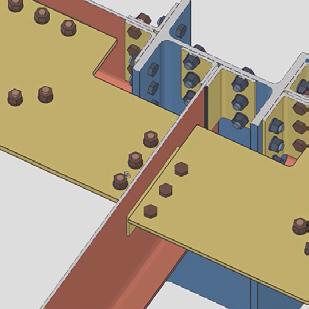

Install cladding and curtain-wall connections with the new Edge-Tie™ system from Simpson Strong-Tie. This innovative solution utilizes bolts that allow installers to easily position and adjust anchors along a continuous slot. A reusable guardrail also can be bolted to the beam while it’s still on the ground. By eliminating field welding, the Edge-Tie system saves time and labor costs while increasing safety at the jobsite. It’s simply a smarter, faster way to get the job done.

Put all of our structural steel solutions to work on your next project. To learn more, visit go.strongtie.com/edgetiesystem or call (800) 999-5099

M & P S p e c i a l t y I n s u r a n c e p r o v i d e s i n s u r a n c e a n d r i s k m a n a g e m e n t s e r v i c e s f o r h e a v y l i f t i n g a n d m o v i n g i n d u s t r i e s .

S P E I A LT I E :

S T E E L E R E C T O R S

T E E L E R E C T O R S

H E A V Y H A U L E R S

AV Y A U L E R S

A R E N TA L

C R A N E R E N T A L

R I G G I N G

G G N G

F A B R I C A T O R S

A B R I C AT O R S

S T R U C T U A L M O V E R S

T R U C T U R A L M OV E R S

L i c e n s e d n a t i o n w i d e , M & P S p e c i a l t y I n s u r a n c e o f f e r s c o m p r e h e n s i v e c o v e r a g e , e x c e l l e n t c u s t o m e r s e r v i c e , a n d c o m p e t i t i v e p r e m i u m s U n d e r w r i t t e n b y A + r a t e d c a r r i e r s , o u r t e a m e m p h a s i z e s t h e i m p o r t a n c e o f a l i g n m e n t b e t w e e n i n s u r a n c e p r o d u c t s , c o n t r a c t u a l d e t a i l , a n d r i s k m a n a g e m e n t p r a c t i c e s .

L i c e n s e d n a t i o n w i d e , M & P S p e c i a l t y I n s u r a n c e o f f e r s c o m p r e h e n s i v e c o v e r a g e , e x c e l l e n t c u s t o m e r s e r v i c e , a n d c o m p e t i t i v e p r e m i u m s . U n d e r w r i t t e n b y A + r a t e d c a r r i e r s , o u r t e a m e m p h a s i z e s t h e i m p o r t a n c e o f a l i g n m e n t b e t w e e n i n s u r a n c e p r o d u c t s , c o n t r a c t u a l d e t a i l , a n d r i s k m a n a g e m e n t p r a c t i c e s .

L i c e n s e d n a t i o n w i d e , M & P S p e c i a l t y I n s u r a n c e o f f e r s c o m p r e h e n s i v e c o v e r a g e , e x c e l l e n t c u s t o m e r s e r v i c e , a n d c o m p e t i t i v e p r e m i u m s U n d e r w r i t t e n b y A + r a t e d c a r r i e r s , o u r t e a m e m p h a s i z e s t h e i m p o r t a n c e o f a l i g n m e n t b e t w e e n i n s u r a n c e p r o d u c t s , c o n t r a c t u a l d e t a i l , a n d r i s k m a n a g e m e n t p r a c t i c e s .

SOLUTIONS

Valued at $24,000

$10,000 per member

SteelPros Training Portal

DISCOUNTS TO STRETCH

Savings of $6,500

$2,500 in first year & $1,250 each subsequent year

SEAA is the only national trade association representing the interests of steel erectors, fabricators, and related service providers. Connector reaches both small and large contractors working in union and open labor markets.

Premium

$1,000+ per year

Workers Comp Program provides opportunity to earn

5% return based on injury performance

BBSI reimburses companies for achieving and maintaining AISC certification

$1,000 per member

SEAA Erector Members receive 50% discount on AISC Membership

Steel Erectors Association of America

353 Jonestown Rd, Suite 207

Winston-Salem, NC 27104 336-294-8880 www.seaa.net

OFFICERS & EXECUTIVE STAFF

David Deem, President

Jack Nix, President Elect

Chris Legnon, Industry Member Vice President

Carrie Gulajan, Associate Member Vice President

Bryan McClure, Secretary

Greg Phillips, Treasurer

R. Pete Gum, Executive Director

PUBLISHING PARTNER

Chris Harrison, Publisher connectorsales@seaa.net

Phone 660-287-7660

Tracy Bennett, Managing Editor editor@seaa.net

Phone 816-536-7903

Macie Murie, Assistant Editor macie@mightymomedia.com

Roger Ridpath, Art Director roger@ridpathcreative.co m 816-792-9669

ADVISORY COMMITTEE

Chris Legnon, Chairman, Cooper Steel

Glen Pisani, Vice Chairman, MAS Building & Bridge

Nathan Bloch, SDS2

Nick Caratelli, Nelson Stud Welding

Oliver Gleize, OTH Rigging

John Hughes, Industrial Training International

Kris McLean, High Plains Steel Services

Jackson Nix, Shelby Erectors

Jim Simonson, Steel Service

Michael Waltman, Group Steel Erectors

Connector™ is published quarterly by the Steel Erectors Association of America 353 Jonestown Rd, Suite 207 Winston-Salem, NC 27104

Copyright 2023 by the Steel Erectors Association of America. No material may be reprinted without permission from the Executive Director. While the information and recommendations contained in this publication have been compiled from sources believed to be reliable, the Steel Erectors Association of America, its affiliates, employees, contributors, writers, editors, designers, photographers, and media advisory committee, makes no guarantee as to, and

By David Deem

By David Deem

Following the conclusion of SEAA’s Convention & Trade Show in St. Augustine, Fla., held in March, there were four takeaways that stuck with me. We often talk about lessons learned in the field, but business owners also need inspiration and reminders to make our companies better.

Most of us have probably watched the movie Rudy, depicting Daniel “Rudy” Ruettiger’s determination to play football for Notre Dame. What I found even more impressive about his story was the perseverance it took for him to get his dream movie made. Some people apply the attitude of “never quit” to everything in their lives.

The same can be said of Zach Burick, president of DS Duggins Welding Inc., who shared his thoughts on leadership and team building. Zach started working for the company he now owns while still in college. After graduation he worked full time, gradually taking on more responsibility and setting a goal to buy the business someday. It is always beneficial to get other leaders’ perspectives. A review of my notes shows phrases such as: “Leadership is a responsibility,” “Winners like to be with winners”, and “Get comfortable being uncomfortable.”

Often the jobs highlighted in the Project of the Year presentation share obstacles that many of us face regularly. On more than one occasion a solution from a winning job helped our firm tackle a similar challenge. But occasionally I’m truly amazed at the creativity and ingenuity of my colleagues.

How do you erect fly over bridge girders that weigh 250 tons within a 6-hour window, during which you have to move cranes and material into position, then remove the cranes before morning rush hour begins? Williams Steel Erection Co., Inc., did just that, earning them the Structural Class III award.

How do you construct a 200,000 square foot, 9,000-ton expansion on top of an existing, fully operational convention center? Derr-Gruenewald put a 300-ton crawler crane on top of the existing roof, and took home Structural Class IV recognition. These two companies made the improbable possible. Watch for a full recap in the Fall issue of Connector. This month, see page 30 for a review of the other winners, which successfully dealt with site logistics, time restraints, and other obstacles.

During crane operations, data shows that if a Pre-Lift Meeting is not conducted, an accident is 335 times more likely, compared to when a Pre-Lift Meeting is utilized. This is just one piece of info that SEAA hopes to put to use for its members as a result of our recent Memorandum of Intent to Collaborate with the Crane Safety Research Laboratory at Texas A&M University, administered by Crane Risk Logic, LLC (CSRL/CRL).

The goal is to utilize data and forensic engineering to minimize risk and increase safety of crane operations. To date, the organization has analyzed data on 1,275 crane accidents that occurred between 1983 and 2023. It is hoped that members will provide metrics for additional research and training.

Crane safety is one of the two most important aspects of steel construction (the other being fall protection) so I was surprised to learn during Jim Wiethorn’s presentation that OSHA does not specifically identify accidents associated with cranes or rigging. This initiative to confidentially share risk intelligence data will enhance crane safety and save lives.

For business owners who can see retirement on the horizon, a session on succession planning by Terry Resnick of Resnick Succession Group was probably quite an eye opener. It was for me. To put it in context, 90% of all U.S. Businesses are privately owned. Ineffective or non-existent succession planning is a leading cause of business failure. Less than 15% of family-owned businesses make it to the third generation. Succession planning is also about protecting your family. Resnick advises:

• It’s never too early to think about the eventual transition of ownership.

• Start with what can you proactively control.

• Make a business succession checklist and have it independently reviewed.

• Life insurance mistakes cause a tremendous loss of capital, and the policy is typically the owner’s second largest asset.

There were also great sessions on structural fastening, fall rescue, and common OSHA citations. Members can find the recordings by logging into your SEAA account.

Attending convention is one of the primary ways I learn new information that I take back to my business. I want to thank the speakers for sharing their knowledge, and the sponsors and vendors who support the event. make plans to join us next year—April 2-5, 2024, at the Renaissance Hotel in Glendale, Arizona. •

Summer Board Meeting

Sponsored by Hilti

Irving, Texas

July 20, 2023

Summer Meet & Greet

Las Colinas Resort

Irving, Texas

July 20, 2023

Fall Meet & Greet Raleigh, N.C.

October 12, 2023

Dave Schulz Memorial Golf Tournament

Lonnie Poole Golf Course Raleigh, N.C.

October 13, 2023

“Good safety records, comprehensive training aligned with long-term career paths, and awards recognitions, are among the criteria that prospective employees consider when deciding where to apply. Beyond the inherent value of being a safe company, it’s also a great marketing tool in a highly competitive market,” said outgoing Safety & Education Committee Chairman Bryan McClure.

The Safety Excellence Award goes to seven member companies in three categories. Recipients were selected based on their EMR ratings, OSHA 300A statistics, and safety program processes over the last three years. Scoring was based on points assigned to a multi-criteria analysis, conducted in blind review by members of SEAA’s Safety & Education Committee.

Two companies received the 2023 Craft Training Award. Applicants were evaluated on the portability of credentials, availability of apprenticeship programs, training, and recruitment efforts.

Evaluations for Craft Training Excellence are made in comparison to other companies of similar size, based on the number of ironworkers employed from Jan. 1 to Dec. 31, 2022. Note that there were not submissions by employers in all size categories for 2023. The World Class honorees each receive $1,500 to further their training program initiatives.

SAFETY EXCELLENCE WINNERS

World Class Premier Gold

Derr & Gruenewald Construction, LLC Brighton, Colo.

Gardner Watson Decking Oldsmar, Fla.

High Plains Steel Services Windsor, Colo.

Empire Steel Erectors Humble, Texas

L.R. Willson & Sons Gambrills, Md.

CRAFT TRAINING EXCELLENCE WINNERS

World Class Category 1

Derr & Gruenewald Construction, LLC Brighton, Colo.

Black Cat, LLC Cheyenne, Wyo.

Shelby Erectors, Davie, Fla.

World Class Category 2

Shelby Erectors Davie, Fla.

SEAA has entered into an agreement to collaborate with Crane Risk Logic, a technology and data service provider dedicated to global crane risk improvement. SEAA supports member company participation in the Crane Risk Logic Federation, which is a joint venture administered by Crane Risk Logic with the Crane Safety Research Lab at Texas A&M University on behalf of crane users, OEMs, trade groups, and related industry stakeholders.

“The goal of our collaboration is to reduce and mitigate crane risks for our members, through access to research, training materials, and insights from subject matter experts,” said David Deem, President of SEAA.

Crane Risk Logic and the Crane Safety Research Lab uses an innovative information exchange between crane designers, manufacturers, and owners, and organizations

that transport, erect, and dismantle cranes, as well as site supervisors and safety managers of crane operations. “Findings are generated from anonymous accident data, real-time telematics, and equipment and device testing using engineering-based research, Artificial Intelligence (AI), Predictive Analytics models and other tools,” explained Kevin Cunningham, President and CEO of Crane Risk Logic.

“SEAA is committed to continual investment in our industry by connecting industry leaders, creating a strong network of support, and increasing member value through collaborations such as this,” said Pete Gum, Executive Director of SEAA. This agreement is the latest in a series of investments SEAA has made in hiring, training, insurance, and risk mitigation tools for its members. •

IronBOT from Advanced Construction Robotics (ACR) successfully completed its inaugural project in February on the Port St. Lucie West Boulevard Bridge in Port St. Lucie, FL alongside Shelby Erectors, Inc. The originally estimated duration of the rebar installation was 14 days. By augmenting Shelby’s crew with the BOT Bundle, the same amount of work was completed in only seven days.

During the pilot, IronBOT placed 147,032 lb of rebar while TyBOT completed 58,068 ties over 6.5 production shifts. Shelby Erectors, ACR’s Integration Partner, has already been boosting crew productivity with TyBOT for over two years. “We were excited to be able to have IronBOT and TyBOT work together alongside our crews on this project. We were impressed that we could slash our rebar installation schedule in half. We are actively looking for new projects to incorporate the BOT Bundle in our operations,” said Jack Nix, COO of Shelby Erectors, Inc.

Essential Perimeter Safety Systems (EPS) along with InCord showcased the newest technology in jobsite safety netting last month at SEAA’s 2023 Convention and Trade Show in St. Augustine, Fla. The EPS Debris Containment System (DCS) is designed to attach to steel columns that are already part of the erecting schedule. This is done on the ground. Rope and cables are tied to the base of the column and once the column is set in place a net is raised two floors above splice locations allowing all erecting to take place behind vertical netting. The DCS has proven to be the safest netting system for jobsite protection and is more efficient in its installation, maintenance and removal. Multiple patents ensure that EPS will be the leader in containment solutions for new and rehab construction projects.

Magni Telescopic Handlers, a global leader in Rotating Telehandlers introduces the TH series of fixed boom telehandlers. The lineup includes 6 models with lift capacities ranging from 10,000-12,100 lbs., lifting heights from 25-79 ft. and max reach from 14-63 ft. The spacious cab design with unrivaled visibility, full-color digital display, and Load Moment Indicator (LMI) provides operators with a comfortable, user-friendly, and safe working environment. In addition, the Magni TH line is the only in this class in the United States with LMI and Load-Limiting Technology as standard. A variety of attachments are available, including forks, winches, jibs, and work platforms.

OuickFrames has released a new Drop-In Frame, a fully assembled version of QuickFrames’ classic adjustable structural support roof frames. Designed for fabricators and erectors that are accustomed to dropping in frames before the roof deck is down, these new frames deliver the convenience of fully assembled frames while allowing for adjustability in the field. This prevents some of the most frustrating hassles and expenses on new construction projects, including changes in mechanical locations, measurements, and equipment sizes. With Drop-in Frames, users can detach the rail system, attach new bolt-in connectors and install the frame from elsewhere. Built to work with steel joists or beams with metal decking, the frames can save fabricators valuable shop time.

In response to industry demand for durable and engineered equipment stabilization at a lower price point, DICA has designed a new crane pad, EcoMax. EcoMax combines alternating solid composite “tim bers” and steel I-beams connected with through-bolts for maximum load distribution. The new crane pad is ideal for medium to larger sized equipment with reaction forces of 100,000 lbs. EcoMax Crane Pads are non-ab sorbent, easy to clean, and resistant to rot and decay, providing long-lasting and predictable equipment support. 1-866-733-3272

Years ago, David Deem worked as a project manager at a structural fabricator that did its detailing in-house. If he had a question about sequencing, connections, or any other, well, detail on the details, he’d walk over to the detailing manager’s office. Today, Deem is President of Deem Structural Services, Longview, Texas, and President of SEAA.

Today he brings an erector’s perspective. A beam leaving the fab shop doesn’t have much value on its own, at least not until the steel erector does its job. So how can that beam have the most value—to make the most money for everyone involved? “It’s all about good communication,” Deem said, “and asking the right questions.”

Challenging elements of the job site can

Tim Heston is the senior editor of The Fabricator magazine. He has covered the metal fabrication industry for 25 years. This article is excerpted with permission from his original article “Best communication practices in structural steel fabrication.” Read the full article here.

cause

small problems to snowball into large ones in a hurry, which can make communication problems in construction especially costly. Today’s software can track beams from the time they’re drawn to the time they arrive on-site, flagging problems far ahead of time. But things happen and beams sometimes don’t arrive when they’re needed. This is why no software can replace good communication practices.

“It’s always good practice to get on-site to see what the erector is dealing with,” Deem said. He described a snow-covered job site at a university campus. The erectors had just two days, from early Saturday morning to late Sunday afternoon, to build a pedestrian bridge. That particular job was completed on schedule because everyone was on the same page, and all drawings and other documents had exactly what the erector needed to know.

Picture a crane picking a beam between two buildings with no extra room for maneuvering. The structural beams needed to be delivered in just the right sequence at just the right times. This calls for close collaboration

among the detailer, erector, and fabricator.

But if a fabricator and detailer move ahead before an erector is chosen, it can lead to greater costs and extended schedules. When the erector is finally chosen, they are told to start with Building A. But it’s abundantly clear from looking at the drawings and the job site that it would be so much easier to start with Building B. But the ball’s already rolling, and the erector makes do, though expenses and delays keep mounting. Good communication could have avoided all these headaches, and much of it could have been covered during the site-specific erection and safety plan.

“We love to have the detailers involved, when possible,” Deem said. “Regardless, though, there are things detailers can ask fabricators from the get-go. These involve the sequence and schedule, as well as shipping requirements.”

Say a detailer sees a girder in the plans that’s 100 feet long, but the site won’t allow for a 100-ft. girder, be it because of space constraints, limited crane capacity, or a combination of both. “If that’s the case, what splices do we need? Where are they? Are

they bolted or welded? Is there value engineering involved? Will it be shop welded or field welded? These are all things that, as erectors, if we’re invited to the party, we’ll be glad to discuss,” Deem said.

Just one missing beam can add entire days to the project schedule, sometimes more. Cranes need to be at the right spot for a particular pick. Weights on trusses need to be added and removed in just the right sequence for structural stability during erection. “In many cases, all the material has to be there in the right place, with the crane in the right spot, or it’s just not going to get erected,” Deem said.

“You now have a lot of connection design responsibility being delegated to fabricators, who then delegate it to the detailer,” Deem said. “And in many ways, that’s a good thing, because the erector can communicate directly with the detailer to achieve connections that are safe, more efficient, and work better for everybody.”

Deem called these “erector-friendly” connections— those that are safe, easy to perform, and abide by OSHA requirements. If a worker needs to climb a high ladder just to access a connection, there’s a good chance the connection is not erector-friendly.

From the steel erector’s perspective, there can never be too many erector aids, such as L-shape plate welded onto the end of a hollow structural section that provides necessary support during the erection sequence.

On multistory structures, specific column-splice locations also make the erector’s job easier. Deem emphasized that practices might vary depending on the job and erector, but his company prefers column splices to be about 4 ft. from the top of steel (deck plate), spaced in such a way so that the erector can erect two floors at a time. With the first floor installed, the erector would work upward, installing girders and deck plate for the second and third stories, with a column splice 4 ft. above the third-story deck plate. The next column splice would be two stories up from there, 4 ft. above the fifth-story deck plate, and so on. This column-splice sequence allows erectors to work in twostory “batches.” Place those splices farther apart, and the erector needs to strategize how to pick, manipulate, and place interior beams between those tall columns.

Some structures, like three-story

buildings, might specify single tall columns with no splices at all. It’s not ideal, Deem said, and it does require some upfront discussion, particularly if exterior columns make it impossible to place interior beams. The key again is communication.

OSHA does not allow double connections at columns and beam webs—that is, two

connections sharing connection holes— without certain erector aids. Bolts do need to be staggered, so that no one bolt needs to support all three members. But the staggered arrangement still needs those erection aids. These can be an angle seat (welded angle iron support) or connection flange with a notch that allows space for at least one bolt from the opposite member to remain in place as the second member is bolted in

place. Without these, the erector needs to have a welded seat or a member to support the load during the double-connection process. Fabricating these on-site isn’t ideal, of course, with a massive crane on-site and a schedule to keep.

If beam connections share the same hole pattern, yet only one beam has an angle seat at the connection, the drawings should specify on which side of that connection to start, per the sequence. Or, a fabricator can simply place an angle seat on both sides, so that no matter the sequence, the connections go together per OSHA requirements.

OSHA also requires erectors to use perimeter safety cables before erecting the next tier, and those cables need to go through holes or otherwise be securely attached to the perimeter columns. “If a fabricator sends me a perimeter column without holes or tabs to run our cables through, OSHA says I’m not allowed to stand that column until I do something about it,” said Deem.

Specifics vary depending on the job, but often the ideal column has four anchor bolts or rods; holes at the top of columns for a shackle or a pull pin; holes for perimeter

cables; plenty of double-connection aids; perhaps even a few tie-line holes for a fall-arrest system; bolted joist seats; and, not least, some extended shear tabs to allow easy connecting, including the bolting and torqueing that’s needed at moment connections.

The right shear tabs can make an erector’s job much easier, faster, and safer—and it’s a key erector aid that can be discussed, especially if connection design has been delegated to the fabricator. With representatives from the erector, detailer, and fabricator sitting at the table, the three can discuss if and where shear tabs make sense. With everyone on the same page, the fabricator then can write a request for information (RFI) to get those shear tabs approved.

Deem conceded that extended shear tabs do require welding, which is something fabricators may not want to do. In these cases, Deem has proposed a shear-tab alternative, if the loads will allow. “It’s essentially a shear-tab connection that’s a bolted angle clip. Those angles are bolted in the shop. Then when it comes to me, it’s essentially a shear tab.”

Another common issue comes with bracing connections, with HSS or similar

As the industry adage goes, errors cost $10 for a detailer to fix, $100 for the fabricator, and $1000 for the erector. Many software solutions still depend on the structural steel detailer to examine the complete node, consider conflicts that might occur during erection, and make tedious adjustments on each member in the model or drawing. SDS2’s automated connection design is built with the end goal in mind—a completed project. It is the only steel detailing software with erectability intelligence, considering the complete node in its connection design calculations and reducing the potential for human error when it comes to identifying job site complications.

Below are ten common field issues that SDS2 automatically checks and adjusts for as you generate your model and drawings. Some functions—in particular, those built on AISC, CISC, or OSHA specifications—run by default with SDS2’s automated connection design functionality. But many can also be controlled and customized with additional setup options according to fabricator and erector preference.

1. Insufficient Bolt Clearance

2. OSHA Safety Connections

3. Erection Aids

4. Inadequate Framing Clearance.

5. Incorrect Material Orientation.

6. Conflicts with Opposing Connections

7. Inadequate Connection Clearance

8. Tool Clearance

9. Shank Out

10. Over-Designed Connections, such as eliminating unnecessary bolts

member connecting at a 45-degree (or nonperpendicular) angle to a base member. It’s common for those bracing connections to have just one hole. That means the erector must partially bolt and then use tools to ensure everything is properly aligned before tightening the connection. In these cases, two or more bolt holes make an erector’s job much easier. The company’s preferred connection is bolted bracing, which eliminates welding—a time and money saver.

The more field welding and cutting a project takes, the more complex and expensive it becomes. Deem described several instances in which an erector’s initial bid assumed connections would be bolted. Then as the contract documents made their way through approvals, the engineer increased the loads, which in turn required more full-pen welds.

Are those fillet welds sufficient to take the loads? They might be sufficient, or they might not. But if the erector is involved in the discussion, then at least the question is being asked.

Often a fabricator will send the angles

for the erector to field-cut, which can be problematic, because on many job sites, no one can fire up a gas cutting torch without approval from the engineer of record. Of course, doing more fabrication in the shop doesn’t always make erection easier. A fabricator might think adding stiffener plates on both sides of a beam is helping, but on-site the beam with both stiffeners simply doesn’t fit. So the erector has no choice but to cut the plate out and field-fabricate during erection. With the right communication with the erector, the detailer and fabricator would have known to leave one stiffener plate off, to be welded in the field.

Another pet peeve: a weld-all-around symbol on a drawing. “That’s every erector’s favorite weld symbol,” he said sarcastically. “Sometimes you can’t even weld all the way around. And we know we probably don’t need to weld it all the way around. This is where we need detailers, through the RFI process, to ask the question.”

Welding costs money. A continuous weld costs more than a stitch weld. Overhead welding costs even more. Tough-to-access full-penetration welds are costlier still.

Imagine a situation in which the detailer contacts the general contractor and asks about a dimension for an elevator shaft in the middle of a building.

He doesn’t get an answer, so to protect himself, he puts the connecting beam on hold. Of course, that hold halts the entire erection sequence—all because of a few W10x12 beams.

“So now I’m out there with a huge crane, and I can’t hang any of the building, all because of these little W10s,” Deem said. “But if we’re proactive, we can keep things on schedule.”

The erector can field-fabricate to the dimensions when they’re available. In the meantime, erection can continue on schedule. Yes, this might increase field fabrication costs slightly, but it’s nothing compared to the days lost while beams are on hold as an RFI remains unanswered.

“I can get paid for work I did,” Deem said. “But anyone will tell you that it’s extremely difficult to get paid for work you didn’t do.” When a project is on hold, it can be extremely difficult to get paid for those lost hours. •

Ironworkers have the highest rate of suicide of all construction trade workers. And the total numbers are heartbreaking.

When discussing fatalities in construction, we generally refer to OSHA’s on-the-job data—in 2018 that number was 1,000 deaths. But when you factor in the number of people in the United States who died by suicide whose occupation was in the construction industry—the number is five times higher. (5,400 people whose occupation was in construction took their own lives in 2018.)

The Centers for Disease Control and Prevention breaks the data down further by occupational groups with more suicides than the general population. Of the 11 construction occupations cited for men, structural iron and steel workers was #1 and reinforcing iron and rebar workers was #2.

And these statistics don’t reflect the thousands more who died by drug overdose.

According to a January 2023 CPWR Data Bulletin on Construction Worker Causes of Death, more than 14,000 construction

workers died due to overdose in 2020. Consider for a minute the number of fatalities due to falls in steel erection (11 in 2021, according to BLS data). Consider how much emphasis the industry puts on fall prevention. For the record, suicides on the job equaled the same number of people who died from falls (11 in 2019.)

On and off the job, the ugly truth is that far more people in construction are impacted by a suicide than they are by a death due to a fall. That leads to two questions: Why? and Why aren’t we incorporating prevention into our safety and training programs?

Why is suicide so prevalent in construction?

“Stress levels in construction are off the charts,” said Sally Spencer-Thomas, a clinical psychologist, founder of ConstructionWorkingMinds.org, and an ENR 2021 Top 25 Newsmaker. “The stakes are high, schedules are tight, and we are asking people to do more with less.”

It takes unique skills to be an ironworker. It also takes a unique mindset. “Many working in this industry are tough-minded, which is essential to wanting to work high up on the steel,” she said. “But their super-power is also what makes them more vulnerable to mental

While human interaction is key to preventing suicide in construction, an AI-driven test from Predictive Safety called AlertMeter® provides field supervisors with a powerful tool to mitigate risk driven by worker fatigue, emotional distress, family crisis, and drug and alcohol use.

Fatigue compounds stress and interferes with mentally and physically demanding tasks, reducing capacity to focus and slowing reaction times. As fatigue increases, it has a negative impact on concentration, can impair judgment, and is detrimental to short-term memory. No other technology can evaluate a person’s cognitive fitness as compared to their normal cognitive function.

“Testing outside ‘normal range’ is a notification to a supervisor or manager to have a safety conversation that otherwise would not have occurred. Those conversations can then lead to various outcomes. The tool empowers supervisors to have a data driven conversation,” said Peter Hay, Vice President of

But are we listening when ‘kryptonite’ makes them vulnerable?Tracy Bennett is Managing Editor of Connector and President of Mighty Mo Media Partners, LLC. Reach her at tbennett@mightymomedia.com.

health concerns because they don’t tend to reach out for support. They don’t see despair, depression, or anxiety as a mental health issue, they attribute the problems instead to external factors that are causing them stress.”

There are a few other reasons why the problem exists.

Men outpace women four to one in suicide deaths and construction remains a male-dominated industry. Among the reasons: men are less likely to seek help, are more likely to self-treat with alcohol and other substances, and are more likely to use lethal methods. However, among women, workers with the highest suicide rates were in this industry, which says something about the work environment. (2020 CDC report: Suicide Rates by Industry and Occupation-National Violent Death Reporting System, 32 States, 2016.)

According to A Construction Industry Blueprint: Suicide Prevention in the Workplace, available at ConstructionWorkingMinds.org, there are other risk factors.

Nature of the work: Cyclical work with regular periods of lay-offs and re-hiring causes uncertainty about employment. Workforce and skill shortages result in laborers working overtime to complete projects. The combination results in a “pressure cooker” atmosphere that can overwhelm employees.

Exposure to physical strain or psychological trauma: Workplaces that expose employees to physical or psychological injury through traumatic life-threatening events can experience symptoms of chronic pain, post-traumatic stress, or burnout that can contribute to suicide despair.

Culture of substance abuse: Workplaces that informally support a culture of self-medication to relieve stress can experience escalating substance abuse problems that also increase the risk of suicide.

Workplace suicides, 1992-2019

Sleep disruption: Working long or abnormal hours can affect sleep, causing mental and physical exhaustion. This effects performance, increases the probability of injury, and can exacerbate other mental health concerns.

In construction, training is conducted essentially for two reasons: to improve productivity and to reduce injuries and fatalities. Poor mental health checks both of those boxes. According to a 2022 Gallup Panel, workers with fair or poor mental health are estimated to have nearly 12 days of unplanned

This NIOSH validated screening takes just 60 seconds, is non-lingual, and objective. While the company claims that AlertMeter has demonstrated 40% reduction in worker’s comp claims and 35% reduction in TRIR, it is also possible that it could provide insight into mental wellness.

“Through the objective engagement, we have seen employees be willing to share struggles they are going through and the company then supporting them in various ways, including changing work tasks, taking time off, providing counseling, etc.,” said Hay. And feedback from employees has been positive. “They now feel the company cares about them rather than just wanting them to get to work,” he said.

Learn more at predictivesafety.com

absences annually compared with 2.5 days for all other workers. Missing work is projected to cost the economy $47.6 billion annually in lost productivity.

“Science has proven that the brain does not fire normally when the person is suffering from poor mental health. That affects decisions made on the job,” said Spencer-Thomas. “For example, we may not know why a person makes a decision to work and not tie-off. There could be an emotional root-cause and no amount of fall prevention training is going to change that when the decision to harm oneself is intentional. That’s why mental wellness is a safety issue,” she said.

We provide emergency training to improve outcomes when there is an incident. For example, we conduct fall rescue training, we teach workers how to give CPR. Managers would not hesitate to give employees CPR training without concern for liability because it is considered basic emergency training. The same should be true for suicide prevention. Spencer-Thomas reports that safety and health professionals working with construction unions and large general contractors, have successfully led the change to incorporate mental health training into their organizations.

At ConstructionWorkingMinds.org, Spencer-Thomas provides two documents that outline action steps for companies and leaders. The following recommendations come from “10 Action Steps Companies Can Take to Save Lives” and “10 Questions Leaders Must Ask Themselves.”

Companies must first cultivate leadership that will make good mental health a priority. This includes improving mental health literacy, teaching coping skills, and building a caring culture.

Next, develop intervention steps that will help detect emerging mental health problems before they become life-threatening. This includes promoting employee assistance programs, screening for mental health conditions and substance misuse, and training field supervisors how to have difficult conversations. It’s worth noting, that in the previously referenced Gallup Panel, 31% of construction workers said their employer did not provide easily accessible mental health support services and another 44% didn’t know whether these services were available.

Finally give employees tools. Promote the 988 Suicide & Crisis Lifeline. The hotline removes the barriers of cost, travel, and waitlists to provide people in crisis an immediate response. For callers who are in an acute

life-threatening situation, call centers can engage in more aggressive interventions, such as tracing calls and sending emergency personnel. Beyond that, work with employees to create a safety plan and establish procedures to prevent tragedy.

“Prevention means providing tools for how to start a conversation, how to be empathetic and to be a bridge to resources. They have to practice the conversation just like practicing to give CPR,” said Spencer-Thomas.

Certainly, construction has shown that top-down leadership is essential to improving corporate safety cultures. In “10 Questions Leaders Must Ask Themselves,” Spencer-Thomas and Cal Beyer of Holmes Murphy, encourage construction company leaders to make mental health and suicide prevention one more piece of that conversation:

“Leaders who are truly intent on creating lasting change in their efforts to develop a robust mental health promotion and suicide prevention program will look beyond one training session or single awareness campaign. Rather, they will look for innovative ways to incorporate changes so that suicide prevention and mental health promotion becomes woven into the company health and safety processes and therefore more likely to be sustained. Pioneering leaders have incentivized mental health practices through their wellness programs. Others have promoted the messages of suicide prevention in their daily toolbox talks or have found ways to integrate supervisory training on having difficult conversations about mental health into their new manager orientations and ongoing leadership development training.”

occupational groups meeting reporting criteria with higher† than the population rate (all occupations) and associated major occupational groups and rates — National Violent Death Reporting System, 32 states,§

CERTIFICATION

OSHA’s Subpart CC requires signal person qualification by a third-party qualifier.

While an OSHA letter of interpretation recognizes apprenticeship programs that train and assess riggers and signal persons as third-party qualified evaluators, many contractors, states and municipalities require a Qualified Rigger and Signal Person Certification.

Third party certification comes with a hefty price tag without input on testing from subject matter experts, ironworkers and their contractors. The Iron Workers’ certification eleminates the recertification cost of $500 per person.

Ensuring that only trained, skilled and competent ironworkers complete rigging and signaling tasks elevates workplace safety standards and reduces risk.

Iron Workers International Certification Board’s (I.I.C.B.) Rigging & Signalperson Certification Program is accredited by the National Commission for Certifying Agencies (NCCA), the accrediting body of the Institute for Credentialing Excellence. The I.I.C.B. joins an elite group of more than 130 organizations representing over 315 programs that have obtained NCCA accreditation.

6,000 HOURS OF HANDS ON EXPERIENCE

3-PART EXAM

TESTING & RECERTIFICATION EVERY 5 YEARS

IRON WORKERS RIGGING & CRANE COURSE

WORKERS INTERNATIONAL SETS THE STANDARD HIGH WITH ACCREDITED RIGGER & SIGNAL PERSON

The Steel Erectors Association of America hosted another wonderful Convention and Trade Show this past March at the World Golf Village Renaissance in St. Augustine, Fla. Over the course of four days, there were multiple excursions, 12 education sessions including an inspiring keynote presentation from Daniel "Rudy" Ruettiger, the Trade Show where almost 50 exhibitors shared their latest innovations, and a beautiful President’s Dinner.

The association has seen a tremendous amount of growth in the last few years and it truly showed at this year’s convention. Be sure to mark your calendars for future events! The Dave Schulz Memorial Golf Tournament will take place at the Lonnie Pool Golf Course in Raleigh, N.C on October 14, and the 2024 Convention and Trade Show will be held in Glendale, Arizona, April 1-5.

More photos from 2023 Convention & Trade Show can be found at seaa.net. Go to News and click on Photo Gallery in the dropdown menu. Images can be purchased from Carl Kerridge Photography at carlkerridge.com/SEAA/2023.

Steel Erectors, Fabricators, Steel Deckers, and Rodbusters come together for a common goal

300 Scarlet Blvd.

Oldsmar, FL 34677

813.891.9849

Fax: 813.891.4105

Estimating:

Geoff Kress: 727.463.3074

Jason Kulvinskas: 727.463.3078

For the second year, a networking event exclusively for first-time attendees and new members, was a hit. “We want to help our members grow and succeed in this industry and breakout events like our First Time Attendee and New Member Reception allows us to meet our new members and help them get the most out of their membership,” said Jack Nix, Chairman, Membership Committee. New members were paired with a board member to facilitate introductions and future mentoring opportunities.

The event featured a mix of full education sessions, mini sessions, and multiple panel discussions which were powerful and eye opening. “We heard personal stories on how members succeeded against all odds, got practical advice on how to plan for the succession of your company, and saw demos of best practices for fall and rescue training,” said Carrie Gulajan, Events Committee Chairperson. Friday’s presentation on risk management principles for crane operations in steel erection was an eye-opener and has led to a new partnership with Crane Risk Logic and the Crane Risk Logic Federation. (See more info in Perspective, page 8, and Business Operations, page 38.)

The Project of the Year panel discussion shared insights from these award winning jobs. “Whether you’re an Erector, Fabricator, Rodbuster or Steel Decking Company, we all go through challenges on projects, but the more we talk about how we overcome those challenges, the better off our industry will be,” said David Deem, President of SEAA.

The Safety Excellence and Craft Training Excellence Panel included the winning companies from the 2023 Safety and Craft Training Awards Programs. These member companies are leading the industry with stellar safety and training programs. “This was the second year we held the Safety and Craft Excellence panel and the discussion with this group of winners was excellent. It’s important for us to recognize them for their efforts, and learn from companies that are doing it right,” said Bryan McClure, Former Chairman, Safety and Education Committee.

The President’s Dinner brought everyone together to congratulate the 2023 Project of the Year winners and the Safety Excellence and Craft Training Excellence Winners. Geoff Kress of Gardner Watson Decking received the association’s highest honor, The William Davis Service Award, which is given to an individual that has dedicated his career to improving the steel erection industry. Bryan McClure of Trivent Safety Consulting received the 2023 Person of the Year award for his continuous support and mentorship for others within the association. •

The annual Project of the Year awards program for SEAA members includes two categories—Structural and Miscellaneous Metals. There are four classes by erection contract size in the Structural category and two classes in Miscellaneous. This year, there were no entries for Structural Class II.

Projects that were topped out in 2021 or 2022 were eligible and must have been completed without significant accident or injury. Submissions are reviewed by an independent panel of judges from an engineering firm not affiliated with the association. “SEAA appreciates the time and expertise these volunteers contribute, which

Brightline Station, Aventura, Fla.

Structural Class I (Up to $500,000)

Erector: Hodges Erectors, Inc.

Fabricator: George’s Welding Services, Inc.

Architect: Zyscovich Architects

Structural Engineer: Desimone Corp.

GC: Lemartec Corp.

Tons of Steel: 98 tons

Topped Out: October 2022

makes it possible to fairly judge these projects and benefits our members,” said Drew Heron, Chairman of the Awards Committee.

This article is Part One in a Two Part Series, featuring three of the five winning projects. Part Two will appear in the Fall 2023 issue.

Structural Class III ($1 Million to $2.5 Million) Williams

Brightline is a privately owned passenger train line in Florida. More than just a transportation service, the overall project is part of a real estate vision to re-energize neighborhoods with transportation hubs by building modern, attractive stations. The Aventura Station, for which Hodges Erectors, Inc., assembled and placed a pedestrian bridge is one of those stations.

The passenger trains are designed to accommodate wheelchairs and other assistive devices. They feature bike storage, luggage check, and dining. The high-speed locomotives are American-made and are powered by clean biodiesel for lower emissions and reduced noise.

“Brightline’s new south terminal at Orlando International Airport is part of the company’s Phase 2 expansion into Central Florida, and eventually Western Florida with a Tampa hub. Ultimately the project is expected to have a $6.4 billion economic impact on the state. We are very proud to be a part of this major Florida project,” said Jorge Amador, President of Hodges Erectors, Inc.

Assembling the pedestrian bridge on the street side of a space-constrained job site took several weeks to complete, and was the easy part of this project. Unforeseen circumstances added complexity to a task that already required close coordination

with the GC, Lemartec Corp., Florida East Coast Railway, and Florida Power and Light. It was decided early on that the only way to accommodate our work was to make the lift at night,” said Jorge Amador, President of Hodges Erectors. Disruptions to traffic on an adjacent roadway and live railroad track with high voltage power lines overhead had to be minimized.

First, Hurricane Ian delayed the date that the bridge was to be installed. The crane that Hodges Erectors’ crane rental partner had planned to use—a 650-ton all-terrain crane with Superlift attachment—was no longer available due to being requisitioned for emergency powerline repairs in the aftermath of the hurricane.

“Beyel Brothers came up with an alternative plan to use a 300-ton crawler crane instead and were generous to discount the cost based on our original crane choice,” said Jeff Justice, General Superintendent for Hodges Erectors.

The Liebherr LR 1300 SX lattice boom crane required more loads to be trucked in, more room for setup, and had to be setup in a different location than originally planned. In addition, the railroad required that the crane be de-rated to 50% capacity for any lifts over railroad tracks.

Justice mapped out on site the exact location for the center of the crane and the minimum and maximum radii, and carefully calculated the actual total weight of the bridge, accounting for weight added for galvanizing, bolts, decking, etc.

Tulsa Downtown Pergola, Tulsa, Okla.

Misc. Metals Class I (Up to $500,000)

Erector and Fabricator: Basden Steel Corp.

Architect and Structural Engineer: Corgan

GC: Flintco

Contract Value: $478,415

Tons of Steel: 37.3 tons

Topped Out: December 2022

Structural Class IV ($2.5 Million and up) Derr & Gruenewald Construction

Beyel Brothers then used 3D Lift Plan from A1A Software to establish the lifting plan and rigging plan. They checked for clearances to nearby power lines (that were to be de-energized for the lift), confirmed

TIA Blue Side Expansion, Tampa, Fla.

Misc. Metals Class II ($500,000 to $1 Million)

Erector: Shelby Erectors

Fabricator: Commercial Metals Company

Architect and Structural Engineer: Hensel Phelps

GC: Superior Construction

Contract Value: $728,796

Tons of Steel: 834 tons

Topped Out: May 2022

adherence to the 50% de-rating, and established ground bearing pressures.

“Then just a week before the crane was due to be delivered, the crane operator was in a car accident. Beyel Brothers didn’t have anyone else available that was qualified to operate this crane,” said Justice. They had to hire someone new.” In the meantime, construction continued on the structures where the bridge was to be set, creating an even more challenging bridge placement maneuver. The 78-ton, 135-foot long bridge had to be lowered into 16 foot wide sections on either end with less than 2 inches of

leeway on the sides.

“To make sure the bridge section would fit, the GC conducted an as-built analysis on the structure, measuring anchor bolts, embeds, and concrete structures. Hodges Erectors did the same for the bridge,” said Justice. “With that information, we determined, that although tight, it would fit, as long as the bridge remained plumb during the lift,” he said. The day before the lift, the team conducted a load test to confirm the weight was below the restricted capacity and to verify that the bridge would lift up level, adjusting rigging as needed.

“We coordinated with Florida Power and Light to de-energize the power lines between 5 am to 11 am the day the crawler crane arrived, and again the next day from 2 am to 8 am.” During that time, the road where the crane was set up was closed to traffic, and the railroad closed the tracks to all trains from 2 am to 5 am. Previously, the railroad and Hodges Erectors had established a plan for aborting the lift if a freight train were to arrive ahead of schedule.

“Three hours, this was the maximum time allotted for us to get the bridge lifted and set in place—so it had to be a perfect fit,” said Amador. At 2 am the crane lifted the bridge just off the ground and waited. At 2:30 am the railroad sounded the all clear whistle. By 5 am the bridge was in place, then the crane was moved away from the tracks.

And if that wasn’t enough pressure, this project had attracted the attention of local media and the public. More than 50 onlookers watched the bridge placement. “That’s the most eyes I’ve had on an active bridge erection in all my years of doing this job,” said Justice, which was an indication of the importance of the project to the community.

A developer for a prominent downtown building in Tulsa, Okla., was looking for a structure to provide shade at a newly renovated café area on the second floor terrace. Seeking an elegant, eye-catching design, the 100-foot long pergola consists of five arches. The AESS Category 1 structure is made of white galvanized rolled 10-inch WF for the columns and arches, with 3-inch pipe infill and 10-inch HSS connecting the columns and bearing the center arches. Each arch is just over 18 feet tall and 20 feet wide.

The AESS finish of the design was inherently one of the three primary challenges Basden Steel Corp. had to overcome. This project received a white paint over galvanized base and required multiple full pen welds.

The other challenges were the timing and the location. The project came to Basden at the beginning of winter, and the entire project was designed, fabricated, and erected in less than four months. Limited available space for crane setup in the urban downtown meant that multiple lanes on a major street had to be closed.

To deliver the design team’s vision, Basden Steel first altered weld locations from the middle of the 10-inch WF rolled beams to actual connection points, to allow for better fit up and to allow for more tolerance in the connections with the roll of the radius.

The arches needed to be assembled individually at street level and then lifted as fabricated domes. “Trying to adjust the radii in the air would have proven very difficult. With the AESS requirements, we had to limit our use of erection aids and splice plates for temporary stability,” said Austin Jones, Contract Administrator and Field Operations Manager.

Developing an erection sequence that provided for all the design intendents was critical to the success of the project. The engineered erection plan was prepared by the late Rodney Baxter. He also determined that the four-prong rigging system was the solution to perfectly level picks of the arches. On site, minor adjustments were made using chain falls. “He was invaluable to ensuring all parts of the project were planned. He is highly missed,” said Jones.

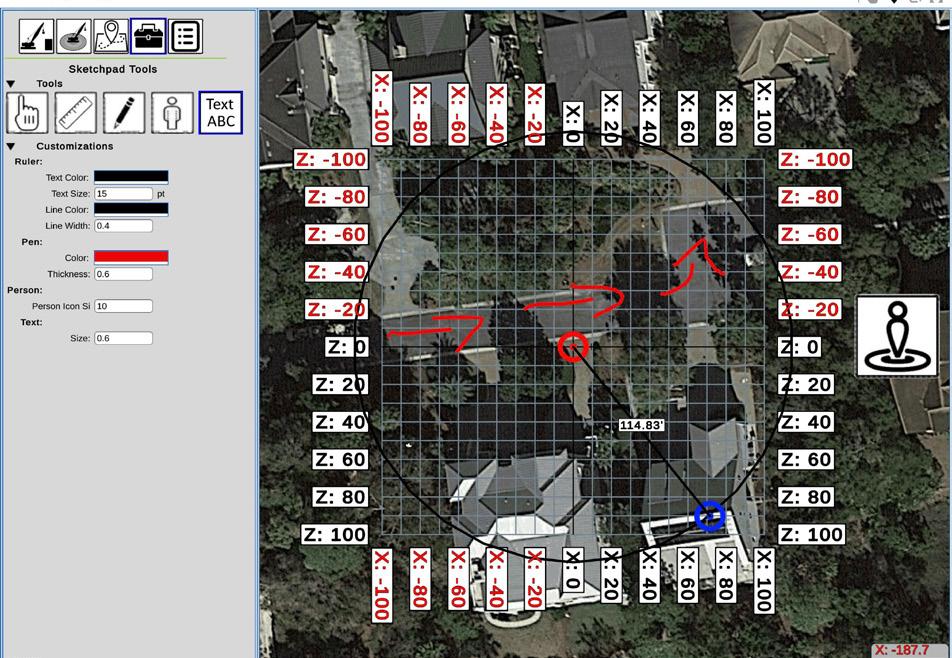

Rigging Designer App Gives Users A Faster Way To Create Custom Rigging Plans.

• Point, Click, Drag, and Drop. No more X-Y-Z factors needed.

• Import into 3D Lift Plan for use later.

• Build rigging plans for forklifts, gantries, overhead cranes, and other equipment.

• Choose from hundreds of pre-built rigging products, loads, and objects.

The Same Sketch Pad You Love For Creating Bids, Only Better!

• Sketch preliminary job site data to use for bids and estimates.

• With GPS location services on your device, add a scaled Google Map of the job site location.

• Easily establish crane location, travel path, add 3D objects, job details, and more.

• Print your sketch plan or convert into a 3D Lift Plan.

“After several reviews of the erection plan, site visits for field dimensions and site coordination with other trades and the general contractor, we thought we had it all accounted for. The rigging was purchased, new training was established for the rigging supervisor, city permits were pulled for lane closures, and a date was set,” said Jones.

As the date for installation neared, the Basden team discovered that information that had been provided to them regarding the crane placement had never been field-verified by the GC. Turns out that the location would have put the crane in an unstable area where there were potential voids below the street and sidewalk.“I was walking the site with Sean Carter, the Superintendent. We noticed a manhole cover about five feet from where one of the outriggers was to be placed. Sure enough, an entire service tunnel was directly under where we had planned to put the crane,” said Jones.

They identified a better setup location that was further from the building and still enabled the use of Big B Crane’s Terex AC 140 all-terrain crane lifting at a 53 ft radius and nearly 100 ft of boom extended. The problem was that this meant three of four lanes of the street would have to be shut down, increasing city permit costs. “The GC ended up spending an extra $7,000 in lane closures, plus oversize permits for each delivery of the assembled structure. Needless to say, we were encouraged to move quickly,” said Jones.

Basden Steel had previously been advised of working hour restrictions— between 9am and 4 pm weekdays only. But just as installation was ready to begin, they also learned that the crane had to be removed each Friday and returned for setup on Monday.

“That meant losing 3-4 hours of hosting time each Friday and Monday—essentially a full day of work each of the four weeks we were on the job,” said Jones. Another cramp on production was the need to pre-heat the steel for full pen welds as the temperatures dropped in December.

“Mid-way through the second week, we got into a groove. Installation was complete in three weeks with an additional week for weld clean up, Bondo for AESS, and touch up painting,” said Jones.

Tampa International Airport is the first in the U.S. to debut Express Curbsides, allowing passengers without checked bags to bypass the ticketing level and arrive directly at the transfer level of the Main Terminal. This decongests curbsides and terminal, and allows for an easier, more seamless passenger experience.

Shelby Erectors, the reinforcing steel subcontractor, placed the reinforcing steel for three bridges at the entrance, main terminal, and exit. The company installed all of the rebar, drilled shafts, footings, columns, caps, decks, and railing, totaling 834 tons of steel.

The 17-month schedule for the airport Blue Side Expansion was a bit tighter than similar projects, primarily because of the need to have as little impact on the traveling public as possible. “This was an active, open airport and it was essential that the project not impede traffic flow,” explained Jack Nix, COO for Shelby Erectors. Because this was an addition to the airport adjacent to areas the public was using, the access roads for travelers were the same access roads the contractors had to use. Throughout the project very close coordination with GC was essential. “We work closely with GC who was responsible for redirecting the public when needed, for scheduling materials delivery, and preparing for concrete pours,” said Nix.

The other primary challenge was also related to the location.

Widening the access area for Express Curbsides at an existing terminal meant that Shelby Erectors’ five-to-six person crew was working under existing structures. The laydown area for materials was small and work took place in locations with limited headroom. This makes it was more difficult to place materials into the job. “Most of the time we can use cranes to lift materials, but this required a smaller crane with a short boom and the use of telehandlers to move materials around,” said Nix. In addition, beams are usually pre-tied and lifted into place, but for this job they had to be built on location.

Beams for one of the decks ran transversely from edge to edge, rather than longitudinally or lengthwise. This shorter

beam design is a less common construction method for bridges, explained Nix. Likewise, two of the curved ramps did not use beams. Instead, the slabs were more than 1-foot thick, “requiring #9 rebar in the top and bottom mats, running in both directions,” said Nix. This unique deck design required the rebar to tie directly through the pier caps.

“For reference, #9 rebar is 1-1/8” in diameter. This project took 834 tons of steel and 29,300 sq ft of deck was installed,” said Nix.

The volume and size of rebar installed for this job was significant. “The work we do directly impacts the job schedule. The relationship between the rebar work and the concrete pours requires a very close relationship with GC,” he said. •

Arecent construction industry report published by Construction Dive indicates that “despite OSHA’s efforts, the construction death rate hasn’t budged in over 10 years.” BLS Data shows that approximately 10 per 10,000 construction workers continue to be fatally injured each year.

In crane operations, the largest number of those fatalities involve people other than crane operators and riggers. Speaking to attendees at the SEAA Convention in March in St. Augustine, Fla., Dr. Jim Wiethorn, P.E., founder of Crane Risk Logic and ICC Forensics, said: “Thirty-two percent of the people killed on the job when a crane incident occurs are field personnel.”

No improvement in the construction death rate is unacceptable and change is needed. There are many contributing factors driving these dismal results, but when we know better… we do better. Today, there are new risk solutions that tap the power of data to measurably improve the factors that contribute to serious crane accidents and fatalities. To have the greatest impact, it will take collective industry participation.

There is a growing interest among trades such as steel erection in the US, Canada and Europe, which regularly use cranes, to utilize shared risk intelligence data platforms for more precise, directional risk improvement information.

The Crane Safety Research Lab (CSRL) at Texas A&M University (TAMU), administered by Crane Risk Logic (CRL), is one such platform. The goal is to reduce and mitigate crane risks through an innovative information exchange between crane designers, manufacturers, and owners, and organizations that transport, erect, and dismantle cranes, as well as site supervisors and safety managers of crane operations.

This digitally intensive crane risk services platform, composed of a collaboratory of diverse organizations, is supported by a cyberinfrastructure built upon extensive technology resources. It will enable a continuous flow of data and related information from, between and among Crane Risk Logic Federation members for direct data engagement with the CSRL at TAMU, as illustrated below. The Federation is a joint venture project administered by CRL with the Crane Safety Research Lab at Texas A&M University on behalf of

trade groups,

The Steel Erectors Association of America is one of several crane-user trade groups interested in tapping this powerful data as a new service for its members. In March,

A study analyzing level of responsibility from 701 crane accidents compared 11 different entities, such as crane manufacturer, crane operator, lift director, rigger, etc. While the crane operator was identified most often (23.8% of the time) and the lift director was second most cited (19.8% of the time), the findings tell a very different story when put on a timeline. Since 1990, the annual cumulative percentage of operators responsible for a crane accident has steadily declined. The opposite trend has occurred for lift directors. This data helps to inform employers of the importance of training for individuals who serve in the role of lift director on the job site as a way to reduce future risk.

October 12, 2023

Board Meeting, Peer Group, and Meet & Greet

Raleigh, NC

October 13, 2023

Golf Tournament

Lonnie Poole Golf Course

North Carolina State University

Registration Opens May 1, 2023 at SEAA.net

the SEAA Board of Directors entered an agreement to collaborate with Crane Risk Logic (CRL) and the Lab at Texas A&M. The purpose is to work together to create user-friendly methods for dealing with data, increasing efficiency and reducing risk in crane operations typical of steel erection activities.

“SEAA is pleased to support a strategic alignment with Crane Risk Logic (CRL) to access the resources at the Crane Safety Research Lab at Texas A&M University. Our intention is to evaluate data science-based crane risk improvement methods to bring new levels of information to enhance SEAA Member safety and risk management programs,” said David Deem, President of SEAA.

Historical data provided by Dr. Wiethorn provides just a glimpse into the relevance for steel erectors. Ironworkers, specifically the person working as the Connector, are the third most frequently injured and fatally injured worker on a job site when crane accidents occur. Other trade groups and leading crane owners are entering into similar agreements.

“We, at Bragg Companies, are pleased to support Crane Risk Logic’s efforts in providing new technological advancements involving accident data in our industry. The subject matter expertise by CRL in crane engineering and risk management coupled with vast opportunity to learn from real time proven risk factors through digital learning hub platforms at the Crane Safety Research Lab is of keen interest to us,” said Ian Johnson, P.E., Vice President and Chief Operating Officer of Bragg Companies, a national full-service crane, rigging, and heavy haul company based in Long Beach, Calif. “CRL’s advanced computing combined with secure data sharing in an interactive forum with other owners has all the ingredients to change the paradigm in crane safety,” he said.

With the assistance of Bragg Companies leadership, CRL is working to develop collaborations with the Mobile Crane Owners Group (MCOG - Southern California) and the Crane Owners Association (COA – Northern California), to mutually align interests in similar fashion to the SEAA agreement. We will begin collaborating between SEAA and each of these groups and their respective memberships this summer.

Dr. Jim Wiethorn, P.E., had the foresight more than 35 years ago to manually catalog crane accident causation metrics from his forensic engineering assignments. Overtime, this raw information became extensively refined into a spreadsheet format, from which he further dissected accident facts in comparison to OSHA and ASME standards. This one-of-a-kind database is the foundation on which future crane risk factors will be identified to measurably improve the stagnant construction fatality results mentioned previously.

According to Dr. Wiethorn: “The time has come to bring established safety-related procedures, based on an actionable accident data base, that will continue to grow and improve safety for both national and international crane users. Thanks to Texas A&M for believing in the crane safety program. The Crane Safety Research Lab is the realization of my dream to give back to an industry that has done so much for me.” •

“Advanced computing, secure data sharing, and a forum has the ingredients to change the paradigm in crane safety.”

Jim

Wiethorn, P.E., founder of Crane Risk Logic and ICC Forensics, on using data to improve crane risk and reduce crane accidents.A little bit of friendly competition never hurt anyone, which is why SEAA is launching a new Member Referral Program starting in 2023. Individuals employed by member companies will be recognized for referring companies to join the association.

To receive a Trailblazer award, you must recruit three or more member companies in a calendar year. The individual that recruits the most members in a calendar year will receive the Top Trailblazer Award. Submit your referrals through the website at seaa.net/trailblazer.

Looking for resources to send to a prospective member? Visit seaa/net/member-benefits.

The 2023 Trailblazer Award Winners will be announced at the 2024 Convention & Trade Show in Glendale, Arizona, April 2-5, so you better get to recruiting!

The Center for Construction Research and Training (CPWR) Data Center monitors industry trends, including the top hazards facing construction workers: Falls (35.1%), Struck-by (17.1%), Electrocutions (7.7%), and Caught-in/between (5.8%). Labeled the “Focus Four,” these hazards accounted for 65 percent of fatal injuries in the industry from 2011 to 2021. Find additional data at CPWR.com. Click on Research then Data Dashboards.

A.B. Holling Construction Inc., Ravenel, S.C., provides full-service steel erection, structural welding, and crane and rigging services.

Recruited by: Division Five Steel Inc., Nelson Stud Welding

Allen Steel Erection Inc., Merritt Island, Fla., is a steel erector serving the state of Florida.

Recruited by: Skyline Decking

Connect-EZ, LLC, Spring Valley, Ohio, founded by Bob Foley and Terry Tincher, combines 70-plus years of experience in structural engineering, steel fabrication/erection to create a series of shop-welded connect devices that eliminate welding in the field, speed construction and reduce the need for skilled labor on-site.

Recruited by: Armondo Perez

Corfix, Kanata, Ontario, provides project management services, timekeeping, and health & safety documentation united in one easy-to-use software. Corfix helps companies from one-man shops to major enterprises build better.

Recruited by: Zach Burick, D.S Duggins Welding

Cumberland Steel Company, LLC, Cleveland, Ohio, specializes in supplying your metal product needs, such as steel, stainless, aluminum, copper, brass, grating and expanded metal, titanium, aerospace materials, and plastics.

Recruited by: Richard Bostick, Piedmont Structural Company

Division 5 Steel, Inc., Starke, Fla., is a mid-sized structural steel fabricator servicing contractors and construction managers on their projects in the Southeast. Division 5 Steel provides full fabrication services and coordination of the materials and installation of the entire structural steel portions of construction projects.

Recruited by: Geoff Kress, Gardner-Watson Decking

EquipmentShare, Columbia, Mo., is a nationwide equipment and digital solutions company serving the construction industry with equipment rental, retail and service solutions using cloud-connected technology.

Recruited by: Richard Bostick, Piedmont Structural Company and David Deem, Deem Structural Services

Full Sail Logistics, Dayton, Ohio, is a tech-forward, client-centric third-party logistics provider that is transforming client service within the industry. Whatever your shipping needs may be Full Sail Logistics can develop a custom-tailored solution just for you.

Recruited by: Bryan McClure, Trivent Safety Consulting

Fall Edition September 2023

Ad Deadline: August 18, 2023

ConnectorSales@seaa.net

“When you know better, you do better.”

Vulcraft’s flush frame connections are modernizing steel joist floor systems. Designed to reduce floor-to-floor heights, simplify MEP installation, and accelerate deck installation, studies have shown that our flush frame connections also significantly mitigate floor vibration.*

Long recognized as a leader in innovation, versatility, and cost efficiency, Vulcraft’s steel joist floor systems provide more options and less vibration.