3 minute read

11. Target 12.2: Material Footprint

Target 12.2: Material footprint

Indicator 12.2.1 is material footprint, material footprint per capita, and material footprint per GDP.

Advertisement

Responses

1. Building in the form of modular system concept to emphasize more on open spaces and minimized over-usage of materials. 2. Window are emphasized to increase natural lighting being diffused into the space, reducing the amount of artificial lighting. 3. Use of conventional lighting such as T5 fluorescent lighting and LED lighting that are energy and cost efficient. 4. Implemented rainwater harvesting, to optimize water usage and eliminate usage of portable water. 5. Exposed exterior finishing to reduce overall material footprint.

Challenges

Inefficient and insufficient research of usage and choices of material with high environmental effect poses a challenge to the designer as they are unaware of the insufficient and inefficient amount of choices of materials that are recyclable, biodegradable and reusable hence, creating a big impact on the material consumption.

Contributions

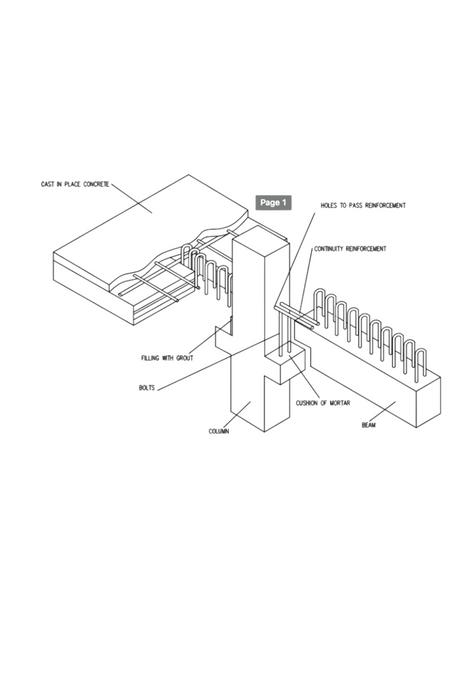

Usage of pre-stressed concrete.

The load-bearing characteristics of the building structure are reduced when

prestressed concrete is used. Prestressed concrete leads to a more sustainable conclusion by emitting fewer dangerous chemicals that threaten our health and the environment. Steel and bare concrete are used less frequently, highlighting the need of maintaining an environmentally friendly atmosphere. The overall steel and beams are able to be recycled which reduces the material footprint for future projects.

Figure 7.1 how pre-stressed concrete was used as the principal construction material to maintain the structure and increase the building's tensile strength without the need of unnecessary steel beams.

Figure 7.1 Pre-Stressed Concrete

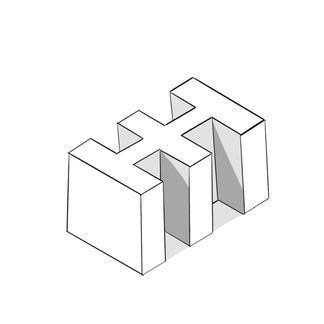

Modular system for building organization and layout

The flexibility of the layout, which is in the shape of a "H," leads to more open spaces and reduces the need of pre-stressed and raw concrete finishes because it requires less maintenance. This provides for a cost-effective maintenance and restoration campaign.

Figure 7.2 depicts the modularity of the university's Blocks A, C, and D, which emphasize open spaces that allow for greater natural lighting and ventilation. The use of concrete is minimized, as evidenced by the building's finishing.

Usage of energy-saving lighting in common areas

Figure 7.2 Modularity System

The use of T5 fluorescent lighting and LED in the common areas, such as hallways, staircases and lecture theatres as it occupies a wide range of space. Hence this reduces the energy consumption. The remaining open spaces uses natural lighting, and this emphasizes a passive design strategy to maintain sufficient daylight into the building.

Figure 7.3 shows lighting fixtures are mostly installed in the hallways connecting academic blocks and staircases as it poses a wider radius and space hence energy and cost-saving lighting are used.

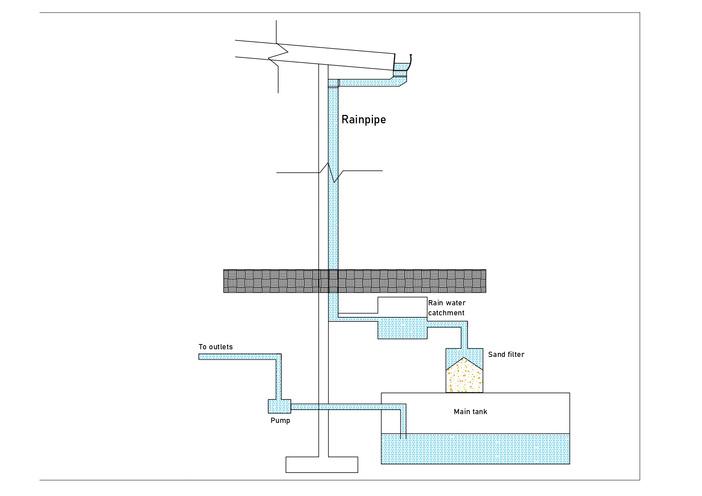

Pitch roof system

A pitched roof is in contrast to a flat roof which, technically, is any roof with a slope less than 10°. Taylors has adapted this typology of roof in response to its hot climate to provide immense shading. The pitch roof also contributes with long eaves extending out providing maximum shading for the users. Furthermore, it is a way of collecting rainwater. Overall, the design for Taylor's roof is a smooth sloping roof which performs the best quality for harvesting water.

Figure 7.4 shows the pitch roof system that is designed and implemented in a way to reduce the water pressure and enhance the rainwater harvesting method proposed by Taylors.

Exposed Finishing

To put it simply, exposed aggregate is a form of finish in which the top layer is removed to reveal the aggregates, such as stones and sand. Taylors' architecture is based on its structure. The basic philosophy of this method is to limit the use of interior finishing by creating a very raw, yet still rough, unfinished surface appearance, hence lowering overall material use. As a result, a reduction in the net material usage in the whole project itself.

Figure 7.3 Passive Daylighting & LED Lights

Figure 7.4 Rainwater Harvesting System

Figure 7.5 shows the exposed ventilation, lighting, fire safety systems, ventilation pipes and electrical wiring to have a characteristic of a minimalistic look with the usage of them as a decorative element whilst reducing the overall material footprint around the building.