DIRECTOR: Mark A. Barker

INTERNATIONAL MEDIA DIRECTOR: Anthony Stewart anthony@senglobalcoms.com

EDITORIAL MANAGER: Beatriz Romao beatriz@senglobalcoms.com

DESIGN DIRECTOR: Jana Sukenikova www.fanahshapeless.com

FINANCE DEPARTMENT: Akash Sharma accounts@senglobal.co.uk

RESEARCH & CIRCULATION: Jessica Chapman jessica@senglobalcoms.com

COVER IMAGE: iStockphoto ©

PUBLISHED BY: Senglobal ltd. Unit 5.02, E1 Studios, 7 Whitechapel Road, E1 1DU, United Kingdom

Tel: +44 (0)20 4541 7569 Email: info@senglobalcoms.com www.international-biopharma.com

All rights reserved. No part of this publication may be reproduced, duplicated, stored in any retrieval system or transmitted in any form by any means without prior written permission of the Publishers.

The next issue of IBI will be published in Winter 2022.

ISSN No.International Biopharmaceutical Industry ISSN 1755-4578.

The opinions and views expressed by the authors in this journal are not necessarily those of the Editor or the Publisher. Please note that although care is taken in the preparation of this publication, the Editor and the Publisher are not responsible for opinions, views, and inaccuracies in the articles. Great care is taken concerning artwork supplied, but the Publisher cannot be held responsible for any loss or damage incurred. This publication is protected by copyright.

2022 Senglobal ltd. Volume 5 Issue 3 – Autumn 2022

Establishing a foundation for proactive quality requires taking a cross-functional view of processes and documentation and then streamlining and standardising them. Some are starting efforts in the QC lab and with validation. Robert Gaertner at Veeva Vault Quality will focus on two critical areas that are receiving more attention: improving quality control laboratories, processes, and systems and establishing paperless validation management.

According to Retraction Watch, over 250 papers regarding COVID-19 published since the start of the pandemic have since been retracted. While retractions are an acknowledged necessity for academic journals, the growing justifications demand attention. Much focus is concentrated on checking the text of manuscripts, but in the digital age images are often more important when conveying results to readers. Dr. Dror Kolodkin-Gal at Proofiger Ltd. discusses the importance of image integrity and common sources of issues.

There is growing excitement about the potential shown by cell and gene therapies, particularly in rare diseases. First, though, these therapies face challenges both in development and in aligning to regulatory guidance that was established long before the advent of advanced therapeutic medicinal products (ATMPs). Francesco Lanucara at PharmaLex explores the challenge of navigating guidelines that don’t always reflect the complexity of ATMPs and the importance of achieving regulatory convergence across different regions.

Extractable and leachable studies on primary packaging systems are well established in the pharmaceutical industry. For extraction studies, guidelines and best practice guides mandate a worst-case approach, taking the active, the formulation and the container closure system into account. However, an assessment of the proteinreactivity of extractables are not in the scope of standard extraction procedures. André Stratman, et al at A&M Stabtest discusses a proposed modification of the protein-reactivity screening, by adding an electrochemical oxidation step, to not only evaluate extractables, but to also see, if there is a subset of extractables, which oxidized derivatives have protein reactive properties.

Since May 2022, Medicilon has successfully assisted no less than ten ADC drugs on their path to approval for clinical use, and it’s committed to continuously improving the research capabilities of ADC drugs. As a matter of fact, half of these drugs target the protein HER2 (human epidermal growth factor receptor 2), member of the HER family of membrane tyrosine kinases, developed for many years as an important target in breast cancer treatment. The design idea of the ADC drugs is to couple antibodies with cytotoxic drugs, to simultaneously exert the high specificity of antibodies and the high toxicity of cytotoxic small molecules. The emergence

www.international-biopharma.com

of ADC drugs fills the gap between antibody drugs and traditional chemotherapeutic drugs, increasing the specificity of drugs and improving the therapeutic window.

The pandemic laid bare inefficiencies and vulnerabilities across laboratory operations where global supply chain issues, alongside high testing volumes, and the demand for faster turn-around-times disrupted the pace of innovation and productivity. May Huxley and Robin Aris at Synergy explore new innovative models in scientific services are helping laboratory operations advance, while minimising risk and returning time back to science.

The biologic market has grown expediently over the past few years, driven not only by the pandemic but also by the increasing demand for innovative therapies, the continued rise in chronic disease areas such as oncology and the loss of patent exclusivity of leading biologic drugs. That has led to rapid growth of aseptic processing, which is expected to reach $24.36 billion by 2031, growing from $10.63 billion in 2020, witnessing a CAGR of 7.9% (2021–2031). Tom McGrath at PCI Pharma Services notes that with the pharmaceutical industry’s growing pipeline of biologics, the need for technically advanced manufacturing and specialized packaging support has grown considerably.

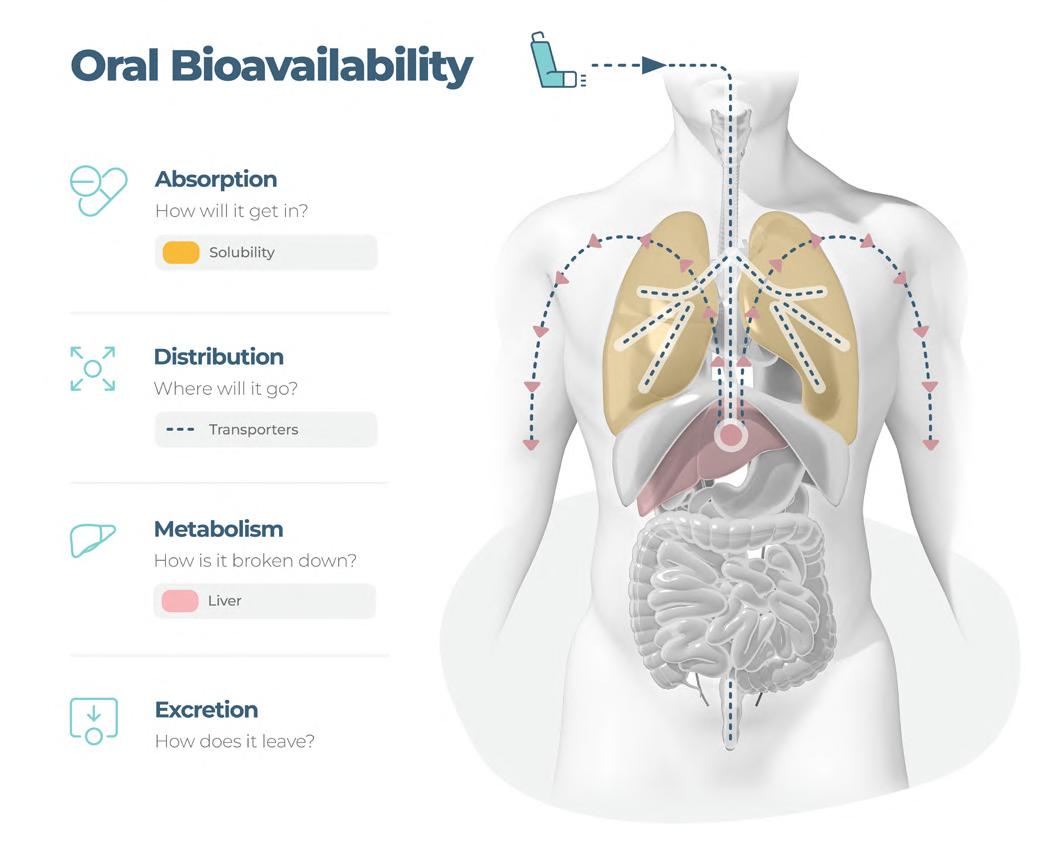

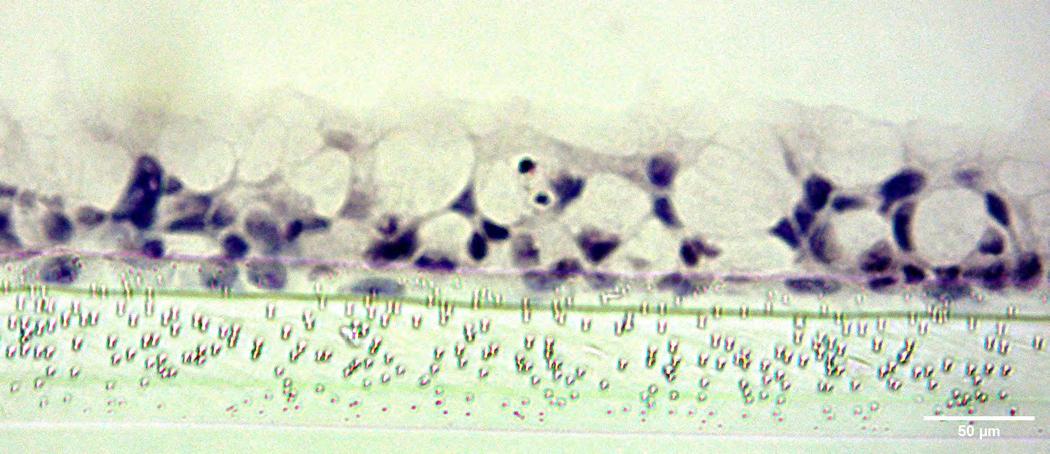

The delivery of therapeutics by inhalation is a medical process dating back thousands of years. The first written evidence of this can be found ca. 1550 BC in Egypt, where vapours of the black henbane plant were used to treat patients with breathing difficulties. We now know this vapour likely contained anticholinergic chemicals similar to those now used in modern inhalers to reduce inflammation and bronchoconstriction in the airways. Despite major advances over the past three millennia in the treatment of pulmonary disease patients with inhaled medications, there is still no single therapy that controls the underlying lung disease, only temporary, symptom management-based approaches. Emily Richardson at CN Bio Innovations outlines the future of inhaled medication testing.

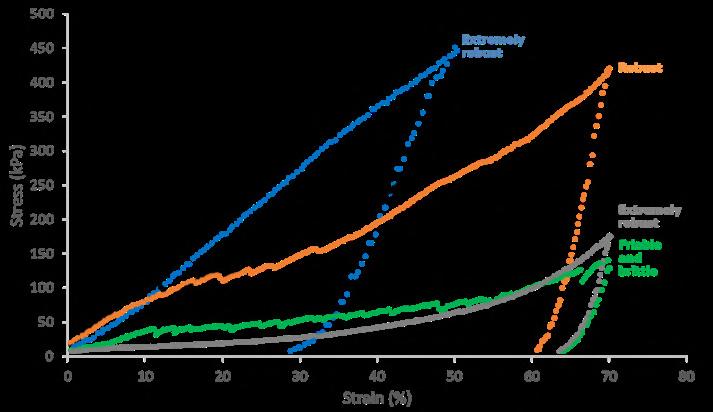

The development of lyophilised products helps reduce the impact of cold chain management from refrigerated warehouse to point use. These products, typically, benefit from lower shipping costs, simplify product use, and provide a longer shelf life within the diagnostics, biologics, pharmaceuticals and nutraceutical industries. Biopharm Group explains the importance of Lyobeads and using the MicroPress to determine quality metrics.

are Scientific Protein Laboratories.

over

years of expertise in development and cGMPcompliant manufacturing,

have become a trusted global source for innovation, customization, and

manufacturing of high quality

Custom process development

supply chain

naturally derived pharmaceutical

I am particularly pleased to see the that this issue features an article about antibody-drugconjugates and to have Medicilon sharing their experience in the ADC field. The development of ADCs is a complex business The production and QC analysis of monoclonal antibodies alone is challenging, but the addition of a suitable linker and toxin payload to the antibody, adds to the complexity. Identifying CDMOs capable of handling ADCs is another challenge. As many CMOs for antibody production are not necessarily particularly experienced in the CMC aspects of drug conjugation, let alone have the capability of handling highly potent toxins.

Complex molecules like ADCs, may require the implementation of different production sites and QC laboratories often located on different continents. This poses challenges in managing the overall quality of these products. Therefore, it is important to implement proactive quality management systems to improve and streamline processes and systems early on. A key feature of successful multi-site operation is to have paperless systems in place. Robert Gaertner gives an insight into the systems offered by Veeva Vault Quality to overcome these challenges and his expertise in implementing proactive quality management systems.

The COVID-19 pandemic has taught us all lessons about the vulnerability of supply chains of, products and materials our lives and businesses depend on, but also on the supply and integrity of reliable scientific information.

In times where information can be distributed to a global audience with a tap on a screen it becomes increasingly difficult, to scrutinize information for its accuracy and authenticity. Images and figures conveying scientific information need to be accurate and unambiguous, so that cannot be taken out of context support “alternative” narratives. Dr. Dror Kolodkin-Gal from Proofiger Ltd talks about the importance of image integrity and why we should not only scrutinize scientific texts but also images and figures.

Laboratories around the world are still facing a disruption of supplies. In the past months many organizations had to spend

• Ashok K. Ghone, PhD, VP, Global Services MakroCare, USA

• Bakhyt Sarymsakova – Head of Department of International Cooperation, National Research Center of MCH, Astana, Kazakhstan

• Catherine Lund, Vice Chairman, OnQ Consulting

• Cellia K. Habita, President & CEO, Arianne Corporation

• Chris Tait, Life Science Account Manager, CHUBB Insurance Company of Europe

• Deborah A. Komlos, Senior Medical & Regulatory Writer, Clarivate Analytics

• Elizabeth Moench, President and CEO of Bioclinica – Patient Recruitment & Retention

• Francis Crawley, Executive Director of the Good Clinical Practice Alliance – Europe (GCPA) and a World Health Organization (WHO) Expert in ethics

• Hermann Schulz, MD, Founder, PresseKontext

• Jim James DeSantihas, Chief Executive Officer, PharmaVigilant

considerable resources to mitigate or overcome shortcomings of supplies by either finding alternative sources or implementing stocks. Many organizations found that dealing with these situations disrupted or delayed necessary innovation and productivity. May Huxley and Robin Aris at Synergy explore new models in scientific services to regain lost resources to advance lab operations and scientific innovation.

The first available COVID vaccinations brought to light how drug supply and global availability is influenced by defined storage and shipping condition. Therefore, the handling conditions of a drug should be addressed early on in development and therefore finding ways to enhance thermal stability e.g. by lyophilization should be explored. Defining the right conditions to ensure consistent quality of lyophilizates is challenging. XXXX at Biopharm highlights how Lyobeads and MicroPress can help to determine quality metrics.

The efficient co-development of a pharmaceutical formulation and application device is key to the success of inhalable drug development. To support the development process fast access to analytical data about aerodynamic particle size distribution, delivered dose and dose variability is important. Emily Richardson of CN Bio Innovations shares her insight on the future of inhaled medication testing.

Recent advances in cell and gene therapies offer a chance to not only treat but cure diseases like cancer or even genetic disorders. These revolutionary treatments will force pharmaceutical companies, clinics and regulators to partly redefine the quality rule book. But in the meantime Francesco Lanucara at PharmaLex can offer some guidance on how to play by the rules initially defined for small molecule and biomoleculebased drugs.

Lastly, A&M STABTEST proposes a novel approach to simulate aging-related effects on extractables to evaluate their potential for future protein reactivity.

Dr. Steven A. Watt, Head of Business Development at A&M STABTEST GmbH• Jeffrey W. Sherman, Chief Medical Officer and Senior Vice President, IDM Pharma.

• Lorna. M. Graham, BSc Hons, MSc, Director, Project Management, Worldwide Clinical Trials

• Mark Goldberg, Chief Operating Officer, PAREXEL International Corporation

• Maha Al-Farhan, Chair of the GCC Chapter of the ACRP

• Rick Turner, Senior Scientific Director, Quintiles Cardiac Safety Services & Affiliate Clinical Associate Professor, University of Florida College of Pharmacy

• Robert Reekie, Snr. Executive Vice President Operations, Europe, Asia-Pacific at PharmaNet Development Group

• Stanley Tam, General Manager, Eurofins MEDINET (Singapore, Shanghai)

• Stefan Astrom, Founder and CEO of Astrom Research International HB

• Steve Heath, Head of EMEA – Medidata Solutions, Inc

We are a global Contract Testing Development and Manufacturing Organization (CTDMO) providing strategic partnership to cell and gene therapy pioneers

Your single supplier from discovery to commercialization

Work with us to accelerate your time to market

Advanced technologies, manufacturing and testing solutions

Promoter and capsid optimization and cell line development

Custom and off-the-shelf plasmid manufacture and supply

Optimized platforms for viral vector and cell therapy manufacture

analytical development and testing services

Regulatory support packages

To view more,

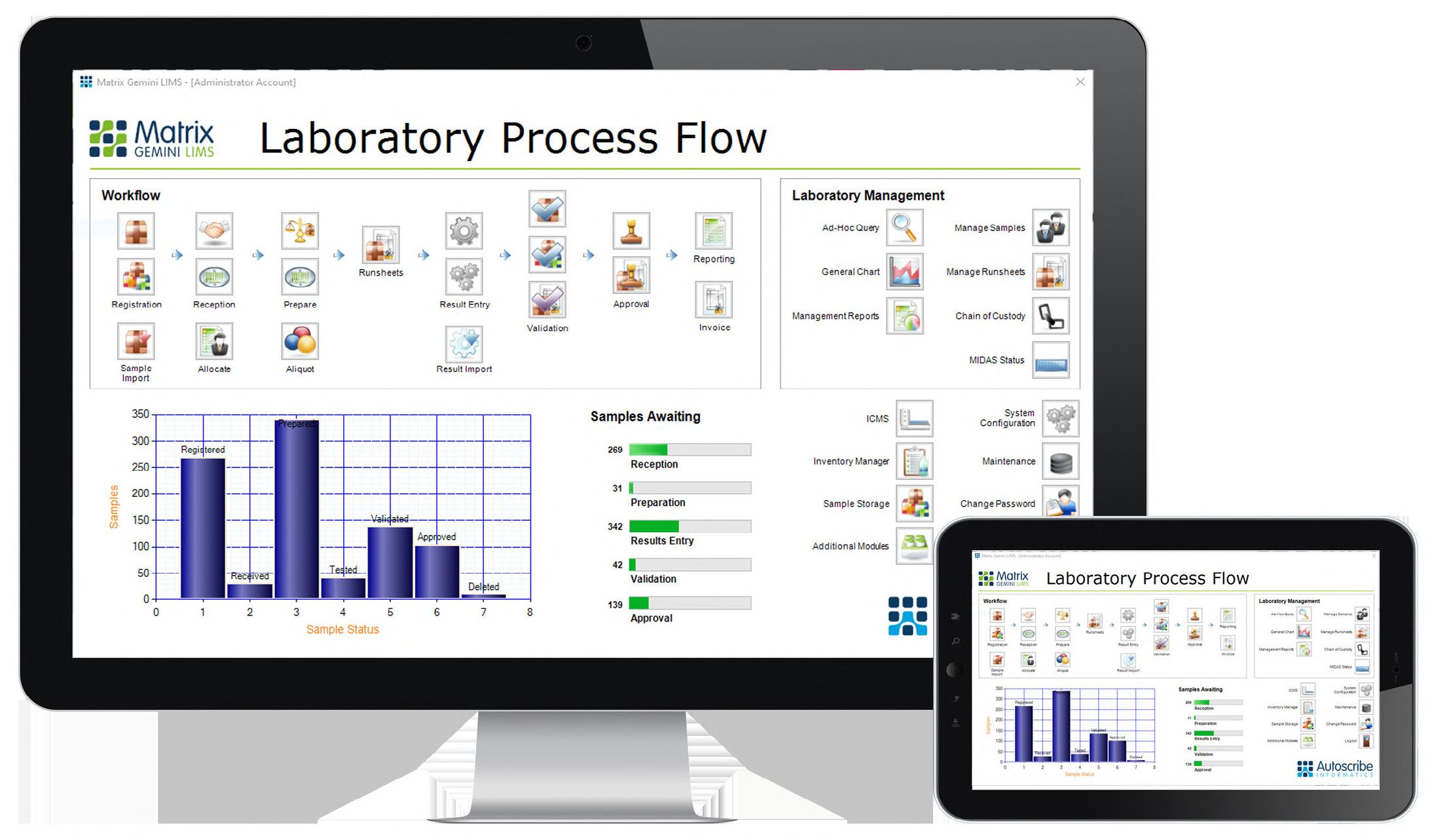

More organisations have adopted modern quality systems to move beyond manual and paper-based processes. However, a recent survey found that nearly half of companies that were modernising their quality management practices still had limited ability to use data for proactive quality management.1 More foundational work will be needed if the industry is to harness the power of automation, predictive analytics, and artificial intelligence (AI) for trending and improved decisionmaking.

The first step in this work is to assemble cross-functional teams to analyse processes from different user perspectives and standardise them. This article will focus on two critical areas that are receiving more attention: improving quality control laboratories, processes, and systems and establishing paperless validation management.

As part of incremental efforts to improve QC lab efficiency over the years, quality leaders at many companies installed different point applications to optimise specific outcomes. Over time, this resulted in a situation where each lab, even those within the same organisation or facility, was using different tools with different logins, making it difficult to find, share, and report on data with colleagues in other divisions. Disconnected workflows left companies ill-prepared to keep pace with evolving business needs. Given the importance of QC to business goals, focusing foundational work in this area alone can significantly impact business results.

To develop more agile digital laboratories, QC leaders whose systems have become disconnected will need to reimagine an approach that advances a connected quality ecosystem. This requires thinking beyond specific tools and problems to consider a holistic approach to modernising QC and how it will fit within the organisation's overall technology modernisation efforts.

Before considering potential technology solutions, quality leaders need to evaluate the problem carefully and from different points of view. Accomplishing this goal will require a cross-functional team whose daily work processes depend on quality data to develop the best approaches for resolving it. The team will eliminate bias by considering processes within a broader cross-functional context. Together, members can consider such questions as whether standards might be used to organise work processes or whether procedures might be combined or improved.

For this challenge, a comprehensive solution based on a single technology platform could streamline sample management and lab investigation processes and decrease inventory expenses.

It could also bring QC and QA processes closer together, streamlining lab operations for faster batch release.

However, selecting technology should formally start only after the team has analysed the problem in depth from different perspectives. In this case, the need for connectivity should drive analysis and consideration of potential solutions.

QC operations usually include manual processes that depend on paper, spreadsheets, homegrown systems or vendor point solutions. First, the cross-functional team needs to take a step back and evaluate the complete quality ecosystem. The team should ask how multiple business processes could be improved and then map out processes end-to-end to determine what activities or systems can be streamlined. Looking at lab issues holistically is key to more effective overall results.

It’s never too early to think about change management because technology users do not accept will never result in change. Assemble another team across functions to lead the strategy for change management, prioritise efforts, and keep projects on track. Leverage vendor services and consulting firms for expertise that strengthens the initiative. A committee with internal leaders, quality experts, and third-party partners can deliver the right combination of people to drive a successful transformation.

To move the conversation forward toward technology selection, design a matrix that includes current and future needs, as well as new and existing products, services, and support. The ultimate goal should be driving more connection and collaboration throughout quality and manufacturing.

When deciding on the systems that will support this initiative, consider 24/7 access to data, seamless information sharing, and the user experience and interface. Solutions that provide connectivity via open APIs enable easy integration with existing systems, simplifying information sharing across teams.

In a typical scenario, team members must use different logins to different systems to upload, download, and share files with various departments. Through modernisation efforts, users will gain a unified document repository, creating a single source of truth and eliminating the pain points associated with multiple logins and screens.

Ultimately, taking this approach, and focusing on one problem, empowers quality leaders to drive change while up-levelling the entire QC environment.

Managing validation projects is an area in need of innovation and advances efforts to enable proactive quality management.

Historically, using paper-based processes for validation management has led to unreliable data and questionable results. A rise in regulatory citations for data integrity violations is driving change in the industry, including regulatory guidance that re-emphasises the need for compliance with current good manufacturing practices (cGMPs).

More companies are establishing a path to streamlined validation by enabling paperless process execution. To do so, the industry will need regulatory support and alignment, best practices and guides, and advanced applications.

Regulations emphasise the need to prioritise data integrity throughout the cGMP data lifecycle across the creation, modification, processing, maintenance, archival, retrieval, transmission, and disposition of data.2 Digital tools make detecting unusual results, errors, or omissions easier and faster, especially compared to older IT systems.

Moving to digital validation management will streamline processes such as organising validation activities, managing a global library of test scripts, and digitally executing protocols. Faster and more efficient validation projects will lead to robust data-collection practices in the short and long term. Built on a solid foundation of quality data, the result is improved audit and inspection readiness.

Industry standards can also help prioritise data integrity efforts while driving standardisation. In cases where using specific industry standards isn't possible, some modern cloud technology solutions offer embedded best practices so that quality leaders don’t recreate old processes in a new environment.

The following best practices can help your organisation advance validation transformation:

1. Bring cross-functional stakeholders into the project early to ensure that needs are met across teams.

2. Create and share the validation vision and process to identify what needs to be done. Consider integrated systems, applications, facilities, utilities, and equipment.

3. Create a global governance team to oversee the management of templated validation content before implementing a digital validation solution.

4. Evaluate technologies such as flexible, cloud-based solutions that meet your organisation's requirements against industry best practices. Explore solutions that enable different experiences based on user level throughout the validation lifecycle and accommodate both on- and off-site support.

5. Integrate ongoing change management, including training and support. Consider a phased approach to avoid overwhelming teams adjusting to new processes.

As outsourcing continues transforming pharma manufacturing, more large pharma companies have included their contract

partners in quality modernisation efforts. One company, which counts on contract partners for about 70% of its output, used cloud-based quality applications to onboard all manufacturing partners and collaboratively author product specs, quality agreements, and other critical documents. It also implemented a compliant digital archive of validation records. Contract development and manufacturing organisations (CDMOs) are also establishing their own foundation for process consistency and compliance using modern quality systems. To support these efforts, regulators emphasise the need to bring quality metrics into day-to-day operations, while pharma companies adopt an organisation-wide quality mindset. This includes reducing variability in their processes and taking a proactive approach to quality as an enabler of operational excellence.3 As a result, some companies benefit from process improvements and use quality as a strategic asset rather than a cost center.

The ability to deliver consistent product quality has emerged as an essential differentiator. Organisations that leverage data-driven techniques achieve better control over manufacturing processes, whether handled internally or through a CDMO.

The industry’s goal is to accelerate discovery and access to new therapies and improve patient outcomes. Digital cloud technology can help make this happen by bringing together departments, systems, teams, and geographies. Robust technology that leverages and encourages industry standards, automates processes, and meets regulatory requirements, offers a path from reactive to proactive quality management.

However, the proper foundation must first be established, with a cross-functional view and seamless, standardised processes. How you get to that foundation via localised projects or a ‘big bang’ effort is up to you, but once you do, powerful tools are there to automate processes and bring more insights from quality data to improve business results.

Systems, Enabling Proactive Quality Management Webinar,

for Industry, Data Integrity and Compliance with Drug CGMP, (CDER, CBER, and CVM),

of St. Gallen, 2020 Quality Benchmarking Study, 2020

Robert is Veeva's senior director of strategy for quality in Europe. With more than 20 years of experience in the life sciences industry, he has a deep understanding of processes and systems in GxP-related areas. After starting his industry career at Fresenius Kabi, Robert led various large programs implementing quality-related systems, including eDMS, eQMS and LIMS at different customers in pharma, biotech, and medtech. As a subject matter expert and industry consultant, he has worked for leading companies such as PwC Consulting, IBM, Lodestone, and Infosys.

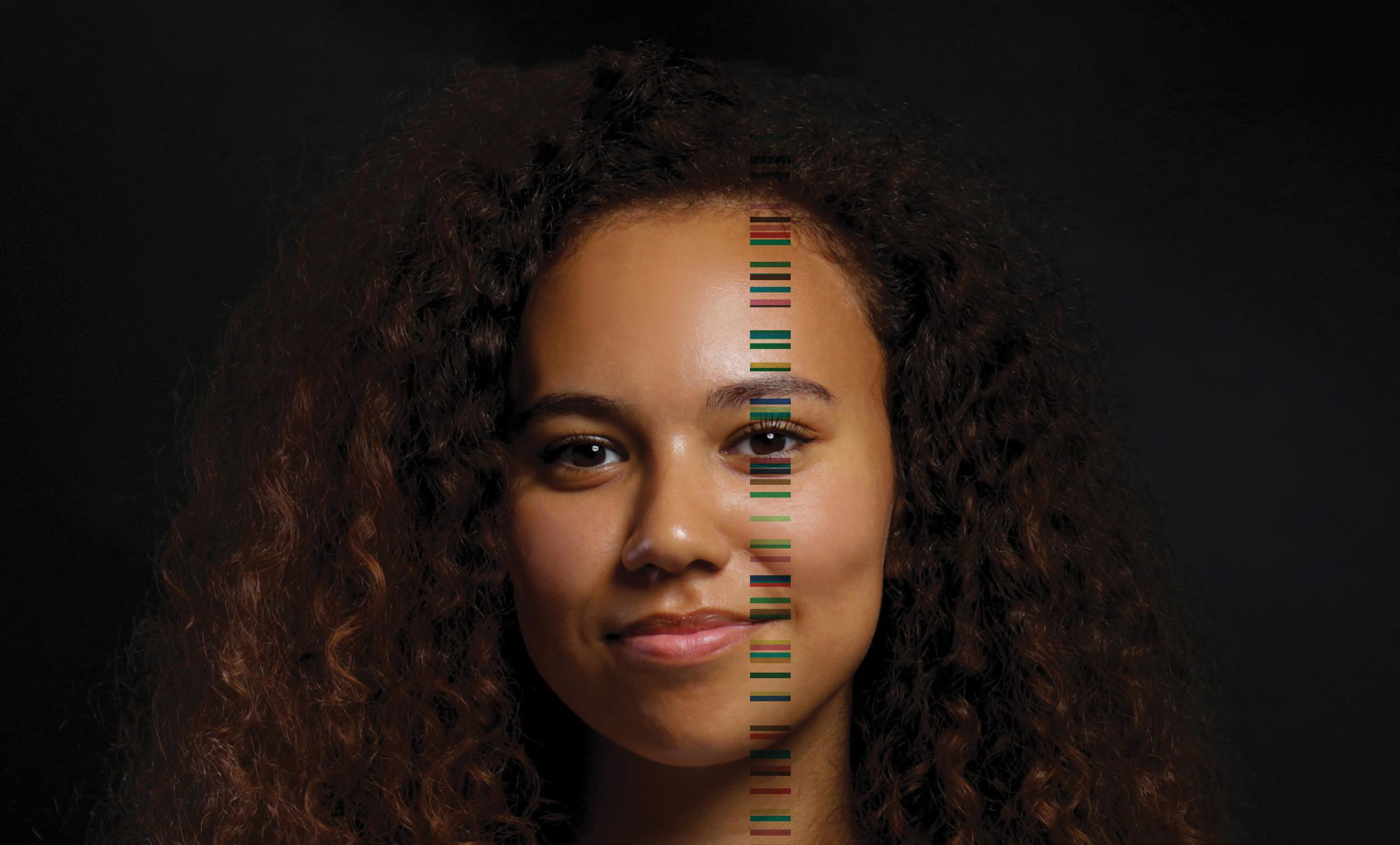

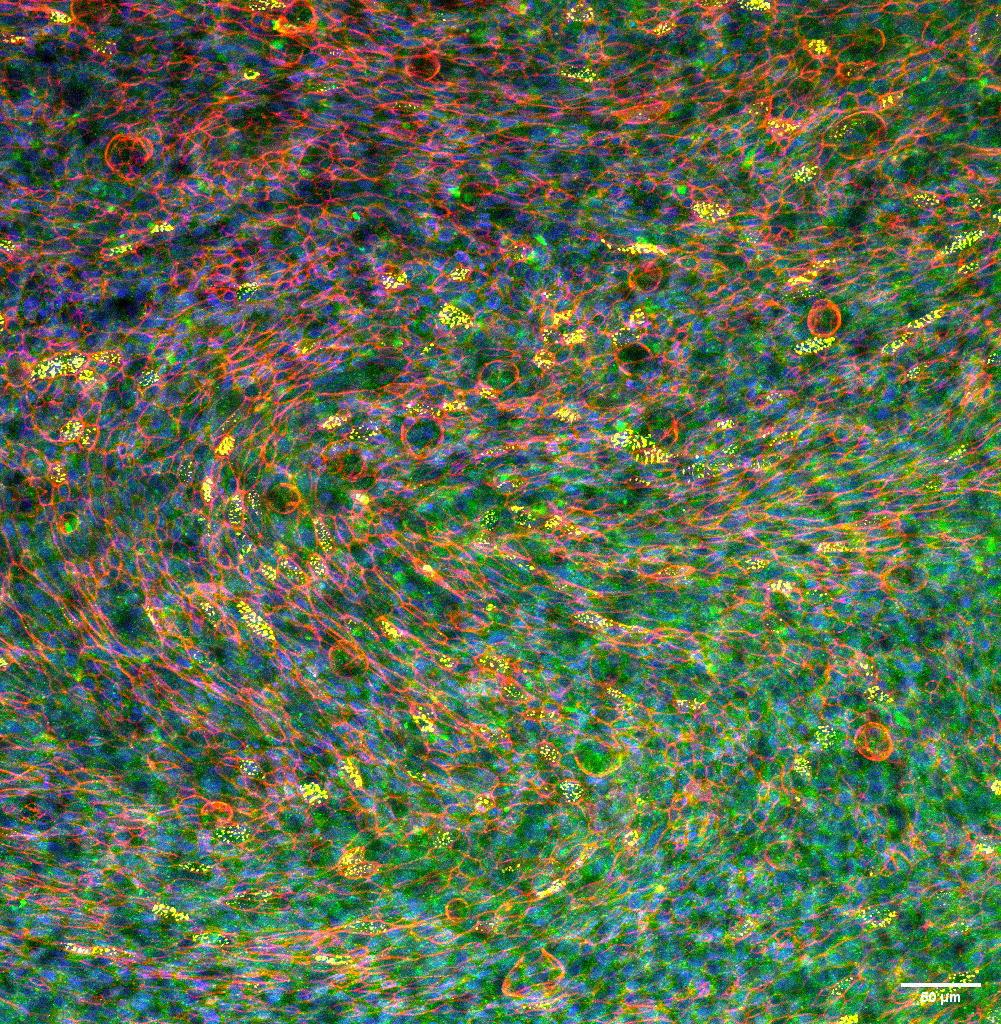

According to Retraction Watch, over 250 papers regarding COVID-19 published since the start of the pandemic have since been retracted. While retractions are an acknowledged necessity for academic journals, the growing justifications demand attention. Much focus is concentrated on checking the text of manuscripts, but in the digital age images are often more important when conveying results to readers. Here, Dr. Dror Kolodkin-Gal, founder of automated image integrity checking software Proofiger Ltd., discusses the importance of image integrity and common sources of issues.

According to the STM Global Brief 2021 – Economics and Market Size report, the global science, technology and medical publishing market was worth 26.5 billion USD in 2020. Scientific research papers are seen as the gold standard for increasing our understanding of the world. Given the high regard in which academia is held, along with the growing size of the publishing market, the importance of maintaining the integrity of the industry is unquestionable. It is vital for the industry to ensure that findings and methodology are kept to rigorous standards to prevent reader misinterpretation and maintain credibility.

Retractions and amendments have always been a part of academic publishing, especially considering the recognised notion that science is self-correcting. However, according to the previously mentioned report, roughly 48,000 scholarly peer-reviewed journals are published yearly. Furthermore, the recent surge in misinformation, particularly involving COVID-19 and vaccines, reaching public opinion as well as steady retraction rates, it has highlighted an important issue – that the review process must be modernised.

Scientific image integrity covers a broad scope, with different journals holding unique guidelines for ensuring integrity. Recent developments, such as the joint guidelines issued by representatives from eight publishers in late 2021, offered detailed information for specific scenarios. The three categories listed covered scenarios where some images have been altered or beautified whilst avoiding affecting the research’s conclusions, to level three which involved “severe manipulation”. Each category contains examples of issues, as well as actions for journal editors to take.

According to the International Journal of Cancer, a Wiley published journal, the most frequently found errors are duplicated panels deriving from copy and paste errors, magnification errors in microscopic images, and inappropriate splicing of gel sections together. The prevalence of duplication errors in life sciences manuscripts can be attributed to a variety of factors. Notably, many authors from different

locations can now contribute to the same study and work on the same manuscript, opening the door for duplication errors through human error and miscommunication.

Accidental image duplications can be missed by researchers, editors and peer reviewers because identifying overlapping sections of complex images is difficult for the untrained human eye. Taking many microscopy images – with or without using different levels of magnification – can lead to small overlaps within the same samples. Technically, it is difficult to completely avoid overlaps, and it’s even harder to detect these issues.

The acknowledgement of purposeful manipulations as part of fraudulent research is also unavoidable. This is an increasingly worrying issue in the academic industry, with most publishers being the target of systemic academic fraud via paper mills. This is the illegal and unethical manufacture and sale of articles, some of which are completely fabricated, by companies to researchers who claim the articles are the fruit of their own research.

Paper mills increase the pressure on the scientific community. When such papers make it through the peer-review process, it undermines the credibility of real research. Publishers and researchers need the tools to help make sure credible researchers are recognised for their contribution to the field.

Paper mill articles are difficult to detect in isolation, but comparisons of multiple papers from different sources makes it much easier. The review process must adapt to cover unusual similarities or the use of stock images across several papers. As already mentioned, the joint efforts of publishers are a start, but a wider collaboration between publishers and investigators is necessary to ensure awareness and effective action across the whole academic sector.

According to a recent report, one publisher found that 77 of its published journals were affected by fraudulent papers, with an average of 14 per cent of articles affected in each journal published or submitted between 2019–2021. Catching fraudulent papers before they reach publication will reduce the risk and associated costs of academics conducting future research built off low integrity papers.

Any published work with image integrity issues can have a lasting negative impact on all involved parties once retracted. For the publisher, retractions can tarnish the journal’s impact factor, as readers may question the journal’s credibility after a retraction. Institutions associated with the study may also experience reductions in trust and funding.

Researchers will also face consequences for image integrity issues, even if it was an honest mistake. If an image issue is

reported post publication, the publisher must take action, leading to a long and costly investigation for the researcher, during which they might struggle to gain funding for other projects or publish other work.

An often-overlooked consequence for researchers is the already prevalent mental health issues faced particularly by PhD students. One study found that more than 40 per cent of PhD students in the UK met the criteria for moderate to severe depression or anxiety. The high pressure and workload that researchers experience contributes to the increased likelihood of mistakes, and the greater mental impact that rejections or retractions can have. These consequences need to be understood by both researchers themselves and their institutions to ensure their safety and quality of work.

The consequences felt by the prevalence of poor scientific integrity encompass everyone involved in academia, and thus needs to be recognised and actioned by all parties as well. Collaboration between researchers, institutions and publishers can ensure innocent parties are corrected, guilty parties are punished and that only the research of most integrity is published.

The technological revolution has had prominent effects on almost every industry, and academia is no exception. Increased access to high quality imaging equipment gives researchers the tools they need to ensure they can convey results using high-quality images. A study found that as many as 72 per cent of cell biology1 related papers included image-based figures to convey results, highlighting the prevalence and importance of images to manuscripts.

The increasing commonality of images in papers has made interpreting results more accessible, as digesting visual

stimuli can be easier than processing text. Despite this, it has not endured the same scrutinisation as text during quality assurance checks, a problem exposed in research from image data integrity analyst Jana Christopher, who found when reviewing manuscripts checked at acceptance, the percentage of manuscripts flagged up for image-related problems ranges from 20 to 35 per cent.2

As the format of research papers evolve, we should also consider how the traditional peer-review process should evolve. This is particularly true for the image integrity review process, which is traditionally checked manually. It can be difficult, or even impossible to compare variations between sub-images by eye, supporting the need for tools to assist. Plagiarism software, such as iThenticate has long been established and widely used to detect plagiarism in education, so why has there been so little development for automated image checking software?

Recent exciting developments in AI and computer vision technology have allowed for more advanced methods of checking images. The trend has therefore been for publishers to adopt software, such as Proofig, as part of their review process.

Anyone in academia can use AI software for quality assurance and to check images for possible duplications or manipulations in minutes, streamlining the review process. Computer vision also works more quickly and accurately than the human eye, reducing the risk of image integrity issues being missed before publication.

The use of such software can also provide an extra level of confidence for researchers, journal editors and grant committees. Researchers can proactively check their papers so that they can be confident that their work has the best chance of being published with no accidental image integrity issues tripping them up. For journal editors, they can be confident in the knowledge that published work is of the highest quality or thoroughly investigate any reports of issues and grant committees can make sure that they provide the grants to the best candidates.

No scientist wants their integrity called into question unjustly, so by using automatic image checking software before submission, researchers can check their data while keeping it confidential. This shifts the focus to the view that researchers are to be helped and encouraged toward high quality science rather than demonised.

The benefits of effective image integrity checking software are evident. By checking images proactively, journals can maintain or improve their impact factor and secure the quality

of future research. Institutions and funding bodies can better recognise valuable routes of research that will have the most significant positive impact for the community and researchers can be confident that they are sharing impactful research with accurate data.

Although retraction rates are high, and scientific integrity is facing challenges, there are actions that can be taken to improve integrity. Tools such as Proofig are vital for the future of the scientific community in ensuring that only the most credible research is published, and the consequences of problematic papers and retractions are minimised.

1. https://journals.plos.org/plosbiology/article?id=10.1371/journal. pbio.3001161

2. Jana Christopher, M.A., Image Integrity Analyst https://ukrio.org/ research-integrity-resources/expert-interviews/jana-christopherimage-integrity-analyst/

Dr. Dror Kolodkin-Gal, Ph.D. is a life sciences researcher that specialises in new ex-vivo explant models to help understand disease progression and treatments. During his research, he became familiar with the issues surrounding image duplication and image errors in scientific publications. Dror co-founded image check software provider Proofig to help colleagues avoid unnecessary reputational damage and the financial implications of an investigation into their careers, as well as academy institutions and publishing houses. Dror and his teams created Proofig’s artificial intelligence algorithms to help detect image duplication and manipulations in scientific papers. The software checks papers prior to submission and publication, preventing unexpected rejections and helping to improve article quality and credibility.

There is growing excitement about the potential shown by cell and gene therapies, particularly in rare diseases. First, though, these therapies face challenges both in development and in aligning to regulatory guidance that was established long before the advent of advanced therapeutic medicinal products (ATMPs). Francesco Lanucara of PharmaLex explores the challenge of navigating guidelines that don’t always reflect the complexity of ATMPs and the importance of achieving regulatory convergence across different regions.

There have been significant advances in the field of cell and gene therapy in recent years with the approval of a growing number of therapies that target rare diseases. As knowledge is continuously gained on key aspects of the manufacturing processes and the quality attributes of cell and gene therapy products, regulatory guidance also continues to evolve.

Both the European Medicines Agency (EMA) and US Food and Drug Administration (FDA) have been busy in the past few years publishing new guidance for advanced therapeutic medicinal products (ATMPs). For example, the FDA produced two new guidances this year – one on CAR T cell products1 and one focused on products incorporating genome editing (GE) of human somatic cells.2

Largely, though, developers have had to find ways to work with long-established ICH guidelines that were designed with more conventional biotechnological products in mind, such as monoclonal antibodies. Due to the complexity of ATMPs, the regulatory framework has evolved differently in various jurisdictions, as is reflected by the diverse approaches from EMA and FDA to aspects of the development process, particularly with regards to implementation of GMP compliance and the definition of starting materials.

The evaluation and regulation of cell and gene therapy products would benefit from greater convergence and harmonisation of requirements and standards across different regions, supported by collaboration between industry, non-profit, academic and other organisations, and regulatory authorities.

The ICH was established more than 30 years ago as a global platform for harmonisation of technical guidelines and requirements for the development and registration of pharmaceutical products. Today ICH has 20 members and 35 observers, and many health authorities worldwide now apply ICH guidelines to their regulatory framework. Some countries take ICH guidelines that don’t easily fit to the complexity of ATMP medicines, resulting in developers of

ATMPs struggling to meet expectations during the evaluation of their submissions.

While ICH has developed some guidelines relevant to gene therapies, for example, guidance on nonclinical biodistribution studies in the development of gene therapies, 3 many activities covered by well-established ICH guidelines don’t easily apply to cell and gene therapies. There is, therefore, a need for guidance to be updated to take into consideration the variety, complexity and challenges of cell and gene therapies.

As an example, requirements for batch release testing cannot be applied in the same way to cell-based products as they are to an antibody. Typically, with cell-based products, tissue is taken from the patient, which is then genetically modified and returned to the patient. Cell-based products are often characterised by short shelf-lives, challenging the execution of traditional release testing, such as sterility, in a time frame that allows delivery of the product to the patient without compromising the product quality.

The challenges associated with ATMPs are recognised by schemes such as EMA’s PRIME programme, which provides developers of innovative ATMPs with options to adapt their CMC (chemistry, manufacturing and controls) development to the restricted timelines that are typically faced in the approval of these products. As an example, alternatives to the standard process qualification and validation as described in the ICH are described for ATMP programmes, where the number of batches manufactured at the time of submission of Marketing Authorisation Application may be limited.

While the flexibility provided by schemes such as PRIME is welcome, harmonised ICH guidance to support ATMPs that can’t go through standard development processes would be preferable since this would ensure a smoother process across all regulatory authorities.

The pathways for ATMP developers are also made more difficult by differences in what regulators in Europe and the US require to assess clinical trial applications (CTAs). Drug developers typically outsource production to contract development and manufacturing companies (CDMOs) who often restrict proprietary information on the manufacturing process to Drug Master Files (DMFs) or Regulatory Support Files (RSFs) which are submitted to the agency for evaluation but are not visible to the sponsor.

The new Clinical Trial Regulation (CTR), which came into effect in the EU on 31 January 2022, does not include the option to submit a separate supporting file (similar to a DMF or RSF) for investigational medicinal products as part of the Investigational Medicinal Product Dossier (IMPD).

by regulators in another region to inform their decisionmaking – could be of particular value for gene therapies, whose complexity could strain the infrastructure of smaller regulatory agencies. “For example, approval of a gene therapy product by the FDA or EMA could form the basis for approval in other countries, leveraging the dossiers used to support initial approval,” the authors wrote.

There are efforts underway to better standardise and harmonise processes and improve industry-regulatory collaboration. For example, the FDA has joined a publicprivate consortium, the Bespoke Gene Therapy Consortium (BGTC) which is part of the Accelerating Medicines Partnership program.8 The goal is to build platforms and standards to speed the development and delivery of gene therapies. More such efforts are needed to achieve the objective of bringing innovative, life-changing gene and cell therapies to patients.

Additionally, Annex VI of the new CTR states specific labelling requirements for IMPs, including labelling of the expiry date on the immediate packaging, which challenges the practicality of updating expiry dates for those packaging configurations designed to store the product in frozen conditions, such as the cryobags typically used for cell-based ATMPs. This requirement is a further issue for sponsors who initiated clinical trials in jurisdictions outside the EU and are now having to redevelop their labelling to comply the Annex VI.

While the introduction of the CTR poses some issues, the new regulation does bring harmonisation to CTA evaluations. Previously, the clinical trial evaluation was country-specific in Europe, which meant companies had to deal with different expectations with their ATMP trial applications. With the CTR, the application will be reviewed by one body, representing many countries, and applicants will receive one EU-based opinion, rather than many national opinions. This is expected to speed up clinical trial approvals.

ATMPs face another hurdle that other regulated products do not: mutual recognition. The EU has mutual recognition agreements with many other authorities for conformity assessment, which, among other things, allows authorities to waive batch testing of products imported into their territories.4 This agreement does not extend to ATMPs, which means sponsors must retest batches in the EU before their cell or gene therapy can be released in the EU by the qualified person (QP).

There have been exceptions with cell and gene therapies where companies were able to justify not retesting based on the limited amount of material, as was the case for Luxturna5 and Zolgensma.6 While the European public assessment reports for both products noted that the mutual recognition agreement for GMP between the US and EU or UK does not apply to ATMPs, GMP guidelines do allow some flexibility for release testing due to the small batch size of these orphan products.

As the authors of a June 2021 paper in Molecular Therapy noted,7 regulatory reliance and work sharing between regions – where regulators in one region use assessments performed

1. https://www.fda.gov/regulatory-information/ search-fda-guidance-documents/considerations-developmentchimeric-antigen-receptor-car-t-cell-products

2. https://www.fda.gov/regulatory-information/ search-fda-guidance-documents/human-gene-therapy-productsincorporating-human-genome-editing

3. ICH guideline S12 on nonclinical biodistribution considerations for gene therapy products, ICH guideline S12 on nonclinical biodistribution considerations for gene therapy products

4. Mutual recognition agreements (MRA), https://www.ema.europa. eu/en/human-regulatory/research-development/compliance/ good-manufacturing-practice/mutual-recognition-agreements-mra

5. Assessment report, Luxturna, September 2018, https://www.ema. europa.eu/en/documents/assessment-report/luxturna-epar-publicassessment-report_en.pdf

6. Assessment report, Zolgensma, March 2020, https://www.ema. europa.eu/en/documents/assessment-report/zolgensma-eparpublic-assessment-report_en.pdf

7. Global regulatory progress in delivering on the promise of gene therapies for unmet medical needs, Molecular Therapy: Methods & Clinical Development, June 2021, https://www.sciencedirect. com/science/article/pii/S2329050121000668#:~:text=Review-

The Accelerating Medicines Partnership Bespoke Gene Therapy

(BGTC), https://ncats.nih.gov/programs/BGTC

Francesco Lanucara is Senior Manager Regulatory Affairs CMC, Biopharma Excellence. Francesco joined Pharmalex (BioPharma Excellence) in June 2021 and has since been providing CMC and regulatory support for ATMP projects, including in vivo and ex vivo gene therapy. Previously, he held a number of roles as analytical lead and analytical development senior scientist in the biopharmaceutical industry. Francesco received his PhD in Pharmaceutical Sciences from the University of Rome in 2008.

Extractable and leachable studies on primary packaging systems are well established in the pharmaceutical industry. For extraction studies, guidelines and best practice guides mandate a worst-case approach, taking the active, the formulation and the container closure system into account. The data from the extraction study should enable a meaningful risk assessment about the possible occurrence of impurities leaching from packaging components during the products shelf-life. The guidelines and best practice guides recognise packaging materials as a potential source of impurities and assess their direct toxic or genotoxic effect on the patient. However, an assessment of the protein-reactivity of extractables are not in the scope of standard extraction procedures. Changes to the protein structure caused by compounds acting as a catalyst or by direct covalent reaction, may render the Biopharmaceutical inefficacious or even immunogenic. Previously, we have described a screening assay for packaging material extracts, to identify possible protein-reactive extractables, enabling an assessment including the risk of possible leachable having a direct or indirect effect on the protein structure. However useful this proposed assay is, it only allows an evaluation of the reactivity of extractables during the extraction process. It does not consider extractables, which are not reactive per se, but may be converted to a protein-reactive derivative caused by aging processes, which might occur over the shelf-life of the product. In this article, we propose a modification of the protein-reactivity screening, by adding an electrochemical oxidation step, to not only evaluate extractables, which are reactive during the extraction process, but to also see, if there is a subset of extractables, which oxidised derivatives have protein reactive properties. This modified assay does not only evaluate the reactivity of extractable during the extraction process, but also takes into account, that leaching processes are time dependent and therefore, potential leachable are like the drug product prone to aging dependent degradation or modification, which may have an impact on the reactivity of the compound.

Biopharmaceuticals, drug products with protein- or peptidebased active ingredients, are mainly administered as parenteral solutions. These solutions prepared either prior to application by reconstitution of a lyophilized product with a suitable diluent or are formulated directly as a liquid-for-injection. Parenteral drug products are mainly stored in glass container closure systems sealed with a rubber stopper/septum; the standard vial-stopper configuration. In some cases, the product may be filled directly into syringe, a so-called pre-filled syringe. These consist of a glass barrel, which may be lubricated, a rubber-based plunger and a syringe needle held in place by an adhesive and a capping device. All these components and adhesives are potential sources of leachables, which may migrate into the product over it´s shelf life. To evaluate the risk of leachables migrating into the product,

extraction studies are performed. Extractions studies should be designed in a way, that they represent a worst-case scenario in terms of the extractive properties of the extraction media and extraction conditions, mainly temperature and time. Here it is important to note, that a forensic-style evaluation the primary packaging, e.g. by completely dissolving each component under the harshest of conditions, does not give rise to a representative extraction profile. The USP chapters <1663> and <1664> offer guidance on the design, justification and evaluation of data from extractable and leachable studies, but do not propose exact experimental conditions for extraction studies.1,2 The Product Quality Research Institute (PQRI), however published a widely accepted best practice guides for Orally Inhaled and Nasal (OINDP) as well as for Parenteral and Ophthalmic Drug Products (PODP).3,4 The guideline covering parenteral formulations, proposes three different extraction media considering aqueous buffered formulations at basic and acidic pH, as well as water with organic solvent to simulate the extractive properties of often highly concentrated protein-based actives and excipients like polysorbates, aiding protein solubility. The guideline also proposes a Safety Concern Threshold (SCT) considering the parenteral and ophthalmic route of administration, under which a daily exposure to an unknown compound is considered to likely have no adverse effect on the patient. The SCT is an extrapolation of no observed effect levels (NOEL) obtained for different substance classes in animal models.5 For the evaluation of the extraction profiles, the SCT is translated into an analytical evaluation threshold (AET), which takes into account the maximum daily delivered dose of the drug and the extraction volume. Any extractable, which falls short of the concentration limit defined in the AET, are not further evaluated, since they are unlikely to either leach in the product over it´s shelf life or at least are very likely to stay under defined SCT. Compounds in the extract, that are detected above the AET need to be identified and toxicologically assessed to evaluate whether the compound needs to the monitored during a leachable study. The analytical techniques applied must be capable of detecting a single compound, in case of a leachable study, or multiple compounds from an extraction study at the defined AET level. Furthermore, for the evaluation of extracts the analytical techniques must be suitable to detect an array of extractables from inorganic compounds, e.g. metals from glass components, to organic compounds with divers physico-chemical properties, e.g. from rubber components or adhesives.

The general concepts of the guidelines mentioned above regard extractables and leachables as compounds, which may have a direct concentration-dependent genotoxic, toxic or other ways adverse effect in the patient. The evaluation based on SCTs reflects the approach described in guidelines concerning genotoxic and toxic impurities e.g., ICH M7.6 For protein-based biopharmaceuticals however, an evaluation of extractables purely on a NOEL concept does not consider the potential direct effect an extractable may have on the active itself. This may be a covalent reaction of an extractable with an amino acid side chain

or by acting as a catalyst by e.g., oxidising amino acids prone to oxidation, as already shown for some metal ion leachables.7

Apart from this being a potential quality issue, the slights changes to the amino acid sequence can render a protein inefficacious, altering the three-dimensional structure, causing e.g. aggregation,8 or in a worst-case scenario, triggering an immune response in patients. An immune response can lead to the induction of anti-drug antibodies (ADA) changing the drugs pharmacokinetic properties9 or, in case the ADA binds to the active site of the drug (so-called neutralising antibody), rendering the drug completely inefficacious in a patient, often for life.10 Because immunogenic reactions and their severity are highly dependent on the immunogen, the route of administration and the individual genetic makeup of each individual patient, there are no established SCT levels for potentially immunogenic substances available. Le et. al. however, have proposed a limit for protein modifications based on LC-UV peptide mapping data. They suggest that modifications greater than 2% on peptide level should be investigated in regard to immunogenic effects.11 Furthermore, biopharmaceuticals such as monoclonal antibodies, have a large molecular weight, making it difficult to observe small mass modifications using established standard stability indicating methods. Even the use of sophisticated mass spectrometry applications has its limitations, if screening low level unknown or unexpected modifications. Therefore, a screening assay for protein-reactive extractables is as useful tool to enable a comprehensive risk assessment, based not only on the abundance of each individual compound in the extract in relation to the defined AET, but also indicates which of those compounds might be protein-reactive. The additional information about protein-reactive compounds enables the analyst to either conduct further experiments to verify, if the extractable also reacts with the biopharmaceutical or to aid a screen for such modifications in stored drug product samples.

We have previously described a screening assay for proteinreactive extractables, which can be directly integrated into the extraction process. The screening-assay we proposed uses Glutathione as a surrogate compound. This surrogate is a worst-case scenario when it comes to mimicking the reactivity of amino acids, because in addition to a primary amino group, it also offers a highly reactive free thiol. Other screening assays using peptides or small proteins with no or closed disulfide-bonds as surrogate compounds, arguing that these more closely resemble the drug product. We however believe that Glutathione, as a more reactive compound, is in line with the worst-case evaluations proposed in the guidelines discussed above. Already our assay has proven useful to indicate protein-reactivity of several rubberoligomers readily found in butyl-rubber extraction studies.12 But more importantly, the assay helped to identify polysulfides, which are formed by vulcanising agents during the vulcanising process of rubber materials as potential agents capable of modifying disulfide bonds in proteins. These polysulfides usually go undetected in extraction studies, mainly because polymeric substances of undefined chain-length are challenging to analyse, especially so, if they are inorganic. Even though the screening assay we have proposed has shown its use to indicate protein-reactive extractables, it only identifies compounds which are reactive during the extraction experiment. Since leaching processes are time dependent, the extraction studies are performed under accelerated conditions, namely elevated

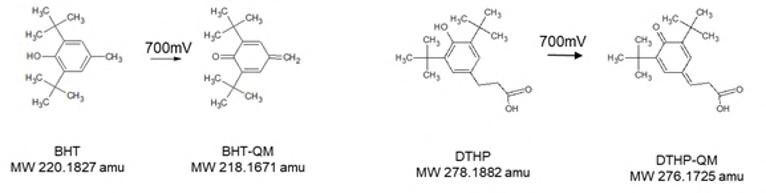

temperature. We recommend 121°C for eight hours. As conditions like this accelerate the extraction process, mimicking the leaching of compounds from the immediate packaging system over the products shelf-life, it does not accelerate aging processes, apart form those which are solely temperature dependent. Therefore, compounds that leach into the product over time are, like the drug substance, prone to aging-dependent degradation, e.g. by oxidation. Therefore, we propose an addition of the established protein-reactivity screening by oxidising extracts to evaluate, if any of extractables designated as non-protein-reactive can be converted into protein-reactive degradation products. For the oxidation, a method described by the work group of Uwe Kaarst,13 which utilises electrochemical oxidation to simulate cytochromemediated activation of drug substances, was adapted. As a proof-of-concept and to establish the oxidation procedure, two commonly found rubber extractables, Dibutyl hydroxytoluene (BHT) and Dimethylethyl hydroxyphenyl (DTHP), a degradation product of IrganoxTM, were used.14,15 These Hydroxytoluene’s are commonly used as antioxidants in rubber formulations and were not indicated as protein-reactive in our Glutathione screening assay. However, these compounds can be converted into Quinone methide (QM) derivatives upon oxidation, which are nucleophilic and therefore should be potentially protein reactive. The addition of an oxidation step to the Glutathione screening assay proposed here, should increase our understanding of the potential fate of compounds leached from the immediate packaging system into the to drug product over it´s shelf-life. The additional information gained from these experiments will enable a more comprehensive risk assessment of the extraction study.

L-Glutathione reduced (Cat.No.: G425); human Angiotensin II (Cat.No.: A9525) and Dibutyl hydroxytoluene (BHT) (Cat.No.: W218405) were purchased from Sigma Aldrich/ Merck KGaA Darmstadt, Germany. Isopropanol (Cat.No.: Nr. AE73.2), Acetone (Cat.No.: KK40.1) and Acetonitrile (Cat.No.: HN40.2) were purchased from Carl Roth GmbH & Co. KG Karlsruhe, Germany. Ammoniumacetate (Cat.No.: 012441) and Formic Acid (Cat.No.: 069141) were purchased from Biosolve B.V. Valkenswaard, Netherlands. Dimethylethyl hydroxyphenyl (DTHP) was purchased from ABCR GmbH, Karlsruhe, Germany.

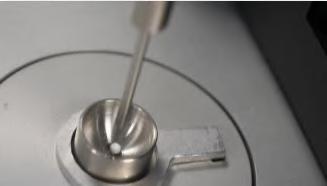

The electrochemical oxidation was performed with 500 µL of diluted solutions of BHT and DTHP in a ESA Coulochem II installed with a cell 5021 at a flowrate of 50 µL per minute at 700 mV. For the control samples, the voltage in the coulometric cell was set to 0mV. BHT and DTHP were each diluted to a concentration of 0.5 mM in 50% acetonitrile in water prior to treatment in the coulometric cell. The oxidised BHT and DTHP were each incubated with and equal volume 0.1 mM solution Glutathione at 37°C for 30 min (5:1 ratio of BHT/DTHP to GSH). Angiotensin II diluted to 0.2 mM and treated with and equal volume of BHT and DTHP (1:2.5 ration of Angiotensin to BHT/DTHP).

For the rubber stopper extraction, 1.5 g of a bromo butyl stopper was cut in small pieces and extracted for 8 h at reflux in 5 ml 2-PrOH. The extract was then diluted 1:1 with with 20 mM ammonium acetate in water. 500 µL of the diluted extract was subjected to the coulometric cell and incubated with Glutathione as already described.

The samples were separated on a Shimadzu Prominence LC20 HPLC System equipped with an Inertsil C8, 100x2.1 mm, 5 um column heated to 50°C. For analysis, 10 µL of samples were in injected into a 300 µL per minute flow. The separation of the samples performed with the following mobiles phased: Eluent A: 0.1% Formic Acid in water and Eluent B: 0.1% Formic Acid in Acetonitrile. The Glutathione treated samples were separated by an HPLC gradient starting at 50% eluent B, which increases to 100% B within 3 minutes and remains at 100% for additional 4 minutes before returning to the starting condition. The Angiotensin II treated samples were separated by an HPLC gradient starting at 10% eluent B which increases to 100% B within 5 minutes and returning to the starting condition after 0.1 minute.

The HPLC flow was directed into an Orbitrap XL system equipped with and ESI ion source. The ion source parameters were set to positive ion mode with a spray voltage of +5kV, tube lens at +90V. The resolution of the mass detector was set to 30000 and the mass range was set to 100 to 1000 amu for the GSH samples treated with BHT and DTHP, 300 to 1500 amu for the Angiotensin samples treated with BHT and DTHP and from 100 to 1500 amu for the GSH samples treated with the rubber extract.

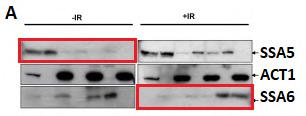

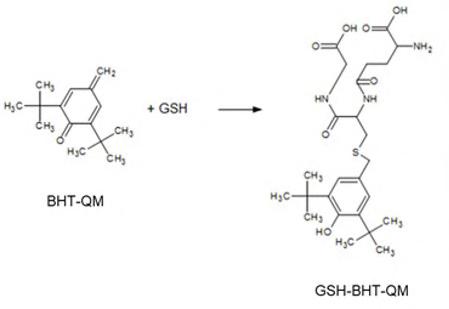

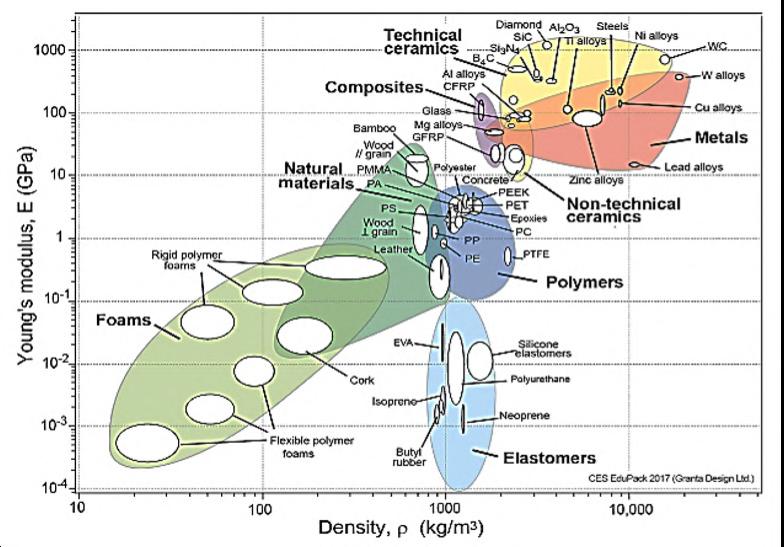

The optimal voltage for the electrochemical conversion of Hydroxytoluene based antioxidants in coulometric cells has been previously described by McCabe and Acworth to be between 675 mV and 825 mV. The conversion rate has been reported to be at about 100%.16 Therefore, we have decided to set to coulometric cell to 700 mV. For the establishment and proof of principle we used standards of antioxidants typically found in rubber formulations as well as in PE and PP-plastic. Whereas PE- and PP-primary packaging materials are commonly not used to store therapeutic protein, butyl-rubber materials are typically used as vial-stoppers or syringe-plungers of many marketed Biopharmaceuticals. Both antioxidants are commonly detected in extraction studies.14,15 The Hydroxytoluenes Dibutyl hydroxytoluene (BHT) and Dimethylethyl hydroxyphenyl (DTHP), a degradation product of IrganoxTM, convert in the coulometric cell to their quinone methide derivatives, which represent reactive (electrophilic) intermediates (Figure 1).

In the screening assay described here, Glutathione is used as a surrogate for amino acid side chains in biopharmaceuticals. The Glutathione (GSH) added to the electrochemically

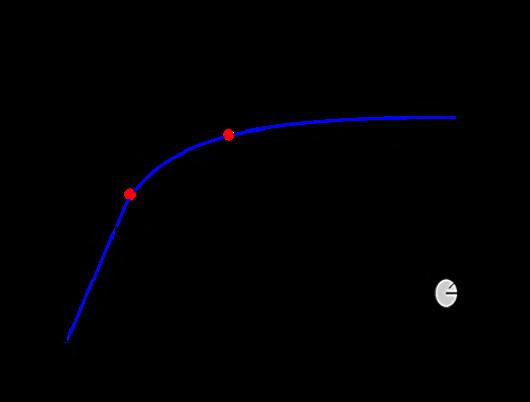

activated antioxidants should represent potent reaction partners for the quinone-methides (QM), resulting in the respective Glutathione-BHT-QM or -DTHP-QM conjugates (Figure 2).

Figure 2: Reaction scheme of Glutathione (GSH) with the oxidised Dibutyl hydroxytoluene quinone method (BHT-QM).

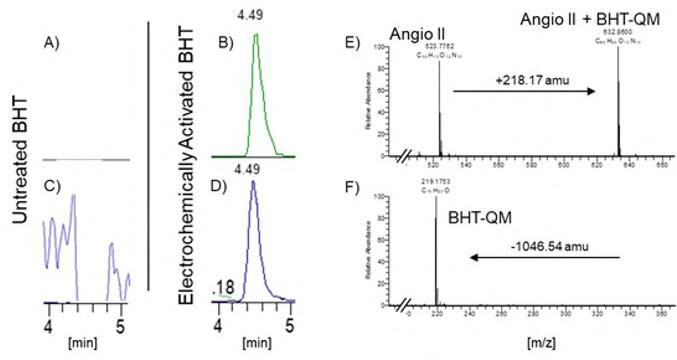

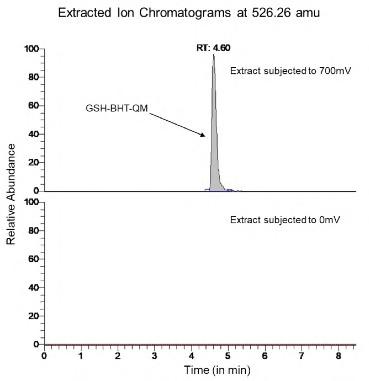

Electrochemically activated BHT and DTHP samples were treated with Glutathione and subsequently analysed by LC-MS. The LC-MS method applied was the same as in the previously described screening assay.12 The reactivity-assay with Glutathione was performed with BHT and DTHP, which were either subjected to electrochemical activation in a coulometric cell or left untreated. The treated and untreated samples were subsequently analysed by LC-MS and screened for masses corresponding to the Glutathione-quinone-methide conjugates. The Glutathione-BHT-QM conjugate should have a mass of 526.26 amu and the Glutathione-DTHP-QM conjugate of 584.26 respectively.

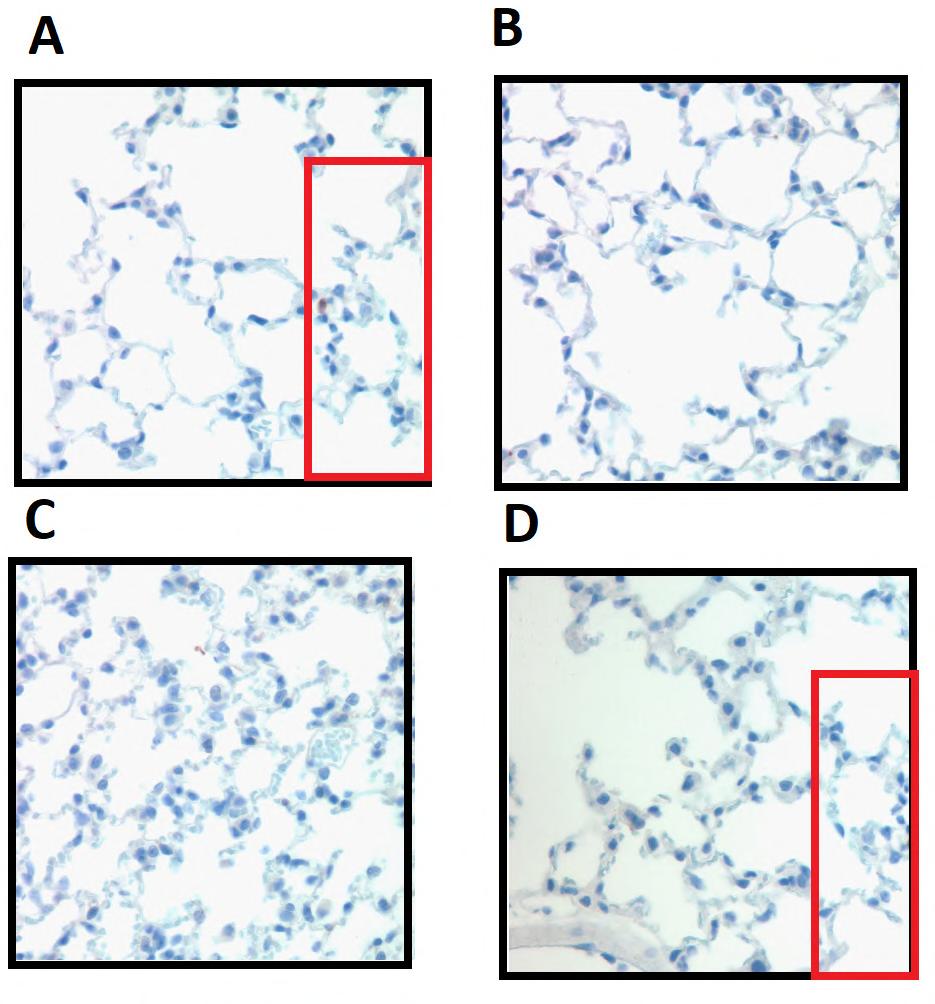

The experiments highlighted in Figure 3 clearly support the hypothesis, that the unreactive antioxidants BHT and DTHP can be converted into their reactive quinone-methide derivatives, which readily react with the Glutathione surrogate compound offered as a reaction partner.

Reaction of Electrochemically Activated Antioxidants with Angiotensin II

Glutathione with its free thiol is a very reactive compound, therefore it is often argued, that it is not a suitable surrogate to evaluate the protein-reactivity of extractables. It is true, that biopharmaceuticals usually do not contain amino acids with free thiols and that all cysteines in the sequence are paired with another cysteine to form a less reactive disulfide-bond. To

Figure 1: Scheme of the electrochemical conversion of Dibutyl hydroxytoluene (BHT) and Dimethylethyl hydroxyphenyl (DTHP) at 700 mV in a coulometric cell to their respective quinone-methide (QM) derivatives. Below the molecules their masses are given in atomic mass units (amu).

Figure 3: Results from the LC-MS based screening for Glutathione-quinone-methides conjugates. The peaks in Total Ion Chromatrogams (TIC) represent the main component in each experiment. In the experiments with the untreated Hydroxytoluenes Dibutyl hydroxytoluene (BHT) and Dimethylethyl hydroxyphenyl (DTHP), Figures A and C, on ions representing the Glutathione-quinone-methide conjugates could be found in the mass spectra. Whereas in the samples with the electrochemically activated BHT and DTHP, Figures B and C, the corresponding signals, indicating the presents of GlutathioneBHT-QM (526.26 amu) and Glutathione-DTHP-QM (584.26 amu) could be identified in the mass spectra. Further more the Extracted Ion Chromatograms (XIC) of the proposed conjugate masses, indicate real compound eluting from the column.

evaluate, if the quinone-methides generated by electrochemical activation in a coulometric cell, also react with other amino acid side chains, we performed the same experiments using Angiotensin II as a reaction partner. Angiotensin II does not contain any disulfide-bond or cysteines for that matter. Like in the experiments before, BHT and DTHP were with treated in the

coulometric cells or left untreated and then added to the reaction partner. In the following only the results for the results from the experiments with BHT as shown as an example. The experiments carried out with DTHP led to the same results (data not shown).

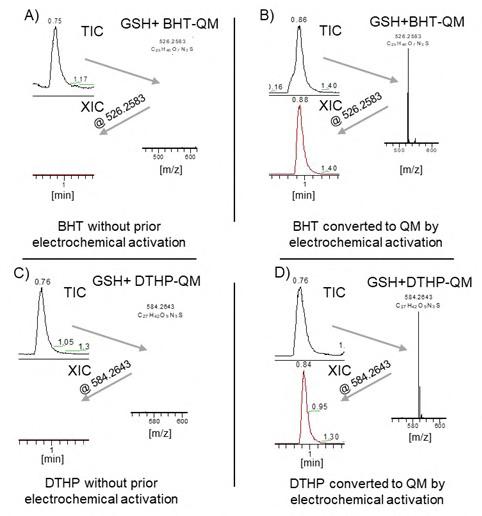

The experiments clearly indicate, that BHT converted to its reactive quinone methide intermediate by electrochemical activation, reacts with Angiotensin II giving rise to its conjugate (Figure 4 B and E). This conjugate can be fragmented by in-source fragmentation to liberate the BHT-QM, further proof of the conjugate (Figure 4 F). As expected, the untreated BHT did not react with Angiotensin II.

The experiments with Angiotensin II firstly underline, that the quinone-methide derivatives of Hydroxytoluene-based antioxidants are very likely protein-reactive. Secondly, that at least for this class of substances, the screening assay using Glutathione as surrogate compound is predictive for studying the potential protein-reactivity of extractables subjected to simulated oxidative aging.

Electrochemical Activation of a Butyl-rubber Stopper

For proof of principle, a rubber stopper extract was used, because this packaging material is more relevant for Biopharmaceuticals. In the following example a bromated butyl-rubber was extracted by a sealed-vessel extraction procedure with Isopropanol as an extraction medium. The extract was subjected to a coulometric cell and electrochemical oxidation was achieved by applying a voltage of 700mV. As a control, an aliquot of the same extract was placed in the coulometric cell without applying a voltage. Both extracts were subsequently incubated with the Glutathione surrogate compound. The previously described LC-MS method was used to screen for Glutathione conjugates indicative of reactive extractables (see Figure 5).

As previously described the rubber extract contains BHT as a typical extractable. This extractable does not react with the Glutathione surrogate molecule, as we could show previously

Figure 4: Mass spectrometric analysis of Angiotensin II samples treated with BHT and BHT converted to its quinone-methide derivative. In the sample where Angiotensin was incubated with BHT (Figures A) no signals corresponding to conjugates (1263.72 amu) could be identified. On the other hand, where BHT was converted to its quinone-methide, an extracted ion chromatogram indicative of the Angiotensin II BHT-QM conjugate could be identified at 4.5 minutes (Figures B)). The corresponding mass spectrum features the signal of Angiotensin II at 1045.56 amu und another signal shifted by 218.17 amu, indicative of the conjugate (Figure F). Furthermore, if an in-source fragmentation is performed, the BHT-QM can be liberated from the conjugate, resulting in a signal at 219.18 amu which leads to an extracted ion chromatogram with the same retention time as conjugate (Figure D)).

to know more?

Figure 5: Extracted ion chromatograms (XIC) of 526.26 amu the mass representative for the Glutathione-BHT quinone methide (GSH-BHT-QM) conjugate. The upper XIC displays the trace obtained form the extract subjected to 700mV. The lower trace represents the control sample where no voltage was applied.

with our screening assay for electrophilic extractables.12 Only if the rubber extract is subjected electrochemical oxidation by means of applying a voltage in a coulometric cell, a Glutathione conjugate with BHT-QM can be observed (see Figure 5). This clearly shows that the approach of electrochemical oxidation can be successfully applied to real packaging material extracts to simulate aging-dependent oxidation of extractables.

The previously described screening assays to evaluate the protein-reactivity of compounds in packaging material extracts12 have been shown to give useful additional information to conventional extraction studies. The information from theses reactivity screenings enables a more comprehensive risk assessment of the extraction study. Whereas a conventional extraction study only allows to evaluate the risk of individual compounds based on their abundance in respect to a predefined AET, a reactivity screening, highlights compounds, which are difficult to monitor, once reacted with the biopharmaceutical drug substance. Knowledge about these compounds enables the investigator to perform further experiments, e.g. to screen for packaging alternatives which yield less protein reactive extractables, to evaluate the real risk of a drug substance to be influenced by a protein-reactive compound, to employ additional methods the monitor potential reaction products in stability- or leachable studies, or to come to the conclusion, that there are no further actions required. Whatever the outcome of a risk assessment based on a reactivity screening might be, it is needless to say, that a potential risk can only be evaluated, if it is known.

Based on the idea to broaden the foundation of the risk-based evaluation of extraction studies, we propose to include an evaluation of aging-associated reactions of extractables. The reactivity screening assays already proposed,

only evaluate the reactivity of extractables during the relatively short extraction process, usual several hours or up to a day.11,17 Therefore, extraction studies can be viewed as an accelerated leachable study, however they are definitely not set up as accelerated stability studies of the leached compounds. This excludes an evaluation of the fate of potential leachabes during the shelf-life of the product. There is a possibility, that some of the commonly found non-reactive extractables might degrade over time to form protein-reactive compounds. Therefore, a risk assessment based on an extraction study with reactivity screening will fall short to evaluate potential aging-associated degradation of leachables over the self-life of the product.

One of the common aging-related reactions monitored during stability studies are oxidations, which affect not only the drug substance and excipients, but all substances in the drug product, including leachabes. We have established an electrochemical oxidation using a coulometric cell. This approach has been previously successfully applied to study CPY-mediated oxidative conversion of small molecule drug substances.13,18 To establish the oxidative aging of packaging material extracts, two commonly found rubber extractables were used. Dibutyl hydroxytoluene (BHT) and Dimethylethyl hydroxyphenyl (DTHP), a degradation product of IrganoxTM, are typical antioxidants used in rubber formulations.19,20 These Hydroxytoluene based antioxidants, which are not protein reactive are known to be converted into electrophilic quinone-methide intermediates (Figure 1).21 In this study these two antioxidants have been subjected to electrochemical oxidation, to evaluate if this approach can be applied to simulate aging-dependent oxidation. The experiments shown here clearly indicate that BHT and DTHP can be oxidized to their respective quinone-methide derivatives, which expectedly react, like all previous tested electrophilic extractables, with the Glutathione surrogate compound (Figure 3). To address the argument, that Glutathione is a too reactive surrogate to study protein-reactivity, the same experiments were repeated with Angiotensin II as a surrogate. Angiotensin II is a polypeptide with eight amino acids, none of which have a reactive free thiol and therefore features amino acid side chains that are more representative of common therapeutics proteins. The results of these experiments confirm, that BHT (Figure 4) and DTHP (data not shown) can be oxidized to yield electrophilic quinone-methide derivatives, which are capable of reacting with less-reactive amino acid side chains. Which of these amino acids are involved in the reaction with the quinone-methides still needs to be investigated.

A proof of principle experiment with an extract obtained from a bromated butyl rubber stopper, commonly used to seal glass vials containing Biopharmaceuticals, could show that the procedure of electrochemical oxidation can be applied to real packaging material extracts. The BHT extractable, as expected, does not react with Glutathione as could be shown previously.12 However, if the extract is subjected to electrochemical oxidation, BHT is converted to its reactive quinone methide derivative which readily reacts with Glutathione (Figure 5).

The reactivity screening of packaging material extracts after electrochemical oxidation, is a valuable addition to the previously described reactivity assay. Whereas, the commonly used assays are successful in highlighting electrophilic

extractables as protein reactive, they do not account for the potential fate of leachables over the shelf-life of the drug product. During storage, aging-processes, e.g. oxidation may convert previously unreactive leachables into proteinreactive degradation products as could be shown here for the Hydroxytoluene-based antioxidants. The finding, that Hydroxytoluenes can be converted into electrophilic quinonemethides by oxidation is not particular surprising. However, the routine application of this approach to extraction studies of different packaging materials, might enable the identification of a previously overlooked extractable, as it was the case for polysulfides and their possible interaction with disulfide discovered previously.12

Do any of the already identified protein reactive extractables or possible reactive degradation products of leachables pose any real danger to patient safety in terms of eliciting an immunogenic response by modified biopharmaceuticals? At least the great majority of biopharmaceuticals marketed to date in standard immediate packaging systems suggest there is not. But for the sake of a thorough risk assessment, it worthwhile to make the effort, because we are only able to assess risks that are aware of!

1. USP <1663> Assessment of extractables associated with pharmaceutical packaging/delivery systems

2. USP <1664> Assessment of drug product leachables associated with pharmaceutical packaging/delivery systems

3. Paskiet, D.; Jenke, D.; Ball, D. et al. The Product Quality Research Institute (PQRI) Leachables and Extractables Working Group Initiatives for Parenteral and Ophthalmic Drug Product (PODP). PDA J Pharm Sci and Tech. 2013; 67: 430-447.

4. Norwood, Daniel L., et al. "Best practices for extractables and leachables in orally inhaled and nasal drug products: an overview of the PQRI recommendations." Pharmaceutical research 25.4 (2008): 727-739.

5. Kroes, Robert, et al. "Structure-based thresholds of toxicological concern (TTC): guidance for application to substances present at low levels in the diet." Food and chemical toxicology 42.1 (2004): 65-83.

6. International Conference on Harmonisation (ICH) M7; Assesment and Control of DNA (Mutagenic) Reactive Impurities in Pharmaceuticals to Limit potential carcinogenic risk.

7. Zang, Li, et al. "Residual metals cause variability in methionine oxidation measurements in protein pharmaceuticals using LC-UV/MS peptide mapping." Journal of Chromatography B 895 (2012): 71-76.

8. Dean, Roger T., et al. "Biochemistry and pathology of radical-mediated protein oxidation." Biochemical Journal 324.1 (1997): 1-18.

9. Hermeling, Suzanne, et al. "Structure-immunogenicity relationships of therapeutic proteins." Pharmaceutical research 21.6 (2004): 897-903.

10. Sharma, B., Immunogenicity of therapeutic proteins. Part 2: Impact of container closures Biotechnology Advances 25 (2007) 318–324

11. Li, Kim, et al. "Creating a holistic extractables and leachables (E&L) program for biotechnology products." PDA Journal of Pharmaceutical Science and Technology 69.5 (2015): 590-619.

12. Haep, Ramona. et al. “Protein-Reactive Extractables - A Screening Assay Which Adds Additional Value to the Traditional E/L Workflow” Pharmind, 1, (2018):104-110.

13. Lohmann, Wiebke, Heiko Hayen, and Uwe Karst. "Covalent protein modification by reactive drug metabolites using online electrochemistry/liquid chromatography/mass spectrometry." Analytical chemistry 80.24 (2008): 9714-9719.

14. Yu, Xiaochun, et al. "A study of leachables for biopharmaceutical formulations stored in rubber-stoppered glass vials." (2010).

15. Sogding, Thorsten, et al. "How sterilization of primary packaging influences the results of E&L studies: as the demands that are being placed on the quality and stability of medications continue to increase, the interactions that take place between the primary

packaging container and filled drug product are becoming increasingly important." Contract Pharma 17.5 (2015): 88-95.

16. McCabe, D. R., and I. N. Acworth. "Determination of synthetic phenolic antioxidants in food using gradient HPLC with electrochemical array detection." American laboratory (Fairfield) 30.13 (1998): 18B-18D.

17. Qi, Li, et al. "A holistic approach of extractables and leachables assessment of rubber stoppered glass vial systems for biotechnology products." Journal of Pharmaceutical Sciences 110.11 (2021): 3580-3593

18. Lohmann, Wiebke, and Uwe Karst. "Simulation of the detoxification of paracetamol using on-line electrochemistry/liquid chromatography/ mass spectrometry." Analytical and bioanalytical chemistry 386.6 (2006): 1701-1708.

19. Lu, Na, et al. "Effectiveness of different kinds of antioxidants in resin-cured bromobutyl rubber vulcanizates." Advances in Polymer Technology 37.6 (2018): 2075-2084.

20. Yehye, Wageeh A., et al. "Understanding the chemistry behind the antioxidant activities of butylated hydroxytoluene (BHT): A review." European journal of medicinal chemistry 101 (2015): 295-312.

21. Minard, Aisling, et al. "The unexplored potential of quinone methides in chemical biology." Bioorganic & Medicinal Chemistry 27.12 (2019): 2298-2305.

ASAS Analytische Standards Andre Stratmann Service Labor GmbH

A&M STABTEST Labor für Analytik und Stabilitätsprüfung GmbH

A&M STABTEST Labor für Analytik und Stabilitätsprüfung

A&M STABTEST Labor für Analytik und Stabilitätsprüfung