3 minute read

In-Space Manufacturing & Assembly

In-Space Manufacturing and Assembly

Overview

Advertisement

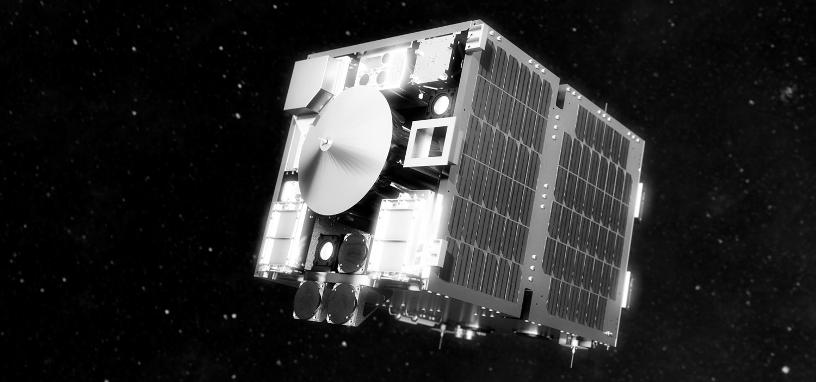

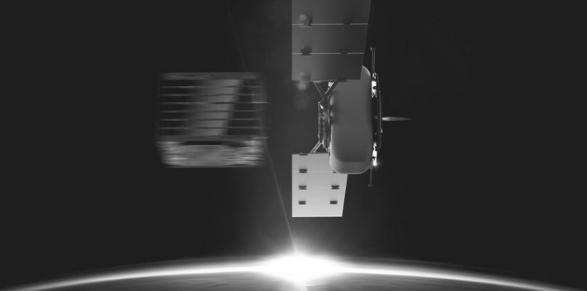

In space manufacture refers to creating spacecraft or other assets in orbit, rather than on the ground. This includes assembly of large structures, such as the International Space Station, and additive manufacturing in space. This could be used for assembling spacecraft larger than a rocket fairing will allow, or augmenting the capabilities of smaller spacecraft, by creating larger solar arrays or antennas. Drivers for such activity include lunar missions, large space antenna supporting satellite phones, remote additive manufacture or specialist products made in micro gravity.

Market size

For the augmentation of smaller satellites, the market size would be all satellites that require large amounts of power or large antennas. This includes telecommunication satellites and radar satellites. For very large spacecraft missions, the market is small and dependent on these single missions. In the short term, revenue will be from earth-based R&D and the operation of testbeds as well as development of enabling technologies such as vision systems. There is a clear path for opportunities in constellation manufacture, launch and on-orbit servicing through to inspace manufacture and construction as new materials, techniques and concepts develop. The work of CASIS and others in exploiting the International Space Station (ISS) has set the baseline. The CASIS portfolio of projects has leveraged more than $100m from non-NASA and non-CASIS sources.

Market drivers

If developers of these technologies can prove that it augments the capability of current spacecraft designs, it is more likely to be adopted.

Certain future very large spacecraft missions will require in-space assembly. Other opportunities:

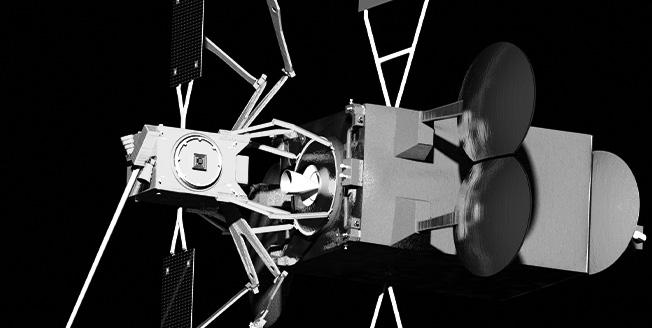

Manufacture of massive antennae (enabling mobile phone users on Earth to roam seamlessly from terrestrial to satellite networks as they travel) New in-space solar power farms New in-space infrastructure (hubs with power, propulsion, service, refuelling) Developing major new activity in space, including human habitation beyond Earth orbit, and scaled-up commercial tourism in Earth orbit. Thales Alenia Space believes LEO mega constellations will drive a need for an orbital partner that is capable of performing a range of in-orbit missions, such as changing payload. Current technology on the ISS has proven

the ability to have reliable, complex and transformative robotics in space; Canadarm 2 and Dextre, built by MDA, have been performing on-orbit infrastructure servicing operations together since 2008. MDA lead the way in space robotics and are providing robotic solutions for NASA’s Restore-L and Darpa’s RSGS servicing vehicles. Existing LEO infrastructure, such as the International Space Station (ISS) offers new opportunities to be capitalised upon, enabling experimentation and commercial use, particularly around the microgravity environment (more efficient therapies and better vaccines; stronger and more conductive materials; fibre optics; developing new plant varieties that are better adapted to extreme conditions).

Market Barriers

Current spacecraft manufacturers are risk averse to novel missions that require many moving parts. This risk will have to be mitigated in part through government funded missions. Ambition and commercial cases need development. The demand for very large spacecraft missions is low, with only a handful planned for the next decade.

UK Capability

The UK is particularly strong at high value manufacturing and Industry 4.0, including additive manufacturing. The high value manufacturing Catapult is investigating the future of space robotics. Using AI to increase autonomy in robotics, FAIR-SPACE is developing technologies that will ultimately support in-space manufacturing requirements. However, NASA/US has currently led the way with in-space manufacturing on the ISS. ESA has not copied these missions. Expertise in deployable mechanisms (e.g. Oxford Space Systems) or large structures such as heat shields (Reaction Engines) is an advantage for UK ambitions. In-space construction, in general, is a growing area of interest and something the UK space sector is coalescing around, with the aim of driving toward a leading position for the UK as it evolves.