Alpine Aerotech is a full-service helicopter support and maintenance provider with facilities In Kelowna and Abbotsford, British Columbia.

Founded in 1990 as a structural repair shop, Alpine Aerotech has expanded its portfolio to include services such as part manufacturing, avionics modifications, maintenance, helicopter leasing and aircraft parts sales. The company has grown from four employees to a staff of one hundred and fifty and growing.

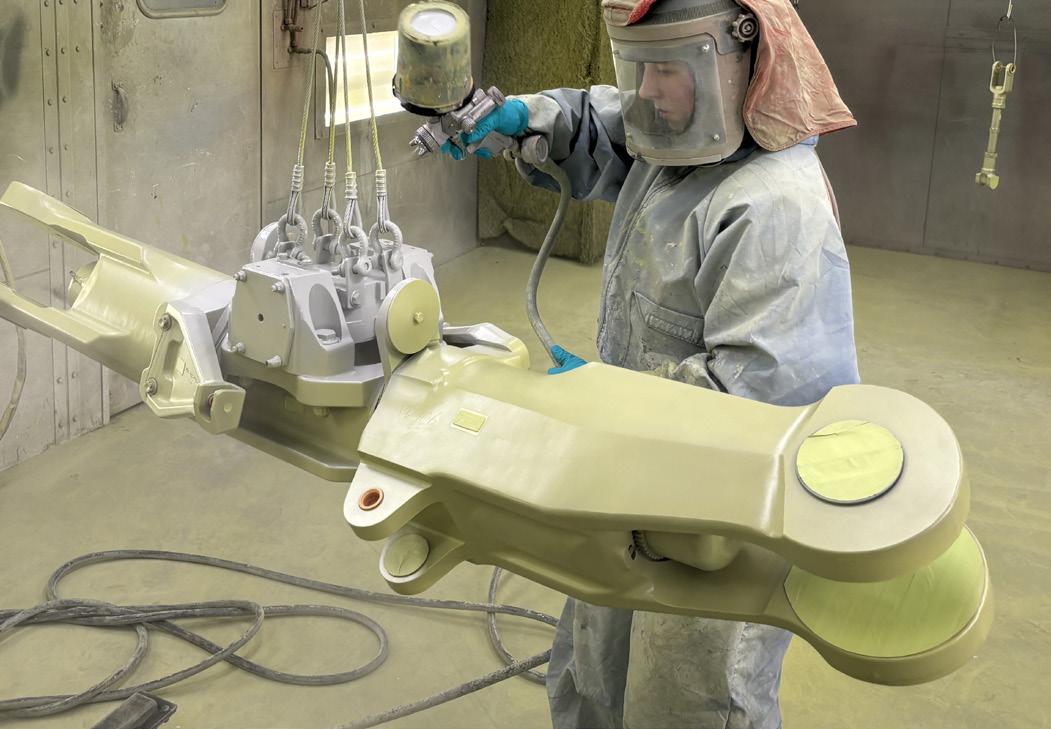

As a structural repair and heavy maintenance facility, Alpine Aerotech is qualified to perform major aircraft refurbishments for all sized helicopters. From minor touch-ups to complete paint jobs, customer requested paint schemes and detailing of aircraft. Alpine Aerotech is an approved service facility for AIRBUS, Bell Helicopter Textron and Leonardo Helicopters.

SATA Canada had the opportunity to chat with George Foster, paint shop manger about his twenty plus years of experience with Alpine Aerotech and his team of painters.

“In my role as paint shop manager, I organize the day to day for the painters, preppers, body technicians and blasters. I work with other departments to keep up with deadlines and schedules. In aviation things change rapidly which requires that we constantly adapt our approach and planning in order to get the best quality of work out in the most efficient amount of time we can ”

Alpine Aerotech has various paint booth set-ups between both locations. The Kelowna facility has a large R.V sized cross draft booth, approximately 14x42 feet along with a medium size parts booth. Abbotsford has a much larger down draft booth

The process of painting rotorcraft is not entirely dissimilar to what goes on in the collision sector. As George explains it “we plastic media blast everything down to bare metal, we do some chemical stripping as well but not much, maybe only five parts on an entire aircraft.”

The team then gets to work meticulously performing prep and bodywork, applying aerospace sealants followed by epoxy primer, sealers, topcoat and clear.

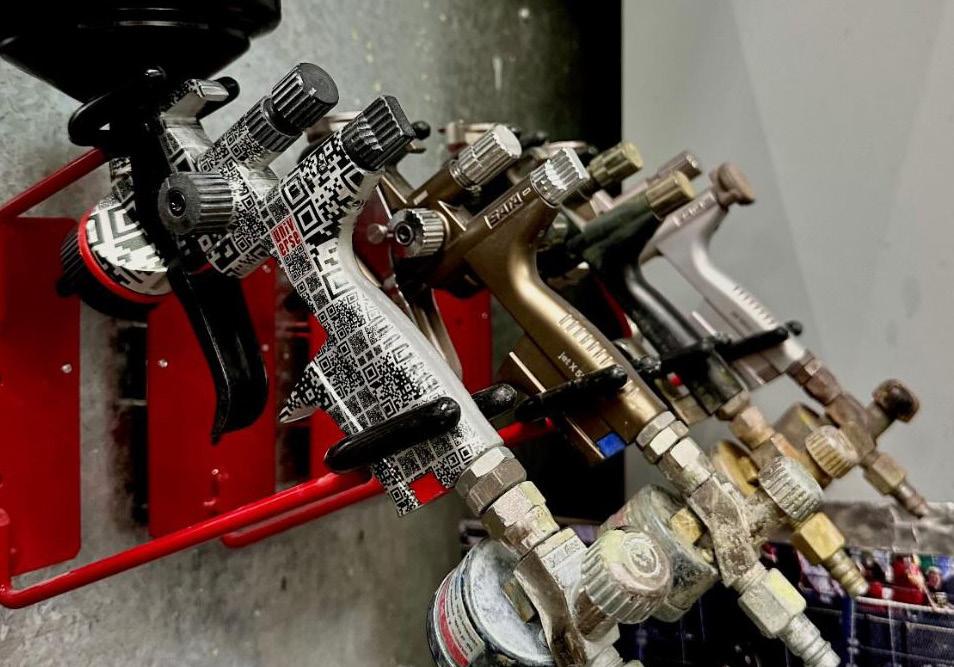

The choice of spray guns at Alpine is up to painters, “we are not specifically a SATA shop, my team can use any gun they want, and they all use SATA.

Between them is a mix of SATAjet 5000 B and SATAjet X 5500. Breathing protection and filtration is also SATA supplied, the painters use both the SATA vision 2000 and SATA air vision 5000 combined with a 500 series SATA filter.”

The majority of customers come from the mining industry, heli-seismic, heliskiing and fire prevention. A complete paint job often requires complex designs in a company’s paint scheme. “We do about 12-15 plus complete paint jobs per year, each taking approximately 1,300 to 1,500 hours.”

As in the automotive refinish industry, aviation customers want a perfect deep finish.

Alpine Aerotech’s reputation for excellence has won them contracts from around the globe, with customers sometimes having to book a year in advance.

George proudly pointed out a sign he has displayed in the paint shop, “you never get a second chance at a first impression” ...“especially as the first thing a customer sees is the paint job.”

Speaking with some of Alpine Aerotech’s painters, provided a new perspective on refinishing on a grand scale.

The differences between automotive and aviation painting, we were told, is the product used, but at the end of the day, the techniques are the same. The refinish job is just on a larger canvas and as a result requires a lot more planning.

Up to three painters will work in the booth simultaneously, if it’s a large job. One painter will do the underside and the other two painters will spray the sides and top of the helicopter so there is consistency and no area of dry spray build up.

The fuselage is mounted on a rectangular stand at its hard points. With ladders employed to reach high spots, painters start at opposite ends across from each other and meet in the middle of their pass. Most jobs encompass the entire airframe.

Complete paint jobs are often required either for new paint scheme designs or because of general wear. Companies especially in the logging industry put a lot of hours on their aircraft, requiring regular refinishing.

Mitch Olive, one of Alpine Aerotech‘s painters is a big fan of SATA,

“We are a high production shop, very quality driven, so we rely on SATA for quality finishes that are consistent and meet the high expectations of our customers. We are always on the lookout for what SATA is coming out with next, anything that makes life easier for the painter.

For my gun set up, I have a SATAjet X 5500 1.3 RP “0” nozzle Universe special edition. I also use SATA RPS cups as much as possible.”

There are three other painters in the shop, using a variety of SATA guns, including a PHASER X 5500, regular SATAjet X 5500, SATAjet 5000 B and a SATAjet 1500 B SoLV RP as well as a SATAminijet 4400 for touch ups.

“In the shop we pride ourselves in providing industry leading paint services for all types of rotorcraft. Routinely exceeding the expectations of customers is very rewarding.”

“Our projects get a lot of recognition, pilots will land somewhere and get asked, ‘where did you get that aircraft painted?’ ; we often get new business that way and it’s a small part of what makes us all proud to be working for Alpine Aerotech.”

Landon Houde, Head Painter

• Collision school 2007

• Started aviation in 2007

• Left to do autobody 2012

• Came back to Aerotech in 2018

• Received Red Seal in 2020

• Received CCAA aviation ticket 2018

“Enjoy the satisfaction of long term projects leaving the door with a quality of excellence that’s unmatched in Canada.”

Matt Bullock, Crew Chief

• Automotive Red Seal painter

• CCAA aviation certificate

• switched to aviation in 2018

• fixed wing to Rotory in 2021

“I like seeing my work in the sky not just on the roads.”

Daarien Kunz, Painter

• Left Collision school in 2021

• Painting in aviation since 2022

• Working at Alpine Aerotech for 1 year

• Working towards paint certific ation

“Aviation is a rewarding industry rounding out my different skill sets.”

Mitch Olive, Painter

• Left collision repair school in 2015

• Became an aviation painter in 2017 with fixed wing aircraft

• Moved to Alpine Aerotech in 2021

• Received my CCAA ticket in 2023

“I love to see large projects leave with happy customers and the feeling of fulfillment with the team’s hard work.”

above are: Jason Gravenhof, Vice President of SATA USA Inc., George Varagic, President of SATA USA Inc. and SATA Canada Inc., Tony Larimer, Director of Sales & Marketing SATA USA Inc.

A joint agreement was recently signed for the acquisition of the Dan-Am Company in Spring Valley by SATA USA Inc., a subsidiary of SATA GmbH & Co. in Kornwestheim.

“We are excited about this new chapter in the history of both Dan-Am and SATA. This acquisition will allow us to continue to provide our industry partners and customers in the USA and Puerto Rico with the best equipment and outstanding service they know and love from SATA and Dan-Am now and, in the future.”...said Mike Carlos Wolf, CSO of SATA GmbH & Co. KG.

The acquisition of Dan-Am Company, a renowned company with a long history of success in the distribution of SATA products in USA and Puerto Rico, represents a significant milestone for SATA and is part of the company’s strategic growth initiatives to strengthen its presence in the whole North American market and expand its product portfolio.

SATA is committed to making the transition process smooth; maintaining and strengthening Dan-Am Company’s existing relationships with customers, suppliers, and employees. Dan-Am Company customers can continue to expect the quality reliability and service which they have been accustomed to.

SATA USA Inc. joins SATA Canada Inc. as a wholly owned subsiduary of SATA GmbH & Co. SATA Canada and SATA USA will also share George Varagic as President of both companies.

SATA Canada was at the Lordco 34th Annual tradeshow, April 3 – 4 at the PNE Coliseum/Agrodome in Vancouver, BC. Our participation in the show was great success, with special thanks to RXN Motorsports and Mike Hall of Rust Brothers fame.

A big thanks to all those who dropped by our super-sized booth to check out the great deals on SATA products and to ask about SATA spray guns, fresh air systems and of course the SATA RPS cups. We look forward to seeing everyone next year at the 35th edition.

Mike Hall dropped by the SATA display to to speak with Mike Murphy, SATA Business Development Specialist, BC. Kyle Olson, Western Regional Manager and George Varagic, SATA USA and Canada president.

Mike (Hall not Murphy, sorry Mike) can’t help drawing a crowd thanks to his popular TV and YouTube presence. Mike was gracious enough to sign autographs for an ever-growing line of fans.

The awesome 69 Chevelle SS on display at the SATA booth was built by RXN Motorsports of Pitt Meadows, British Columbia. Expect an in-depth story on RXN in the fall edition of SPRAYER.

See text box on LH for the specs on the Chevelle.

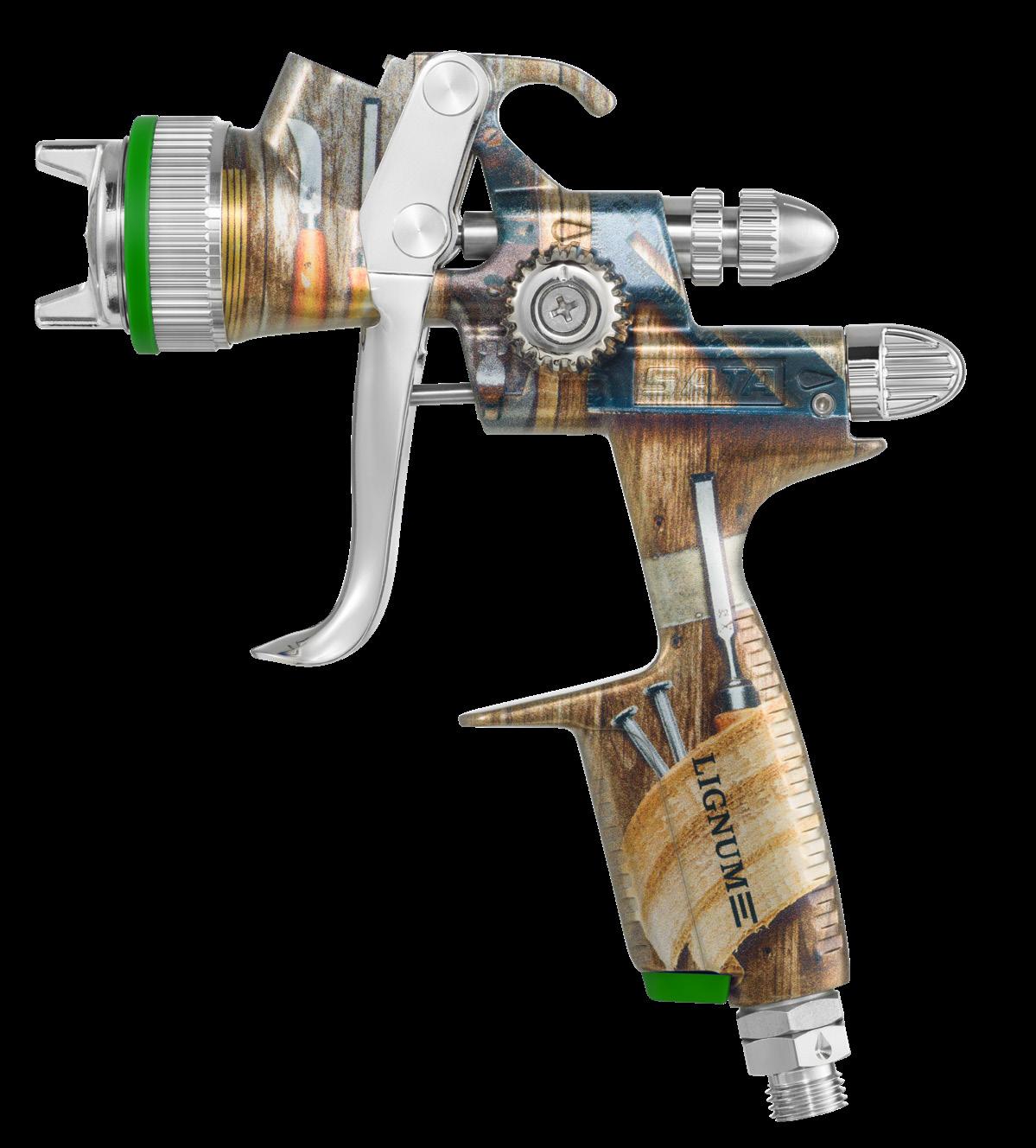

The SATAjet 1000 B LIGNUM 3 is a must for every finisher. Due to its comprehensive range of available nozzle sizes and its versatile selection of accessories, such as pressurized and agitator cups, a host of many different spray media can be perfectly applied: from low-viscosity wood stains and clearcoats to glues and other thixotropic materials. With extensions available in various executions, even areas of difficult access can be easily coated.

For the ultimate safety and protection Whatever environment you are working in: Whether you want cooled or heated breathing air or simply looking for absolute safety from particle contamination – with the new add-on modules complementing the SATA air vision 5000 breathing protection system, you can be sure your health and comfort are both efficiently catered to.

Rigid bump cap for safer work conditions

Large field of vision: approximately 116" at a maximum possible angle of 220°

Replaceable visor foils allow unchanging clear view

Soft-stream flow-optimized air distribution in the hood

Where finishing is not an “F” word!

Jim Carrigan began Jeco Inc. back in 1998 as a wood finishing specialty shop.

The company’s founding pre-dates the introduction of the SATAjet 2000 HVLP in 1999, RP technology in 2000 and even the SATA RPS cup in 2005!

Jeco Inc.’s 12,000 sq ft. Calgary facility makes it the region’s largest independent finishing shop, serving the cabinet and building industries.

As Jim explained in a recent issue Wood Industry magazine,

“A lot of cabinet makers were just building stuff on site and then letting the painters deal with it. So, I started specializing in just cabinet finishing and wood finishing in these large custom homes and then eventually decided that that was my niche.”

Jeco Inc.’s business is approximately 95% pre-finishing. “We partner with cabinet makers and builders that don’t have finishing as part of their process, so then they are able to bid on projects where builders or clients require a pre-finished product.

We do a minimal amount of on-site finishing, usually in cases where there are certain pieces, like overside bulkheads or built in structural elements that need to be done in concert with the cabinetry, items that are virtually impossible to pre-finish.”

Jeco Inc. has a mix of clients, though the residential construction share has grown considerably,

“Residential is fairly hot right now, mid to high end builds is the biggest part of our business, but we also have commercial millwork clients that do things like dentist offices, schools, office towers and apartment buildings.”

The Jeco Inc. facility contains two paint booths, the largest being 20,000 cfm with a smaller booth where more of the finer wood finishing is done. Of the staff of fifteen, five are finishers.

“Some of our painters have been trained in-house but we also have some more experienced finishers from the furniture and cabinetry industry.

I came from an industrial painting background, I started out working for my father learning how to spray aggregate equipment, conveyers, hoppers and rock crushers, the sort of machinery you would see on the Gold Rush reality TV series. I will also admit to doing some automotive painting in the 1980s.”

“Just as in a body shop, prep work is a big part of our job,” says Jim. “I have a significant portion of my shop space dedicated to prep and sanding. Prep is key to a good finish, the only real difference here is that substrate is wood or MDF. The fundamentals of getting a good finish are pretty much the same as the automotive refinish sector.”

Jim tells us that SATA is the choice of both himself and his painters,

“Once I had started using the SATA system over 15 years ago, there was definitely no going back, it’s so easy to use, the spray guns are easy to clean, and the SATA RPS cups are perfect for quick colour and material changes. So basically, once my finishers started using SATA they love it too.

We have eight SATA guns at Jeco Inc., they are in rotation all the time across two shifts.

There are two primary spray guns we employ at Jeco Inc., the first is the SATAjet 5000 B HVLP with a 1.4 nozzle, for shading, toning, and blending of colours.

Second is the SATAjet 100 B F RP 1.8 nozzle, we have six of these, I consider this the most versatile gun

that I have ever used.

In SATA RPS cups we use all three sizes, 0.3 I, 0.6 I and 0.9 I depending upon the size of the job we are doing.”

Jeco Inc. also has the distribution and training rights for VeroMetalTM, a metal alloy suspended in a polyester resin, that can be sprayed on almost any surface, giving it a fine metal finish.

“We use a ratio 2:1 or 3:1, the larger portion being the metal alloy, ground so fine that it becomes homogeneous when mixed with the resin. The VeroMetalTM coating is sprayed with a SATAjet 100 B F RP with a 1.8 RP nozzle.

We can spray it on cold, run it though the oven, after heating we are able to sand, machine and polish it to a fine sheen.”

Jeco Inc. recognized the importance of social media early on and have built a name for themselves online, across social media platforms including LinkedIn, Instagram and Facebook. If you follow wood finishing or even refinish you may be familiar with their process videos.

“We put an effort into social media, it absolutely gets us a lot of business. I would say we get six to a dozen inquiries a month from social media, which is pretty good considering it’s B2B enquiries, and some turn out to be evergreen clients. It’s been a consistently good investment for us to continue to work on our social media presence.”

Jeco Inc. will be giving away a SATAjet 1000 B Lignum III RP 1.8 in as a 25K subscriber Instagram promotion.

Better hurry and check them out online, they will be there soon!

JP Kleniewski

Business Development Specialist

Ontario & Maritimes

Cell: 647 549 SATA (7282) jeanpaul.kleniewski@sata.ca

Kyle Olson

Western Regional Manager

Cell: 431 374 SATA (7282) kyle.olson@sata.ca

Michael Murphy

Business Development Specialist

British Columbia Cell: 778 956 SATA (7282) michael.murphy@sata.ca

●

Todd Marshall

Business Development Specialist

Ontario

Cell: 437 350 SATA (7282) todd.marshall@sata.ca

Donald Hall

Business Development Specialist

Alberta & Saskatchewan

Cell: 587 435 SATA (7282) donald.hall@sata.ca

Patrick Creaney

Business Development Specialist

Quebec

Cell: 514 915 SATA (7282) patrick.creaney@sata.ca

Thomas Gierens

Business Development Specialist

Alberta & Saskatchewan,

industrial and automotive Cell: 587 582 SATA (7282) thomas.gierens@sata.ca