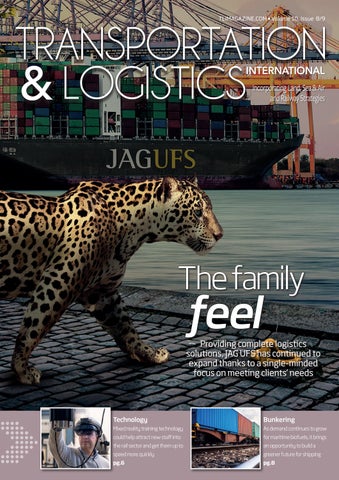

TLIMAGAZINE.COM l Volume 10, Issue 8/9 Providing complete logistics solutions, JAG UFS has continued to expand thanks to a single-minded focus on meeting clients’ needs Bunkering As demand continues to grow for maritime biofuels, it brings an opportunity to build a greener future for shipping pg.8 Technology Mixed reality training technology could help attract new staff into the rail sector and get them up to speed more quickly pg.6 The family feel

Hello and welcome to the September issue of Transportation & Logistics International. With fuel hitting the headlines, it’s no surprise that haulage firms are considering greener options, and one of our authors this month highlights that this could be a driver for more investment in electric HGV technology. Although as energy prices also continue to rise, is this option still going to be so appealing in a year? Only time will tell. We also take a look at green fuel options for shipping, as well as technology solutions for training and autonomous delivery. is also covered, both on rails and water. also look at two more innovative solutions in our Patent of the Month pages to Withers & Rogers, prior written permission of the publisher.

Freight

who have been a dedicated contributor for several years! Reliable suppliers – don’t they make life easier? XX ON THE COVER XX.\ XXXXXXX XXXXXXXXXX Xxxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx XX.\ XXXXXXX XXXXXXXXXX Xxxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx XX.\ XXXXXXX XXXXXXXXXX Xxxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx XX.\ XXXXXXX XXXXXXXXXX Xxxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx XX.\ XXXXXXX XXXXXXXXXX Xxxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx XX.\ XXXXXXX XXXXXXXXXX Xxxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx xxxxx xxxx xxxx xxxx COLUMNS AND CONTRIBUTIONS FROM OUR EDITORS AND WRITERS Incorporating Land, Sea & Air and Railway Strategies Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Schofield Publishing, and may not be copied, stored in a retrieval system, or reproduced without the

© 2022 Schofield Publishing Ltd Chairman - Andrew Schofield Group COO - Joe Woolsgrove Editor - Libbie lhammond@finelight-media.comlibbie@schofieldpublishing.comHammond Assistant Editor - Mary Floate Staff Writers Daniel Baksi • Alex Caesari • Danielle Champ Editorial Administrator - Amy Gilks Managing Art Editor - Fleur Daniels Art Editor - David Howard Art Editor - Paul Gillings

Artwork Administrator Rochelle Broderick-White Sales Director Alasdair Gamble Business Development Director Philip Monument Operations Manager Adam Blanch Research Managers Michelle Fontaine, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Basil Sharpe, Laura Thompson Editorial Researchers Victoria Burke, Mark Cowles, Jeff Goldenberg, Dan Harrison, Melanie Joyce, James Page, Wendy Russell, Richard Saunders, Kieran Shukri Advertising Sales Johanna Bailey, Mike Berger, Jessica Eglington, James Fuller, Will Gwyther, Alex Hartley, Reid Lingle, Sam Surrell Head of Global Media Programs - Mark Cawston Florida General Manager - Ryan Finn Boston General Manager - Joy Francesconi Digital Sales - Mike Psimis Subscriptions i.kidd@schofieldpublishing.com

Volume 10, Issue 8/9

The family feel Libbie Hammond EDITOR libbie@schofieldpublishing.com

Our cover story this month looks at JAG UFS Group, a business providing air, sea, and road freight logistics services. Successfully navigating the challenging environments of the past few years by prioritizing customer service, the business has plans for continued growth, but never at the expense of excellence. “Above all, we need to make sure our clients continue to receive the service they deserve,” agreed Gary Wilcox, Group CEO. The full story starts on page 30.

Providing complete logistics solutions, JAG UFS has continued to expand thanks to a single-minded focus on meeting clients’ needs Bunkering As demand continues to grow for maritime biofuels, it brings an opportunity to build a greener future for shipping pg.8

– thanks

Technology Mixed reality training technology could help attract new staff into the rail sector and get them up to speed more quickly pg.6

We

From the Editor TLIMAGAZINE.COM 1

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir Schofield Publishing Ltd - Corporate Head Office Cringleford Business Centre, 10 Intwood Road, Cringleford, Norwich, NR4 6AU, U.K. Tel: (312) 854-0123 Tel: +44 (0) 1603 274130 Finelight Media LLC 2240 West Woolbright Road, Suite 402 Boynton Beach, FL 33426 T: (561) 778 2396

4 SUSTAINABILITY

8 BUNKERING

WAREHOUSING

13 INNOVATION

Phil Smart takes a look at rail freight and explains how growing this area requires a partnership between the state and the private sector, with targets for both 16 RIVER TRANSPORT and, potentially, license it to third parties

22 NEWS

TLIMAGAZINE.COM2 Features Profiles 26 Clugston 16

What will the warehouses of the future look like? Author Padraig Regan believes that automation and robotics will play a role, but as part of a technology mix Mobile robots could be used to autonomously deliver products door-to-door, but innovative technology is needed in order to help them cross the road safely RAIL FREIGHT

The cost of fuel in the UK is causing haulage firms to consider green options, and that might drive forward investment into a viable electric HGV charging network

The latest news, announcements and updates from transportation and logistics, across land, sea and air

For the rail sector, which is facing a mass exodus of experienced workers, solutions must be found to support and teach employees - mixed reality could be the answer Companies turning to biofuels to decarbonize their activities now span all shipping segments, and this has accelerated the need to ramp up bio energy production 10

14

6 TECHNOLOGY

TLIMAGAZINE.COM 3 36 Evri COVER STORY JAG UFS Group5030 All-Ways Forwarding Int’l Allied Trucking 54

One of the issues we have is that much of the infrastructure required for a viable electric HGV network does not yet exist. A report commissioned by the Competition and Markets Authority revealed that there were only 1,000 public electric vehicle charge points outside of London in April 2021. That pandemic. In a May survey of 73 haulage firms, asked what problem was restricting their growth: 50 percent said finding good drivers, 43 percent stated finding new contracts, and 27 percent said cost of running theirThefleet.UKcannot afford to lose these businesses. Our supply chain depends on them, our economy depends on them, because in a consumer-driven economy, we need access to goods in order to drive growth. If these owner-operator and medium sized fleets disappear, our economy is in realHowever,trouble. there may be a way to turn this crisis into a best-case scenario. Today’s prices mean that – for now at least – it’s cheaper

to charge an electric HGV than it is to fuel a diesel one. High charging costs previously made this an unattractive proposition, but today we have the chance to truly pioneer a national switch to zero-emission goods vehicles. The government has committed to a switch from 2035 anyway, but there’s no reason we can’t accelerate those plans. The case for moving to greener goods vehicles is much more compelling.

Turning the fuel crisis into a ‘green’ opportunity.

By Clemente Theotokis Never has there been a better time for the logistics sector to accelerate its drive to sustainability. With the cost to fuel a lorry now more than £25,000 a year, the fuel crisis is pushing many small and medium-sized haulage firms to the brink. The knock-on effect will be the continued rise in price of goods as supply chain actors are forced to respond to ever-more expensive transport costs. The haulage sector in particular stands out for its vulnerability. About 70 percent of the sector comprises small owner-operator fleets with fewer than ten trucks. Many of these businesses were already struggling to recover in the aftermath of Brexit and the recent

The resilient option

TLIMAGAZINE.COM4

TLIMAGAZINE.COM 5 figure is even smaller for charging points specially designed for electric HGVs. These figures are growing, but it needs national coordination by the government. The second issue is that the cost of electric vehicles is still almost twice the cost of a diesel HGV. More support is needed to help smaller firms upgrade their fleets.

in the long term, as electricity generation can more easily be produced without imports. In time, we could switch to completely national electricity generators, truly delivering a sustainable economy that is also a sustainable and sound environmental strategy.Thefact is, if we want our economy to grow, we need to ensure that the flow of goods, raw materials and produce throughout the UK can be kept in motion, and transforming to a zero emission network is the most resilient option. v

Today’s fuel crisis could be the perfect impetus to drive forward tomorrow’s investment in the future of transport. We need the government to recognize this opportunity and move to implement the EV Recharging Infrastructure Fund as quickly as possible: this £690 million fund is designed for a national grid of electric charging stations. At Zeus, we see that the key distribution hubs ports and factory areas. We have the opportunity here for the UK to capitalize on the fuel crisis by building resilience into our supply chain. But for us to move to the next stage, we need the government to step up to the plate. Shortterm incentives will help support hauliers, but we also need to be looking further ahead. This means fast-tracking the roll out of the Local Electric Vehicle Infrastructure Fund from the Office for Zero Emission Vehicles, which will help unlock the resources needed to make much of this possible.

Clemente Theotokis is Chief Executive Officer at Zeus Labs, a tech start-up simplifying the haulage industry and driving the sustainable freight agenda.

www.zeuslabs.com

Founded by Jai Kanwar and Clemente Theotokis in 2019, Zeus Labs enables shippers and hauliers to unlock new advantages, streamline the delivery process, cut down on unnecessary administration, reduce unused freight capacity, and increase the productivity of supply chains across the UK.

By Yan Simard

reality and digital content comes together to allow employees to interact with real-world and virtual objects, which can be applied to a multitude of tasks and projects.

T

With adaption critical, the employees best placed to adapt are those most in-tune with current processes and are likely to be older and more experienced. While younger engineers will be keen to take on new skills, developing their experience baseline is a critical foundation to enable them to adapt as quickly.

he rail industry is facing a mass exodus of workers. As many as 15,000 rail industry employees are set to retire by 2025, and when these workers call time on their careers, their expert knowledge leaves with them. To add complexity to this concern, much of this knowledge is entirely undocumented, with organizations rarely facilitating transfer of information before workers depart. Whenever this happens, companies suffer a net loss as skills shortages become apparent, and this is further exacerbated by the pace of change in railway and industrial engineering. The number of unplanned scenarios and increased complexity of tasks adds to the seriousness of the issue. However, as technology evolves and becomes more sophisticated over time,

The future is here

Empowering railway workers

TLIMAGAZINE.COM6

Adopting this approach is highly valuable during complex operations. Having the ability to tackle issues in real-time with mixed reality technology is especially beneficial in eradicating any equipment downtime and engineering knowledge is more quickly becoming outdated.

To battle this issue, technology that empowers railway workers is pertinent to augmenting their cognitive capabilities and ultimately assisting them in navigating complex situations and dynamic environments. An example of this is mixed reality-based worker support, where physical Keeping the train on the tracks with mixed reality.

Remote workers are able to communicate with older industry experts via a video or audio call when assistance with a complex issue is needed. Even more beneficial is the fact that the older industry expert can be located anywhere, while still being able to see what the remote worker sees and utilize holographic assets to help support completion of the task. This can all be achieved while keeping the user heads-up and hands-free.

It’s likely to be the case that some workers are hesitant to use new technology, but such devices are intuitive and easy to get to grips with, particularly for those already used to navigating a smartphone. Workers do however have to show a willingness to try something new, and the best way to ensure adoption is to begin with the enthusiasts. These workers can then show others the benefits and encourage widespread usage.

A bright future Mixed reality is the future for the rail and transport sector. The ongoing issue in less experienced workers missing out on support when inspecting, maintaining and repairing equipment has raged on, and mixed reality technology provides the answer.

Technology TLIMAGAZINE.COM 7 reducing the time-to-resolution. On top of this, the expert engineer doesn’t have to spend time or money travelling to a site to supervise or undertake an engineering operation.Employees undertaking an operation for the first time are also more likely to retain information and knowledge from learning on-the-job, as opposed to reading a manual about how to do it before undertaking a task.

As the industry better identifies how its workers can be supported, the conversation between vendor and customer is now more focused around defining use cases and operationalizing the solution, both in terms of worker support and transferring of knowledge.Thewider advantages of the technology will become more apparent over time.

Yan Simard is CEO at Kognitiv Spark. Since 2016, Kognitiv Spark has worked closely with global partners to guide industrial augmented reality solution development, with an emphasis on user-centered development. Led by an executive team with deep expertise in cybersecurity, oil & gas, industrial engineering and aerospace & defense, Kognitiv Spark delivers robust and integrated solutions that surpass advanced performance and security requirements. www.kognitivspark.com

Hardware performance will improve, battery life will be longer and headsets will become smaller. This will enable such devices to be used more regularly and become part of an engineer’s daily toolkit, rather than just oneoffAsscenarios.5Gbecomes more widely available and low earth orbit satellites gain in number, usage of mixed reality will also grow, while security will also need to be a key consideration as this happens.

Varying applications Beyond the rail industry, mixed reality can be applied to everything from bagging machine repair on the production line to troubleshooting satellite assembly operations. Whatever the application, the focus is on efficiently completing the job and an additional benefit is the tuition of younger engineers as they learn on-site. In addition, mixed reality is already widely used for both routine inspections and ongoing equipment maintenance, plus the more complex troubleshooting and problem-solving.

Many organizations will likely have reservations about the cost of implementation. However, with regular use and implementation across a wide number of workers in the organization, the technology essentially pays for itself and provides a rapid return on investment (ROI).

Ultimately though, these developments will lead to richer applications and broader use cases, creating a bright future ahead for the technology in the rail and transport sector. v For a list of the sources used in this article, please contact the editor.

ROI is also improved from saved costs as experts don’t need to travel to site and incur any related costs.

shipping segments, including dry bulk, containerships, tankers, ro-ro operators and, more recently, cruise operators. The sheer numbers of owners and operators throwing their hat in the ring prove that biofuels are no longer the preserve of a handful of first movers. So far, this significant shift has mostly been driven from within the industry itself. Given the urgency of the climate crisis, consumers’ demands for better, greener practices are being sounded out loud and clear – and these consumers are increasingly putting their money where their mouth is. As a result, industry giants have pledged to zero-carbon transport, and crucially they are ready to pay a premium to ensure their cargo is transported sustainably. In practice, Dirk Kronemeijer discusses the move to more sustainable biofuels in the shipping sector

Time moves quickly in shipping. Just a few short years ago, biofuels were a marine fuel option being adopted by environmentally minded pioneers. Today, biofuels are in the mainstream, with a dramatic increase in demand leading to customers in an ever-wider range of countries and market segments trialing and adopting the fuel at scale.

Welcome to the new fuels normal

The sourcing challenge

the capacity to deliver carbon-free shipping is already a key factor in tenders and for when cargo owners choose their supply chain partners. Aware of the importance of sustainability for the supply chains of the future, investors are also closely monitoring companies’ ESG credentials when making investment and lending decisions.

TLIMAGAZINE.COM8

The acceleration of demand for low carbon fuels has led to a fundamental paradigm shift. We are now in a seller’s market, and the days of fossil parity are over. Increasing production and sourcing new feedstocks to ensure we can continue to respond to the industry’s needs are challenges that we must address today, not in some hypothetical future.

If the first eight months of the year are any indicator, 2022 will be recorded as the point that this demand transitioned from speculative to permanent, driven by the increasing pressure on the industry to decarbonize and the industry scrambling to find immediate ways to reduce its emissions. Companies turning to biofuels to decarbonize their activities now span all

Huge effort is being expended on the part of suppliers like GoodFuels to ramp up production and find new sources of renewable bio-energy. We must also do this without compromising on sustainability, ensuring that all feedstocks are sustainably sourced and certified as 100 percent waste or residue.

is goal-oriented and technology neutral, and does not allow for the preferential treatment of any technology unless it concerns the phasing out of fossil energy.

On the customer side, the barrier to entry is low, which is proving to be a real differentiator versus other alternative marine fuels that are further off in terms of their development. Sustainable marine biofuels can ‘drop in’ to existing engines and infrastructure, without the need for any downtime. They require no technical changes on the part of the operator or crew but, critically, can make an immediate and measurable sustainability impact, slashing CO2, NOx and SOx emissions. However, despite the increase in demand, it’s obvious that a broad range of future fuel options will be needed to help shipping achieve its radical decarbonization transformation. Biofuels will be one critical piece of the puzzle, but we are moving away from an era of commodity fossil-based fuels and into a more fragmented landscape that will see a plethora of renewable, sustainable, low and zero-carbon options bunkered around the world. The internationalization of biofuels On the biofuels front, it’s important to recognize that supply has now ‘gone global’ in a way that other alternative marine fuels are still aiming to do. From what began as an essentially Western European market, more regions are opening up. After all, a global industry needs globally assured supply. This is a key driver behind GoodFuels’ determination to cement our presence in Asia, with the opening of our office in Singapore earlier thisInyear.addition to growing interest in Asia, there is also a significant and growing demand in countries like the United States, the United Kingdom and France, where more favorable legislation provides additional incentives for companies and suppliers. The role of legislation in encouraging future fuels update can’t be understated. In order to truly decarbonize shipping, regulators must ensure that new legislation

www.goodfuels.com

For example, GoodFuels’ current stock of fuels can be composed of sustainable waste materials including sawdust, crude tall oil (a by-product of wood pulp manufacture), tallow, sewage sludge and used cooking oils from industrial applications. As demand expands, it’s inevitable that more sustainable sources will be transformed into advanced marine fuel.

The coming decade will be full of challenges as GoodFuels continues its work to meet the new normal demand for biofuels, but this also comes with fantastic opportunities to create new partnerships and have a tangible impact in more regions of the world. The planet cannot wait – to limit the impacts of climate change, we need decarbonization action to start today. And with biofuels, we have a powerful tool at our disposal to allow more cargo around the world to be transported carbon neutrally in the immediate term. Let’s work together to create the greener, cleaner future for shipping that we all want to bring about for our own businesses, our children, and generations to come. v

Dirk Kronemeijer is CEO of GoodFuels, a Netherlands-headquartered global pioneer in sustainable marine fuels, with offices in Europe and Singapore. The company has created a one-stop shop for marine industry customers, integrating the entire supply chain for sustainable marine biofuels. From feedstock to tank, GoodFuels’ proposition covers elements of sourcing feedstock and ensuring its 100 percent sustainability, the production and refining, the global distribution, quality assurance and marketing programs with ports, governments, and cargo owners.

Bunkering TLIMAGAZINE.COM 9

Partnerships based on trust In this new normal, trusted and reliable partners are more important than ever, and independent validation and verification are key building blocks of that trust. All of GoodFuels’ biofuels are certified under the global International Sustainability and Carbon Certification (ISCC) system, ensuring true sustainability and transparency within the fuels supply chain. Additionally, the type of feedstocks GoodFuels uses are approved by an independent sustainability board, to make sure all of the company’s biofuels come from sustainable feedstocks that do not cause landuse issues, compete with food production or cause deforestation. At the same time, technology is also likely to play a greater role in ensuring transparency and accountability. For example, blockchain technology can facilitate tracing and guarantee that the products genuinely meet all sustainability criteria.

TLIMAGAZINE.COM10

The per fect mix I

The business and economic landscapes of the future will continue to present us with unpredictable challenges. The successful warehouse of the future must be underpinned by agile and resilient technology solutions that allow warehouse operations to embrace the change that such challenges drive, enabling them to pivot their business models as necessary.

t’s difficult to define what the warehouse of the future will look like. But the unpredictability of the last couple of years has highlighted that for businesses to survive, regardless of their geographic location, size, or sector, they must be flexible, adaptable, scalable, and able to cope with change.

Future warehouse operation leaders will face the same barrage of information, hype, and noise around the latest and greatest technology solutions as those of today face.

its anticipated heights across warehouse environments. Deploying voice was historically expensive and complex and, while some companies deployed large transformational voice solutions, many simply could not afford the cost, risk or RFIDdisruption.wasfeted to become the identification tool to end all identification tools. Although successful in some verticals, particularly in retail, it has not taken over as the ubiquitous solution many foresaw. Today, automation and robotics are presented as delivering everything the warehouse needs. There is no doubt that automation will increase across the industry over the coming years, but how many companies will have a 24/7/365 dark warehouse in the future and use a drone for cycle counting? Not many. So, these technologies will join those that do not becomeHowever,ubiquitous.therewill still be a place for Warehouse operations of different sizes, and serving different vertical sectors have - and will always have - specific requirements to ensure that goods, whatever they may be, flow in and out of the warehouse as smoothly and efficiently as possible.

We should learn from history. How many technologies have promised to deliver the very thing that every warehouse operation needs but have gone through the all-toofamiliar technology adoption life cycle? Moving from the hype to deployment by industry innovators, through to deployment by the early adopters, and then perhaps the early majority, but never quite making it to something close to mass adoption. Voice technology never quite reached The future of the warehouse is not all about automation – it’s about plug and play! says Padraig Regan

One size does not fit all There will not be one dominant technology. For the warehouse environment, a one size fits all is not an option, despite what some vendors may say.

Learn from history

Warehousing TLIMAGAZINE.COM 11 them, or their latest iterations, within the warehouse of the future. Because what will become ubiquitous in the warehouse of the future is the deployment of a mixture of technologies, all working in harmony, to meet the requirements of specific tasks in different areas of the warehouse. Technology that augments the work of warehouse employees, not necessarily replacing them Mix of technologies to meet a changing landscape Deploying a mixture of technologies, without a huge investment in any one, will allow future warehouse operations to easily scale up or scale down and deploy new technologies to meet a changing landscape.Thismixture of technologies will include real-time location tracking, temperature monitoring, humidity tracking and solutions for monitoring impacts and drops, ensuring goods can be tracked and monitored through their entire lifetime in the warehouse.

Cost effective software solutions are available today that drive this evolution by providing translation capabilities, enabling the WMS to seamlessly talk to the technology it needs to. All without the need for code to be written, no need for scripting to take place, and with no need to rip and replace the WMS.

A mix of the right technologies will enable the warehouse of the future to be both agile and resilient and make this evolution as simple as plug and play v Padraig Regan, Chief Product Officer, StayLinked, a market leader in terminal emulation (TE) solutions for the supply chain industry, is headquartered in California, US with an innovation centre in Oxfordshire, UK. www.staylinked.com

This will see a demand for sensors and tags, in turn driving a surge in demand for sensor and tag readers. These sensors and tags will enable broader deployment of automation. Full automation will be easier for simple workflows and individually trackable/ transportable items, but human decisionmaking will still be needed for more complex small items and mixed-pallet environments. In this scenario, autonomous mobile robots (AMR), will assist employees with their workflows.Voicetechnologies, and other hands-free technologies, including heads-up displays, will be deployed in appropriate areas of the warehouse in combination with sensors and beacons to help guide the workflows.

Plug and play The warehouse of the future will move towards a ‘plug and play’ approach, which allows the easy adoption of new technologies enabling warehouses to evolve with freedom and flexibility.

Technologies working together

These solutions allow warehouse operations to take a transitional approach to the introduction of new technologies, by enabling small step changes. New technologies can be monitored to ensure they are performing as required. Changes and tweaks can be made to ensure each technology is optimized to deliver as expected, or quickly dismissed as not the right choice, before costly investment has been made in further deployment.Smartwarehouse operations are already successfully bringing together different technologies. The secret to this success now, and in the future, is to work with an implementation partner who understands the business challenges driving the move to deploy new technologies. Ideally, a partner who offers a technology platform that enables new technologies to seamlessly talk to the WMS and each other.

All these technologies will need to work seamlessly together to make the workflows as efficient and accurate as possible, and to make the worker experience as good as it canThebe.challenge will be to make all these technologies work well together. The sensor and tag data will need to be fed into the warehouse management system (WMS), the WMS instructions will need to be sent to AMRs, data from beacons will need to feed into the workflows to direct workers effectively and intuitive hands-free workflows will need to work with all these technologies.Bringingtogether different technologies can be a nightmare, as it usually involves complex integration into an existing WMS. The cost associated with this integration frequently stops companies from evolving.

TLIMAGAZINE.COM 13

Chris Froud is a partner in &atPhysicsComputingElectronics,the&groupWithersRogers.Established in 1884, Withers & Rogers LLP is a leading European intellectual property (IP) firm providing expert advice on the protection and enforcement of IP rights particularly for inventions, designs and trade marks. Reflecting the firm’s distinctive entrepreneurial personality, its patent and trade mark attorneys come with a depth of specialist understanding, and pride themselves on helping businesses to commercialize their IP. The firm’s client portfolio stretches across the Americas, the Far East and Australia as well as mainland Europe.

Delivering the future: reinventing how to cross the road safely. By Chris Froud to be commercially important. This allows them more time to explore the commercial viability of the innovation and establish which territories are likely to be most receptive to its product before committing to filing patent applications in multiple countries. With patent protection in place, Starship will have a monopoly right. This means that it will be able to prevent others from copying its innovation, or potentially offer licenses for third-party use in exchange for royalty payments. Just by seeking intellectual property protection, Starship has also improved the value of its business, making it more attractive to potential investors in the future. v

Innovation

In the example crossing plan shown (a), the robot waits for the moving object to pass before starting to cross the road.

Accordingpedestrians.tothepatent application, as a mobile robot (10) approaches a road crossing, sensors (35) such as radar or lidar on the mobile robot detect moving objects (20) on the road crossing. The trajectory of any such moving object is predicted, for example, based on its past direction and velocity of travel. Based on the trajectory of both the moving object and the mobile robot, the time and location of a potential collision can be predicted.

A s transport and logistics industries around the world continue to evolve to find more efficient and revolutionary ways to deliver goods to consumers, a number of emerging technologies have come to the fore. This ‘Patent of the Month’ focuses on one of these technologies - autonomous delivery carts – to find out how innovators are helping to pave the way for a new era in door-to-door delivery. Being small in stature and travelling at walking pace to utilize footpaths and pedestrianized areas means that these carts could face challenges that are not often experienced by human delivery agents. For instance, safely crossing roads requires innovative solutions to allow the carts to reach their destination safely while avoiding a collision which could potentially cause injury to other road users.

www.withersrogers.com

International patent application number: WO 2021/219404 A1

The collision predictions are based on noisy sensor data and there is, therefore, a degree of uncertainty about the precise collision point. To overcome this, collision predictions can be adjusted using historical data from the road crossing, which recorded the way cars had previously driven down the road. By updating the collision predictions based on historical data, it is possible to improve their reliability.

By filing an international patent application, Starship Technologies is able to delay having to make a decision over which countries are going

Patent of the month

Using the technology, a time-to-collision map (420) is generated based on the adjusted location and improved predictions. This map highlights collision zones (422) - regions in time and space where a collision is more likely. This map can then be used to generate a road crossing plan (430), which guides the mobile robot to an efficient road crossing while steering it away from collision zones (422) where there is a higher probability of a crash.

Existing techniques for avoiding collisions during road crossings in the presence of moving vehicles rely on monitoring traffic lights or pedestrians crossing the road. This limits where road crossings can be made. Starship Technologies has recently applied for an international patent application WO 2021/219404 A1, which seeks to provide an improved method for mobile robots to cross any kind of road safely, without relying on lights or copying

The call for evidence is in two parts. Before constructing a target mechanism, GBRTT is keen to know more about what drives the market for rail freight. It wants to hear evidence from existing users but also from those who do not currently use rail to Is rail freight growth a moving target asks Phil Smart

The first question that springs to mind is why set a target? The White Paper recognizes that to get more freight on rail requires behavioral change - Rail Freight Group strongly supports this view and believes this change needs to be embedded in every route and region as well as within the governance of Great British Railways

identify some of the barriers, whether real or perceived, that might frustrate further modal shift to rail. There are 17 questions grouped under four headings: - Understanding your views on the rail industry; Understanding current and future demand; Understanding the opportunities and challenges to rail freight growth and Understanding your priorities and future engagement. These seek to identify everything from attitudes to decarbonization, why customers choose their current mode of delivery (cost, journey time, reliability, flexibility)?, have they tried using rail previously?, over what distances do they typically send freight consignments? What are the opportunities for growth over the next five, ten or 30 years? What target should we set?

T

Getting freighton track

TLIMAGAZINE.COM14

he UK’s Rail Reform White Paper (AKA Williams-Shapps Plan) included a welcome ambition to increase the amount of freight carried by rail in the UK and underpin this by setting a growth target.

On 5th July, the Great British Railways Transition Team (GBRTT) launched their document Rail Freight Growth Target - A call for evidence on designing and delivering rail freight growth target options for the rail network. Although we have given evidence to previous forward-looking consultations, such as the Whole Industry Strategic Plan (WISP),

The second part deals with measuring growth. What should be the preferred metric for judging success or otherwise? And in January this year, this latest evidence gathering demonstrates that our messages in previous consultations have become embedded in mainstream thinking and that rail is seen as a desirable mode for moving freight. It is accepted for example, that rail has only a quarter of the carbon footprint per unit load compared with road transport, suggesting that carbon escapement will be challenging for road, and that one train can do the work of 76 lorries, which suggests our messaging around congestion and road maintenance has been well received.

Evidence from users and potential users of the railway

Rail freight TLIMAGAZINE.COM 15 discusses several possible measures in turn:

Value of freight £x; not a measure used currently and one which might be difficult to measure, particularly as it tends to become eroded with inflation! Nonetheless it might help to justify investment. Lorry movements avoided; This would require accurate measurement of lorry miles over addressable distances to fully understand, though measuring rail freight could be used as a proxy. This is one of the measurements informally applied in Scotland. Carbon tonnes saved; This could be derived from the above measure but may become less reliable the greater the use of alternative fuels by competing modes. Net tonne kilometers; The standard metric used currently as it measures work done. Any increase in this metric would still need to understand if it was because of new traffic from road or as a product of cyclical economic changes. Tonnes (of freight lifted); although distance agnostic, it might not capture growth. More aggregate trains and fewer intermodal trains would increase this value without necessarily achieving modal shift. Freight distance in kilometers; the mirror of the above which may under-record a reduction in aggregates if intermodal traffic grows. Trains per annum; This would be good to measure new flows but might add the perverse incentive to run trains empty (as if we could afford to do that!)

Although the CFE asks us to choose a metric, the only way we can really understand growth is to apply a blend of measures and use them as Key Performance Indicators (KPIs). But what should the target be? Should it simply follow industry unconstrained forecasts or should targets be stretching? There have been calls for rail freight to treble by 2050, requiring a compound annual growth rate of four percent. Should there be intermediate targets set? To achieve a three-fold increase requires 26 percent more freight to be carried by the end of every periodic review compared with the last.

Whose target is it anyway?

The CFE asks us to identify growth opportunities over the first five years, five to ten years and ten to 30 years and what investment might be needed to support them. At the same time, it makes clear that at least in the short term (zero to five years) money for investment will be tight and any proposals for enhancement must demonstrate value for money. This already sets alarm bells ringing as constraints in the network, such as at Ely, are already suppressing growth.

www.rfg.org.uk

There are examples of more modest, freight-friendly investments including lengthening loops to allow longer trains, strengthening bridges to allow heavier axle weights, raising bridges (or lowering track beneath them) to increase the loading gauge. These could be achieved in the short-term.Longerterm we need to see investment in network enhancements and a rolling programme of electrification. Not only will this further reduce the carbon footprint, but also speed up freight services which brings several benefits. It reduces the time lost in ‘loops’, as it becomes easier to integrate with the passenger timetable, it offers more competitive end-to-end journey times, and it makes more efficient use of wagons and locomotives. A train that can complete its journey in a single shift is cheaper than one requiringGrowingtwo.rail freight must be a partnership between the state and the private sector, and the state must be set investment targets too. Our members are ready to play their part, but not to become targets for blame if we fail. v Phil Smart is Assistant Policy Manager at The Rail Freight Group (RFG). The Rail Freight Group (RFG) has been the UK’s leading rail freight trade association since its formation in 1990. It has more than 120 corporate members active in all sectors of rail freight from ports, terminal operators, customers, through to operators and suppliers. RFG’s aim is to grow the volume of goods moved by rail, delivering environment and economic benefits for the UK. RFG works hard for the interests of its members representing their views and providing a wide range of advice and information.

Which brings us to another problem, that of capacity and the actions needed to support growth. GBRTT cannot be allowed to set targets for others to fail. The rail freight industry relies on private investment in locomotives and wagons. Many more of both will be needed if we are to get anywhere near a three-fold increase. With two to three years lead times for delivery, this investment will only be forthcoming if there is guaranteed investment in the infrastructure. Investing to hit a target is not just about buying more arrows, someone needs to improve the bow!

Head to the water

W

TLIMAGAZINE.COM16

Every 1,000-ton barge of goods transported along the river removes the need for roughly 100 trips made by

ith an estimated 700 million parcels currently delivered annually in London, the potential for handling light freight on the River Thames provides a unique opportunity to rethink the logistics of goods transportation. There is a fast-growing desire across public and private sector organisations to

cutting congestion. There are clear benefits to shifting light freight from road to river including slashing non-exhaust PMx emissions (generated through breakdown of brakes, clutches, tyres and road surfaces) which are a significant contributor to poor air quality, especially in central London and across UK cities. In their action plan, ‘The Green Blue’, transport light freight, alongside the heavier freight already moved on the river, to secure environment and logistical benefits. Making better use of the river could significantly contribute to net zero ambitions. It could also help improve air quality.

lorry,Making light work of large scale freight on the river Thames

the Thames Estuary Growth Board set out an objective of delivering the world’s greenest, most productive Estuary. A key part of this is to explore how the River Thames can be better used for freight and it is the commitment of the Thames Estuary Growth Board that will ensure river freight is a viable competitive alternative to road transportation.

River transport TLIMAGAZINE.COM 17

A suite of design solutions demonstrate how a shortlist of prime pier locations along the Thames could be modified to support light freight as either a partial or continuous service in addition to the potential

There is a growing body of evidence and guidance supporting movement of freight from roads on to rivers and inland waterways. This includes a ‘Light Freight: Design Solutions for Thames Freight Infrastructure’ study co-commissioned by the Thames Estuary Growth Board, the Port of London Authority (PLA) and Cross River Partnership (CRP), that considers the design of the existing piers along the River Thames and how they could be modified to accommodate the requirements of a light freight service.

construction costs involved. The study highlights that while a partial service may be more financially viable to begin with, the volume of cargo would be limited. Whereas a continuous service would require more significant investment but would support a larger operation. A future-proof vision of safe, sustainable and predictable movement of large-scale light freight in a city that is notoriously difficult for making deliveries is currently being mapped out to realise this. A report published by Thames Estuary Growth Board in partnership with the PLA ‘Light Freight on the River Thames’, prepared by WSP, clearly defines what a commercially viable river freight solution might look like, alongside a well costed business case. A precedent for this has already been set with multiple trials on the river including Guys and St Thomas NHS Trust / CEVA / Livetts, and DHL. DHL in particular is determining factor for many businesses is cost. However, while the cost may be seen as a barrier for short term and lowscale uses, a long-term look at light freight reveals substantial economies of scale. And many businesses appreciate the reliability of a service unimpeded by congestion and roadworks.

TLIMAGAZINE.COM18

In response to this, Thames Estuary Growth Board and PLA recently published The ‘Mode Shift Revenue Support (MSRS) – Light Freight Analysis Report’, which provides a succinct evidence base that informs the case for exploring this potential for expansion after a positive trial. Ben Hiles, Senior Director for Engineering and Infrastructure, DHL Express UK said: “Our river boat has an impressive 98 percent journey time reliability, which is a huge asset given the time definite service we offer our customers. We are already moving 50,000 parcels a year using this mode and continue to explore opportunities to further expand theTheproject.”co-location programme, which is bringing together historic markets of Smithfield, Billingsgate and New Spitalfields to a purpose-built site at East London’s Dagenham Dock is also looking at using the Thames. This mode of moving freight to and from the markets is cleaner, greener and efficient and importantly, instrumental in helping to reduce the capital’s carbon footprint. Aside from lack of awareness that waterborne freight is an option, the

The wider environmental and social benefits are recognised as significant and potential users can unlock subsidies or incentives, including the Government’s Mode Shift Revenue Support (MSRS) scheme. The MSRS was developed with the aim of enabling modal shift away from road transport, but applications from parties interested in waterborne freight have been extremely low.

For a list of the sources used in this article, please contact the editor. fundamentals are there, now it is a matter of getting the supply chain linked up and operational to deliver the volume that will make waterborne freight a commercially sound option. There is no wrong door and the Thames Estuary Growth Board, together with partners including the PLA, Logistics UK and CRP can help connect different businesses interested in participating in this ecosystem and exploring the possibilities light freight can offer. Together we will get the dialogue on what is possible moving at a faster pace with

To find out more about light freight in the Thames Estuary and connect with the Thames Estuary Growth Board, visit thamesestuary.org.uk or to join the conversation and be part of the light freight economy in the Estuary contact Findenquiries@thamesestuary.org.uk.outmoreaboutthePLA(pla.co.uk)

Right: Perry Glading, Deputy Chair of the Thames Estuary Growth Board

River transport reforming the MSRS scheme to better support the shift to water. The report considers both light and heavy freight, the different needs of river and maritime services, and highlights a number of barriers as well as enablers, including focussing on net zero (such as environmental reporting), technology andFourinnovation.simplechanges can make the scheme more effective, according to the report by consultants, WSP. They recommend adjusting the scheme: taking account of the additional barriers faced by waterborne operators; encouraging innovation, particularly in light freight; developing pilot studies to test alternative modes for specific cargo types; and allowing grant funding for capital expenditure in setting-up new operations, rather than just operating costs.

With investment and development opportunities to make piers, wharves and river vessels fit for purpose – essential in handling large scale river freight – now is an exciting time to be involved in moving goods on the Thames. v

19

Logistics UK (logistics.org.uk) and CRP We’re(crossriverpartnership.org).inagoodplaceforgreener freight. Join us.

Perry Glading, Deputy Chair of the Thames Estuary Growth Board said: “We’re now inviting businesses to come to talk to us. The all interested stakeholders, including the DfT, and then turning that into a real shift from road to water.”

TLIMAGAZINE.COM

Nicola Anderson is an associate and

Patent of the month

International patent number: GB2593692

Innovating electrically powered train units to meet UK net zero goals. By Nicola Anderson typically receive location data for each train unit. The DGS then determines which train units are within a predetermined track block, where each track block corresponds to a power supply section. For a given track block, the breaker closing time delay is calculated based on the numbers of train units in the section, enabling the delay times to be optimized, minimizing the overall delay times compared to systems with arbitrary breaker closing time delays.

Hitachi Rail electric units equipped with the patented reconnection system have the potential to increase the overall reliability of the rail network. This is particularly important in incentivizing consumers to choose rail over less sustainable forms of transport, contributing directly to the Government’s decarbonization targets. With patent protection secured, Hitachi Rail benefits from an exclusive right to bring its invention to market and, potentially, license it to third parties. This period of exclusivity extends for up to 20 years, preventing competitors from copying its invention during this time. v

GroupEngineeringtheattorneypatentinAdvancedatEuropean intellectual property firm, Withers & Rogers LLP. Withers & Rogers LLP provides expert advice on the protection and enforcement of IP rights particularly for inventions, designs and trademarks.

The DGS can be integrated with existing trackside monitoring systems, which

Innovation A s the transport industry continues its work to meet the Government’s commitment to achieve net zero by 2050, in addition to the recently released Transport Decarbonisation Plan, electrification has quickly become a sought-after alternative for decarbonization. This month’s patent relates to an improvement to electrically powered train units. Typically, multiple electric train units are connected together in series and draw power from an external power supply via an overhead line. Each of the train units includes a safety function, where a breaker disconnects the traction equipment when electrical power supply to the train unit becomes abnormally high or low. Once it is determined that the issue has been resolved, the breaker is closed and the power supply is However,reconnected.aproblem arises when each of the train units powered by a common electric power supply disconnects the traction equipment at the same time. When the breakers are closed and power returns, an influx of high current to each train unit can be created that would impose a significant load on the electric power supply. One solution to this problem is to allocate each unit a separate arbitrary breaker closing time delay, thereby staggering the influx of current to the electric source. This can, however, lead to unnecessary delays to the train schedule and reduce the reliability of the Hitachinetwork.Railhas been granted UK patent GB2593692 (fig. 2) for providing an alternative solution to this problem. The reconnection system of the UK patent optimizes the breaker delay closing times of each of the train units using a delay generating system (DGS).

The DGS is located trackside and communicates wirelessly with a train supervision system located on each of the train units. The train supervision system controls the disconnecting and reconnecting of the breaker based on a command signal received from the DGS. This differs from traditional systems where the breaker closing time delay is fixed.

TLIMAGAZINE.COM 21

www.withersrogers.com

innovative 50 percent-scale Cavorite X5 prototype.

The full-scale aircraft will be powered by a hybrid electric system that can recharge the battery array in-flight while providing additional system redundancy. Comprehensive testing of the scale model will reduce technical risk moving forward as Horizon continues to develop its full-scale model.

What’s in store?

Bristow’s Chief Information Officer, Noel Malcaba, explains: “Because of the reliable service and advanced technology Speedcast delivers, our team can conduct their work, ensure flights run seamlessly and stay connected, no matter the flight path or “Speedcastdestination.”will be conducting technology enhancements and equipment upgrades at many critical base locations, ensuring Bristow benefits from the latest advancements in hybrid connectivity,” says Richard Elson, Executive Vice President, Energy at Speedcast. Taking flight Horizon Aircraft Inc., (Horizon), an innovative leader in hybrid electric Vertical Take-off and Landing (VTOL) aerial vehicles, has constructioncompletedsuccessfullytheofits

Brandon Robinson, CEO of Horizon explains that “with a wingspan of 22 feet and speed of over 250 kilometers per hour, the prototype is an impressive aircraft.” Highspeed flight testing will soon take place to prove the Cavorite platform is the most advanced and flexible VTOL design in the market.

One of the UK’s largest storage and material handling companies, Flowstore, is partnering with Sorion, a global leader in end of line test and guided assembly systems. Sorion’s technology is expected to bring substantial time savings and efficiencies to Flowstore clients.

“The application evolved from our clients’ desire to understand how the Bentley iTwin platform can solve the types of problems they might encounter,” says Mark Stefanchuk, CTO of Phocaz,“TDDMInc.isa great example of how digital twin technologies can improve roadway design and construction by automating the capture of design quality issues and increasing data trust across traditionally siloed discipline domains,” elaborates Adam Klatzkin, Vice President, iTwin Platform at Bentley Systems.

Applying solutions Phocaz, Inc. has released Traffic Design Data Manager (TDDM). The new application is designed for the transportation industry and leverages the Bentley iTwin platform to aggregate design data and graphic workflows.

Houston-based Bristow Group is the global leader in innovative and sustainable vertical flight solutions, providing aviation and Search and Rescue (SAR) solutions to government and civil organizations, with 222 aircraft in its global fleet. This contract follows ten years of connectivity partnership between the organizations.

TDDM makes it easy for transportation agencies to create feature reports, capture quality issues, and generate quantities for traffic design projects. The application simplifies data navigation by synchronizing report records with feature location, and tracks design issues such as missing lengths, pay items, or alignment names.

TLIMAGAZINE.COM22 News In Brief

Horizon’s innovative approach and technology allows the aircraft to fly 98 percent of its mission in a very low-drag configuration like a traditional aircraft. Flying most of the time as a normal aircraft is safer and should make the aircraft easier to certify than radical new e-VTOL designs.

Already using some of the industry’s most advanced and innovative storage and material handling technology, Flowstore boasts household names, such as Tesco, BMW, Rolls Royce, BAE Systems, Jaguar Land Rover and Aston Martin as just some of its Speakingclients.about the strategic partnership with Sorion, Simon Bolton, Sales and Marketing Director at Flowstore says: “Working with some of the world’s largest brands, it is absolutely vital that we consistently evolve our technology and solutions, constantly bringing into play new and advanced methods that mean our clients continue to benefit from storage and handling solutions that are founded on the principle of implementing lean management. Our strategic partnership with Sorion brings about exactly that and means we ourefficienciesbringsavingssignificantthattechnologiesnew-to-marketintroducewilladdtimeandmultipleforclients.”

Connecting flights Speedcast, a leading communications and IT services provider, has signed a multi-year contract with Bristow Group Inc. to deliver technology upgrades, and future-proof more than 40 remote sites across the globe.

The company will increase its fleet to 45 heavy transport locomotives and 1000 multi-purpose wagons. Progress Rail will handle the manufacturing and supply of the new electro-motive diesel locomotives while China’s CRRC Group will be responsible for the new fleet ofMohammedwagons. Al Marzouqi, Executive Director of Rail Relations at Etihad Rail says: “Upon completion and becoming fully operational, the network will contribute to revitalizing and bolstering economic growth in the UAE, particularly during the next 50 years, by providing reliable and safe freight services with high efficiency. This achievement comes as part of the company’s preparations to operate the network according to the highest global standards in the future.”

TLIMAGAZINE.COM 23

Roll on Etihad Rail, the developer and operator of the UAE National Rail Network, has achieved a new milestone with the arrival of first batches of the company’s new and advanced rolling stock fleet. The achievement was announced during an event attended by His Excellency Shadi Malak, Chief Executive Officer at Etihad Rail, alongside Marty Haycraft, President and CEO at Progress Rail and Henry Pang, Executive Director, MENA at CRRC.

News Luxury living style, exceptional quality and exhilarating performance, this yacht will not goInunnoticed.arevolutionary design move, the full-beam master suite has direct access to an aft deck entertainment area and beach club. She is the only yacht in her class to offer such an arrangement, and the exceptionally large master suite affords the owner uninterrupted views via the full-beam sliding glass door. A social seating arrangement offers a fantastic spot for entertaining and the platforms facilitate easy access to and from the water. The entire space is protected from the elements by a retractable hard top. With an estimated 33-knot top speed, her five-foot draft makes her ideal for coastal cruising and island hopping. The LSX 67 is scheduled to make her international debut at the next Miami Boat Show, February 15th - 19th 2023.

new-build Liquefied Natural Gas (LNG)-powered, wind-assisted CO₂ carriers commissioned by Northern Lights. Northern Lights is developing the transportation and storage component of Norway’s Longship project to decarbonize industrial emissions. Norsepower estimates that the rotor sails will reduce the fuel and CO₂ emissions from each vessel by approximately five percent. The two first-of-its-kind carriers have been designed by Northern Lights and are being built by Chinabased Dalian Shipbuilding. Tuomas Riski, CEO of Norsepower, comments: “Vessels are being built today to operate efficiently ahead of 2050. As fuel prices increase and a carbon levy is initiated, getting newbuild vessels as efficient as possible is essential for long term commercial success. We are pleased to be supporting shipowners in achieving greater climate alignment compliance scores and contributing to the greater sustainability of supply chains as a whole.”

Future-powered Norsepower Oy Ltd., (Norsepower), the leading global provider of auxiliary wind rotordeliveryIndustryDalianasystems,propulsionrevealscontractwithShipbuildingCo.Ltd.forofsinglesailsonboardtwo

The achievement comes in line with Etihad Rail’s efforts to achieve the objectives of the UAE Railways Programme, the largest land transport system of its kind in the UAE, which was launched as part of the Projects of the 50, the largest set of national strategic projects that seek to set up a new phase of development across UAE for the next 50 years. The UAE Railways Programme aims to set a new roadmap for transporting goods and passengers via train across the country, which will contribute to developing a sustainable land transport system that connects the cities of the UAE via railways.

Driveninnovationby

The combustion of a hydrocarbon-based fuel, regardless of its quality, is never 100% complete. In a complete combustion reaction, the key elements of any fuel – carbon, hydrogen, and oxygen – are converted to carbon dioxide (CO2) and water (H2O). When incomplete reactions occur, carbon monoxide (CO), soot (unburned hydrocarbons), and other chemical variants are generated. Such emissions are harmful and are significant contributors to air pollution.

Consistent with its commitment to innovation, Dorf Ketal Chemicals continues to develop and improve its line of multifunctional performance fuel additives that are marketed under the milEx® and mph® brand names. These additives are formulated with cutting-edge components (generally referred to as Deposit Control Additives or DCA), that are designed to both cleanup and keepclean engines and hence protect the entire fuel system against lost performance due to deposit formation. In addition to detergent additives, which have become a standard component of gasoline and diesel fuels, Dorf Ketal also developed a family of novel unique combustion improvers, which deliver benefits when used in both gasoline and diesel engines. This combustion improver, in combination with deposit-control additives, delivers instantaneous and tangible performance benefits such as unsurpassed fuel savings and reductions in particulate emissions (PM2.5 and PM10) that are documented in independent fleet trials in various parts of the world. Fuel economy and better air quality Fuel economy is becoming one of the most critical measures of fuel performance. This is being driven by greater demand for more tangible benefits from both motorists and other end-users, as well as increasing concerns relating to emissions reduction and their direct impact on climate change. Many countries are already legislating to achieve ‘Net Zero Carbon Emissions’ by 2050. While improvements have been seen in several parts of the world, global emissions continue to increase. Despite global aspirations to ‘leapfrog’ to alternative sources of energy that are more carbon-neutral, there are significant costs associated with this transition and timelines will vary enormously from nation to nation. For more than 70 years, the fuel additive industry has focused and relied on DCA to control and improve engine performance. The ability of DCA to remove and control engine deposits has also shown benefits in terms of improved fuel economy, reduced emissions, and better drivability. However, whilst DCA is known to deliver fuel economy, such a benefit is not instantaneous, and is achieved primarily as a result of cleaning up vital engine parts. Furthermore, such fuel economy benefits may not be significant - especially if the engine is new or relatively clean and so, does not have much deposit build-up. To deliver additional and significant benefits, new components are being considered in multi-functional fuel additive packageClimateformulations.changeisbecoming one of the biggest challenges the world faces today and as a result, legislation relating to vehicle and fuel economy are driving OEM advancements on engine technology. As more sophisticated engine designs are introduced, the fuel appetite for the new hardware drives the need for improved fuel quality. Oil refiners are producing fuels with more of the lighter components in the final fuel blends to meet the more stringent fuel quality requirements. However, these new fuels are more expensive to produce and so fuel economy is becoming even more important to consumers. This is exacerbated further as crude prices continue to rise along with record-high inflation rates. For the additive industry, DCA continues to play a key role to enhance the performance of fuels. In addition to DCA, the additive industry also introduced friction modifiers whereby the friction modifier acts like a film, or lubricating barrier along the chamber walls and internal surfaces that helps reduce the wear of metal components of the engine. As a result, the impact of the use of such friction modifiers can improve fuel economy by reducing the mechanical losses due to the action of the piston assembly. Fuel consumption benefits for fuels containing DCA and friction modifiers are in the range of 0.5 to 1.5%. Apart from controlling deposits/engine cleanliness and friction modification, there have been few, if any, breakthrough technologies developed that have been looked at in these areas of fuel performance. To date, the industry continues to rely on such technologies. However, over the past four years, Dorf Ketal has focused its R&D efforts on combustion efficiency. The novel and unique combustion improver that Dorf Ketal has developed works in synergy with its deposit-control additives to promote the free-radical formation, which is a critical element in the chemistry relating to any fuel oxidation process.

Dorf Ketal Performance Fuel Additives TLIMAGAZINE.COM26

The novel combustion improver technology

Aileen Valera, Senior Consultant, and Reinaldo Nascimento, Global Marketing Lead, at Dorf Ketal Performance Fuel Additives, discuss game changing and dynamic technology beyond detergency F uel quality becomes more important as more emphasis is given to improved energy efficiency and better air quality. Performance fuel additives continue to play a key role in fuel quality enhancement, supporting the global increase in demand driven by the rapid adoption of additives to improve fuel efficiencies and reduced emissions, as well as the technical marketing needs of the oil industry.

Performance demonstration

In an internal combustion engine (ICE), these typical reactions occur simultaneously albeit to various degrees depending on the efficiency of the entire system. In a new ICE, where all components are still clean and new, chemical reaction (1) is predominant, and efficient fuel utilization occurs. When engine components begin to foul (form deposits) or wear, chemical reactions (2) and (3) increase their contribution thereby requiring more fuel to perform the same amount of work. As more fuel is consumed, more combustion gases are also emitted, including CO2 which has now become a key concern because of its very significant greenhouse effect, resulting in increased global warming. Other emissions also contribute to the ‘Greenhouse Effect’ but nowhere near to the same degree as CO2.

DCA/CI combination technology enhances combustion, thus generating significant fuel economy, and reducing emissions. Furthermore, it achieves these benefits instantaneously.

Fig.1 - Complete combustion Fig.2 - Incomplete Combustion Considering a typical methane fuel, the general reactions are shown below: (1) CH4 + 2O2 g 1CO2(g) + 2H2O(v) + heath H = -802 kJ/mol (2) CH4 + 3/2O2 g 1CO(g) + 2H2O(v) + heatm H = -520 kJ/mol (3) CH4 + 1O2 g 1C(s) + 2H2O(v) + heati H = -408,5 kJ/mol

For gasoline, tests were conducted in a VW GDI passenger car that ran on E27 gasoline-ethanol blend test fuels. Fig 4 – VW Virtus 200 TSI (Fuel – Gasoline E27)

The result is the occurrence of a more efficient combustion process that maximizes chemical reaction (1) whilst minimizing chemical reactions (2) and (3), thus releasing more energy, improved efficiencies, and lower fuel consumption. As a direct consequence, by reducing the amount of fuel required to perform a given task, lower emissions of CO2, CO, and unburned hydrocarbons (such as soot) areOurachieved.patented

To demonstrate the performance benefits of our DCA/CI combination technology, real-life tests were conducted in both gasoline and diesel vehicles. Tests were conducted on a controlled track at the RANDON Technology Center located in Brazil. Fig 3 – VOLVO FH460 equipped with Dynafleet® system

For diesel, a VOLVO FH460 truck (460 HP), equipped with the Dynafleet® system that measures emissions and fuel consumption was used in the test with a B12 (12% bio-component) test fuel. Results are shown in the table below.

Table 1 - Track test under controlled conditions performed by RANDON Technology Center – Brazil

These are just examples of controlled vehicle tests that were conducted in Brazil. However, more data is available covering comparable trials that have been conducted in other parts of the world. Component Non-additized Additized % Reduction (emission/100 km) (emission/100 km) CO2 (ton) 0,13369 0,12715 4,89 CO (kg) 0,05121 0,04900 4,33 HC (kg) 0,05337 0,05062 5,16 NOx (kg) 0,35688 0,33974 4,80 SO2 (g) 0,16927 0,16198 4,31 Particulate 0,00593 0,00486 18,06 Fuel Non-additized Additized % Reduction (km/l) (km/l) Diesel B12 2,0 2,09 4,5% Vehicle Non-Additized Additized Fuel VW Virtus GDI Autonomy (km/l) Autonomy (km/l) Economy (%) QXD 4498 13,58 15,25 12,3

TLIMAGAZINE.COM 27

The results obtained in VOLVO’s Dynafleet® system demonstrate real fuel economy directly impacting emissions reduction. The additized diesel delivered fuel economy of 4.5% and reduced particulate emissions in the order of 18%, which clearly demonstrates that the combustion improver favors chemical reaction (1).

Fig 6c result is an efficient use of the calorific power of the fuel, reducing fuel consumption and greenhouse gas emissions Ketal

Performance Fuel Additives www.dorfketal.com ChemicalsServices: manufacture TLIMAGAZINE.COM28

Injector

– The

The science behind the differentiated performance of milEx® and mph® In various field tests and fleet trials with our DAC/CI combination technology, several customers have been extremely pleased with the performance benefits as described, that the milEx® and mph® performance fuel additives have delivered. For example, fuel savings of more than 10% are extremely rare and are usually due to some other criteria, however, the science supports the performance and real-life data that are observed when using the milEx® and mph® technology.Morebasic and fundamental research continues within Dorf Ketal and leading technology institutes around the world to further understand and improve the technology, but the basic mechanism of the DCA/CI combination is a combination of detergency action and free-radical formation that impact the kinetics of combustion reactions.

Dorf

– Now a cleaned

injector

injector

Fig 5d Restored normal combustion Second mechanism – Improving Combustion

–

First mechanism – Deposits Clean-up Fig 5a diesel Fig 5b process

Dorf Ketal Performance Fuel Additives

– Dirty

Conclusions Whilst DCA will remain an important and integral component of any multi-functional fuel performance additive in the future, a step-change in performance is being delivered by Dorf Ketal’s CI technology.Thetechnology is unique and uses novel chemistries, which deliver significant benefits when used in both gasoline and diesel fuels/engines. The combination of Dorf Ketal’s DCA and CI chemistries delivers instantaneous and tangible performance benefits such as very significant fuel savings and emission reductions such as CO2 and particulate emissions. In real-life fleet tests, consistently positive numbers - as high as 10% depending on the type of fuel and engine technology – are beingThesedelivered.results directly contribute to the reduction of vehicle operating costs and the reduction of regulated emissions that can lead to improved Sustainability and reduced Carbon footprint claims. The set of benefits demonstrated in this article by milEx® | mph® performance fuel additives technology redefines the concept of ‘fuel efficiency’ as it considers new functionalities in addition to standard detergency and tribology performance.

Fig 6a – The droplets in blue oxidationcompletionareofenhancedrepresentformationfreeradicalsthatcriticalfortheofafuelprocess Fig 6b – The presence of the completerateflamefuelimprovercombustionenhancesburnrateandpropagationtopromoteamorecombustion

– Detergent cleaning

Figf 5c diesel

AHEAD OF THE CURVE

Utilising our customer’s data in the right way enables us to benefit their fleet’s performance; developing tools that can help reduce insurance premiums, establish fuel insights and offer pence per kilometre prices that’s inclusive of damage, thereby reducing large admin costs. Our vision for the future is simple - running fleets by data and giving our customers one price per kilometre, helping us to build lasting, collaborative relationships with them. Another example of how providing total transport solutions keeps our customers ahead of the curve and around the next bend when they rent, purchase or lease any trailer, truck or van from us.

As the industry continues to move towards the use of increasingly smarter technology, Hireco prides itself on not only being technologically advanced, but being at the forefront of the industry’s advances in this field.

0330 124 5651 HIRECO.CO.UK

The family feel

JAG UFS Group https://jagufs.com Air,Services:sea,and road freight logistics JAG UFS Group TLIMAGAZINE.COM30

TLIMAGAZINE.COM 31 With more than three decades of experience, JAG UFS is celebrating the roll out of its all-new 3PL and ecommerce fulfilment service, the latest innovation in its ongoing customer-oriented approach to business

J AG UFS Group (JAG UFS) was originally formed in 1981, by James Gourlay and Colin Wilcox. Initially working from the front rooms of their homes, the pair established a headquarters at Heathrow Airport, serving a range of sectors including retail, fashion, and aircraft spares. From those humble beginnings, the company quickly began acquiring new business. Accordingly, the year 1983 saw the opening of a new office in Felixstowe –designed to serve a single principal customer, the multi-national toy superstore chain Toys R Us.Speaking to Transportation & Logistics International, Gary Wilcox, Group CEO of JAG UFS, and son of Colin, reflects on what was a significant milestone for the company. “The opening of our Felixstowe site coincided with the entry of Toys R Us into the UK market,” he explains. “We were responsible for importing all of their new store fixtures and fittings from the USA and Asia, and we remained their forwarder for the next 35 years, until they sadly shut their doors on the UK market in 2018.” But as one era ends, another begins. Not only does JAG UFS’s Felixstowe office continue to thrive, but it now sports a series of further sites. The first of these, located at Southend Airport, opened in 1991, with a view to servicing the aircraft spares industry. Further offices then followed in Southampton, China, and the US. As Gary indicates, it’s all the result of hard work and organic growth. “It’s always been about what the client needs,” Gary explains. “Before moving to China in 2005, we saw it as a clear next progression, because our client base was then gravitating towards the Chinese market. The same is true of when we opened in the US, around seven years ago. To achieve that, we’ve not sought any outside funding. Instead, we’ve moved at a steady place, taking calculated risks where the opportunity arose.”

All services are delivered in-house at JAG UFS, which brands itself as a ‘one-stop“It might be old-school to say so, but the phone is the best tool in business. Being able to pick up the phone to a client and build a relationship is still the most important thing for us. Likewise, we’ve sought to give that family feel to the company, so everyone knows that my door is always open, and they can come to me with any problems. We make sure everyone knows that they’re a vital part of our machine”

TLIMAGAZINE.COM32 JAG UFS Group

It’s been successful, too. The last five years or so have been difficult for stakeholders throughout the logistics sector, as Brexit, followed by the Covid-19 pandemic, precipitated delays to supply chains across the globe. But few have been able to manage the chaos as effectively as JAG UFS. “Brexit was a big challenge, because the information coming from the UK Government was either not forthcoming, or changing by the minute,” Gary recalls. “We managed to partner with an accountancy company which specializes in Amazon, and through which we were able to identify solutions to quickly get Amazon UK sellers into Europe. Amazon then did a promotion on our service.

TLIMAGAZINE.COM 33 shop’. For Gary, it’s this that has proved the company’s key differentiator in a competitive market. “We’re a medium-sized company,” Gary notes. “With that, comes agility: if a client needs us to change direction, we’re able to do that rapidly, to the extent that some of the bigger names in the market cannot. Where we’ve tried to stay, is in that sort of arena where we can adapt our service very quickly to what the customer requires, rather than the customer adapting to us and what we can offer.”