Good bonds last.

Sabre leads the way in bonding and sealant technology.

Sabre’s smart quality control system is at the core of our technical expertise, ensuring the consistency of our category leading adhesives – every time.

Our intelligent and innovative products are the result of close collaboration with customers.

We start with an extensive audit process to better understand the problems and issues we need to solve.

Then it’s back to our lab to formulate, prototype, test and analyse each product thoroughly before it’s used in the field.

Because of our obsession with continuous improvement, Sabre solutions aren’t just fit for purpose, they’re fit for tomorrow.

Industry Challenges

Water Ingress

Water Ingress can be caused by many factors including joint design, material compatibility, and application. Regardless of the cause, it can be a significant recurring warranty cost. Sabre adhesives and sealants are formulated to deliver ultimate waterproofing and moisture protection in the toughest conditions.

Material Compatibility

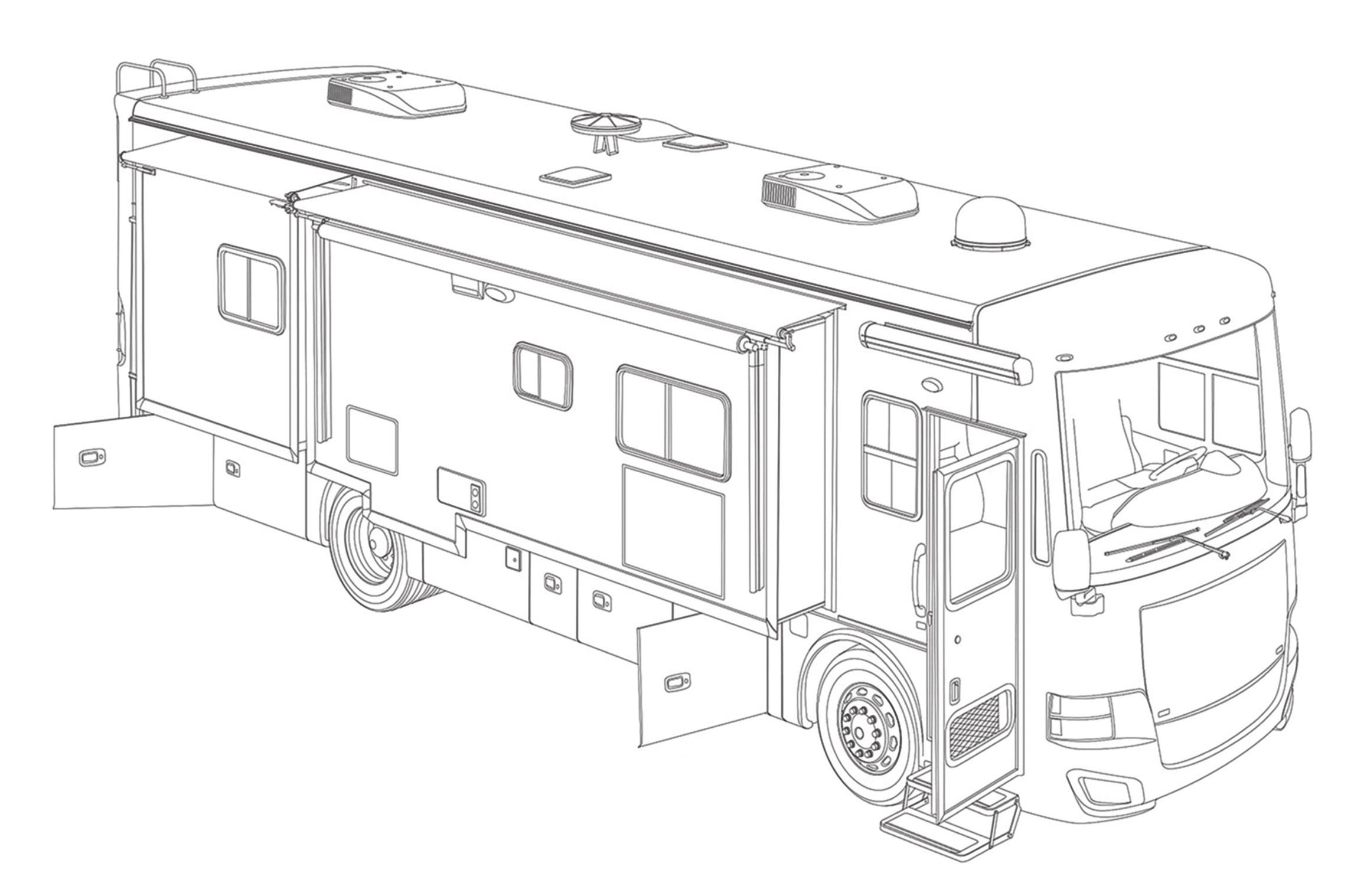

Recent years have seen dramatic changes in the materials and technologies used to fabricate recreational vehicles, as manufacturers seek to reduce vehicle weight, improve fuel economy and enhance user comfort. Our unique primerless adhesion technology enables durable bonding on a wide spectrum of materials.

Integrity & Durability

RVs are expected to last for years in challenging environments with high UV exposure and extreme temperatures. Ensuring durability and integrity throughout a vehicle’s service life is vitally important. Our adhesives are specifically formulated to increase the lifespan of recreational vehicles.

Production Output

A surge in demand for RVs has created unprecedented challenges for manufacturers as they seek to fill extensive backlogs. Sabre works closely with OEM management teams to identify solutions and bonding processes that increase their processing throughput and labour efficiencies.

SabreBond Technology

Sabre’s range of MS polymers are truly primerless and purpose-designed for motorhomes and caravans. They reduce manufacturing costs, work in progress and total life costs.

SabreBond

Filler

Polymer

Plasticiser

Pigment

Adhesion Promoter

Catalyst

Thixotropic Agent

U.V. Absorber

Stabiliser

Other manufacturers

Filler

Polymer

Plasticiser

Pigment

Adhesion Promoter

Catalyst

Thixotropic Agent

U.V. Absorber

MS polymers are the natural choice for RV manufacturing because they combine all ‘the best bits’ of one-component polyurethane and silicone with antimicrobials and 'stay white’ properties. Sabre’s modified silane chemistry offers high weathering resistance ensuring durability and integrity in the toughest climates.

Applications Overview

Glazing

Sealing

Panel Lamination

Sabre provides market-leading single-component and two-component polyurethanes, and PUR reactive hotmelt adhesives in the production of panels.

With extensive experience in bonding technology for panel lamination, Sabre’s solvent-free polyurethane adhesives can be found in a range of applications including bonding sidewalls, roofs, floors, and other composite panels.

A solvent free, two-component polyurethane adhesive developed primarily for structural bonding of insulated sandwich panels such as RV door panels.

Technical Advantages:

• Very high long-term panel strength

• Bonds to a wide variety of substrates

• Excellent temperature resistance

• Impact resistant

• Contains no solvents and is non-flammable

SabreBond PU2002

Sealing

Effective sealing of the vehicle body against water ingress is essential for the elimination of expensive warranty costs and quality claims from end customers.

Watertight sealing protects the panels, electrical appliances and the vehicle’s interior. Sabre offers an extensive line of high-performance silicones, modified-silane polymer, and butyl sealants for bonding the many dissimilar substrates used in RVs. Sabre’s products provide better external durability, flexibility, and long-term bond performance - giving manufacturers the ultimate waterproofing protection.

SabreSeal SG

High performance anti-fungal neutral silicone sealant formulated specifically for sanitary-grade applications, where high humidity and temperature exist.

Technical Advantages:

• High UV resistance

• Flexibility

• Hygienic – anti-fungal

• Easy to use

• Low dirt pickup

Assembly Bonding

Caravans and motorhomes are increasingly incorporating fibreglass composites, advanced plastics, and sandwich panel elements as manufacturers seek to reduce vehicle weight, improve structural integrity, enhance thermal stability and increase vehicle durability.

Sabre’s range of 1K & 2K assembly bonding adhesives are developed using the latest silane modified polmer (SMP) technology combining the high-performance properties of traditional polyurethane technology with the high weathering resistance of silicone technology.

A high-performance (SMP) adhesive and sealant —ideal for bonding and sealing in the assembly of motorhomes and caravans. Engineered for primerless adhesion to a wide range of substrates, it offers outstanding flexibility and high mechanical strength.

Technical Advantages:

• Primerless technology

• Exceptional durability

• High-strength

• Fast curing

• Unrivalled UV resistance

Glass & Windscreen Adhesives

Sabre’s industry-leading high-performance MS Polymer adhesives for primerless direct glazing have helped assembly lines push the boundaries for decades.

Our innovative range features products with high green strength and quick build-up of end strength. This offers the advantage of retaining glass in position following installation – eliminating the need for secondary fixing.

• Excellent paint compatibility Technical Advantages: High-performance MS Polymer adhesive for primerless bonding of windscreens and automotive glass with high green strength and quick build-up of end strength.

• Fully primerless adhesion

• High initial tack

• Very high bond strength

• Excellent UV resistance

SabreBond SE2

Testing & Development

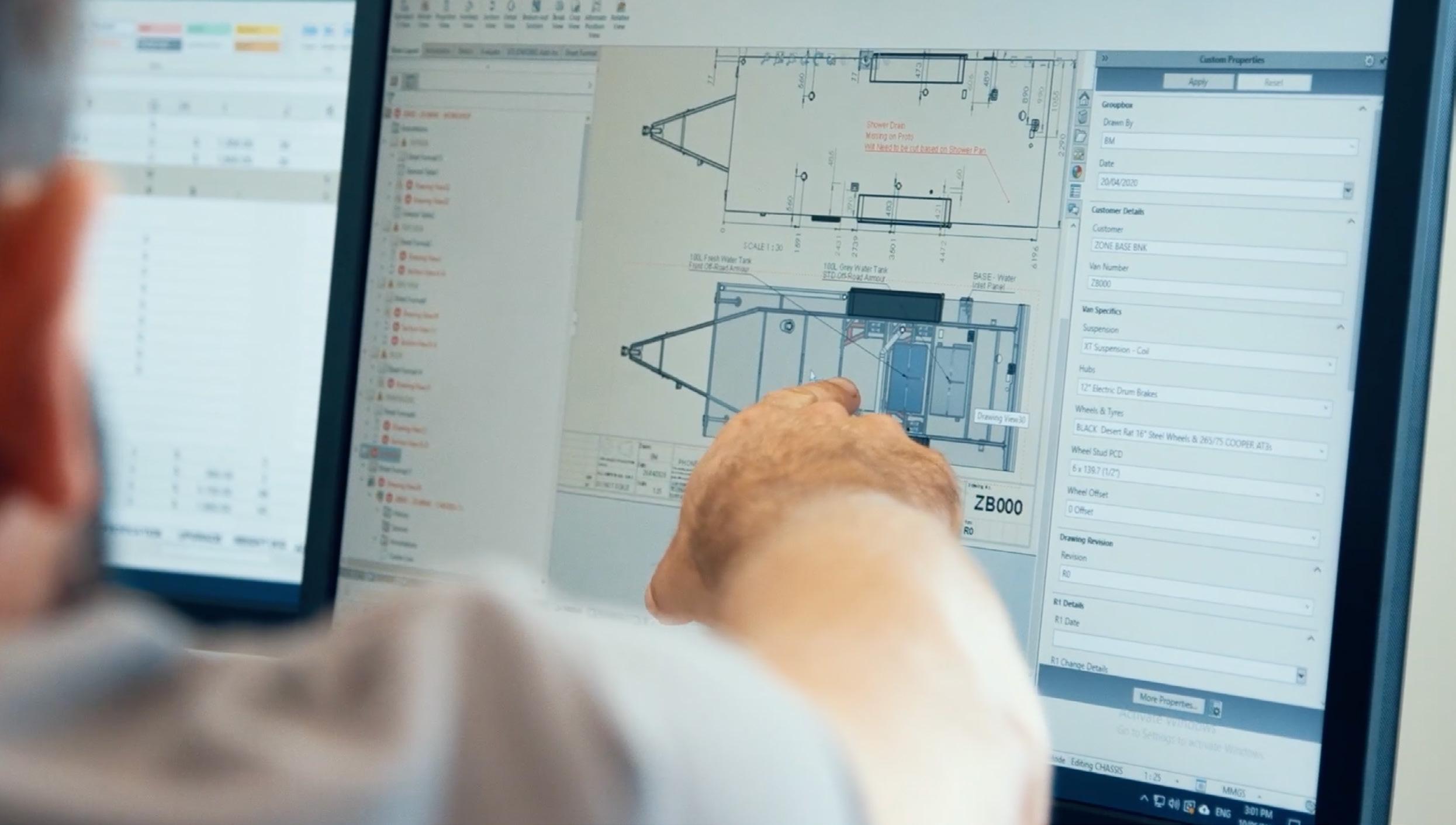

We partner with our customers to create bespoke quality control and validation systems. Sabre’s fully equipped in-house laboratory and testing facility ensures the correct products are specified and supplied to meet the long-term functionality of any given bonding requirement.

As vehicle design evolves and bonded components and materiality changes, Sabre conduct ongoing and comprehensive testing to ensure durability and full functionality.

Mechanical Testing

Sabre products are tested to destruction, analysing the mode of failure and bond strength characteristics. Procedures are designed to test tensile strength, shear strength, and flexural strength to ASTM standards, as well as testing the mode of failure and optimum strength of the adhesive.

Compatibility Testing

Sabre provides comprehensive analysis of substrates, surface characteristics and application requirements. We conduct adhesion testing on the compatibility of the adhesive to specific substrates - ensuring the best methods of bonding are recommended.

Environmental Testing

Sabre conducts QUV accelerated weathering testing to reproduce the damage caused by high heat, moisture etc. which enables us to review the impact on the performance of prolonged external exposure. This ensures our adhesives are fit for purpose to withstand the harshest environments.

Onsite Technical Support

Sabre delivers more than just great adhesives. The real key for bringing tangible ongoing value to our partners is to regularly provide on-site technical support. With regular adhesive auditing in place we will track the production line’s usage and performance, and work closely with our customers to optimise on-site quality and efficiency.

RV Product Portfolio

Sabre presents a comprehensive range of specialist structural adhesives and sealants tailored specifically for the challenges faced by RV manufacturers.

Vehicle Assembly Bonding

SMP45

Multipurpose Adhesive Sealant

• This chemically neutral adhesive does not contain isocyanates, silicone or solvents, making it an excellent choice for a wide range of applications.

• Stable at temperatures from -40 °C to +80 °C

• Paintable and non-corrosive

SMP50

Adhesive Sealant

• Premium MS Polymer adhesive and sealant with high UV resistance

• Primerless sealing and bonding in transportation, marine, and construction

• Unique rheology, making it excellent for both bonding and sealing

SMP60

High Grab Adhesive

• Fast-curing, flexible adhesive and sealant based on MS Polymer

• Primerless bonding of metals, alloy, glass and plastics

• High dielectric strength and excellent resistance to climatic conditions

SMP65

High Strength Adhesive

• Very high performance, hybrid polymer adhesive for high-strength, structural elastic bonding in vibrating constructions

• Fast build-up of handling strength

• High shear strength after full cure

SMP1045

2K High Strength Adhesive

• High strength, fast-curing two-component MS Polymer adhesive

• Very high service temperature resistance and resistance to climatic conditions

• Free of solvents, silicones, and isocyanates

Sealing

NC

Neutral Cure Silicone

• A premium high-performance 100% neutral cure silicone with superior adhesion properties

• Suitable for use in weather sealing and glazing applications on most common construction substrates, including metals, glass, timber, and concrete

• Exhibits high UV and weathering resistance

SG Sanitary Grade Silicone

• Anti-fungal 100% neutral cure silicone sealant tested to ASTM G21

• Ideal for sanitary-grade application where high humidity and temperature exist

• Excellent UV resistance, ideal for indoor and outdoor applications

HT

High Temperature Silicone

• Temperature resistant up to 250°C

• A permanently flexible 100% silicone sealant which is temperature resistant up to 250°C

• Forms leak-proof gaskets that resist cracking, shrinking and migration caused by thermal cycling

• Ideal for heavy-duty industrial sealing

Glass & Windshield Adhesives

055

Glazing Adhesive

• High-quality MS Polymer adhesive/sealant with high stiffness and very high adhesive strength

• High UV resistance and long-term durability

• Excellent extrudability and tooling properties for bonding and sealing

SE2

Glazing Adhesive

• High-performance MS Polymer adhesive for primerless bonding of windscreens and automotive glass

• Very high initial tack and rapid strength build-up

• Excellent UV stability and long-term durability

SMP62

Glazing Adhesive

• High-quality MS Polymer adhesive/sealant with a long open time

• Developed for use in hot/humid climates

• High UV resistance and long-term durability

Panel Lamination

SabreBond PU2002 Polyurethane Adhesive

• Solvent free, two-component polyurethane adhesive developed primarily for structural bonding of insulated sandwich panels such as RV door panels.

• Contains no solvents and is non flammable

• A wide range of working times available

Leeson PU5256

Polyurethane Adhesive

• Next generation, single-component moisture curing urethane adhesive

• Developed for panel lamination applications, particularly caravan panels

• Excellent flexibility, bond strength, and heat resistance

Primers

Surface Activator

• To be used as a cleaner / primer on non porous surfaces

• Suitable for silicone, polyurethane and MS Polymer® based sealants and adhesives

• Liquid, easy application