Marine Sealants & Adhesives

The harshest conditions demand the strongest adhesives.

The harshest conditions demand the strongest adhesives.

Many of our product breakthroughs come directly from our work with customers who need unique solutions for specific needs. Our intelligent and innovative products are the result of close collaboration with our customers. This is what sets Sabre apart.

We start with an extensive audit process to better understand the challenges and problems we need to solve. Our technical team then formulate, prototype, test and analyse each product thoroughly before recommending only the best solutions, backed by the latest technologies.

Sabre’s relentless focus on innovation fuels a continuous drive to redefine adhesive technology. This commitment propels us to ensure that Sabre solutions consistently advance to address the everchanging demands of manufacturers, both today and in the future.

Water Ingress can be caused by many factors including joint design, material compatibility, and application. Regardless of the cause, it can be a significant recurring warranty cost. Sabre adhesives and sealants are formulated to deliver ultimate waterproofing and moisture protection in the toughest conditions.

Recent years have seen dramatic changes in the materials and technologies used to fabricate boats, as manufacturers seek to reduce weight, improve fuel economy and enhance user comfort. Our unique primerless adhesion technology enables durable bonding on a wide spectrum of materials.

Boats are expected to last for years in challenging environments with high UV exposure and extreme temperatures. Ensuring durability and integrity throughout a boat’s service life is vitally important and our adhesives are specifically formulated to increase the lifespan under the harshest conditions.

A surge in demand for boats has created unprecedented challenges for manufacturers as they seek to fill extensive backlogs. Sabre works closely with OEM management teams to identify solutions and bonding processes that increase their processing throughput and labour efficiencies.

Sabre’s range of MS polymers are truly primerless and purpose-designed for the marine industry. They reduce manufacturing costs, work in progress and total life costs.

SabreBond

Filler

Polymer

Plasticiser

Pigment

Adhesion Promoter

Catalyst

Thixotropic Agent

U.V. Absorber

Stabiliser

Other manufacturers

Filler

Polymer

Plasticiser

Pigment

Adhesion Promoter

Catalyst

Thixotropic Agent

U.V. Absorber

MS polymers are the natural choice for the marine industry because they combine all ‘the best bits’ of one-component polyurethane and silicone with antimicrobials and 'stay white’ properties. Sabre’s modified silane chemistry offers high weathering resistance ensuring durability and integrity in the toughest climates.

Exterior & Interior Upholstery

General Bonding

Window Bonding & Sealing

Structural Bonding

Our comprehensive range of specialist structural adhesives are designed to deliver ultimate bonding performance and retain their strength and durability in harsh marine environments.

With extensive experience in bonding technology for the marine environment, Sabre's range of structural adhesives can be found in a range of applications including bonding internal structures such as bulkheads and stringers to the hull & securing hull and deck joints.

A high-performance methacrylate structural adhesive range formulated in a wide range of working time options. The SA10 series is designed with low boiling tendencies and high strength to adhere to assemblies of thermoset composites and plastics and is formulated to be primerless on most metal surfaces.

Easy 10:1 mix ratio

20 MPa shear strength and up to 120% elongation

Primerless on most metals

Good chemical resistance

Excellent fatigue characteristics and shock load resistance

Watertight bonding and sealing is crucial in the production of vessels to protect against water ingress and corrosion. Sabre’s industry-leading high-performance MS Polymer adhesives for primerless direct glazing have helped assembly lines push the boundaries for decades.

Our innovative range features products with high green strength and quick build-up of end strength. This offers the advantage of retaining glass in position following installation – eliminating the need for secondary fixing.

Very high-performance silyl modified polymer adhesive for high strength primerless bonding and sealing during construction and assembly.

Technical Advantages: SabreBond

• Fast initial grab

• Primerless bonding of metal, alloys, glass and plastics

• Very high bond strength

• Fast-curing, flexible adhesive and sealant based on MS Polymer

• Excellent UV and weathering resistance

For bonding the many dissimilar substrates used in boating manufacturing, Sabre offers an extensive range of high-performance silicones, modified-silane polymer, and butyl sealants.

Sabre's products provide optimum external durability, flexibility and long-term bond performance around windows, hatches and deck fittings, giving manufacturers the ultimate waterproofing protection.

Next-generation silyl modified polymer adhesive/sealant for multipurpose elastic bonding and sealing. Formulated with a bespoke adhesion profile, unrivaled durability and a unique application rheology.

Technical Advantages:

• Primerless technology

• Exceptional durability

• High-strength

• Fast curing

• Unrivalled UV resistance

Marine-grade contact adhesives are used to bond and seal the upholstery, such as seats and cushions, and other components to the boat’s deck or interior.

Unlike traditional adhesives, contact adhesives are applied to both surfaces, left to dry, and then brought together for an instant, strong bond. Contact adhesives deliver an unparalleled bond strength that ensures durability and resilience in marine environments.

Sabre's industrial strength sprayable contact adhesives offer high heat and water resistance and superior bond strength.

Industrial strength, sprayable contact adhesive with fast tack, excellent bond strength, and high heat resistance.

Excellent green strength

High heat resistance

High solids content

Water resistant

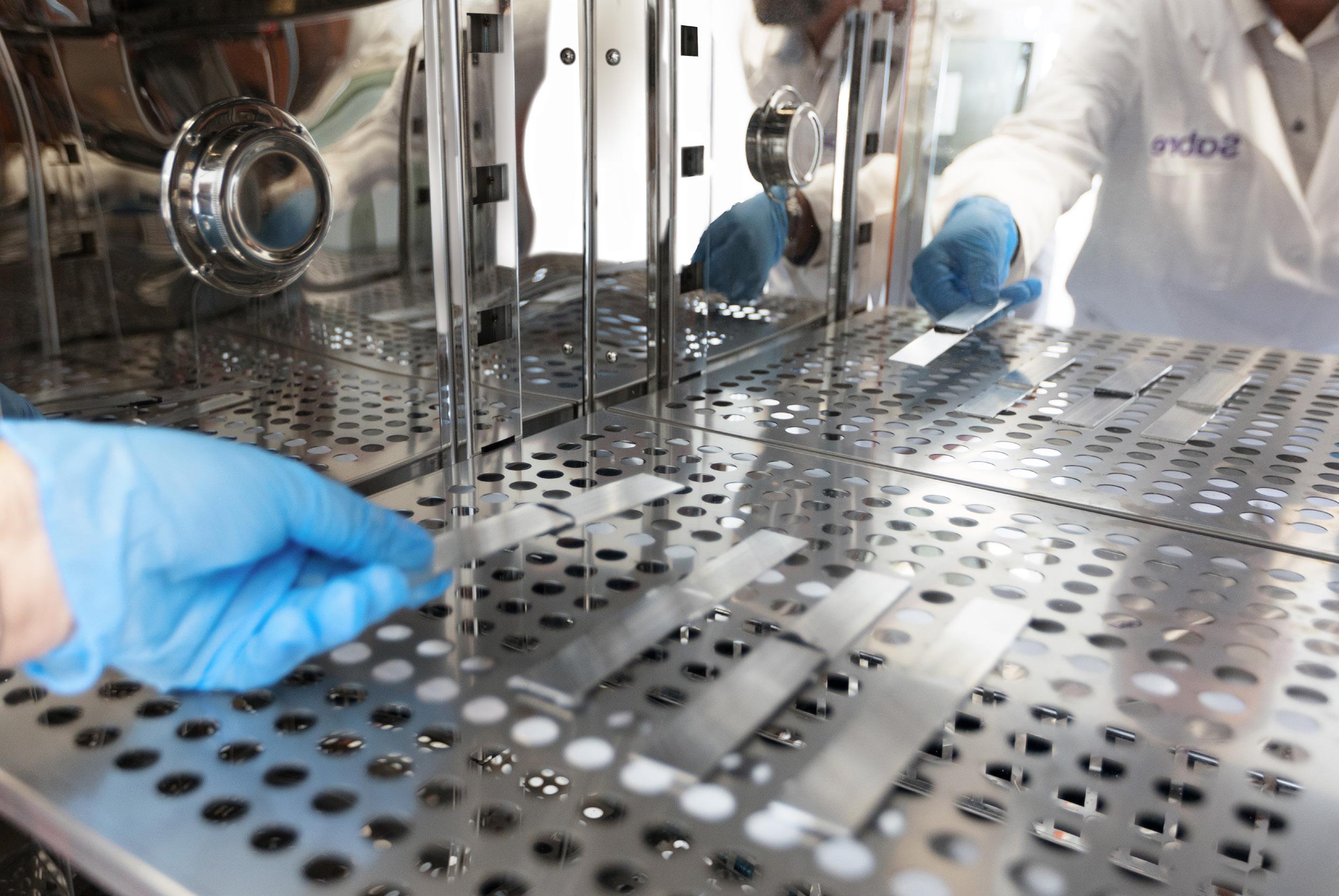

We partner with our customers to create bespoke quality control and validation systems. Sabre’s fully equipped in-house laboratory and testing facility ensures the correct products are specified and supplied to meet the long-term functionality of any given bonding requirement.

As boat design evolves and bonded components and materiality changes, Sabre conduct ongoing and comprehensive testing to ensure durability and full functionality.

Sabre products are tested to destruction, analysing the mode of failure and bond strength characteristics. Procedures are designed to test tensile strength, shear strength, and flexural strength to ASTM standards, as well as testing the mode of failure and optimum strength of the adhesive.

Sabre provides comprehensive analysis of substrates, surface characteristics and application requirements. We conduct adhesion testing on the compatibility of the adhesive to specific substrates - ensuring the best methods of bonding are recommended.

Sabre conducts QUV accelerated weathering testing to reproduce the damage caused by high heat, moisture etc. which enables us to review the impact on the performance of prolonged external exposure. This ensures our adhesives are fit for purpose to withstand the harshest environments.

Sabre delivers more than just great adhesives. The real key for bringing tangible ongoing value to our partners is to regularly provide on-site technical support. With regular adhesive auditing in place we will track the production line’s usage and performance, and work closely with our customers to optimise on-site quality and efficiency.

New Zealand (HQ)

+64 (06) 366 0007 salesNZ@sabreadhesives.com

Level 1

40-42 Cambridge St South

Levin 5510

Melbourne +61 (03) 8657 5507 salesAU@sabreadhesives.com

1-23 Letcon Drive

Bangholme

Melbourne

VIC 3175

sabreadhesives.com

Brisbane +61 (02) 9098 8244 salesAU@sabreadhesives.com

15 / 243 Bradman Street

Brisbane QLD 4110

Sydney +61 (02) 9098 8244 salesAU@sabreadhesives.com

Level 6

10 Herb Elliott Ave

Sydney Olympic Park

NSW 2127