SUPERVISION PORTFOLIO

My Take

Being involved in construction work has made me understand the real challenges like material shortages, labor issues, and tight deadlines, which taught me the importance of designing with practical solutions in mind. I have come to see that construction methods have a big impact on the environment, through resource use, waste generation, and energy efficiency. Through working closely with tradespeople, I have learned how construction can support local communities and improve social wellbeing. My experiences onsite have also shown me how important it is to think about the economic side of building, using strategies like lifecycle cost analysis and circular economy ideas to make sure projects stay strong and sustainable over time. I am committed to creating buildings that respect the environment, support society, and make financial sense — truly balancing planet, people, and profit.

References

The following individuals serve as testimony to the quality and impact of my work.

Ar. Sunita Subedhi

Head of Department of Architecture, Acme Engineering College sunita.subedhi@acme.edu.np

Ar. Sagun Sthapit

Managing Director & Principal Architect, Sthapit Architects dsasthapit@gmail.com

Ar. John Dangol

Managing Director & Principal Architect, Archivitus Design Studio Pvt. Ltd. johnofficeworks@gmail.com

Er. Prakash Shrestha

Managing Director, Nidal Engineering Research & Construction nidalengineering75@gmail.com

INDEX .

01

Club 16

Club Supervision in Pokhara, Nepal

02

C.K Cinema Hall

Cinema Hall Supervision in Sitapail, Nepal

03

Residence Supervision

Residence Buildings Supervision

04

Good Brick Factory

Residence Buildings Supervision

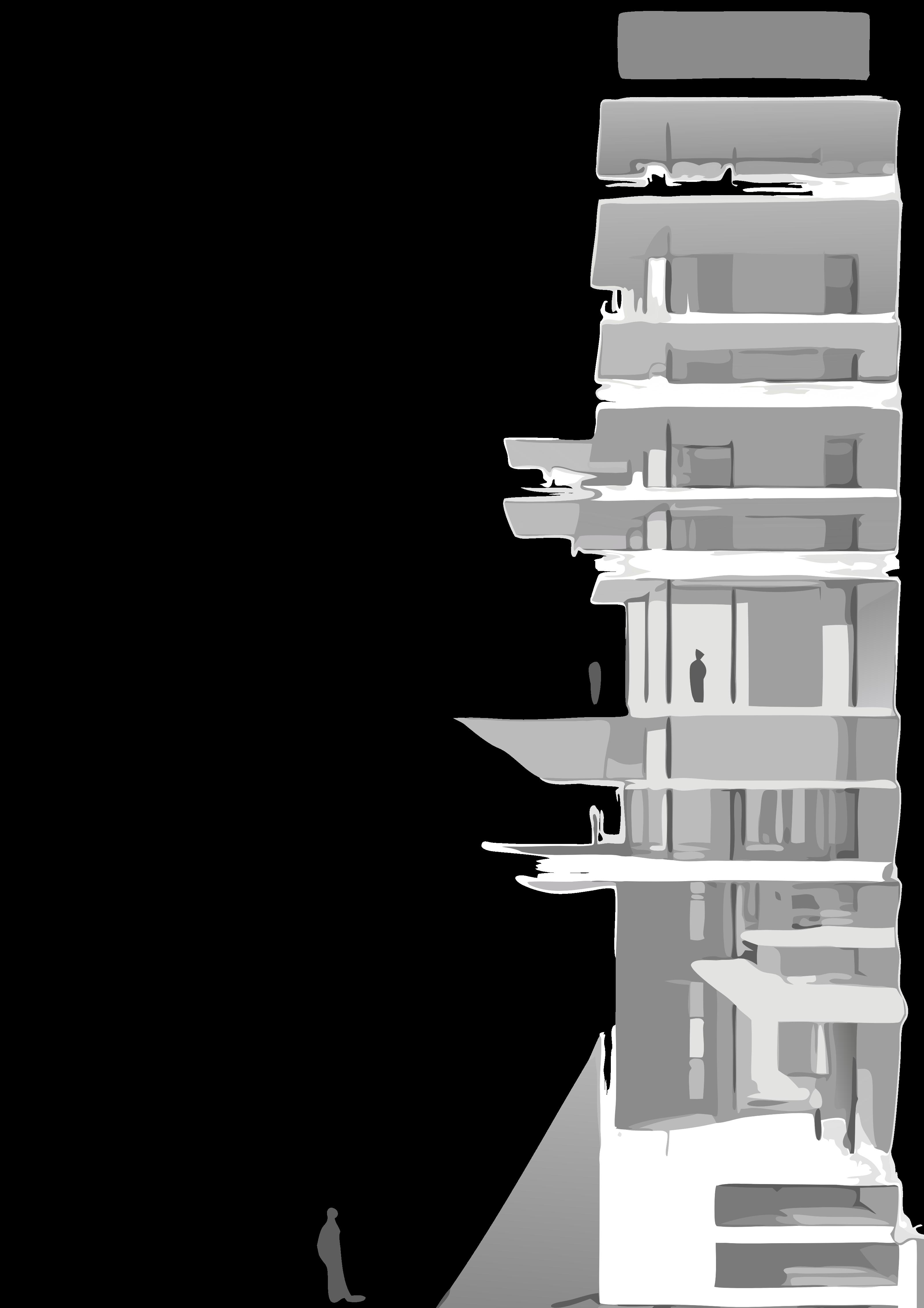

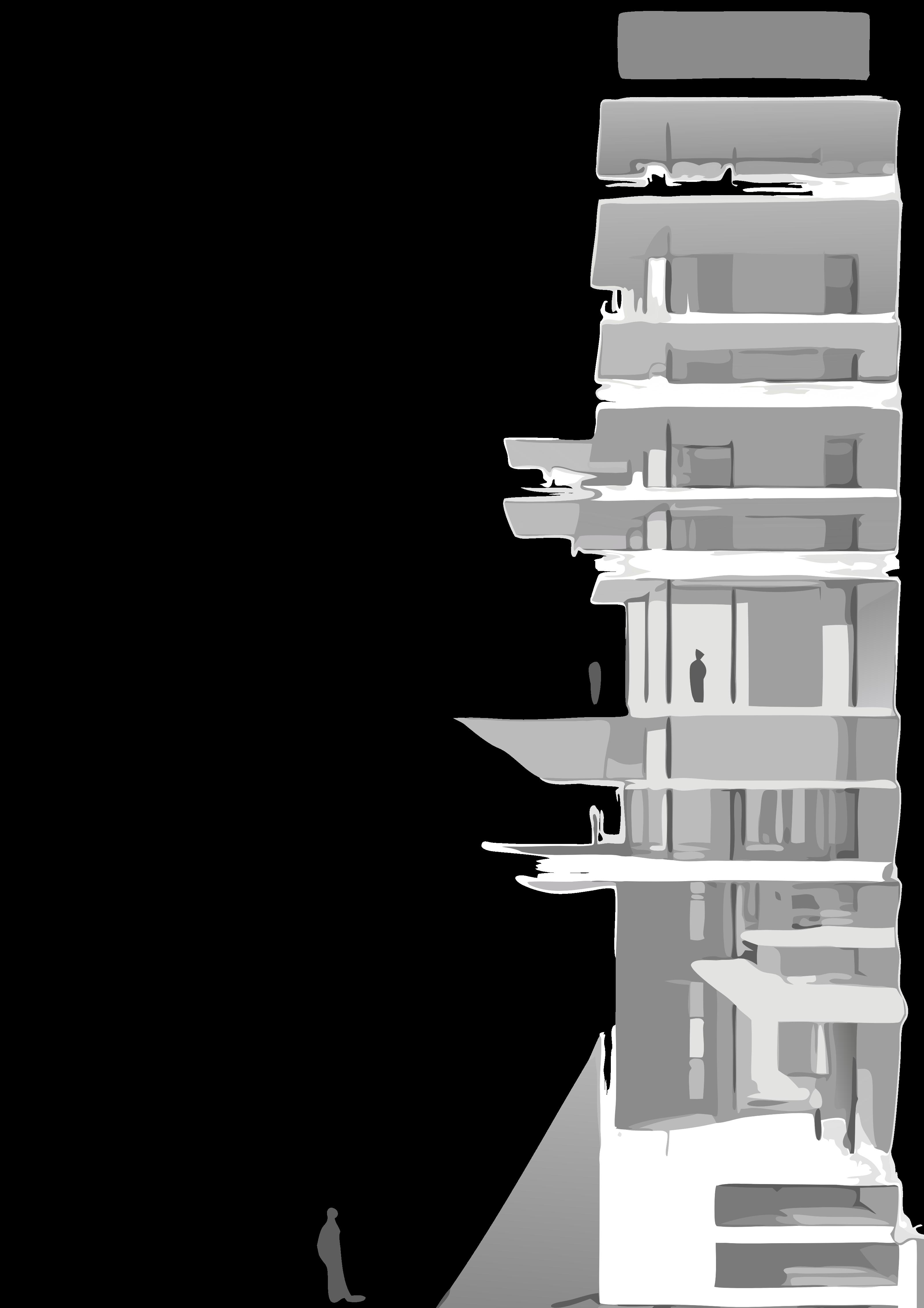

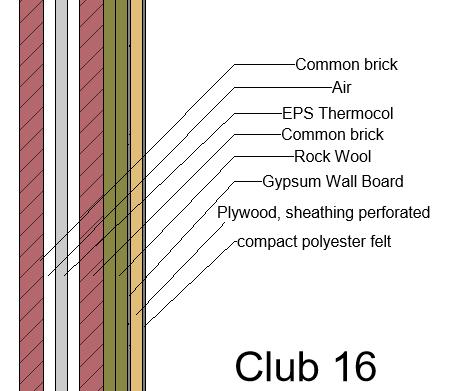

CLUB 16

Project Brief

Location: 16 Street, Pokhara.

Site Area: 2818.21 sq. ft.

Involvement : 3 months

Supervised the interior site of a club, ensuring design elements were practical and available. Oversaw the use of various saw machines, including a circular saw for ACP, table saw, router, hand saw, hack saw, chisels, and a multi-cut blade with flange for grinding and cutting marble. Additionally, supervised the implementation of metal cutting blades and soundproofing materials like Rockwool and Thermocol. Addressed challenges such as the sunmica board, which, although cheaper than a mirror, scratches easily. This issue was resolved by applying transparent stickers typically used in car mirrors.

Entry design provided

Entry Design As Per Drawing

Client: Mr. Binod Singh

RESIDENTIAL BUILDING

Location: Baluwatar , Kathmandu

Site area: 1711.476 sq. ft.

Building Type : Residence Involvement : 5 months

Project Brief

The project site is located in Baluwatar, Kathmandu, and features a variety of soil types, including clay, silt, and sand, which become evident as we move deeper into the ground. Given the heterogeneous nature of the soil and its classification as filled soil, a raft foundation was chosen over isolated or combined footings to ensure better stability and uniform load distribution. To improve soil conditions, water treatment was employed, and instead of traditional bricks, boulders were used for soil stabilization. This approach was aimed at enhancing the overall foundation strength and ensuring the long-term durability of the structures being built on this site.

3D Render - Ar.John Dongol

Wall For Lower Tie-Beam

Wall For Upper Tie-Beam Checking Rebar

Laying Chinese Brick after Finishing Structural Part

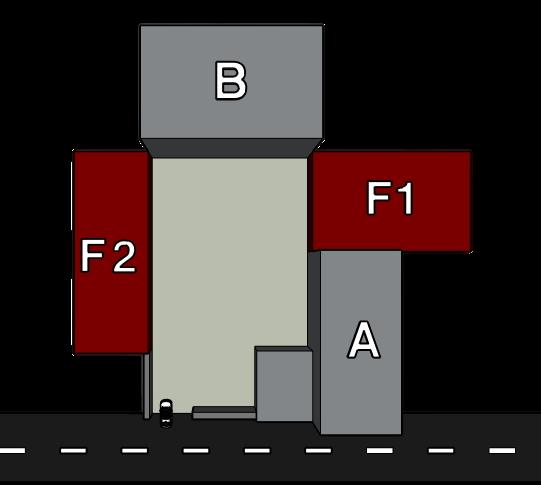

Client: Good Bricks

INNOCSR Nepal Pvt. Ltd.

Location: Jorpati , Kathmandu

Site area: 4565.58 sq. ft.

Building Type : Reprogramming of industrial space

Involvement : 45 days

Project Brief

The project involved the industrial adaptive reuse of a decommissioned soda-bottling factory into the new headquarters and demonstrative facility for Good Bricks Company. During F2’s erection, misaligned truss roof threatened the required drainage slope; rather than re-lifting the entire assembly, I proposed excavating a targeted trench beneath the footing to lower it by2m, restoring the 1 % pipe gradient without costly crane mobilization—an approach that kept the schedule and budget on track. The result is a fully operational demonstrative factory producing sample compressed bricks for client presentations, alongside a bright, functional headquarters that exemplifies sustainable adaptive reuse and innovative problem-solving on a historic industrial site.

Site Plan

F2 Chemical Factory Waterproofing

F1 Factory Machine Installation

Interior Of A Block

Service Area

Reception Area

Conference Hall

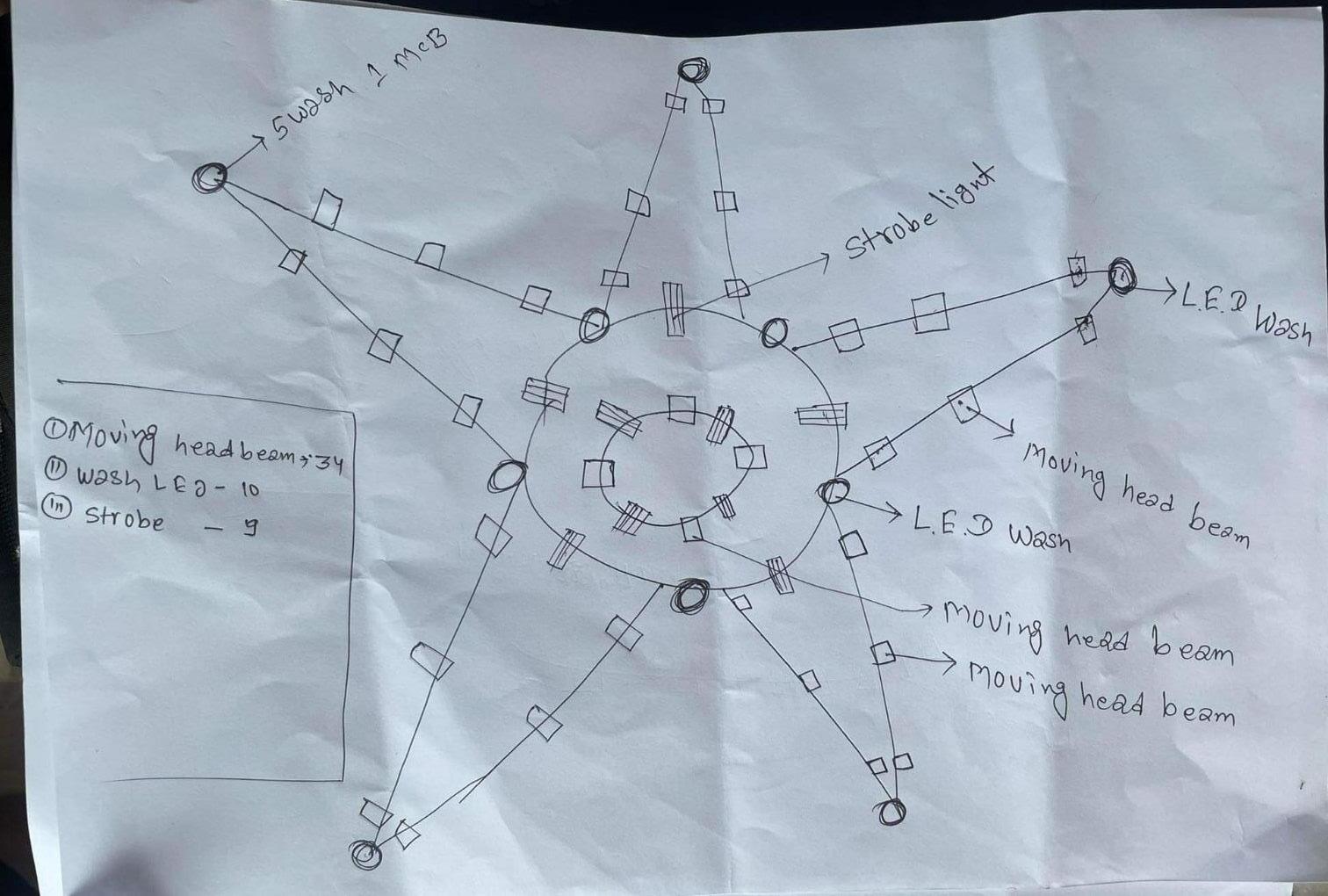

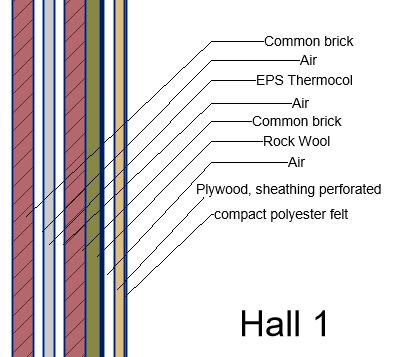

CK CINEMA HALL

Client: Mr. Chhabi Timalsina and Kishwor Khatiwada

Location: Sitapaila, Kathmandu

Site area: 12761.40 sq. ft.

Building Type : Cinema Hall

Involvement : 80 days

Project Brief

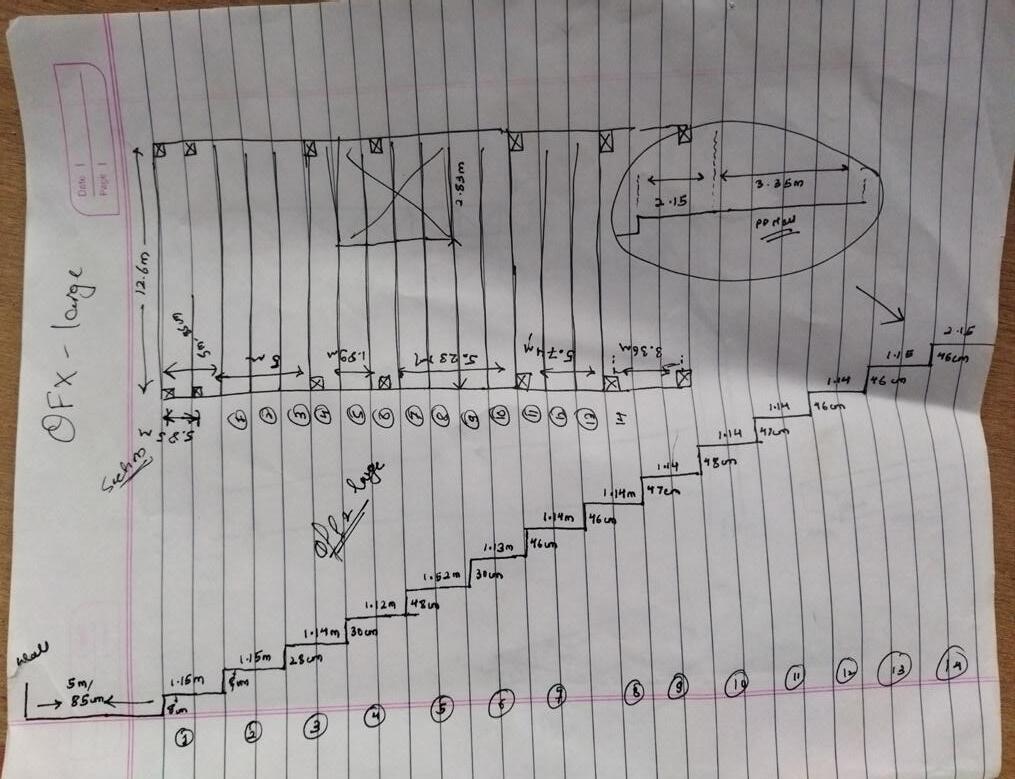

This project is about the design and construction of a film hall. It helped me understand wall soundproofing, crowd movement, and the importance of coordinating architectural planning with ventilation and HVAC systems. I also learned about using modern structural components like steel and designing interior elements around expansion joints. One challenge I faced was managing HVAC duct routes without lowering the ceiling too much. By working closely with the MEP team, I redesigned the layout to keep the space comfortable and functional. This experience strengthened my ability to solve technical problems while maintaining both design quality and user comfort.

WALL SECTION IN 2D

WALL SECTION IN SITE

Reference Render by Ar.Rickky Maharjan

AAC Block

Rock Wool Insulation

Architectural Portfolio

https://issuu.com/sagarmahat/docs/portfolio_rf4-compressed curriculum vitae

https://issuu.com/sagarmahat/docs/cv

Concession Stand

Lobby render by Ar.Rickky Maharjan Lobby Space