Icodextrin used in peritoneal dialysate led to negative patient effects. Since PG is typically not detectable apart from the detection of the living bacteria themselves, residual PG in a product after sterilization has eliminated the living producers of the PG can

remain both problematic and undetectable. The SLP assay can fill this need for both icodextrin production as well as any product that has the potential to lead to a human immune response due to the presence of undetected PG.3

The SLP assay’s unique features has led to the exploration of several novel applications of the assay. Once area that has seen much research in the past two decades has been the potential as a diagnostic tool to provide rapid detection and broad identification of bacterial infections. Meningitis can be bacterial or viral. Studies have indicated that the rate of gram-positive bacteria causing meningitis are on the rise, and the treatment of the disease is specific to the cause of the meningitis.1 The use of the SLP assay along with the LAL assay can be used to detect the presence of bacteria as well as provide the broad classification of gram-positive or gram-negative, all within an hour. Since PG is found in both gram-positive and gram-negative bacteria, the SLP test can be seen as a broad test for the presence of bacteria in general. The application of the LAL test can then be used to judge between the presence of gram-positive and gram-negative bacteria since the LPS molecules are only found in gram-negative bacteria. Studies have shown accuracy rates of around 90% of the SLP in detecting the PG of gram-positive bacteria in this situation.4

However, caution is raised since this test is an indirect means of detecting gram-positive bacteria. Specifically, the presence of peptidoglycan does not perfectly directly align to gram-positive bacteria counts of the sample. Because of this much research is still needed in the potential of the SLP assay in conjunction with the LAL assay to provide rapid, valuable data on the nature of a bacterial infection.5

SLP’s potential in peptidoglycan detection

SLP, as mentioned above, already has a proven track record in fulfilling the need of PG detection in the manufacture of icodextrin for peritoneal dialysis solutions. SLP shows the same potential for any parenteral product that is at risk of harmful effects from PG contamination. In similar manner to the adoption of LAL reagents to fill the need for the test of bacterial endotoxins, the need has already risen for one product, and may arise for other products, for the need to test for PG as an exogenous pyrogen. The risk of undetected PG, although less in magnitude than the risk of endotoxin contamination, is present as a member of the category of exogenous pyrogens.

The potential uses of SLP lead to many areas of manufacturing that may benefit from the use of the SLP assay to ensure that their product contains no peptidoglycan. Potential users could fall in one of three categories. First, manufacturers of products that need a test for bacteria may benefit from the use of the SLP reagent. As a product of bacteria, a test for peptidoglycan may provide a sensitive, rapid test for the presence of bacteria.

Second, as an exogenous pyrogen, manufacturers will want to ensure that their product remains peptidoglycan free as well as endotoxin free. A third potential user of SLP may be research institutes that may wish to explore the potential of the SLP reagent to detect peptidoglycan in a diagnostic setting. The manufacturers and distributors of the SLP reagent, FUJIFILM Wako Pure Chemicals in Japan and FUJIFILM Wako Chemicals U.S.A., are willing to assist and provide samples to any users that may potentially benefit from the adoption of the SLP reagent for the detection of peptidoglycan.6

1.

https://academic.oup.com/femspd/article/28/1/49/486267

2. https://www.usp.org/sites/default/files/usp/document/ harmonization/gen-method/q06_current_webpage_stage_6_ monograph_23_nov_2011.pdf 3. https://www.researchgate.net/publication/9021064_Exposure_ to_the_Peptidoglycan_Contaminant_in_Icodextrin_May_Cause_ Sensitization_of_the_Patient_Maintained_on_Peritoneal_Dialysis 4. https://onlinelibrary.wiley.com/doi/ epdf/10.1111/j.1348-0421.2003.tb03439.x

Timothy Francis is the Technical Specialist for the LAL Division of FUJIFILM Wako Chemicals U.S.A. Corporation. He comes into the Technical Specialist role with 5 years of experience teaching the natural sciences at a college level. He is proficient at taking the complex, technical aspects of a topic and breaking them down into clear, understandable pieces that all connect back to the big picture. He draws upon this experience to provide professional technical support and training for the PYROSTAR™ line and to help you with your technical needs. Outside of the work environment, he enjoys backyard astronomy, disc golf, kayaking, and enjoying time with his wife as they care for their pets.

• Endotoxin-specific reagent eliminates the risk of false positives from (1-->3)ß-D-Glucan

• 100% animal free • Quantitative range: 0.001 to 50EU/mL

• High sensitivity with less lot-to-lot variation

• Stable storage after dissolution (4 hrs. at 2-8°C and 2 weeks at -30°C)

Promising broader patient access to critical medicines, biosimilars offer a more cost-effective alternative therapeutic option compared with originator products. With many patents for "blockbuster" commercial biologics set to expire in the next few years, biopharma developers have become increasingly drawn to the biosimilars market.

Understanding the benefits of having more readily available cutting-edge treatment options available for patients, a number of government and regulatory body-backed incentives are being introduced to streamline the biosimilar development process. In this article, Jim McNally, Chief Scientific Officer and Lynn Kamen, the company's Scientific Officer, explore the incentives, regulations, and other trends pushing biopharma companies down the biosimilar development route.

At the onset of 2010, the biopharmaceutical industry witnessed an unprecedented wave of top-selling drugs reaching their patent expirations. Drug developers reacted quickly, recognising the potential for new biosimilar products when entering a market previously dominated by one player and acting to further establish the biosimilars market. With a total of 26 blockbuster molecule patents set to expire between 2022 and 2026, it can be expected that more developers in biotherapeutics will turn their hand to the biosimilars market.1

The potential to benefit financially from new exposure in the market is not the only driving force toward biosimilars. Lower development costs and more competitive product pricing quickly result in broader patient access to critical medicines. Innovator products that may have previously been too costly to distribute to patients in developing countries widely must make way for these often more affordable alternatives.

With the many advantages that can come from entering the biosimilars market as soon as possible after patent expiration, time is of the essence in what can be expected to be a competitive race to market. If timelines to critical milestones in biosimilar development cannot be accelerated, there is a risk that one of the many competitors will overtake, gaining the market share.

Moving towards an era with a continually steady stream of blockbuster therapeutic molecules coming off patent, biosimilar developers must carefully consider all areas where opportunities for increased speed lie - from process development to bioanalytical assessment. However, the biopharma industry is not alone in the push for more biosimilars to enter the market. Several noticeable trends have begun to emerge, driven by the desire of drug developers as well as government and regulatory

changes to provide a wider patient population access to vital therapeutics.

Policy Changes in the US

One notable trend in the market is the promotion of biosimilar use over innovators through policy changes. An example of this can be seen in the US, where policies have been introduced to provide favourable reimbursement for biosimilars.

In 1992, the US federal government introduced the 340B drug pricing program. The aim of 340B was to facilitate outpatient drug access to uninsured and/or low-income patients by allowing hospitals, clinics, and outpatient facilities to purchase these therapeutics from manufacturers at discounted prices. However, in 2018, the Centres for Medicare and Medicaid Services (CMS) significantly reduced drug reimbursement for therapeutics purchased through the 340B drug pricing program. These Medicare cuts severely impacted sales of both innovators and biosimilars, discouraging developers from entering the market.

In 2021, policy changes in the US awarded biosimilars a "pass-through status". This means that for 340B-designated hospitals (those recognised by Section 340B of the Public Health Service Act to care for many uninsured and low-income patients), biosimilars are now reimbursed at a higher rate than before. Now, biosimilars are reimbursed at a rate of average sales price (ASP) plus 6%, as opposed to the previous rate of ASP minus 22.5% which still applies to the innovator products.2

This policy revision has completely changed the face of the biosimilars market, incentivising 340B-designated hospitals to prescribe biosimilars over innovator products. However, there has been some backlash from developers of originator products claiming that biosimilars should not be awarded pass-through status as they are highly similar to existing products rather than being "innovative". Despite this, these policy changes are likely to be retained and continue to help patients access critical therapeutics.

Improved patient access to biological drugs is not only being facilitated in the US but is now predicted to be seen globally through more streamlined methods of biosimilar approval. The World Health Organization (WHO) is revising its 2009 guidelines for developing biosimilars following scientists highlighting the need for policies to effectively make biosimilars less costly to attain.

The 2009 guidelines were introduced as a "living" document, providing scientific principles and a stepwise approach to demonstrate the similarity between a biosimilar and the originator. The WHO Committee recommended a revision of the guidance in 2020 to evaluate new developments and identify areas where guidance could improve flexibility without compromising its basic principles.

The revisions propose that if biosimilarity can be inferred from other parts of the comparability exercise, an "adequately powered" comparative efficacy trial may not be necessary.3 This means that the large and often expensive Phase III trials previously required to demonstrate confirmatory efficacy could be forgone with suitable alternatives, effectively reducing development and manufacturing costs.

The WHO has highlighted that the decision to revise these guidelines is to reflect the anticipated increase in biosimilar availability, leading to increased competition and decreased pricing, which should improve access to biosimilar products.

With WHO guideline revisions remaining on the horizon, for now, some developers are aiming to outsource to Australia, where clinical trials can be conducted under a streamlined timeframe and at a lower cost.

Currently, Australia offers developers increasingly attractive tax incentives that aim to enable innovation and growth by offsetting some of the costs of certain R&D activities. This means that some biopharma companies are eligible to receive a tax rebate of up to 43.5% on clinical trial-related R&D expenses.4

Relief of the biosimilar clinical trial burden is further supported by the flexibility of the Australian clinical trial process, which offers increased speed while achieving comparable quality to data sourced from US clinical trials. In a market where accelerated timelines to market can make or break gaining a market share, it is not surprising that more than 50% of global clinical trials have treatment sites in the Asia-Pacific region.

With these incentives and benefits set to drive developers towards an increasingly cost-effective biosimilars market, those taking on the challenge will need to carefully consider options that can minimise delays and compress timelines. If not, there will be a risk of missing out due to growing competition.

Speed to market requires development programs that can operate under compressed timelines while minimising delay risks. A key element that must be considered to achieve this is the need for thorough and complete assay development and validation of bioanalytical assays that support biosimilar programs.

Initial assay development and validation of bioanalytical assays supporting a biosimilar program must also be thorough and complete. This will involve incorporating all necessary evaluations to assess critical program characteristics, ultimately allowing for meaningful interpretation of necessary comparability study data.

As process development and analytical method development typically go hand in hand, appropriately designed and robust assays will be required promptly to avoid bottlenecks and process hold-ups. However, analytical development and validation take time, especially if platforms or basic methods do not already exist. Relying on support from those with analytical

expertise and experience in development and validation could prevent a product from being delayed on its journey to market and potentially missing the opportunity for success.

As the patents for approved blockbuster drugs naturally come to an end, the desire for increased patient accessibility is being further facilitated by regulatory revisions, policy changes, and reduction in development costs. Offering attractive prospects for financial gain, the biosimilar market will likely continue to swell, with competition translating into a reduced cost burden for patients.

However, being first to the post in the race to market is no simple feat. Biosimilar developers will need to contemplate how processes can be accelerated without detrimentally impacting safety and efficacy. One important area that cannot be overlooked is bioanalytical development, where the results of the assays performed will influence the determination of whether the drug is "highly similar" enough to be considered a biosimilar.

1. https://www.statista.com/statistics/1247142/expiring-patentsblockbuster-small-molecule-drugs-worldwide/

2. https://www.ropesgray.com/en/newsroom/alerts/2022/06/ Supreme-Court-Overturns-Reduction-in-Reimbursement-forOutpatient-Drugs-Purchased-by-Hospitals

3. https://cdn.who.int/media/docs/default-source/biologicals/ who-guidelines-on-evaluation-of-biosimilars---4-nov-2021. pdf?sfvrsn=f17799ae_5

4. https://www.svb.com/industry-insights/healthcare-life-science/ the-advantage-of-oz-offshore-tax-rebates-for-lshc-rd-inaustralia#:~:text=Key%20Takeaways,and%20accelerate%20 time%20to%20market.

Jim McNally, Ph.D., Chief Scientific Officer has an extensive background in bioanalytical assay development and program leadership spanning nearly 20 years working in the pharmaceutical and biotechnology industry.

Lynn Kamen is a Scientific Officer at BioAgilytix. She earned her Ph.D. in Immunology at the University of Michigan and completed a postdoctoral fellowship in immunology at the University of California San Francisco. Lynn has over a decade of experience working in drug development, from early target discovery through clinical development for both large and small molecules at several companies including Portola Pharmaceuticals, and Alector. More recently, Lynn was a principal scientist at Genentech where she supported the in vitro biological characterization of large molecules and lead the development of immunogenicity assays including ADA, NAb and immunogenicity risk ranking assays. She is co-lead of the AAPS NAber working group and member of the AAPS NAb drug tolerance sub-team.

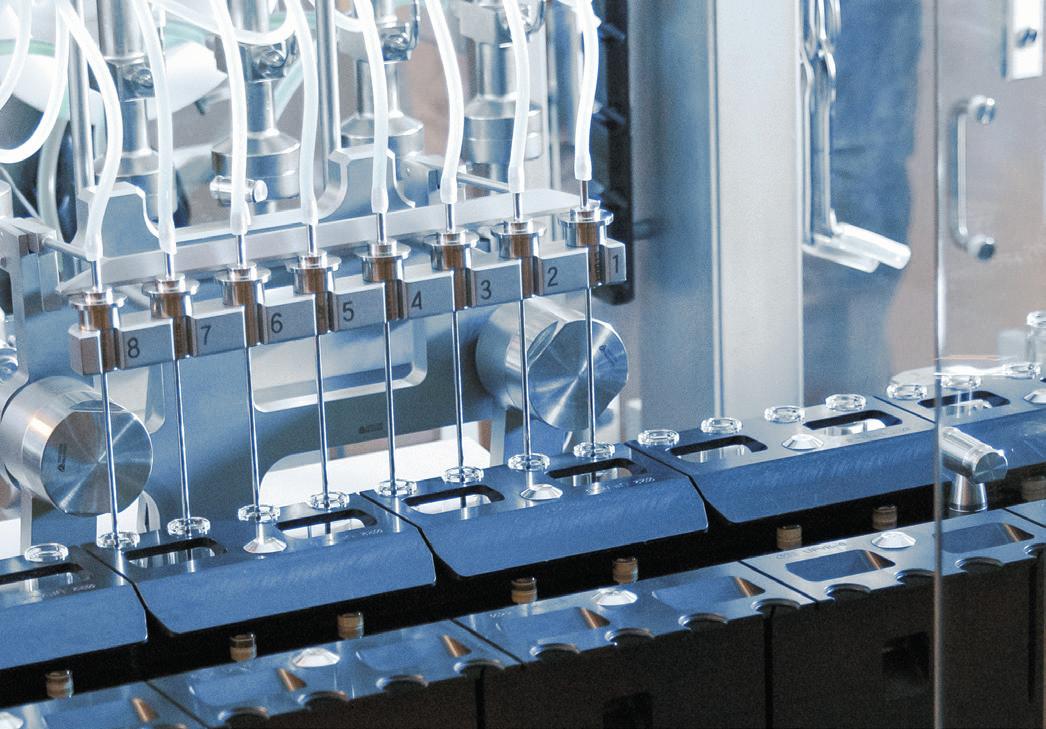

The refinement of sterile manufacturing processes had a central part to play in enabling the pharmaceutical industry to successfully deliver billions of doses of COVID-19 vaccines to tackle the coronavirus pandemic. But, are there further efficiency savings that can be made to enable an even faster response in the future? Jon Reed, Head of Strategy, Recipharm argues “yes”.

The manufacturing and commercialisation of vaccines to tackle COVID-19 took place at an unprecedented speed and on a scale never before seen in the pharmaceutical industry. Billions of doses of effective mRNA vaccines have now been delivered to patients around the world, and Billions more continue to be manufactured.

Overall vaccine spending in 2021 has been higher than any other year on record,1 and total cumulative expenditure for the COVID-19 vaccine is projected to reach $157 billion by 2025.2

The last 24 months have demonstrated the value of mRNA vaccine technology. Harnessing messenger RNA (mRNA) technology and commercial manufacturing partnerships, pharma companies were able to accelerate development and deliver an effective mRNA-based response to the virus. They have shown how the pharmaceutical development and manufacturing process can be taken to new levels of speed and efficiency, all

while maintaining optimum levels of sterility required for vaccine production.

In addition, they highlighted the importance of partnerships with contract development and manufacturing organisations (CDMOs). These outsourcing partners were able to provide ready-made sterile processing infrastructure for large-volume aseptic fill and finish of the vaccines. For example, with the help of their commercial partners, Moderna and Pfizer/ BioNTech have been able to deliver more than 4 billion doses to patients to date. The support of experienced sterile processing specialists with aseptic manufacturing capabilities was essential, providing pharmaceutical companies with immediate access to the infrastructure needed to develop mRNA vaccines and commercialise them successfully.

Nevertheless, the success of the COVID-19 vaccine roll-out does pose a challenge for pharma companies and their outsourcing partners when developing new vaccines and biopharma treatments for the next influenza or coronavirus outbreak. The general public, investors and other key stakeholders now have heightened expectations about what the industry can achieve and how quickly they can deliver. As such, there is pressure on pharma companies to achieve even greater speed and effectiveness next time.

With this in mind, companies must reflect on what they got right and what went wrong during the vaccine drive over the past year to ensure they are well prepared for future wide-scale drug developments.

Having received both EU and FDA approvals for its COVID-19 vaccine, a developer was poised to commercialise its mRNA vaccine candidate and to distribute it to global healthcare providers (HCPs) as quickly as possible. In keeping with contemporary drug development and commercialisation business models, the decision was made to outsource to Recipharm and two other external manufacturing partners to deliver the capabilities and capacity to fill and finish billions of doses of its vaccine before the end of 2021.

As one of the two mRNA vaccine candidates approved to fight the current strain of COVID-19, this vaccine developer needed to commercialise its formula with minimal delay. Once engaged, Recipharm defined the capacity and capabilities it would need to fill, finish and package the vaccine, enabling it to meet the company’s ambitious commercialisation goals.

Recipharm also had to work flexibly to overcome the temperature requirements – a maximum of 96 hours was allowed from the thawing of the drug substance to the final freezing of the drug product in secondary packaging. Exposing the formulation to room temperature conditions for longer than this period would impact stability and in turn efficacy of the vaccine.

The many advances the pharmaceutical industry made in its efforts to tackle coronavirus resulted in many difficult lessons. Nevertheless, this education has been invaluable, delivering a new development paradigm with better practices, new efficiencies and technologies. For Recipharm, the features of this new paradigm include:

• Capability must be flexible and adaptable

A crucial asset for any future large-volume sterile processing project is flexible and dynamic capacity. During the COVID-19 pandemic, existing sterile filling infrastructure had to be upgraded and changed over rapidly to support the filling of large vaccine batches.

In addition, many new lines had to be constructed from the ground up to expand capacity. Recipharm worked with a supplier of prefabricated modular sterile production lines to deliver additional vaccine filling capacity at its site at Monts, France, within months instead of years, in order to support a COVID-19 vaccine developer.

Now that the intensity of COVID-19 vaccine production is diminishing, these lines – new and old – are being changed over to support new projects. Flexibility is crucial to enable the rapid and efficient transitioning of sterile filling lines to new projects during “normal” non-pandemic conditions. This can ensure the new infrastructure delivers value for the industry day-to-day, while also making sure required capacity is on hand in the event it is needed for a future outbreak.

• Sterile filling infrastructure needs to handle a diversity of packaging

To support with flexibility, sterile filling capacity needs to be capable of handling a diverse array of primary packaging ranging from vials and ampoules to pre-filled syringes and cartridges for auto-injector devices. This is vital to enable sterile fill and finish infrastructure to be easily upgraded and changed over either to ramp up vaccine production in an outbreak situation, or to allow production of new injectable products in non-pandemic conditions.

Digital automation and adaptable processing equipment can help achieve this diversity in the future, enabling CDMOs and other manufacturers to deliver sterile filling support to any project that needs it.

Knowledge sharing of process performance is key

Another key lesson from the COVID-19 is the importance of collating and sharing insight into process best practice to support

companies in delivering high-quality vaccine doses as quickly and efficiently as possible.

For each COVID vaccine, the product’s chemistry and formulation attributes had to be carefully evaluated, then optimised during manufacturing to minimise dead volume and to enhance the efficiency of process flows.