Exploring The Intricacies

of Probe Card Manufacturing Bridging The Gap in Semiconductor Technology

In the ever-evolving landscape of technology, semiconductor manufacturing stands as a cornerstone, enabling the growth of countless industries. From the microchips powering our smartphones to the intricate components embedded in medical devices, semiconductors are the unsung heroes powering the modern world. At the heart of this expansive realm lies an indispensable tool - the probe card.

Probe Cards Unveiled A Gateway to Quality Assurance:

• The Nexus Between Manufacturing and

Testing

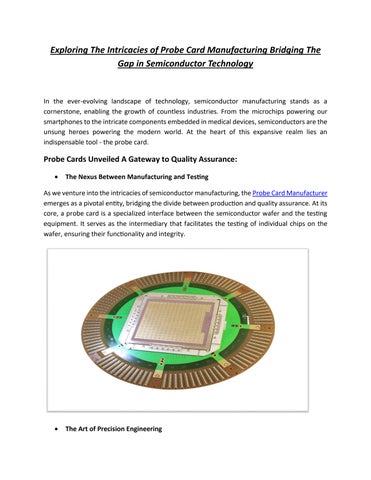

As we venture into the intricacies of semiconductor manufacturing, the Probe Card Manufacturer emerges as a pivotal entity, bridging the divide between production and quality assurance. At its core, a probe card is a specialized interface between the semiconductor wafer and the testing equipment. It serves as the intermediary that facilitates the testing of individual chips on the wafer, ensuring their functionality and integrity.

• The Art of Precision Engineering

Manufacturing a probe card is a symphony of precision engineering. Every aspect, from the materials used to the design layout, demands meticulous attention. The delicate probes, often micro-scale needles, delicately touch the bond pads of the semiconductor chips. These probes require a harmonious balance between flexibility and rigidity, enabling reliable electrical contact without causing damage to the fragile chips.

Crafting the Masterpiece, The Probe Card Manufacturing Process:

•

Blueprinting the Brain of the Probe Card

The journey of crafting a probe card commences with meticulous planning and design. Engineers work in tandem with semiconductor manufacturers to comprehend the specific requirements of the chips to be tested. The layout of the bond pads, the intricacies of the chip design, and the electrical characteristics all influence the blueprint of the probe card.

• The Dance of Materials Choosing the Right Substrates

Central to the construction of a probe card is the selection of suitable substrates. The substrates, often made of ceramics or organic materials, provide the structural foundation for the probes and the electrical pathways. The choice of substrate material is a delicate balance, factoring in properties like thermal expansion, electrical conductivity, and cost-effectiveness.

• Precision Etching Giving Birth to Probes

The creation of probes is a microcosm of sophistication. Precision etching techniques are employed to carve out the minuscule needles that will make contact with the semiconductor chips. The etching process requires an amalgamation of chemical reactions and controlled erosion, all guided by advanced computer algorithms.

• Assembly Symphony Piecing it All Together

Like assembling a complex puzzle, the various components of the probe card come together in this stage. The probes are attached to the substrate, and intricate wiring is integrated to establish the electrical pathways. The delicacy of this process requires skilled hands and state-of-the-art equipment to ensure a seamless and reliable assembly.

The Marvels of Innovation Pushing The Boundaries of Probe Cards:

• Beyond Conventional Advanced Probe Technologies

The world of semiconductor testing is in a perpetual state of evolution, prompting probe card manufacturers to explore innovative avenues. One such advancement is the emergence of

vertical probe cards, where probes are oriented perpendicularly to the substrate. This allows for increased probe density, enabling the testing of chips with ever-shrinking dimensions.

• Navigating Nanotechnology

As semiconductor technology delves into the realm of nanometers, probe card manufacturers are tasked with developing probes that can interact with components on an atomic scale. This demands not only precision engineering but a profound understanding of quantum phenomena that come into play at such diminutive scales.

• The Rise of System-Level Testing

Traditionally, semiconductor testing focused on individual chips. However, the surge in complex integrated circuits necessitates a shift toward system-level testing. Probe card manufacturers are rising to the challenge, devising innovative approaches to simultaneously test multiple interconnected chips, mimicking real-world usage scenarios.

Challenges on The Horizon Navigating The Future of Probe Card Manufacturing:

Redefining Reliability in an Unpredictable Environment

As the semiconductor landscape becomes increasingly intricate, the reliability of probe cards becomes paramount. Factors like temperature fluctuations, material degradation, and the demands of nanoscale interactions pose significant challenges. Probe card manufacturers are investing in research to enhance the durability and longevity of their products.

• Sustainable Manufacturing Balancing Progress and Ecology

The technology industry is making strides toward sustainability, and probe card manufacturing is no exception. Innovations in materials, manufacturing processes, and recycling techniques are emerging to reduce the environmental impact of producing intricate probe cards.

• Human-Machine Symbiosis The Future of Probe Card Manufacturing

Artificial intelligence and automation are redefining industries, and probe card manufacturing is not exempt. Collaborative efforts between human expertise and machine precision are paving the way for faster, more efficient, and error-free manufacturing processes. Skilled artisans and intelligent machines are forming a symbiotic relationship, driving the industry forward.

Conclusion:

In the intricate realm of semiconductor technology, Probe Cards stand as the unsung heroes, enabling the quality assurance that underpins the industry's progress. From their inception as

intricate blueprints to their transformation into complex assemblies, probe cards embody the relentless pursuit of precision engineering. As technology leaps forward, the boundaries of probe card manufacturing are pushed, giving birth to innovations that shape the very fabric of our digital world. The future holds promise, where challenges become opportunities and human ingenuity converges with machine efficiency, propelling probe card manufacturing toward unprecedented horizons.