THE SCAFFOLDING MAGAZINE THE QUEEN’S TOWER

A majestic restoration project on one of London’s iconic landmarks

ALSO FEATURING: I-SCAFF’S BRIDGE TO SUCCESS USING LAYHER’S AWARD-WINNING TWIXBEAM SYSTEM

Scaling new heights: The remarkable rise of Creator Scaffold Designs

Once-in-a-lifetime project: Manchester Town Hall restoration revisited

A second chance at success: In-depth Q&A on NASC’s Returning Citizens Campaign

Contents

REGULARS

6 NEWS ROUNDUP

Good news from NASC’s 2023 accident report, BIGBEN launches ScaffOil, the latest on Working at Height Regulations, CCM’s new training facilities, and a significant milestone for the Scaffolding Association.

13 EVENTS & AWARDS

The Scaffolding Association announces its 2023 conference, and we report from ScaffChamp 23 – recently held in Lithuania.

18 INTERVIEWS

ScaffMag Editor, Daniel Norton, finds out about the NASC’s Returning Citizens Campaign from NASC Training Officer Henry Annafi. Plus Ian Hines tells us about his journey from scaffolder to recognised mental health advocate.

FEATURES

26

“A ONCE-IN-A-LIFETIME PROJECT”

The extraordinary restoration of Manchester Town Hall and the groundbreaking scaffolding works by Lyndon SGB.

32 SCALING NEW HEIGHTS

The Berry brothers tell ScaffMag about a remarkable triumphant decade for Creator Scaffold Designs.

14

32 54

36 A WORK OF ART

Award-winning UK sign company Lavastar on the benefits of producing beautiful building wraps.

41 THE BUSINESS

Des Moore, former CEO of the TRAD Group, reflects on his life in scaffolding. Plus Millcroft’s Billy Jones explains how diversification can play an important role in his company’s expansion plans.

52 PRODUCTS & SERVICES

TRAD UK launches its all-new lift shaft gate – the ultimate safety solution for multi-storey construction projects, and AT-PAC Ringlock Modular Scaffold System partners with Connolly Scaffold Ltd at Thorn Court.

56 SYSTEM

What impact is climate change having on UK scaffolding projects? ScaffMag investigates.

62 PROJECTS

We take a close look at the prestigious Queen’s Tower in London and a new pinnacle of ingenuity and engineering on the M8 South Sliproad Bridge in Livingstone, Scotland with I-Scaff Access Solutions Ltd.

Welcome

Welcome to issue 19 of ScaffMag, your comprehensive guide to the extraordinary and ever-evolving world of scaffolding and construction.

In this issue, we are privileged to share some remarkable stories of innovation, resilience and societal impact from the scaffolding industry. The scaffolding world never fails to amaze us with its capacity to push boundaries, foster change and shape the future of our cities and societies.

Our cover story features a grand feat of engineering –the restoration of London’s iconic Queen’s Tower. An unprecedented collaboration between JDC Scaffolding Ltd, RDG Engineering and Russell Cawberry Ltd. has given rise to an extraordinary testament to the remarkable capabilities of modern scaffolding. It’s a story of heritage meeting innovation, and you won’t want to miss it on page 62.

This issue also shines a spotlight on the incredible societal contributions of our industry. On page 18, our in-depth Q&A with Henry Annafi explores the National Access & Scaffolding Confederation’s (NASC) Returning Citizens campaign, a groundbreaking initiative giving former prison inmates the opportunity to rebuild their lives through scaffolding training and job placements.

We also bring you an exclusive interview on page 41with Des Moore, a stalwart of the scaffolding industry. As he steps down as CEO of the TRAD Group after a commendable 30-year tenure, we reflect on his extraordinary journey from a young scaffolder to leading one of the industry’s top companies.

In our people section, we introduce you to Isaac Morrison, a former scaffolder who’s making waves with his new podcast. An exclusive interview on page 23 explores what inspired this transition and how he aims to bring the construction community closer together through this medium.

In addition to these captivating stories, this issue is packed with more interviews, project features, mental health stories, equipment reviews and so much more. It’s a testament to the vibrant and diverse world of scaffolding.

As we put this issue together, we’re reminded of the importance of every story we tell. These are stories of transformation, perseverance and resilience that deserve to be heard, shared and celebrated.

My heartfelt thanks to our dedicated team, our contributors, advertisers and you, our readers. Your unwavering support and enthusiasm are what make ScaffMag possible. We hope you enjoy this issue as much as we’ve enjoyed creating it.

Happy reading and stay safe!

Daniel Norton – Editor dan@scaffmag.com

EDITORIAL

Editor Daniel Norton

T 01472 476024

M 07776 218831

E dan@scaffmag.com

@ScaffMagDan

Features writers

Grahame Anderson

Richard Trenchard

Design

Demot Rushe

Dermotrushe.co.uk

CONTRIBUTORS

Billy Jones - Millcroft

Scaffolding

Des Moore - MOR1X

Garry Griffths - UKSSH

ADVERTISING

Manager Jessica Norton

T 01472 476024

M 07776 218831

E jess@scaffmag.com

PUBLISHED BY ScaffMag Ltd

Office G8

The Enterprise Village Prince Albert Gardens

Grimsby

DN31 3AT

facebook.com/scaffmag

twitter.com/ScaffoldingNews

NASC 2023 safety report reveals lowest accident rates in nearly 50 years

The National Access and Scaffolding Confederation (NASC) has released its 2023 Safety Report, revealing the lowest Accident Incident Rate (AIR) and Accident Frequency Rate (AFR) since 1975

❖ According to the scaffolding trade body, its latest report underscores the effectiveness of regulated NASC membership in ensuring safe scaffolding and access operations.

In 2022, NASC’s 240+ contracting member firms saw a 26% reduction in reporting of injuries, diseases and dangerous occurrences regulations (RIDDOR) accident rate, falling from 90 incidents in 2021 to 67 incidents.

This reduction was most notable in the 16–20 age bracket, where incidents decreased by 63%.

These improvements were achieved despite a 10% increase in the scaffolding workforce, which grew to 17,315 operatives.

The 2023 Safety Report shows an AIR of 3.87 and an AFR of 0.20, the lowest figures recorded since 1975. This achievement translates to more

NASC member company employees working without incident or harm.

David Brown, the new NASC President from IBN Scaffold Access Ltd, praised the members for their proactive approach to health and safety. “Our figures for 2022 speak for themselves,” Brown said. “Our members are proactive in their approach to improving health and safety for their employees and also for the wider construction industry who use our scaffolds on a daily basis.”

He further emphasised the importance of early training for younger workers, noting the 63% reduction in injuries in the 16–20 age bracket. The president also mentioned the upcoming SG6 manual handling guidance suite, which should further reduce accidents.

NASC Managing Director Dave Mosley pointed to the report as evidence of the commitment to safety by NASC members, who are “strictly audited, highly regulated, well trained and proactive”.

Steve Kearney, NASC Health and Safety Manager, added: “We can all be very proud of the work that the NASC and its contracting members are doing to make this inherently dangerous industry safer, day by day.”

This year’s report, which comprehensively analyses accident and injury statistics of its members, is publicly accessible on the NASC website: www.nasc.org.uk

BIGBEN LAUNCHES ECOFRIENDLY SCAFFOLDING LUBRICANT: SCAFFOIL

BIGBEN has launched ScaffOil, an eco-friendly lubricant designed for the scaffolding and construction industries.

❖ According to its makers, the revolutionary new product offers unmatched efficacy and versatility and has already gained attention in the market.

ScaffOil ensures the smooth operation of scaffolding systems by facilitating the easy release of fittings and brackets while also providing long-lasting lubrication to prevent rust and corrosion.

It can withstand harsh weather conditions, allowing construction workers to leave scaffolding fittings in place without compromising stability. The exceptional penetrating power of ScaffOil enables it to reach intricate corners that

other lubricants cannot, revitalising ‘dead’ fittings and improving the efficiency of scaffolding systems.

The product is now available through trusted supplier Leach’s in various sizes, including 210-litre drums, 25-litre drums, and 5-litre tubs. ScaffOil aims to set a new industry standard by offering premium performance at an affordable price.

Working at Height Regulations may be spared

The UK Government has reversed its decision to repeal specific EU laws, including the Working at Height Regulations, according to recent reports.

❖ Initially, the Revocation and Reform Bill aimed to eliminate over 2,400 EU-derived regulations, but now it is expected that only 600 will be scrapped.

Key safety regulations like the Working at Height Regulations, Manual Handling Operations Regulations and Personal Protective Equipment at Work Regulations are likely to be retained.

The Access Industry Forum (AIF) and other trade associations had campaigned

against the repeal, emphasising the importance of these regulations for worker safety. The AIF welcomed the potential victory and highlighted that these regulations had been a part of UK law for almost two decades and have proven effective.

The Chief Executive of the Scaffolding Association expressed optimism about the announcement, crediting the engagement of industry representatives with government officials for influencing their decision. The AIF continues to encourage various sectors to write to their MPs in support of integrating the Working at Height Regulations into UK law.

FROM THE GROUND UP, WE NEVER COMPROMISE ON SAFETY

We exist to make life safer for people working in challenging environments. We promise to never rest on improving and innovating for safe access solutions and services all over the world.

Green Innovation at CCM

In a notable move towards sustainability, Construction College Midlands (CCM) has launched a £1m hightech scaffolding training facility and eco-focused skills courses

❖ This investment marks the college’s commitment to fostering green construction practices. The Birminghambased college, an affiliate of Walsall College, has seen a 300% increase in training delivery in scaffolding and related areas since acquiring its site in 2020.

The new facility, partially funded by Greater Birmingham and Solihull Local Enterprise Partnership’s (GBSLEP) Growing Places Fund, will offer enhanced apprenticeships and industryrecognised qualifications within the Construction Industry Scaffolders Record Scheme (CISRS).

Jatinder Sharma CBE DL, Principal

and Chief Executive of Walsall College, stated that the facility would aid employers in finding urgently needed skilled workers.

In addition, the college’s Green Skills Sustainability Centre was unveiled, providing courses to assist businesses in decreasing their carbon footprint.

Sharma voiced enthusiasm for the college’s sustainability initiative, aligning their values with industry needs and eco-friendly practices.

This significant development by CCM marks a stride towards a greener, more sustainable future for the construction industry.

SCAFFOLDING ASSOCIATION REACHES 600 MEMBERS

The Scaffolding Association (SA), the largest trade association for the UK’s scaffolding and access sector, is celebrating a significant milestone as 600 new members join its ranks.

❖ This achievement reflects the SA’s commitment to delivering exceptional service and fostering a collaborative community. In a press release, CEO Robert Candy expressed his enthusiasm: “Reaching this milestone is a testament to the trust and value scaffolding

companies place in our association to advocate for their interests and facilitate growth.”

The SA’s expanding membership base strengthens its network of professional organisations united in envisioning an ambitious future for the industry.

Candy highlighted the association’s role in promoting unity and positive change, stating, “The ongoing expansion of our membership base signifies a positive shift in the industry.”

The diverse membership, ranging

from small-scale businesses to industry leaders, represents the extensive and multifaceted scaffolding industry. Candy further emphasised the SA’s dedication: “We take immense pride in cultivating a community embodying the extensive scaffolding industry.”

With 600 new members propelling its mission forward, the SA is poised to continue advocating for the industry’s interests, promoting collaboration and driving positive change in the scaffolding and access sector.

THE LOW WEIGHT HIGH STRENGTH

MULTIFUNCTIONAL SOLUTION

SCAFFOLDING CONFERENCE 2023 ANNOUNCED

The Scaffolding Association has recently announced the date for its second annual Scaffolding Conference, set to take place on October 12, 2023

The event will return to the Heart of England Conference and Events Centre in Warwickshire, the same venue that successfully hosted the conference last year.

After a highly successful inaugural event in 2022, the upcoming conference is poised to draw an even bigger crowd. With plans for more exhibitors, an expanded seminar schedule and increased opportunities for discussion, this year’s conference promises to be an unmissable event for industry professionals.

Last year’s conference – the first ever dedicated to the scaffolding and access industry – attracted over 150 attendees from various sectors. Open to both members and non-members of the Scaffolding Association, the event provided a valuable platform for addressing multiple topics of industry relevance.

The 2022 conference was filled with informative and lively discussions on a range of topics, including a live contract review, celebrations for National Scaffolding Week, and issues like labour

shortages, skills and training, scaffold insurance and the HGV price-fixing scandal.

Attendees also engaged in forward-looking discussions about the future of scaffolding and the crucial role of system scaffolding.

As the scaffolding industry continues to grow and evolve, the Scaffolding Association’s 2023 conference is designed to facilitate the exchange of ideas and promote best practices to ensure safe and efficient operations.

The conference is expected to attract a diverse group of professionals from the industry, providing opportunities to network, learn from experts, and stay up to date on industry trends and practices.

The Scaffolding Association urges all industry professionals to mark their calendars for this important event. With the active support of industry players, the conference promises to be a valuable resource for scaffolding and access professionals, promoting excellence and safety within the industry.

ScaffChamp 23: A towering success in Vilnius

Last month, the third annual international scaffolding championship, held in the Lithuanian capital, truly soared above expectations. The event attracted over 400 people from across the globe and was live-streamed to thousands more, creating an inspiring atmosphere of camaraderie and competition

The event, now dubbed ScaffChamp, not only celebrated the high-level skills within the scaffolding industry but also reinforced the global sense of community amongst its professionals.

The international scaffolding industry came together in a grand spectacle at the annual ScaffChamp 23. This event, hosted recently in Vilnius, Lithuania, by the Baltic Scaffolding Association (BSA) and Layher Baltic, celebrated its third successful year, continuing to grow in size and significance globally.

From its humble beginnings in 2019 to the present, the championship has seen an impressive surge in growth and popularity. This year, it drew a diverse audience of over 400 attendees from across the world, demonstrating its expanding influence in the scaffolding industry.

Again, the competition was live-streamed, which captivated a diverse global audience with skilled commentary by professionals from the USA and Germany, who delivered insightful commentary throughout the event.

The key highlight was the intense competition among 15 international teams. Their challenge: erect and dismantle a specifically designed Layher Allround scaffold structure as swiftly and safely as possible, turning the event into an exciting race against the clock.

The Swedish team, Kaefer AB, emerged victorious, setting a new record with a time of 59 minutes and 1 second. Lithuanian teams Globalita and defending champions Hotrema secured second and third positions respectively, demonstrating their strong scaffolding prowess.

Oleg Abramov, Project and Marketing Manager at Layher Baltic, reflected on the successful execution of ScaffChamp 23. In an interview with ScaffMag, Abramov highlighted the event’s growth from its planning stage in October 2022 to its

OPPOSITE and ABOVE

LEFT: Glittering prizes on offer at the third annual international scaffolding championship, ScaffChamp 23.

TOP: Fifteen international teams battled it out for the title.

ABOVE: Some of the 400 competitors are put through a strenuous warm-up ahead of the event.

LEFT: Competition was intense but the rivalry was friendly.

for Scaffolders

How scaffold contractors can work with us!

SUSPENDED SCAFFOLD

Installing a suspended scaffold over water?

PARTNERSHIP WORKING

Hire a ScaffFloat to your customers.

Safer & faster.

Access: We can supply you with a ScaffFloat pontoon, with propulsion and skipper if needed, to give your scaffolders a safe and stable platform to work from.

Payload: The ScaffFloat has a payload of several tons to store tube, clips, beams and boards.

Transport: If there is limited access next to the project, we can load gear up or downstream and then transport it to and from site.

Height: Build a scaffold platform up from the pontoon to give you access to the underside of the structure. Full stability assessment provided.

Adding value together.

We provide: 1) The floats, engines, mooring lines, anchors, safety pack and other equipment 2) The on water management & RAMS 3) Qualified skippers & crew if necessary 4) Designs and certification 5) Stability assessment 6) Licences and permissions

You provide: 1) The relationship with the client 2) You invoice your client 3) The scaffold and if needed labour for the mob & de-mob 4) Local knowledge

Proven: This is now a well tested business model and we are always looking for forward thinking scaffold companies to work together with on projects.

grand culmination, calling it an “exhilarating adventure filled with determination, collaboration and the pursuit of excellence”.

One of the most heartwarming moments Abramov noted was the participation of the Mongolian team, NBIK Hawks. “Watching the Mongolian team who had endured a 16-hour flight to Lithuania to take part was my best moment during the event,” said Abramov. Their dedication underscored the sense of global community fostered by this event.

Mark Parkin, Business Development Manager at Richter from the UK, was one of the invited referees at the event. Speaking about the assessment criteria during the competition, he said, “While refereeing, we looked at a number of different things. In the UK we work to SG4 but the rest of the world doesn’t and as this is an international event we looked at the teams walking on ledgers and how many boards they were working from and marked them up or down accordingly.”

Parkin reminisced about the inception of ScaffChamp, “I remember talking to Victor when he had the idea for ScaffChamp; he was worried that only a couple of teams would attend. But look at it now,” he said. “Fifteen teams from around the world with the possibility of 20 plus teams attending next year. It’s been an incredible event.”

Speaking after the event, Abramov extended his gratitude towards the event’s sponsors, KEWAZO, ScaffPlan, and Layher Baltic, UAB. He also emphasised the importance of fostering networking opportunities and building a robust scaffolding community. He lauded the team effort behind the event, thanking referees, broadcast commentators and influencers for their pivotal roles in ScaffChamp’s success.

The success of ScaffChamp 23 underlines the growing recognition of scaffolding as a skilled profession and its central role in global construction. As the event continues to grow each year, it not only elevates the level of competition but also cements the bonds of this unique international community.

In Abramov’s words, “I invite you all to join in celebrating the success of this incredible journey.”

ScaffChamp 23 attracted teams from all over the world, with the event live-streamed everywhere. Kaefer AB from Sweden were the eventual champions and hope to defend their crown next year.

A SECOND CHANCE AT SUCCESS

ScaffMag Editor, Daniel Norton, holds an in-depth Q&A on NASC’s Returning Citizens Campaign with NASC Training Officer Henry Annafi

The National Access & Scaffolding Confederation (NASC) has been positively impacting society with its Returning Citizens campaign, aimed at training former prison inmates in scaffolding and providing them with job placements upon their release. NASC Training Officer Henry Annafi has been leading the charge on this innovative scheme, supported by NASC members and CISRS-approved training providers by travelling to prisons throughout the UK and conducting interactive VR sessions that give inmates a feel for working in the scaffolding industry.

For a Q&A, ScaffMag’s Editor, Daniel Norton, caught up with Henry for an update on the progress and impact of the Returning Citizens (RC) campaign within the industry.

Daniel Norton: Thank you for taking the time to talk to our ScaffMag readers and for taking the time to answer our questions. Can you provide an update on the progress of the Returning Citizens campaign since we last spoke?

Henry Annafi: The scheme is going from strength to strength. Since we last spoke, we have been invited to seven more prisons, and in that time, six men have been released across those prisons, with five of them being recruited by NASC members.

All of them are still in employment after their (on average) first six weeks. Their employers couldn’t be more pleased. Two of them have been described

as exemplary by their employers, and they have both committed to participating in case studies, so you and your readers will get to meet them soon!

DN: Have there been any new NASC member companies that have joined the initiative?

HA: We have had an additional 17 members join the scheme, so we now have 104 in total. Once we have more regional coverage regarding the prisons and other organisations we work with, I anticipate this will increase rapidly.

DN: What kind of feedback have you received from former inmates who have completed the training and secured job placements?

HA: Every single RC has shown nothing but gratitude and enthusiasm for an opportunity for a career.

As you know, training as a scaffolder is an ongoing process, but they have enjoyed all their training to date, and as an aside, every single RC we’ve recruited has requested overtime whenever it’s available.

DN: Have there been any challenges or obstacles faced in delivering the campaign in various prisons across the UK?

HA: As with any such scheme, there have been some challenges. The first and most obvious is to ensure that this scheme can benefit any of our participating members irrespective of geography. That can pose challenges with ensuring that an RC can get to the place of work; if a member is quite remote, that

presents issues. There is the usual stigma that’s attached to RCs from some members, but as I remind them, I’m not here to convince them of the value of the scheme. I’m here to support them in their recruitment needs, and if we have a pool of talent that WANT to work for us, it’s a bit of a no-brainer to give them a chance. The only other real challenge is getting delivery set up on prison premises, but we are making progress with this and anticipate delivering courses in three new prisons by the end of the year.

DN: What is the initiative’s success rate in reducing recidivism rates?

HA: Presently, with the recruits since February, it’s 100%! I don’t have figures for the delivery from Fulcrum, but I know Dave Abraham has had immense success in placing people with multiple scaffolding companies – both NASC and non NASC members – which can only be good for the industry.

DN: What plans are in place for expanding the initiative in the future?

HA: As mentioned earlier, we intend to increase on-site delivery by 80% this year. We are also planning to have a minimum of 200 members signed up for the scheme by the end of the summer, as well as three additional mentoring organisations. We are in discussions with prions north of the border to implement the scheme formally in Scotland, and will have at least two prisons referring

to our burgeoning Scottish RC scheme by October. I also want to ensure that across each of our five NASC regions of the country, we can facilitate employer visits and on-site interviews at least once a quarter.

DN: How has the wider scaffolding industry responded to the Returning Citizens campaign? HA: Despite the natural and understandable competitiveness of the industry, feedback has been universally positive. I’ve had conversations in particular with two companies that are nonmembers who have been fulsome in their praise and asked for advice as to how they can get involved or develop a line of communication with prisons. Best of all, for the NASC, they have both applied to become members. What is even more gratifying is that major contractors are talking to us about participating in the scheme, and we are at an advanced stage of discussions with Galliford Try to deliver more hybrid sessions in prisons. They recently joined the NASC and the NASC President’s company, IBN Scaffolding, for sessions in HMP Moorland and HMP Hatfield to deliver the immersive experience and talk about the opportunities across their supply chain. It was an incredible couple of days, and we are excited at the possibilities of such a partnership, as are they.

DN: As the scaffolding industry, unfortunately, already has a stigma for employing ‘colourful

An Industry-Wide Pre-Qualification System

Pre-qualification costs the construction industry up to £1 billion each year. Build UK is rolling out the Common Assessment Standard to improve efficiency and reduce duplication in the pre-qualification process.

Accepted by a growing list of contractors and clients across the industry Annual certification from your choice of Recognised Assessment Body

Two levels of certification – desktop and site-based – to suit your business Recognises other certifications such as ISOs saving time during the audit process

Option to share your key pre-qualification data with other Recognised Assessment Bodies so it is visible to more contractors and clients

characters’, some believe the last thing the industry needs is more, especially with previous convictions; what would you say to them?

HA: I hear this and understand to some extent, the underlying concerns. The first thing I would say is that, if at all possible, EVERYONE should visit a prison. Doing that would help them realise that prisoners are just people, and if we believe in the concept of justice in our country, then we should accept that prison is where people are sent as a punishment for their crimes, not to be punished.

The second thing, which follows very closely from this, is that when prisoners are released, they are coming back to live with ALL OF US. If they aren’t given opportunities to work, then what can we expect from them? What would we do to feed our families if nobody would employ us? Beg? Borrow? Steal? Everyone deserves a chance for redemption if they say that’s what they want, and frankly, I know of lawyers, accountants and other professions that present far more anti-social behaviour and criminality than scaffolders. I know because I’ve met them in prison and elsewhere.

The final thing I’ll say on this – and I could say so, so much more – is that an RC has more to prove and more to lose than any other employee. As such, the likelihood of them committing a transgression is far more remote than your ‘ordinary’ employees. They are also far more liable to give you loyalty as you gave them a chance when nobody else would. There is always a risk in employing ANYBODY. At least with the RCs, you know exactly who they are, what they’ve done, and what they say they want to achieve. Plus, we have mentoring support to mitigate risk.

DN: Can you speak of the importance of mentorship in helping former inmates integrate back into society?

HA: Most people are unaware of the challenges RCs face when they leave prison. They are given £87 and an appointment at the Job Centre. Then, they sign on to Universal Credit, and, if they are fortunate, they’ll receive benefits within six weeks. In reality, it is usually 10 weeks or more. Could you survive on £87 even for a week, let alone if you have your old associates dangling the carrot of quick, ‘easy’ money?

A significant number do not have anywhere to live, and, even if they do, they still must contend with the financial issues I’ve just described. Some have no bank accounts or ID. A lot of them will be unfamiliar with the new digital age in which we live (smartphones, apps, etc), and these are things

which they are left on their own to navigate. The system is literally setting people up to fail.

For these reasons and more, the mentoring scheme is essential for any RC who wants it. This professional individual can be that guiding support when temptation arises, they can support the RC with the administrative elements of life, and they can be an interface between the employer and the RC so that the employer is aware of any challenges they are facing that could impact their ability to do their job.

DN: What message do you have for those interested in getting involved with the Returning Citizens campaign?

HA: For anyone that wants to get involved, get in touch. I’m happy to share my experience and discuss ways in which we can work with organisations and make the scheme even more accessible. There has been nothing more gratifying in my role than genuinely helping to change someone’s life for the better and, even more importantly, the lives of their families and especially their children. We’re also helping to make a difference in society by reducing the burden on the public purse. We won’t always get it right, but that’s the same for ANYBODY that we recruit. Let’s make a difference.

The Returning Citizens Campaign aims to bridge the gap between the scaffolding industry and newly released prisoners looking for a second chance at employment.

“Everyone should visit a prison. Doing that would help them realise that prisoners are just people.”

Former scaffolder, now entrepreneur, Isaac Morrison has taken to the airwaves with his new podcast, connecting the construction community and beyond. But what lies behind it? ScaffMag finds out more

THE VIEW WITH VERTEX

With two decades of experience working in the scaffolding industry, Isaac Morrison has seen it all. From working as a yard labourer to an advanced scaffolder, supervisor, instructor, and consultant, Morrison has travelled the globe, honing his skills in places like Germany, Australia, Malta, and the Shetlands. In July 2020, he co-founded a scaffolding business with two friends, which, despite the pandemic, achieved rapid success. However, after separating from the company in December, Morrison established Vertex Training & Consultancy, driven by his passion for engaging in conversations and helping others achieve their goals.

“I started a scaffolding business with two friends back in July of 2020, which, despite of the pandemic, became quite successful in a relatively short space of time,” says Morrison. “As pleasing as all of this early

success had been, I found myself missing all of the interesting conversations that training and consultancy brought and the sense of fulfilment that came with helping others to achieve their goals.”

Morrison’s latest venture, The View with VERTEX podcast, combines his love for podcasts and his industry experience to create a unique platform for people in the scaffolding and construction sectors. By focusing on the stories of exceptional individuals, Morrison’s podcast aims to provide insights into the habits and mindsets that drive success and overcoming adversity.

“I’m a huge podcast fan. I enjoy all kinds of different shows, especially those that provide an insight into the lives, habits, and mindsets of exceptional people,” Morrison shares. My hope is that by tuning in, those listening to the show will come away with an insight into what makes successful people succeed, what mistakes and pitfalls

to avoid, and how to overcome adversity, potentially leading to positive change in both a professional and personal sense for the listener.

Although primarily targeted at those in the scaffolding industry, the podcast’s emphasis on guests’ personal stories creates a broader appeal. Episodes featuring the likes of Ant Jones, a “beer geek,” and Vicky Welch, the UK’s first female Advanced Scaffolder, ensure that there’s something for everyone.

“I’d say the target audience is primarily people from the scaffolding industry; however, for the most part, the subjects we cover tend to people’s stories, which I’m hoping will give the show crossover appeal,” explains Morrison.

The podcast’s uniqueness lies in its focus on the guest and their story rather than the industry they work in. By creating a studio experience, The View with VERTEX promotes cross-trade and crossindustry communication, allowing for valuable knowledge exchange between different sectors.

“I think we’re unique in that, although others have launched industry-specific podcasts, we like to provide a studio experience and focus more on the guest and their story than the industry and trade they happen to be in. If anything, I’d say it’ll open up channels of cross-trade/cross-industry communication and allow others to learn from our industry and vice versa,” Morrison adds.

Upcoming episodes tackle a range of topics, such as suicide prevention, mental health and spirituality, and the future of the scaffolding industry. Guests include Graham Campbell, a scaffolder who lost his son to suicide; Rose System Scaffolding’s Operations Director, Chris Howson; and Oleg Abramov from

Layher Baltic, discussing the Scaffolding World Championships ‘ScaffChamp.’

While Morrison acknowledges that the podcast might indirectly raise awareness about Vertex Training & Consultancy, his primary goal is to share engaging conversations with listeners. “It’s a labour of love, at the minute, the goal is to have interesting conversations and share them,” he explains. From a professional perspective, I suppose it might have the benefit of letting people know who we are and what we do. It›s great if that leads to opportunities, but that›s certainly not the aim.

Tune in and subscribe to The View with VERTEX to hear the latest episodes and follow the podcast on social media to stay up-to-date on upcoming guests and special events. Be inspired by the stories and insights of the construction industry’s most innovative minds, as well as the unsung heroes making a difference in their communities.

I’M A HUGE PODCAST FAN. I ENJOY ALL KINDS OF DIFFERENT SHOWS, ESPECIALLY THOSE THAT PROVIDE AN INSIGHT INTO THE LIVES, HABITS, AND MINDSETS OF EXCEPTIONAL PEOPLE.”

SEASONS CHANGE

Ian Hines’ journey is no ordinary one. From a scaffolder to a recognised mental health advocate, his story is a testament to human resilience and the transformative power of empathy and kindness

As a young man, Hines had no ambition to become a scaffolder, having held a number of labouring jobs on building sites. His life took a darker turn in the late ’90s when a battle with substance abuse led him to prison. Upon release in 2000, he found himself homeless, relying on charities like ‘Let’s Feed Brum’ for survival and selling The Big Issue, a publication supporting homeless people. These experiences, while challenging, provided an invaluable perspective on human desperation, resilience and the often-unseen struggle of mental health.

His turning point came during a stint at a rehabilitation centre, where he encountered talking therapy for the first time. This powerful experience revealed the effectiveness of listening, compassion and identifying personal triggers in managing addiction. It was a life-changing revelation that guided him toward a new dream –becoming a counsellor.

In pursuit of this dream, Hines began working for Lyndon SGB in 2001, starting as a labourer. He simultaneously attended night school to train as a therapist. Over the years, he progressed within the scaffolding business while completing his qualifications. By 2008, he had achieved his credentials as a therapist and was studying for his master’s degree in Psychotherapy.

His two seemingly contrasting worlds began to intersect on construction sites as fellow workers started confiding in him about their personal struggles. Hines was struck by the rampant stigma and fear around mental health within the industry. This drove him to use his knowledge and skills to increase awareness and help tackle the alarming suicide rates among construction workers.

With the support of Lyndon SGB’s leadership, including Robert Lynch, Mark Collinson and Jon Cooke, Hines developed a mental health

programme. He trained employees in mental health first aid and suicide prevention, eventually building a network of first aiders that expanded beyond the company and into the wider community.

In 2018, Lyndon SGB launched a 24/7 helpline operated by Hines, who had then trained as a Samaritan. Over time, they taught over 50 people mental health first aid within the company and extended the service to external companies like Lendlease, Balfour Beatty and Wilmot Dixon.

Despite these successes, Hines was not immune to the stresses of his dual role. He experienced burnout, highlighting the need for self-care in mental health work. This led him to a critical decision – leaving his position in scaffolding to fully dedicate himself to mental health advocacy.

Following his redundancy, he found himself part of the Lighthouse charity, an organisation dedicated to mental health support and suicide prevention in the construction industry. Through his work with Lighthouse and private firms such as DENHOM Industrial, Hines has continued his life-saving work on a larger scale.

Today, Hines is a recognised mental health specialist and service provider in the National Access and Scaffolding Confederation (NASC). His company, Training in Mind, offers bespoke training in mental health awareness, suicide prevention and relevant issues, like menopause.

Hines’ story embodies a message of resilience and a clarion call to address the silent epidemic of mental health issues in industries that are often overlooked. His continued work serves as a reminder of the importance of destigmatising mental health and ensuring everyone has access to the help they need.

If you require any training regarding mental health or wellness, you can reach Ian Hines on 0754 508 0011 or visit the Training in Mind Website. www.traininginmind.info.

HINES WAS STRUCK BY THE RAMPANT STIGMA AND FEAR AROUND MENTAL HEALTH WITHIN THE INDUSTRY. THIS DROVE HIM TO USE HIS KNOWLEDGE AND SKILLS TO INCREASE AWARENESS AND HELP TACKLE THE ALARMING SUICIDE RATES AMONG CONSTRUCTION WORKERS.”

“A once-in-alifetime project”

ScaffMag’s Editor, Dan Norton, revisits and explores the extraordinary restoration of Manchester’s iconic Town Hall and the now complete groundbreaking scaffolding works by Lyndon SGB that have set a new benchmark in engineering prowess

In the heart of Manchester, the Grade I-listed Town Hall has long been a symbol of pride and heritage for the city. Since its completion in 1877, this architectural masterpiece has witnessed countless events, from royal visits to political milestones.

However, time has taken its toll on the grand building, and it has started to show its age. But now, the multi-million-pound restoration project, dubbed ‘Our Town Hall’ is well under way and breathing new life into this iconic structure, led by Manchester City Council and management contractor Lendlease with scaffolding specialists Lyndon SGB by BrandSafway.

At the heart of the restoration that began in March 2020 lies the now fully erected, massive scaffolding structure that completely encases the building, designed and engineered by scaffolding specialists Lyndon SGB. The company’s unmatched expertise in the field has allowed it to create a masterpiece of engineering that not only supports the restoration work but also dazzles with its sheer magnitude. So much so, there’s no wonder this colossal scaffolding

OPPOSITE: Manchester’s Grade I-listed Town Hall under wraps while it undergoes extensive restoration works with scaffolding by Lyndon SGB.

project towering above the city has earned the title of Europe’s largest commercial scaffolding project; it’s quite simply a marvel to behold.

With a combined weight of 3,700 tonnes, Lyndon SGB has provided more than 200 bespoke scaffolding structures for the project. The list includes a giant tube-and-fitting perimeter scaffold with Class-B protection fans, an array of internal crash decks, birdcages, roof saddles, temporary roofs, and a bespoke and a highly technical 90m-high clock tower scaffold, not to mention the company also provided designed and installed access for 34 substantial chimney stacks.

Thanks to the large team of in-house Lyndon SGB designers in the UK – as well as further engineering support from leading global access provider BrandSafway’s Dutch and American team, and 50+ of the UK’s best and most highly skilled scaffolders, access across every nook and cranny of the Town Hall’s historic building structure has been provided.

The 42 lifts of the perimeter independent scaffolding rise to meet the Town Hall’s towering spires, enveloping the structure in a protective cocoon. At the same time, a 12,000 square metre roof – one

of the most complex temporary weather-protection roofs the industry has ever seen – tops it off and provides a protective shield against the elements.

“The roof was incredibly difficult and a highly technical phase for our in-house design team. We had a 300-tonne crane brought in and positioned in Albert Square to lift the roof up in sections,” says Lyndon SGB’s Contracts Manager, Craig Parry. “We did this to minimise our working at height and to not put our workers at risk.”

Parry also provided ScaffMag with some overall figures for the scaffolding project: more than 15,000 square metres of scaffold shrink wrapping was used and installed in-house, a colossal 1.5 million scaffold fittings were used across all structures, and a staggering 180,000-man hours were exceeded to complete all scaffolds. Impressive numbers, to say the least, that highlight the scale of the project and the incredible effort that has gone into preserving Manchester’s architectural gem.

Lyndon SGB Northwest Regional Manager Jon Cooke described the project as an “unbelievable team effort”. “It’s amazing when you get with a team that shares the same vision and passion, amazing things happen. This project will never happen again, not in our lifetime,” he said.

THE PERFECT TRAINING GROUND

With the sheer number and variation of scaffolds erected on the site, The project has provided the perfect training ground for apprentices and trainee scaffolders alike at Lyndon SGB. With a workforce of 1,100 across multiple branches covering the whole of the UK, the business currently employs more than 60 apprentices – 14 of which have been based on the Manchester Town Hall project for the last two years.

Trainee scaffolder Mark Davies, 26, who at the time of speaking in February was just about to complete his CISRS Part 2, said he loved working on the Town Hall project: “Yeah, I love it here. It’s right on my doorstep so it’s ideal, I am just gutted that I didn’t find the scaffolding trade earlier in my life.

I worked as a forklift driver previous to this job but feel like I have wasted the last five years. I wish I had started scaffolding after leaving school. This is the first job I have ever had where you’re given the opportunity to progress all the time.”

Scaffolder Michel Smith, who has worked for Lyndon SGB for around five years and has already gained his CISRS Part 2 with the firm, felt a sense of privilege to be working on the prestigious project and enjoys the trade immensely. “I love it,” he said, “it keeps you fit and its fun, and I think it’s really good for your mental health. People know it’s a physical job, but I don’t think they realise how technical scaffolding is.”

Lyndon SGB boasts a 90% rate of retaining its apprentices. But it wasn’t always like that, as Cooke explains: “Ten years ago we used to employ apprentices, and that was it, we didn’t do any more than that, but now we invest the time and nurture them and have committed 100% to it as a company.

“Within four weeks of an apprentice starting with us, we register them with a college if we think they are suitable; they work three months in our yard getting to know all the materials and complete a two-week foundation course with the college, who then give us feedback on each of them from the instructors and tutors. We don’t rush things,” he said.

“Everyone is different and learns at their own pace, but we support them every step of the way and provide the opportunity to progress all the time, and we are now reaping the benefits from it.”

As the Manchester Town Hall project progresses, the efforts of Lyndon SGB and its talented workforce have not only set a new standard in engineering but also served as an invaluable learning opportunity for the next generation of scaffolding professionals.

The legacy of this ‘once-in-a-lifetime’ endeavour will continue to inspire for years to come, as the iconic Town Hall is well on its way to being restored to its former place in the heart of the city and remain a symbol of Manchester’s proud history and a beacon of progress for the future.

“Yeah, I love it here. It’s right on my doorstep so it’s ideal, I am just gutted that I didn’t find the scaffolding trade earlier in my life.”

SCALING NEW HEIGHTS

From a tiny Portakabin to towering success, the Berry brothers’ Creator Scaffold Designs has defied the odds and carved a niche for itself in the world of scaffolding and temporary works. As they celebrate a decade of triumphs, ScaffMag explores the remarkable journey of two visionary siblings whose unwavering dedication and relentless pursuit of excellence transformed their bootstrap start-up into a leading national player

“Ican’t believe that it’s 10 years already,” muses Ryan Berry, one of the directors/founders of Creator Scaffold Designs and Temporary Works Consultants. And no wonder! It seems such a short time, but so much has happened to the company in that brief decade. It has grown from a couple of brothers working in a cramped Portakabin, to a leading national player in the field, operating out of a spacious office with a team of 18 skilled professionals handling some of the most massively complex projects in the country.

It’s a hard-earned progression for the Berry brothers, Ryan and Brad, who 10 years ago, on the last day of October, decided to cut the employment strings and strike out on their own, applying the limit state design approach to scaffold design that Ryan had become a leading expert in. While confidence and a little genius are requisite to starting out in any field, their working conditions made sure that they kept one foot on the ground. These days the popular image of a start-up is a state-of-theart office full of vaping hipsters dividing themselves between the workstation and the foosball table. The brothers’ tiny Portakabin couldn’t fit them and a football table. It could just about fit them and the layers of overcoats that they had to wear in winter, although they did get some breathing space in the hot summers as the thermally challenged Portakabin imposed the need to work in budgie smugglers and little else.

The Berry brothers, Ryan, Brad and Karl outside their new premises.

OPPOSITE: The Creator office is an upgrade to their previous Portakabin.

NEXT PAGE: The Creator team are expanding rapidly.

In those formative days they were geographically and personnel-wise constrained to getting work from the surrounding locality, but in no time at all there was more work knocking on the door than they could deal with between them. Anyone who has built a successful business knows only too well that exciting but daunting moment in its development when you have to make the decision to go all in. After all, up until then they only had to look after themselves, now they were involving other people and a lot of other peoples’ money.

So they moved to their two-storey headquarters in Rotherham and a blooming roster of staff. In the three years between 2014 and 2017, their workforce multiplied like a culture in a petri dish, growing from two to 12. If this turned out to be a flash in the pan, then it was going to be devastating to more than just Ryan and Brad.

There was no reason to worry on that front, for, by now, they had leapt almost

overnight from miscellaneous local gigs to massive ongoing national projects such as the restoration of the Houses of Parliament, the restoration of St. Paul’s Cathedral and, to all intents and purposes, the neverending behemoth that is the Sellafield Nuclear Decommissions Project. One look at the acres of scaffolding on the Houses of Parliament gives you an idea of the breathtaking scale of these works. Not that they would ever consider any job is too small for them. They are proud of their record of taking on any job, regardless of size, location or level of complexity. They are obsessed with providing customer satisfaction, regardless of the project. It’s that dedication that has seen their growing success.

It’s no wonder, then, that in no time at all those 12 became 18, and there’s no indication whatsoever that it will be stopping there. Oh, and not counting the six ‘production babies’ that have materialised on the way!

It’s a lot of growth and development

IN THE THREE YEARS BETWEEN 2014 AND 2017, THEIR WORKFORCE MULTIPLIED LIKE A CULTURE IN A PETRI DISH, GROWING FROM TWO TO 12

from a bootstrap start packed into just 10 years. Ten years of recurring profit from the off – an enviable record in any fledgling business. Even the Covid lockdown didn’t cause a stumble. Far from it – because the building industry was one of the few industries still operating, they found themselves deluged with orders.

It’s no wonder Ryan can’t believe that it’s been 10 years already. They haven’t even stopped to take a breath yet. Perhaps they should. From the look of things, the next few years might well be even busier.

A work of art

From the towering skyscrapers of London to the historical mansions of Kew, construction sites have long been an inconvenience and clutter for many. But a Hampshire-based company is reshaping the landscape, turning scaffolding into pieces of art and beauty. Daniel Norton reports

Lavastar, an award-winning UK sign company, is not only making construction sites more attractive but it’s also helping many scaffolding contractors expand their services portfolio and ultimately increase their business revenue.

Since establishing in 2015, Lavastar has been turning heads and winning awards. After only two years in operation, they were crowned the ‘Small Signmaker of the Year 2017’ – a testament to their unique approach and unwavering commitment to quality. However, their expertise isn’t just confined to the UK, as demonstrated when they scooped up the ‘Wide Format Project of the Year 2019’ award for their work on a popular retail store in Spain. This achievement further solidified their place as industry leaders, not just locally, but internationally.

“We initially made a name for ourselves by producing printed graphics hoardings on construction sites,” shares Ed Kelsing, Lavastar’s Founder and

Managing Director. “Then a job came up in London where they wanted graphics on both the lower-level hoarding and the upper scaffolding. We didn’t have a clue how to do it, but we said yes and figured it out. It was a case of picking brains and studying other projects which had been completed in the city.”

The benefits of building wraps are manifold. From a marketing perspective, they provide an unparalleled level of brand visibility. However, they also contribute to community wellbeing, with residents expressing appreciation for the screening of sites and the subsequent reduction of dust and noise pollution.

Lavastar’s portfolio boasts collaborations with leading construction companies and scaffolding contractors across the UK. Their recent project at Wakehurst Mansion Kew, a National Trust building steeped in history, particularly stands out. The graphics were produced by visual artist Catherine Nelson, and Kelsing is excited about this trend of incorporating more artistry into their work.

WE ARE NOW WORKING CLOSELY WITH A NUMBER OF CONTRACTORS WHO ADD OUR SERVICES TO THE PACKAGES THEY OFFER THEIR CLIENTS TO GENERATE MORE REVENUE

NEW REVENUE STREAM FOR SCAFFOLDING CONTRACTORS

But Lavastar isn’t just about making construction sites look good. They’re also about helping scaffolding contractors make more money. With an in-house design team, Lavastar manages projects from start to finish, offering services like CGI renders of the original facade or new developments. This level of visual quality has become increasingly popular, and Lavastar is committed to ensuring they deliver the highest quality.

“We are now working with a number of national scaffolding contractors who work closely with us and add our building wraps/hoarding services to the packages they offer their clients to generate more revenue,” Kelsing explained.

This is a significant shift in the scaffolding industry. Traditionally, contractors have focused on the practicality of their work, ensuring that buildings are safe and accessible. But with Lavastar’s innovative approach, they can now offer an additional service that enhances the aesthetic value of the construction site, thereby attracting more clients and revenue.

Lavastar is a testament to the power of creative thinking and innovation in transforming industries. Whether you’re a construction company, scaffolding contractor, or simply a passer-by, it’s hard not to appreciate the ‘wow’ factor that Lavastar brings to the table.

For scaffolding contractors looking to expand their services and increase their revenue, Lavastar seems like a bright opportunity.

To find out more about their services and how you could potentially collaborate with Lavastar, reach out to their team. As they continue to redefine construction sites across the UK, one can’t help but wonder: what will they wrap next?

www.lavastar.co.uk

journey A remarkable

In an exclusive interview with the Former CEO of the TRAD Group, Des Moore reflects on a lifetime in the scaffolding industry

Des Moore, a true industry veteran and a prominent figure in the scaffolding business, has recently announced that he will step down as CEO of the TRAD Group. With an illustrious career spanning over 30 years, Moore has played a pivotal role in the growth and success of the company he served.

In this candid and insightful interview, ScaffMag delves into Moore’s humble beginnings, his transformative tenure at the TRAD Group, and his thoughts on the future of the scaffolding industry.

Q: You’ve had a remarkable career in the scaffolding industry and as the CEO of the TRAD Group. Can you remind our readers what initially attracted you to the industry?

A: I left school at 15 and went into a few labouring jobs, including at R Whites Lemonade and as a market trader. I ended up stacking bags of sugar as they were packaged at Tate & Lyle. One of my brothers also worked at Tate & Lyle

in the maintenance team, which brought in scaffolding contractors for large projects. He challenged me to get us both a job with one of the contractors, and so I did – I have never worried about being up front and asking for things!

We started with Mills Scaffolding, working on the support scaffolding for the bridges over the M11, which was being constructed at the time. My first job was nailing base plates into timber deals – all day long. So, like many people in the industry, I fell into scaffolding, really. It was good money for hard work – something that’s been part of my approach to life since I left school. I was determined to do well and, although my first manager wouldn’t let me go on a scaffolding course, I eventually managed to get on one, so I could advance my career. Ironically, I later employed that manager in a business I worked in – and unfortunately had to let him go – not out of spite, but because of poor performance.

Q: Throughout your tenure, TRAD Group has seen substantial growth.

What do you attribute this success to?

A: I think it’s down to having a complete focus on getting the job done. Focus, dedication, persistence, hard work and a great team. Over the past 30+ years – which I’ve worked out is 12,195 days, or 288,000 hours or 17,280,000 seconds – I have lived and breathed TRAD. My family will tell you that I never really ‘finished’ work for the day, or even for a holiday. I was always thinking about what I could do to improve TRAD, to build more business and drive more successful results. My family has always come first, but TRAD has been a very close second.

Q: In your opinion, what are some of the most significant changes you’ve witnessed in the scaffolding industry since you started?

A: When I joined the industry, it was dominated by large national companies, like SGB, Palmers, Deborah Grayston and GKN Mills. These businesses are now either completely gone or have been merged with or bought by other companies. The make-up of the market is now more about large regional players, giving local service but with the buying and service capabilities of large businesses. I think TRAD was one of the companies that led this trend, together with the likes of D&R Scaffold Group and Lyndon Scaffolding.

A clear improvement since I started working in scaffolding is in health and safety. It was practically non-existent when I began, compared to the excellent progress and procedures we have now – in part, brought about by the NASC. It has now rightly improved beyond all recognition, and there is still much to do across the industry as a whole, including with mental health, which I

believe still needs a bigger spotlight. This focus on safety and a professional approach is one of the reasons why scaffolding is now seen as a skilled trade, rather than semi-skilled.

Q: What do you think has been your greatest challenge as CEO of TRAD Group and how did you overcome it?

A: Every day is a challenge in one way or another! In fact, I worry if there are no challenges on the horizon. If you just sit there thinking everything is fine, you’re not looking for where the next challenge or problem will be – but it is always there. I never want to stand still or be complacent. So, the more challenges, the better. Someone in TRAD once referred to this as ‘critical unease’, and that’s exactly what it is.

Q: Could you share a pivotal moment in your career that significantly impacted the course of TRAD Group’s future?

A: It would have to be the merger of the various TRAD companies. Like many other businesses of its size and type, TRAD Scaffolding was not consistently cash positive. I joined the business in 1991, at the heart of a hard recession and businesses were folding all over the place. After working to build what was then Sevenhurst into the business that became TRAD Scaffolding Systems, I came up with a business plan to merge that with the existing TRAD business.

That merger created a strong and robust financial platform that enabled TRAD to become a major force in the UK scaffolding industry and allowed us to generate enough cash to invest in

a new business – TRAD Hire & Sales to begin with and then TRAD Safety Systems. This set the foundation for the TRAD Group as it is today.

Q: What is your proudest achievement as the CEO of TRAD Group?

A: My proudest moment was being made Managing Director of TRAD Scaffolding, and, of course, a significant personal and professional achievement was working with Hayden Smith on the sale of TRAD Group to the international Altrad Group in 2013, navigating a very stringent and rigorous due diligence process.

I was also delighted to be invited to be a Director of the NASC, and subsequently President, which allowed me to start some important conversations in the industry and also to work with a great team of people.

Q: How do you envisage the future of the scaffolding industry? What trends or advancements do you see on the horizon?

A: I think that modular scaffolding is the way forward. It’s easier to erect, very safe, adaptable and I think there is more innovation to come in that area, from the various original modular scaffolding systems manufacturers that operate in the UK today.

I’ll also be interested in keeping an eye on powered access, such as mast climbers. Although they have been around for a number of years, in my view they have still to capture a significant percentage of the market – and I suspect they will. It will be interesting to see how that can transform the way the industry works.

Q. We know you’re not stopping work – can you shed some light on your future plans?

A: I’m definitely not stopping work.

I want to use my skills and experience to support businesses through nonexecutive director roles, advisory boards and consulting services. I have set up a business – MOR1X Management and Consultancy Services – to do this and anyone who wants to explore using my services can contact me on des@mor1x.co.uk or connect with me on LinkedIn. I’m currently not actively looking for another full-time opportunity, but I have always been up for a challenge, so who knows?

Q: Finally, what’s the legacy you hope to leave behind at TRAD Group, and how do you want the company to remember your tenure?

A: I don’t really think of things in terms of a personal legacy – for me, it’s about what the business has achieved. But I’d like to think that I’m recognised as someone who really cared about TRAD and was very passionate about wanting the best for

the people working there.

I’ve definitely taken some hard decisions during my time, but they have always been to protect the business and the jobs of the majority. Being a leader means being prepared to take those decisions, and being transparent and fair about them. Sometimes, they weren’t right, but they were always done for the right reasons.

TRAD being recognised today as an industry leader, with great feedback from customers, suppliers and the wider industry, is really important to me. I feel that TRAD has created an environment that has allowed other scaffolding companies to raise their own game – it’s always been critical to me that we support our customers to be successful and profitable, rather than just concentrating on our own success. I have loved my time in the scaffolding industry, and I intend to remain involved as I move into a new stage of my career – hopefully, one more final challenge to come!

In conclusion

Des Moore’s journey from humble beginnings to the helm of the TRAD Group stands as a testament to hard work, perseverance, and an unwavering commitment to excellence. Through his transformative leadership, TRAD Group has emerged as a leading force in the scaffolding industry, leaving an indelible mark on the market.

As Moore bids farewell to his role as CEO, his dedication to the industry remains resolute, as he prepares to embark on a new chapter focused on sharing his expertise and supporting businesses. His legacy at TRAD Group will be defined by his passion for the company, his unwavering commitment to the wellbeing of its people, and a relentless pursuit of success.

“Every day is a challenge in one way or another!

In fact, I worry if there are no challenges on the horizon. If you just sit there thinking everything is fine, you’re not looking for where the next challenge or problem will be.”

EASIER. SAFER. SMARTER.

As an industry-leading provider for scaffolding and construction safety products, TRAD UK has always championed innovation. Our extensive range sets new standards for access equipment and safety systems.

Our efficiency and safety is matched by the highest levels of service delivered by our experienced team and nationwide support network of depots. So it’s easier than ever to find the right solution for your project.

INTRODUCING THE NEW TRAD LIFT SHAFT GATE

TRAD Lift Shaft Gate provides the ultimate safety solution for one of the most dangerous areas of any multistorey construction project – lift shafts.

Fully compliant with BS EN 13374 and BS 7255, the TRAD Lift Shaft Gate provides edge protection and multiple containment options for lift shaft openings, while its unique 30kg aluminium design allows easy installation by just two operatives working within manual handling guidance.

The TRAD Lift Shaft Gate boasts a double ‘stable gate’ so the top half of the gate opens independently, allowing access whilst still providing edge protection, while the gate can also be locked when access is not required. The TRAD Lift Shaft Gate is designed to fit a standard 1.2m lift shaft opening, with panels of various sizes which can be fitted to the sides to increase coverage for larger lift shaft opening.

Features and benefits:

Fully compliant with BS EN 13374:2013+A1:2018 Class A and BS 7255:2012 standards for safety

Lightweight 30kg aluminium design for easy installation

Boasts a double ‘stable gate’ for easy access while still providing edge protection

The gate can be locked when access is not required

Fits standard 1.2m lift shaft opening, and can be easily extended with additional panels for larger openings

Available for hire and sales

STEAMING AHEAD IN RAIL

Billy Jones, Managing Director at Millcroft, explains the role diversification plays within scaffolding as the company continues to expand into new markets

No one in construction can sit back and become complacent as we ride through some choppy waters in our economy. We experienced the sharp decline in the market in 2020 due to the global pandemic and although the scaffolding and access equipment sector grew by 11% the following year (according to AMA Research) none of us can afford to rest on our laurels. Facing such headwind and coming out the other side of the pandemic was a really important time for the entire industry to get work going again, as we also faced other major challenges including the energy crisis, inflation and the war in Ukraine.

This is why, as a sector, diversification is key when it comes to survival and success – a concept we align with at Millcroft thanks to our 50 years in business and experience within multiple niches. Diversity of our projects has a big role to play within our business – not only does it reduce risk from a revenue point of view, but it means we can continue to grow and expand into new areas.

RAIL AND HS2

One area we have come to specialise in over the years is the rail sector. We’ve worked with TfL for 40 years, as well as Crossrail and, more recently, have become a preferred specialist contractor for HS2. As the biggest rail project in Europe and the most important UK infrastructure investment in a generation, this is a key area for business growth as plans to expand the network across London and beyond continue to evolve.

ON SOME OF OUR PROJECTS, THANKS TO OUR HIGH STANDARD OF TRAINING AND COMPETENCY, OUR OPERATIVES BECOME PART OF THE RESCUE TEAM FOR THE ENTIRE SITE.”

In the last couple of years, the team at Millcroft has come up against some strong competition to win a number of frameworks in and around London. This includes a five-year programme of scaffolding works for HS2 in central London involving design, installation, adaptations and project management of access and safety scaffolding requirements across eight different terminals on the route.

We were also chosen as the specialist scaffolding contractor for the second phase of a multi-million-pound contract to provide temporary works infrastructure, acoustic and public protection screens, and all required access and containment solutions to support the main contractor, Skanska, in delivering the enabling works at London Euston to facilitate the construction of the new HS2 Euston Station.

Other recent rail infrastructure projects include scaffolding works to support the construction of the piers for the Colne Valley Viaduct as part of HS2 Phase One, along with projects at Liverpool Street Station, Whitechapel and the Elizabeth Line, Paddington.

To meet the demand in growth and the scope of the HS2 work, we have opened a secondary office and scaffolding yard in Acton where a dedicated Millcroft HS2 team of around 40 employees (and growing!) manage the work. We’re investing in new fleet and materials all the time – most recently a new electric forklift truck – to efficiently service this side of the business, and we are always on the lookout for new talent to join our team here.

MISSION CRITICAL REQUIREMENTS IN RAIL

Having an experienced and knowledgeable team on board is crucial to meeting the strict health and safety criteria within such a demanding sector, and this starts with effective communication and clear briefing. Both the Euston HS2 and Elizabeth Line, Paddington projects, for example, are major infrastructure improvements that take years to deliver and require existing rail services to operate safely and efficiently throughout.

Developing the right solution is a collaborative process, which looks beyond the brief to provide the most effective and safe response to the project. This includes considering the phasing of the project, safety factors such as live lines, public access and segregation of the work area, and the flexibility of the scaffolding to enable both planned and unplanned adaptations.

With any project that’s delivered over a number of years, it can involve some change of scope during the works. This is why the communication across the scaffolding and client teams needs to be candid and effective to ensure an agile response when required.

HEALTH AND SAFETY

It goes without saying that meticulous health and safety protocols, appropriate accreditations (from ISO to FORS to ROSPA) and continual training are key in our game. All scaffolding sites require best safety practice and reporting

to be embedded in site routines and the right mix of skills on site; that’s a given. But in the rail sector, training related to the specific risks of the environment and toolbox talks to maintain a clear focus on health and safety are even more important.

A lot of our rail projects involve working in live, highvoltage environments, tunnels and confined spaces, resulting in the need for rescue-at-height training and safety training for operatives working close to the live line, too. On some of our projects, thanks to our high standard of training and competency, our operatives become part of the rescue team for the entire site.

TICKET TO SUCCESS

The establishment of a dedicated Millcroft team and site in Acton is just the latest development in a sector which is an important part of our portfolio. We thrive in these highly controlled, precise environments, where we can really put our technical know-how, skills and processes to best use.

As a company, we continue to aspire to the highest of standards and our growth and strong commercial results are down to the hard-working team we have at Millcroft. We’re only as good as the last job we did, so we make sure our focus is on delivering to the best of our ability each and every time.

TEAMWORK

Ludwigshafen, Germany –KEWAZO, a leading construction robotics company, has recently piloted its lifting robot together with BASF at the world’s largest chemical plant in Ludwigshafen, Germany. A unique lifting solution was needed for a disassembly project with specific safety requirements. The project involved dismantling a recently constructed flake, which was encased in a 52m-high scaffold located in an ATEX zone.

The traditional lifting solutions, such as material hoists and cranes, required a lot of space and a constant power supply, which could not be provided without influencing the production capacity. This posed a significant challenge as the onsite space was limited, and production was always running, with trucks and vans passing through.

To address these challenges, KEWAZO’s LIFTBOT, a wireless and completely battery-powered material lifting robot, was used. LIFTBOT could be applied even in an ATEX zone with a hot work permit. Within two hours, LIFTBOT and 50m of rails were installed. By offering a rotatable transport platform, scaffolders were able to securely load and unload materials without the need for bending over, effectively minimising the risk of falling parts.

The collaboration between KEWAZO and BASF is a perfect example of how start-ups and corporates can work together to tackle industry problems such as labour shortage, safety and efficiency by bringing the latest innovations onsite. With KEWAZO’s innovative solution, the disassembly project was completed without any interruption to production.

The success of the pilot project was acknowledged by all parties involved, including KEWAZO, BASF and the scaffolding assembly contractor Nachbauer Geruestbau. The scaffolders reported feeling less fatigued, while the HSQE department noted a significant increase in safety at every stage of the project.

KEWAZO’s cutting-edge technology gives industrial service providers and scaffolding assembly subcontractors a powerful advantage over its competitors. The joint project between KEWAZO, BASF and Nachbauer demonstrates the importance of innovation and collaboration in addressing industry challenges. By leveraging the latest technologies, companies can achieve better results while improving safety –thus increasing productivity.

https://youtu.be/CmsA53K4GdY

LIFT ME UP T

RAD UK has announced the launch of its all-new lift shaft gate – an easy-to-install, lightweight aluminium design that is completely customisable to construction needs.

Fully compliant to the latest safety standards – BS EN 13374:2013 + A1:2018 Class A, and BS7255:2012 – TRAD’s lift shaft gate is available as a standalone single gated system, or can be supplied with a range of panels and fittings to cover lift shaft openings with standard configuration widths from 1,000mm to 2,900mm. The system can be recessed into lift shaft openings, surface mounted, or provide boxed-off protection, with areas wider than 2,900mm being possible with consultation from TRAD UK’s Technical Department.

Weighing just 30kg and made from strong, durable aluminium, the gate can be easily installed by just two people, and features 150mm toe boards and 10mm diamond mesh to prevent debris from falling through the system. A full Yale lock is fitted to the top door and the gate can be opened from the inside without a key. An additional safety feature is a fixed sliding bolt to the lower door, which can only be released if the installer has

the Yale lock key. All of these features are designed to improve both security and safety on site.

“Like all TRAD products, the updated lift shaft gate has been designed by people with extensive site experience,” says Alan Slater, Head of Technical and Product Support at TRAD UK. “Our lift shaft gate system uses the latest design technology to create a fully modular system. The system is lockable by key, however, exiting from the lift shaft is made simple, ensuring that site workers are always safe, secure and that egress in the case of emergency is a straightforward operation.”

You can find out more about this revolutionary product on the TRAD website www.products.traduk.co.uk/lift-shaft-gate

TRAD UK has just launched the all-new lift shaft gate. The upgraded product is to deliver the ultimate safety solution for multi-storey construction projects

UKSSH: The UK’s leading Haki Systems Specialists Hire or buy with total confidence

PUBLIC ACCESS STAIRCASES

PUBLIC ACCESS BRIDGES

WEATHER PROTECTION

TEMPORARY BUILDINGS

TEMPORARY ROOFS

HAKI SYSTEM

SUSPENDED

SITE STAIRCASES

TRIPODS

UKSSH are there to support you every step of the way.

With over 150 years of collective knowhow and experience, substantial stocks and a commitment to excellence, you can trust UKSSH to get it right every time.

To find out more visit www.UKSSH.co.uk

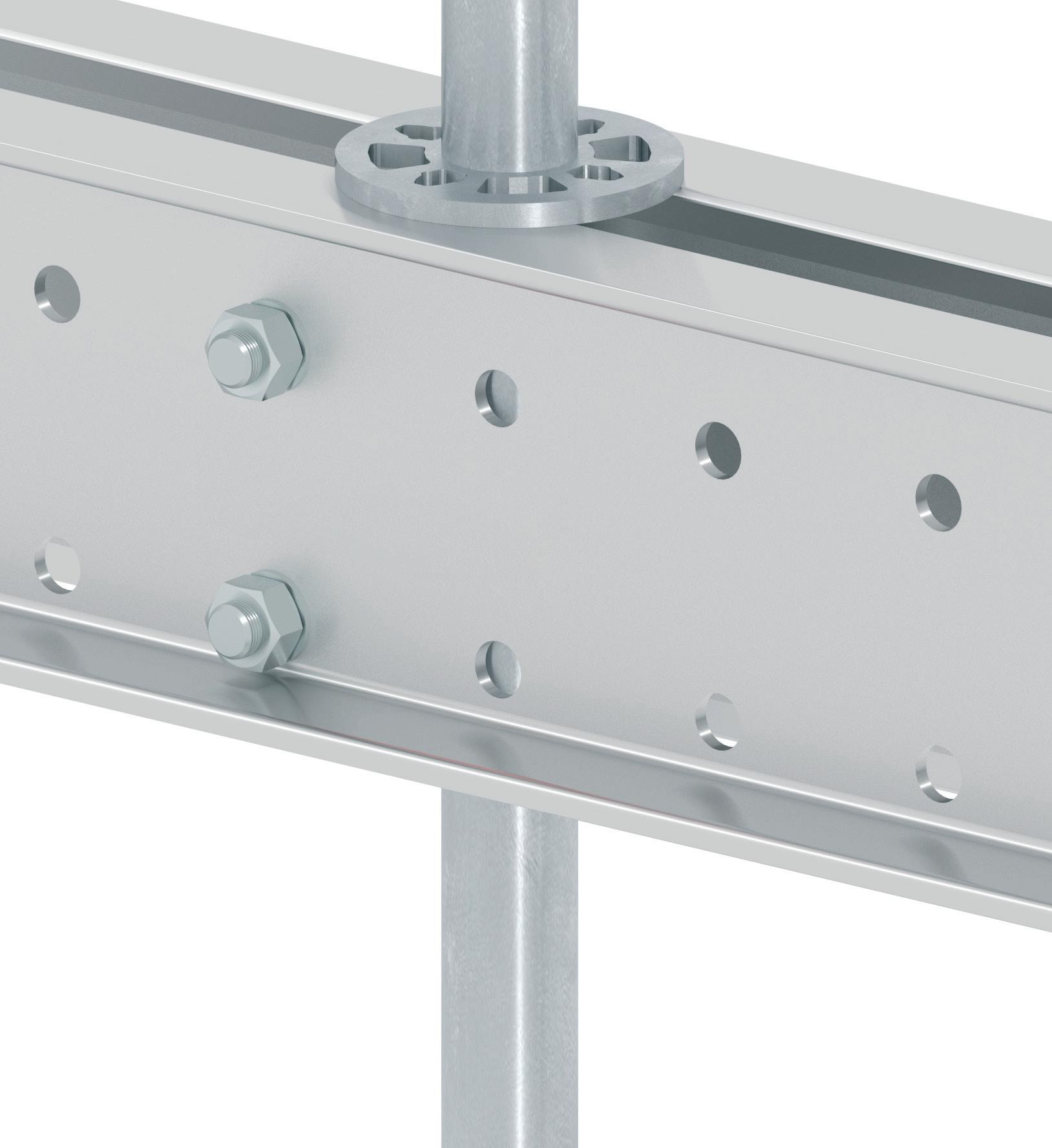

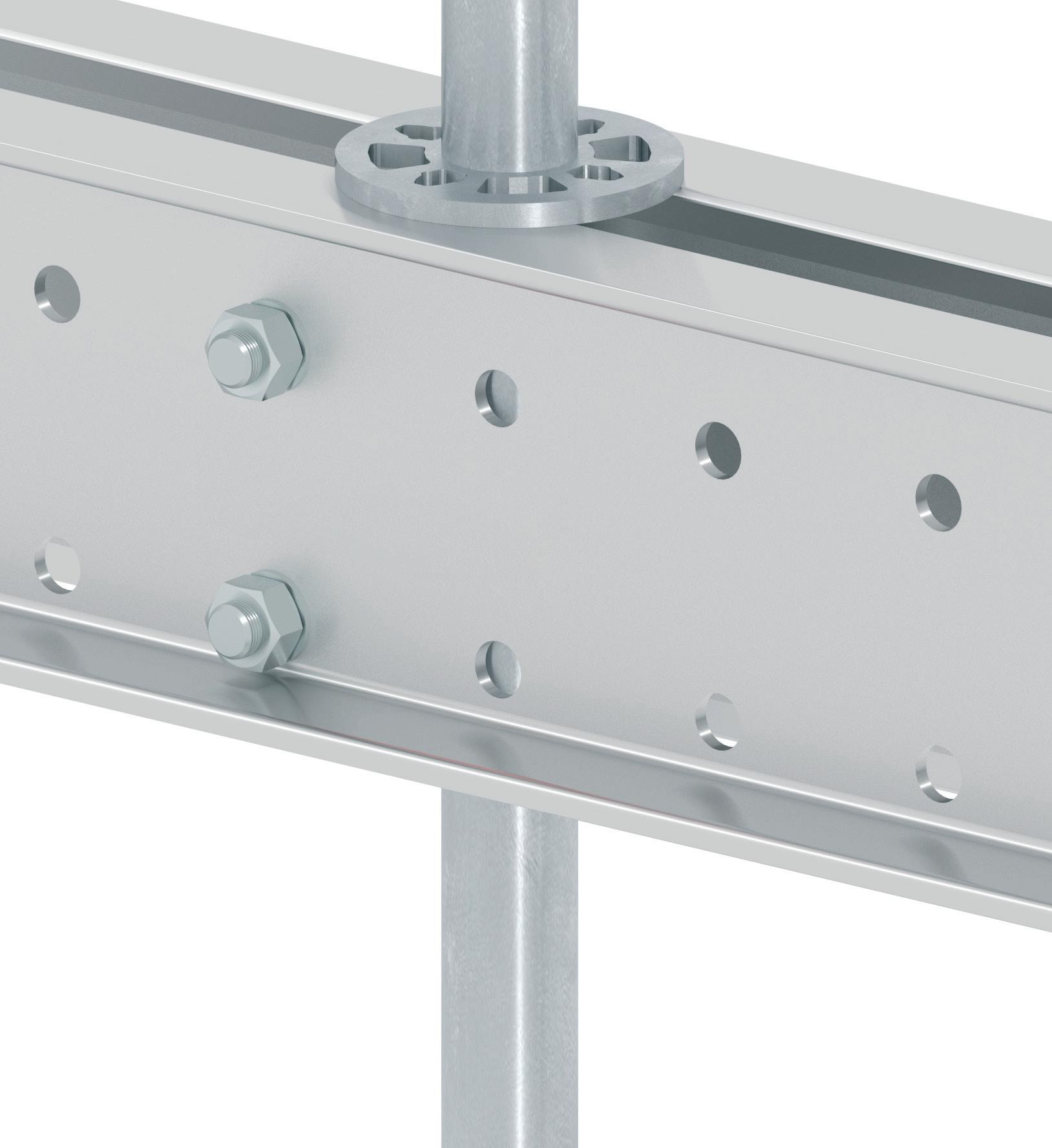

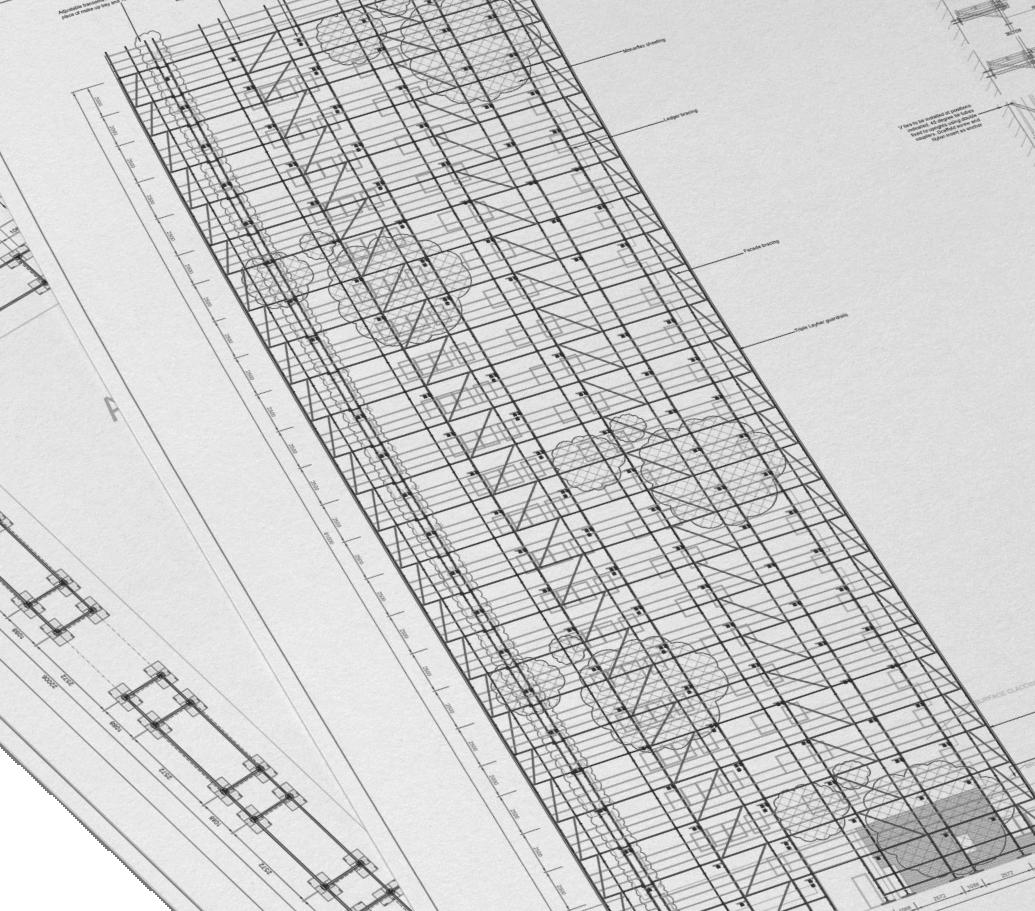

AT-PAC Ringlock Modular Scaffold System sets new standard for Connolly Scaffolding Ltd

SETTING SUN

In the third quarter of 2022, AT-PAC partnered with Connolly Scaffolding Ltd to provide a comprehensive scaffolding solution to perform the refurbishment works of Thorn Court, one of the largest residential buildings in the Pendleton estate, which dominates the Salford skyline.