This project was a studio collaboration with YouthBuild Boston and Autodesk and because of this opportunity, this is the first class I’ve had at Wentworth where it was structured similar to an architecture office. We had the class work together in both interchangeable and strategic teams where we spent the semester designing the mockups and preparing accurate construction documents for the team at Autodesk to manufacter for Youthbuild Boston.

The design of this pavilion was largely inspired by Hiroto Kobayashi’s Veneer House series where construction is imbedded into the architecture through a system of precut components which makes it easy for builders to construct on site. Because of our access to cnc machinery and traditional construction tools, as well as being mindful to the Youthbuild team that would ultimately construct the pavilion, a pre fabricated style was decided on for the farmstand. I primarily worked within the manufactering and manufacturing document set that we provide to Autodesk.

The site was a local community farm and the project was to create a pavilion shed to replace their temporary tent. Many integral members of the community came and visited our studio during the entire design and mockup process teaching me the importance of understanding the community desires and aspirations. Many iterations of our design was presented which proved to iron out what motions the community members favored in their pavilion.

This was the decided design of the pavilion. Everything from the columns to the back waffle storage wall and even seemingly small details like the center table was designed with mindfulness to material stock use and ease of assembly. Each of these compnents had to have their own section in the CD set for assembly. I had focused my design work especially on the foundation, columns, and cartridge floor system assembley.

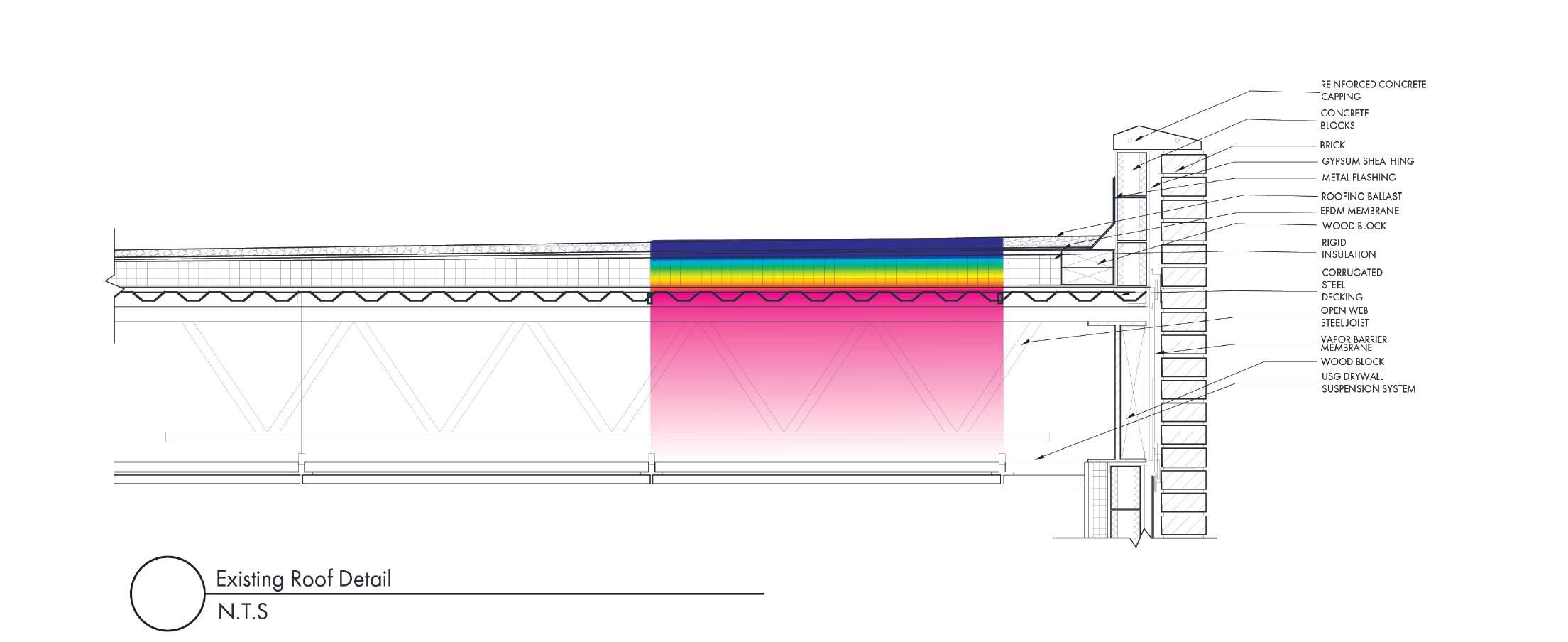

Leading the team in manufacturing construction documents meant that the accuracy and relavence of the details we provided needed to be clear and understandable to anyone who is required to understand the construction of key elements.

Options like creating a separate system for the perimeter were taken into consideration, this way we would be able to have a uniform floor assembley and could deal with corner conditions separate. We dealt with the different condition ultimately by addressing the condition within the floor cartridge construction itself.

This in turn allows for less unique pieces and materials as well as remove the risk of structural failure because the column footings had to be taken into account while designing the edge condition for the floor. Diagrams like this aid in the assembley of these parts

Simple details like this aided in the full scale mock ups of our roof system.