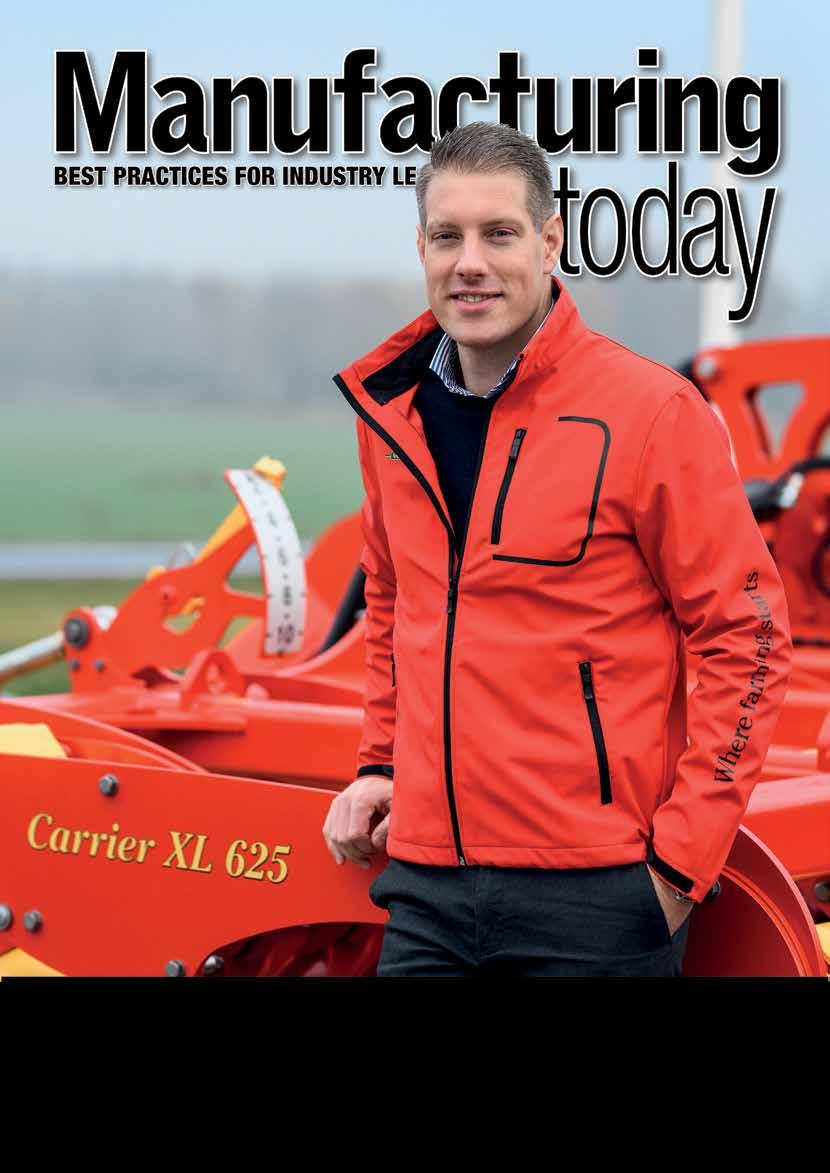

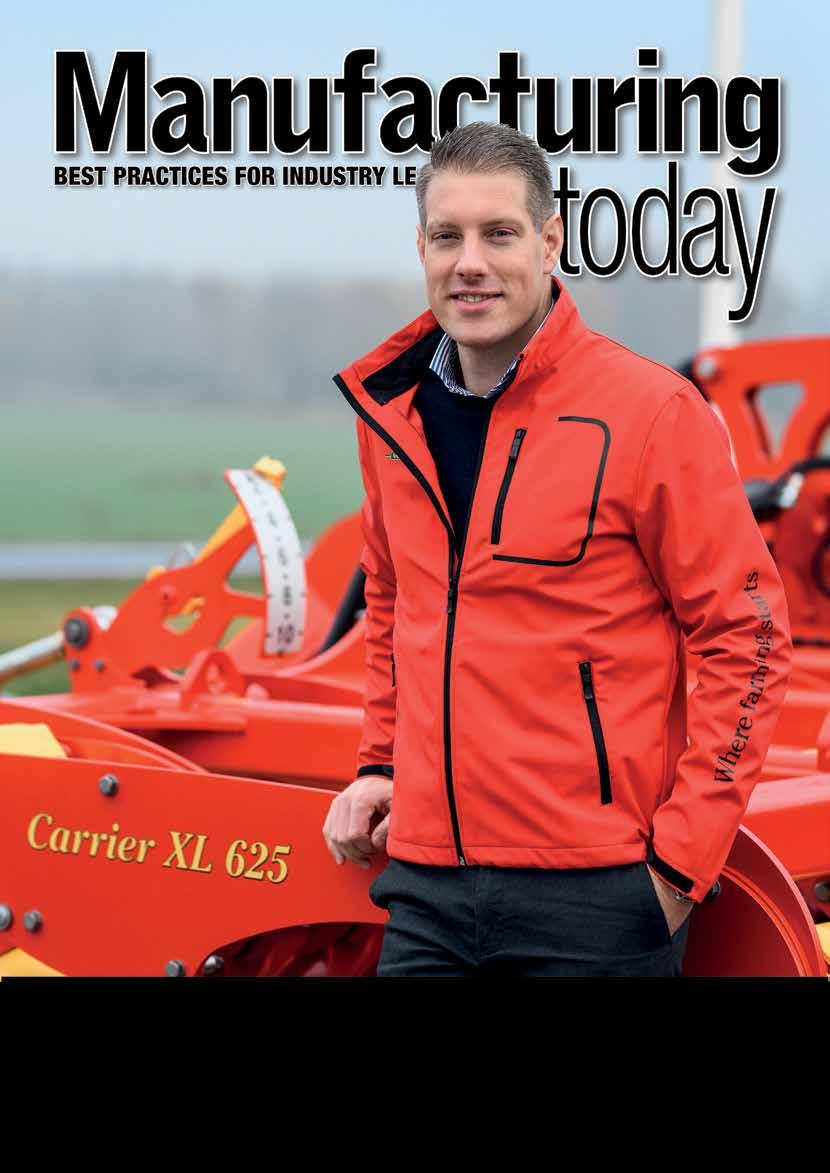

Blazing the trail

Henrik Gilstring, CEO at leading global agricultural equipment manufacturer, Väderstad, reveals how the business places innovation at the heart of its operations

Electric vehicles: There are still many questions to be answered around EVs, as Markus Winkler reports, not least of which is the customer experience

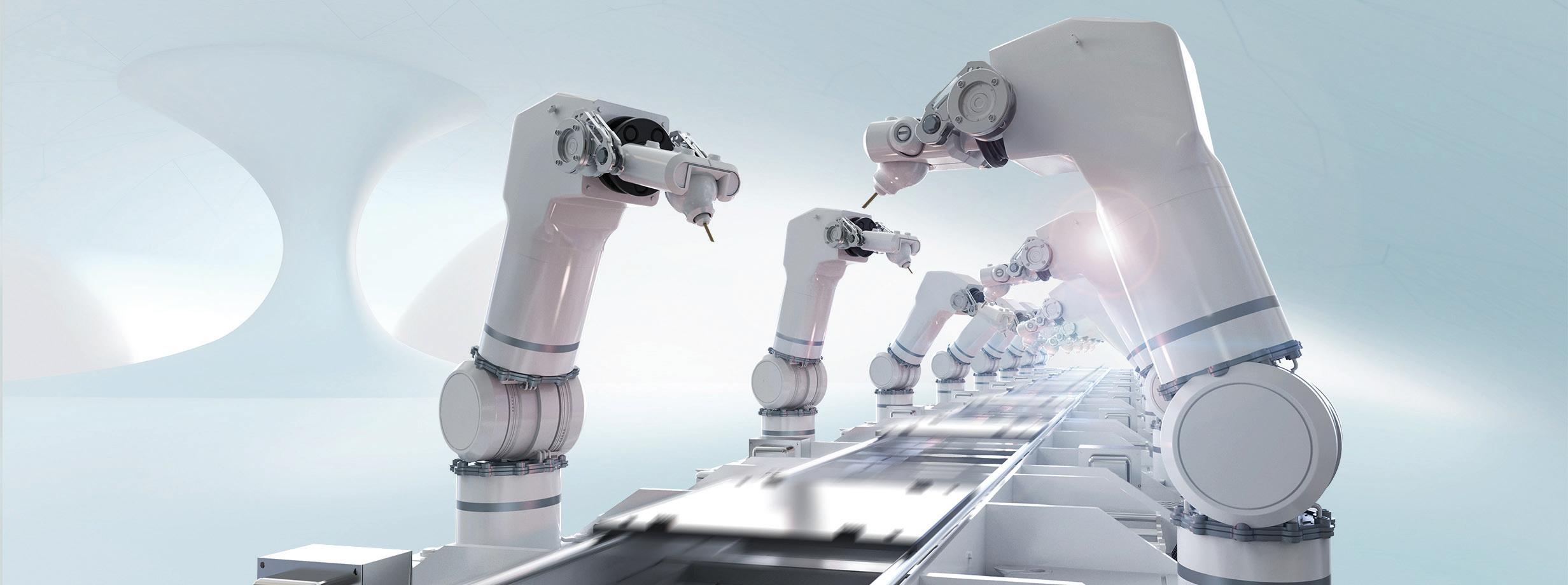

Additive manufacturing: AM can be implemented to help future-proof supply chains and manufacturing plants, providing on-demand solutions at the point of consumption

Digital transformation: Most industrial assets are still not connected and manufacturers are missing out on the power to make better decisions – why?

Issue 202 2022www.manufacturing-today.com

Editor’s Letter

Hello and welcome to the July issue of Manufacturing Today

If there is a topic that we are definitely going to be returning to time and again in 2022, it’s electric vehicles. As consumer confidence and demand continues to grow and manufacturers launch new models and commit to increased battery manufacturing operations, this market is primed with opportunities. But as our contributor Markus Winkler, Executive Vice President of Global Automotive at Capgemini, discusses in his feature this month, there are still many questions that need to be answered around electrification, including battery issues. It’s an interesting perspective and worth a read.

We also look at additive manufacturing – something else I feel has been bubbling around on the agenda for a little while now. Farhan Khan, Senior Manager Applications Engineering at Xerox EMEA talks about the benefits of adding 3D printing to the supply chain, something which recent supply chain challenges has brought to the fore as a possible solution to disruption.

Finally, Sherif El-Meshad, Digital Lead, Electrification at ABB, shares his take on digitalization, and links it to sustainability, with these two areas being two of the biggest drivers of change across industries today.

I hope that there’s something in our pages that you find interesting – if there’s a topic you’d like to talk about, then please do get in touch.

Our cover story this month looks at the activities of the Väderstad Group, a leading global manufacturer of agricultural equipment. Having recently celebrated its 60th anniversary, the company may have mature roots, but its approach to R&D and its willingness to adopt new and innovative practices on the shop floor are thoroughly modern. MT was fortunate enough to speak to Henrik Gilstring, the current CEO. Grandchild of Väderstad’s founder, Rune Stark, Henrik understands the importance of family and feelings of connectedness across the company. For the full story of what makes the business tick, turn to page 24.

Blazing the trail

Libbie Hammond EDITOR libbie@schofieldpublishing.com | lhammond@finelight-media.com ON THE COVER www.manufacturing-today.com l 1 Chairman Andrew Schofield Group COO Joe Woolsgrove Editor Libbie Hammond Staff Writers Daniel Baksi • Alex Caesari Danielle Champ • Jessica Olley Editorial Administrator Amy Gilks Managing Art Editor Fleur Daniels Art Editors Paul Gillings • David Howard Artwork Administrator Rochelle Broderick-White Sales Director Alasdair Gamble Business Development Director Philip Monument Head of Global Media Programs Mark Cawston mcawston@schofieldpublishing.com Operations Manager Adam Blanch Research Managers Michelle Fontaine • Natalie Griffiths Jo-Ann Jeffery • Ben Richell • Basil Sharpe Laura Thompson Editorial Researchers Victoria Burke • Mark Cowles Jeff Goldenberg • Dan Harrison Melanie Joyce • James Page • Wendy Russell Richard Saunders • Kieran Shukri Markus Wellington Advertising Sales Johanna Bailey • Mike Berger Jessica Eglington • James Fuller Will Gwyther • Alex Hartley Reid Lingle • Sam Surrell Florida General Manager Ryan Finn Boston General Manager Joy Francesconi Custom Media Sales Dan Bess Subscriptions i.kidd@schofieldpublishing.com Administration Natalie Fletcher • Rory Gallacher Ibby Mundhir Schofield Publishing Ltd Corporate Head Office Cringleford Business Centre, 10 Intwood Road, Cringleford, Norwich, NR4 6AU, UK Tel: (312) 854-0123 Tel: 044 (0)1603 274130 www.manufacturing-today.com Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Schofield Publishing, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

@MfgTodayMag Follow us at: Manufacturing Today Magazine Finelight Media 2240 West Woolbright Road, Suite 402 Boynton Beach, FL 33426, USA Tel: (561) 778-2396 © 2022 Schofield Publishing Ltd

Electric vehicles: There are still many questions to be answered around EVs, as Markus Winkler reports, not least of which is the customer experience Additive manufacturing: AM can be implemented to help future-proof supply chains and manufacturing plants, providing on-demand solutions at the point of consumption Digital transformation: Most industrial assets are still not connected and manufacturers are missing out on the power to make better decisions – why?

Issue 202 2022www.manufacturing-today.com Henrik Gilstring, CEO at leading global agricultural equipment manufacturer, Väderstad, reveals how the business places innovation at the heart of its operations

ISSUE

6 Electric vehicles

Automotive companies face many decisions around electrification. The best way to make those decisions is from the perspective of holistic sustainability

8 Additive manufacturing

Additive Manufacturing may be the answer to operational resilience; future-proofing supply chains and providing on-demand solutions at the point of consumption

10 Digital transformation

Manufacturers are missing out on the clarity of connectivity. With advances and more quantifiable outcomes, the digitalization dilemma is outdated

STORY

2 l www.manufacturing-today.com Contents INSIDE THIS

FEATURES 10 Balluff Evtec Automotive 14 42 COVER

EV FOCUS

www.manufacturing-today.com l 3 Avgol Cambridge Sensotec Väderstad Group Graham Engineering Company, LLC Aerotron Belzona 18 22 24 34 46 52

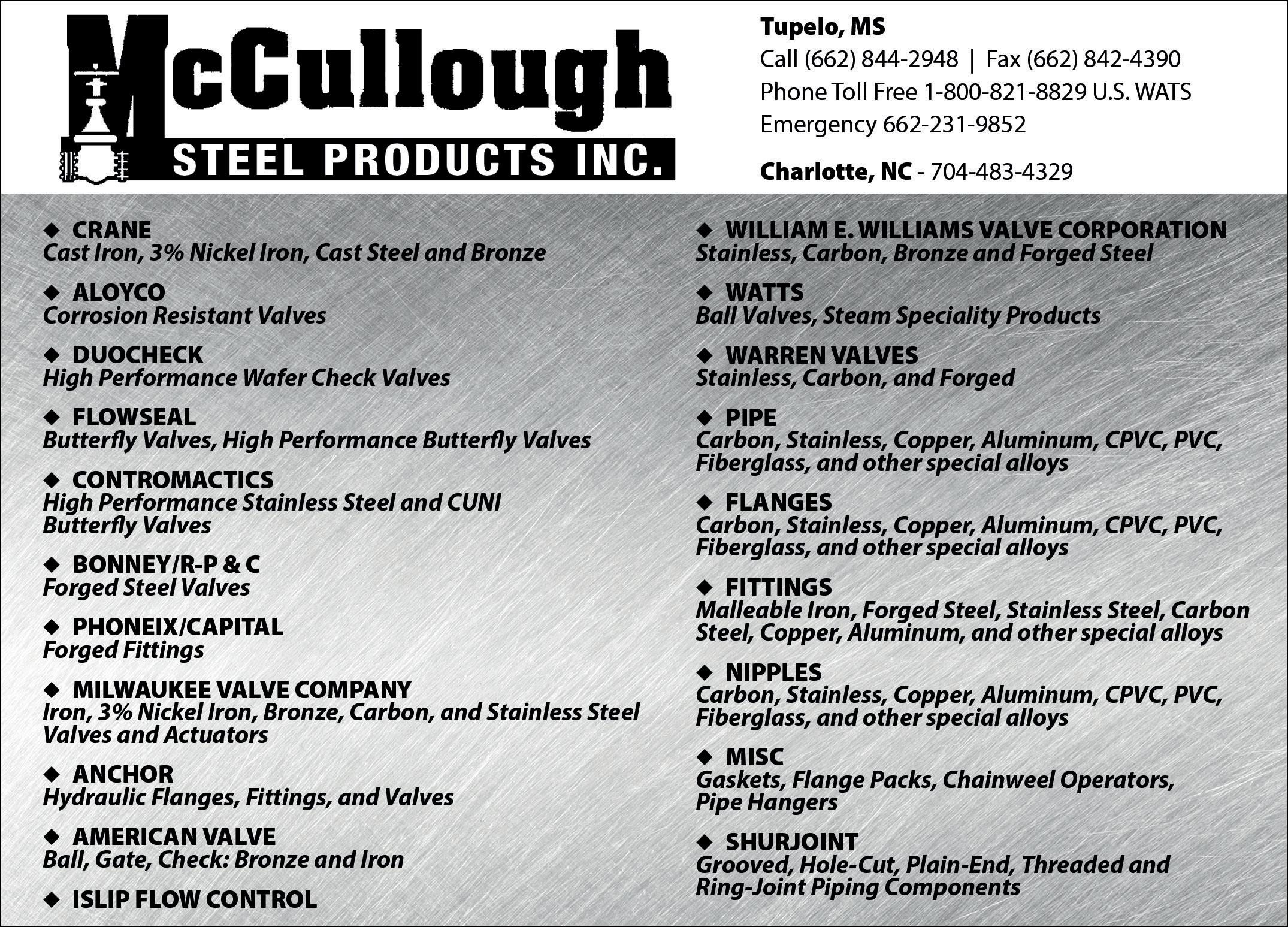

4 l www.manufacturing-today.com ...Contents continued Hi-Force Churchill China The Hammock Source The Systems Group IPS Flow Systems Osborn Manufacturing 58 84 106 64 88 110

www.manufacturing-today.com l 5 Ultra Machining Company Stephenson Walbro, LLC Munchkin Astonish Anomatic 70 94 116 78 100 120

Keep an open mind

Electric ‘pure plays’ are prominent on the automotive scene but traditional automakers, too, are putting battery electric vehicles (BEVs) at the center of their strategies. This makes sense in the context of growing stakeholder pressure for sustainability and already-strong consumer demand for BEVs. However, this article will show that many questions remain around electrification. Some are about how best to achieve it; I’ll explain why success in this area goes far beyond just manufacturing excellent BEVs. I’ll also try to show that the more we widen our view of sustainability, the better our decisions will be.

Battery issues

When thinking about sustainability, it’s easy to fixate on details. For instance, there’s an ongoing quest for alternatives to today’s lithium-ion batteries that will make better use of energy and scarce minerals. Solidstate batteries are a current R&D focus, and may appear in premium markets in the next few years, according to some experts.

This is valuable research, partly because batteries represent a significant proportion of the cost of a BEV and, in my opinion, will continue to do so for the foreseeable future barring a surprise technological breakthrough.

From a sustainability perspective, though, the technological context is arguably even more important. It’s vital to optimize the electric ‘powertrain’ that integrates the electric engine into the vehicle. The key here is software – and effective software-based battery management can make a big difference to battery performance.

Battery sustainability depends not just on performance but on lifetime impact, from production to recycling or disposal. Battery design – like the design of the vehicle as a whole – must facilitate reuse, especially of scarce materials.

Is battery swapping the way to go?

A few brands are exploring swapping pre-charged batteries into cars on the road to avoid the need for drivers to wait while a fixed

6 l www.manufacturing-today.com

The journey to electric vehicles isn’t as simple as A to BEV says Markus Winkler

Other BEV issues

Of course, there’s more to BEV success than battery sustainability. Along with price, cost, and availability, a major success factor will be customer experience, not least in relation to charging. Discussion to date has focused on questions about range and charging time, but what about the way the charging process feels to the customer? There’s a huge difference between wrestling with a heavy charging cable and simply driving your car onto an induction charging pad –something we’ll increasingly see.

Charging infrastructure, too, will be critical, and there are a variety of ways for automakers to influence its development, from building their own charging stations to partnering with specialists. ‘Charging-as-aService’ also brings opportunities for these companies.

Beyond BEVs

Nor are BEVs the only answer to electrification. Hydrogen fuel cells are candidates for powering heavy commercial vehicles such as trucks. Despite intrinsic logistical disadvantages, hydrogen brings practical advantages where batteries would have to be prohibitively bulky and heavy.

Electrification won’t be appropriate for all regions, anyway – for example, in parts of Africa, South America, and Asia, geo-economic conditions will make it difficult to establish the necessary infrastructure. Here, the most sustainable option may be conventional internal combustion engine vehicles powered by alternative fuels. While biofuels are problematic, there may be opportunities to convert biowaste into synthetic fuels using renewable energy to power the process.

Holistic view of sustainability

We need to remember that the real aim is sustainability, not electrification – and sustainability is about much more than the vehicle. Optimization of the manufacturing process is vital too; an Intelligent Industry approach can improve both sustainability and performance.

Automakers are also evaluating new business models that could increase sustainability. For example, mobility services could enable customers to seamlessly combine private vehicles with public transport, bicycle hire, and so on to reach their destination with minimal environmental impact. And simply helping customers to share their cars with others when not in use may reduce the number of vehicles needed.

Automotive companies face many decisions around electrification. The best way to make those decisions is within a holistic sustainability perspective: one that takes account of the whole vehicle lifecycle – including circular economy issues about maintenance, reuse, and recycling – and that considers transportation in the widest sense. And, of course, all of these considerations need to be seen in the context of the company’s strategy and target markets, and balanced against traditional objectives such as profitable growth.

In navigating this complex journey, it’s vital to keep an open mind about technological innovations, considering not just electrification but anything that may – whether sooner or later – contribute to a more sustainable society. v

For a list of the sources used in this article, please contact the editor.

Electric vehicles battery charges. However, this option relies on an infrastructure of battery swap shops, which probably implies battery standardization if the infrastructure is to scale beyond a single company. With battery technology still evolving rapidly, perhaps it’s too early to freeze development by imposing a standard. And, in the meantime, advances in battery charging may weaken the case for swapping… another tricky decision for manufacturers.

Markus Winkler is Executive Vice President of Global Automotive at Capgemini. Capgemini is a global leader in partnering with companies to transform and manage their business by harnessing the power of technology. The Group is guided everyday by its purpose of unleashing human energy through technology for an inclusive and sustainable future. It is a responsible and diverse organization of over 340,000 team members in more than 50 countries. With its strong 55-year heritage and deep industry expertise, Capgemini is trusted by its clients to address the entire breadth of their business needs, from strategy and design to operations, fueled by the fast evolving and innovative world of cloud, data, AI, connectivity, software, digital engineering and platforms.

www.manufacturing-today.com l 7

www.capgemini.com/gb-en

Markus Winkler

A gateway to innovation

Adding additive manufacturing to the supply chain.

By Farhan Khan

Over the past few years, we have all witnessed the fragility of our global supply chains. From Covid-19 to the Suez Canal, the need for operational resiliency to ensure that businesses can maintain operations and recover from unexpected setbacks has never been so important.

Recent challenges have shone a light on the incredibly complex variables of supply chains, where even the smallest change in environment could make manufacturers and customers vulnerable. As it stands our supply chains are only surviving; all it takes it one more storm and teams will once again be scrambling to remain operative.

Unsurprisingly because of this, 89 percent of companies are currently planning to invest in improving the agility of their supply chains over the next two years. Additive Manufacturing (AM) is one solution manufacturers are looking at to build agility and resilience. Already, it has proven to be an essential component for multiple applications, delivering quick cycle times and eliminating costly retooling fees.

More importantly, AM can be implemented to help future-proof supply chains and manufacturing plants, providing on-demand solutions at the point of consumption. Such technologies can act as critical

components to manufacturing and digital warehousing, providing vital support to those orchestrating supply chains around the world.

Time and cost

Across all industries and sectors, organizations are trying to manage a multitude of supply chain inefficiencies. Not only can these mean that it takes weeks before new parts are sourced, but it also comes at a high cost to manufacturers, both in terms of the parts themselves, and the time needed to get production back up and running.

AM can be seen as one solution to this, aiding in the production of a wide range of parts, from a simple component to a highly complex, technical robotic arm. Alongside continued innovations in AM, 3D printers are now increasingly using superior alloys and producing parts with higher functionality to handle challenging operational needs. This not only reduces cycle times but does so for a fraction of the cost manufacturers would have previously forked out.

Next-generation warehousing

Working hand-in-hand, digital warehousing and AM can automate and optimize warehouse processes. Through digital warehousing, supply

8 l www.manufacturing-today.com

chain organizations have the ability to improve the efficiency and accuracy of workflows, with much greater visibility across the entire value chain.

More so, by enabling on demand manufacturing at the point of consumption, AM works as a key enabler – equipping workers with the tools required to continuously reduce cost, improve performance, and reduce lead times. The hope for manufacturers is that this next generation of digital warehousing will remove the need to stockpile parts and reduce logistical migraines caused by having to transport spares and repair parts around the world (in less than 90 days).

Looking local for supply chain resilience

One critical component for successful AM is distributed manufacturing – getting the parts where you need them, when you need them. But this requires a clear strategy in terms of how you’re producing and procuring parts and spares in time to predict disruption.

Manufacturers know that market demand and supply chains are increasingly volatile, so they have to be equipped with agile solutions. Using additive manufacturing to add resilience to local supply chains reduces a company’s reliance on global supply chains, which, while

Additive manufacturing

still important, are also a large contributor to environmental issues.

Research from Capgemini shows that up to 80 percent of greenhouse gas emissions in industries come from the supply chain. So, any organization looking at their environmental cost should be assessing cleaner alternatives for transportation, data transfer, and even communications – AM offers one such solution with a much smaller carbon footprint than traditional production methods.

Looking to the future, it’s clear that organizations in all industries need to assess the fragility of their supply chains and how they can make them more resilient in preparation for any upcoming challenges. Innovative, new solutions are required to support and serve these networks,

enabling them to continue operating and keep economies functioning as normally as possible.

For any new strategies however, manufacturers need to be asking the right questions – could AM bridge the gaps in our supply chain disruptions? Could AM compress innovation lead-time? Does AM provide greater resilience? For a wide number of applications, the answer to all three is a resounding yes, all the while setting businesses up for future success as digital warehousing comes to the fore and sustainability is put under an intense magnifying glass. v

For a list of the sources used in this article, please contact the editor.

Farhan Khan

more than 100 years, Xerox has continually redefined the workplace experience. Today, Xerox scientists and engineers are continuing its legacy of innovation with disruptive technologies in digital transformation,

reality, robotic process automation, additive manufacturing,

Internet

www.manufacturing-today.com l 9

Farhan Khan is Senior Manager Applications Engineering at Xerox EMEA.

For

augmented

Industrial

of Things and cleantech. www.xerox.com

Let’s get digital!

Digitalization is a must for every manufacturer looking to improve sustainability. So why isn’t everyone doing it? Here, Sherif El-Meshad, looks at some of the reasons why businesses are reluctant to embrace digitalization into their operations and puts the record straight about some of the most common myths and barriers to implementation

Digitalization and sustainability are two of the biggest drivers of change across industries today1, with an estimated $7 trillion being spent globally on digital transformation between 2020 and 2023.

In 2022, ABB commissioned a global research study which asked more than 700 key decisionmakers from 12 industrial sectors about their digital transformation and sustainability strategies. Ninety-six percent said digitalization was essential to sustainability, but despite almost unanimously agreeing on the importance of it and the pandemic accelerating most companies’ digital plans, just 35 percent of those surveyed were implementing industrial IoT at scale.

The fact is most industrial assets are still not connected, and only a fraction of the enormous volume of operational data that industry generates is being used to drive decisions. Manufacturers are missing out on the power to make better decisions using the visibility and understanding that comes with connectivity and analytics – but why?

Making the business case for digitalization

The first challenge our customers face is making the business case for digitalization. Decisionmakers want to see a clear return on investment, and there seems to be a misconception that economics

and profitability don’t go hand in hand with sustainability.

That is not our experience; thanks to advances in industrial IoT technology, manufacturers can work smarter, not harder using digitalization. It can make operations more efficient, and the same equipment can give more output using the same – or less – energy. Digitalization is an incremental effort too - the more you do, the more you see the value of it.

Some early adopters are sharing the value of digitalization to their businesses through white papers, so industry knowledge is increasing all the time. This can be used to making a more compelling business case, particularly around how digitalization overlaps mega trends like sustainability.

Creating trust in digitalization

Cybersecurity is another major barrier to implementing IoT solutions at scale. Keeping digital systems safe and secure from unauthorized access is incredibly important, and the first thing customers must consider. But we also need to be able to trust the data the system generates. After all, if you are basing decisions on the data provided, it has to be accurate, and nobody should be able to influence it.

When we started our digital journey with our ABB Ability™ digital

10 l www.manufacturing-today.com

Digital transformation

platform, cybersecurity was, and still is, top of the agenda. That’s why we partner with companies like Microsoft who have invested a great deal in the security of their systems, adding our own guidelines and test protocols as an additional layer to their rigorous security. Without trust in the security and integrity of the data collected by digitalization, actionable insights are on unsteady ground.

Skilled people are needed to implement digital solutions

Digitalization is not just about computers - it needs human knowledge to succeed, from developing the strategy to setting goals. It also needs the input of people with operational knowledge of how assets behave and the input of skilled people who can understand the data collected, clean it and contextualize it into actionable insights. These are distinct skill sets; people with both operational technology and information technology knowledge are few and far between.

Overcoming the skills challenge is not simply about attracting Millennials and Gen Z who are digital natives, as they need to have experience of operating the hardware too. To bridge the knowledge gap between operating technology and information technology, we provide a learning portal with a wide range of training material, that is essential to upskill the workforce. Without suitably skilled people, the insights digitalization offers cannot be understood or actioned.

Reducing energy costs and the transition to renewable energy

The current energy crisis has certainly sharpened manufacturers’ focus on how and where they use energy and how this can be done more cost-effectively. Less fossil fuels and a greater integration of renewable energy is essential to reaching net zero targets, reducing costs and becoming more self-reliant. What many don’t know is that digitalization is key to making this a reality.

Renewable energy sources are intermittent, but of course manufacturers still need to power equipment when the sun isn’t shining, and the wind isn’t blowing. Battery energy storage systems (BESS) can be used to store excess energy so that it can be used when generation drops off; digital tools are needed to regulate this new era of self-supply and demand.

As well as meeting sustainability goals, both renewable energy and BESS integrations are tangible outcomes, which can be measured against digitalization investment to show ROI and quantify savings achieved.

New innovations to bring down barriers

Digitalization is always evolving and there are developments on the horizon which will further open the door for manufacturers to implement it. Advances in edge and cloud computing and new business models will shift the emphasis from paying for everything upfront to paying for services on subscription. By moving from CAPEX to OPEX, these cutting-edge technologies will become more affordable.

Advances in Artificial Intelligence and Machine Learning will move digitalization systems on to the next level of functionality, so a system can learn how to read its own data and take actionable insights unsupervised – for example, turning off an asset if its monitoring system detects lead-to-fault conditions.

The impending roll out of 5G will also make digitalization faster. It has better latency and more bandwidth to send and receive information faster, and action it quicker by sending control signals back to take corrective actions.

Looking ahead

If we fast forward five to ten years, we will see a greater convergence of digitalization and sustainability. Together, these megatrends can move the dial on the 35 percent of companies who have implemented IoT at scale, to match the 96 percent who see digitalization’s importance to a net zero and profitable future. With new business models, advances in technologies and services and more quantifiable outcomes, the question over digitalization for manufacturers will not be why, but why not. v

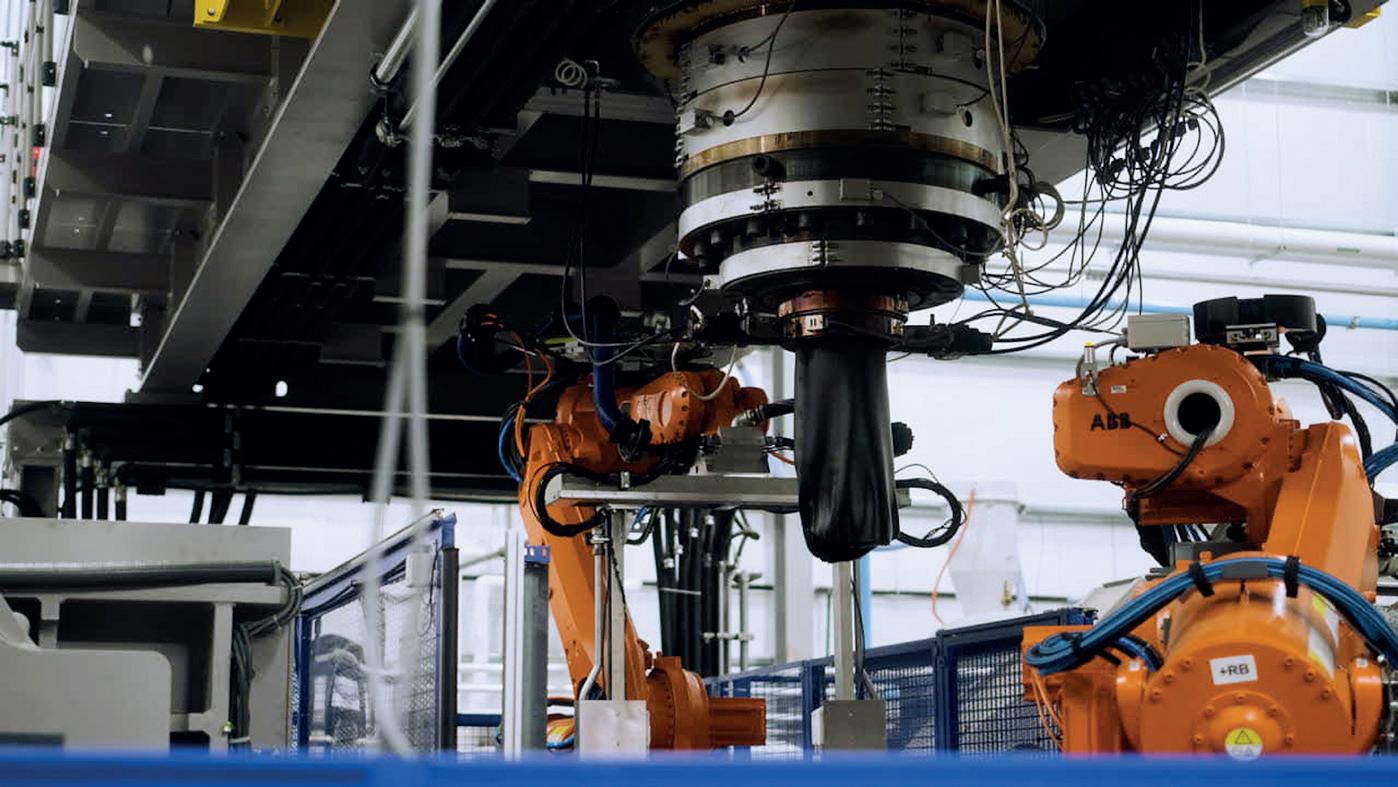

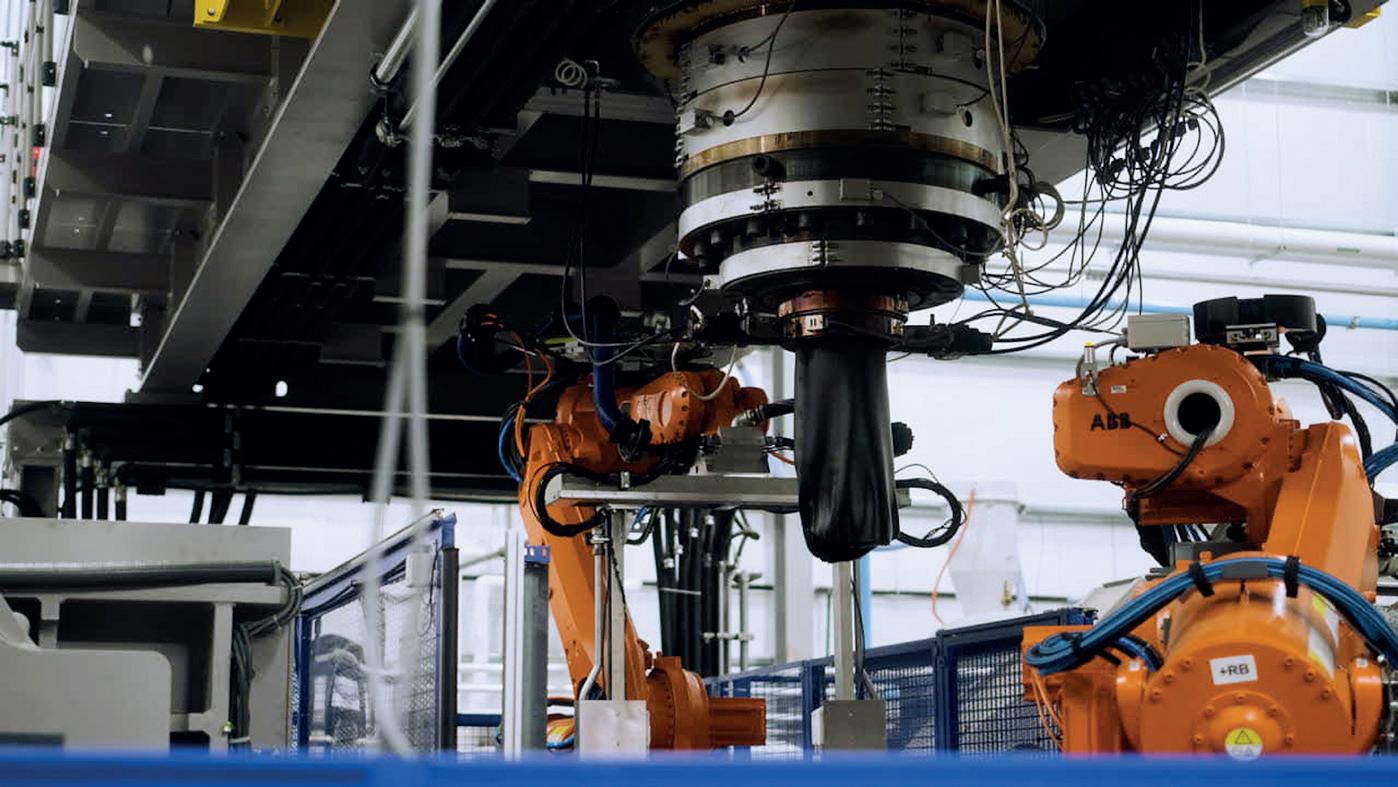

Sherif El-Meshad is Digital Lead, Electrification at ABB. Electrifying the world in a safe, smart and sustainable way, ABB Electrification is a global technology leader in electrical distribution and management from source to socket. As the world’s demand for electricity grows, its 50,000+ employees across 100 countries collaborate with customers and partners to transform how people connect, live and work. It develops innovative products, solutions and digital technologies that enable energy efficiency and a low carbon society across all sectors. By applying global scale with local expertise, it shapes and supports global trends, delivers excellence for customers and powers a sustainable future for society.

www.manufacturing-today.com l 11

1 https://telecoms.com/507803/digital-transformation-spending-forecast-toskyrocket-to-6-8-trillion/

www.abb.com/electrification

Sherif El-Meshad

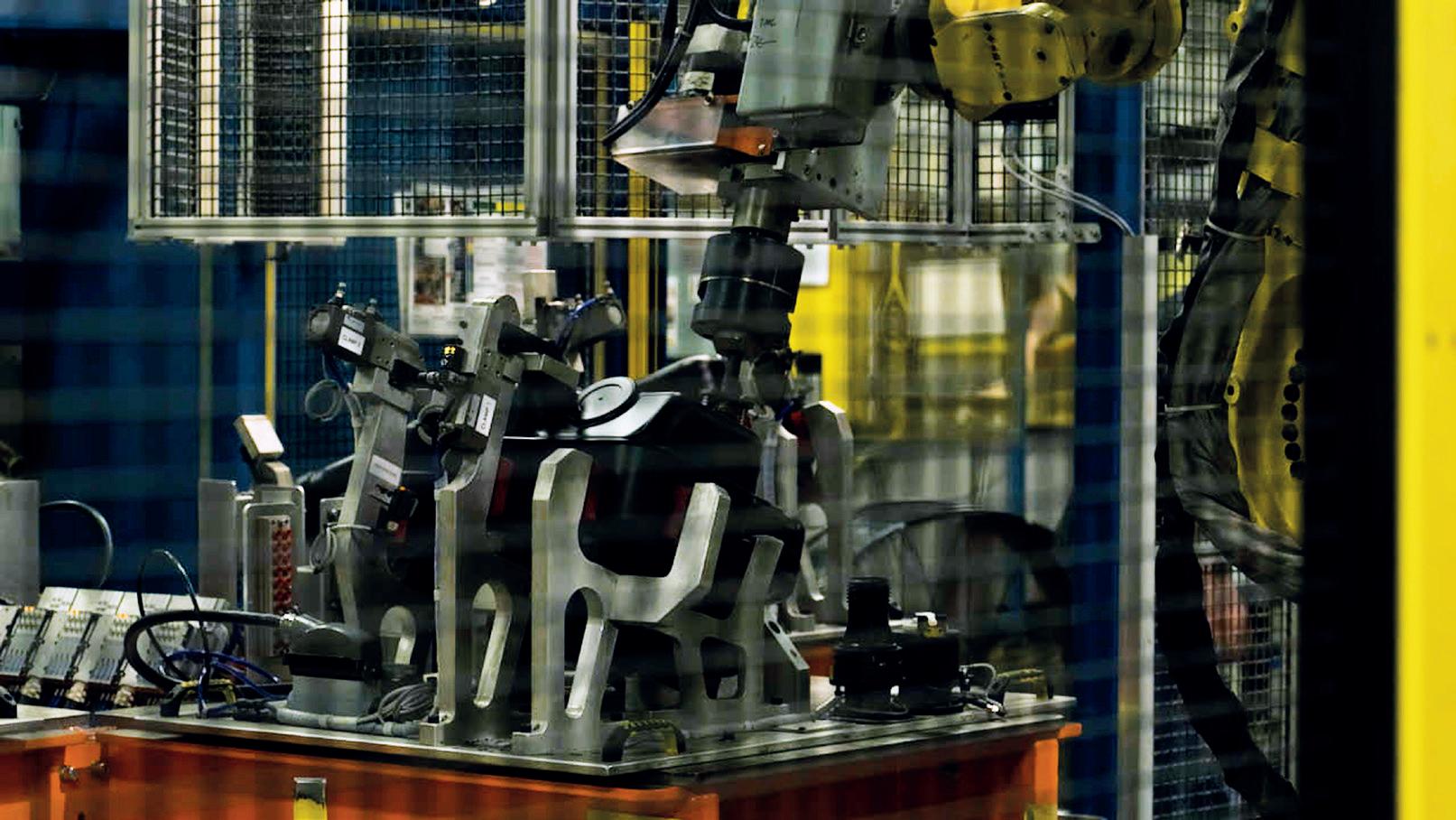

A century of solutions

After celebrating 100 years of business and record sales, Balluff has set the wheels in motion for future growth as it increasingly seeks to dominate sensor and automation markets across a vast range of industrial sectors

Balluff is a globally positioned, fourth-generation family business that specializes in the design, development, and manufacture of cutting-edge sensor and automation solutions for industrial settings. Headquartered in Neuhausen auf den Fildern, Germany, technological innovation and progress have

14 l www.manufacturing-today.com

remained the company’s methodological and ideological anchor for more than a century.

Indeed, 2021 marked a hundred years since the company was first set up by Gebhard Balluff as a small repair workshop in BadenWürttemberg. Both Balluff and its products have come a long way since then.

The workshop soon gave way to a handicraft business for turned and milled parts, before the 1950s saw the company transition to a medium-sized firm manufacturing electrical switchgear products for the machine tool industry. Technical advancements over the next few decades led Balluff to produce inductive proximity switches, the first RFID systems,

as well as magnetostrictive transducers and magnet-encoded position sensors. Today, Balluff leads the way in intelligent automation systems and is driving progress in digitization through groundbreaking software and automation solutions.

As its line of products continued to advance and expand, so too did the company’s global footprint. Balluff established its first Austrian subsidiary in 1971, and soon after expanded into the US in 1985, before establishing its own production site in Hungary in 1986.

Though a strong start, the company would sustain this growth strategy over the coming decades and end up dwarfing its initial footprint; what was once a diminutive workshop has metamorphosed into a truly global company. Balluff now employs over 3600 people in over 60 countries around the world.

Yet 2021 was not merely a cause for historical celebrations. With total sales of 504 million euros, the sensor and automation specialist achieved a record result within that financial year.

Across the group, sales were up from 410 million euros the previous year, showing an impressive 23 percent growth. One key driver of this increased yield was the company’s Asia Pacific region, where one of Balluff’s two major production sites (one in China; the other in Hungary) is located. In China, sales skyrocketed by nearly 40 percent when compared to data from 2020.

While, of course, surges in, say, the e-mobility market have spurred Balluff’s unprecedented growth, it is important to remind ourselves that another fundamental factor behind that explosion in sales is the way in which the company itself operates. Namely, through family. “One of the main advantages of being a family-run company, when compared with firms that are listed on the stock market, is we have complete control over things like sustainability and our long-term orientation,” contends Katrin Stegmaier-Hermle, Managing Director at Balluff. “We have more decision-making freedom to tackle things differently.

“I also believe that this involves employees; in our company, the team determines success or failure, and that fosters extremely strong feelings of togetherness,” she continues. “It is one thing to write that on a poster but something else entirely to really experience a sense of unity in difficult situations. The values that have been passed down over the years give us security. The entire team at Balluff tackles challenges, including those that come from outside of the company, with a sense of openness and commitment. To work on a

worked with purpose.”

Another challenge brought about by the Covid-19 crisis was – and still is – the difficult global supply shortages for electronic components. In order to keep the impact on its customers at a minimum, Balluff established a global task force in early 2021, connecting experts and specialists from various company divisions and assigning attainable production volumes that could be manufactured.

The company also quickly investigated additional sources of supply and developed product variants that were less reliant on scarce electronic components, thereby unpicking many of the constraints that disrupted supply chains had since thrust upon the company. “In the last 18 months, we have had to cope with an economic recession and the Covid-19 pandemic,” reflects Katrin. “This was and still is a great challenge for us. The pandemic was unexpected and could not have been planned for. It was a real challenge – facing up to an unprecedented global health emergency while trying to find the best solutions for Balluff so that we could come out of it again – together. To put this in positive terms: we all developed very quickly.”

That sentiment, as discussed previously, is evident in the data. Despite the economic and health challenges faced by Balluff, the company managed to record its highest ever sales rates in 2021, which was still very much in the heart of the pandemic timeline. “We paved the way for mobile working and Covid-19 showed us that it was a viable model for us,” explains Katrin. “In my opinion, one positive outcome of the pandemic was that, as a global company, our international colleagues were all thrust

www.manufacturing-today.com l 15

Balluff

together via online communication and, as a result, are now closer than before.

“Instead of moving on, we are taking the experience of working through the pandemic with us into the future,” she goes on. “More specifically, the lessons we have learned are being carried forward into our new building in Neuhausen. Firstly, we have clearly demonstrated through the start of the construction work that nothing has changed in our commitment to the plant and our aspiration to offer modern working worlds for our team. Secondly, while we are all naturally looking forward to more social contact, we understand that remote working represents increased flexibility for many employees, and we intend to fulfill that by striking a balance with regards to this workplace going forward.”

Steering companies out of the economic downturn brought on by the pandemic and toward the plurality of prospects offered

by digital manufacturing, Balluff is laying foundations for factories of the future. Once more, though, the path of that progress finds its roots in how the company pivoted throughout the Covid-19 crisis.

As Hubertus Breier, Senior Vice President, Head of Technology at Balluff, tells Manufacturing Today, an incubator program was launched in 2020 to cultivate in-house start-ups and thus accelerate the development of new business concepts with customers. One successful product to come out of the scheme was the Portable Monitoring System (PORTABLE). “The main difference between other electronic development companies and Balluff is that, instead of sending projects and start-ups outside of the organization, we are utilizing our own team to develop them,” he observes. “We start with the discovery phase, where a value proposition is made, and we can then decide how that particular innovation will

be introduced to the market, allowing us to quickly run customer-focused tests.

“Then we move onto the real validation phase,” Hubertus reveals. “Here, the wheels begin to turn regarding the development of a product. By carrying out these processes internally, we are adding value to our offering; it shows that we are creative and have the ability to think outside of the box. Portable, a system which utilizes a standard IO-Link to communicate and transmit data between the life signals of industry equipment (a ventilator, motor, gearbox) and a cloud-based dashboard, was born out of this incubator scheme. We learnt an awful lot and created an incredible product in the process.”

While a centenary and record sales are certainly a cause for celebration, Balluff does not intend to rest on its laurels; instead, the digital manufacturing pioneer intends to keep blazing new trails long into the future. “From a technology perspective, we have lots of new and exciting products in the pipeline, and we will continue to promote recent launches like the IO-Link Wireless, which is an absolute game-changer, especially in the robotics space – an area that will only get bigger in scale,” concludes Hubertus. “In the next five years, we will roll out more IOLink networking innovations, supporting our conditioning monitoring features, and create more smart and accessible technology. We have many good ideas, but we do not intend to talk about them; rather, we intend to use them and systematically achieve the success they so evidently promise us.” v

Balluff

www.balluff.com

Services: Industrial sensors and automation solutions

16 l www.manufacturing-today.com

www.balluff.com The future of automation is digital and connected. As your automation partner, we support you step by step to smart factory solutions. Together with Balluff you are ready for the IloT. INDUSTRIAL INTERNET OF THINGS #B_IIoT

Resins to believe

A leader in the manufacture of high-performance spunmelt nonwovens, Avgol is pioneering innovative new technologies to support the sustainable transformation of the hygiene and medical sectors

“While the pandemic posed a significant challenge to our capabilities and capacities, it wasn’t as if we could simply turn away from the continuing demand,” he goes on. “In many countries, the need for hygiene products was heightened as many consumers began to stockpile. Avgol met each of these incremental requests for component materials while ensuring no existing or new customers were met with shutdowns or loss of supply.”

When Avgol began its operations in 1988, its primary focus was the manufacture of fabrics for baby diapers, along with baby bags, feminine hygiene pads, adult incontinence pads, and other products for the hygiene sector. “Until 2019, that constituted 95 percent of our business,” reveals Tommi Bjorman, CEO at Avgol. “Then along came Covid-19.”

When first identified in late 2019, few could have predicted the full extent of the impact of Covid-19. Although much of life ground to a halt in the ensuing months, Avgol found itself busier than ever – identified as a critical manufacturer,

the company quickly pivoted towards the supply of personal protective equipment (PPE).

“The Covid-19 pandemic was, and continues to be, an event during which Avgol has played a globally pivotal role in doctor, nurse, and patient PPE supply,” Tommi states. “Key component materials required for personal protection and hospital care are now produced on our lines. Although prior to the pandemic we had focused much of our commercial efforts on being a leader in hygiene products, the urgent need to effectively fight against the virus allowed Avgol to rapidly step up and flex its technical capabilities to manufacture products for the medical and PPE markets.

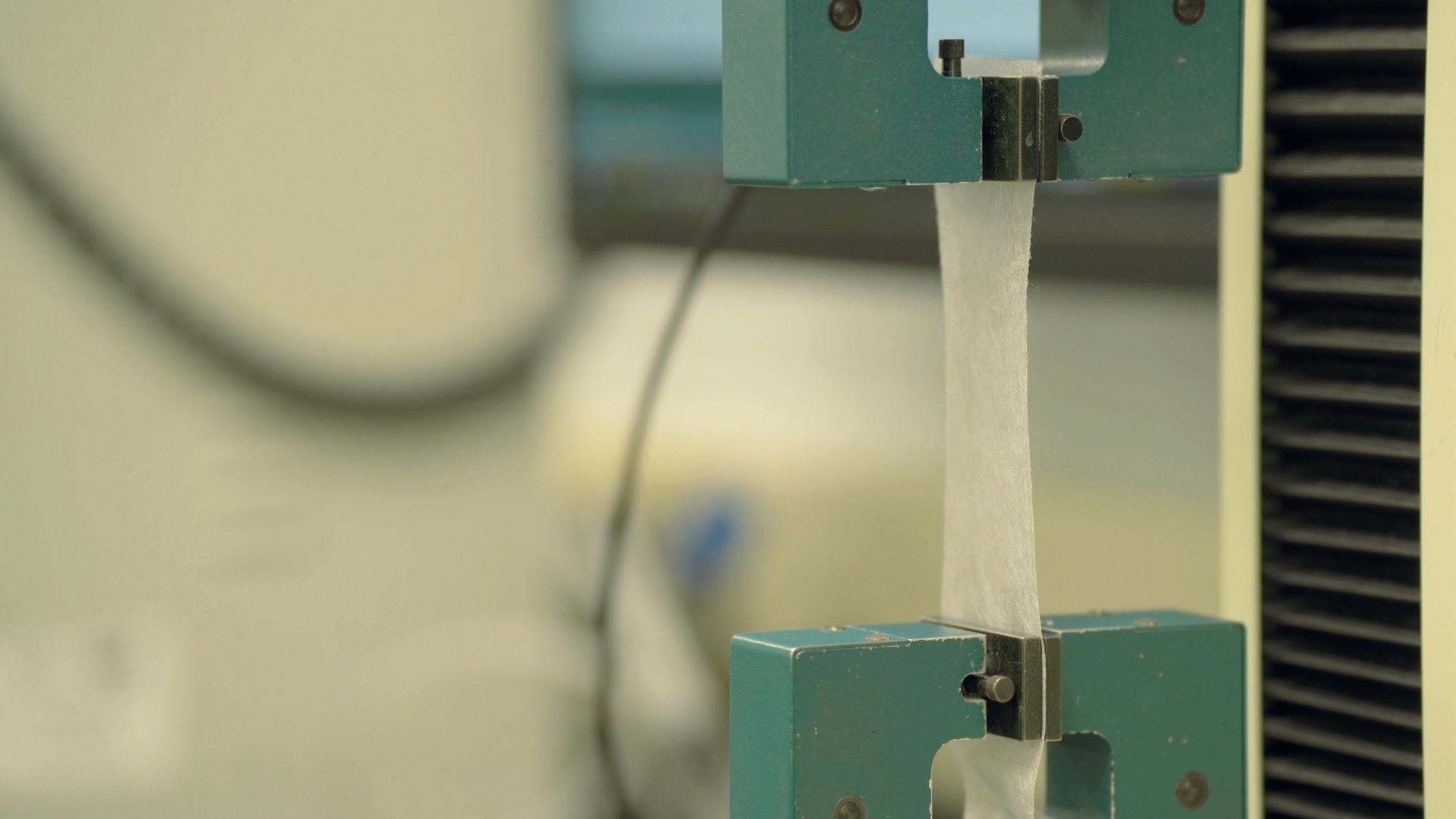

Today, Avgol is the global market leader in the manufacture of high-performance spunmelt nonwoven materials, catering to a wide range of sectors, including hygiene, medical, and functional materials. “Our manufacturing lines typically begin with polypropylene pellets , in volumes ranging from 30-kilogram bags, all the way up to whole train cars full of resin,” Tommi explains. “We take that resin, melt it, extrude it in different ways, and convert it directly into fabric.”

Avgol entered a new chapter in 2018, when the business was acquired by Indorama Ventures Limited (IVL), a world-class chemicals company with a global integrated leader in PET and fibers. But despite the change in ownership, Avgol continues to develop industry-leading products – for which Tommi is keen to stress the continued importance of taking a consumer perspective.

“There is the adage that ‘an ounce of prevention is worth a pound of cure’,” he says.

18 l www.manufacturing-today.com

Avgol

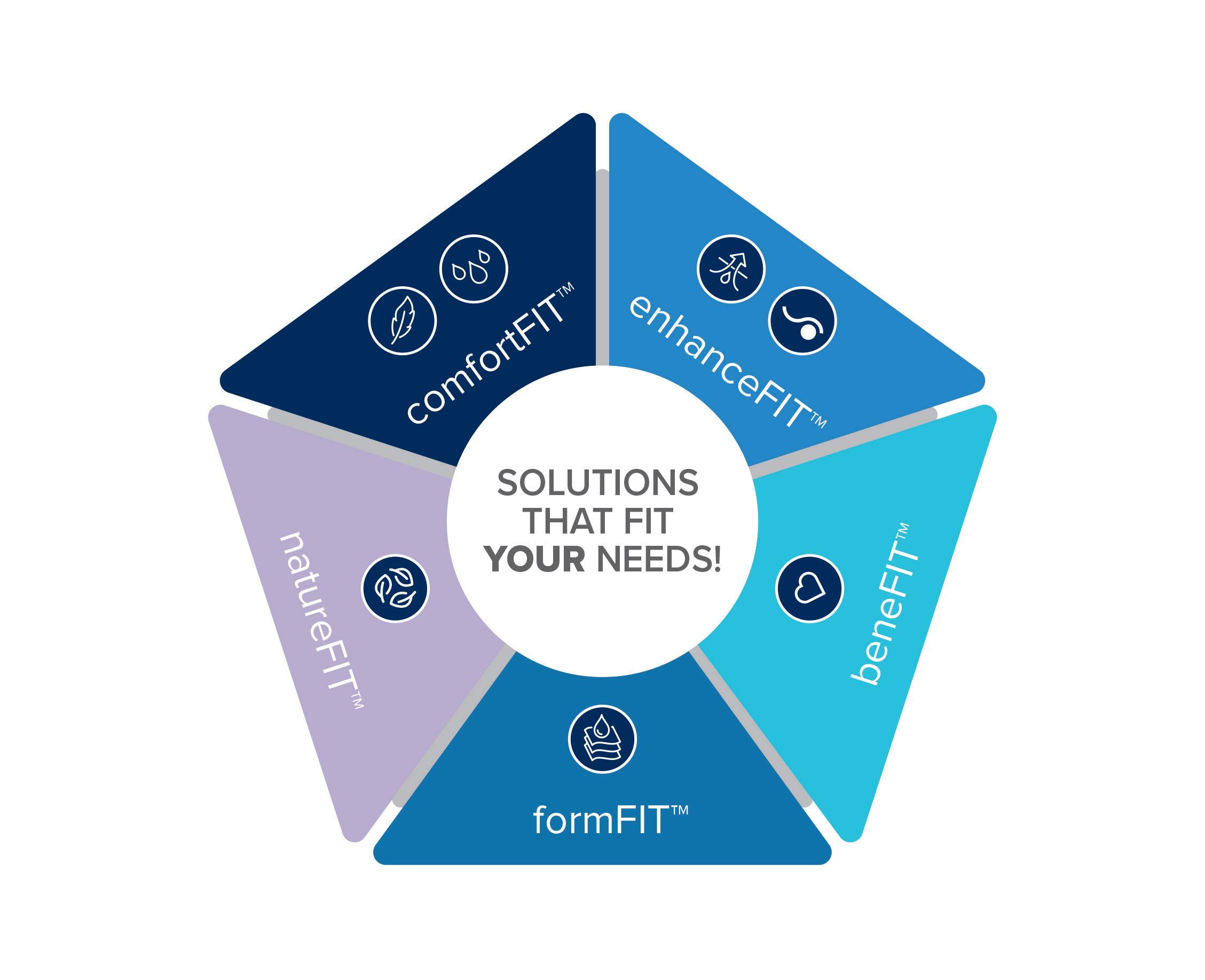

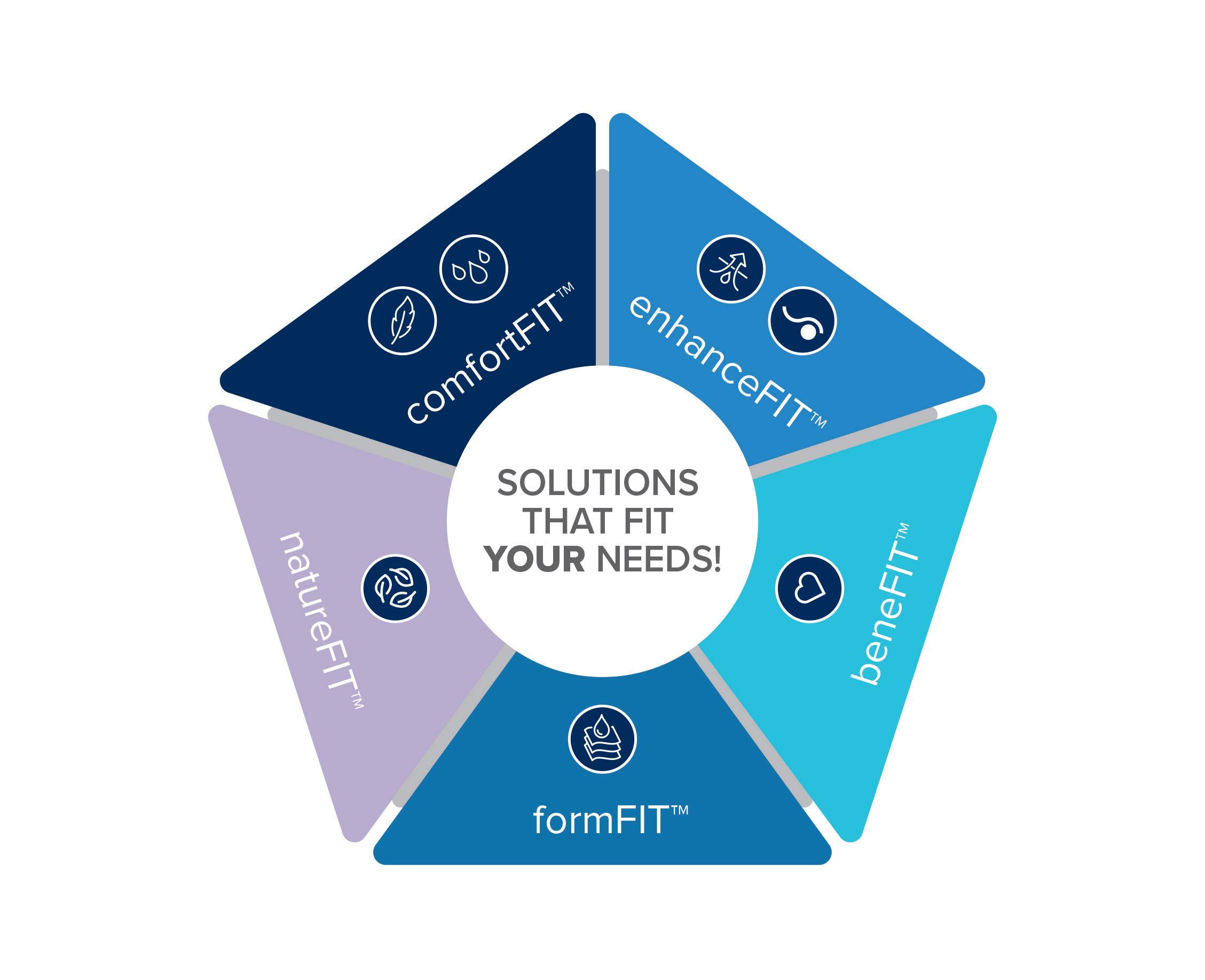

“At Avgol, we could not agree more. That’s why we developed and now follow our Forward Innovative Thinking (FIT) component strategy, allowing product designers the ability to intermix functions and capabilities to generate consumer products that improve the quality of life.”

At the heart of Avgol’s FIT strategy are currently five families of capabilities that specifically target ways to eliminate issues that negatively impact the consumer experience. These are: beneFIT, focused on system components that reduce the potential negative effects of microbes, improve skin integrity and problems such as rashes; comfortFIT, focused on methods to improve user experience including softness and liquid management; enhanceFIT, covering functionalities that address breathable barrier and absorbency enhancement; formFIT, which includes ways and means to change the fundamental fabric construction and composition; and natureFIT, which centers around achieving the above with bio-sourced alternatives, and a reduced environmental impact.

“When the FIT strategy is applied as a combination of capabilities, component materials are produced that help reduce many of the negative issues that consumers can experience when using hygiene products, including those that require personal expenditure to resolve,” Tommi tells us. “Such expenditure includes purchasing salves and ointments, or potentially the worsening of such issues over time and the need for medical attention, and the related complexities of having the time and means for acquiring such remedies. We collaborate closely with our customers to ensure problems such as rashes can be prevented when hygiene products are thoughtfully created, versus having to cure problems that might result.”

The majority of Avgol’s traditional consumer research has centered around comfort, enhancement, and form. But recently, product sustainability has become an increasingly important factor that is driving consumer habits. “Both the diaper and PPE industries generate a lot of waste,” Tommi points out.

“What do you do with all that waste? That’s where we are more involved with new technologies, exploring the environmental impacts of what we produce, and how we produce it.”

For Tommi, it’s possible to breakdown this process into three distinct phases. “The first is the beginning-of-life, where you’re looking for such things as plant-based resins instead of crude oil-based resins,” he outlines. “Then you

www.manufacturing-today.com l 19

get into the in-use phase. In the example of the top sheet for a baby diaper, those fabrics might once have been 20–25 grams-per-squaremeter in weight. Nowadays, you can find products that are 11–12 grams-per-squaremeter, that achieve the exact same, or even better results. This is quite important when it comes to reducing how much resin is used to make these components.”

The final phase is end-of-life. “This is where you get into such things as recyclability, which can be a little complicated when you think about a diaper, because they’re comprised of so many different parts,” Tommi explains. “For us, this is where we look at such things

as making a larger number of components out of the same kind of resin, so that it’s more homogeneous. We can also look at biotransformation technology.”

Biotransformation is a unique functionality, created in close collaboration with Polymateria Limited (www.polymateria.com), wherein a conventional nonwoven fabric can be modified to react to certain triggers, including the combined effects of air, moisture, and sunlight, to initiate a fundamental chemical change of the polymer resin into a wax. This resulting wax is readily consumed by natural bacteria normally found in the environment. Once triggered, the material will continue to the

point of forming low molecular weight wax compounds, with no microplastics left behind to cause other environmental problems.

“End of life issues with products that are comprised of nonwoven fabrics are as complicated as they are numerous,” Tommi concedes. “Used-product wastes, whether the simplest wipe material, the most prolific face masks, or the most complicated baby diapers, all utilize polymeric resins that suffer from a two-edged sword – a high degree of inertness and stability, while also being difficult to recycle and degrade.

“By bringing biotransformation technology to the disposable wipe, PPE, and hygiene markets, we hope to offer a real-world solution to this issue,” he continues. “In particular, we want to address aspects of the creation of fugitive waste, and the removal of such waste from the environment without causing additional, and potentially more dangerous problems.”

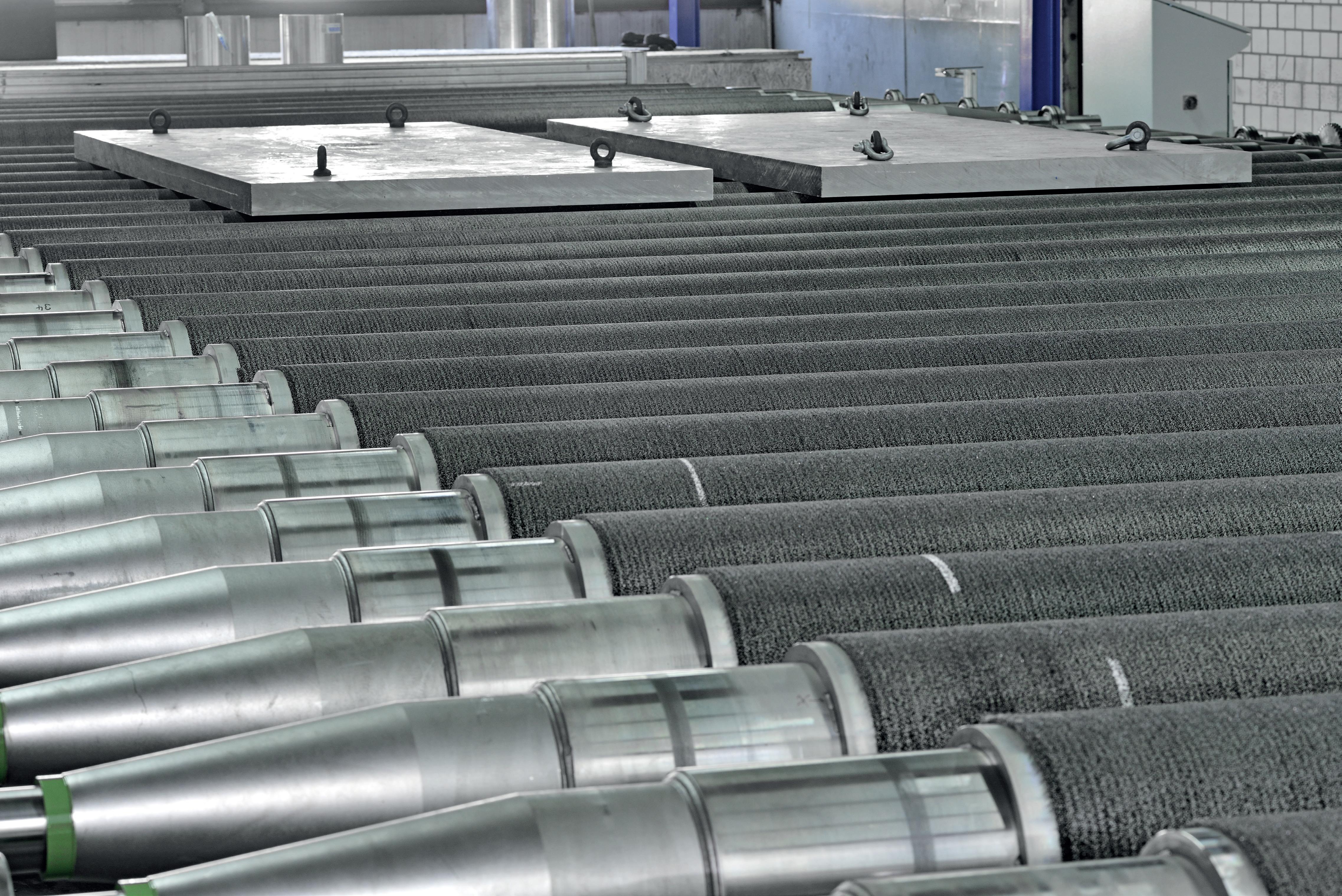

To facilitate these ambitions, Avgol has made some significant investments in its manufacturing footprint across recent years. Among its purchases is a host of new Reicofil equipment from renowned German-based brand Reifenhäuser. “They’re the company with the most patents, and the biggest support infrastructure for equipment for the production of spunlaid fabric,” Tommi indicates. “We currently have Reicofil 3s and Reicofil 4s, but a fifth generation has been introduced, which we target bringing to our future expansions.”

20 l www.manufacturing-today.com

Avgol currently boasts six manufacturing locations throughout Israel, the US, Russia, China, and India. In July, Avgol celebrated the latest addition to this footprint, with a new manufacturing site at Halol, located in the Indian state of Gujurat. It’s a move that’s set to deliver an expanded capacity Reicofil line, while also bringing greater domestic capability to support advanced spunlaid products, including spunbonded meltblown laminates. As Tommi explains, it’s an investment designed to meet Avgol’s increasing demand from the Indian market.

“There’s a growing penetration rate, in which more and more people within that market are looking to use products that include spunlaid nonwoven fabrics as part of their construction,” he says. “With the development of the Indian middle class, families are now finding that they have the discretionary income to purchase items like diapers and incontinence products. India is also a rapidly growing organic market, and one very interested in internalizing its production capabilities, relying less heavily on imports.”

Turning to the future, Avgol hopes to maintain its focus on product design, with plans to introduce yet more sustainable polymer technologies. But for Tommi, the challenge of sustainability can’t be solved by any one company alone. Instead, he argues, the industry will need to work together in order to stay relevant.

“When you look at the nonwoven industry, the vast majority of our products have very short, or single use-lives,” Tommi argues. “With that in mind, we have to be conscious about how we’re using resources, whether it’s the resins we utilize, or how we obtain the energy to run our lines, to being considerate with regards to our logistics. We’ve got to be smarter about how we obtain plastics, how we use plastics, and how we recycle plastics back into alternate or similar applications. We’re pushing our industry organizations to take a lead in making sure we’re working in harmony across all aspects of the supply chain. By doing that, we can make the kinds of improvements that people want to see.” v

Services

Spunmelt nonwoven fabrics

www.manufacturing-today.com l 21 Avgol Avgol https://www.avgol.com

:

manufacturing

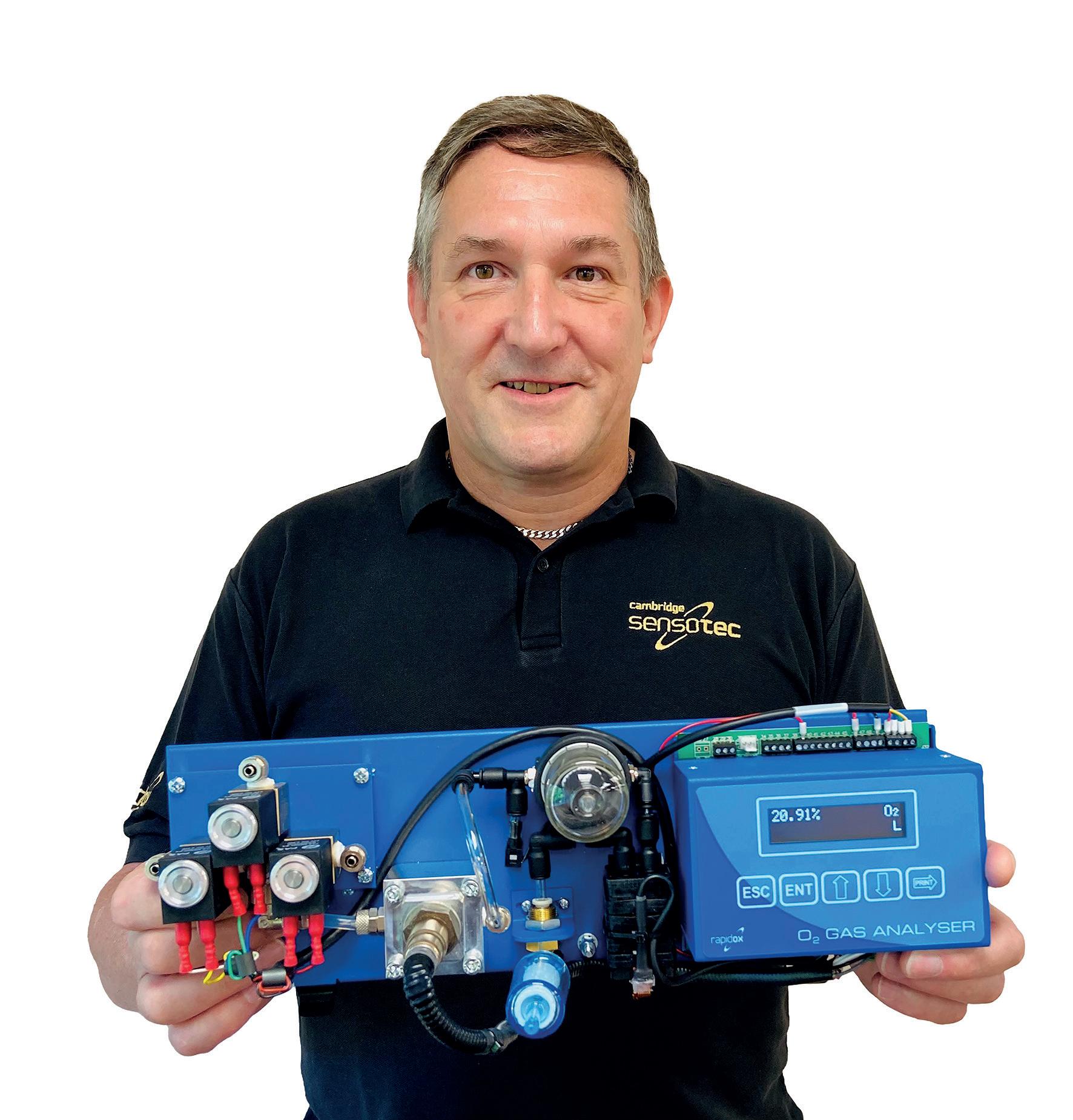

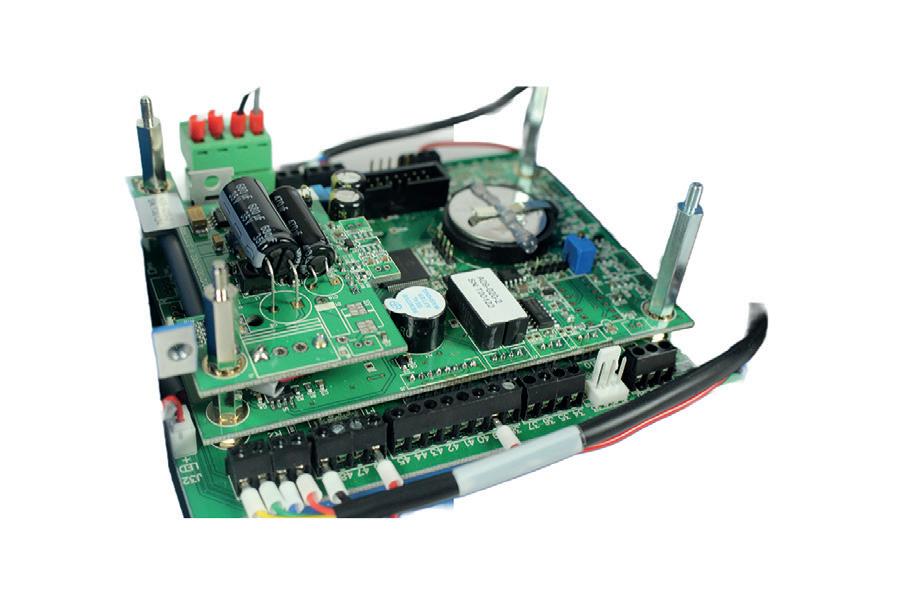

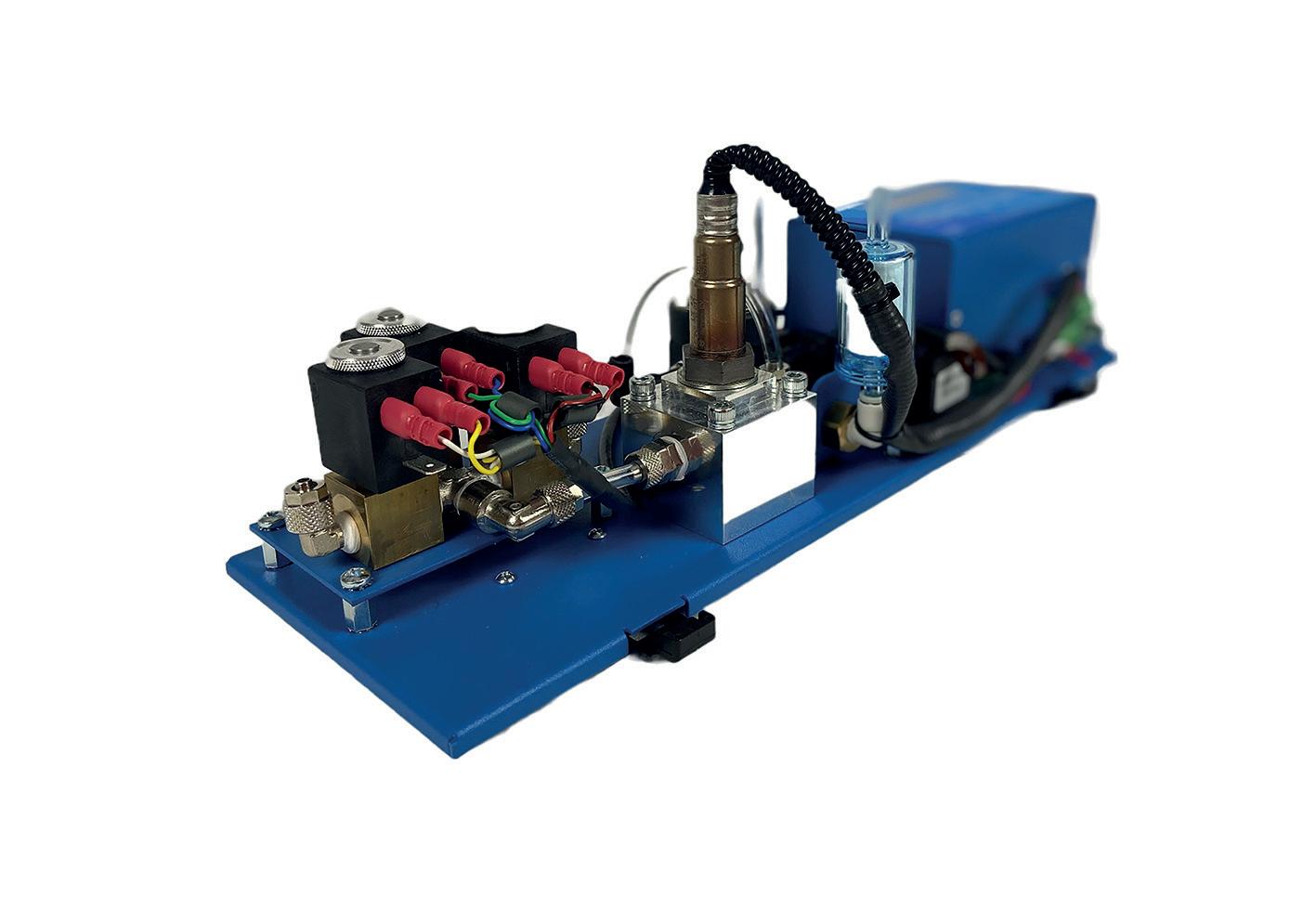

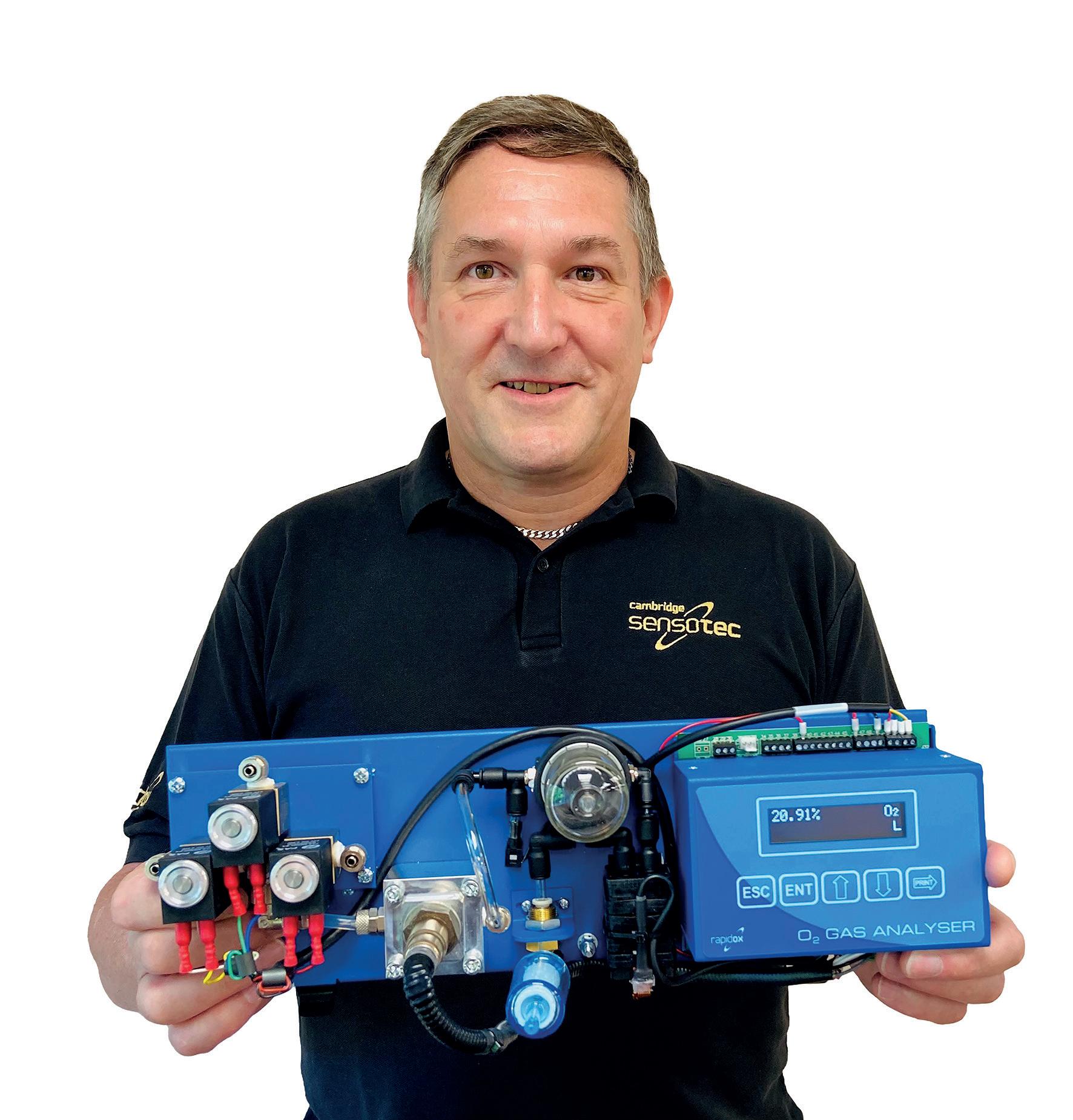

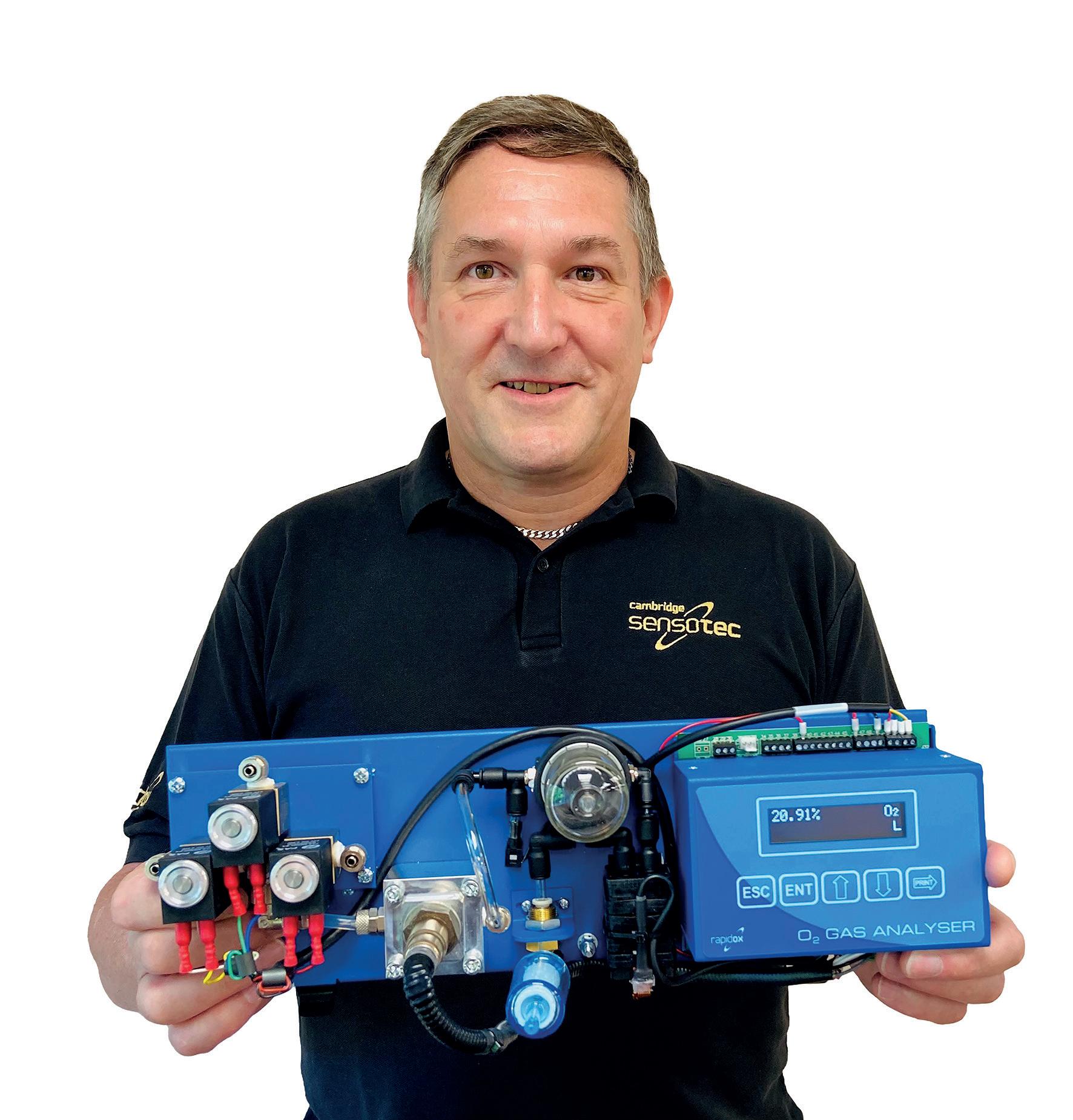

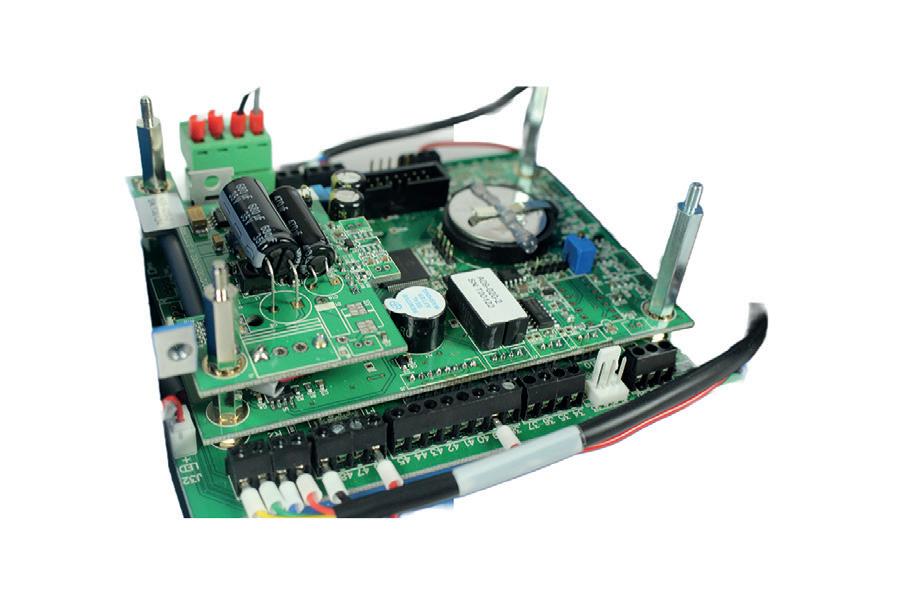

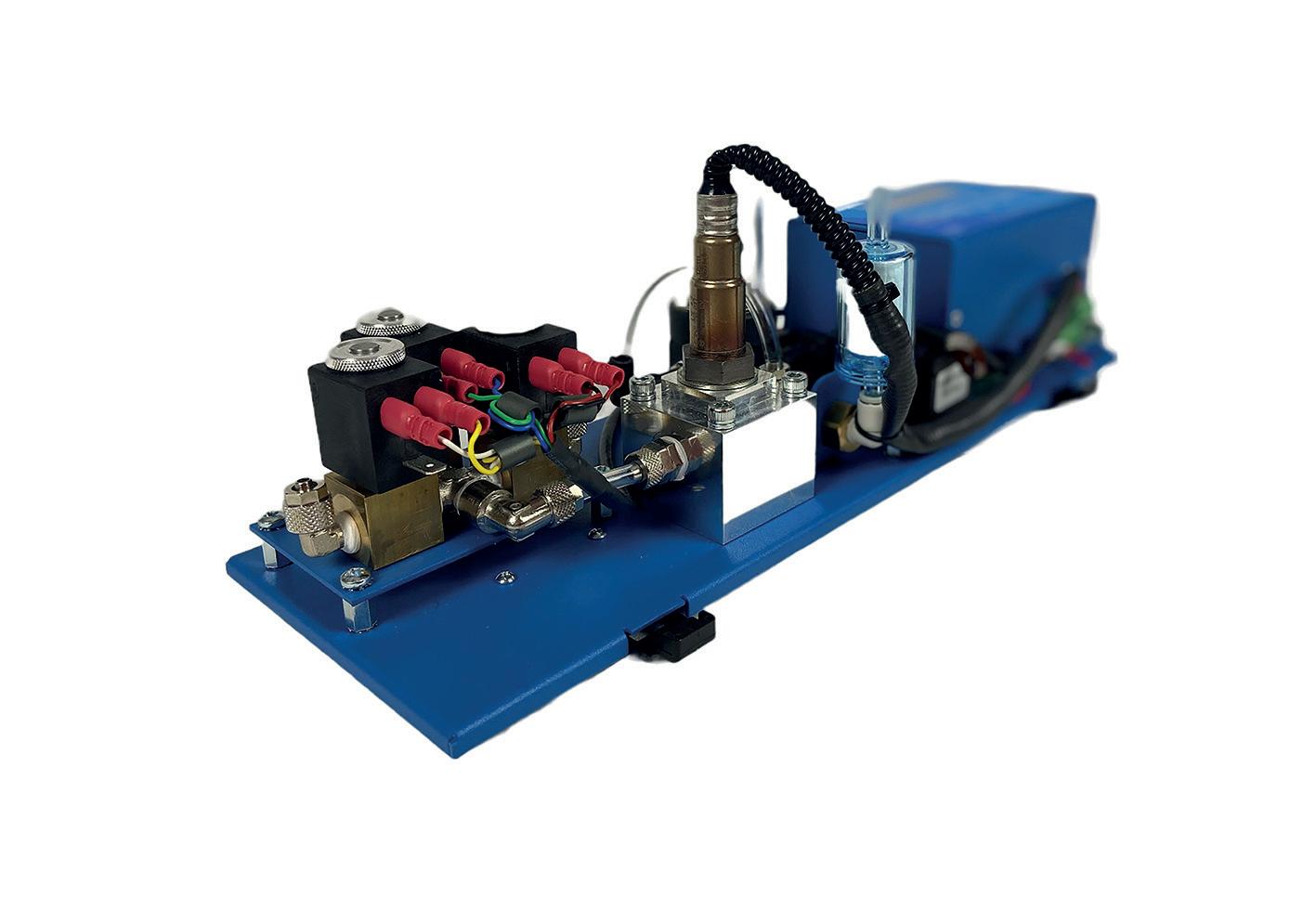

Like so many great ideas, the story of Cambridge Sensotec begins in a bedroom – in this case, that of Mark Swetnam. In the year 2000, he – along with Donald Kings and Victor Stekly – combined their wealth of industry and manufacturing knowledge in order to develop their Rapidox range of bench-mounted oxygen analyzers.

Moving into a small factory premises, the company steadily grew, developing its range to include the analysis of a number of other gases, including oxygen and multi-gas solution options and accessories.

Based – as its name suggests – in Cambridge, today the company boasts a global reach, and supplies products to a host of industries, including medical, pharmaceutical, food, additive manufacturing, biogas, and more. Not only does the company manufacture these products, but it also maintains them; an impressive aftersales service ships back more than 80 percent of serviced machines to customers within just a single week. As Mark Swetnam, now the Managing Director at Cambridge Sensotec, explains: “We are experts in enabling and supporting mid-to-large volume manufacturers with our comprehensive range of OEM products.”

The past five years have seen the company further underline this status, becoming more involved in processes including additive manufacturing, metal heat treatment, and solder reflow in the electronic industry, as it looks to cater to the need among OEMs for an evermore customized set of products.

At the heart of Cambridge Sensotec’s success is a strong emphasis on research and

From strength to strength in gas analysis

Founded at the turn of the century, Cambridge Sensotec has established itself as a leading name in a competitive field, and is now bringing forward an even greater set of innovations to gas analysis

development. Among a number of new product introductions, a significant recent addition has been Cambridge Sensotec’s SF6 analyzer. As Mark explains, the SF6 is principally designed for use in high-voltage environments. “It’s a product that’s under constant development to comply with the changes in the market, for example the move away from greenhouse gasses.”

“We’ve also been investing in bringing our comprehensive range of gas analysis devices for OEM applications to SIL 2 compliance very soon,” Tomas Diaz, Group Sales & Marketing Manager at Cambridge Sensotec adds. “As the industry is turning to relative risk reduction level and performance measurement for safety instrumented functions, supplying SIL 2 compliant devices will enable our OEM customers to improve their competitive position in the marketplace.”

Innovative programs

A history of agility and innovation has driven Cambridge Sensotec since its inception, enabling it to grow and diversify to its present state, and retain its position of relevance within a competitive industry. “We’ve recognized innovation as such an important element for our continuous success, and we have recently rolled out cross-functional innovation programs to emphasize the role it has to play as a core value for both the business and our employees,”Tomas comments. “Ideas and proposals from our innovation programs are studied, weighed and filtered into our new product development process.

“We’re also looking into designing and implementing a lean manufacturing program that

could help us increase efficiency in both space utilization as well as process optimization,” he adds. “This will allow us to maximize productivity without compromising product quality or the working environment.”

Businesses of all stripes and sizes have been hit hard over the last couple of years, and Cambridge Sensotec is no exception. Discussing life during the pandemic, Mark speaks proudly of how the company was able to adapt.

“We set up a designated team who helped us manage the situation,” he confirms.

“That included working with everyone on an individual basis to make sure their needs were being met, and ensuring that they felt comfortable and supported. We introduced new technology to the company, especially in the shape of IT and telephone equipment.

“Owing to the nature of the business, we were also keen on getting our staff safely back to the offices as soon as possible,” he continues. “We introduced enhanced hygiene standards, implementing these throughout the factory in line with the government guidelines. We also developed new working patterns, and remain open to hybrid working if it’s suitable to the job role.”

Bright future

Such was the success of the company’s approach in maximizing productivity, it delivered what turned out to be a recordbreaking year in terms of performance. As Mark explains, it’s once again a testament to the support and dedication of the company’s employees.

22 l www.manufacturing-today.com

Cambridge Sensotec

“From a staffing point of view, the pandemic period really made us realize the degree to which our staff are our most valuable asset,” Mark reflects. “To an extent, that has always been the case – hiring people with the right skills and education is a familiar challenge, but the last few years have really cemented that thinking.

“At the same time, 2022 has been one of our most challenging years, primarily because of the delays and shortages in terms of sourcing supplies and components, many of which are obviously dependent on the circumstances

in other countries,” he adds. “We try to think ahead and adapt the components of our products to spread the risks of postponing our own production. We’ve also changed our processes in terms of planning our stock levels, in order to keep up with the shortages and delays in lead times of the components.”

Before we conclude, Tomas is keen to underline what is a bright future in store for Cambridge Sensotec. “We have a clear business intention to double our sales within the next five years,” he insists. “We’re working on intensifying

business in the domestic market, energizing, our current network of value distribution and OEM accounts, as well as establishing solid partnership agreements with new customers. We will exploit all the knowledge, experience and success gained in the sectors we currently address, while developing unaddressed industry sectors.” v

Cambridge Sensotec

www.cambridge-sensotec.co.uk Services: Gas analyzers

www.manufacturing-today.com l 23

Blazing the trail

24 l www.manufacturing-today.com

Väderstad Group

Having recently celebrated its 60th anniversary, now more than ever, the Väderstad Group aims to push the boundaries of modern agriculture through its groundbreaking machinery and equipment

www.manufacturing-today.com l 25

Väderstad Group

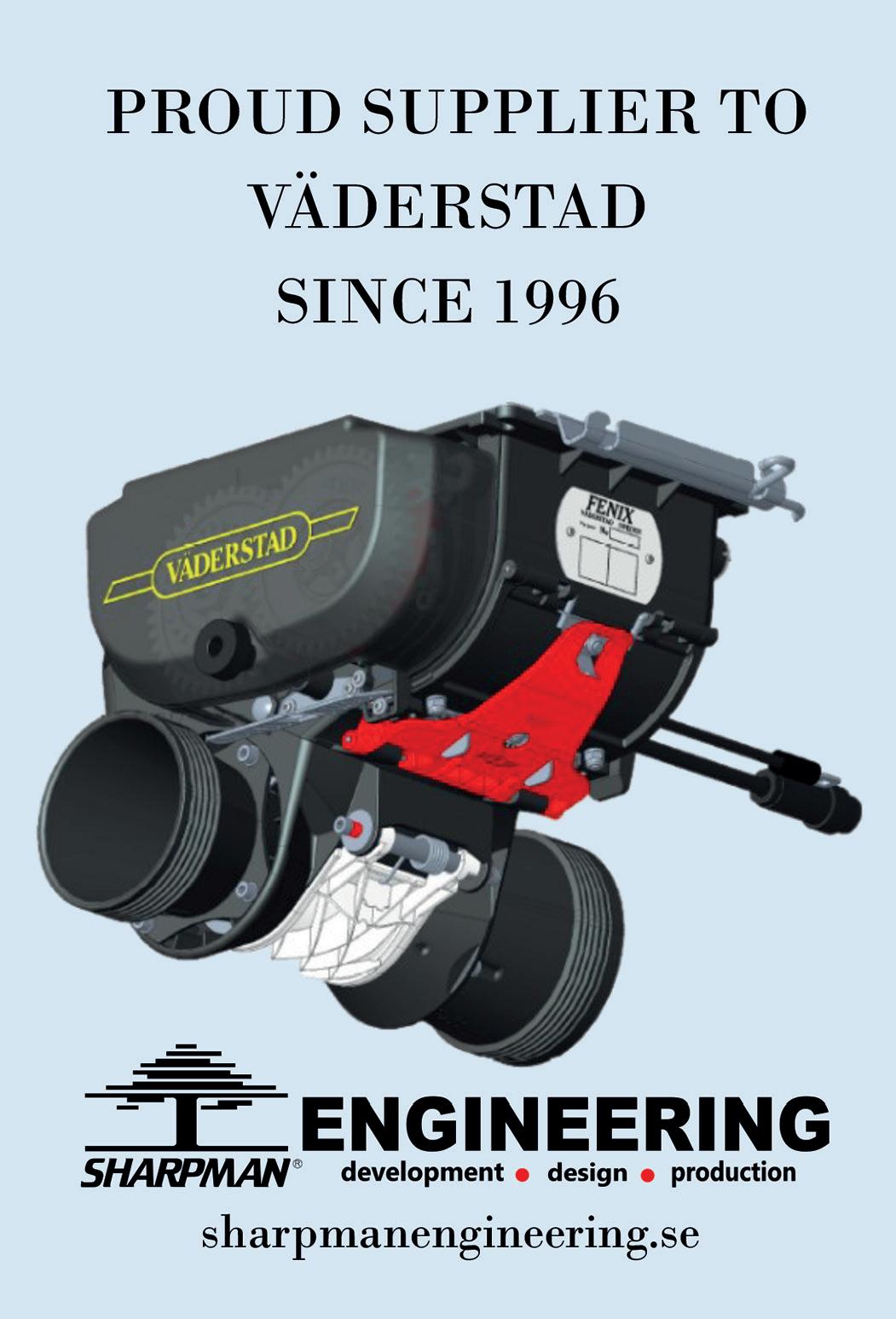

For the Väderstad Group (Väderstad), a leading global manufacturer of agricultural equipment headquartered in Sweden, the last few years have been busy. Since we last spoke, the firm has steadily increased its turnover, peaking at 420 million euros in 2021, as well as its number of employees.

Last year, the Swedish company acquired Agco Amity JV (AAJV), a US manufacturer of tillage and seeding equipment operating out of North Dakota. The investment forms part of Väderstad’s wider ambitions to increase its market share in North America. “We now have a product portfolio that can really help American farmers,” begins Henrik Gilstring, CEO at Väderstad. “With this acquisition, we have access to a large dealer network spanning

Continental

the US, a sizable factory in North Dakota, and many skilled and experienced new coworkers. As a result, we’re in a very strong position to prove to US customers that we’re their best choice for perfect crop emergence – time after time.”

As this acquisition demonstrates, despite recent challenges in the global economy, Väderstad has gone from strength to strength over the last few years. “We were very fortunate not to be hit as hard by Covid-19 as many other businesses,” admits Henrik. “However, naturally, the pandemic has affected us in terms of delivery disruption and the rate of sick leave in our company. In the summer of 2020, when material shortages were at their peak, we decided to keep our factory closed for an additional two weeks, using that extra

time to make some key improvements to the facility and expand its overall capacity. We did not have to seek any financial support from the Swedish Government over the course of the Covid-19 crisis – fortunately, demand for our products has continued to be very high.

“The biggest change for us during the pandemic was probably having to adapt our ways of working,” he adds. “We are a customerfacing company; close partnerships and being able to meet people face-to-face is an integral part of the business. With the pandemic making this impossible, we had to find new digital ways to meet customers and dealers. We learned a lot during this period, and we hope to have gained some useful digital experience that we can benefit from in the future. Needless to say, we are all very happy that the pandemic

With a successful history of over 20 years, Väderstad and Continental have proven that a close cooperation brings the best possible results. In this case, it was efficient seed drills and fertilizing machinery that all farmers can depend upon to help ease the challenges of modern-day agricultural entrepreneurs.

As the right attention has been given to quality product innovation over the years, both partners have developed hoses with special conductive compounds and specific inner layers for the best flow characteristics, as well as hoses that, through the choice of abrasion resistant materials, will guarantee the longest possible life on avant-garde machines.

This has resulted in a range of innovative products, well-adapted to the extreme weather conditions and application circumstances in which top of the range seeding and fertilizing equipment must function.

Even the most difficult challenges of the last few years have not been able to put a dent in the trust and cooperation between these two industry-leading companies that look to the future with great confidence.

26 l www.manufacturing-today.com

the importance of family and feelings of connectedness across the company. Though customer-facing, Väderstad also places great weight on its intra-company relations. “Our values are derived from how we as a family have managed the business and treated both our customers and colleagues over the years,” he explains. “Those values – being innovative, accessible, and reliable – are very much alive in our daily work. I think our staff appreciate the company’s genuine drive to make a difference to the businesses and livelihoods of our customers.

“We have the same drive when it comes to the improvement of our internal processes,” continues Henrik. “We are always looking at how we can make things better and be more

28 l www.manufacturing-today.com

the business helps to make people feel they are seen and that their work is appreciated. We want our employees to be part of our growth journey. That means, as the company develops, so do they.”

In 1962, Väderstad first sought to create new solutions for persistent agricultural problems –60 years later, that spirit lives on. Since its inception, the company has brought multiple gamechanging pieces of equipment to the market, revolutionizing the way farmers approach tillage, drilling, and planting. In turn, Väderstad has secured its

Väderstad Group

place at the fore of the agricultural industry, helping to create the optimum environment for cultivation, seedbed preparation, and seed placement in farms all over the world.

Tine cultivators, rollers, combination and disc cultivators, harrows, rapid seed drills, tempo planters, and front-mounted fertilizer hoppers. All these and more offer cost-effective, highspeed solutions without compromising on quality, precision, or accuracy.

“Some of our most renowned products include the Rapid, the Carrier, and the Tempo, the latter making it possible to plant row crops, including corn and sunflower, at double the speed of what was previously possible with improved precision,” Henrik details. “One of the

keys behind our success through the years is that we always stand behind our farmers. We have a unique partnership with them; we listen to their challenges and help them overcome obstacles by providing technological leaps that push the boundaries of modern agriculture.

Simplifying work and improving results for farmers is in our DNA – and that will never change.”

Indeed, the Väderstad Proceed, a new concept presented last year, represents the pioneering company’s next technological leap. “This machine will set a completely new standard for the industry,” Henrik proclaims.

“Proceed can take the smallest of seeds and place them at the perfect depth with millimeter

www.manufacturing-today.com l 29

30 l www.manufacturing-today.com

Väderstad Group

precision, offering significant improvements to yield levels and reducing the number of inputs (for example, fertilizer) required. Our field trials have shown that Proceed can cut the wheat seed rate by half, compared to modern, conventional seed drills, and that crops emerge stronger and more even across all growth stages. It is a huge leap from current seeding technology; we are very excited about the impact Proceed will have on farmers all over the world, particularly in terms of crop emergence, business viability, and overall sustainability.”

In June 2022, Väderstad blazed new trails with the official launch of its Carrier XT at DLG Field Days, a field exhibition hosted

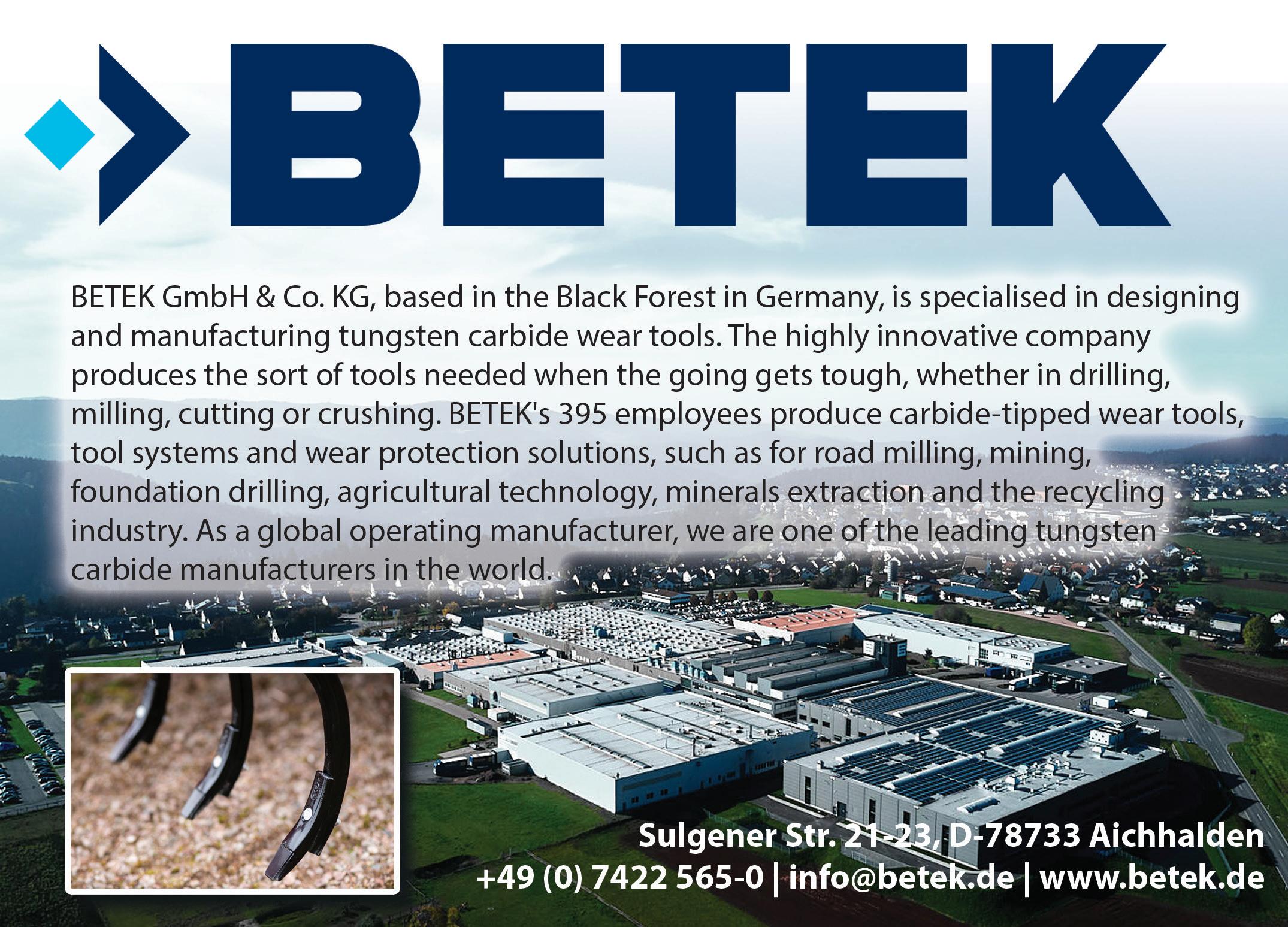

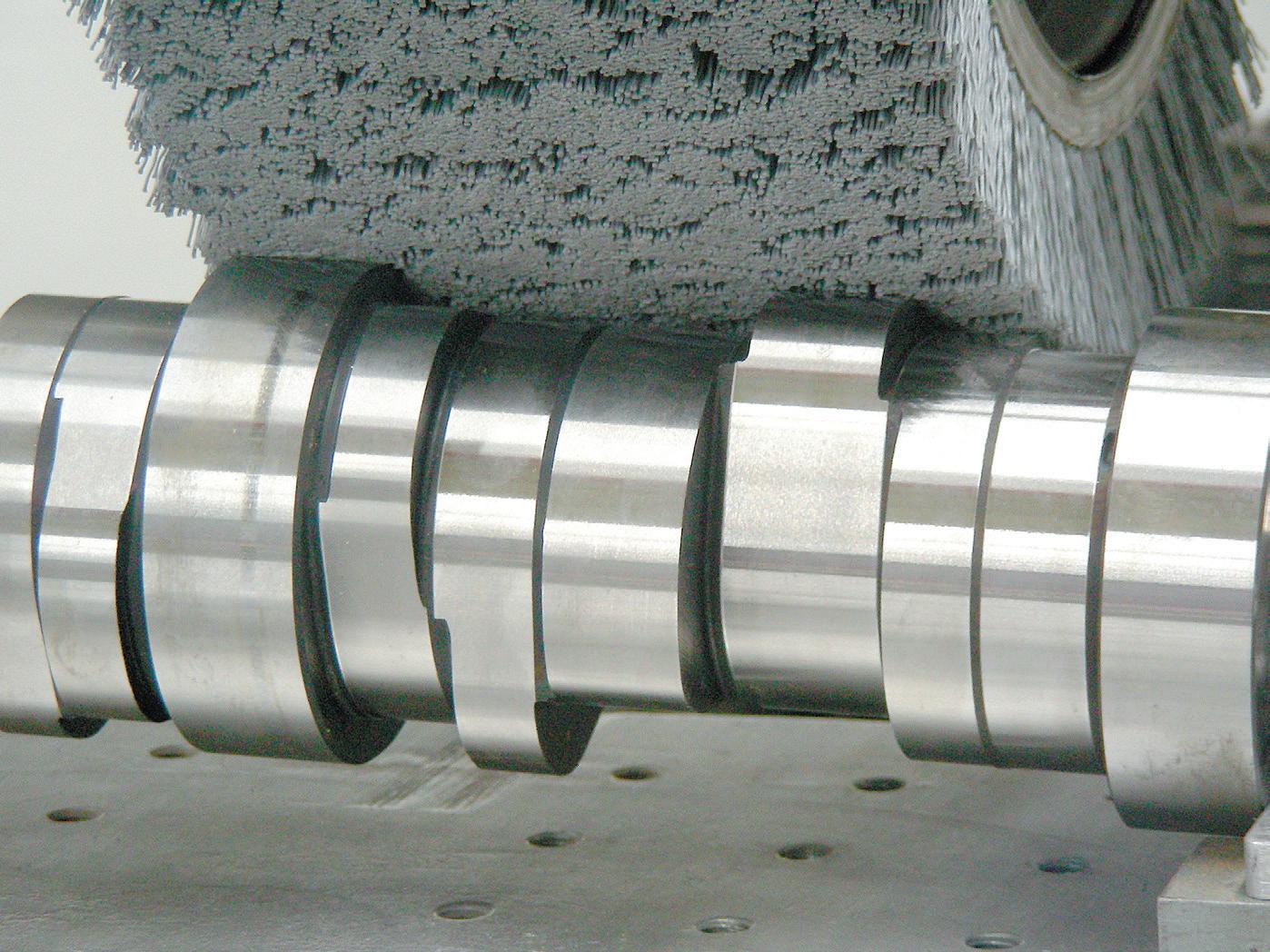

BETEK Agricultural Technologies

by the German Agricultural Society. “The Carrier family of disc cultivators has been an important part of our portfolio since 1999,” explains Henrik. “It can handle everything from ultra-shallow tillage to deeper incorporation.

The Carrier XT has a new feature: hydraulically rotating disc axles. By changing the disc angle towards the soil, farmers will be better able to optimize cut-out performance at shallow depths and increase precision at deeper working depths.

“As this launch makes clear, innovation is at the heart of product development at Väderstad,” he continues. “We have a large research and development team who are intent on bringing new, high-performing

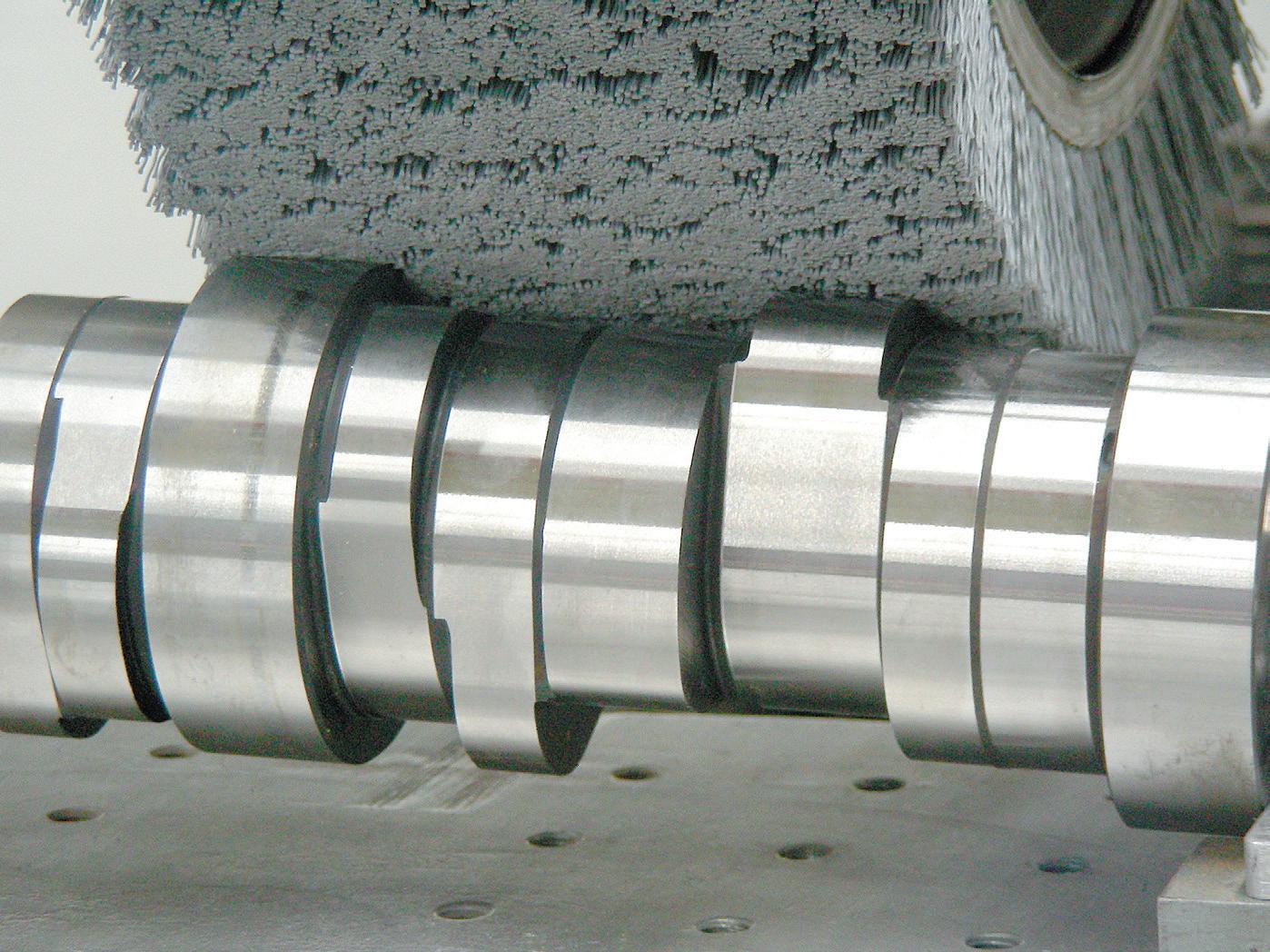

BETEK tungsten carbide-wear tools are developed and tested, together with Väderstad, to ensure perfect performance for all kinds of tillage machines. Only grades of tungsten carbide that are specifically suited in terms of hardness and durability are utilized for these applications. With the patented BETEK tungsten carbide tools for soil tilling machines, you reap the benefits of quality, time and cost:

• Significant longer life time than traditional steel tools

• Consistent working depth and tillage quality

• Permanently sharp cutting edges, less traction power required

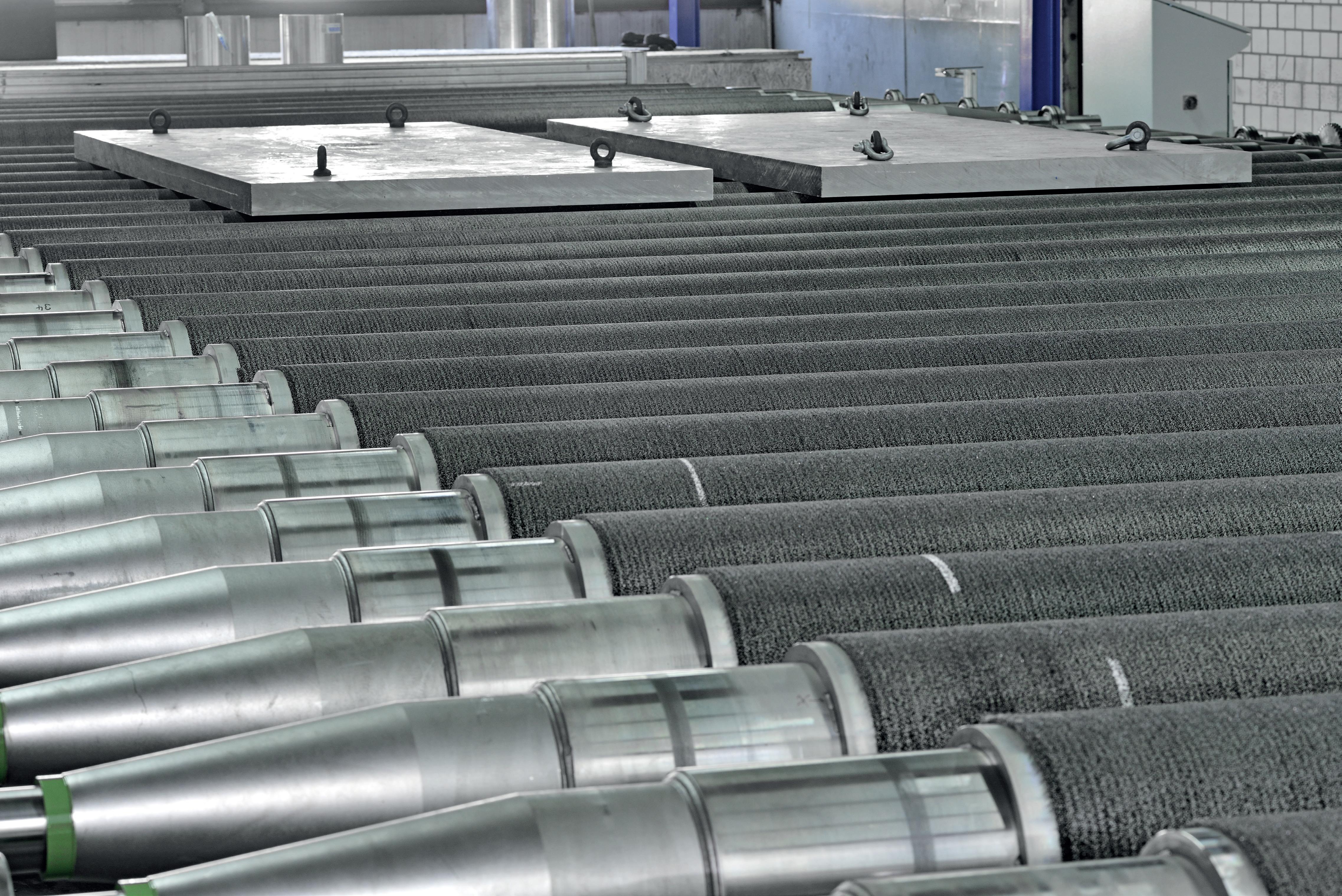

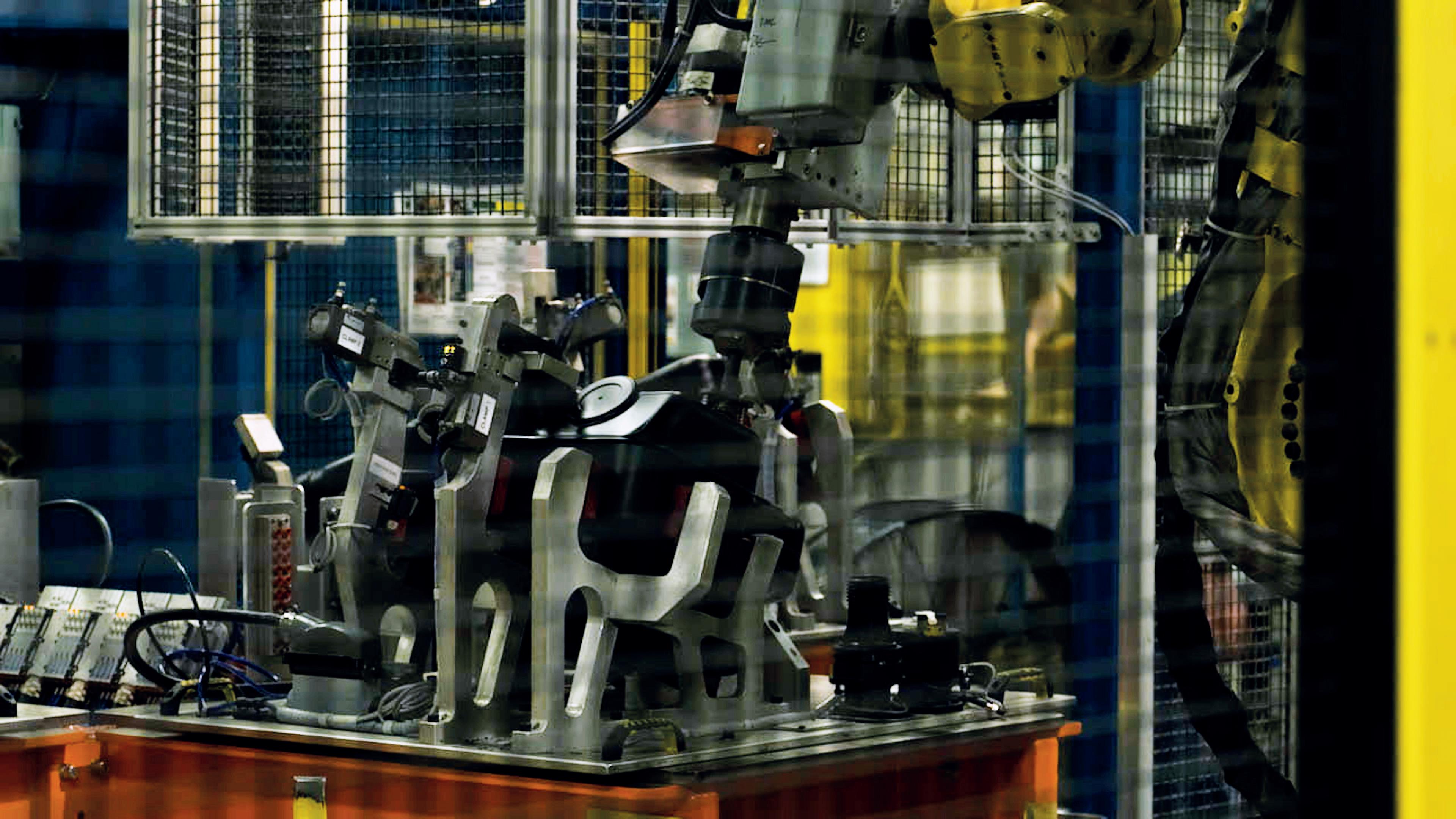

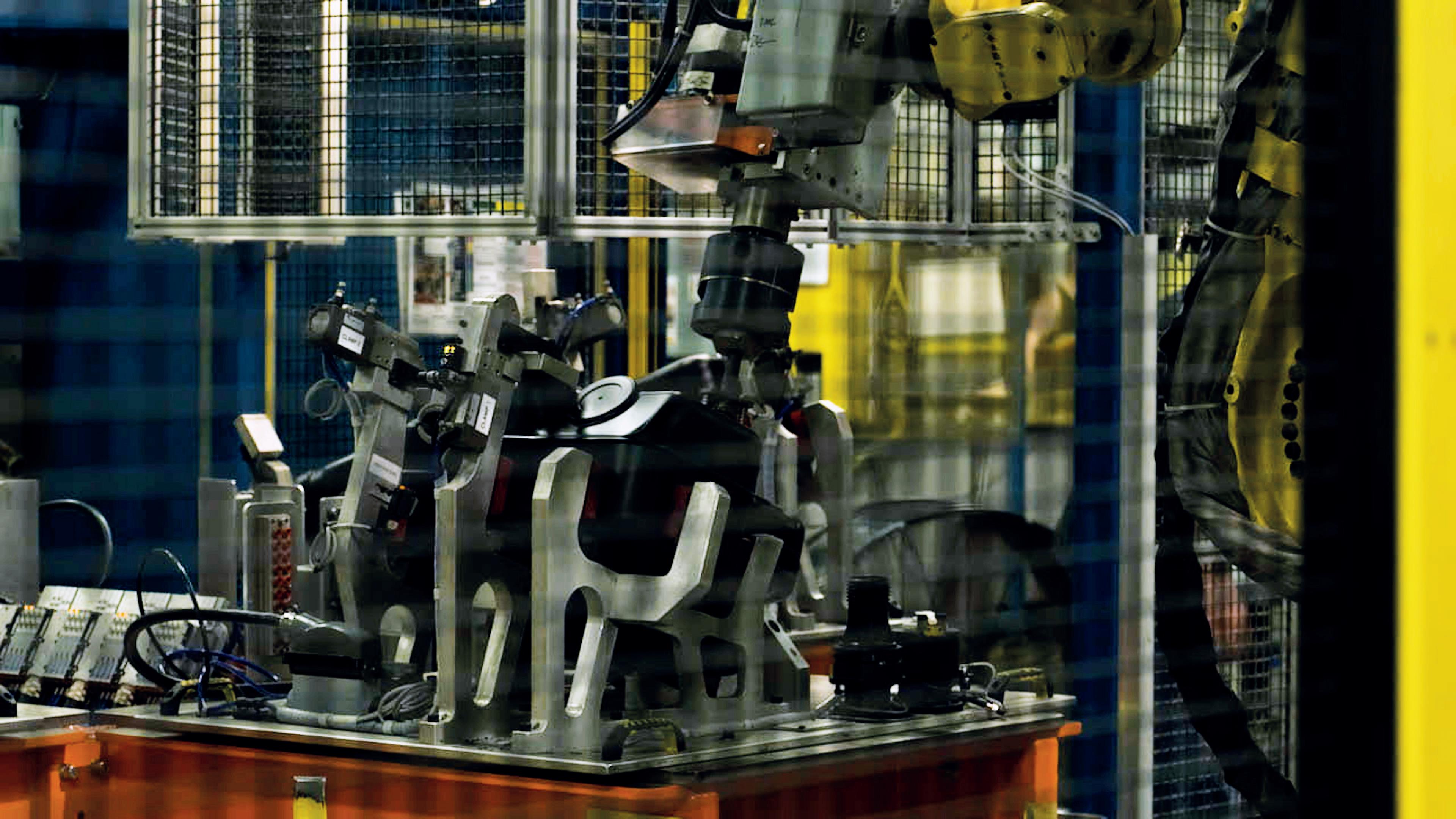

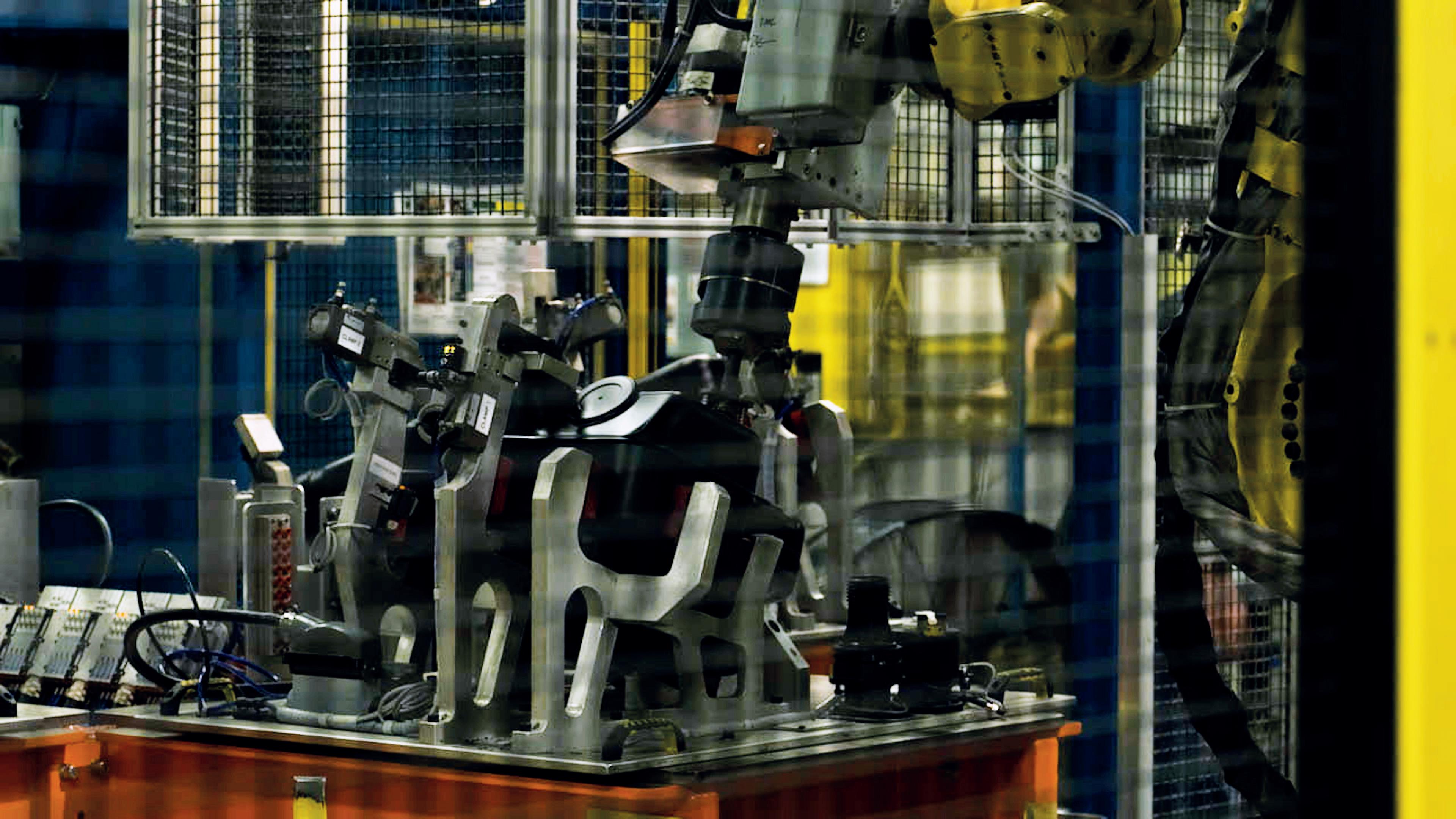

products to the market. Innovation at Väderstad starts with a customer challenge. With our development of new products, we always aim to simplify and improve the work of farmers. For us, product development and innovation go hand-in-hand with company growth and increasing customer value. To achieve consistently excellent results, we have incorporated a high degree of automation and single-piece flow across our component manufacturing lines. In recent years, for instance, we have invested heavily into our laser facilities, enabling the efficient cutting, bending, and machining of tubes and metals with a short throughput time. As a result of increased customer demand, we have several ongoing projects looking at how we can increase manufacturing capacity across all our facilities.”

The Swedish manufacturer has just completed the Väderstad Tour, a massive company-wide event that hosted around 2000 farmers and dealers from all over the world, inviting them to view production facilities, observe field demonstrations, and meet the family behind the groundbreaking machines.

“We haven’t been able to host the event for

www.manufacturing-today.com l 31

several years because of the pandemic, so we’re really excited to finally reconnect with our customers,” explains Henrik. “As we move forward into the rest of the year, we intend to manufacture and deliver as many machines as possible. Sales have been strong recently, and we currently have a large order book;

however, following on from Covid-19, we have experienced constraints and disruptions across our supply chain. Nevertheless, we are aiming for another record year in terms of sales, and we hope to have many happy new Väderstad customers join us by the end of the year.

“Looking further ahead, we see very good growth potential in the US,” concludes Henrik.

“Within five years, we hope Väderstad will have become a true alternative for many American farmers, offering new solutions to keep costs down, improve yields, and maintain good soil health. We also actively work in Chile, Paraguay,

32 l www.manufacturing-today.com

and Bolivia through local importers. Going forward, we intend to progress the scope of our operations across South America. However, this terrible war in Europe, which has caused needless human suffering and increased the

volatility of global markets, means that the future ultimately remains uncertain. Yet we hope, with all our hearts, that the war ends as soon as possible, and that the world goes back to a more normal situation once again.” v

Väderstad Group

Väderstad Group

www.manufacturing-today.com l 33

www.vaderstad.com Products: Agricultural equipment

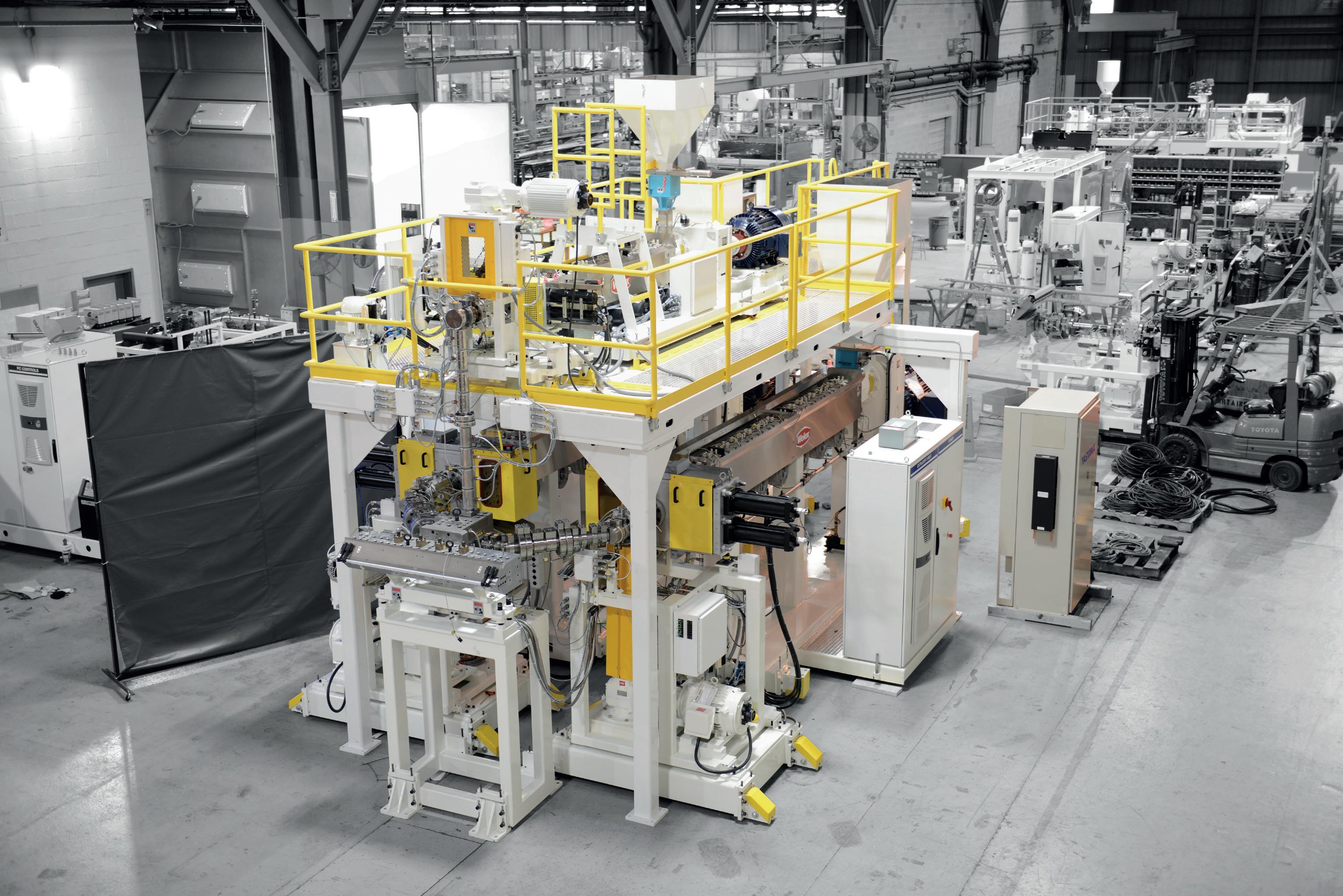

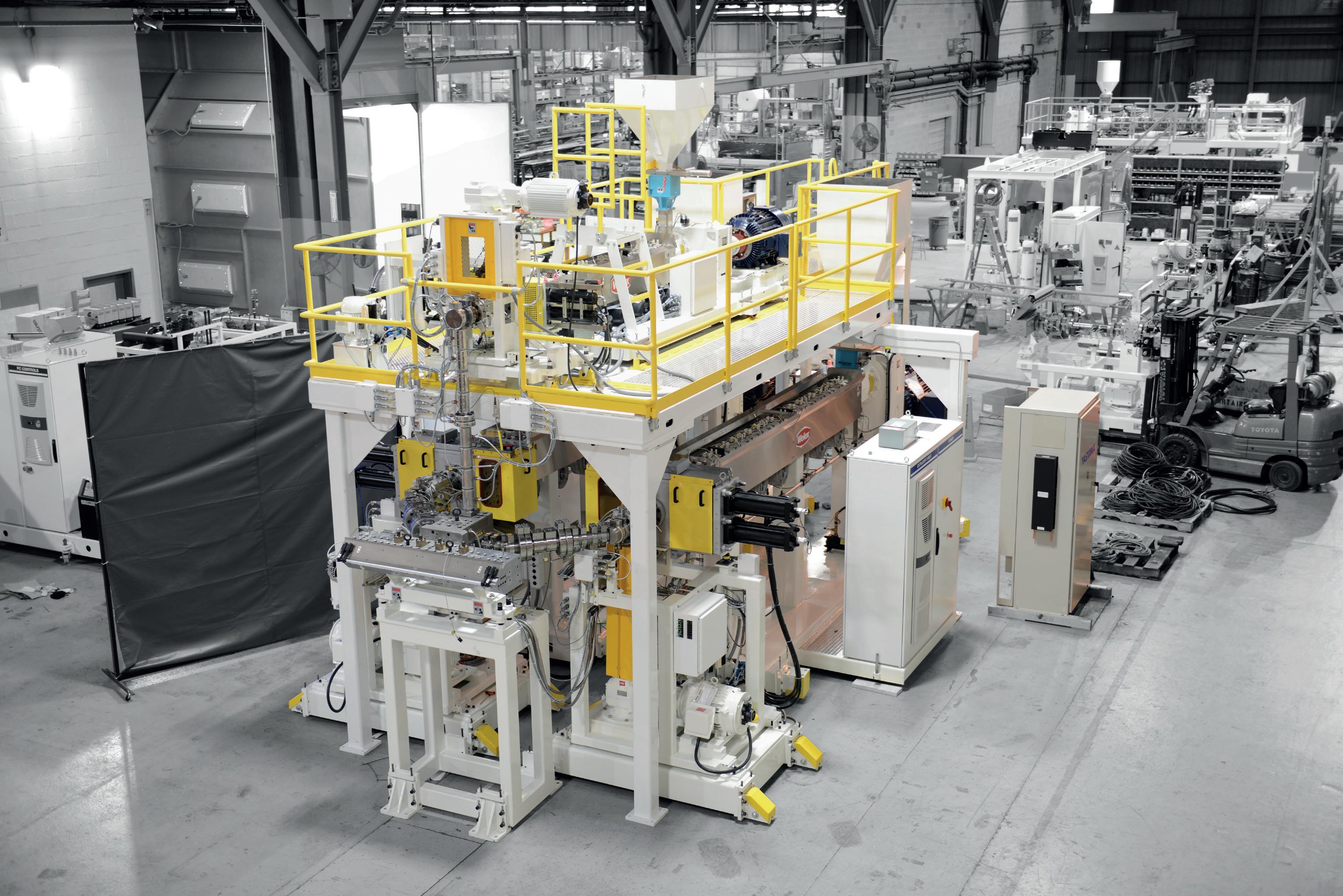

Extrusion made easy

34 l www.manufacturing-today.com

Graham Engineering Company, LLC

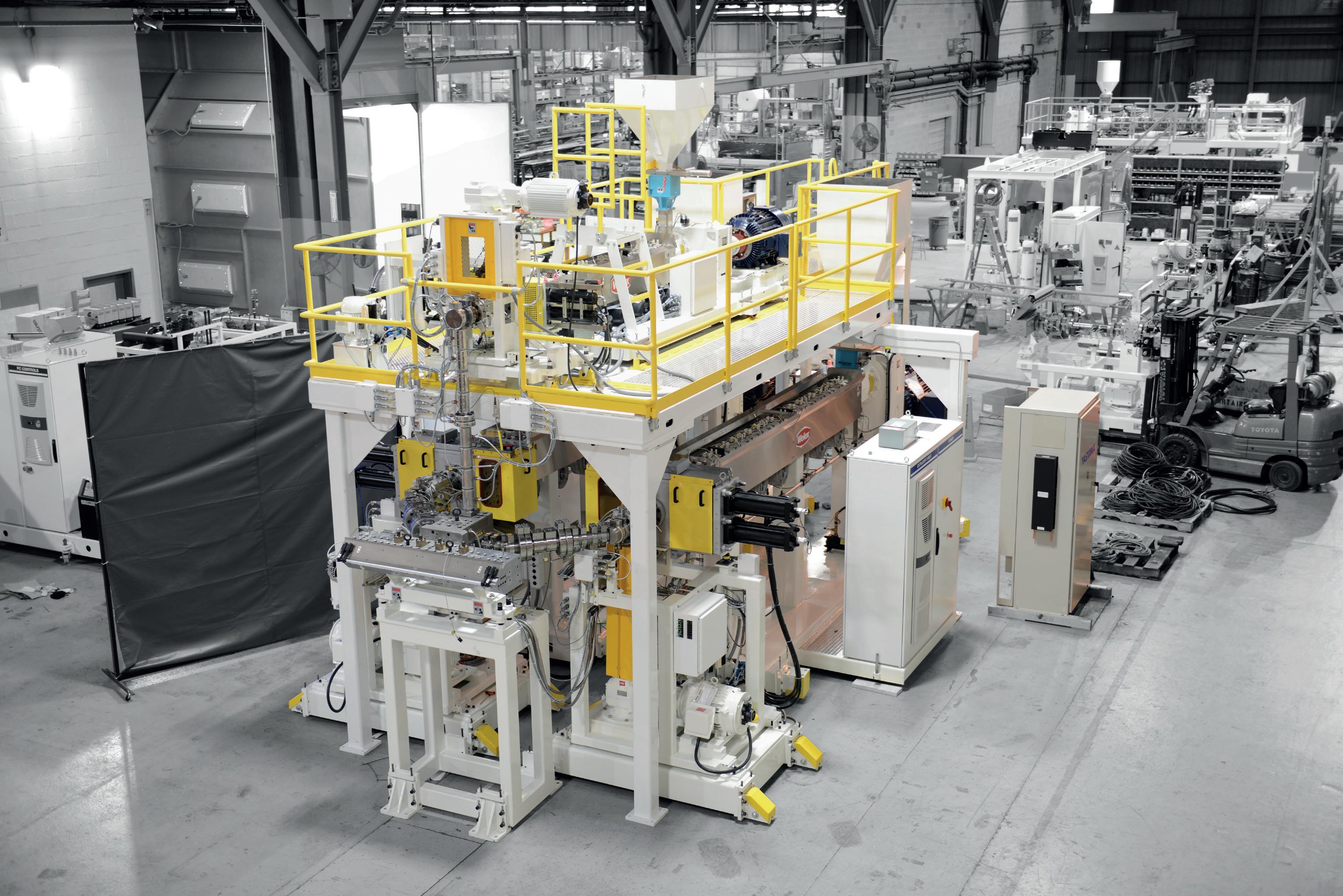

Industry-leading precision engineer, Graham Engineering Company LLC, delivers quality polymer extruders and extrusion systems in blow molding, sheet, pipe, profile, wire and cable, and medical tubing solutions to customers globally, including integrated downstream solutions engineered to maximize manufacturing capabilities

www.manufacturing-today.com l 35

Graham Engineering Company, LLC

Using over 100 years’ worth of combined extrusion experience, Graham Engineering Company

LLC. (GEC), designs and manufactures innovative engineering solutions for customers across a range of industries.

With consistent investment in the latest plant, and a team of industry experts, the company innovates at the cutting edge of extrusion technology. As it continues to adapt its diverse, multi-product portfolio to meet the changing needs of manufacturers everywhere, GEC sees ongoing success and incredible growth.

Decades of engineering excellence have helped make GEC what it is today. As the company’s President and Chief Executive Officer, David Schroeder, discusses: “The company started in 1960. It was founded by Don Graham, an entrepreneurial engineer who introduced the rotary extrusion blow molding wheel, which revolutionized how customers

Plasti-Co Equipment Co

make bottles and containers for detergents, motor oil, and food products.”

From what started from a modest farmhouse basement in central Pennsylvania, evolved into several global manufacturing businesses which were later divested. In 2012 Graham Engineering returned to its roots of focusing on technology and equipment solutions that help customer create a bridge

between manufacturing and technology by leveraging Graham’s extrusion, engineering, and integration capabilities.” With a strategy to diversify into other extrusion end markets, we acquired American Kuhne, a Rhode Island-based extrusion equipment company, broadening our capabilities in wire & cable, pipe, profile, and most notably precision medical extrusion markets. We then went

Since 1982 Plasti-Co Equipment Co has been servicing the plastics injection molding, extrusion and blow molding industry. Plasti-Co’s extensive inventory of finished barrels, screws and valves offer short lead times for the following brands of IMM, extruders and blowmolders: Nissei, Van Dorn, Van Dorn Demag, Sumitomo, Milacron, Robosot, Haitian, Yizumi-HPM, Engel, Arburg, Toshiba/Shibaura, UBE, U-MHI Mitsubishi, JSW, Krauss Maffei, Battenfeld, Borche, Boy, Akron, Davis Standard, American Kuhne, Bekum, Berlyn and others.

With over 2600 screws, 850 barrels, and over 2600 valves in stock, the company’s flexible inventory allows for the shortest lead times in the industry for barrels, screws and nozzle bodies.

Plasti-Co has been a supplier for Graham Engineering since 2019, and has been named its Number One Supplier for barrels and screws.

Plasti-Co’s specialty products offer great solutions to processing issues. Its TYPHOON-X mixing nozzle with a risk-free trial available, boasts a sure-shot valve assembly with fastest shut off and shot repeatability.

36 l www.manufacturing-today.com

on to acquire Welex in 2013, adding sheet extrusion equipment.

“Today, our mission is to use our 100+ years’ of combined extrusion experience to offer unparalleled extrusion solutions and service. We have effectively sewn together what used to be three separate companies, distilled the technologies and capabilities of each, and in doing so we have driven and vetted a range of leading extrusion solutions. It’s worth remembering that Welex and American Kuhne also started in extrusion, so we really do have a wealth of expertise and application experience. Whether you are making a bottle, sheet, precision tubing, polymer extrusion is a vital part of that process.”

Nearly ten years following the acquisitions, Graham Engineering has fully streamlined operations and business processes with project management and service at the heart of everything it does. “Our task was to leverage infrastructure of the York, Pennsylvania facility and consolidate the polymer processes knowledge into a single brand, Graham Engineering. The integration process took nearly five years, between 2013 and 2018, and, in that time, we did a lot of cross-pollination in terms of the technologies and systems that we used, which meant every aspect of the company benefitted from consolidation.

“In addition, we formalized our engineering process. This meant standardizing our engineering design systems, and standardizing

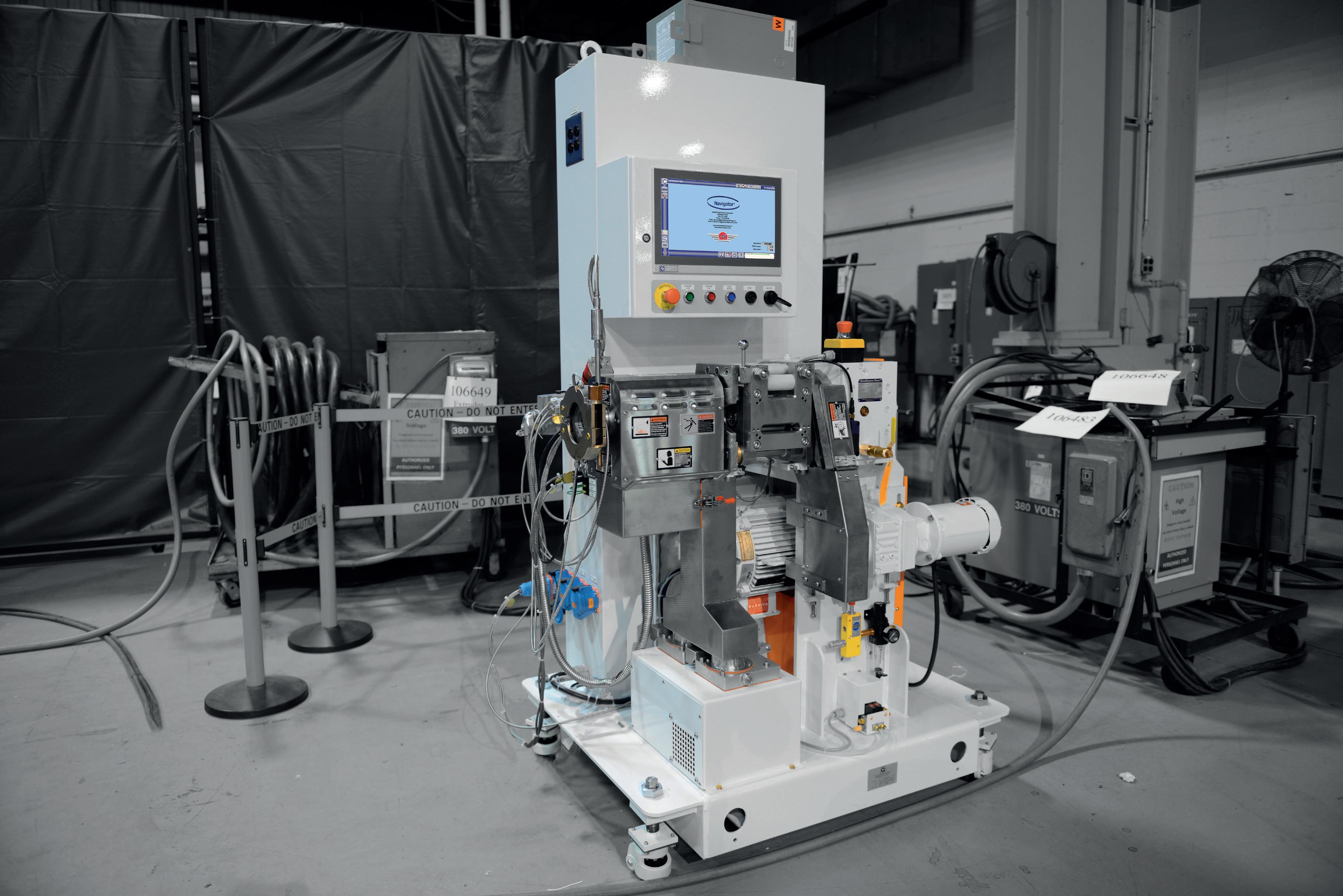

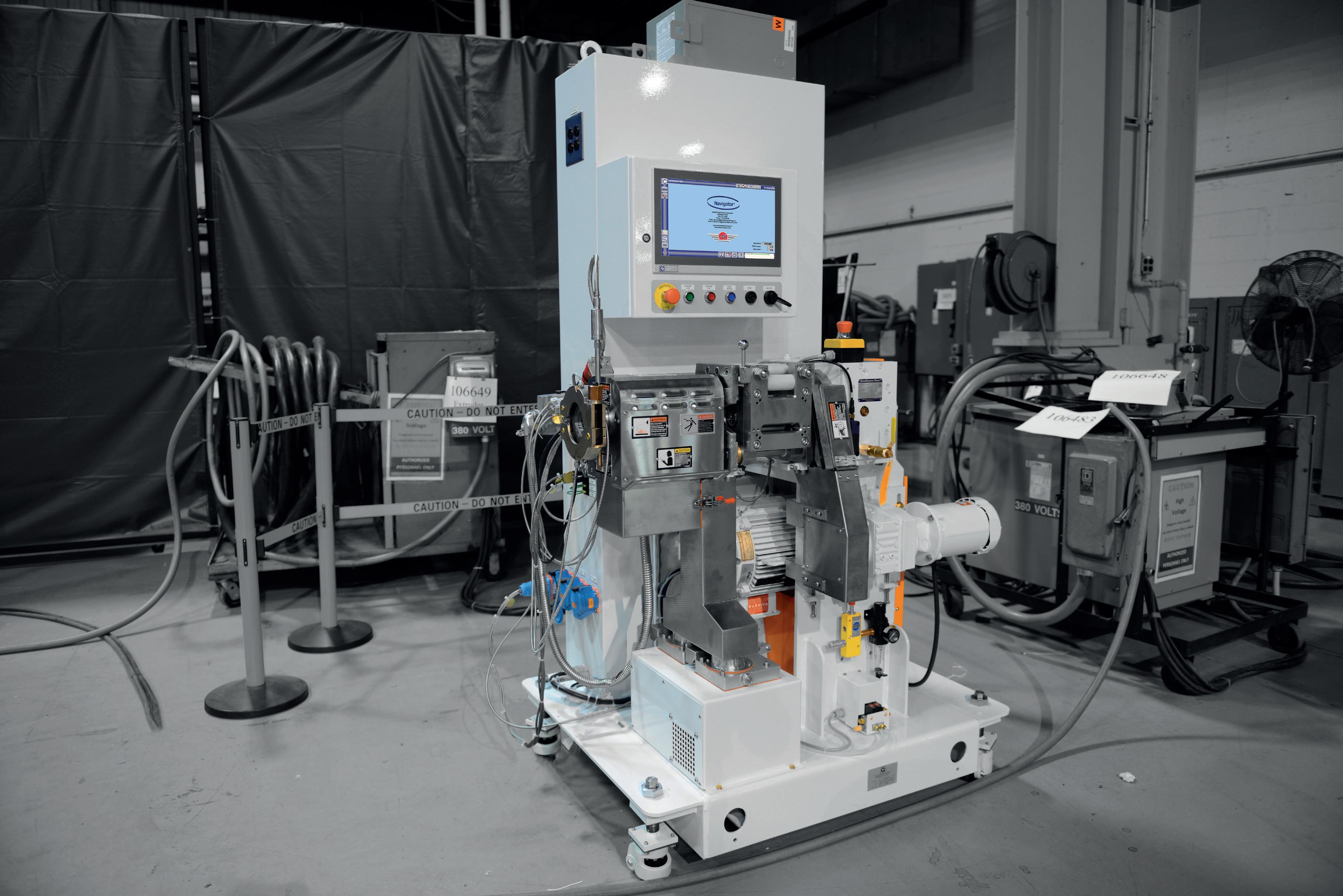

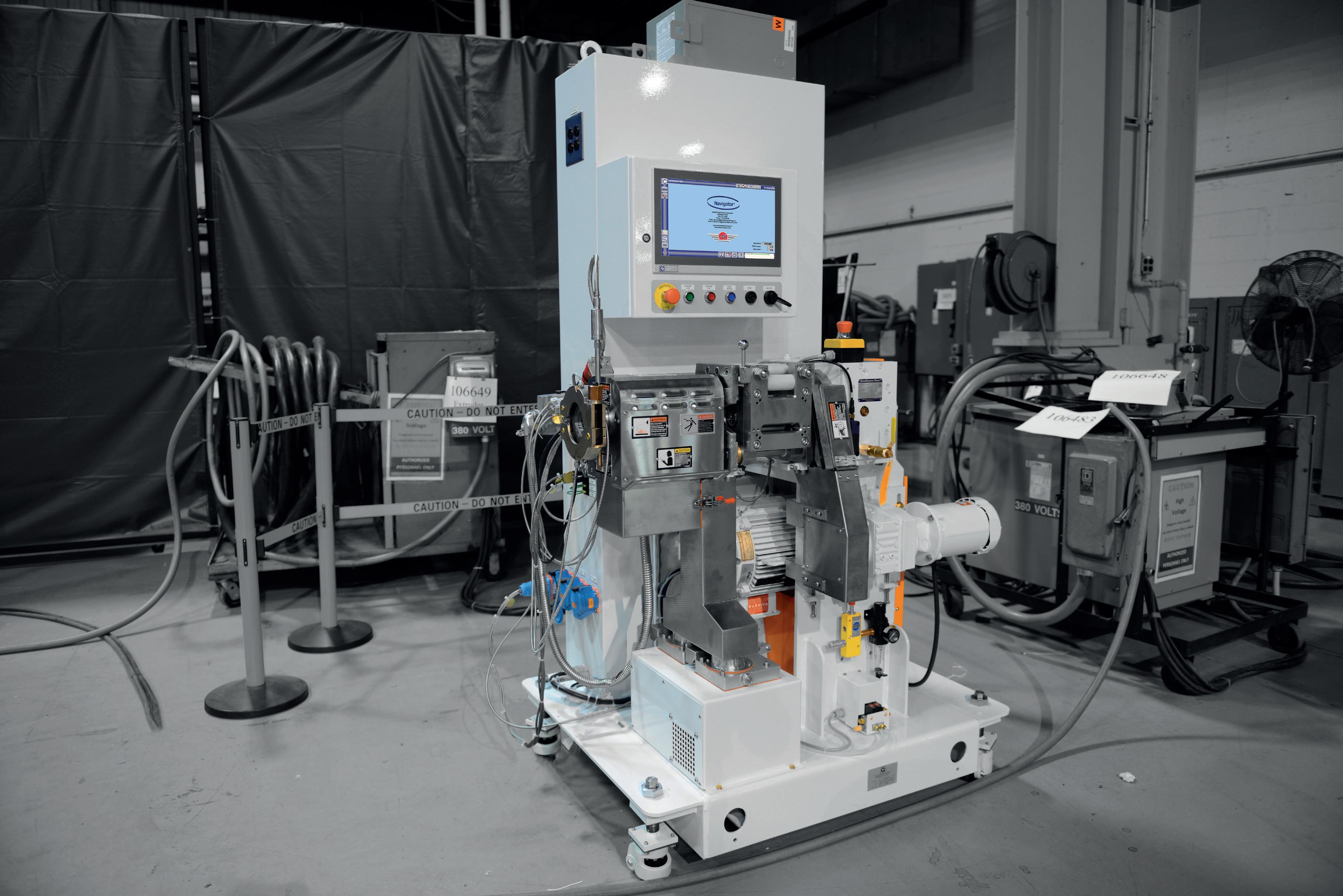

how our engineers and operations teams execute projects. We rolled out Graham’s NavigatorTM control system and intuitive operator interface which enables the ‘Internet of Things’ and facilitates customer service. Today, NavigatorTM is the control system installed across all of our machines, irrespective of the end product,” David reveals.

Now organized as one entity, GEC effectively provides a range of services in four key areas.

“We have integrated extrusion systems with a mix of end markets and products, including precision medical extrusion solutions, packaging, wire and cable, profile, and sheet extrusion. We also sell stand-alone extruders, some of which are standardized and configurable for quick delivery, and others that are fully customizable to unique customer applications.

38 l www.manufacturing-today.com

“The third leg is blow molding, which is typically for bottles and containers. We accomplish this with the use of a rotary extrusion blow molding wheels. For larger articles, such as barrels and tanks, we offer our industrial accumulator head blow molding systems.

“Our fourth, is our true differentiator, our after-market services, such as spare parts, field service, upgrades and maintenance contracts which are critical in supporting over 8000 of our machines installed in more than 70 countries, some of which are over 30 years old. We are here to support customers in maintaining the expected performance of a Graham system to the standard we set. Lifelong service support is foundational to our brand,

Graham

and we will continue to invest and add to our service offering in support of our customers.

“A very important part of our after-market strategy is our customer intimacy model. We don’t acquire materials from lowcost countries, so our products are quality,

and built to last. We dedicate ourselves to looking after our products throughout their lifecycle, by upgrading ageing systems, offering modifications, in-field repairs, relocating equipment and refurbishment services,” David details.

www.manufacturing-today.com l 39

Engineering Company, LLC

Going the extra mile to provide its customers with total integration, GEC routinely works with third-party experts. “Many of our integrated solutions include third party equipment. We work with a handful of trusted up-stream and down-stream suppliers who offer third party insight depending on the client’s application.

“Some customers have preferred suppliers for up-stream and down-stream equipment. From our side it’s all about offering that flexibility, so that customers can enjoy the integrated solutions of their choice engineered, tested, and proven by us and the third parties they trust. Some suppliers have prior experience integrating machinery for our customers, which means they can be a real asset when combining their equipment with our technology to provide a truly comprehensive solution,” David asserts.

The company’s ability to work effectively with third parties and customers across a range of industries and applications has helped it stand out of the crowd. Flexibility and adaptability are key assets for GEC, as

David confirms: “There are three things that set us apart within our industry: innovation, operational excellence, and customer intimacy. We have a strong focus on both innovation and operational optimization, and these assets are vital to our overall strategy of building longterm customer relationships.

“We work closely with customers to ensure that we understand their applications 100 percent. Our mission is to always provide what we call a ‘best total solution’. This often requires the inclusion of downstream equipment and flexibility, but always requires taking the time to be truly listening and understanding the customer’s needs!

“We are not going to try and make a catalog product fit our customers’ application, that’s not what we do. We are an engineering business, meaning we build solutions. We consistently manufacture products that allow our customers to differentiate themselves from others in their market, which in turn sets us apart from our own competition.

“We have a really deep and widespread knowledge of engineering within our team

– starting with our sales team who are consultative, capable of understanding what is important in addressing customer applications. We also keep the door open for lab testing and process development. We have a range of machinery in-house that is readily available for customers to use in developing products, vetting designs, and testing new materials.”

With a strong ability to adapt, and keen insight into industry trends, Graham Engineering keeps its portfolio relevant, diverse and of exceptional quality. As Michael Duff, Vice President of Sales and Service at GEC, affirms: “We are always focused on product diversity. To maintain this, we are continuing to develop new features using our control platform and moving forward with new applications in all

40 l www.manufacturing-today.com

of our diversified markets. This is an ongoing effort that keeps us up-to-date and able to easily integrate our services with customers’ production lines.”

This effective and ever-growing portfolio of products has been vital to GEC’s success over the last few years, as David explains: “We keep our portfolio very diverse, offering multiple products across a range of industries, all with a common core, EXTRUSION. This helps us remain focused on our specialist capabilities, which are in and around the extrusion process, whilst working in a variety of different markets.

“Our multi-product portfolio model helped the company pivot with the market during the pandemic. When elective surgeries were prohibited in hospitals, and medical extrusion

Graham Engineering Company, LLC

negatively impacted, we were able to serve the increased demand in blow molding for wipes, containers and patio furniture as few examples.

“Now that we are post-pandemic, we see the market changing yet again where we have enjoyed the return of building products and industry resulting in increased demand in wire and cable. Because of the diversity of our portfolio, and how we work we have built a business capable of quickly adapting to the market which has resulted in incredible growth.

“The key is being able to adapt. We continue to reinvent ourselves to stay relevant and provide what the market needs. On top of that, we build strong customer relationships, we care and want to help customers solve problems and capitalize on opportunities.”

As a nimble, malleable, and reliable company, GEC sees ongoing success. A strong focus on operational excellence, innovation and customer service will continue to be its focus, as David concludes: “The last few years have been difficult for all of us, but with the support of our amazing team, suppliers, and customers, we have continued to grow, develop our technologies, and extend our capabilities. Graham Engineering combines an incredible depth and breadth of knowledge, which means we can support our customers who in turn support us.” v

Graham Engineering

www.manufacturing-today.com l 41

Company, LLC Grahamengineering.com Services: Polymer Extrusion Machinery & Process Solutions

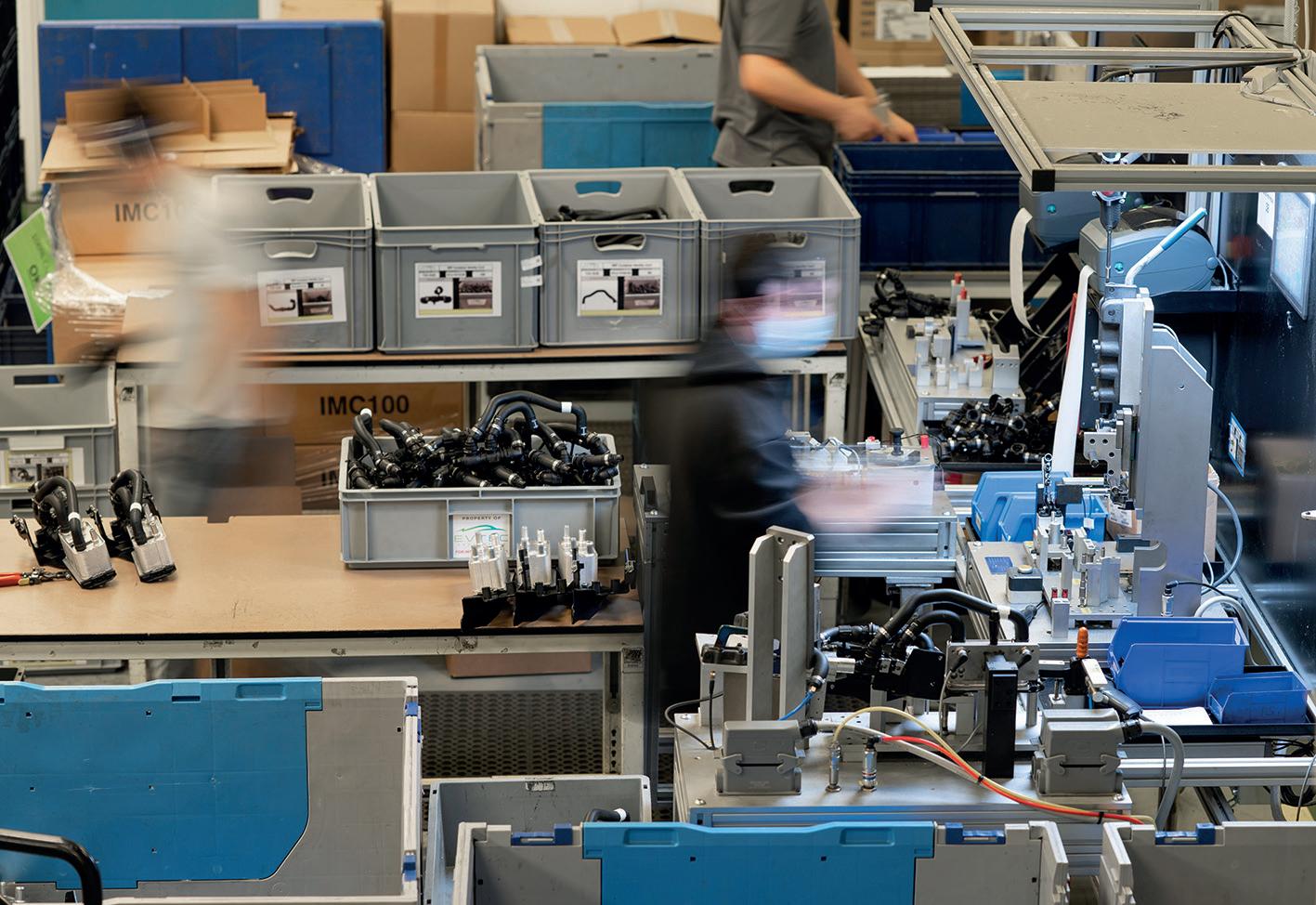

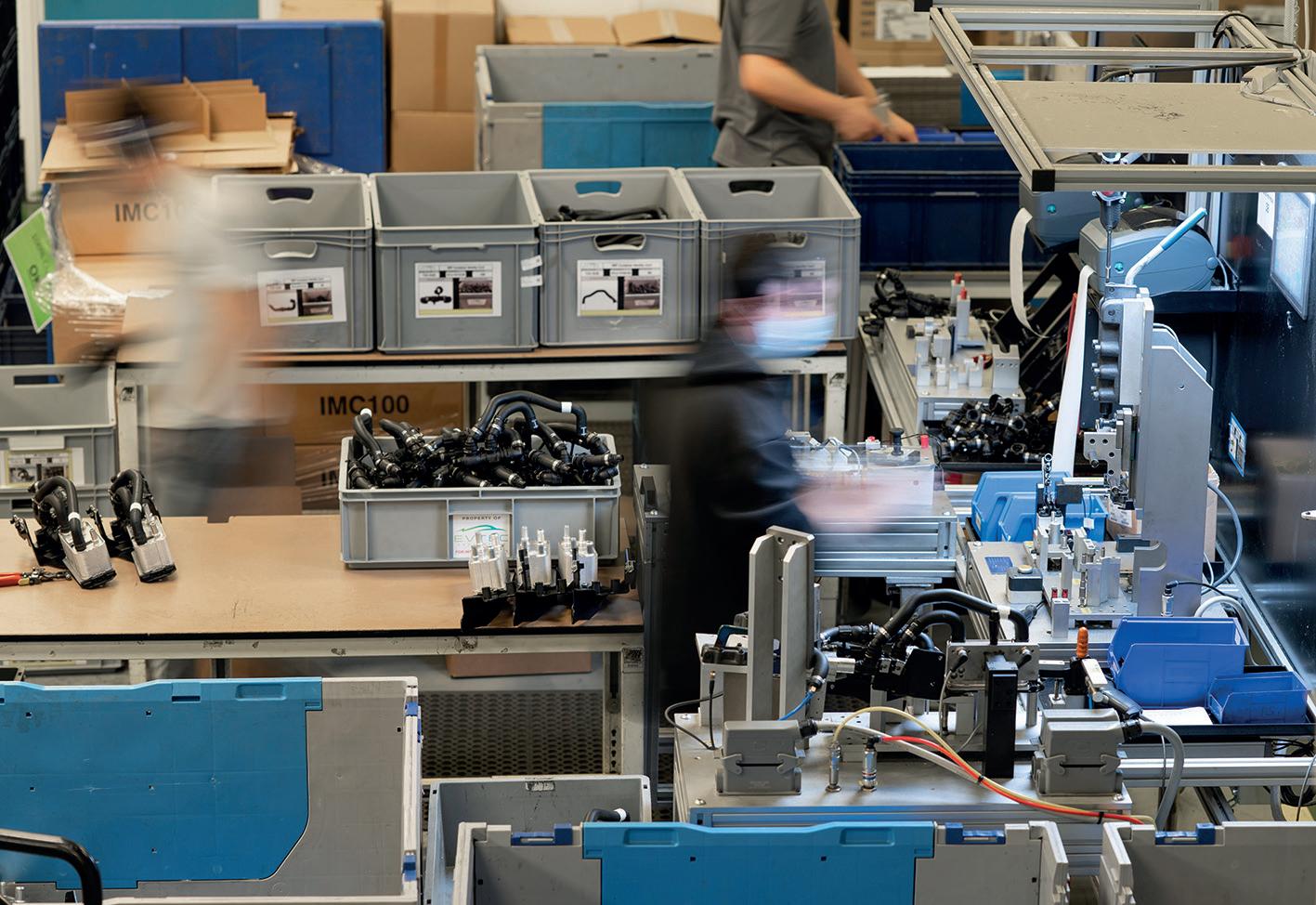

The single-source supplier

What do automotive OEMs including Jaguar Land Rover, Ford, and Aston Martin all have in common? They’re all clients of Evtec Automotive (Evtec), a singlesource, people-led parts and assembly supplier.

As a provider of complete assemblies to leading OEMs, with a sizable percentage of disabled employees, Evtec Automotive is rewriting the narrative around manufacturing as a sector for those of all abilities

As a self-described expert in simplifying customer supply chains, Evtec provides complete assemblies to OEMs, simplifying sourcing, saving time on procurement, and increasing production efficiency. Equipped with its own internal engineering, commercial, quality, and supply chain departments, Evtec’s “everything under one roof” service has the capability to take ownership of all suppliers within the assembly process, up to a total of 25 for any one commodity. In return, Evtec’s customers enjoy a single point of contact, providing exemplary control over each and every

component within the assembly BOM.

“We have a large portfolio of trusted suppliers, many of whom can offer competitive quotations on various materials and components,” explains Kevin Hubbard, Managing Director at Evtec. “At the same time, we can also work with our customers’ chosen or nominated suppliers.

“Our internal engineering department collaborates with our customers throughout the early stages of product development,” he adds. “Working with our customers’ CAD, engineering, and commercial functions from such an early stage in the development allows us to offer suggestions or guidance that can offer cost and assembly efficiencies, such as using the latest manufacturing techniques and materials.”

42 l www.manufacturing-today.com

A new era

The history of Evtec stretches back to 1944, and a government-funded initiative to offer employment to ex-servicemen and people with disabilities: Remploy. The initiative ran for almost 60 years prior to the withdrawal of funding in 2013. Its automotive sector was acquired, however, since which the initiative has operated under private ownership. The company’s Coventry site was purchased by Evtec in January 2021, and continues to offer employment to people with disabilities.

“Evtec is a people-oriented business,” says Kevin. “We’re proud to practice industry leading ESG, and prove that having a sizable disabled workforce has no impact on our ability to deliver on time, and in full.”

As proof of its focus on ESG, Evtec ensures

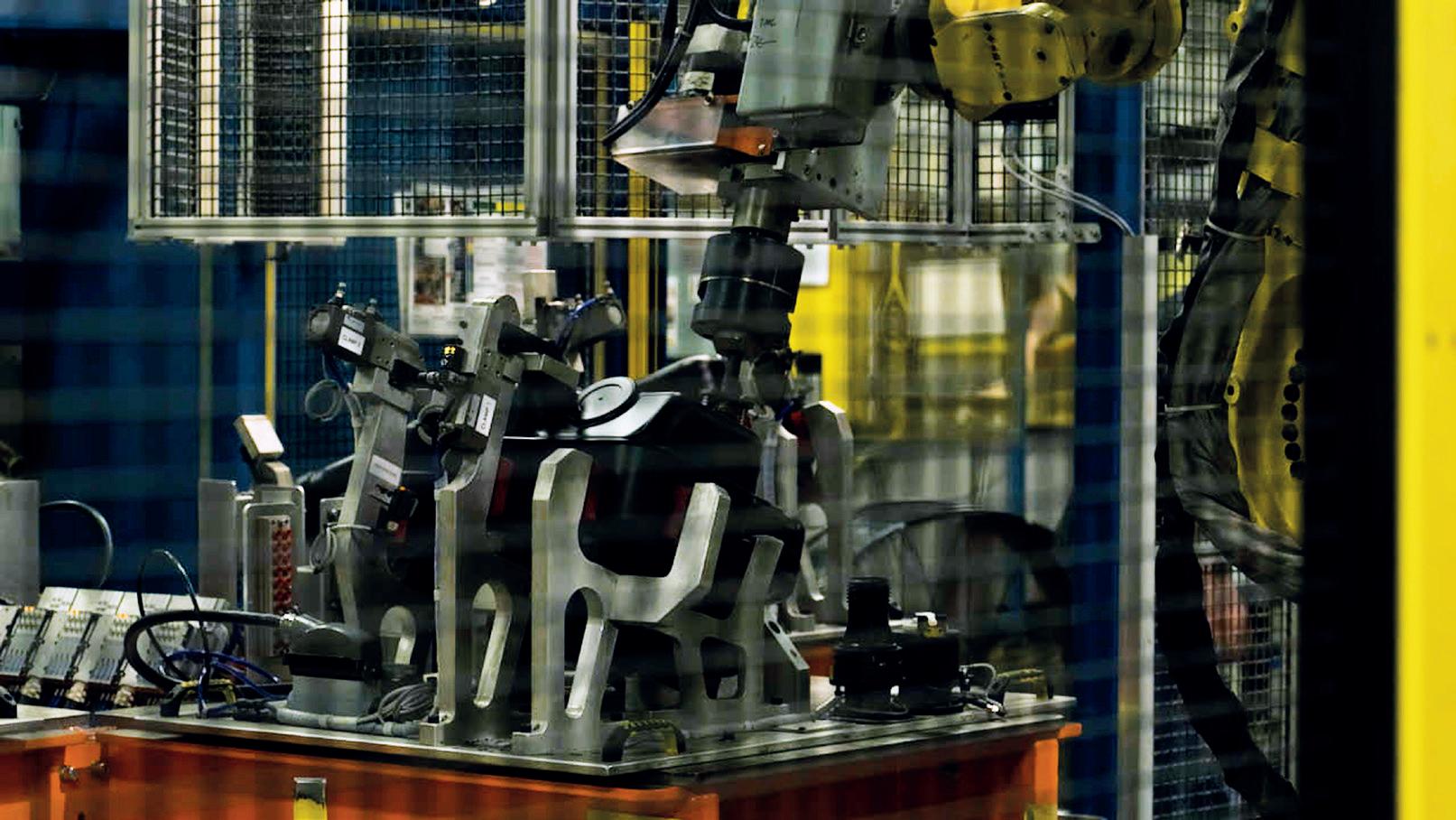

EV

Evtec Automotive

that all of its equipment is accessible for employees of all abilities, with support offered to adapt tooling where necessary. The company also offers as much training as required to ensure complete employee confidence in the use of all equipment.