Featuring the Garmin 3000 Prime and largest touchscreen displays in its class, Professional has been redefined – introducing the brand-new PC-12 PRO.

Pilatus Centre SA

Authorised Sales Centre

10. Guy Leitch

Attitude for Altitude Leading Edge

20. Peter Garrison

26. Jim Davis Plain Talk

38. hugh Pryor 79.

50. Jim Davis Accident Report

84. Morne Booij-Liewes Register Review

In the more than two decades since we introduced the GNS 430, we’ve continued to develop even more advanced capabilities to enhance your flying. The GTN™ Xi series, our fourth-generation GPS/ NAV/COMMs, leads the way with Smart Glide™ technology, coupled VNAV and missed approaches1 , intuitive traffic displays1, terrain and more. See the upgrade advantage at Garmin.com/Navigators.

In my May editorial I had a rant about insurance companies using the AIC 18.19 disaster to wriggle their way out of paying claims.

MY view of the withdrawal of AIC 18.19 (which now enforces the “12-year rule”) is that it is an unmitigated act of stupidity by the CAA. It reinforces every prejudiced notion that the CAA are a bunch of unfunny clowns out to destroy general aviation. The CAA is digging in its heels, so I fear this matter will end up as ‘lawfare’ in court and once again the regulator will be shown up to have been hijacked by either the idiots or the corrupt. With that said, I need to wind my neck in somewhat about what I said in May. I singled out Santam for using the 12-year rule to repudiate a claim, even though the age of the engine had nothing to do with the cause of the accident.

Because I leave these editorials to the last minute, I failed to give Santam a right of reply. I subsequently chatted

to James Godden, Santam’s Manager: Aviation, who has provided his perspective – which is not unreasonable.

Godden points out that it is a requirement of aircraft insurance that the operator must operate within the law, (and indeed, this requirement is common to all contracts of insurance).

So the question becomes; where does the insurer draw the line?

Godden cites the example that it would not be unreasonable for an insurer to refuse a claim if the pilot’s licence had expired. However, he says Santam do make allowances. For instance, when the pilot’s medical has been passed but is not yet registered by the CAA, they may well be open to an ex-gratia discussion. Another exception may be the classic case of the medical kit having expired pills.

Godden therefore says that it’s not unreasonable for Santam to decline the claim of a Tomahawk with an engine older than 12 years which crashed due to pilot error, particularly as it was being used in a flight school. He says the crux of the case is that because of the 12-year rule, the aircraft did not have a valid certificate of airworthiness. That’s equivalent to the pilot not having a licence.

So the lesson we must take from this sad example is that it doesn’t matter if the age of the engine had nothing to do with the cause of the crash. What matters is whether the aircraft was being operated XWlegally, even if the law is an ass..

Since it’s difficult to operate an aircraft 100% legally, there’s a lesson for everyone here.

SALES MANAGER

Kerry Matthysen sales@saflyermag.co.za 082 572 9473

TRAFFIC

Kerry Matthysen traffic.admin@saflyermag.co.za

ACCOUNTS

Bella Leitch bella@taxfinaccounting.co.za

EDITOR

Guy Leitch guy@saflyermag.co.za

PUBLISHER

Laura McDermid laura@saflyermag.co.za

PRODUCTION & LAYOUT

Emily-Jane Kinnear design@saflyermag.co.za

CONTRIBUTORS

Jim Davis

Peter Garrison

Hugh Pryor

John Bassi

Morne Booij-Liewes

Laura McDermid

Darren Olivier

Iris McCallum

ILLUSTRATIONS

Darren Edward O'Neil

Joe Pieterse

WEB MASTER

Emily-Jane Kinnear

© SA FLYER 2025. All rights reserved worldwide. No part of this publication may be reproduced, stored in a retrieval system, or transmitted by any means, electronically, mechanically, photocopied, recorded or otherwise without the express permission of the copyright holders.

This month’s Opening Shot is a celebration of the winter solstice that marks the middle of winter. From the 21st of June the days get longer and warmer. Also, we are grateful to be able to fly far from the northern hemisphere’s madding crowd.

The short Western Cape days around the solstice did not deter a number of sunset flyers

at Stellenbosch. Franki Smith was there to capture them and I really like his image of a humble Piper TriPacer taking-off into the gloaming just six minutes before sunset.

Franki used his Canon 7D with a 100mm – 400mm lens at 320mm. Exposure was 320th second and f8 at ISO 100 with no exposure compensation.

Sometimes it seems that the CAA really loses the plot and sets out to destroy general aviation. (And thus living up to its moniker the Commission Against Aviation). We are in the middle of one of those moments, and for many this is a life or death struggle.

The SACAA will be consigning many GA aircraft to the scrap heap.

Ihave been sitting quietly on my hands watching the noise on social media interspersed with announcements from bodies such as the Commercial Aviation Association (CAASA) and the CAA. In the end the noise-to-signal ratio became hard to unscramble, so I have done something new: I asked Chatgpt’s ‘Run deep research’ button and was amazed at what it produced.

Here is a shortened version that I have taken the liberty of applying a very few of my own changes to, denoted by [square brackets]:

Aeronautical Information Circular 18.19 was a notice issued by the South African Civil Aviation Authority (SACAA) related to aircraft engine overhaul requirements. Originally issued in 2001 (re-issued in 2006), AIC 18.19 effectively provided an exemption from a strict time-based engine overhaul rule: it allowed aircraft owners to maintain airworthiness through periodic inspections, rather than mandating an engine overhaul after 12 years in service, [regardless of how many hours it had accumulated before the manufacturer’s recommended overhaul time in hours.]

In practice, this meant that under AIC 18.19, if an aircraft’s engine was older than 12 years since its last overhaul, a detailed inspection regimen could be used to confirm the engine was still airworthy, instead of automatically requiring an expensive overhaul.

This alternate compliance method was intended to ensure safety while relieving operators of the cost and downtime of a calendar-time overhaul. The circular mainly

benefited the general aviation sector – including private owners, flight schools, and charter operators – by keeping older aircraft flying as long as they passed inspections. For 19 years, AIC 18.19 was part of the SACAA’s published guidance, and many in the industry operated under its provisions.

CAA’S OFFICIAL REASONING FOR UPHOLDING (AND WITHDRAWING)

AIC 18.19

Why did SACAA maintain AIC 18.19 for so long, and why withdraw it now? The SACAA has provided several official justifications:

The CAA will ground many general aviation planes.

In a recent review of legacy AICs, the regulator found that AIC 18.19 was 'out of alignment with current aviation regulations'. Notably, the circular referenced the 1997 Civil Aviation

Regulations (CARs), which had been repealed and replaced by 2011 regulations. In other words, AIC 18.19 was legally outdated – it pointed to rules that no longer existed. This inconsistency created a legal void: the AIC was being used to justify practices not supported by the current law, prompting the CAA to act. The Director of Civil Aviation explained that given these irregularities, it was “necessary for the Regulator to withdraw the AIC.”

SACAA emphasised that an Aeronau-

tical Information Circular is meant to disseminate information, not to grant ongoing exemptions from regulations. In the case of AIC 18.19, the circular had been effectively used as a long-term loophole to bypass the manufacturer’s 12-year engine overhaul recommendation [Note: this is a recommendation by the manufacturers, it is not mandatory] that was embedded in earlier regulations.

The CAA characterised this as an incorrect use of an AIC – since binding requirements or exemptions should be handled through formal regulations or notices, not just an informational circular. This procedural critique was part of the justification for ending the circular’s effect.

The regulator identified AIC 18.19 as a potential safety risk and legal liability. By allowing engines to run beyond the recommended [my emphasis] overhaul interval (based on calendar time), the

circular could increase the chance of engine failure due to age-related factors – a risk that SACAA found unacceptable. SACAA officials noted that the circular was “exempting aircraft owners and operators” from complying with manufacturer-

prescribed overhaul intervals, which raised red flags for both safety oversight and the CAA’s legal responsibility. If an accident were traced to an overdue engine, the existence of an SACAA-issued exemption could implicate the regulator. Thus, continuing to uphold AIC 18.19 was seen as creating liability and undermining the safety mandate of the CAA.

SACAA argues that its duty as regulator is to enforce compliance with manufacturer maintenance manuals and standards, including engine overhaul schedules. Most engine manufacturers (such as Textron Lycoming and Continental) recommend overhauls every 12 years or a certain number of flight hours,

whichever comes first. [Note though that at time of writing, the AIC withdrawal only affects Lycoming, Continental and some Rotax piston engines.] The SACAA’s stance is that adhering to these guidelines is essential to catch problems like i nternal corrosion, metal fatigue, or seal degradation that may not be visible during routine inspections. Overhaul intervals are designed to identify these failures before they become safety risks.” In enforcing the time-based overhaul, SACAA also cites international norms. They point out that authorities like the European Union Aviation Safety Agency (EASA) and even the U.S. Federal Aviation Administration require such overhauls for commercial operations and expect regulators to ensure aircraft are maintained per manufacturer specifications. The SACAA claims it is essentially aligning South Africa’s rules with global best practices on engine maintenance, especially to avoid any issues when South African-registered aircraft fly abroad. There’s an underlying concern that failure to enforce fundamental safety standards could lead to international scrutiny or downgrading of South Africa’s aviation safety rating, should an incident occur. An SACAA official warned that waiting for a major accident involving an ageing engine could be derelict: “If we wait for a major incident to act, we will have failed in our duty of care.” This sense

of pre-emptive safety enforcement is a key reason the CAA has held firm.

According to SACAA, the inspection programme allowed under AIC 18.19 introduced too much subjectivity and variability. Not all maintenance inspectors might catch latent problems in an ageing engine – skill levels vary, and some deterioration can be subtle. SACAA insiders noted that this “blanket inspection exemption created a loophole”, relying on subjective judgments of engine health. The regulator concluded that safety cannot depend on discretionary inspections alone. In their view, a rigid overhaul requirement is a more uniformly enforceable and fail-safe standard. Essentially, SACAA lost confidence that the industry’s on-condition inspections were sufficient to guarantee safety in every case, especially as aircraft age. They even cited an example from the region: a 2019 private aircraft accident in Botswana where an old engine failed after long storage, which was attributed to internal corrosion and missed warning signs – an incident that “raised red flags across the SADC region” about allowing engines to go indefinitely without overhaul. This kind of data, albeit limited, reinforced SACAA’s belief that time limits serve as

an important safety backstop.

In summary, the SACAA’s official justification for upholding the overhaul rule (and thus ending AIC 18.19’s exemption) centres on regulatory conformity and safety assurance. The Authority maintains that its stance is “safety-first”, even if that means imposing economic costs.

As SACAA’s Director Poppy Khoza stated, decisions taken for safety can override commercial interests, and finding a balance isn’t always possible when lives are at stake. The CAA has indicated it will continue engaging with stakeholders and even engine manufacturers to “find a middle ground” or clarify technical requirements, but it has “dug its heels in” on the principle that engines beyond the recommended life must be overhauled for the sake of safety.

After withdrawing AIC 18.19 in late 2023, the SACAA implemented a transition period to give operators time to comply. A general exemption (with conditions) was issued on 1 December 2023 for an initial 180 days, and later extended by another 180 days, ultimately expiring on 26 November 2024.

This exemption essentially temporarily preserved the status quo of AIC 18.19 – allowing affected

aircraft to keep flying under inspection programmes – while the industry prepared for the enforcement of the overhaul rule. SACAA made it clear that after November 2024, no further extensions would be granted; aircraft owners would be required to fully comply with the Civil Aviation Regulations (CAR) 43.02.5 and associated technical standards, which mandate adherence to manufacturers’ maintenance instructions (including any 12-year overhaul recommendations).

Going into 2025, SACAA followed through with this plan. The grace period lapsed, and the CAA began denying Airworthiness Certificates to aircraft that had engines older than 12 years without overhaul. Effectively, those aircraft have been “constructively grounded” until their engines are rebuilt or replaced.

SACAA’s June 2025 media statement emphasises that this policy mainly impacts general aviation aircraft (especially those with Textron Lycoming or Teledyne Continental piston engines) and not large commercial airliners. The regulator also disputes the scale of impact estimated by critics, saying claims of 1,400 aircraft grounded and 300,000 jobs affected are “untested” and believed to be exaggerated. Nonetheless, by mid-2025 there is no doubt that a significant portion of the private and flight-training fleet in South Africa has been forced to stop flying pending costly overhauls. SACAA has acknowledged the industry’s outcry but insists that the ultimate goal is to “ensure aviation safety and security is not compromised”, and it has stood by the enforcement as a necessary tough step.

Industry stakeholders warn that enforcing the 12-year engine overhaul rule has effectively sidelined hundreds of light aircraft, with dire consequences for flight schools, charter operators, and maintenance businesses.

The reaction from South Africa’s aviation community to the withdrawal of AIC 18.19 has been overwhelmingly negative. Aviation industry groups, political figures, and individual operators have voiced serious concerns, arguing that the SACAA’s hardline stance is inflicting economic damage without clear safety

benefits. Key responses and opposition points include:

By the CAA's own estimates, over 3700 aircraft will be grounded due to the new enforcement, representing a large portion of South Africa’s general aviation fleet. These are primarily light planes and helicopters used for pilot training, charter flights, aerial work (like game counting or surveying), and private/business transport. The knock-on effects of suddenly immobilizing this many aircraft are enormous.

Flight schools cannot operate their trainers; charter and safari operators lose business; aircraft maintenance shops and parts suppliers see demand evaporate; and pilots and support staff face layoffs. Industry estimates

suggest up to 70% of the country’s aging general aviation fleet could ultimately be affected, given how many aircraft engines are over 12 years old. A consortium of aviation bodies warned that an “entire sector of the aviation industry could grind to a halt,” with ripple effects on related sectors like tourism, agriculture (which uses planes for surveying and anti-poaching patrols), and even emergency services.

CAASA described the situation as a “serious threat to South African aviation”, noting that many owners may simply quit flying because they cannot afford the required overhaul, potentially crippling general aviation for years to come.

A central complaint is the extraordinary cost of compliance. Overhaul-

BELOW: The GA industry has united in opposition to the AIC 18.12 withdrawal and is campaining vigorously against it.

ing an aircraft engine (especially twin-engine aircraft, common in training and charter) is very expensive in South Africa – often on the order of R1 million to R2.5 million per engine. For older light aircraft, this may exceed the aircraft’s monetary value, effectively rendering them write-offs.

Industry representatives argue that forcing “premature” overhauls – when an engine might have low running hours and be in good working order – makes no economic sense, especially as the country’s aviation sector is still recovering from the COVID-19 downturn.

Each overhaul can take months (if not a year) due to scheduling backlogs and potential parts shortages. Kevin Storie, CEO of CAASA, highlighted that spare parts are scarce and subject to import tariffs,

compounding the difficulty of compliance. The outcome, opponents say, is that many small aviation businesses face bankruptcy or liquidation because they either cannot use their aircraft or must sink unaffordable sums into them.

Both industry stakeholders and the Democratic Alliance have criticised the manner in which AIC 18.19 was withdrawn, saying it was done with no warning, no stakeholder consultation, and poor communication. The withdrawal came “without consultation” in late 2023, surprising many operators

who suddenly found themselves in non-compliance.

Stakeholders argue that SACAA should have engaged the community to develop a phased approach or alternative solutions (such as a tailored inspection programme or a risk-based extension process) instead of an overnight rule change. The Aviation Watch Action Committee and other groups decried the lack of a “clear path forward” when the AIC was pulled, leaving owners scrambling. This perceived heavyhandedness has fuelled resentment and calls for oversight on the regulator’s decision-making process.

A core argument from opponents is that AIC 18.19 worked effectively for nearly two decades without compromising safety. They point out that over the 17 years

that the 12-year overhaul rule was not enforced (thanks to AIC 18.19), South Africa did not experience any spike in engine-failure accidents attributable to “old” engines. In fact, the general aviation safety record during that period remained strong, suggesting that the combination of regular inspections, adherence to hourly maintenance, and sensible preventative care was sufficient to ensure safety. Industry experts have noted the lack of empirical data or accident statistics to justify the new overhaul mandate.

They also challenge SACAA’s claim of “high risk to safety” as unsubstantiated, citing independent studies and manufacturer Service Bulletins that do not show a significant increase in engine failure risk solely due to calendar age, provided proper maintenance and periodic internal inspections are done. In short, the aviation community is asking: Where is the proof that a well-maintained 13-year-old engine is unsafe?

Many see the enforcement as overreach without science, potentially solving a problem that isn’t evidenced to exist in South Africa’s context.

[Surprisingly what has not been mentioned is the widely held belief (which may be empirically proven) that recently overhauled engines are in fact more dangerous than 12-year old

engines with a long record of serviceability.]

Some critics highlight inconsistencies in how the rule is applied. For example, under current regulations, an aircraft operated privately (non-commercially) might still be flown with an engine beyond 12 years (at the owner’s risk), whereas the same aircraft cannot be flown commercially (for hire) once it hits the 12-year mark. This creates a paradox where an aircraft is deemed “unsafe” for paying passengers but “safe enough” for an owner’s personal use or family, which opponents argue “constitutes a mockery of safety”. (It should be noted that as of 2025, even private Part 91 operators and Non-type certified (Experimental) aircraft are now effectively pressured to comply with the overhaul rule for insurance and airworthiness; Sections of the aviation community feel that SACAA’s decision was driven more by bureaucratic or commercial motives than by actual safety data.

The backlash has extended beyond just pilots and plane owners. News of the grounding of [a claimed] 3,000 aircraft made national headlines in mid-2025, portraying it as a “sudden

policy shift” that threatens an entire industry. The story has been covered in mainstream media and aviation publications, often emphasising the potential loss of 300,000 jobs in the aviation value chain (a figure the CAA disputes). Politically, members of Parliament and provincial authorities have been lobbied to intervene. The opposition Democratic Alliance has been especially vocal – not only demanding AIC 18.19 be reinstated or replaced with an

equivalent measure, but also using this case to criticise SACAA and the Ministry of Transport for what they call heavy-handed and ill-informed regulation.

In short, AIC 18.19’s removal has become a flashpoint in the country’s aviation community, rallying a normally fragmented sector into a unified front against the regulator’s policy.j

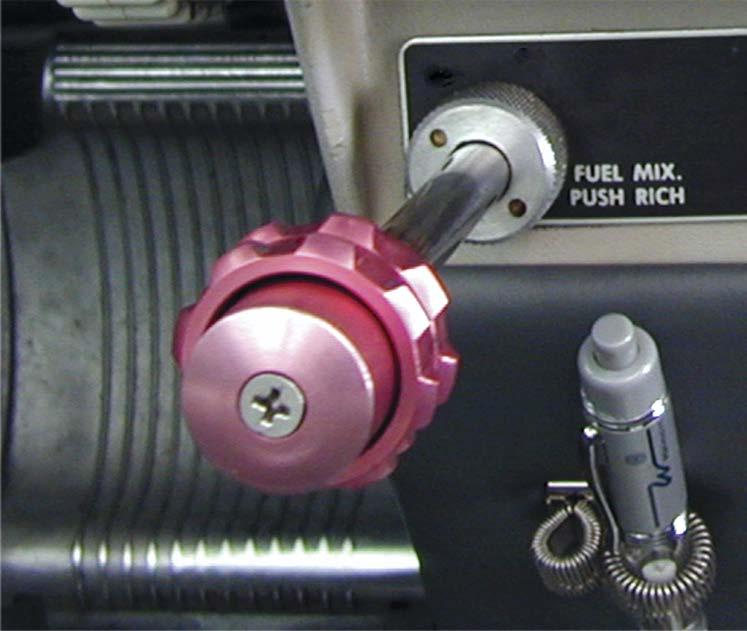

BELOW: Pilots are taught to avoid lean of peak running. A lean mixture makes a reader hot under the collar.

Areader, incensed by my statement that a leanerthan-peakEGT mixture reduces cylinder head temperatures, wrote: Maybe I am missing something, but it is against the laws of physics that a leaner mixture can run cooler, as the more dense the mixture, the cooler the chamber is, thus EGT rises when lean’d, so how can this be “contrary to widespread belief”?

He adds an apocalyptic postscript:

PS We all know that lean mixtures can melt

valves, crack seats, melt heads, destroy plugs, crack cylinders, burn valves, cause premature destruction of all metals

the “hot spot” touches!!

Now some of Peter’s readers will think lean is good - what about the idiot that overleans cuz

Pete says is good cooler and “OK”!! Liability?

Since he doubts, I will call my impassioned correspondent Thomas. His views are those of a great many pilots, though his Shakespearean spelling (“lean’d”) sets him apart from most others. The subject of mixture is not very complicated in principle; where it gets complicated is in practice. Let’s start - since duelling Thomas has chosen that heaviest of weapons, the Laws of Physics - with a little chemistry.

In reciprocating engines, heat is generated by burning a fuel composed of molecules called hydrocarbons, which consist of hydrogen and carbon atoms in various combinations. What we

call burning is a rapid chemical reaction in which oxygen molecules dismantle hydrocarbons and reassemble their components into carbon dioxide (one carbon and two oxygens) and water (one oxygen and two hydrogens). Energy, in the form of heat, is released in the process. The temperature of everything in the cylinder rises, including that of the other gases, like nitrogen, that compose nearly 80% of atmospheric air and do not take an active part in the combustion process. The gases expand, pushing the piston down, and off we go.

If you took high school chemistry, you may recall, if nothing else, that chemical reactions involve atoms matching up in certain definite numerical relationships, like students at a prom - at least the old type of one-boy-to-one-girl prom. If more oxygen atoms are present than there are hydrogen and carbon atoms for them to link up with, they remain, at the end,

BELOW: Having CHT and EGT readings for each cylinder is essential for LoP.

Likewise the hydrogens and the carbons. When the amounts of oxygen and hydrocarbon molecules present are perfectly matched, the mixture is called “stoichiometric” - stow-icky-ohMET-rick. The stoichiometric ratio of air and avgas is about 15.2 pounds of air to one pound of avgas - which may be visualised as a six-foot cube of air and a four-inch cube of fuel.

That is the idealised picture. Reality is more complicated. Because both fuel and air contain a potpourri of components, a lot of other chemistry goes on in the hightemperature environment of the cylinder. Burning, furthermore, is not a pure and instantaneous process; it is affected by spark timing and flame propagation rate and quenching by the relatively cool cylinder walls and various other things. Nevertheless, a few general statements about mixture and engine health can be made. They are not the ones offered by Thomas.

FLYER MAGAZINE - july 2025 wallflowers.

We can’t weigh the air and fuel entering the cylinder while we’re flying, so we measure the mixture by the exhaust gas temperature (EGT) instead. You would expect that an excess of fuel or air would dilute the heat released by combustion and thereby lower the EGT. So it does. You might also assume that the highest power output and the highest cylinder head temperature (CHT) would coincide with the highest EGT, but there you would be wrong, because of some of the aforementioned complications of combustion.

Different engines have slightly different characteristics, but a typical Lycoming chart shows that power output peaks when EGT is about 125º F on the rich side of peak (ROP). Cylinder temperature is highest at 25º ROP.

Efficiency - power produced per

pound of fuel burned - is greatest at about 40º on the lean side of peak (LOP). These figures vary somewhat with power setting and among different engines, but the general trends remain the same.

This Lycoming chart and others like it have the fuel-air ratio as their baseline. Their perspective is that of a researcher, not a pilot. Since pilots can measure that ratio only by EGT, EGT should be our baseline. With this in mind, I have redrawn the chart.

Mixture, measured in degrees Fahrenheit below peak EGT, grows leaner from left to right. The coloured lines show how fuel flow, speed and cylinder head temperature change as the mixture becomes leaner.

You can see at a glance that fuel consumption (blue) is very sensitive to mixture. Speed (yellow) varies little on the rich side of peak, but falls off more rapidly on the lean side.

These changes are expressed as ratios to the values at peak EGT; that is why all the lines converge at the peak EGT point. For example, at 100º F on the rich side of peak EGT fuel consumption is 20% greater than at peak EGT. That is, if you burn 15 gallons an hour at peak EGT, you will burn 18 at 100º ROP.

In a graph like this the steeper the slope of a line is, the larger and more rapid is its response to the controlling variable - in this case, EGT. Lines that are relatively flat reveal small, probably inconsequential variations.

The most interesting line, in the context of Thomas’s prediction of a general deflagration within the engine, is that of CHT (red). CHT rises gradually as the mixture is leaned, hits its maximum a little on the rich side of peak, and drops thereafter. It drops much more steeply on the lean side than it rises on the rich side. Many pilots, trained to shun an overly lean mixture, would find this hard to

believe, but pilots who regularly fly on the lean side of peak know it well: Cylinder heads run noticeably cooler LOP.

So how did Thomas, and others like him, get the idea that LOP operation would fry an engine?

I suppose it may be due to a number of factors. One is historical. Much of the science of high-performance aviation recips was developed before and during World War Two, and applied to highly supercharged engines whose design goal was a high power-toweight ratio. These engines were diffi-

cult to cool and prone to detonation at high power, but could be protected by running rich - in effect, cooling with fuel. There arose, consequently, an association of lean mixtures with possible heat damage, and rich ones with safe, conservative engine management.

The story of Lindbergh teaching fighter pilots in the Pacific theatre to increase their range by leaning the mixture and reducing rpm illustrates that belief. You would suppose that when cruising long distances over open water one would naturally lean the mixture out of concern for one’s own

skin. But pilots were apparently not doing it, I suppose because they believed that richer was better.

That belief filtered down through flight instructors to their students. When fuel was cheap, flight schools didn’t mind using it for cooling. Proper leaning also requires EGT instrumentation that trainers seldom had, and an attention to engine management that students - not to mention most pilots

- did not care to pay. With fixed-pitch props, furthermore, the most salient effect of leaning - only up to a point on the rich side of peak - was to increase power and speed, and that was what pilots liked.

Furthermore, many engines, including most carburettor-equipped ones found in trainers, do not lend themselves to LOP operation because of unequal distribution of fuel to the cylinders. If one cylinder becomes so lean that it begins to miss while another is still running at maximum temperature, LOP cruise is impossible.

The engine manufacturers have vacillated on mixture, with Lycoming usually taking the more conservative stance. GAMI, the Ada, Oklahoma manufacturer of custom injectors designed to even out the mixture distribution among cylinders, strongly advocates LOP operation, and as far as I know has not had to pay for a lot of melted engines. My own practice is to lean to about 50º LOP immediately after takeoff and stay there, climbing and cruising at 65% power or less. As you may guess, I am not uninfluenced by the price of Avgas.

Thomas would - no doubt - call me “the idiot that overleans.” He wouldn’t be the first. But at least my cylinders are cool. Furthermore, at 1,800 hours I have never had any valve or cylinder trouble and my compressions are all better than 75/80.

Sorry, Thomas, but you’re wrong.

de Villiers Engelbrecht is the new CEO of Airlink. In an interview for this issue with Guy Leitch he made the following (in retrospect obvious, but still telling) observation.

“Pilot pay is tied to the dimensions of the aircraft.”

StandardAero Lanseria, a Pratt & Whitney PT6A designated overhaul facility (DOF) and the sole independent DOF approved for the PT6A-140, is pleased to support operators across Africa with Pratt & Whitney’s Flat Rate Overhaul (FRO) program for PT6A engines which combines OEM-level quality with guaranteed “not to exceed” capped pricing. Meaning that you can plan your maintenance expenses with confidence, and without any compromises.

The FRO program does not incur extra charges for typical corrosion, sulphidation or repairable foreign object damage (FOD), and PMA parts are accepted.

As the industry’s leading independent aero-engine MRO provider, StandardAero is trusted by airline, governmental and business aviation operators worldwide for responsive, tailored support solutions.

RAISING THE STANDARD OF EXCELLENCE years of PT6A MRO Excellence

IF YOU WERE FERRYING A 235 CHEROKEE ACROSS AN EXTENSIVE LUMP OF VERTICAL SCENERY IN THE SOUTHERN CAPE WHEN THE ENGINE SUDDENLY BECAME INTERMITTENTLY REBELLIOUS, YOU WOULD BE FACED WITH SOME SERIOUS DECISION MAKING.

WOULD it be a good idea to pull the power right off and do a forced landing on an iffy bit of territory near the bottom of a valley, or would it be better to hope the Lycoming had sufficient fortitude to carry you across the last patch of tiger country?

Being a devout coward, I went for the reasonable certainty of a safeish landing in the valley rather than a nerve-twanging ten minutes of yes-nomaybe across the remaining nasties.

At the time I had perhaps 10,000 hours in Cherokees, much of which was instructing, and much of that was doing glide approaches and practice forced landings, so getting safely into my chosen field should have been easy.

Dear parishioners and instructors, the words should have are the giveaway. Before reading on, take a sip of communion wine, close your eyes

JIM DAVIS

and try to imagine the devils that would conspire to make this forced landing a particularly hellish one. What would make it so much more difficult than all the previous ones?

Okay, here are some of the things that make training forced landings a bit of a farce because they generally don’t prepare you for the real world.

First, it’s very rare that a healthy engine suddenly stops without

it’s very rare that a healthy engine suddenly

warning. Certainly, engines can do this – particularly when you run out of fuel, or run one tank dry. But in these cases it should not come as a surprise.

And if this does happen the following standard procedure will take care of it:

1. Close the throttle – smoothly

2. Change tanks, and

3. Head for the landing area

Let’s run through those points.

Close the throttle. There are two main reasons for this. First, you immediately know where you stand with your aircraft – you are flying a glider.

The engine is not going to give you any unexpected starts and stops that might cause you to keep changing your plans. Second, each time the engine suddenly changes between power and no power, there is a danger that the crankshaft counterweights become ‘detuned’. Here’s what Mr Lycoming has to say about it:

Detuning the counterweight system of the engine can occur when the engine operates outside of its normal range and by abrupt throttle change. When this happens the dynamic counterweights cannot follow the spectrum of frequencies for which they were designed and rapid and severe damage to the counterweights, rollers and bushings may result, culminating in engine failure.

Also, detuning can occur if the power is suddenly cut-off, such as during a simulated engine failure as required for pilot training. To avoid detuning during simulated engine failure, use the mixture control to shut off the engine and leave the throttle in the normal open position until the engine has slowed down due to lack of fuel. Then close the throttle to an idle condition. The throttle being open allows the cylinders to fill with air, maintaining the normal compression forces which are sufficient to cushion the deceleration of the engine.

Obviously, it’s fine if you close the throttle normally and gradually, but that does take away the startle factor of a simulated engine failure.

Even with a real engine failure

after takeoff, it’s important to close the throttle. My mate Neville Austin had one in his Colt. He got the aircraft into a short field with gum-trees at the far end, but just after touchdown the engine came to life again at full power.

Neville found himself in a silly situation with both hands pulling on the donkey’s-dong brake and no spare hand to close the throttle.

Right, that’s dealt with the throttle –now let’s move on to the fuel.

Change tanks. Fuel starvation is by far the most common cause of engine stoppages. So it makes sense to

change tanks – and bang on the fuel pump. NOTE – fuel injected Continentals often don’t like having the pump switched on during flight, so be very careful to follow the POH’s instructions about the pump. Do that NOW – not after the engine failure.

Head for the landing area. If you say; ‘but I haven’t selected a landing place yet’, then please light a big fire in the garden and chuck your license into it. You shouldn’t be flying if you don’t have a back door in mind all the time. It might not be a specific field, but it should at least be an area: towards the

farmlands to my left, or away from the mountains, or away from the forest, or towards the beach, or towards the golf course.

And you don’t need to finish fiddling with the fuel system before you turn. You should close the throttle and change tanks while you are turning.

The story about converting speed to height is mostly nonsense. Think about it – the chance of your landing field being straight ahead are only one in 360, so use your speed to get you round the turn rather than gliding away from the field while you convert speed to height.

In an aircraft that cruises at 120kts and glides at 70 you aren’t going to gain much height by the time you have recovered from the startle factor and taken action.

Finally, I think it’s dubious whether trying to gain height will do any good. If you convert kinetic energy to potential energy, you don’t gain total energy. In our little aeroplanes, if the field happens to be straight ahead, simply hold the nose level until you are at your best angle of glide speed.

And this brings us to another bit of guesswork. The best angle of glide speed only works if there’s no wind. If there’s a tailwind then you need to reduce your airspeed a bit to have the advantage of the tailwind for longer; but if you glide into wind then you need to lower the nose a bit so that the extra airspeed helps you cover more ground.

Exactly how much you need to change your glide speed to allow for how much wind is anybody’s guess.

Here’s a mind experiment to help you understand the wind problem. Let’ say you are a couple of miles offshore at 3000’ when the engine stops. You immediately turn towards the beach and come back to your best angle of glide speed of 70 kts. Unfortunately there is a 70 knot off-shore wind, so you will have a groundspeed of zero. You are stationary and will land in the water immediately below your present position.

However, if you stuff the nose down and glide a 100 kts you will at least be approaching the beach at 30 kts.

Obviously, if you glide downwind, you will have better range if you come back slightly to your best rate of descent speed – but no slower.

So I hope that thought will help you and your pupes remember that you need to increase your airspeed if gliding into wind.

Phew. That covers your initial actions. Just close the throttle, change

tanks and head towards your field. Next TRIM. You and I know that trim is a flying control – not a checklist item. But it’s your job to make sure your pupil uses it all the time to relieve stick pressures. If she doesn’t trim now the whole thing is going to be a dog’s breakfast with the airspeed all over the place. It’s your job to hammer this into her head particularly for a forced landing.

You can do this while you are trimming.

Conventional wisdom says you should have key points at which you should be at a certain altitude. Guys and girls and instructors and pupils and captains and copilots please don’t try to use key points, and particularly don’t teach it – it does not work. For those at the back who are dozing – let me shout that out again – key points don’t work.

Yep, I know you have used them and they do work for you at your home airfield, and where you know its elevation and your altimeter is set to QNH. But for real world forced landings where you don’t know the elevation of the field

and the altimeter is set to something else – key points don’t work. Promise – I’ve been there several times.

So don’t chase the altimeter; it’s a waste of precious time that you should be using for judgement outside the cockpit.

Okay now we have dealt with those initial actions – you are gliding towards an area of decent landing places and the aircraft is nicely trimmed. Here are the last steps:

1. Engine

2. Mayday

3. Pax

4. Landing checks

Do a round-the-cockpit check to see if you can find the problem and get the engine running again. I advise going round the cockpit rather than trying random things. This way you will know you have tried everything – there’s no chance of missing something, and you don’t have to keep wondering about it.

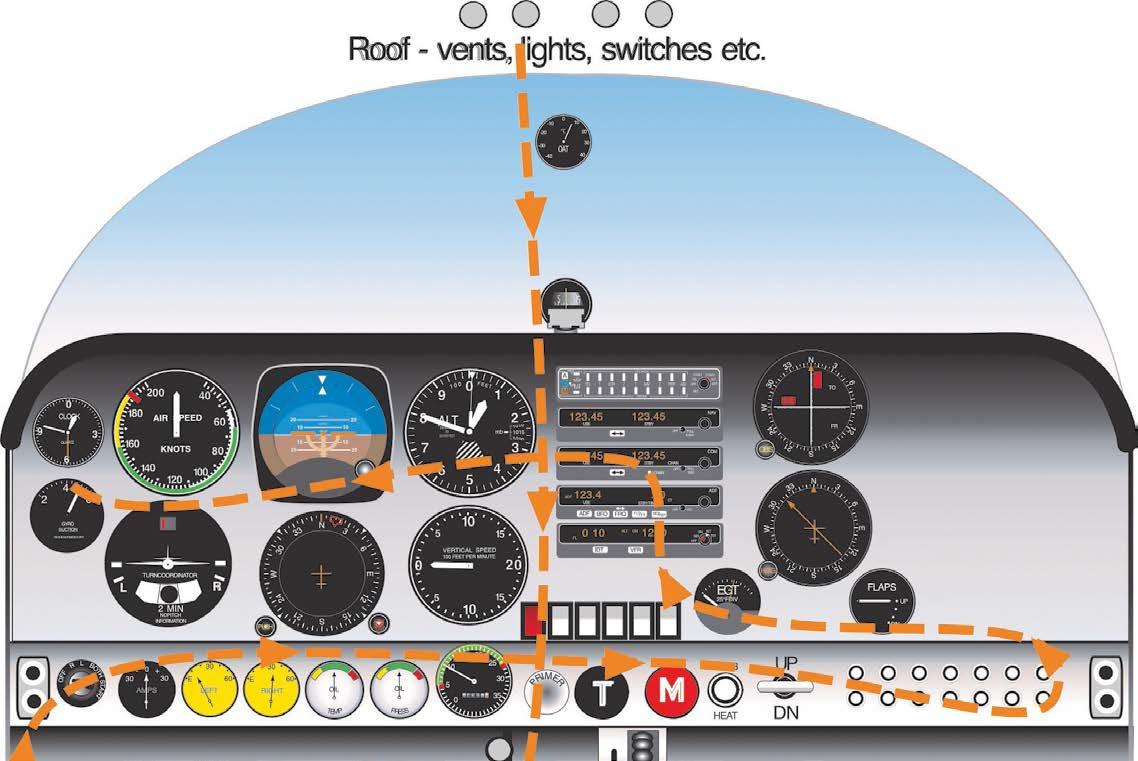

I suggest you start in the roof – go down the windscreen pillar to the centre console and then on to the floor and between the seats. Then you work your way from the fuel selector to the left of your knee (in most of the Piper singles) and then across the bottom panel and back across the top panel.

Have a look at the diagram. This method works for all aircraft – so

you don’t have to memorise different checks for each aircraft.

I’m going to spend a bit of time on this because, surprisingly, there are a number of things you can do in the cockpit to restore either normal or limited power,

Starting in the roof – some aircraft have mag switches there, others have fuel gauges, fuel pumps, and even the throttle, pitch and mixture controls. If this doesn’t apply to the aircraft you are flying, still teach your pupe to start in the roof – one day it will apply if she flies enough types.

What is an engine failure? Actually, the answer is not that obvious. Here are six types, each needing different treatment.

This is the one they teach at flying schools. It’s almost certainly fuel. You have run a tank dry, or there’s a blocked pipe, or the pump has packed up. Putting on the pump and changing tanks will probably fix it.

Try throttle friction and carb-heat first. Otherwise don’t trust the brute – it can dump you at any moment. If you

are over towns or tiger country use the remaining power to get you within gliding distance of a landing place –and then sit.

Don’t worry about fault finding – just plan your descent. Actually you glide a bit further with the prop stopped so you may need to allow for this.

This is nasty. It can give you false hopes and lead you into deeper trouble. Remember my mate Neville in his Colt – it’s a powerful lesson that applies to any engine failure, once you are committed to land – throttle fully back. That way you know where you stand.

Intermittent troubles can be dirt or water in the fuel. Or a baffle in the silencer breaks loose and falls over the outlet pipe. Vibration can cause it to sometimes cover the pipe and sometimes not. I had the mixture cable detach itself in a Grumman Trainer. This allowed the little arm on the carburettor to swing back and forth causing random bursts of power. You might be able to use spasmodic power to get you to a landing spot –but don’t count on anything. Sometimes it’s best just to close the throttle and treat it like a total engine failure.

You see, hear or smell something that tells you there is trouble brewing. While a warning is great, it can easily panic you into making a lethal decision.

A pilot and three pax took off from Wonderboom in a Cessna 182. At 400 feet the oil-cap came off covering the windscreen in black oil. The pilot, thinking he had a catastrophic engine failure, did the worst possible thing. He flung the aircraft into a steep turn to get back to the runway. Halfway round, the aircraft stalled and spun, killing all on board. Investigation showed that the engine would have kept going for a long time. So don’t let an oil leak panic you - it takes very little oil to make a huge mess.

When something starts going wrong look for supporting info to back up your suspicion.

I was flying a Cherokee at low level over the bush when the engine started to smell hot. The gauge confirmed high oil temp then the pressure started dropping. I was heading for a major failure. Fortunately I was able to land on a farm before the big event.

I collected a toilet roll in the air intake of my Tiger Moth – don’t ask. Also had a spark plug unscrew itself and blow out of the cylinder just after takeoff over the Knysna lagoon.

It caused such a lean mixture in the manifold that the engine died completely. I mention this category because machinery has a habit of confounding the wise by inventing new ways of failing.

So that deals with the engine. Remember we said after your initial actions, which had you nicely gliding towards the field with the aircraft trimmed and a plan in your mind, there were four things to do before touchdown, they were:

1. Engine

2. Mayday

3. Pax

4. Landing checks

So we have dealt with the engine. If you can’t get it going, now is the time to make your Mayday call – but only if you have time. We all know the sequence aviate, navigate, communicate. So communicate is the least important.

Brief them – you know the drill which includes popping the door and wedging a shoe into the gap so it can’t close again.

Again, you know what to do but I’m always horrified to see photos of aircraft that have had a forced landing and they often have little or no flap selected.

The Gleitch won’t give me the space to explain why the energy that has to be dissipated after a flapless touchdown is often close to double that of a full flap on-the-stall landing. In plain language a full flap landing is by far your best bet. Instructors – when you explain this, emphasise it’s because of the square-of-the-speed rule. Double the speed causes four times the damage.

Finally discuss your choices on the gear-up or gear-down debate. A lot of it revolves around high-wings tending to nose over and go on their backs if the nose gear breaks off or sinks into soft ground.

The SAAF taught us to put the gear down regardless of terrain. If it broke off that in itself would have a slowing down effect. Also in a low-wing aircraft the gear would keep the wings and fuel tanks off the ground for at least some of the landing roll.

Ultimately it’s an informed decision that you alone can make.

Next time I want to tell you about at least ten controls that you can fiddle with in the cockpit that may restore some or all of the power, as well as some surprising things to consider when you look for a field.

• Now certified for TCAS training.

• RNAV and GNSS Certified on all flight models from single engine to turbine.

Tel: 011 701 3862

E-mail: info@aeronav.co.za

Website: www.aeronav.co.za

It’s not always the pilots’ mistakes which cause the disasters, whatever you may have gathered from all those reports which you have read.

IF the tail fin falls off, like it did on the Japanese 747, there is only going to be one end to the story. The fact that those pilots managed to stay in the air for over twenty minutes in that configuration is extraordinary enough, but that four people should have survived the ensuing meeting between the aircraft and the mountains is a miracle.

In another recent tail fin disaster, the only way the pilots could have avoided the tragedy would have been to refuse the Takeoff clearance. But why should they have done that? OK, they were some seconds short of the statutory separation time, but in how many instances has wake turbulence been found to have torn an aircraft to pieces in the air? That’s right. Never. If a door comes open in flight, then there is generally a more direct trail to the culprit. Who didn’t shut the door properly? Why not? How can we pre-

vent it happening again? And doors have caused their fair share of disasters.

We’ve seen them come off and wrap themselves round the horizontal stabiliser, removing all elevator control.

We’ve had them blow out at altitude, causing explosive decompression which collapsed the cabin floor and seized all the control cables.

There was a recent incident in the Caribbean with a Twin Otter, when a

nose locker door came off. Half of it smashed through the windscreen and the Captain’s head. The other half tore its way through the blades of the left propeller and caused the aircraft to crash into houses on short final.

My incident, although dramatic, was, fortunately not catastrophic.

I had just picked up a surgical team of two doctors, Tom the surgeon, David the anaesthetist and a theatre nurse called Pam, from a place called Kassulu, not far from Lake Tanganyika in

Tanzania. Kassulu is very close to Ujiji, where the American explorer, Henry Morton Stanley, made his famous “Dr Livingstone, I presume” remark upon meeting the legendary David Livingstone, after an epic nineteenth century search.

The aircraft was, once again, the trusty Cessna 402B.

We climbed away and set course for Nairobi. Once established in the cruise, I settled myself down for the beauti-

ful ride over the Serengeti Plains, past the vast crater of Ngorongoro and the Great Rift Valley.

About twenty minutes into the flight, an invasive hissing sound started to bother my left ear. I checked the handle of the pilot’s access window. It was in the locked position. The secondary lock, on the forward frame of the side window, was also closed. I reached across with my right hand to test whether the spade-grip handle was indeed fully locked. As my hand touched the handle, there was a cataclysmic bang, followed by an all-pervasive roar, a crash and an impact on the top of my head. The pilot access door had disappeared.

The view was incredible, since I was now looking out through a gaping hole in the side of the fuselage. My immediate problem was that the cockpit roof continued rhythmically to bang the top of my head. Hurried research revealed that the door, being hinged at the top, had swung open in the wind violently enough to crush the roof of the cockpit. As the broken roof flexed in the passing torrent of air, the flow changed, pushing the door upwards until it hit the clean air above the fuselage. This drove the door down again and the cycle repeated itself...with my head as the buffer.

My immediate reaction was to reduce speed and the immediate reaction of the door was to stop bouncing

the roof on my head. So, obviously, I was doing the right thing, to start with anyway. The next thing to do was to check and make sure that all the other bits of the plane were still on the team. We appeared, with the exception of the door and the cockpit roof, still to be playing with a full pack.

Next thing...we needed to get back on the ground ASAP, or sooner, so I gently turned the nose of the aircraft back in the direction of Kassulu. Now my attention turned to my passengers. I beckoned to the surgeon to come forward and he gingerly left his seat and edged his way cautiously up to my end of the plane.

“Tom!” I shouted against the roar of the passing wind, “The door latches have broken. We’ll have to go back to Kassulu. Everything else seems to be OK, so could you reassure David and Pam and I’ll get through to Ops and ask them to call Kassulu Hospital to come and pick us up.”

“Right, Hugh. Anything else you need us to do?”

“No thanks Tom.” I laughed nervously, “I expect you’ve already said your prayers haven’t you?” Tom was well known to be a rabid atheist, but he saw the joke and carried his laughter into the back, to infect the others.

The flight back to Kassulu was uneventful and the next day engineers came down and stuck the door back in place so that I could ferry the plane

back to Nairobi for repairs. It was discovered that the spade handle main lock could be twisted into the locked position without the latches being pushed fully home in the frame. The shutting mechanism had become deformed through years of use and the latches were only hanging on by their finger nails. Then one day the finger nails broke and the door flew open.

The incident with the window was, as far as I’m concerned, the fault of the design. Out of interest, the internal enquiry found me culpable because “...it is the responsibility of the pilot to ensure that all doors and hatches are secured before flight.”

The fact that the mechanism was found to be faulty was produced as ‘mitigating circumstances’, which meant that I did not have to submit myself for ‘further training’ or any other humiliation. Still the culpability smarted a bit and in fact, still rankles to this day!

Iran and Iraq abruptly closed their airspace following American and Israeli airstrikes on Iranian nuclear facilities.

THE closures forced widespread flight diversions and cancellations across the Middle East, particularly on key routes connecting Asia and Europe.

Airlines such as Emirates, Lufthansa, Air India, and flydubai have rerouted or grounded flights, with some carriers opting to divert through Central Asia and Saudi airspace. Iraq suspended all aviation operations, while Iran imposed a total airspace ban.

Air India confirmed that at least 15

international flights—originating from Washington, Toronto, and London— were rerouted via Vienna, Frankfurt, and Jeddah. Delhi Airport said operations remain normal, though authorities advise passengers to check with their airlines.

Aviation risk analysts note that commercial aircraft have previously been caught in regional conflicts, and caution remains high across Jordan, Israel, and neighboring regions, where airspace restrictions are also in effect.

Day and night, the fun doesn’t stop!

Our catered camp site on the airfield means you won’t miss out on any of the activities – the early morning wake up call of P 51’s getting airborne, the evening ultralight parade, the STOL competitions and of course, the incredible night airshows! Plus all the camaraderie and fun only a camping group can offer.

Our campsite offers you a home from home at Oshkosh, tents and bedding, meals and beverages, charging facilities and sheltered seating – no camping gear required, bring only your clothes!

Tours depart Johannesburg, Durban or Cape Town Friday 18th July and return Tuesday 29th July 2024.

Prices from R40 650, Early Bird specials available!

Neil +27 84 674 5674 info@airadventure.co.za www.airadventure.co.za Secure your place HERE

The twin for our time?

Diamond Aircraft’s DA42 Twin Star has been around for years, but as the twin training fleet ages, the need for a modern replacement becomes all the more evident.

WHAT makes Diamond’s DA42 different is that it is the first successful light twin-engine design in more than 25 years.

The JetA burning engines had a difficult birth. Diamond started out with Mercedes car derived Thielert Centurion 1.7 turbocharged direct-injection diesels of 135hp (a nice round 100kW). The engines feature dual-channel, full-authority digital engine control (FADEC) allowing powerplant and propeller settings to be

LEFT:

BELOW:

governed by a single power lever and allowing almost carefree studentproof engine handling.

Teething gearbox and cylinder head problems bankrupted Thielert. Fortunately the design and concept was deemed worthy of saving and so the engines were taken over by a new company, Austro, who solved the problems.

The sleek airframe with its compound curves is composite carbon fibre, giving the DA42 passive safety levels that meet EASA 21 rules, as well as efficient aerodynamics and an essentially unlimited airframe life.

Key for the multi engine training market is that the latest iteration, the DA42NG features Garmin G1000 NXi integrated digital avionics based around two large flatpanel screens that replace conventional instruments and include a crew alerting system (CAS). The fully integrated Garmin G1000 NXi is complemented by an integrated autopilot and a long list of avionics options - such as weather radar and synthetic vision. The maximum operating altitude is 18,000ft and a cabin oxygen system is fitted to supply all four occupants for extended flights above 10,000ft. This makes it easier to take advantage of the high

altitude speeds available from the two turbocharged engines.

on a C172 camership. We flew out of Hoedspruit Civil on a

The pre-flight is straightforward. There is an inspection panel in each nacelle to check engine oil level. The two locking catches for each baggage compartment door in the nose need to be checked thoroughly. Hoedspruit based former Mirage fighter jock, Koos Kieck, happily agreed to fly the DA42 from the right seat for air to air photos, formating

warn 30-degree Celsius day with two in the front, one in the back seats, minimal baggage and half fuel. This gave a CofG in the middle of the envelope, a takeoff weight of 1,585kg (3,495lb), and still left a very useful 125 kg (275lb) useful load. You get into the cockpit via a small step behind the wing root and handles above the cabin windows to climb on to a

wing walkway. The huge forward tipping canopy makes it possible for each pilot to enter from his own side, but passengers only from the left side. The canopy must be opened carefully in a high wind. The forward-hinged clamshell cockpit canopy is enormous and you tend to step into the seat from above, rather than from the side. Flying in the rain will make the cockpit wet.

Useful for the African sun, Diamond has painted a large fixed

sunscreen on to the canopy to shade the occupants.

From the left seat, the field of view is excellent all the way around to the horizontal stabiliser

above the fin. But the view over the nose is limited by a higher glareshield to accommodate a horizontal row of standby flight instruments above the Garmin screens. Also, the nosewheel leg is long for prop clearance.

The seats are fixed to the floor for crashworthiness and have lumbar adjustment. Rudder-pedal position is adjustable to accommodate the pilot's height and the inertial reel car-type three-point seat belts are easy to use. Storage nets on the cockpit walls secure gadgets.

Unusually for a twin, each pilot has a fighter-like control stick that grows out of the seat squab. This makes for a clean and uncluttered cockpit floor and avoids the pilot’s hand obscuring the instruments.

Pre-start checks are simple. Inserting the ignition key brings up a notice on the screen confirming the diesel glow plugs are energised.

Engine start and propeller rotation is instantaneous, with the ‘glow’ caption disappearing, accompanied by a distinct change in engine tone, after about 5 seconds. The key can then be released, with the geared prop spinning at around 900 rpm.

With both diesel engines chuntering happily on the wings, the avionics master is turned On, bringing up the flight and navigation displays on both EFIS screens. The two FADEC channels on each engine are cycled with a push button and you are ready to taxi.

For taxiing on hot days, the canopy

Throttled right back to 34% power for photos from a C172 fuel flow is just 5.6 USgph.

You

can be locked in a cooling gap position. To get going, power is increased to 1,200 rpm and we moved forward briskly. Once moving, power is reduced to 1,000 rpm to maintain the flight school recommended ‘fast walking pace’.

The wide-track undercarriage gives a solid and stable feel, especially when taxiing over rough grass. The rudder pedals and toe brake arrangement is similar to that in gliders with the pedals pivoted from a central point at their base. Accurate taxiing can be maintained with small pedal deflections. The disc brakes are effective and not grabby.

ABOVE: Nose baggage bay is tight but helps with CofG.

OPPOSITE PAGE: Four seats plus good baggage space makes the DA42 a useful tourer.

The two power levers are the only engine/propeller controls, so the centre console is uncluttered, unlike legacy twin-engined aircraft.

Pre-takeoff vital actions are again short, logical and simple. You enter V-speed bugs on the vertical airspeed tape of the G1000: VR was set at 74 kt and V2 at 83 kt.

We had a brief taxy to the holding point of Runway 35, and the engine warmed quickly for the brief run-up. With full power against the toe brakes, we checked each engine was stable at 2,300RPM and that the CAS field in the G1000 screen was empty.

Takeoff acceleration is brisk. Despite a gusty crosswind, the centreline could

be accurately tracked. Rotation off the runway and into an 8° nose-up climb attitude was done in one easy movement with a small stick deflection. Takeoff distance was about 350m.

Gear was retracted almost immediately after lift-off with no pronounced trim change. The DA42 accelerated to a climb speed of 100kt and 850 fpm and the aircraft is responsive and easy to fly.

For turns up to rate 1, the controls are well harmonised but steep turns require rudder to keep the ball centred. Aileron-only turns, using full stick deflection, resulted in an immediate, opposite heading change of about 5 degrees due to adverse yaw, but this was neutralised by the

aircraft’s natural directional stability after 2-3 seconds.

The engine power levers are easy to use, allowing virtually carefree operation. Diamond recommends the levers are advanced from idle to full power over about four seconds, rather than slamming them open.

each

Both Garmin EFIS screens can show the same basic information, or flight data can be shown on the left display and navigation on the right. The vertical tape presentation of airspeed, altitude and vertical speed take getting used to when converting students from an aircraft with old dial-type instruments.

The latest G1000NXi offers an incredible

array of features as an advanced display and flight-management system combined, and both new and old pilots will need almost as much training on this as the aircraft itself.

Testing the handling straight and level revealed that the natural stability is good. The pitch change phugoid is well damped and, with a period of a stately 60 seconds, would not be obtrusive in cruise flight. The short-period check showed the aircraft was quick to respond to stick input and well damped. Dutch roll was quickly damped within half a cycle without the need for pilot input. Spiral stability was neutral or slightly positive, which is a good safety feature for inattentive students.

Unaccelerated stalls were evaluated with zero, takeoff and landing flap deflection, all at idle power, and were docile. Controls in all axes were effective approaching and in the stall. The stall

warning horn sounded 5-7 KIAS above stall, which was indicated by increasing airframe buffet, a distinct nose drop and vertical descent of about 2-300ft/min. There was no wing drop even with aileron input.

The flaps up stall was around 65 KIAS and with full flaps 58 KIAS. A stall in approach configuration, with take-off flaps and 30% engine load, but with the nose about 20° above the horizon and distinct airframe buffet, had the horn sounding but virtually no sink rate. The plane just mushed and refused to try drop a wing. I reckon any pilot or student would have to more than grossly mishandle the aircraft on approach to stall it.

Our final check was to assess the DA42’s behaviour after a simulated engine failure at V2. We stabilised at 80 KIAS with full power, the nose about 10 degrees above the horizon and then the left power lever was pulled back to idle. The swing

towards the dead engine was instantaneous, but could be held with rudder, although the rudder forces were high. Once the gear was retracted, the rudder force reduced as the nose gear doors were no longer acting as a forward fin.

In cruise at 75% power, in level flight at 165kt and 5,000ft, fuel consumption was 21 litres/h (5.5 US gal/h) per engine, with the EFIS showing a

excellent economy and the latest and highest levels of passive safety.

The DA42 has no natural competitors in its class and sets a benchmark for new generation twin trainers.

Diamond took a bold step in combining so many new technologies in an all new aircraft. As a trainer it was perhaps a plane ahead of its time but now, 15 years since production

1,110km (600nm) range and 4 hours endurance. In a long-range cruise at 50% power and 140kt, fuel flow was 14 litres/h, calculated range 1,480km and endurance 6 hours.

The DA42 is delightfully easy to land. It is stable in pitch and can be held slightly nose-up and allowed to settle. Touchdown was at about 60 KIAS and it was easy to track down the runway.

The DA42 is a delight to fly and easy to operate, combined with high performance, modern technology,

began, it is an aircraft that should be in every flight school’s fleet to produce new generation pilots accomplished in handling modern avionics.

Unfortunately for South African flight schools the massive new price tag of around U$1.5m landed in SA means that the capital cost is hard to justify compared to say an 50 year old Baron 55 or Seneca 2 for a tenth of the price.

SPECIFICATIONS SOURCE: MANUFACTURER’S FIGURES

Engines : 2 × Austro Engine AE 300 168 HP

Propellers: 2 × MT 3-blade constant speed

Wingspan 13.55m 44 ft

Fuel grades: Jet A-1, Jet A

Empty weight without options: 1,420 kg 3,131 lbs

Max. useful load: 579 kg 1,276 lbs

Max. takeoff weight: 1,999 kg 4,407 lbs

Fuel capacity total: 289 l / 231 kg

Max. speed (16,000 ft, MCP): 365 km/h TAS 197 kts TAS

Max. cruising speed (16,000 ft, MCP): 352 km/h TAS 190 kts TAS

Cruise speed at 75% (16,000 ft): 324 km/h TAS 175 kts TAS

Stall speed, landing configuration: 115 km/h CAS 62 kts CAS

Rate of climb (ISA SL): 1,760 kg TOW 5.7 m/s, 1,114 ft/min

Single engine service ceiling (climb rate 50 ft/min):

4,878 m 16,000 ft

Single engine absolute ceiling (climb rate 0 ft/min): 5,335 m 17,500 ft

Range at 60% (12,000 ft, no reserves): 2,038 km 1,100 nm

Max. range (FL 180, 50% PWR) no reserves: 2,269 km 1,225 nm

Fuel Consumption at 60%: 39.4 l/h 10.4 US gal/h.

Short field takeoff and over 50ft: 1,115 ft 375 m / 649 m 1,230 ft / 2,129 ft

Landing ground roll (ISA SL): 340 m

There has been much speculation as to what the long overdue 737 replacement will look like.

Boeing has taken the first real step toward replacing the 737.

ON June 13, the U.S. plane maker issued a formal Request for Information (RFI) to engine makers, asking for proposals on a new 30,000-pound-thrust powerplant—one meant for a future single-aisle aircraft that will succeed the 737 family.

The company made clear it still prefers ducted propulsion over more radical open-fan concepts, though both are still being considered.

That sets the stage for a multibillion-dollar race. Rolls-Royce, Pratt & Whitney, and CFM International (GE/ Safran) are expected to respond, all

armed with new-generation tech from ongoing sustainable engine programs like CFM’s RISE initiative.

CEO Kelly Ortberg said, “We’re not ready… but we need to be when the market is.”

The request marks Boeing’s strongest signal yet that the MAX line will not survive another generation. As regulatory scrutiny, airline frustration, and industry innovation mount, a clean-sheet design is the only way forward.

And for engine makers? This is sure to be the biggest single-aisle contract of the next 20 years.j

Church Belinda Valhalla 079 636 9860 churchbs@live.com

Du Plessis Alexander Athlone Park 031 904 7460 dex.duplessis@intercare.co.za

Erasmus Philip Benoni 011 849 6512 pdceras-ass@mweb.co.za

Feinberg Rodney Lyndhurst 011 882 6010 rodneyfeinberg@gmail.com

Govender Deena Umhlanga Rocks 031 566 2066/7 deena@drdg.co.za

Head Brandon Sandton 010 448 0900 reception@drbradonhead.joburg

Maneli Lumka Sandton 083 471 2051 lumka@doyioccuhealth.co.za

Toerien Hendrik White River, Nelspruit 013 751 3848 hctoerien@viamediswitch.co.za

by Peter Garrison

C-GFFG was a tailwheel modified Cessna 150, which changes fuel readings. Image Guy

DATE: 26 JULY 2023

On the morning of 26 July 2023, the pilots met at Lachute Aerodrome, Quebec, to conduct a day VFR flight to familiarise one pilot with tailwheel flying. There was a delay at the refuelling station, so they did not add fuel. They flew to Hawkesbury, Ontario, where the second pilot practiced takeoffs and landings. At about 11.30 local time they landed and shut down. About an hour later they took off and headed to Alexandria Aerodrome, Ontario. They arrived at 12.55 and completed two circuits on

Runway 25. They then repositioned for takeoff on the threshold of 25.

At 1310:57 a cockpit mounted GoPro showed that shortly after takeoff, and below 200’ agl, they had a momentary partial power loss. The instructor, in the right seat, took control and performed a 180° left turn for an approach to Runway 07.

During the turn there were two more partial power losses. They banked steeply and re-aligned about half-way down the runway. At 1311:35, with less than 1000 feet of runway remaining, the instructor applied power before touchdown and initiated a go-around.

Seven seconds later, during the climb, the aircraft was just below 100’ agl and the ASI was fluctuating between 50 and 60 mph when the flaps were retracted from 10° to the UP position.

Two seconds later the engine revs decreased from 2450 to 1300 rpm. The instructor began a steep right turn during which the airspeed decreased and the bank increased to about 45°.

Six seconds later the aircraft stalled, continued to roll to the right. It descended in a steep nose-down attitude and collided with terrain.

The instructor was fatally injured. The second pilot was critically injured and was transported to hospital

The aircraft was destroyed. There was no fire.

The weather was VMC with very strong, gusty winds from the westsouthwest.

Both pilots held appropriate licences,

ratings and valid medicals The instructor, with 1120 hours, held ratings for seaplanes and aerobatics. He also held a glider pilot license.

The second pilot held a PPL and had 122 hours.

The aircraft systems were examined and no malfunction was found. There were no signs of fuel leaks or contamination. 2.7 US gallons of fuel remained in the tanks.

There were no signs of catastrophic engine or mechanical failures.

Both pilots wore 4-point safety belts consisting of lap straps and shoulder harnesses. However, once the harness is tightened it limits arm movement, and some areas of the cockpit and instrument panel may be out of reach. The video shows that the instructor’s harness was very loose throughout the flight.

The 1962 Cessna 150B had been modified to tailwheel configuration.

The POH gives a wings-level, pow-

er-off stall, with the flaps at 10° of 53 mph. With flaps UP this increases to 54 mph. With 40° bank the stall speed increases to 62 mph; and at 60° of bank the aircraft stalls at 77 mph.

The stall warning sounded as they approached runway 07, after the l ow-level 180° turn. However, it did not sound before the final stall-spin. The investigation could not determine why it failed to work at this stage.

The POH requires pilots to visually check the fuel quantities, and to confirm this by checking the gauges. The aircraft’s calibrated dip stick had been broken for some time and was not available.

The investigation determined that pilots operating this aircraft rarely, if ever, used a dip stick. Instead, they either conducted a visual inspection of the fuel levels or relied on the gauges.

The total usable fuel was 22.5 US gallons (11.25 per tank), and the unusable fuel was 3.5 gallons (1.75 per tank).

The fuel gauges are marked E for empty, ½ for half full, and F for full, with graduations at ¼ and ¾. The gauge readings from the previous flight were estimated at ½, and slightly below ½. If these readings were accurate, this would give 5.6. gallons in one tank and slightly less in the other.

The gauges in this aircraft model are known to be inaccurate and unreliable [Jim’s emphasis].

For a daytime VFR flight, the Canadian regulations require the aircraft to carry sufficient fuel to fly to

the destination plus 30 minutes at normal cruise speed. The aircraft did not meet this requirement.

Given the weight of the occupants, cargo and fuel, the aircraft was overweight by about 69 pounds at the start of the flight.

Many fatal accidents have resulted from pilots attempting to turn back following an EFATO. This often leads to a stall or loss of control at low altitude.

The FAA recommends that180° turns be avoided and suggests using the best available landing area within an arc of about 60°.

The message here seems to be a matter of repeating the old warning about not turning back. How-

ever there’s quite a bit more to this.

First, let’s deal with this ridiculous, and oft repeated, message that you should avoid turns of more than X° following an EFATO.

Why on earth specify any number of degrees? If you are at 50’ your turn has to be very limited, and if you are higher than the amount of turn depends on the aircraft type, the wind, your skill and a herd of other factors.

In a Grob at 200’ you can circle back to your departure runway. In a Bonanza at 200’ your landing spot is directly ahead.

Why put numbers to it? You simply turn towards the best available field. It couldn’t be simpler. That’s what the RAF and the SAAF recommend. It makes sense.

Next, this modified and seemingly unloved Cessna didn’t stand a chance.

Unloved? Absolutely. The dipstick was lost ages ago and no one cared to replace it. It would have saved the instructor’s life.

And then there’s the word calibrated dipstick. Making a new one is a tedious, but critical job. You must drain all the fuel and then mark the new dipstick bitby-bit as you add say two gallons at a time. Here are some pointers:

1. The normal Cessa dipstick must be banned. It doesn’t read correctly for the tailwheel version.

2. The aircraft must be on level ground – fore-and-aft and side-toside.

3. Don’t expect the gauges to agree with your calibration – they are made for the level flight attitude .

4. Use metal or very hard wood for the stick – the fuel creeps up soft wood alarmingly.

5. Don’t varnish or paint the stick –the fuel may dissolve it.

6. Put a ‘T’ piece across the top so you can’t drop it in the tank. So it seems we have a classic stall-spin during an attempt to turn back following an EFATO. But there’s a lot more to this.

The engine didn’t fail – the pilots failed. They didn’t put fuel in at the start of the flight. They made the fatal mistake of being in a hurry. They couldn’t wait for the original holdup at the pumps. So this crash seems to have been caused by being in a hurry.

But wait – there’s more. What was the pilot thinking when he decided to do a go-around with a faltering engine? He had 1000’ of runway ahead and a C150 with full flap can get down and stopped in a very short distance.

And why retract the 10° of flap at low altitude and low airspeed during the goaround? That makes no sense.

Next, the instructor, who had both a glider license and an aerobatic rating, should have been acutely aware of the dangers of increasing bank while running out of airspeed.

It’s also possible the pilot may have survived had he tightened his shoulder harness correctly.

Perhaps the whole accident should be put down to the operator’s slack attitude to safety. When pilots trust their lives to fuel gauges that are known to be “inaccurate and unreliable” this speaks volumes about the operator’s casual attitude to safety culture. The statement that pilots “rarely if ever” use a dipstick, or even look in the tanks, underlines this view.

And, as a final indication that all was not well with the operation, we have the statement that the aircraft was over maximum gross weight by 69 pounds as well as being out of C of G.

Knowing your fuel quantity before takeoff is not a check it’s a life or death essential.

A calibrated dipstick is part of the life and death thing. It’s not only used for little aeroplanes – The pilots of Boeings and Airbusses do exactly the same thing. If they are not sure of the fuel quantities they use a dripstick which works the same as a dipstick but it is done from under the wing.

If airline pilots use this back-to-basics method then it’s good enough for you and me.j

Absolute Aviation has announced that they will acquire a stake in Century Avionics.

CENTURY Avionics is based near Absolute at Lanseria International Airport. Century has built an exceptional reputation over the past 47 years as a trusted provider of advanced avionics solutions for general, business, and commercial aviation.

With this expansion, Absolute Aviation seeks to complement its existing aircraft sales, support, and maintenance capabilities with Century’s specialist avionics expertise.

The current shareholders and leadership team of Century Avionics will remain fully involved in the business, continuing in their existing roles and responsibilities. Century Avionics will retain its identity and

operate as an independent company within the Absolute Aviation Group, ensuring continuity for customers, suppliers, and staff.

“This partnership aligns perfectly with our strategy to offer a complete aviation solution across the lifecycle of aircraft ownership,” said Neil Howard, CEO of Absolute Aviation.

Marc Robinson of Century Avionics joked, “This has been the longest courtship ever — we’ve been engaged for five years, and we’ve finally tied the knot!”

He added, “It made sense to align with Absolute Aviation, whose values and vision make them the ideal partner. We’re excited to grow into regions where Absolute already has a strong presence — Botswana, Mozambique, and Zimbabwe — with Kenya also firmly on the horizon.”

j

When I landed the Aztec at Moroni in the Comoros, there was a VIP car waiting on the apron to collect my passengers. I had my own driver and was told we would meet up later, as they had an afternoon meeting with the President Ahmed Abdullah.

Idid all the pilot things, fuel up the aircraft to the brim, landing fees, flight plan for the following day, cleaned out the sick bags (!) and picked up my night stop kit and went off with my driver.

The drive from the airport was about 20 minutes, on a very narrow winding road and climbing up towards the volcano Mt. Kharthala.