Brief report

Authors: Rita Hofman, Christian Holzner, Hans-Peter Meyer, Nicole Wettstein

27. August 2024 in Bern

Background and course of the SATW discussion forum

Since the first successful oil well was drilled in Pennsylvania in August 1859, oil and gas have been the foundation of transport by sea, land and air as well as the foundation of organic chemistry. These two value chains, fuels and chemistry, are closely interlinked. The defossilisation that is necessary for climate protection and resource scarcity, among others, and the resulting unavoidable intervention in these interlinked value chains has the potential to cause major upheavals, especially during a transition phase. The prices of oil commodities are likely to rise because the demand for combustibles and fuels is decreasing Therefore, less is being invested in their extraction and production. On the other hand, the proportion of Naphta going into chemicals, will continue to increase.

The chemical industry is a major source of greenhouse gas emissions, particularly through the use of fossil raw materials such as crude oil and natural gas as an energy source and as a starting material for the production of chemical products. The carbon contained in chemical products contributes to emissions at the end of their life cycle. However, these emissions can be at least partially reduced by switching from a linear to a circular raw material turn over. There are mature and marketable alternatives for combustibles and fuels, such as electrification or synthetic energy sources based on the use of photovoltaics, hydropower, wind power, geothermal energy or, in the future, new types of nuclear power plants. Organic chemistry is absolutely dependent on carbon and can thereforeunlike energy - not be decarbonised, but defossilised, i.e. converted to renewable carbon sources. For organic chemistry, which is the basis of many industrial processes, there are three approaches to defossilisation:

(1) Reducing raw material consumption, closing material cycles and recycling,

(2) Biomass as source material,

(3) Use of CO2 as a raw material through Carbon Capture and Utilisation (CCU).

In order to achieve climate neutrality and at the same time ensure long-term resource security, the most comprehensive defossilisation possible is required. All three approaches will have to be utilised in the future. There is also increasing social pressure on companies to operate more sustainably. Defossilisation would improve the generally poor image of the chemical industry and strengthen public confidence. Last but not least, the development of defossilised sources of value creation offers a major competitive advantage for innovative companies in the medium to long term. Switzerland could play a pioneering role here and open up new markets.

All areas of the chemical industry are represented in Switzerland, from raw materials trading, basic and petrochemicals to the production of specialty and fine chemicals, as well as pharmaceuticals, and the country is therefore predestined to lead the discussion on suitable ways to defossilise the chemical value chains and develop solutions.

To support these processes, SATW organised a discussion forum in Bern on 27 August 2024 with 21 invited participants from industry, research associations and administration. Three keynote speeches by representatives from the gas supply, chemical and pharmaceutical industries laid the foundation for lively and informative discussions. These highlighted the opportunities and risks of defossilisation, as well as expected changes in the environment. They also discussed which alternative raw materials could be used, which adjustments to the legal requirements appear necessary and where and in what form cross-industry cooperation would appear to make sense.

The main findings of the forum are summarised in the following sections. Finally, the SATW's next steps for dealing with the topic are proposed.

Reducing and recycling raw materials

The chemical industry has been reducing and recycling for a long time and should continue to promote this, if only because it makes economic sense. In addition, however, the use of biotechnology (biocatalysis instead of chemocatalysis) in the chemical industry, especially for the production of structurally complex and optically active molecules, must be accelerated in order to reduce the use of resources. However, solutions for reducing and recycling were not discussed in any depth at the event.

Biomass

The use of biomass for chemicals is only possible to a limited extent for various reasons. For example, the availability of arable land and biomass is limited globally. In addition, biomass is overfunctionalised compared to fossil raw materials and requires a different type of refinery. Furthermore, the available biomass is very heterogeneous. It can be assumed that there will be no competitive non-fossil basis for most basic chemicals in the foreseeable future. The situation is different for higher-value products (pharmaceuticals, fine and specialty chemicals, cosmetics, etc.) where second and third generation bio-based solutions may well be competitive.

Carbon dioxide as a raw material

Using carbon dioxide captured from the atmosphere or from plants with high emissions as a raw material (CCU) could kill two birds with one stone: on the one hand, it helps to protect the climate and, on the other, it allows a non-fossil raw material to be obtained. This approach should be a focus for defossilisation. However, the capture of CO2 is still too expensive and needs to be optimised. Hydrogen is also required for the production of hydrocarbons from CO2 However, the import possibilities or production of sustainably produced and cost-effective hydrogen in large quantities are not yet foreseeable in Switzerland.

Everyday life in the chemical industry

The prices for sustainably produced chemicals are currently far too high, while those for fossil-based chemicals are too low because the costs of greenhouse gas emissions are not fully included in the latter. For this reason, current efforts to defossilise are limited to those industries and companies that have an intrinsic motivation and the financial means to do so.

For the reasons mentioned above, large quantities of platform chemicals can only be partially biobased. Chemical defossilisation must therefore be achieved via recycling or CCU. A large proportion of Swiss chemical companies produce pharmaceuticals and fine chemicals in low tonnages. For such companies, consumables, packaging and transport often represent the greater greenhouse gas emissions than production. Due to the relatively small quantities, these raw materials can be converted relatively easily to renewable sources and sustainable processes.

The pharmaceutical industry and fine chemicals are also characterised by lower quantities and overall lower CO2 footprints of the products compared to petrochemicals and basic chemicals.

However, organic chemistry in this industry has the problem of high E-factors (mass ratio of the waste to the desired product) and high PMI (Process Mass Intensity) values.

The implementation of biocatalytic process steps for complex and optically active compounds, the targeted use of third-generation biomass (microorganisms and algae cultivated in special plants) as a raw material, combined with circular economy approaches, have great potential for innovative solutions.

These aspects were illustrated using the example of a globally active Swiss pharmaceutical company: staff air travel is the largest CO2 emission item in this company and sustainable aviation petrol is used to offset this. In the actual pharmaceutical value chain, on the other hand, the demand for plastics for medical devices, laboratory materials and packaging are very high. The carbon equivalent in the plastics used by the company can far exceed the direct CO2 emissions from production and those from purchased energy. The awareness that plastics represent the greatest lever for defossilisation at pharmaceutical companies has led to the formulation of best practice rules and criteria for handling and purchasing sustainable raw materials. However, such internal company guidelines may not be passed on to other companies for antitrust reasons.

In the discussions at the forum, reference was made several times to third-generation biomass as a promising raw material. Products made from it can fulfil the EU's Single Use Plastics Directive, which bans disposable plastic products from 2030. In general, the participants mentioned "green molecules from third generation biomass" as one of the viable and necessary paths for defossilisation. The utilisation of "indigenous" gases such as methane from biogas plants and captured carbon dioxide is also being discussed.

The energy supply and potential of hydrogen

Defossilisation is a key issue for Swiss gas suppliers, and they are working intensively with renewable gases, in particular biogas and hydrogen. Other energy sources synthesised from hydrogen are hardly being considered at present.

In Switzerland, biomass is used as a raw material for biogas production in the energy sector as well as in the chemical industry. As in the chemical industry, a mix of biogenic raw materials is unfavorable. The production processes work best with consistently homogeneous biomass. This is why many biogas plants are connected to WWTPs, which provide a suitable source material. Another functioning biogas model is the utilisation of agricultural waste, for example pig manure, if the transport routes allow efficient use of this waste in a regional biogas plant. Today, large biogas plants can produce biogas at prices competitive with natural gas. Biomethane currently covers a good 9 per cent of Swiss gas consumption, with only around a fifth being produced domestically. Gas suppliers assume that the potential for biomethane production in Switzerland will be 9 times higher by 2050; there would not be enough raw materials to fully supply the country with renewable methane. One advantage of biomethane is that, unlike hydrogen, it can be fed into the existing distribution network. The chemical industry needs cheap, renewable energy, especially for the generation of hightemperature heat, and green hydrogen (from electrolysis with renewable electricity or steam reformation of biomass) can be part of this solution. According to gas suppliers, hydrogen (H2) can become a competitive energy source and make a key contribution to security of supply in Switzerland if it can be imported cheaply and the necessary infrastructure is in place. An H2 transport network is being established in Europe, but Switzerland's connection has not yet been finalised. It also needs to be clarified in what form H2 can be transported and stored most efficiently, possibly using derivatives such as ammonia (NH3) or other synthetic liquid hydrocarbons (liquid hydrogen carriers, LHCs).

Economic and political uncertainties are hampering the development of green H2 production in Switzerland. Because H2 can be produced cost-effectively using electrolysis in sunny countries such as Oman, imports compete with domestic production if it can then be transported efficiently. Today, the majority of hydrogen is produced from natural gas and methane pyrolysis as a source of hydrogen is a new but not yet scalable technology that could significantly improve the carbon footprint of fossil H2 production.

Overall, politicians are reluctant to adopt a Swiss hydrogen strategy, partly because there is little pressure from industry, even though hydrogen is an important raw material for the chemical industry. In any case, Switzerland should link itself closely to the planned European hydrogen network and plan the corresponding infrastructure.

The challenges of regulation and opportunities for Switzerland as a business location

Regulations are needed that allow for the correct measurement of fossil fuel emissions and cost transparency across entire value chains. However, the forum participants also agreed that regulations and lengthy authorisation procedures due to objections, particularly in Europe and Switzerland, can also hinder the conversion and expansion of the industry.

Clearer framework conditions and cost transparency regarding greenhouse gas emissions and sustainability criteria are desired. In particular, there is no generally accepted definition of sustainability, but this should be a criterion in public tenders.

The Swiss financial industry has a great deal of leverage to promote defossilisation in all areas. Nevertheless, there are too few financial products that prioritise sustainability and the valuation bases are inadequate.

Defossilisation and drug shortages

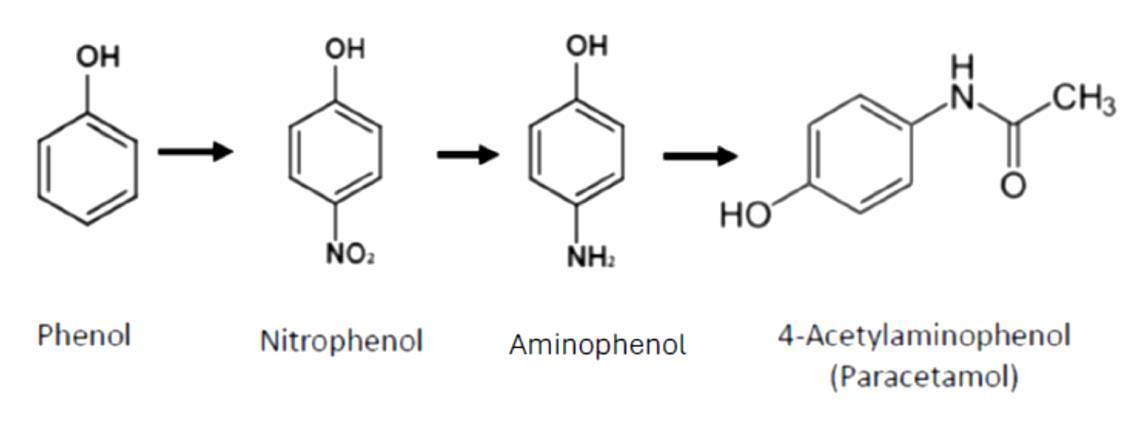

The example of the painkiller paracetamol shows that defossilisation is also directly related to the shortage of medicines. Switzerland requires 190 tonnes of the chemically produced generic paracetamol per year. The illustration shows the steps involved in synthesising the drug from the fossil raw material phenol from the petrochemical industry.

During and after the pandemic, politicians also encouraged production in Switzerland. The resettlement of such production facilities is difficult for many reasons: individual process steps are prohibited in Switzerland or Europe using current processes or are not competitive with large-scale facilities in other regions of the world, and above all, production remains dependent on raw materials and intermediate products from fossil sources. There are no advantages in terms of security of supply and sustainability if only the final process step is brought back to Switzerland.

The above-mentioned reasons can only lead to the conclusion that a secure supply of paracetamol and other generics can only be achieved in cooperation with other countries. On the other hand, the necessary and actively pursued defossilisation offers socio-economic advantages, forces diversified supply chains, better processes and drives innovation for new processes and raw materials (e.g. biobased, carbon dioxide).

Next steps

The SATW intends to pursue the topic of "defossilisation" further. The network of interested stakeholders from the first forum will be further involved and expanded for this purpose. The following activities are currently planned:

A next discussion forum is planned for early 2025 and will focus on a specific aspect of defossilisation, such as carbon capture and utilisation / storage (CCU / CCS) and the use of byproducts from hydrogen electrolysis (oxy-fuel technology). One key question could be: "How can Switzerland play a profitable pioneering role with sustainable production and products?"

In preparation for the next forum, the SATW will also exchange ideas with its national and international partners on questions such as: "Where is innovation most important?", "What are the directions for Europe?", "What problems do all players have?", "How can greenwashing be prevented (e.g. with life cycle assessments)?".

Politicians and the public are not sufficiently aware of the current achievements and challenges of defossilisation. For this reason, case studies from practice are being sought and documented to better sensitise people to the topic.

In the longer term, the activities should aim to strengthen the coordination of the relevant players in the defossilisation of the chemical industry in Switzerland and to examine by whom and in what form a permanent cooperation ("network") could be established.

In its network, SATW is discussing the development of interconnected structures (technical infrastructures) for green electricity, hydrogen, CO2, and other components of a sustainable energy and raw materials supply in Switzerland

About the SATW

The Swiss Academy of Engineering Sciences SATW is the most important network of experts for engineering sciences in Switzerland and is in contact with the highest Swiss bodies for science, politics and industry. The network is comprised of elected individual members, member organisations and experts.

On behalf of the federation, SATW identifies industrially relevant technological developments and informs politics and society about their importance and consequences. As a unique expert organisation with high credibility, it conveys independent and objective information on technology – as the basis for establishing well-founded opinions. SATW also promotes the interests and understanding of technology in the population, including young people in particular. It is politically independent and non-commercial.

SATW Swiss Academy of Engineering Sciences SATW St. Annagasse 18 | 8001 Zürich | +41 44 226 50 11 | info@satw.ch | www.satw.ch