Grain Power Station

33 Years of History

...an enduring legacy

Sectional arrangement of generator stator.

Drawing issue: 1-9/75

...an enduring legacy

Sectional arrangement of generator stator.

Drawing issue: 1-9/75

a great

The story of Grain is a fight for survival, a story of adaption, innovations and flexibility

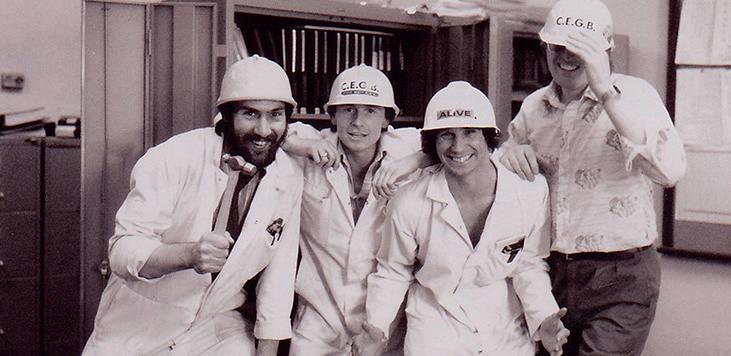

Twice in its life the plant has been identified for closure, but eventually, at the final calling the plant closed on the 31st December 2012. Through its long life time, and partly due to the adversity faced, one thing that Grain has become renown for is the spirit of the staff and support teams.

It is testament to these people that the site gets a second lease of life through the CCGT power station, but there can be no doubt that it is the enduring legacy of the oil plant and its staff that has and continues to make this site the success that it is.

played a critical role in electricity generation within the UK. flexibility which run throughout its turbulent life span.

This book has been compiled in memory of the plant and its people, to capture the many phases of its life. Someone at Grain once told me ’ ..... we are only custodians of the plant, we pass the baton on from generation to generation.’ Well in that context this book is a celebration of the generation s of staff that have been the custodians of Grain over its life.

We hope you enjoy the trip down memory lane.

Life before Grain, in 1918 British Fighter aircraft of the First World War were des igned and built by the Port Victoria Marine Experimental Aircraft Depot on the Isle of Grain.

This photo shows a Short Bomber and Port Victoria PV7 Grain Kitt en fighter together in 1917. The Short Bomber was a British, two-seat, lon g-range reconnaissance, bombing and torpedo carrying aircraft designed b y Short Brothers.

The Port Victoria P.V.7 Grain Kitten was a prototype British Fighter aircraft of the First World War, designed and built by the Port Victoria Marine Experimental Aircraft Depot on the Isle of Grain.

A very small and light biplane intended to fly off platforms on Royal Navy Destroyers, it was unsuccessful, only a single prototype being built.

11 Plant Managers have had the

Throughout the early years of the plants life, 1970’s, 1980’s and early 1990’s, the station ran as its own business unit.

Eugene McEvoy (1974 - 1980)

Alan Cowler (1980 - 1983)

Eugene McEvoy (1974 - 1980)

Alan Cowler (1980 - 1983)

Fred Kirkby (1983 - 1994)

Fred Kirkby (1983 - 1994)

Throughout the leaner periods of Grain’s life, late 1990’s and most of a combined management team. Throughout this phase Grain was often their own site, with many going on to have successful careers within

Peter Jones (1996 - 1998)

Jim Lightfoot (1998 - 2001)

Peter Jones (1996 - 1998)

Jim Lightfoot (1998 - 2001)

of the 2000’s, the plant was joined with Kingsnorth with often used to give emerging talent the opportunity to run the indus try.

Adrian Smith (2001 - 2002)

Martin Baker (2003 - 2006)

Adrian Smith (2001 - 2002)

Martin Baker (2003 - 2006)

From the late 2000’s, and the advent of the CCGT plant, Grain again became its own business unit.

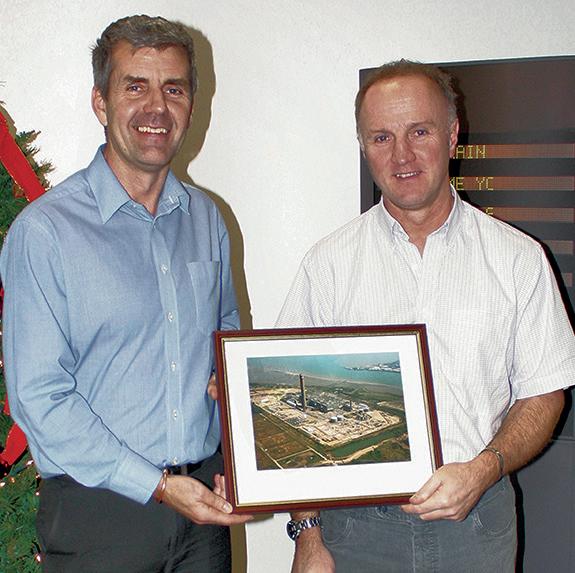

Alan Sanderson, MBE (2006 - 2008)

Mike Felgate (2008 - 2010)

Alan Sanderson, MBE (2006 - 2008)

Mike Felgate (2008 - 2010)

The first half of 2013 also saw us review our fleet contract team sizes and skill sets, again as a consequence of the Oil Plant closure. At the same time we were devising, a new contracting management structure that saw the birth of the fleet cooperative approach, later named Phoenix.

Paul Morton (2010 - 2013)

Paul Morton (2010 - 2013)

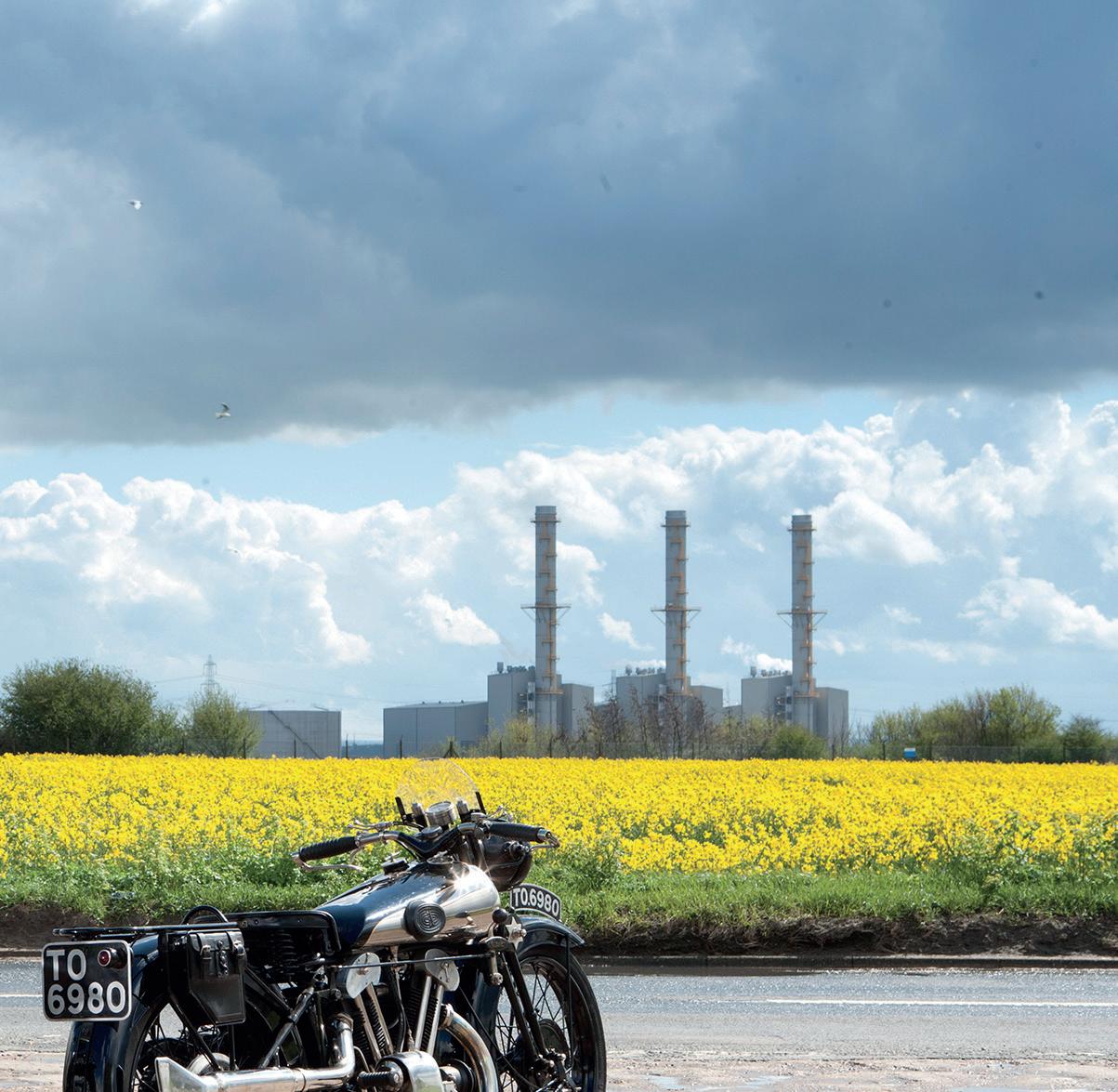

The Isle of Grain has been a hub for industrial Britain for over 100 years. This image shows the current landscape that boasts a Liquid Natural Gas (LNG) import terminal capable of supplying 20% of Britain’s gas demand, and 3 power stati ons capable of supplying over 7% of UK power demand. The huge scale of the Grain Power Stati on is clear to see, but if you look closely you can sti ll see the impact and scars that the massive BP oil refi nery left on the island. It was this proximity that led to the Power Stati on being designed as oil fi red, but also why it is positi oned where it is today.

The United Kingdom enjoyed a long period of rapid growth and prosperity in the 1950’s and 1960’s. According to the OECD, the annual rate o f growth (percentage change) between 1960 and 1973 averaged 2.9%. However, following the severe shock of the 1973 oil crisis and the 1973–1974 stock market crash, the British economy had fallen into recession. Edward Heath’s Conser vative Party were ousted by Harold Wilson’s Labour Party as he took office for the second time. It was a time of Trade Union militancy, power cuts, rubbish left uncollected in the streets and the time of the ‘three day week’.

During the 1970’s Britain started to feel the early stages of an energy crisis, critically for Grain the once abundant fuel source oil, started to become expensive.

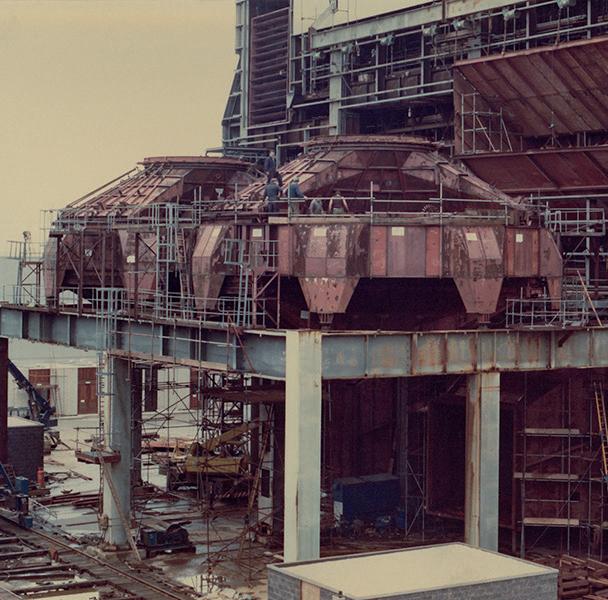

Grain Power Station was built throughout the 1970’s, with the first unit commissioned in 1979, but the station wouldn’t be formally opened until 1984.

During the miners’ strikes in the 1970’s and early 1980’s oil fired power stations were critical to keeping the lights on across the country, at Grain the commissioning team were under intense pressure to come online as soon as possible.

The site prepared Grain power station would be the largest oil-fired power station in Europe (3000MW) and was operated by the Central Electricity generating Board (CEGB).

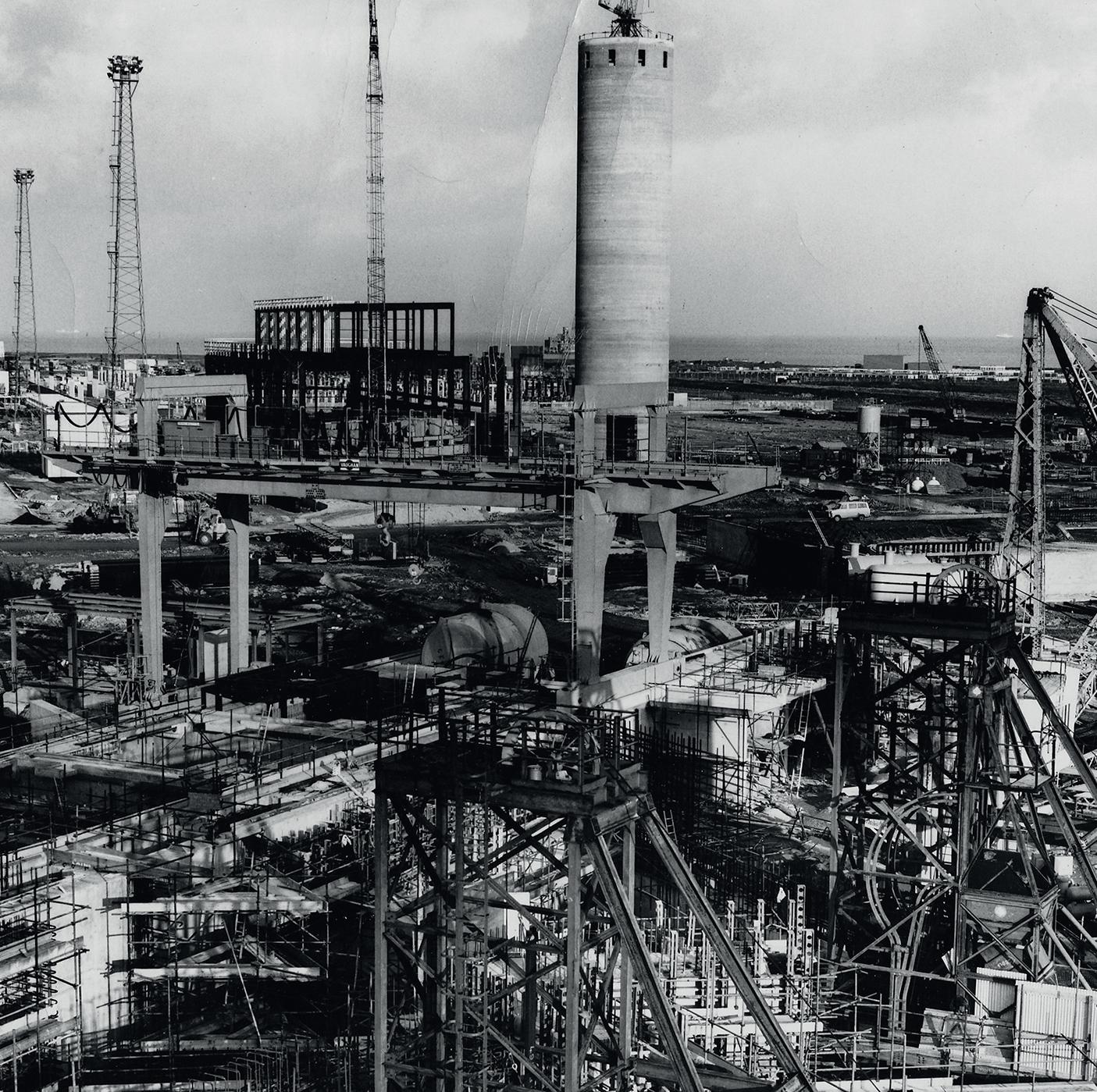

Initial design work started in 1972, within two years more than 1,000 men were engaged in construction activities.

An early artist impression of what the finished power station would look like.

A striking and elegant design, the rounded corners and grey aluminium cladding made the plant look very modern compared to its peer group of that time.

Grain power stati on approach road in 1973. At the height of the industrial acti on of the 1970’s Grain power stati on was regularly visited by picketers. In this photo one of the main boiler steam drums is prevented from arriving on site.

Grain was built on a 250-acre (1.0 km 2) site for the Central Electricity Generati ng Board.

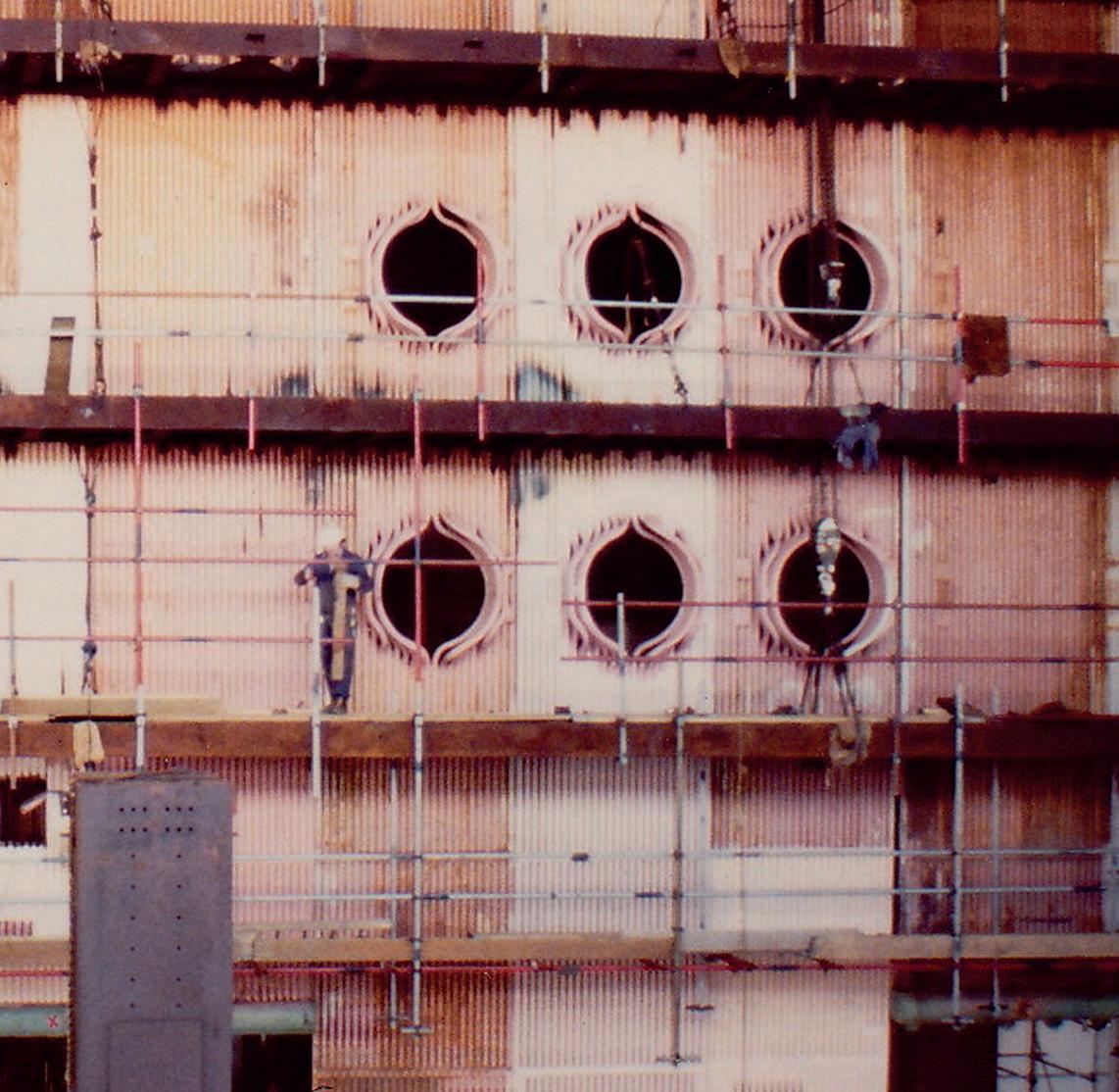

The giant boiler houses and turbine hall that make up most of the power station all began life as a frame of giant steel girders. These would bear the weight of the massive furnaces, each was 4000 tonnes in weight and suspended from the roof. This would allow it to expand and contract by 165mm in operation.

The steel frame also had to carry the building’s own weight as they enclosed huge spaces. The turbine hall was 400m long and over 50m wide.

To service the five planned generating units a true engineering feat had to be designed. A 244m or 801 feet tall chimney, the second tallest ever built in the UK.

The top of the chimney was painted pale blue to match the sky, making it seem to disappear on sunny days. The chimney became such a famous local land mark that it was used as a navigation aid for ships entering London through the Thames and was visible for tens of miles out to sea.

This large population brought with it a considerable and ever increasing demand for electricity. To provide for this high demand and to avoid power losses that come from transmitting electricity long distances, new power generators were needed in the area. There was a shortage of sites suitable for large, modern power stations in the south east of England but Grain had key advantages:

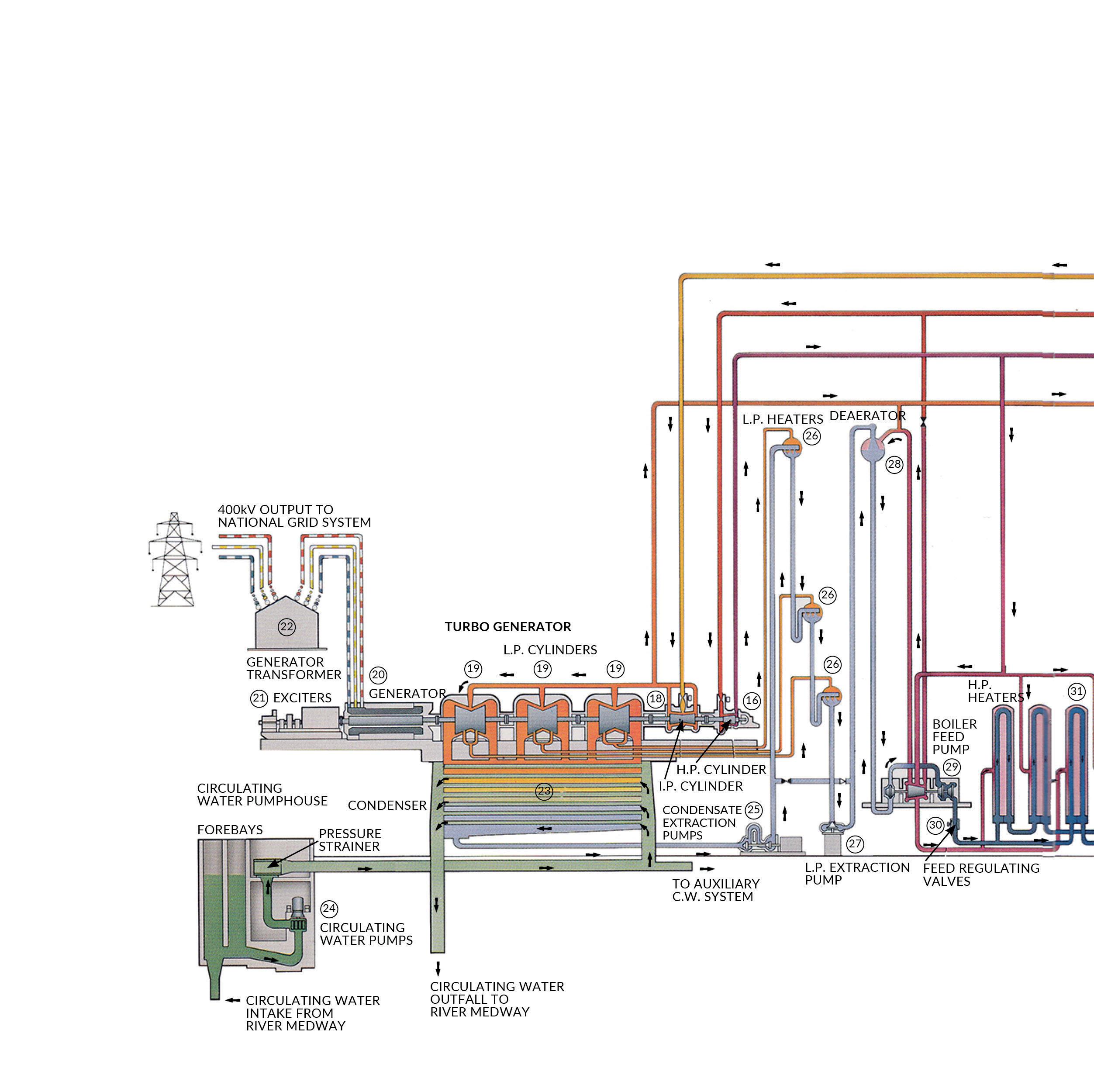

• Plentiful supplies of cooling water were available from the River Medway, with no serious intrusion upon the navigable waterways.

• The land at the site was unsuitable for agricultural development or new housing.

• Fuel supplies were readily available, initially from the nearby B.P. oil refinery, and later from both the refinery and the nearby Kingsnorth power station.

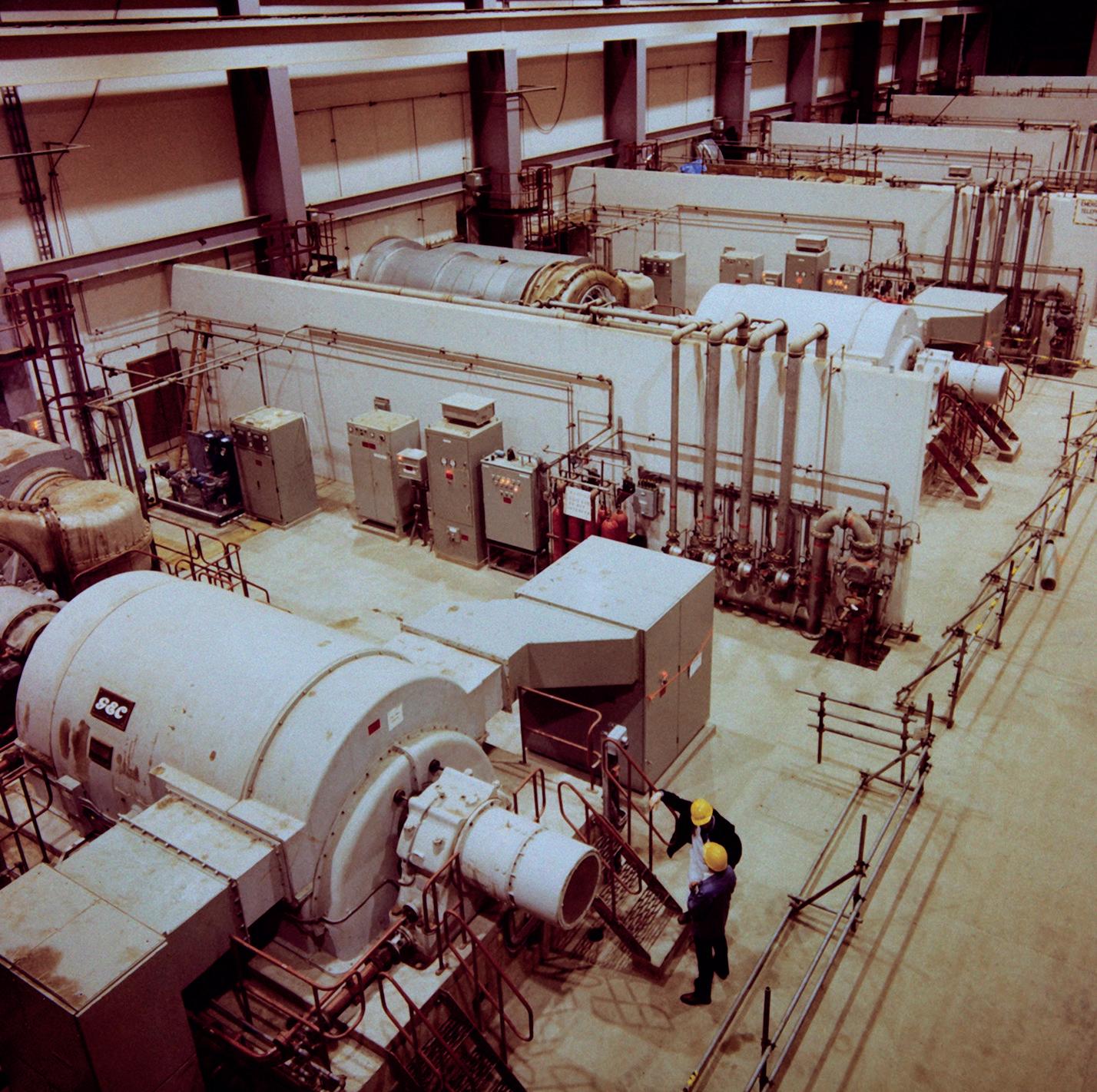

The dominant structure of the power station was the chimney at the centre of the site. Behind the chimney were the five boiler houses, these were designed to complement the natural circulation boilers, approximately 50m high and 40m square. Behind the boiler houses was a single turbine hall, designed to house the five planned turbo-generator sets. The shafts were arranged end-to-end meaning a huge enclosed space, over 400m long. The control block was situated between unit 2 and unit 3 including the central control room and the water treatment plant.

At the southern end of the station the fuel oil system was linked to the B.P. oil refinery and by a 12km pipeline to Kingsnorth power station. Grain could receive fuel from either of these sources. The small gas turbine house was also on the south side of the station. This allowed Grain power station to black start, or, begin generating with no support from the national grid after a power supply crisis.

On the eastern side of the station was the large national grid switch yard and beyond that the cooling water intake and outfall. At the northern end of the station were the offices, workshops, stores, welfare facilities and fire station that kept the power station running.

The station extends over 58 hectares of the Isle of Grain and represented the very best of heavy industrial engineering.

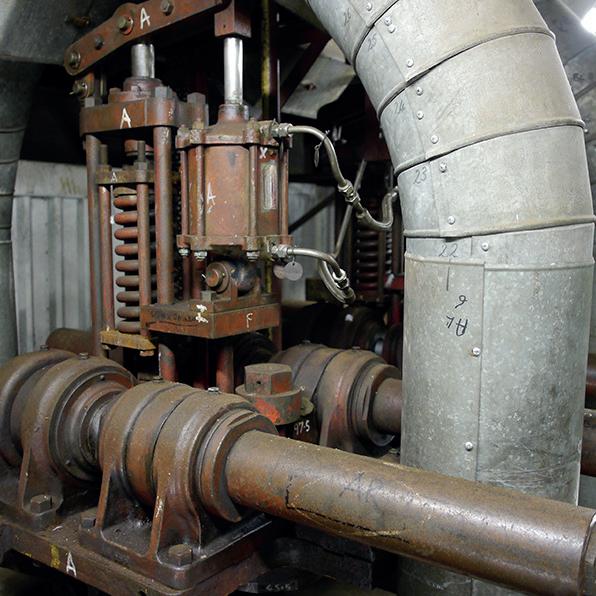

Fuel oil was supplied by a 12km pipeline (1) from Kingsnorth power station or from the B.P. oil refinery and passed into two storage tanks at Grain (2). Oil was drawn from the duty tank by the pumps (3) and flowed under pressure through steam fed heaters (4). The heating made the oil more fluid in preparation for burning. The oil was then passed to the boiler burners (5) where it was atomised by steam mixed with hot air from the forced draught (F.D.) fans (6). The air was drawn from the air intake (7) and heated by a steam air heater (8) and an exhaust gas air heater (9). The heat given off by the burning oil converted water to steam. Exhaust flue gases were sucked out of the furnace by the induced draught (I.D) fans (10) and passed to the chimney (11). A portion of the flue gas was passed back to the furnace by the gas recycling (G.R.) fans (12) this helped to control the steam temperature.

The boiler was fed with extremely pure demineralised water, known as boiler feed water, which was pumped into the economiser (13). The economiser allowed the water to absorb heat from the exhaust gases before passing to the steam drum (14). From the steam drum the water naturally circulated to the bottom of the boiler where it entered the hundreds of miles of tubing that formed the furnace walls. The heat released from the burning oil was absorbed by the wall tubes and the water was converted to steam which rose to the steam drum.

Unit 2 boiler name plate.

Unit 2 boiler name plate.

Steam passed from the steam drum to the superheater (15) which was located in the hottest area of the furnace. The superheater increased the temperature of the steam before it passed to the high pressure (H.P.) turbine (16). The steam flowed over blades in the turbine causing it to rotate. The steam then returned to the boiler for reheating (17) before passing to the intermediate pressure (I.P.) turbine (18) and from there to the three low pressure (L.P.) turbines (19). The five turbines in each set were all connected and drove a single generator (20). The generator consisted of a stationary outer section, stator, which was wound with internally-cooled copper conductors and a central rotating section, rotor, which was a large cylindrical electro-magnet.

The electrical current for the rotor was supplied by the exciters (21). The rotor was connected to the turbines. The turbines rotated, driven by the steam from the boiler and made the rotor turn within the stator. The rotating magnetic field induced a voltage in the stator conductors and when the generator was connected to a power demand current flowed.

The electricity produced by the generator was increased in voltage by the generator transformer (22) for reduced energy losses during transmission by the overhead power lines of the national grid.

The steam, which had exhausted its useful energy, was turned back to water in the condenser (23) to be used again in the boiler. The condenser contained thousands of titanium tubes filled with flowing cooling water pumped from the river Medway by the cooling water pumps (24).

The high purity, boiler feed water was extracted from the condenser by the condensate extraction pumps (25) and passed through the L.P. steam heaters (26) and pumped by the L.P. extraction pump (27) up to the deaerator (28), a heated storage tank that removed any dissolved gasses from the water.

From the deaerator, the water was pumped by the boiler feed pump (29) through regulating valves (30) to the H.P. steam heaters (31) which further increased the water temperature before the water returned to the boiler at the economiser.

Here, an overview of the electricity production process sheds some light on the engineering excellence needed to make Grain a success.

Each of the boilers contained approximately 483 kilometres of carbon and special high temperature steel tubes. The boilers were divided into three sections, a furnace at the front, followed by a superheater/reheater enclosure, and a rear enclosure containing the economiser. Each furnace was 21.4m wide, 10.7m deep and 25.9m high. A vertical water-filled tube wall cut the furnace in half from front to rear, forming two combustion chambers of equal size. Each furnace was fitted with 24 oil burners equipped with gas/ electric torch igniters to start the combustion.

The steam drum was a large cylindrical pressure vessel full of water and steam, suspended above the front of the furnace. The drum was 33m long, 2.5m across and had walls 141.4mm thick to contain the high pressures and temperatures. Each drum contained 268 cyclone separators and primary steam scrubbers and 256 secondary scrubbers to ensure only dry steam left the drum. The steam passed through the radiant superheater and then the primary and secondary superheater pendants before heading to the turbine. After passing through the H.P. turbine the steam was returned to the reheater section. From the reheater, the steam passed on to the I.P. and L.P. turbines.

Large fans were required to move the vast amount of air needed for combustion on this scale. Forced draught (F.D.) fans pushed air in to the furnace; two of these were needed on each boiler, each requiring 3700 horsepower to run.

Induced draught (I.D.) fans sucked exhaust gas out of the furnace; two of these were needed on each boiler requiring 4600 horsepower each. Two gas recycling (G.R.) fans on each boiler required another 710 horsepower each.

Grain used heavy fuel oil (HFO) as fuel; an extremely thick black oil which is the end product of the refining process during which the lighter, useful components such as petrol are extracted from the crude oil. Oil from the storage tank was pumped through steam oil heaters and oil filters to the 24 burners in each of the boilers. Each burner had an oil firing capacity of 6.6 tonne per hour.

Associated with each of the turbo-generators is an oil-fired boiler capable of supplying 579kg of steam per second at a pressure of 163.5bar and a temperature of 541oC.

Conditions at 100% C.M.R.

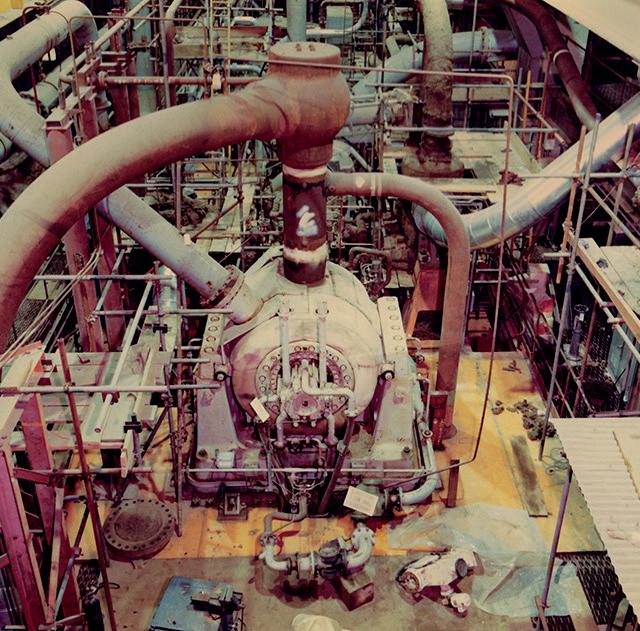

Each turbine had a high pressure (H.P.) turbine, an intermediate pressure (I.P.) turbine, and three low pressure (L.P.) turbines. The entire turbine set weighed approximately 170 tonnes.

The steam sent to the turbines carried around three times more energy than could be extracted by the turbines, so it was very hot and at very high pressure.

• 159.6 bar 538°C at the H.P. cylinder.

• 38.95 bar 538°C at the I.P. cylinder.

• 4.89 bar 259°C at the L.P. cylinder.

The turbine was heavily insulated to prevent loss of heat, but if you could have seen it, the steam inlet would have been glowing red hot. As the steam flowed through the turbines it transferred the heat and pressure in to mechanical energy that turned the generator. During this process, the steam expanded in volume many times; each turbine needed to be bigger than the one which preceded it. To prevent the turbines becoming too large there were three L.P. turbines to handle the expanded volume.

The turbines were three stage, five turbine, impulse/reaction sets, with reheat, rotating 3000 times a minute.

The generator rotor was an electro-magnet, rotation of which induced a voltage in the windings of the generator stator. The electromagnet was powered by the main exciter and rotating rectifier unit, which was mounted directly on to the rotor shaft.

Hydrogen, a highly explosive gas, was used to cool the generator as it is an excellent heat carrier and imparts as little wind resistance as possible to the rotating parts. It was forced through the system by centrifugal fans mounted one on each end of the rotor.

Each generator was a two pole, three phase hydrogen and water cooled machine driven directly from steam turbine.

ROTOR 76 tonnes (75TONS)

STATOR CORE 236 tonnes (232TONS)

STATOR CASING 118 tonnes (116TONS)

RATED TERNINAL VOLTAGE 23kV

RATED STATOR CURRENT 19491 amps

STATOR WINDING WATER COOLERS (2 PER UNIT):-

CONDENSATE COOLS DEMINERALISED WATER

STATOR WATER FLOW 21.2 litres/sec. (280 gal/min)

CONDENSATE FLOW 52.9 litres/sec. (700 gal/min) per cooler

HYDROGEN COOLERS (4 PER UNIT):-

CONDENSATE/D.W. COOLS HYDROGEN

GAS FLOW 7.1 litres m3/sec. (15000 ft3/min) PER COOLER

CONDENSATE FLOW 29.2 litres/sec. (386 gal/min) per cooler

VOLUME OF H2 SPACE 140m3 (1650 ft3)

NORMAL H2 PRESSURE 4.14 bar (60lb/in2)

The cooling system was totally enclosed, the hydrogen itself was cooled by water coolers mounted within the outer casing of the generator. The stator windings were cooled by extremely pure water which is non-conductive.

RATED VOLTAGE 470V

RATED CURRENT 3870 amps

PILOT EXCITER:RATED VOLTAGE 220V

RATED CURRENT 250 amps

EXCITER COOLER:-

CONDENSATE/D.W. COOLS AIR

AIR FLOW 4.95 m3/sec. (10500 ft3/min)

COOLING WATER FLOW 12.5 litres/sec. (165 gal/min)

RECTIFIER COOLER:-

CONDENSATE/D.W. COOLS AIR

AIR FLOW 3.54 m3/sec. (7500 ft3/min)

CONDENSATE FLOW 9.1 litres/sec. (120 gal/min)

DISTILLED WATER COOLER:-

A.C.W. COOLS DISTILLED WATER

DISTILLED WATER FLOW 139 litres/sec. (1830 gal/min)

A.C.W. FLOW FLOW 303 litres/sec. (4000 gal/min)

The generators weighed 320 tonnes and could produces 660MW at 23kV.

It was the decade of the Space Hopper, the Stylophone, Action Man and Barbie Dolls, Raleigh Chopper bikes, the Ford Cortina, the record player and cassette recorder.

Events

It was a decade of strikes - postal workers, miners and dustmen. It ended with the ‘winter of discontent’ in 1979 when ITV went off the air for eleven weeks. A three-day week was imposed during February 1972 to save on electricity at the start of the miners’ strike.

During the summer of 1976 the weather turned so dry that water supplies reached critical low levels. In 1977, the whole nation celebrated the Queen’s Silver Jubilee with street parties.

Household Goods

1974 - First domestic microwave cooker was sold.

1978 - VHS video recorder went on sale.

1979 - Sony began selling the Walkman personal stereo.

Television

People could now watch television programmes in colour. Three stations had began broadcasting in colour between 1967 and 1969.

British Prime Ministers

1970 - 1974 - Edward Heath.

1974 - 1976 - Harold Wilson.

1976 - 1979 - James Callaghan.

Population

1970 - 55,663,000.

64% of homes had a washing machine.

The Cortina was Ford’s mass-market compact car and became Britain’s best-selling car of the 1970’s.

During the 1980’s most state-owned enterprises were privatised, taxes cut and markets deregulated. GDP fell 5.9% at first but growth rose to 5 % at its peakin 1988, one of the highest rates of any European nation.

However, Thatcher’s modernisation of the British economy was far from trouble free; her battle against inflation resulted in mass unemployment with the jobless count passing 3,000,000 by the start of 1982 compared to 1,500,000 three years previously. This was in part due to the closure of outdated factories and coal pits which were no longer economically viable; this process continued for most of the rest of the decade.

Grain Power Station will help Britain avoid blackouts this winter.

It was capable of generating enough power to supply 5% of Britain’s electricity demand.

Grain’s largest output year was 1984 (18.4TW), driven by keeping the lights on during the miners’ strike of the 1980’s. Sadly the site would never see output of these levels again.

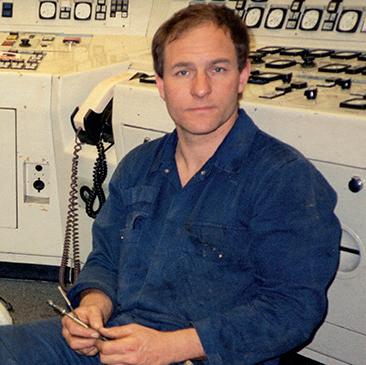

The main control room was on the 27m level of the control block which is situated between numbers 2 and 3 boiler houses.

Each boiler and turbine unit could be controlled by one man from its associated horseshoe-shaped control desk. At the end of each control desk a recorder panel gave a continuous trace of certain critical plant operating trends. In addition, a computer system, linked to each desk continuosly monitored the readings of hundreds of sensors located around the operating plant. These were printed out at regular intervals and the computer raised an alarm immediately if it detected any reading to be outside permitted limits. Computer programs to control, for example, turbine and boiler loading were also available. In the event of computer failure enough ‘conventional’ instrumentation and alarms were provided to enable the boiler and turbine unit to be run for a short period or shutdown safely.

In the centre of the control room was the station services desk from which the main ancilliary plant was controlled.

This included common plant such as cooling water pumps, the fuel oil system and the auxiliary boilers.

An Open Cycle Gas Turbine (G.T.) desk enabled the gas turbines to be run up and shut down and also provided monitoring facilities.

Most of the station electrical system was diagrammatically represented on a large mosaic diagram. This showed the major electrical items and their associated circuit breakers. The position of each of the circuit breakers, i.e. open or closed, was relayed to this board so the operational condition of the system was always correctly presented. On the end of the mosaic the fire system alarm panel was located.

Another desk, in front of the electrical system mosaic, contained the important generator electrical status information, and the telephone system by which contact between the station and grid control was maintained.

Critical to the function of every electricity generating station is its control and operation .

1. Brian Bakewell

2. Doug Tizzard

3. John Sellers

4. Phil Nixon

5. Chris Head

1. Brian Bakewell

2. Doug Tizzard

3. John Sellers

4. Phil Nixon

5. Chris Head

- at the time (1980), the largest oil fired station in Europe.

With Kent snowbound after four days, officials helicoptered 500 pounds of food to the isolated power station to feed the staff.

January 1987, The Lewiston Daily Sun.

This was the decade of British Prime Minister Margaret Thatcher, Rubik’s Cube, My Little Pony, BMX bikes, Yuppies and chunky mobile phones.

Events

1982 - Argentina invaded the Falklands Islands and Britain went to war.

30 July 1981 - Prince Charles married Lady Diana Spencer

23 July 1986 - Prince Andrew married Sarah Ferguson

Computers

Home computers such as Amstrad and Commodore went on sale and among the best buys of 1981 was the Sinclair ZX81.

1985 - Windows program invented by Microsoft. 1989 - World Wide Web first proposed by Tim Berners-Lee.

Television

Channel 4 began transmission in November 1982, whilst TV-am began in February 1983.

British Prime Ministers 1979 - 1990 - Margaret Thatcher.

Population 1980 - 56,314,000.

In 1986, 39% of employees were working with computerised equipment.

The Rubik’s Cube reached its height of mainstream popularity in the 1980’s making it the world’s top-selling puzzle game.

The British economy slid into recession during the second half o f 1990, concurrent with a global recession, and caused the economy to s hrink by a total of 8%. Unemployment increased from around 1,600,000 to nearly 3,000,000 by early 1993, but when the recession ended the subsequent economi c recovery was extremely strong. Unlike the early 1980s recession the reco very saw a rapid and substantial fall in unemployment, which was down to 1,700,000 by 1997.

The Labour Party, led by Tony Blair, returned to power in May 1997 after 18 years in opposition.

The 1990’s were a lean period for Grain. Oil prices were very high, station utilisation was extremely low and units were stood idle for long periods of time, with Unit 3 desynchronising for the last time at 12:25hrs on 12th February 1998, this was the decade of the ‘dash for gas’.

The construction of Unit 5 had never been completed due to the sustained rising cost of oil and the withdrawal of funding for completion. Despite successive attempts by Grain Plant Managers to finish the build, the Unit 5 project was finally abandoned. As the decade drew on units were mothballed or closed.

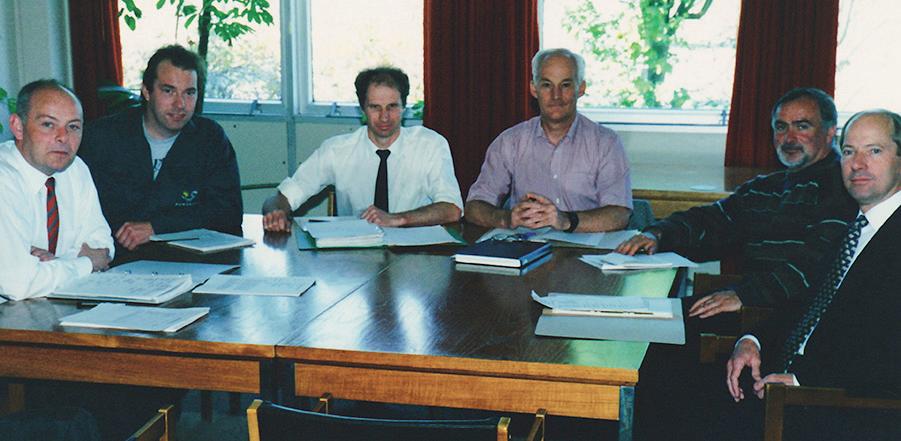

1. David Dance

2. Lord Wakeham

3. Fred Kirkby

4. Robert Malpass

5. Dr David Parry

1. David Dance

2. Lord Wakeham

3. Fred Kirkby

4. Robert Malpass

5. Dr David Parry

The present electricity market in the UK was built upon the breakup of the CEGB into sixteen separate companies in 1990. Its generation (or upstream) activities were transferred to three generating companies - ‘PowerGen’, ‘National Power’, and ‘Nuclear Electric’ (later ‘British Energy’, eventually ‘EDF Energy’); and its transmission activities to - the ‘National Grid Company’. The distribution business was split in to 12 regional companies.

In 1997 Tony Blair’s New Labour came to power with a parliamentary landslide, winning the biggest majority held by any government since 1935. It was the decade when the internet took hold, the National Lottery was launched in 1994, 24-hour shopping and Sunday trading.

Iraq invaded Kuwait, setting off the events that culminated in the first Gulf War. The United States responded quickly, leading a U.N. coalition force into the region and defeating Iraq to end the occupation.

The British Prime Minister Margaret Thatcher resigns and was replaced by Conservative leader John Major, who would lead the country for the next 7 years.

Panic about the Y2K bug, a perceived software glitch that would affect computer systems at midnight on New Year’s Eve, 1999 reached the height of its intensity.

Computers

1991 - The Nintendo GameBoy was released.

1991 - World Wide Web first available to the public.

1993 - The Pentium processor invented.

1994 - Sony Playstation launched.

British Prime Ministers

1990 - 1997 - John Major.

1997 - 2007 - Tony Blair.

Population 1990 - 57,237,000.

In 1996, ten million computers connected to the Internet.

Comet, Hale–Bopp was discovered on July 23 1995, it was visible to the naked eye for a record 18 months.

For Grain the 2000’s ended with a revival as E.ON announced in 2007 that it would build a modern CCGT at the site.

The UK economy had been one of the strongest EU economies in terms of inflation, interest rates and unemployment, all of which remained relatively low until the 2008–09 recession.

The latter 2000’s will be remembered for the banking crisis whic h lead to the world recession that started in 2009. State currencies faltered , banks failed and unemployment soared. For the electricity industry in the UK it was a period of reduced demand and excess supply, all putting Grain under additional pressure. Throughout the decade Grain ran when spare generating capacities were low and the security of supply of electricity was at risk. It was in this role that the plant would see out its last decade of generation.

Additional staff were recruited for the combined site team and numbers increased from 36 to 74.

In 2007 at the ceremony to celebrate the start of the work on G rain’s new CCGT site, an announcement was made to launch a fund to the benefit the local community. After 4 and half years and 122 applications the fund closed in 2011 with the mon ey successfully allocated to 83 community projects. Many of the awards were for equipment or community hall repairs, leaving a lasting legacy for many years to come.

Grain continues to raise funds for charity, some of our recipients have included Kent Air Ambulance, Cancer Research UK, NSPCC, British Heart Foundation, C hildren’s Liver Disease Foundation, Make A Wish Children’s Charity, Alzheimer’s Society, Children’s Hospices UK, Scope, Heart of Kent Hospice, Prostrate Cancer, Red Nose Day, Children In Need and Sponsorship has been given to, Medway Business Awards, Pride in Medway, 24th Borstal Scouts, Eagles Football Club, Grain Fete, St James Primary School, Medway Barge Sailing Match, Wilsonian Sailing Club, to name but a few.

It was the decade of the personal computer and iPod. Tony Blair resigned as Prime Minister of the United Kingdom, and was succeeded as by Gordon Brown.

The growth of the Internet was one of the prime contributors to globalisation during the decade, making it possible for people to interact with other people, express ideas, introduce others to different cultures and backgrounds, use goods and services, sell and buy online, research and learn about anything, along with experiencing the whole world without having to leave home.

Television

2000 - Big Brother.

2001 - The Office.

2005 - Coast.

2007 - Britain’s Got Talent.

British Prime Ministers

1997 - 2007 - Tony Blair.

2007 - 2010 - Gordon Brown.

Population 2000 - 58,868,000.

The verb “to google” enters the Oxford English Dictionary in 2006.

In 2005, there were more mobile phones in the UK than there were people.

The Millennium Dome, appears as a large white marquee with twelve 100 m-high yellow support towers, one for each month of the year, or each hour of the clock face, representing the role played by Greenwich Mean Time.

The UK, a leading trading power and financial centre, is currently the third largest economy in Europe after Germany and France.

The UK has large coal resources, but its oil and natural gas re serves are declining and the UK became a net importer of energy in 2005. The electricity market is changing rapidly in the UK. Many of the older coal fired power stations are closing under the Large Combustion Plant Directive (LCPD). Renewa ble generation in the form of wind and solar are starting to influence the generation market and the shape of fossil fuel generation is changing rapidly. Gas appears to be the only affordable alternative to renewable and nuclear ge neration.

The first unit of Grain CCGT power station went into commercial operation (Unit 7) in June 2011. 2012 also saw the official takeover of the combined heat and power system supplying heat to Grain LNG, but also, following a financial review, the closure of the oil plant was brought forward from 2015 to December 31st 2012.

It was the decade of the Eyjafjallajökull volcano eruption in Iceland, the newly formed coalition government comprising of MPs from the Conservative Party and the Liberal Democrats and the first iPad was released.

Pope Benedict XVI visited Britain in 2010, the first papal visit to Britain since 1982.

The country was once again deluged by heavy snowfall as it endured its worst cold spell since the winter of 1981-82.

The cheque guarantee card scheme – which ensures some cheques are honoured even if the account holder does not have sufficient funds in their account – was withdrawn after operating for over 40 years.

Television 2010 - Come Fly with Me. 2010 - Downton Abbey.

British Prime Ministers 2010 - David Cameron.

Population 2010 - 61,113,205.

52.7 million internet users in the UK by December 2011 - nearly 85% of the population.

The wedding of Prince William, Duke of Cambridge, and Catherine Middleton took place on 29 April 2011 at Westminster Abbey in London.

More than 27 members of staff started their careers at Grain and were still working here at the closure of the plant on the 31st December 2012.

Martin Allen (September 1979)

Stuart Beasley (September 1981)

James Barrett (Sept 1988)

Martin Allen (September 1979)

Stuart Beasley (September 1981)

James Barrett (Sept 1988)

Peter Coleman (March 1979)

Steve Crooks (November 1975)

Robert Crisp (May 1984)

Peter Coleman (March 1979)

Steve Crooks (November 1975)

Robert Crisp (May 1984)

Whilst some of these have left and come back to Grain as part of their career ...

Kevin Braine (July 1980)

Martin Burrin (September 1981)

Derek Brown (September 1977)

Paul Clark (September 1981)

Kevin Braine (July 1980)

Martin Burrin (September 1981)

Derek Brown (September 1977)

Paul Clark (September 1981)

Ray Eyles (September 1979)

Paul Head (September 1980)

Laurence Hayward (September 1981)

Ray Eyles (September 1979)

Paul Head (September 1980)

Laurence Hayward (September 1981)

... a few have been at Grain throughout the 33 years of its life.

Robert Hull (August 1973)

Peter Kingbrooks (July 1979)

Martyn Johnson (May 1987)

Russell Knowles (September 1976)

Robert Hull (August 1973)

Peter Kingbrooks (July 1979)

Martyn Johnson (May 1987)

Russell Knowles (September 1976)

Stephen Medhurst (1980)

Russell Tolhurst (November 1988)

Timothy Sharp (September 1975)

Stephen Medhurst (1980)

Russell Tolhurst (November 1988)

Timothy Sharp (September 1975)

1,069 accumulated years of service within the current Grain team.

Simon Warrington (December 1984)

Brian Young (April 1976)

Stephen Wray (June 1984)

Simon Warrington (December 1984)

Brian Young (April 1976)

Stephen Wray (June 1984)

The last commercial run for Grain was on Unit 1 during the winter of 2010. Whilst Unit 1 was run up to 3000RPM for testing purposes during 2011 and 2012, it would never run commercially again.

The announcement of closure was made in August 2012 and during the later part of 2012 decommissioning activity started in earnest. Sections of boiler flue gas ducting were removed to formally put the plant beyond generating capability.

Fuel oil was drained and pumped back to Kingsnorth, to be burnt off prior to Kingsnorth ceasing generation in December 2012.

Propane tanks were flared off, lubrication oil tanks drained and the oil recycled.

Whilst celebrating its illustrious past, we should remember that Grain Power Station is already helping to shape the future.

So, this was a story of a massive 3000MW oil fired power station, designed and built as the pinnacle of the CEGB’s capabilities, that operated for 33 years and played a critical role of being the last line of defence for keeping the lights on.

It is a story of a team of staff and contractors that were techn ically very competent, a flexible team, an innovative team and a committed team that operated the plant to its limits and beyond during the miners’ strike of the 1980s, but also fought to keep the plant open through the challenging times of the late 1990’s and 2000’s.

In the late 2000’s Grain adopted the emblem of the Phoenix, apt due the many rebirths the site has gone through over its 33 years. Whilst we are all sad to see the oil plant close, it does leave us with our enduring legacy, a solid platform for our futures.

The passing of the titan is not the end. In the shade of the oil plant is the newest of E.ON’s generating plants in the UK. It is the most efficient large scale fossil fuel plant in the E.ON fleet, in combined heat and power mode has a maximum station efficiency of 72%. It represents the future of fossil fuel generation in the UK.

Whilst decommissions of the oil plant is underway, demolition could well give way to construction of future CCGT units at the site. Quite possibly by the end of the decade Grain could be a 3000MW site again. .

We hope you have enjoyed our trip down memory lane spanning the past 33 years in the life of Grain Power Station. Many people have contributed to this book and in particular, we would like to thank:

Brian Young, Steve Crooks, Derek Brown and Steve Topham - Grain Oil Power Station stalwarts whose enthusiasm and wisdom have been unstinting.

Laurence Hayward and Brian Young - who supplied some excellent photographs that have captured the essence of Grain Oil Power Station and its people.

Paul Morton, Helen Turner and Scintilla Design - without whose tireless dedication and organisational skills this book wouldn’t have happened.

The following people for their invaluable photographs and memor ies:

Steve Allsop

Roy Bellinger

Ian Boyle

Kevin Braine

Derek Brown

Matthew Chaplin

Steve Crooks

Jenny Curley

Michael Dale

Taz Duffy

Mick Fillingham

Angie Fryer

Graham Flack

Jodie Gamble

Paul Graham

Margaret Green

Marcus Hamilton

Ralph Hayter

Robert Hull

Pete Kingbrooks

Malcolm Lewis

Steve Medhurst

Derek Pedley

Michael Rahilly

Mal Roberts

Keith Slucock

Julie Wantling

Simon Warrington

And everyone who has helped make this book a fitting tribute to Gr ain Oil Power Station’s 33 years.

Sectional arrangement of exciter.

Drawing issue: 2-3/89