Issue 205 - 2022 Interactive technology Four tech trends manufacturing executives need on their radar Interview Following a $3bn merger, CEO Julie Schertell steers Mativ into the future Digital transformation Digital technologies and their benefits to output, productivity and success How Mercedez-Benz USA is getting ready for the rollout of electric vehicles Luxury on the move

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative

Data

Tom Vince

Insights

Editor Libbie Hammond

Assistant

Jaione Soga

Mary Floate

Daniel Baksi, Alex Caesari, Danielle Champ

Content

Editorial Administrator Amy Gilks

Managing Art

Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork

Rochelle Broderick-White

Alasdair Gamble

Project

Philip Monument, Joy Francesconi

of Content Management Adam Blanch

Head of

Mark Cawston

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Laura Thompson

Content Managers Johanna Bailey, Mark Cowles, James Fuller, Jeff Goldenberg, Melanie Joyce, James Page, Wendy Russell, Richard Saunders

Hello and welcome to the October issue of Manufacturing Today. Do you like our freshly updated look? The magazine has been through various evolutions over the course of its history and it is always exciting to enter a new era and see what the readers think!

The design may have changed but the quality content remains and this month we are looking at interactive technology, strategy and digital transformation. I was also fortunate enough to speak to Julie Schertell, the CEO of premium specialty materials manufacturer Mativ, and she shared her insights into not just taking the business to new levels of success, but also her own personal journey to CEO and her belief in stepping out of your comfort zone. Read more on page 6.

Libbie Hammond Editor

Media

Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

Ryan Finn

Matt Bone

Co-ordinator Rosie Clegg

Iain Kidd

Natalie Fletcher, Rory Gallacher, Ibby Mundhir

© 2022 Finelight Media Group

Head

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

(312) 854-0123

+44 (0) 1603 274130

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

(561) 778-2396

LH@finelightmediagroup.com

Hepner, Director of Global Vehicle Logistics and Customs at Mercedes-Benz USA.

to page 26 to learn more.

Follow

manufacturing executives need on their radar Following $3bn merger, Mativ into the future Digital technologies and their benefits to output, productivity and success How Mercedez-Benz USA is getting ready for the rollout of electric vehicles Luxury on the move Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Our cover story this month reveals insights into investments and operations from Rory Anne

Turn

manufacturing today at @mfgtodaymag manufacturing today

Director

&

Director

Editor

Editors

Editor

Administrator

Sales Director

Directors

Head

Global Media Programs

Sales

General Manager Florida Division

Marketing Manager

Social Media

IT Support

Administration

Corporate

Office

T:

T:

US Office

T:

Welcome manufacturing-today.com 1

Inside this issue

Julie Schertell, CEO of Mativ

Digital transformation Interview EMS Summit Interactive technology Strategy 6 12 22 16 20 Contents 2

Mercedes-Benz

USA

Cover

story

Channellock

Mitsubishi Chemical UK

Volution Group AME Group Doncasters 64 38 70 58 52 26 manufacturing today manufacturing-today.com 3

82 GPA GlobalEnvair Technology MISUMI Wellborn Cabinet, Inc Resilience Millerbernd Hamilton Caster VA Technology Schumacher Packaging 9488 76 116 124 106 112 100 Contents 4

Bettcher Industries, Inc Hercules Industries Newmor Excool Life Line Emergency Vehicles Morland

Moonpig Group

160 152 142 136 156 146 130 manufacturing today manufacturing-today.com 5

Schertell,

of Mativ, thinks

AND

RISKS

Julie

CEO

you should step outside your comfort zone BE BOLD

TAKE

6

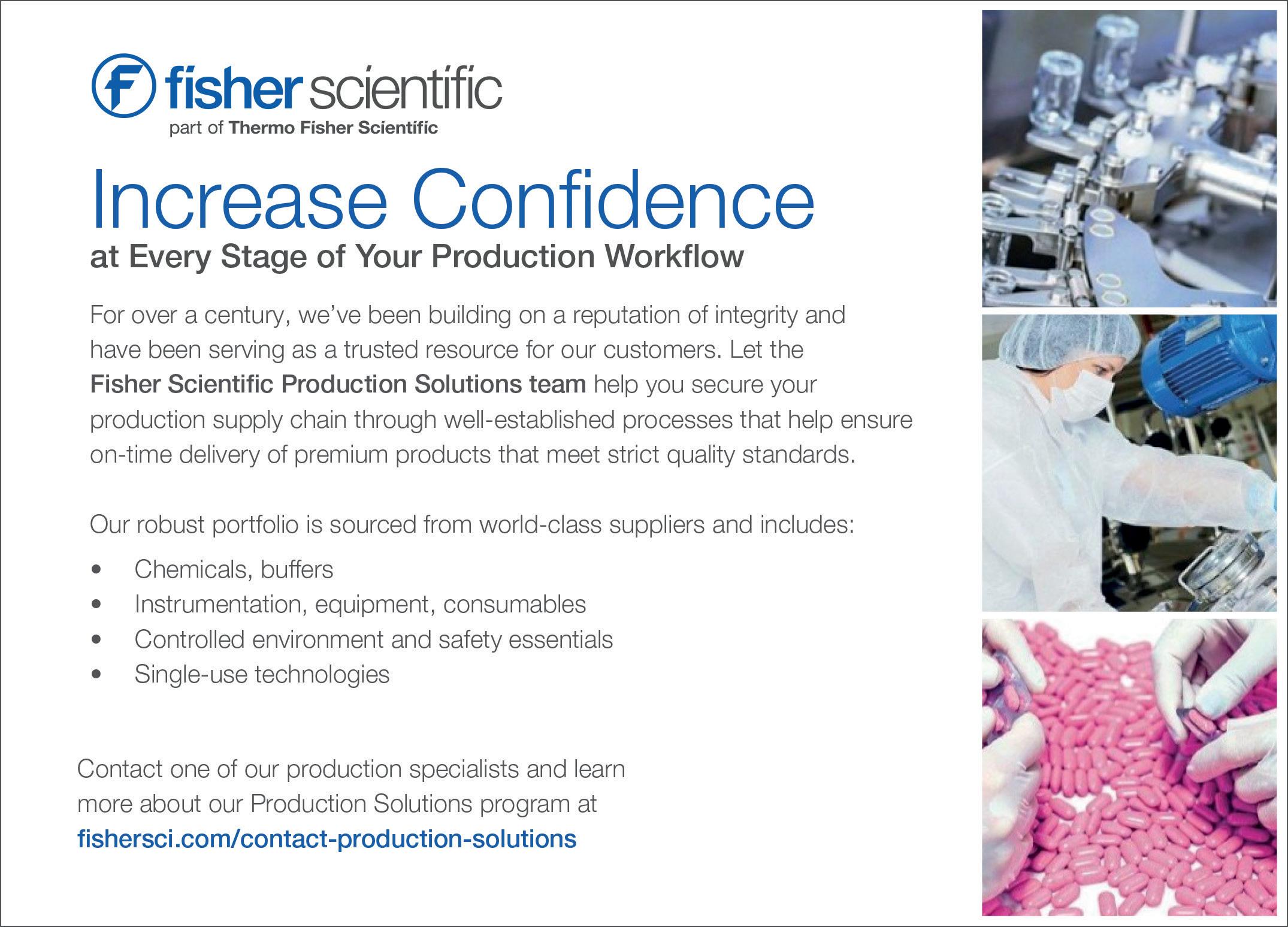

The result of a $3 billion merger between Schweitzer-Mauduit International (SWM) and Neenah, Inc. in July this year, Mativ should be considered a young company. However, given the fact these two players were both powerhouses in their segments, it’s clear to see why their fusion has already created a formidable business.

The Mativ of today is a manufacturer of premium specialty materials that are made from fibers and films. With approximately 7500 employees around the world, and 48 plants across North America, South America, Europe and Asia, the business has two segments - Advanced Technical Materials, which includes the business units of filtration, protective films, release liners, health care solutions and industrial products, and Fiber-Based Solutions – which includes packaging, specialty papers and engineered papers.

Steering this new entity through the merger process and beyond requires the vision of a strong and experienced leader and this role has been taken by Julie Schertell, the former CEO of Neenah, now CEO of Mativ. She sees the merger as a ‘unique opportunity to boldly reimagine our future as a stronger and fastergrowing global enterprise.’

Interview 7manufacturing-today.com

“It’s important to recognize that both SWM and Neenah were very successful as standalone companies,” she begins. “They had solid positions in common categories so the industrial logic behind the merger was strong and combining the business has created $65 million of synergies that we will accomplish in the next three years. It has also given us scale – as a larger company we can make different decisions, move at a different pace, and develop different capital structures.”

Finally, the two companies had a great cultural fit, which is important to Julie. Keen to ensure that the transition was successful, Mativ embraced the workforce at all levels, with Julie and her team creating a transformation office to lead the integration efforts. “We were clear from the very beginning that this is probably the most value-creating opportunity we will have in our careers and we cannot treat it as a hobby. The transformation office features our top talents, and they are ensuring we are making progress and holding us accountable for results.”

A communication team is also helping to ensure a smooth assimilation and Julie is delighted with the level of messaging that has been put in place, in a short time frame. “We do a podcast with our leadership team and ‘get to know’ videos, townhalls, and global team calls. But on top of that, I am a big believer in the value of face-to-face interaction,” she added. “One of my favorite parts of my job is being out in the plants, spending time with employees, learning from those that are closest to our manufacturing process, looking for opportunities, and getting to know the team better.” Demonstrating her dedication to this approach, when we spoke

to Julie, she was about to embark on a tour of nine of Mativ’s plants on the East Coast of the US, before visiting several of its European facilities as well in the coming months.

Clearly on the cusp of an exciting growth journey, Mativ is benefiting from Julie’s experience across multiple sectors and her confidence to take bold steps when required.

Her own career path, which she describes as ‘non-linear’, offers the ideal foundation from which to direct this newly combined enterprise. Her first role as a cost analyst at a Georgia-Pacific paper mill sparked a passion for manufacturing that still burns as bright today. She then got involved in process improvement programs, moved from finance into operations and then supply chain, and eventually became leader of a large customer service group and a sales and marketing team. “I wanted to get closer to customers and better understand the marketplace and how we could meet their needs. The role included logistics, sales technical support and packaging engineering, so it was a great experience from the standpoint of learning to lead. There was an amazing infrastructure around me, which ensured I couldn’t fall down - to some degree!”

Speed with purpose

Having learned so many valuable skills at Georgia-Pacific, Julie was recruited by Neenah to lead the supply chain for fine paper and packaging – its largest segment. “From there, I moved into sales and marketing and then held a general manager role with full P&L responsibility and decisions rights.” Leading that group for several years, Julie brought all her experience to bear and was able to find ways to grow the division for seven consecutive years.

One of my favorite parts of my job is being out in the plants, spending time with employees, learning from those that are closest to our manufacturing process “ “

“ “

8

9manufacturing-today.com Interview

Remaining hungry for challenges and new experiences, she moved over to lead Neenah’s Technical Products division, before becoming COO and ultimately CEO, at around the same time as the pandemic struck. “It was a trial by fire so to speak; but it really helped us gel as a team and work together on how we were going to offset some of the headwinds we were facing,” she says of this time. Finally, following the merger, Julie became Mativ’s President and CEO.

“Taking on all these different roles and challenges has given me every opportunity to grow and learn,” she emphasizes. Believing that ‘the rewards are in the risks,’ this approach does require energy and determination (a quality that Julie celebrates is ‘grit’) and she admits that she is known for her ‘bias for action’ or simply, getting things done. “Internally, we call this ‘speed with purpose,’ and I am a firm believer that speed matters, particularly in the current business environment, which is very fluid, with strong competition. What’s important

is understanding that, when you are moving quickly, you are going to make mistakes. That is OK if you learn from them, move on and continue your forward momentum.”

Julie went on to highlight some further values that are prized at Mativ. “We value safety above all, and that isn’t just in our sites, but covers everything, from sales staff driving to an appointment to our operators on the floor. It’s important to us that everyone understands that safety is THE priority at Mativ,” she stated. “We also talk about ‘confident humility’, which requires the confidence to move forward and take a little bit of risk, while remaining humble enough to know we all still have a lot to learn.

“This ties into ‘actively experimenting’ – encouraging everyone to try something different across the organization, so that we are always creatively deconstructing what we do to make it better, faster, safer and more effective.

“We also believe in ‘assuming positive intent’. If you think a fellow employee is not moving in the same direction as you, the chances are they are just coming at it from a

10

different perspective. It’s better to assume that everyone has a ‘positive intent’ behind their actions and if you discuss it with them, you will find ultimately you are trying to achieve the same goals. Of course, our values evolve all the time, but these ones are key.”

These principles tie into the overall ambition of Mativ, which is, of course, to delight the customer and act as a trustworthy and reliable partner. Thanks to her sales and customer service experience, Julie prioritizes creating ‘customer intimacy’. “We win when our customers win, so we must stay in tune with that vision throughout our entire organization and keep customers at the center of our strategy.

“This results in some of our products being co-developed with our clients, including working very closely across different touch points, not just research and development, but also marketing, communication, operations, customer service and sales.”

This holistic approach helps to drive Mativ’s purpose of finding the ‘potential in the impossible’ – Julie and her team always strive to create products that solve problems in the future. “We identify opportunities by understanding the markets in which we compete and how our customers win in those markets. Often, we address those unmet needs before the customer has even articulated a requirement for a product. Those are important parts of our strategy, unlocking growth with our with our customers enabling them to win in the marketplace is the only way we will continue to grow.”

Sharing information, customer feedback, staff insights and the different approaches taken across global sites can yield valuable results; and to that end, Julie and her team are keen to embrace digital solutions that connect

not just its own operations but also extend out to customers. “It’s important to have real time visibility to performance, so having processes digitalized and the data instantly available increases our learning speed and improves how we communicate. Furthermore, our customers expect an efficient digital solution for how we engage and interact, and as a B2B company we mustn’t lose sight of that. The customer experience continues to evolve, and technology is a key part of maintaining and improving the relationship with our customers.

Exciting possibilities

“From a manufacturing standpoint, customers are looking for a global supply chain with local supply because of the fluidity of today’s supply chain challenges. That is a trend that has reversed from what we have seen historically. Mativ has global supply chain strength, as well as availability locally, and that latter factor also addresses the increasing importance of sustainable operations.” When Julie took the helm as Mativ CEO, her message to the combined workforce was that this was a fresh start. With plans now announced for a new, combined HQ in Alpharetta, Georgia, which will bring teams together in a space designed especially for them, the next few years look full of exciting possibilities. “I couldn’t be prouder and more honored to be part of this merger,” Julie ended. “I am thrilled with the opportunities we have in front of us, the strength of the team we have put together and the progress we are making. Everyone is extremely focused and aligned and I am excited to see what we will do in the marketplace in the next 12 months.” ■ www.mativ.com

Sharing information, customer feedback, staff insights and the different approaches taken across global sites can yield valuable results...

“ “ “ “

11manufacturing-today.com Interview

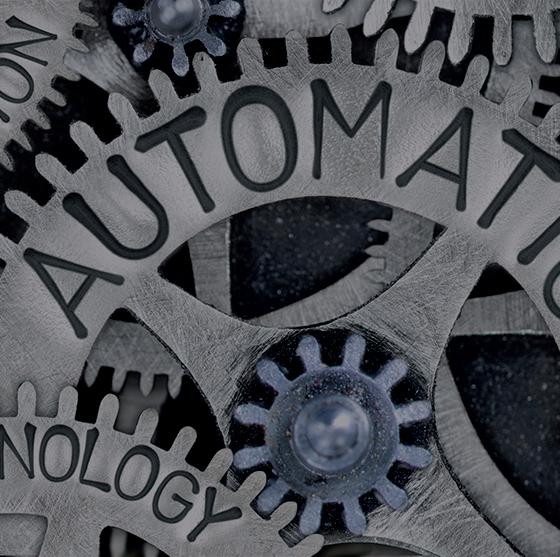

12

PRODUCTIVITY REVOLUTION

When it comes to digital manufacturing, what’s really at the heart of the conversation is data.

Without the collection of information from smart machinery, manufacturers would simply not be agile, resilient and adaptable to modern challenges. It’s the ability to access and analyze this data that is critical for smart factories be successful and productive.

Over the past two years, modern businesses have been inundated with disruption around every corner. This ranges from supply chain struggles and the ongoing war in Ukraine, to a significant skills shortage and huge inflation increases. With competition more fierce than ever, and consumers demanding more than they ever have before, businesses have needed to work smarter and with far greater efficiency. The organizations that have done this best, have been those who have embraced information and data. For many, harnessing data has not only helped them to stay afloat, but grow and thrive.

In some areas, the uptake of technology and smart machinery has been slow. In fact, for many, there was

a reluctance to move away from the traditional way of doing things, where pen and paper and phone calls were the only way to identify how successfully a manufacturing line was operating. But, as it became increasingly clear that information held the key to unlocking productivity, and as more competition started to adopt smart machinery, almost all have been forced to evolve their processes.

Delivering Industry 4.0

At the heart of this change is Industry 4.0. Since its onset, organizations have continued to drive advancements, and have found themselves in an overall enhanced state of productivity. For instance, the speed at which the mRNA vaccines were developed during the pandemic is a case in point. Not only were they incredibly fast to be approved, but they were manufactured in a way that the industry had never seen before. Manufacturers had to leverage a data-led approach to keep up with the huge global demand, cope with ongoing social distancing requirements and reduce the costs involved with creating a totally new vaccine.

Digital manufacturing solutions are defining the future of productivity and output says Greg Moyle

Digital transformation 13manufacturing-today.com

The beauty of smart manufacturing, where data is at its center and productivity is its result, is that it doesn’t require lots of investment. In previous revolutions, organizations have had to completely rearrange their operations, purchasing entirely new equipment, installing new utilities and sometimes tearing down factory buildings in favor of something much bigger. But with Industry 4.0, it’s all about smartening up existing factories, step by step, and augmenting them with digital manufacturing tools and solutions to help reach their desired goals more efficiently and effectively.

This level of efficiency is going to be critical when it comes to ongoing success. Currently, the manufacturing industry is, like many others, experiencing a drastic talent shortage which is seeing it’s productivity dip. Recent research from Nineteen Group found that 78 percent of UK industrial companies are struggling to find the employees with the skills they need to assist in their productivity.

Failure to fill these roles is ultimately going to lead to downfall, but if manufacturers can find ways of identifying where automated technologies can assist in certain parts of the chain and redistribute resources elsewhere.

Bringing in autonomous operations

Automated manufacturing is nothing new. In fact, we’ve been using smart, robotic devices that feed on data for far longer than we think we have, whether it’s conveyor belt systems or automated packaging. Having robotics running the show is, in fact, saving manufacturers vast amounts of time and money. More often than not, the repetitive tasks which are now being completed by automated machinery occur in conjunction with other machines and humans in an environment such as an assembly line. Automation is essential in delivering the speed, accuracy and productivity needed for large scale and effective manufacturing.

14

Autonomous manufacturing is an intelligent and enhanced version of automated manufacturing. Embedding Industry 4.0 technologies like AI and machine learning into a smart manufacturing system that is already capturing data on consumer feedback, supply and demand, and machine capacity, will have a huge impact on the success of the production line. By being able to read, digest and implement changes automatically based on the data collected, managers can ensure a more efficient and optimized workflows is achieved.

Final thoughts

Making manufacturing operations ‘smart’ with new digital technologies is no doubt changing the industry’s productivity levels. Whether it’s a manufacturer who has already fully upgraded its operations, or one who is planning to do so in the near future, it’s evident that without digital, manufacturers will quickly lose their competitive edge, and resilience against future challenges.

The long standing benefits to output, productivity and success are already being noted by many and with the introduction of autonomous manufacturing and the recognition of the importance of data, the industry is set for an even bigger productivity revolution. ■

For a list of the sources used in this article, please contact the editor.

Greg Moyle www.sap.com

Greg Moyle is Head of Energy & Discrete Manufacturing for SAP UKI. SAP’s strategy is to help every business run as an intelligent enterprise. As a market leader in enterprise application software, it helps companies of all sizes and in all industries run at their best: SAP customers generate 87 percent of total global commerce.

Digital transformation 15manufacturing-today.com

Modern manufacturing

Four trends driving the new inter-connected workplace

By Kevin Tucker

At the onset of the pandemic, a monumental shift occurred, and the manufacturing industry found itself at a crossroads. Many companies had been focusing on support for legacy systems while trying to retain talent as many employees moved into retirement. There was a widening gap between those gaining benefits from digital transformation, and those negatively impacted by Covid-19 because they were behind on the maturity curve.

Although these challenges were felt universally across all industries, the manufacturing world has a unique set of problems that add additional volatility for CIOs to contend with, making the job both scary and appealing. Manufacturing organizations were unprepared for the shift to remote work, the need to produce goods with fewer people due to illness, and solving supply chain uncertainties.

In order to be successful in a new workplace dependent on interactive tech and collaborative solutions, there are four trends that manufacturing executives and IT leaders need to be on top of.

Modernization and Industry 4.0 Historically, manufacturing has carried a stigma of being a harsh work environment, including technology stacks that have lagged behind other industries, constrained IT budgets, and a slow recovery from the pandemic. The typical manufacturing business is cost-conscious and lacks advanced IT skills, with weak IT/OT convergence. The new generations of workers expect automation, which can’t be delivered without a sound strategic modernization plan.

“ “

Currently though, many manufacturing operations still require high numbers of staff to be physically on location

“ “

Interactive technology 16

17manufacturing-today.com

Durable Goods Manufacturing Industry 4.0: Trends Report I. Trends Radar 2. Business Capability Map The higher the pulse score, the more available, applicable, and impactful the trend is to the industry. The Info-Tach Pulse Score represents the weighted impact across two sets of criteria: Advanced manufacturing trends that create a streamlined marriage of cyber-physical automation for real-time, data-driven decision making. 61% Pulse Score 60% Pulse Score 45% Pulse Score 61% Pulse Score Modernization Building the ecosystem for innovation & efficiency. ■ Industry Internet of Things (lloT) ■ Cloud ■ Additive Manufacturing 3D ■ AR/VR/Wearables ■ Autonomous Resiliency On-time-in-full for customer satisfaction. ■ On-shoring ■ Diversified ■ Hyperlocal ■ Digital Twinning ■ Demand driven Planning Green Manufacturing Building a clean future for people and planet. ■ Secure ■ Circular ■ Compliant ■ Clean Energy ■ Integrated Disruption Join the revolution of adaptive business. ■ Microfactory ■ Robotics ■ Artificial Intelligence (AI) ■ Machine Learning (ML) ■ Natural Language Processor (NLP) ■ Hyperlocal ■ Nimble Organization ■ Omnichannel 18

Currently though, many manufacturing operations still require high numbers of staff to be physically on location, even though they may be able to leverage technology to offer more employees the ability to work remotely. This starkly contrasts with other industries where employees traditionally needed to work from the office but have now developed methods for ensuring quality production while offering hybrid work.

“

For manufacturers to thrive in the Industry 4.0 age will mean melding together the old and the new: an inperson environment with more integrated automation and IT solutions. Not only will this allow the organization as a whole to keep up with the pace of innovation, but the day-to-day lives of employees will be greatly improved by giving them more flexibility.

Disruption and rapidly capturing market share

Manufacturing businesses are traditionally slow to adopt new technology, but the industry’s technology adoption rate has increased rapidly since the onset of the pandemic. As the number of connected devices is projected to grow exponentially in the near future, manufacturing businesses can no longer afford to be complacent and need to shift from slow today to fast tomorrow.

Manufacturing CIOs need to investigate strategic foresight, a methodology that clarifies what is happening in the organization’s external environment and guides them toward meaningful solutions. This methodology identifies signals that enable the organization to identify market shifts and attach themselves to the waves of change with specific strategic initiatives and the context that will lead them toward success.

Resiliency and a continuous supply chain

Micro-factories and intelligent systems enable new and niche players to become relevant and disrupt incumbents rapidly. The story of the software company in a garage is now a manufacturing startup in a garage, which is close to the customer and highly technology-centric.

The pandemic has taught an important lesson: the importance of a diverse and blended supply chain, combining on-shore and off-shore capabilities. During these times, buffers and safety stock planning become vital.

The pandemic has caused a significant change in the roles of manufacturing executives, which are now in a state of turmoil as markets have become increasingly more volatile. An IT leader in the manufacturing space needs to be a technology thought leader and a master communicator, ensuring that the business clearly understands the importance of a business-wide technology transformation. Focusing on keeping the lights on with 20–30-year-old applications and equipment leaves the door wide open for them to be disrupted by the competition. ■

Kevin Tucker is Principal Research Director and the Manufacturing and Supply Chain Industry Lead in the Industry Practice at Info-Tech Research Group, one of the world’s leading information technology research and advisory firms, proudly serving over 30,000 IT professionals. The company produces unbiased and highly relevant research to help CIOs and IT leaders make strategic, timely, and wellinformed decisions. For 25 years, Info-Tech has partnered closely with IT teams to provide them with everything they need, from actionable tools to analyst guidance, ensuring they deliver measurable results for their organizations.

Kevin Tucker www.infotech.com

“ “

Micro-factories and intelligent systems enable new and niche players to become relevant...

“

Interactive technology 19manufacturing-today.com

Challenge or opportunity?

A playbook for Agile in Manufacturing

By Steve Martin

The concept of Agile, its systems and project management methodologies, is widely recognized across the manufacturing industry and so are its benefits. Since Japanese industrial engineer and businessman Ohno Taiichi introduced the ‘Kanban’ system in Toyota in the 1950s, the industry has kept an open mind to lean manufacturing processes that can help identify waste areas, improve output and yield higher profits. Even though Agile has been around for a while and has infiltrated other industries evolving along the way, the manufacturing industry often still associates it with tech processes and improvements, focusing only on the operational side of things.

Agile teams over Agile systems

It’s true that Agile processes and transformation can help companies develop a competitive advantage in today’s fast-moving marketplace. After all, it was Toyota’s Production System that laid the foundation for modern management techniques and transformed the company, which at the time was operating at a loss, into the global competitor it is today. However, these historical benefits are perhaps what can hold the industry back from looking at how far Agile has come and how it’s embedded itself as a philosophy in many successful organizations. One of the biggest breakthroughs for Agile

20

has come from the software industry, which as part of its Agile Manifesto states that individuals and interactions are prioritized over processes and tools.

Having systems in place which ensure the ongoing efficient and smooth running of the overall operation is great, but Agile is much more than that. Agile is the overarching mindset which can become the backbone of the entire organization. It builds a culture where your teams can find it easier to pivot and try different approaches when it’s needed. It’s about getting rid of the ‘this is how we’ve always done it’ mentality and empowering employees to become true system thinkers who can visualize both the individual areas of the operation and the bigger picture. Knowing that it’s OK to shift towards a new way of doing things when they don’t get the key results and quality they want, is what can help your teams to create fluid work systems to get the maximum value out of the minimum steps possible.

Top-down and bottom-up innovation for success Innovation has always played a vital role in manufacturing but for it to be truly transformative it requires the right organizational environment and culture. That’s where Agile comes in, as its values support having a welldefined innovation process.

Adopting Agile is about being innovative right across the organization, not only in the areas traditionally associated with new ideas. This means that your innovation department isn’t siloed and that adopting new ways of thinking and experimenting becomes the new norm across the organization. The Agile systems ensure that everything is within one stream, so the strategic objectives and vision is set at the top and any ideas and opportunities that originate from teams across the organization feed into those. Freeing up innovation and letting it flow increases the likelihood of new ideas being implemented and increases the chances of them adding value to the business.

An opportunity for leadership

For Agile to deliver results, senior leadership cannot simply set the vision then walk away from it. There needs to be continuous dialogue between people on the ground and middle management and making sure that there is that alignment at the top. A common blocker for developing a truly Agile culture is the fear which comes from change. Employees with a deep knowledge of their department may feel threatened because of Agile’s philosophy to assess everything on an ongoing basis. An Agile culture is laid upon transparency and flexibility and it’s up to the leadership to help teams feel at ease with this new way of working by building trust, developing clear boundaries, and encouraging teams to work together to deliver the best possible value. By doing this you can help your people to work collaboratively without letting fear get in their way.

As in every sector, the manufacturing industry is faced with increasing pressure to accommodate changes in customer behavior and embrace new technologies and ways of doing things while operating under turbulent global economics. It’s up to leaders to look at Agile either as a challenge or as an opportunity that can be seized to shape the future of the manufacturing industry. ■

Steve Martin is the CEO of Agilistic, which simplifies transformation for businesses. He has worked with organizations including BT, Vodafone, HM Revenue & Customs, William Hill and The Department for Environment, Food and Rural Affairs.

Steve Martin www.agilistic.co.uk/what-we-do/

Steve Martin www.agilistic.co.uk/what-we-do/

Strategy 21manufacturing-today.com

European Manufacturing Strategies Summit

Industry experts to gather in Berlin for the 18th annual European Manufacturing Strategies Summit. Delegates can anticipate a packed program of industry insights

The 18th annual European Manufacturing Strategies (EMS) Summit will take place on 7th to 9th November at the Maritim proArte Hotel in Berlin. Situated on one of Berlin’s main shopping streets, this central location ensures a short walk from the sights and sounds of Berlin’s tourist hotspots.

EMS is the only strategic manufacturing conference and networking event to reveal best practice and highlight the latest solutions in preparing for an upturn over the next 12 months. Manufacturers in the industry will be sharing case studies and insights on how the world has irrevocably changed in the aftermath of recent and ongoing geopolitical events. The annual EMS Summit provides an international forum for manufacturing leaders to share and discuss strategies for the best way forward in this new world.

Boasting a packed three-day, threestreamed schedule of 51 engaging and informative sessions, attendees can expect

a wealth of industry experience and expertise. Delegates can anticipate workable and relatable case studies from the past couple of years, presentations from active senior industry professionals and plenty of networking opportunities.

The EMS Summit is now a CPD-accredited event. This means attendees can expand their knowledge and gain a certificate of attendance that counts towards professional development. The lessons learned at the summit can be applied in the workplace.

The summit’s key themes will explore maintaining an effective and functional workforce, highlighting the key parameters in switching to Net Zero, and transferring digital thread and technology capabilities.

There will be several keynote presentations from notable heads of industry. Marc Winkelman, Global Director of Manufacturing Innovation Capability at Proctor & Gamble will discuss the seven actions leadership needs to accelerate the operational excellence

22

journey and deliver its results. Widelyregarded as an industry leader, Marc will extrapolate the capabilities that have helped P&G to experience a year-on-year program of cost-saving, inventory reduction, service improvements and employee satisfaction.

In another exciting scheduled keynote presentation, Frank Polky, Head of OT Security at Mars will discuss finding the balance between trust and zero trust. Having experienced a cyber-attack five years ago, Frank will talk through the Mars journey from onboarding stakeholders to staff training in their global defense and its impact on productivity.

Delegates can also attend a range of panel discussions. Topics are scheduled to include a framework for smarter manufacturing, growth pressure points and tailoring the customer experience to create a customercentric supply chain.

Case studies will cover a range of industry insights. From the Internet of Things (IoT)

and technology to advanced production and strategic operations, heads of industry will explore subject matter pertinent to modern manufacturing.

Delegates can enhance their learning by attending networking brunches, one-to-one meetings and solution spotlight sessions. The summit is delighted to welcome heads of business from industry leaders, such as Staedtler, Electrolux and MTU Aero Engines, alongside esteemed academics from the University of Warwick, UK and the Institute of Mechanical Engineering of the School of Engineering of EPFL, Switzerland to this year’s advisory board. ■

European Manufacturing Strategies Summit

Dates: 7th to 9th November 2022

Location: Maritim proArte Berlin, Friedrichstraße 151, 10117 Berlin, Germany

Website: www.ems-summit.com

European Manufacturing Strategies Summit 23manufacturing-today.com

on the move

Going electric with Mercedes-Benz: the latest from a car-making colossus Luxury

26 Cover Story

Founded in 1926, the MercedesBenz brand traces its roots all the way back to 1885, when Karl Benz first constructed the Benz PatentMotorwagen. Widely regarded as the first practical automobile, the self-propelled vehicle resembled a motor tricycle, fixed with a rear-mounted engine. Close to a century later, the Mercedes-Benz Group AG (MBAG) is one of the globe’s leading suppliers of premium and luxury cars, and an independent manufacturer of commercial vehicles. Headquartered in Stuttgart, Germany, within the state of BadenWürttemberg, the group achieved revenues of 169 billion euros in 2021.

It was thanks to the work of Max Hoffman, an Austrian-born, New York-based importer of luxury European automobiles, that importation of Mercedes-Benz vehicles to the US began in 1952. Hoffman recognized a growing demand for existing and new models in the post-war American market, one on which he sought to capitalize. Among the cars brought across the Atlantic was the iconic Mercedes 300SL Gullwing, introduced at the 1954 International Motor Sports Show

Mercedes-Benz USA manufacturing-today.com 27

in New York City. More than 80 percent of the 300SL’s total production of approximately 1400 units were sold in the US, making it the first Mercedes-Benz widely successful outside its home market. So significant was the Gullwing’s impact, the model is now credited with changing the image of MercedesBenz in the US from a manufacturer

of solid but staid luxury automobiles, to one capable of producing highperformance sports cars.

Unique position

Buoyed by the success of the Gullwing, by 1957, Mercedes-Benz was in a position to expand its reach across the US. The company entered into an initial distribution agreement with Studebaker-Packard Corporation, before striking out on its own eight years later, with the formation of Mercedes-Benz USA (MBUSA). Now a wholly owned subsidiary of MBAG, MBUSA is a nationwide organization, responsible for the distribution, marketing, and customer service for all MercedesBenz passenger and commercial van products in the US.

“ “

For all the plants, there’s a central MBAG sales team that moves all the cars built in Europe to markets throughout the world

“ “

28 Cover Story

“We occupy a unique position within MBAG,” explains Rory Anne Hepner, Director of Global Vehicle Logistics and Customs at MBUSA. “For all the plants, there’s a central MBAG sales team that moves all the cars built in Europe to markets throughout the world.

Diversified Automotive

Diversified Automotive has been a premier service provider for Mercedes Benz since 2005. Our team of professional car haul drivers achieved the prestigious Mercedes Benz 2017 ‘Best of the Best Carrier Recognition Award’. Delivery of the Mercedes Benz vehicle to the company’s retailer begins and ends with the professional handling of our team of drivers. We could not achieve all that we do without these true professionals.

Leadership takes many forms, and presents itself not only when times are good, but, most importantly, when our industry is faced with challenges. Rory Hepner and

MBUSA is not only a market that receives those cars, but we also act on behalf of MBAG, moving cars out of the USA.”

Both a customer and a vendor of MBAG, MBUSA employs approximately 1,600 people across the United States. The company also

the Mercedes Benz logistics team were first in our industry to recognize the challenges of the last two years, and the needs of their business partners. Mercedes Benz took immediate action to ensure that their partners remain in a position to succeed. No one can do it alone. A successful 17-year business partnership with any company can only be achieved when a respectful understanding of each partner’s goal is commonly shared. We are proud to share a common vision with Mercedes Benz, and we are very fortunate to have them as a true business partner in all respects. Thank you, Mercedes Benz.

Mercedes-Benz USA manufacturing-today.com 29

has 383 associated dealership partners and offers a diverse line-up of models, from the sporty A-Class sedan to the flagship S-Class and the all-electric EQS. In the US, one type of vehicle stands apart: the SUV, or Sports Utility Vehicle.

Virginia Transportation Corp

Virginia Transportation Corp (VTC) is a worldclass auto-hauling company based in West Warwick, Rhode Island. The company’s operational footprint spans North America, including all 48 contiguous States and Canada, with the majority of its operational activity occurring in the eastern half of the US.

Founded in 1994 with a single truck, VTC has grown to nearly 500 power units, and is one of the largest suppliers of finished vehicle logistics for all the major automobile manufacturers. The growth of VTC’s asset base has been accompanied by a corresponding growth in human capital, and VTC has assembled a phenomenal team of

As the name suggests, SUVs’ combination of utility, luxury, and reliability makes them a popular choice for families, while appealing to a particularly American appetite for adventure. It follows, then, that Mercedes-Benz large SUVs

leaders and problem solvers at all levels of the organization that enable it to serve both its people and its customers.

On the customer side, VTC has become known for its unconventional and agile approach, with a focus on being a true business partner by way of collaborative problem solving and expedited response to customer needs. As an employer, VTC puts its people first by providing best-in-class pay and benefits, equipment, tools, training, and support for its workforce. Prioritizing both customers and employees has resulted in VTC both setting and operating to the highest standards in the industry.

30 Cover Story

are manufactured exclusively in the US, at the Mercedes-Benz US International (MBUSI) plant in Tuscaloosa County, Alabama. Working with MUBSI, MBUSA will collect the finished vehicles for distribution, including the GLE, GLS,GLE Coupe and Maybach GLS. There is more to come, too. The company started production of the EQS SUV in August 2022 and is set to roll out its electric EQE SUV later this year, with MBUSA already gearing up to distribute the vehicles across the US and beyond.

“If you talk to any company that’s involved with the moving of finished electric vehicles, there’s a whole new abundance of learning curves to process,” Rory indicates. “For instance, there are limits to the allowed level of charge for vehicles that travel across the ocean, on trains, or via trucks. The heaviness of the vehicles also impacts our load factor, which in turn challenges our ability to safely load vehicles while still supporting our carriers

with fair rates for moving such vehicles.”

“As sustainability becomes an ever more important factor across the sector, and particularly for MBAG, we need to do our best to help the Mercedes EQ family,” she goes on. “We launched the first EQS last year. Now, with other EQ models to follow, we are witnessing the beginning of what is the biggest innovation currently being undertaken across the brand. At the same time, we need to continue to provide our customers with the most luxurious experience possible, and to define what that experience looks like in the context of an electric vehicle.”

Operational efficiencies

As it pivots towards electric vehicles, MBUSA is also investing heavily in the installation of charging infrastructure at its key facilities, including at its Vehicle Preparation Center (VPC), located in Brunswick, Georgia. The site

Mercedes-Benz USA

Mercedes-Benz USA

manufacturing-today.com 31

is one of five VPC facilities in the US that serve as the first stop, after US Customs, for new Mercedes-Benz vehicles destined for Mercedes-Benz dealerships throughout the country, while also serving as the company’s largest port for exports.

“We’re also heavily investing in providing our people with the necessary training to move electric vehicles safely,” Rory continues.

“Electric vehicles pose different challenges to internal combustion cars; for the company, it’s like starting again after 130 years, and for our employees, that means being careful, and being confident in what you’re doing. As the Tuscaloosa plant rolls out a greater number of electric vehicles,

we need to take things one step at a time to ensure that we’re able to fulfill our responsibility safely and efficiently.” These investments sit within broader efforts at MBUSA to streamline its port operations. “It’s our responsibility to get MercedesBenz cars to the ports, and then out of the country to their destination markets,” Rory reiterates. “When finished vehicles wait at a port, they aren’t getting any prettier – we need to keep them moving. With that in mind, we have recently launched a focus on operational efficiencies. We’ve improved how long we hold the cars at port, both through engaging directly with the shipping lines, and through the launch of a dedicated team to handle our finished vehicles exports.”

Since taking these steps, MBUSA is already reaping the rewards. Rory reveals that operations at both the Tuscaloosa facility and the Brunswick port have become more cost and time efficient – an impressive feat, given the ongoing delays influencing shipping routes around the globe. “We’ve been tracking our progress since taking over these responsibilities in August of 2020,” she notes. “Our inventories at the Brunswick port have fallen by around 50 percent, simply because we’re singularly focused on moving vehicles at the port as quickly as possible.

“With ownership and control, it also allows us to be more disciplined,” Rory adds. “From a quality standpoint, we’ve worked closely with MBUSI to develop our own inspection procedures, which take place at the last gate before the vehicles leave the US. For MBAG, meanwhile, they no longer have to concern themselves with the movement of vehicles, because that responsibility falls to us,

We’re also heavily investing in providing our people with the necessary training to move electric vehicles safely

““ ““

32 Cover Story

and it represents our number one priority. Overall, it’s been a very positive development both for MBUSA, and for the MBAG enterprise worldwide.”

All of MBUSA’s efforts over the last two years have taken place against the backdrop of uncertainty, as the initial arrival of the Covid-19

USAL Solutions

Established in 2021 and headquartered in Houston, TX, USAL Solutions is a vehicle transportation broker and logistics provider. Our organization arranges for the safe, high-quality transport of vehicles by pairing available freight with our team of professional, USAL-certified carriers.

We differentiate ourselves from other auto brokerage services, by offering greater customer care, and flexibility for our partners.

“Good business starts with being respectful, trustworthy, and accountable. While we offer

pandemic gave way to months of supply chain volatility, with shortages, increased lead times, and delays posing fresh challenges to companies across the manufacturing and distribution sectors. The shortage of semiconductor chips has proved a particular obstacle for the automotive sector, combined

very competitive rates and high-quality freight to our carriers, we take great pride in building relationships by establishing trust and providing timely communication about our operational goals,” says Doug Bennett, president of USAL Solutions. “And, our robust back-end support resources allow us to provide payment terms that best meet our carriers’ needs.

USAL Solutions and its sister company, US AutoLogistics, a regional interstate carrier, make up the USAL brand of companies and are part of The Friedkin Group.

Mercedes-Benz USA manufacturing-today.com 33

Norfolk Southern Corporation

Since 1827, Norfolk Southern Corporation (Norfolk Southern) (NYSE: NSC) and its predecessor companies have safely moved the goods and materials that drive the U.S. economy. Today, it operates a customer-centric and operationsdriven freight transportation network. Committed to furthering sustainability, Norfolk Southern helps its customers avoid 15 million tons of yearly carbon emissions by shipping via rail. Its dedicated team members deliver more than seven million carloads annually, from agriculture to consumer goods, and is the largest rail shipper of auto products and metals in North America. Norfolk Southern is the number-one originator of finished vehicles, with 61 automotive facilities served and 35 destination ramps. It also has the most extensive intermodal network in the eastern US, serving a majority of the country’s population and manufacturing base, with connections to every major container port on the Atlantic coast, as well as the Gulf of Mexico and Great Lakes. Learn more by visiting www.NorfolkSouthern.com

with an exodus of workers from the rail and trucking industries that constitute the vehicle supply chain.

“Every single mode of transportation has been impacted by the pandemic,” Rory reflects. “Moving finished vehicles is complicated enough, but we’ve nevertheless had to do our best to diversify. If at one point transportation via rail was proving to be challenge, we had to shift our emphasis to trucks. That in turn will then throw up its difficulties, and we will have to shift once again.

“We’re fortunate to have launched a brand-new SAP-based system, VOIS, in 2019, which has given us the agility to be able to alternate how we move our vehicles with relative speed,” she continues. “We’re able to put in new rail routes fairly easily, add truck routes on a daily basis, and the system gives us the

34 Cover Story

transparency to know at exactly which point in our supply chain vehicles are located, and to keep them moving accordingly.”

Managing relationships

VOIS isn’t the only software that MBUSA has onboarded. The company has also adopted Cognosos, a cloud-based inventory management software, providing instantaneous access to real-time location information across the company’s yard at the MBUSI Alabama facility. “As chip or part shortages have become more frequent, we’ve encountered situations where we’ve had cars waiting in the yard that weren’t ready to distribute to market,” Rory explains. “Cognosos gives us the ability to conduct tracking far more efficiently, combining data from our yard with data from MBUSI. As vehicles are moved throughout the site, their locations are updated automatically on the system. We’re

therefore able to keep much better track of the vehicles, and find them more efficiently.”

Moving into the latter half of 2022, the automotive industry continues to grapple with a number of supply chain disruptions. For MBUSA, it’s a period that’s underlined the importance of a robust network of suppliers – or “partners”, as Rory is keen to emphasize. “Throughout the supply chain, we’re all under stress: from production, through to your carriers, and 3PL, as we try to navigate current challenges,” she confirms. “We’re all working with limited resources, and some days you won’t be their number one priority. However, it’s important to recognize that no one is purposely trying to make your job difficult.

“Instead, it’s about how you manage that relationship with respect, trust, and transparency,” she continues. “If your partners inform you that they have an issue, and let you know when they’ll have it fixed, there’s no

Mercedes-Benz USA manufacturing-today.com 35

benefit to be had from beating them up if they fail to meet that deadline. Rather, you’ve got to work together to find new solutions. It’s the same when we’re working to get cars to our dealers: yes, we want everyone to be our priority, but we have to be realistic. If you offer your partners that transparency, they’ll give it back to you.”

Not to be forgotten, underpinning MBUSA’s hard work are the company’s employees. “In the Finished Vehicle Logistics team, we’re a group of 33 corporate office employees, and just over 140 individuals total, moving close to 500,000 vehicles in the USA; all with the goal to make a difference and get stuff done,” Rory

We love what we do at MBUSA, and take great pride in the vehicles that we produce and distribute throughout the US and the world

“ “ “ “

36 Cover Story

insists. “They’re the hardest-working people I’ve seen in logistics. When you’re moving cars, you’ve consistently got to bring your A-game to the table and execute every day. If not, there will be consequences in the months to follow.

“Our team embraces this challenge,” Rory continues. “At the same time, we’re

supportive of each other, and we make sure to keep things fun. Every day, I remind my team of the need to put our work in perspective. What we do is important, but ultimately, we are just moving luxury products around the world – we are not conducting brain or heart surgery. Developing that culture has been a key component of the work we have done over the last couple of years, and it goes hand in hand with our efforts to improve and streamline our operations.

“We love what we do at MBUSA, and take great pride in the vehicles that we produce and distribute throughout the US and the world,” Rory concludes. “Through an everchanging environment, we continue to work hard every day to meet the demands of our customers.”

www.mbusa.com/en/home

INDUSTRY LEADING RAIL,

roadandrail.com DELIVERED. SOLUTIONS

LOGISTICS AND AUTOMOTIVE SUPPORT FOR OVER 35 YEARS.

■ manufacturing-today.com 37 Mercedes-Benz USA

RECKONED WITH TO BE

FORCE

A 38

One of the world’s largest chemical producers, Mitsubishi Chemical UK (Mitsubishi Chemical), is taking to greater heights as the company pushes to expand its capabilities. Motivated by the mantra, ‘one company, one team’, the Mitsubishi Chemical Group has shifted from its previous structure, in which the holding company and each operating business were managed individually, to one in which the entire group is operated in an integrated manner. This strategy will serve as a catalyst for greater potential for Mitsubishi Chemical’s future.

“ “

Motivated by the mantra ‘one company, one team’

The removal of these organizational barriers between each of the operating and affiliated companies to realign them based on corporate functions and business units, has enabled the organization to respond quickly to a range of market changes and demands. As a result, the group can now maximize the power of its resources, technologies, and human resources, thereby forging the future.

“ “

How KAITEKI is pushing Mitsubishi Chemical UK’s success and motivating its sustainability efforts

Mitsubishi

Chemical UK manufacturing-today.com 39

Expanding offering

The business was formed in April 2021 by the consolidation of the separate Mitsubishi Chemical subsidiaries in the UK. These were Lucite International UK Ltd, Lucite International Speciality Polymers and Resins Ltd, MC Ionic Solutions and Nippon Gohsei UK Ltd. Taking a leap further back, in 2004, the Nippon Gohsei UK site re-branded to Mitsubishi Chemical UK Ltd, which birthed the SoarnoL Division, and led to the development of the Saltend Chemicals Park in Hull.

Manufacturing Today learns from the company’s Managing Director, Peter des Forges, about new ventures that are taking place to expand Mitsubishi Chemical’s offering, particularly regarding the SoarnoL division, as well as the ways in which it is refining its capabilities to remain a leader in the manufacturing industry.

Honeywell

The pressure is real for industrial operators to minimize automation project costs and risks, which means making technology implementation easier and less disruptive.

There is a need for a more efficient approach to control system engineering, and one that can be adopted incrementally, and used interchangeably with existing systems and infrastructure.

By decoupling control software from hardware, new control engineering methodologies open a range of possibilities. This includes hosting control in a data center, dynamic controller loading on-process, and easier temporary implementations during expansion projects or plant turnarounds.

In addition to increasing project speed and efficiency, the latest control engineering and implementation approaches enable plant engineers to decouple assignment of I/O modules and control strategies from specific controllers, while focusing on an entire group of controllers. This technique eliminates complexity by shifting I/O to the field, making it fully accessible to any physical controller, taking individual controllers and distributing the load so they appear as a single controller. Industrial operators face critical transformational demands, and automation technology advancements provide real solutions to these challenges through flexible new functionalities that result in safe, efficient, and sustainable operations.

40

Mitsubishi

Chemical UK

Growing demand

One of the most recent and exciting announcements is the new production line in support of SoarnoL, Mitsubishi Chemical’s gas barrier, which is used in high performance packaging. “Our SoarnoL division produces ethylene-vinyl alcohol copolymer (EVOH) under the brand name SoarnoL,” begins Peter. “EVOH has a high gas barrier property for oxygen, carbon dioxide and nitrogen, which makes it suitable to extend the shelf life of food through multi-layered food packaging that utilizes one layer of EVOH.

“Other applications for the product can be seen in bottles, pipes and plastic fuel tanks, and, subsequently, we have pushed the company to specialize in high quality, high performance EVOH that matches

customer requirements,” he shares. From Peter’s observations, global demand for EVOH resin has been expanding. This has been as a result of growth in emerging markets, as well as an increasing use of individual packaging, owing to lifestyle changes in recent years and the rising calls to limit the use of preservatives and food additives. Due to these factors, Mitsubishi Chemical anticipates solid growth in demand for EVOH resin in the coming years.

Although the three SoarnoL EVOH resin production sites in Japan, Texas, and the UK are thriving, the British-based facility is set to undergo some impressive expansions.

RAS Ltd

RAS Ltd has worked with Mitsubishi Chemical UK Ltd SoarnoL Division consistently over the past decade, during which time a strong professional relationship was formed. We have supported the existing site, and the PUMA project team on a wide range of projects, providing expertise and support on all aspects of process safety and risk assessment, including COMAH report preparation, hazard study facilitation, layer of protection analysis, demonstration of ALARP, basis of safety development, permit applications and best available technique studies.

Due to the long-term and consistent support provided, there is an ease and efficiency with which work is carried out, and we are confident that our relationship in the process safety space will continue to be a healthy one for many years to come. We look forward to supporting Mitsubishi Chemical UK Ltd through the PUMA project, delivering line two at the Hull site.

“ “ This has led to the impressive expansion plans in Hull

“ “

42 Mitsubishi Chemical UK

RISK & HAZARD MANAGEMENT

and

covers the full range of

SAFETY

BUSINESS ENVIRONMENT

Only when the risk facing an organisation is well understood can it be effectively managed. Key to the successful identification, assessment and management of risk is engagement with the right people, using the right processes at the right time. We believe we are different to many of our competitors and our approach is distinctive, we don’t always walk the well-trodden path but look at each client’s particular risk context and develop a tailored solution, working in partnership with our client.

We work across all aspects of risk, from Quantitative Risk Assessments and Predictive & Consequence modelling, through to the ‘softer’ risks which may affect an organisation’s reputation.

(PSMO)

Authorized distributor for Wolters Kluwer – BowTieXP software

RAS

+44 (0) 1244 674 612 • enquiries@ras.ltd.uk • ras.ltd.uk

Cogent assured providers –Process Safety Management for Operations

Understanding

facilitating

the effective management of

risk

is

our core business. Our expertise

risk assessment

and

management services.

The company will meet soaring demand for food packaging materials by increasing its annual production capacity and establishing a structure to grow the business. It will not only increase production capacity to capitalize on rising demand, but will also speed up development of the business by continually offering food packaging-related solutions, and making full use of Mitsubishi Group’s collective strength. This has led to the impressive expansion plans in Hull, which will focus on state-ofthe-art manufacturing facilities, equipment and technology. This operation, where more than 125 people are already employed, has seen a steady and significant increase in demand as food manufacturers have sought to lower their environmental footprints. The new plant will be constructed on land next to the current facility, and is expected to be completed by mid-2025. “The EVOH production facilities at Hull have a capacity of 18,000 tonnes per annum, and with this latest investment, we are expecting to see that double, making the production site the largest capacity in Europe.

As a Japanese company, Mitsubishi Chemical follows the mantra of continuous improvement in improving efficiencies and safety throughout the process, which is why the investment at Hull is set to push the existing capacity to over 36,000 tonnes. “Most of this will be for the export market. Overall, the market is growing at around five percent per year, so these investments are necessary to keep up with customer demand.”

“ “ “ “ Mitsubishi Chemical follows the mantra of continuous improvement

44

When it comes to product innovation of this scale, Mitsubishi Chemical draws its inspiration from its loyal and supportive clients. “New products are created to meet the ever-changing customer demands, and new grades are developed in Japan by utilizing the full research and development capabilities of Mitsubishi Chemical. The packaging industry, especially in Europe, is pushing recyclability, which is why EVOH has many advantages compared to other barrier material. This increases the demand for our product and will continue its growth in the future,” Peter explains.

Sustainability goals

Tying in with the environment focus that drives Mitsubishi Chemical’s product innovation, Peter goes on to discuss the second development that has been in motion for several years: sustainability. In line with the international Sustainable Development Goals, which highlight global targets from the UN’s Sustainable Development Summit in September 2015, Mitsubishi Chemical is on track to minimize its carbon footprint.

Goglio

Goglio is a family-owned company, headquartered in Italy, with a global presence of manufacturing sites and commercial branches to closely support our customers.

Active in the development and manufacturing of flexible packaging for more than 170 years, Goglio operates in multiple markets like coffee, food packaging and detergents for consumer goods, and in the B2B, with aseptic bags (from bag in box to 1.400lt bags) and industrial bags (25 kg bags, FFS and liners for octabins and big bags).

Over the years, a complete system - the Fres-co system® - has been developed to offer a complete range of solutions (flexible packaging, filling machines, degassing valves and service) to safely pack customers’ products. Whenever your product needs protection, Goglio is ready to support.

manufacturing-today.com 45 Mitsubishi Chemical UK

This vision comprises 17 goals and 169 targets for realizing a sustainable world, in which governments and civil society are expected to utilize their resources and coordinate efforts to help decrease the impact the manufacturing industry is having on global warming.

By working in accordance with its vision of realizing KAITEKI, the sustainable wellbeing of people, society and the planet, Mitsubishi Chemical adopted improving sustainability as one of its management axes in 2011. Since then, the business has worked tirelessly to ensure that each milestone of its overall success does not negatively impact the longevity of the environment in which it works. This is where the concept of KAITEKI comes into play.

Neill & Brown Global Logistics

Neill & Brown Global Logistics has been a supplier for Mitsubishi Chemical UK for almost 20 years. Originally, the business served as a supplier for UK and European transport, then evolved into warehouse and storage, worldwide deep-sea coverage, and customs clearances, giving it the full logistics package.

From day one, the services level requirements have been very high. Each day multiple updates are given, highlighting when shipments throughout Europe have been delivered. Ontime delivery and ensuring customers receive shipments in full is a standard that is helped by a fleet of Neill & Brown Global Logistics’ own vehicles and UK drivers in Europe.

As cooperation together continues to grow, Neill & Brown Global Logistics is very proud to be a supplier of Mitsubishi Chemicals UK.

Mitsubishi Chemical UK

“ “ This vision comprises 17 goals and 169 targets for realizing a sustainable world

“ “

46

The company aims to not only help solve environmental and social issues but contribute to the sustainable development of society and the planet. As such, it believes that many aspects of its vision of realizing KAITEKI run parallel to the Sustainable Development Goals set by the UN. “Although we acknowledge numerous challenges lie ahead in this regard, considering the opportunities that come with it, every effort is important.

“We embrace these new challenges with optimism that we will overcome difficulties that once held us back, elevating the company to the next level. Through this, we remain fully committed to advancing our goals to achieve carbon neutrality, finding solutions to marine plastic pollution, and creating hope for the future. To that end, in December 2021, we announced our new management

48

policy, Forging the Future, which lays out a clear strategy to unlock the growth potential of our Group and drive operational excellence.

“In addition, as we mentioned earlier, in April 2021, we shifted to an integrated management structure, operating with greater efficiency as ‘one company, one team’. Under this new structure, Mitsubishi Chemical Group will take on the challenge of realizing a better future together with our shareholders, customers, employees, communities, and all other stakeholders,” Peter expresses.

This is why the SoarnoL division project is proving to be a major success for the business. Because sustainability is integral to the company’s success, the new development will contribute positively to Mitsubishi Chemical’s environmental goals, as well as its overall prosperity. “This is a fantastic benefit for SoarnoL, as it extends the shelf life of food, and ultimately minimizes food loss. There is

Wernick Hire

Wernick Hire (Wernick) provides specialist blast accommodation for Mitsubishi Chemical UK.

Wernick is proud to supply Mitsubishi Chemical UK with specialist blast resistant buildings and portable accommodation for its Saltend Chemicals Park project.

Established in 1934, Wernick is the largest independent hirer of portable and modular accommodation in Britain, with 28 hire depots strategically located throughout Britain. Wernick offers high quality products and a premium service to clients that include many of the top 100 UK contractors.

With the environment being a core value, Wernick is committed to being carbon zero by 2040. It also offers a range of eco-friendly accommodation to help clients reduce their carbon footprint.

manufacturing-today.com 49 Mitsubishi Chemical UK

There is minimal packaging waste as well, through reducing the plastic within the structure and through recycling. On the operations side, we are exploring the possibilities of receiving power, generated from blue hydrogen, thereby reducing our carbon footprint significantly. This would involve us linking in with the Hydrogen to Humber scheme, which our government is considering very seriously at the moment,” Peter divulges.

Optimistic outlook

While these developments do provide a positive outlook for the future, Peter is also aware that there are challenges that must still be

“ “ it aims to enhance the company’s approach to sustainability

“ “

50

tackled. One such challenge that Peter references was of course the pandemic. Although Covid-19 brought with it a few obstacles that impacted the business, Peter shares that he is proud of how the company was able to overcome these difficulties. “During the pandemic, we managed to keep the plant running to help fulfil our customer needs. In fact, customer demand rose during this period as there was an increase in people eating at home rather than at a restaurant, which results in more food packaging.

“As for supply chain challenges, we were holding high stocks of raw material as a contingency of Brexit. Fortunately, we have excellent relationships with our major suppliers and logistics providers who helped us

through the period without us having to stop production,” he explains. With these measures in place to see through the industry difficulties, Peter’s forecast for the future is optimistic. He is excited to see how the development of the SoarnoL division will continue to prosper, as it aims to enhance the company’s approach to sustainability, while further expanding its operation. “With the new line scheduled for completion in mid-2025, the company will see a larger critical mass, and further employment both directly or indirectly and the ability to satisfy our customers growing demand for top quality EVOH,” he concludes. ■

www.mitsubishichemical.co.uk

Mitsubishi Chemical UK manufacturing-today.com 51

TURNING METALS INTO MOTION

Ijoined as CEO on 9th March 2020,” begins Mike Quinn, CEO at Doncasters, a leading international manufacturer of high-precision superalloy components that can withstand even the most demanding conditions. “Everything ground to a halt four days later when the pandemic swept through the UK and across the rest of the world.”

A trial by fire, indeed. As he goes on to explain, Mike went 18 months without visiting a single work site due to restrictions imposed by the brusque arrival of Covid-19. However, ultimately, he assures us at Manufacturing Today that the company has come through the whole ordeal as a more robust, resilient business.

“The pandemic forced us to address our material and non-labor cost base,” explains Mike. “Furthermore, in doing so, we improved our productivity, efficiency, and scrap rates; the company has truly gone from strength-to-strength since March 2020. Of course, the supply chain remains upside down – it has been a real

The latest on Doncasters: the superstar of superalloys and casting

52

. . .alongside

the

Doncasters Production System

and

our new ERP

system, we will be

investing around £100 million

into the

renewal

of

our machinery

and

equipment “

“

“ “ Doncasters manufacturing-today.com 53

challenge. But we have adjusted operations to mitigate external issues, including buying in and storing more stock to protect ourselves as well as investing in new working capital. As a result, we have managed to continue delivering products on-time to customers throughout the entire pandemic and supply chain turmoil.”

Major investments

Founded in 1778, Doncasters is one of the UK’s oldest manufacturing companies. With nearly 250 years of business under its belt, it is fair to say that the pandemic was not its first rodeo with adversity. Evolve, adapt, and overcome seems to be the mantra by which Doncasters operates.

The newly-launched Doncasters Production System represents another part of this commercial evolution. The Lean program is being rolled out across all of the company’s sites, meaning that no matter which Doncasters location one visits, they will all look the same and utilize the same metrics.

In addition, Mike reveals the team is currently busy setting up a new Enterprise Resource Planning (ERP) system – the first in the company’s history. Going forward, it will be applied to all sites within the next two years. “We are making some major investments and carrying out some mammoth undertakings across the company,” details Mike. “For instance, alongside the Doncasters Production System and our new ERP system, we will

ICD Europe

ICD Europe are experts in the procurement, processing and supply of a wide range of specialized metals and alloys. From our strategic global locations, we directly supply consumers in a wide variety of industrial sectors including the aerospace, medical, petrochemical, automotive,

electronics and industrial gas turbine industries.

As part of the ICD Group, we have an extensive global supply chain. Since its formation in 1952, the ICD Group has had a presence in over 50 countries dealing in a diverse range of commodities, including lumber, plastics, pigments, minerals, chemicals and metals.

Doncasters 54

be investing around £100 million into the renewal of our machinery and equipment. This period is really motivating for our staff; it shows commitment and they can see the investments materializing in the factories before them.”

Vertical integration

Working in superalloys and manufacturing complex casting products, Doncasters offers an unparalleled range of solutions for high-performance and specialist applications across myriad markets. It utilizes a 2800-strong workforce and 15 advanced production facilities to serve aerospace (airfoils, combustion components, heat shields), industrial gas turbines (cast structural components, seal segments), superalloys (both vacuum- and air-melted), and automotive (turbocharger components and study welding systems) sectors.

Doncasters also acquired Uni-Pol, a leading manufacturing company specializing in investment casting technology, earlier this year, acquiring four additional production facilities in China, India, Mexico, and the UK in the process. Through this work – by turning metals into motion, as the company tagline puts it – the firm has garnered clients like Siemens, GE, Rolls-Royce, and BorgWarner. “We have two main areas of focus: superalloys and precision castings,” explains Mike. “For the latter, we have two plants – one in Sheffield, UK and another in Los Angeles, California. We are the second largest seller of Nickel based superalloys in the world, and we benefit tremendously from having an internal supply chain because we do not have to rely on external vendors.

“Moreover, while we sell superalloys to a number of markets, we also utilize them in our casting facilities by vertically

56

integrating,” he goes on. “Casting makes up the largest portion of our business. Out of our 15 sites, 13 of them are dedicated to the manufacturing of complex precision casting components that will be used in, for example, an aircraft engine or industrial gas turbine.”

Focus on ESG

As our conversation has made clear, Doncasters might be in the business of turning metals into motion, but it is also in the process of getting its own ball rolling – and that means an ethos of continuous improvement.

“We are always looking at ways we can be better at what we do and how we do it,” says Mike. “It is a way of life at Doncasters; everyone – from myself as CEO to a team member at entry-level – knows that each and every day we must do better. We are always

looking out for our people and ways in which we can make their work lives better. In the end, the best endorsement a company can have is a workforce that would gladly recommend it to friends and family. Going forward, we want to work on creating an environment that fosters such a response.

“Another concept that we have launched, and look to expand on in the future, is Environmental, Social, and Governance (ESG) reports,” he concludes. “We recently published our first one online, and it firmly lays out our ambition for the coming years. For instance, we have set ourselves a wealth of metrics: zero landfill, reducing our energy usage by ten percent, moving to a circular economy, and a more diverse and inclusive workforce – just to name a few. That is a big deal for us, and we look forward to making it become a reality.” ■

www.doncasters.com

Doncasters manufacturing-today.com 57

Thesynergyo

f owtserehps

How development and design have catapulted AME Group’s long-term growth

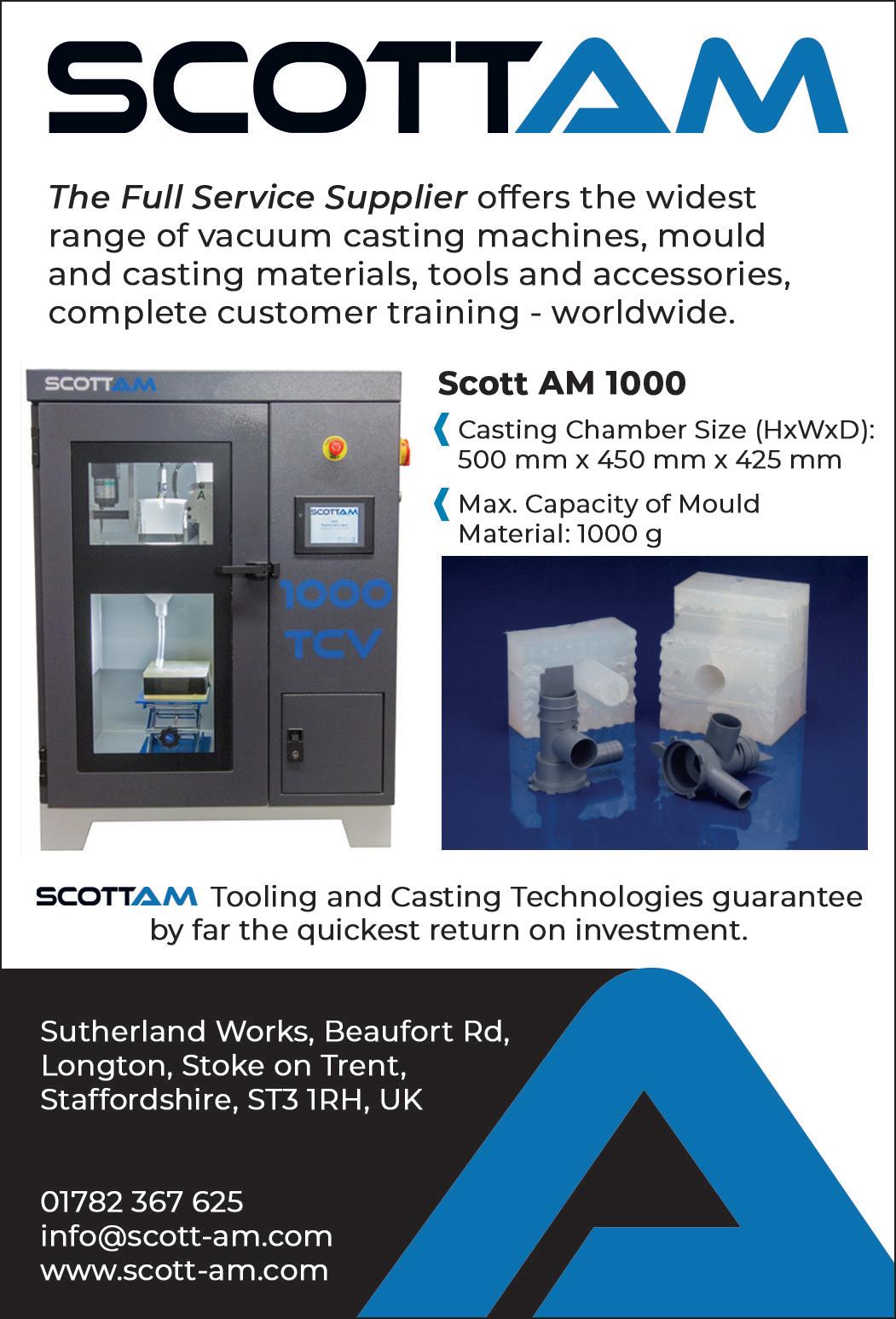

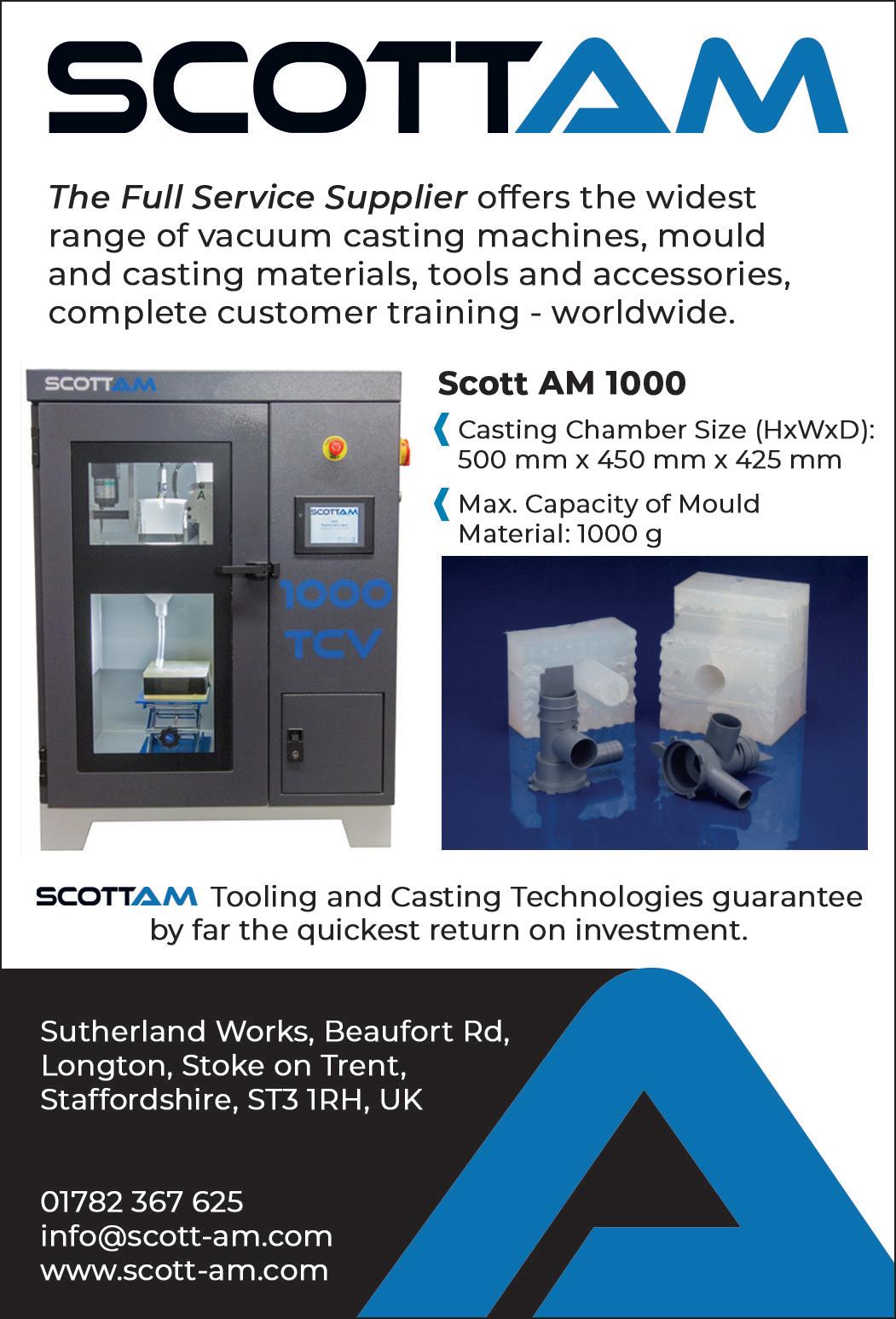

Prototype development is a key part of the manufacturing process, and AME Group is determined to be the reason why companies utilize innovation, and push their businesses forward. Working for a variety of wellknown companies, such as B&Q, Smith & Nephew, Unilever, VAX and Hornby, AME Group has built its reputation as a leading prototype developer in the UK. The last 12 months have been especially exciting for the company with the installation of three new machines to handle the increase in business, about which Managing Director Rich Proctor shares more. He also discusses with Manufacturing Today the advancements taking place at AME Group, and how it is using the latest

58

“ “ . . .

the