BACK TO HIS ROOTS

Fonterra’s managing director co-operative affairs Matt Bolger is a big fan of the co-op model. PAGE 5

STATE OF PLAY

Strong prices, growing risks Page 14

KiwiSaver stoush

SUDESH KISSUN sudeshk@ruralnews.co.nz

FEDERATED FARMERS is brushing aside concerns that the Government’s intention to allow farmers to use their KiwiSaver funds to buy a first farm could be problematic.

Feds dairy chair Richard McIntyre told Dairy News that KiwiSaver is designed to help New Zealanders grow their wealth to financially support them in their retirement years, but farmers tend to take a different pathway to financial security.

“For a young dairy farmer that pathway is to get into sharemilking early, build up equity and a herd, and to eventually buy their own farm. It’s a well walked progression pathway,” he says.

“As they get into their older years, they might choose to bring on a sharemilker themselves, giving another young farmer the same opportunity they had, and the cycle continues.”

But Sam Stubbs, co-founder of KiwiSaver fund, Simplicity is warning the Government against allowing farmers to withdraw their KiwiSaver to buy their first farm.

“While it might seem like the existing first home withdrawal, this change is problematic,” says Stubbs.

“It could weaken KiwiSaver’s core purpose as a retirement savings scheme and offers only marginal benefits to a small group of people, while impacting millions of members.”

Stubbs believes the change, if approved by the Government, would have limited impact on farmers.

“KiwiSaver isn’t well-suited for self-employed individuals, including

many farmers, as it lacks employer contributions and government subsidies have been whittled away over time,” he says.

Only an estimated 12,000-25,000 self-employed or employer farmers are KiwiSaver contributors, he points out.

The average KiwiSaver first home withdrawal is about $25,000. This amount is only 0.6% of the average farm price ($3.9 million for a 286-hectare farm), meaning it would offer only marginal help.

“A farm is not a home. Unlike a typical home, a farm (average 286 hectares) is a large business asset,” he says.

Finance Minister Nicola Willis signalled at Fieldays that the Government may change the rules to allow farmers to withdraw their

KiwiSaver to buy their first farm. However, the Government has poured cold water on a Fed’s request to allow withdrawals so that sharemilkers could buy their first herd.

Stubbs claims the Government is weakening KiwiSaver for millions.

He notes that this change impacts 3.4 million KiwiSaver members, to benefit at most 0.75% of them.

“KiwiSaver’s primary goal is to provide long-term savings for retirement through regular contributions and compounding returns. This proposal risks weakening it from a retirement (and first home) fund to something else.

“If farms are included, what prevents future proposals for other business investments (like a plumbing business or a home-

based office)? We need to stop using KiwiSaver as a political plaything. This is not some kind of government/public asset, it’s our money.”

But McIntyre doesn’t think that anyone would be too surprised to hear that kind of thing from “an Auckland-based KiwiSaver fund manager”.

“But for the avoidance of doubt, I totally disagree with him.

“What Sam Stubbs is really saying with that statement is that he thinks he can do a better job investing a young farmer’s KiwiSaver balance than they can, and that’s total nonsense.

“While he might see it as a marginal benefit for a small group, I can tell you that for young people trying to get into sharefarming, the benefits would be significant.”

Open Country’s foray into butter. PG.07

Some KiwiSaver fund managers oppose allowing young farmers to withdraw funds to buy their first farm. Photo: DairyNZ Facebook page

Middle East unrest helps ease fall in GDT prices

BIG GOALS TO SOLVE A GLOBAL PROBLEM

THE UPHEAVEL in the Middle East may have eased the fall in global dairy prices last week.

Last week’s Global Dairy Trade (GDT) auction saw prices slip, however Middle Eastern demand for milk fats increased.

Whole milk powder prices dipped 2.1% to US$4,084/tonne. Skim milk powder price was down 1.3%. But butter prices continue to climb, rising 1.45 to US $7,890/ tonne.

According to NZX market analyst Lewis Hoggard, the demand outlook seemed to be weakening over the past few weeks as buyers wait for new season product.

However, he believes there was a degree of stockpiling pressure due to elevated geopolitical risk in the Middle East which helped ease the fall in commodity prices.

“Due to another flare up in tensions in the Middle East, we had a keen eye on what their buying behaviour would be at this GDT.

“Similar to early last year at the start of the Israel-Hamas war, Middle Eastern demand for milk fats increased

which put upward pressure on NZ prices. Thirtytwo per cent of butter at this auction was sold to the Middle East, a stark contrast from the previous auction where they bought no butter.”

The Middle East was also the second largest purchaser of AMF at this event and bought a whopping 47% of the cheddar

on offer, which helped bid the price of cheddar up 5.1%, just shy of the US$5,000/t mark.

Hoggard notes that NZ product outperformed the futures market expectations prior to last week’s auction, especially for butter which saw yet another increase in price.

“Coming into the event there was plenty of

downward pressure on milk powders, especially at GDT Pulse, and the futures market had seen some selling pressure down the curve.

“We also noted that the premium for NZ SMP over EU has fallen below $100/t, as EU prices have rallied in recent weeks against falling NZ SMP prices.”

JESSICA MARSHALL jessica@ruralnews.co.nz

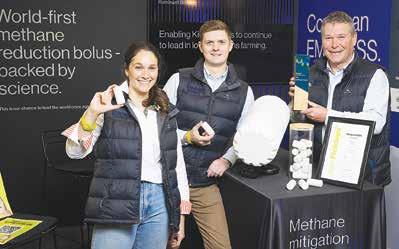

NEW ZEALAND’S Ruminant Biotech says that while it has big goals, the scale of the problem it seeks to solve requires it.

The company aims to have 100 million cows across the globe using its Emitless bolus technology by 2035 to reduce the enteric methane produced by cows.

“We’re starting local, with a focus on working closely with Kiwi and Aussie farmers to deliver a solution that’s practical, impactful, and easy to adopt,” Tom Breen, chief executive of Ruminant Biotech, told Dairy News

been synthesised to ensure purity and consistency. It works by temporarily blocking a key enzyme that methaneproducing microbes need to do their job, so instead of releasing methane, the animal digests feed more cleanly,” says Breen.

“This compound is a naturally occurring organic molecule that’s been synthesised to ensure purity and consistency. It works by temporarily blocking a key enzyme that methane-producing microbes need to do their job, so instead of releasing methane, the animal digests feed more cleanly.”

He says it is easy to use and doesn’t require any special infrastructure.

He says that from there, the company will scale up to meet growing overseas demand as more countries seek out proven, science-backed methods of reducing emissions without compromising animal welfare or productivity.

“If we can reach 100 million cows with Emitless, the climate impact would be equivalent to taking 20 million cars off the road. That’s the scale we’re aiming for,” Breen says.

Emitless is a bolus that sits in a cow’s rumen and slowly releases an active compound over the course of more than 100 days.

“This compound is a naturally occurring organic molecule that’s

“It’s the kind of tool farmers can adopt at scale, and that’s exactly what we need if we’re serious about reducing emissions from agriculture.”

The product won the Prototype Award at the recent Fieldays Innovation Awards, something Breen says is an “important signal” that the technology is market ready.

“It’s especially meaningful to have this progress recognised by the Fieldays judges, not just for the strength of our science and product development, but also for our understanding of the regulatory and commercial environment we’re entering,” he says. “That kind of feedback reinforces that we’re building something both practical and impactful.”

SUDESH KISSUN

Tom Breen

Whole milk powder prices fell 2.1% last week.

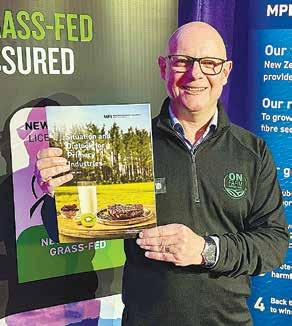

A passion for co-ops brings Bolger back to Fonterra

CO-OP

FONTERRA’S

model and what it does for New Zealand has lured one of its bright stars back on board.

Matt Bolger took up the role of managing director, co-operative affairs at Fonterra in March this year, five years after he had left the co-op to run the business school at the University of Waikato.

Speaking to Dairy News at Fonterra’s Fieldays site, Bolger said he’s always liked Fonterra as an organisation.

“Particularly what it does for New Zealand, and the co-op model appeals to me. It’s an interesting model of both wealth creation and wealth distribution.”

Bolger’s role includes overseeing Farm Source, the co-operative’s rural trading arm, which deals daily with farmer shareholders.

He says working for the co-op means a lot to all employees.

“You see the farmers and their families here at Fieldays, knowing that these are the people you work for. They come in

gumboots as families, kids, multiple generations.

“And you know that if we do a good job, then the financial benefit is flying out, keeping all those small towns across New Zealand running.

I think there’s a lot of meaning in that.”

Bolger also points to Fonterra’s prowess on the global stage.

“It’s a great organisa-

tion in terms of what it does on the world stage. And we don’t always see that in New Zealand, but it is a real leader.”

Bolger knows this having studied and worked for Fonterra in the US during his first stint with the co-op.

While he grew up mostly in Wellington, Bolger also spent a lot of his childhood on what was then the family sheep

and beef farm in Te Kuiti. When his father – former Prime Minister Jim Bolger – was appointed Ambassador to the US, he studied there.

After finishing university, Bolger says he was keen to work for a NZ company in the US.

“I realised then that there isn’t a long list,” he says.

He joined Fonterra in 2002, working in Harris-

burg, Pennsylvania and his first role was “answering phones”.

“I answered the phones, put the orders on the system. I don’t know if I was the best at that. And, then I did a little bit of other work with the strategy team in the States.”

He moved back to Fonterra’s head office, then based near Auckland Airport, in 2003.

FONTERRA IS not pulling back from its value-add business, says Matt Bolger.

He says the co-op’s divestment plan is more about doubling down on value-add across its food service and ingredients businesses.

Bolger is surprised by some farmers asking him whether the co-op is pulling back from value-add.

“Nothing could be greater than the truth. The two business channels that have been highest performing for us in terms of value add have been our ingredients and our food service business,” he told Dairy News.

He supports the divestment of consumer business.

“The consumer business is a fantastic business with great brands and great people. But we think somebody else probably can take it to a higher level than we can because of scale and synergies,” he says.

He says there’s great growth potential across food service and ingredients.

“We have amazing products, amazing science and amazing customer relationships - the product-market fit.

“We’re going into healthy aging, wellness, medical nutrition: we’re going into food service and out-ofhome consumption. Those are good parts of the market to be in.”

One of his roles then was leading a project to see whether the co-op would commercialise mozzarella that goes into pizzas in China and Asia or park it.

“And we did commercialise it. It’s good coming back in Fonterra in the last few months and just seeing how well the team really turned that into a success.”

Bolger says he’s look-

ing forward to working with Fonterra farmers and helping them make their business more profitable.

While at Waikato University, Bolger maintained close links with the dairy industry. He served as chairman of the Dairy Companies Association of New Zealand from 2022 to 2024.

@dairy_news

facebook.com/dairynews

Matt Bolger says what Fonterra does for New Zealand, and the co-op model appeals to him.

SUDESH KISSUN sudeshk@ruralnews.co.nz

New ute owners warned of looming ‘tax grenade’

stream of rural folk treading the boards.

THERE’S NO doubt that vehicle manufacturers at Fieldays saw a steady

Post-event anecdotes suggest that many signed on the dotted line, no doubt taking advantage of the Government’s invest-

ment boost initiative, offering 20% tax relief over the coming year.

However, farmers and tradies buying utes, often on the advice of their accountants, may

be wishing they had paid a little more attention to the recent budget fine print, meaning they may inadvertently end up owing thousands of dollars in fringe benefit taxes (FBT).

Under subtle changes, scheduled to kick in next year, farmers with a mixed used farm ute costing $70,000 will be hit with an annual FBT

bill of $6,370 at the proposed 26% rate for petrol and diesel vehicles.

Findex tax advisory partner Craig Macalister said the repeal of a work-related vehicle FBT exemption for mixed private and business use, committed to in the Government’s latest Budget, will result in tax implications, that he describes as a “grenade”, for people who use their utes for business.

“Those farmers who were buying vehicles at Fieldays, undoubtedly looking forward to a reduced cost thanks to depreciation deductibility, were likely oblivious to the tax grenade coming their way in 12 months,” Macalister said.

“Worse still, any vehicle over $80,000 – such as a $75,000 ute with $6,000 in extras, or American muscle trucks with big price tickets –will be classified as 100 percent taxable, resulting in a staggering $21,060 in FBT per year in [taxable benefit].”

Macalister said consultation on the tax changes had not been given inadequate consideration, resulting in a policy that over-taxed essential business assets.

“In our view, the use of the current FBT exemption strikes the right balance for workrelated vehicles. Scrapping it will hurt farmers

and other industries reliant on utility vehicles,” he said.

“These utes are not perks or ‘Remuera tractors’ – rather essential tools for carrying equipment, personnel and of course dogs on and off the farm.

“Yet, the IRD seems locked in a paradigm that views any provided vehicle as a perk to be taxed, unless it’s an emergency vehicle,” said Macalister.

Federated Farmers has joined the fray, calling on Revenue Minister Simon Watts to urgently rule out the changes to FBT, claiming it could quickly become ‘Ute Tax 2.0’.

Federated Farmers transport spokesperson Mark Hooper says it seems to be being pushed through by stealth.

“Farmers will be incredibly concerned that the Government are consulting on new rules that could add thousands of dollars of additional tax payments each year.

“This would be a huge cost for farmers, tradies and other productive New Zealanders and unfairly punish the legitimate use of these work vehicles.

“The previous government’s Ute Tax was bad enough, but at least that was a one-off cost. These new FBT charges would be annual and cost farmers an arm and a leg each year.”

MARK DANIEL markd@ruralnews.co.nz

Findex Tax Advisory Partner Criag Macalister.

Open Country spreads into butter

SUDESH KISSUN sudeshk@ruralnews.co.nz

THE COUNTRY’S second largest milk processor hopes to produce its first commercial butter within two months.

With global demand and record prices, Open Country Dairy chief executive Mark de Lautour says entering the butter market is an exciting time for the company.

The company’s new butter plant is located at its Waharoa site in the Waikato beside its existing cheese production facility – part of a multimillion dollar investment programme that includes upgrades of its whey processing plant and main dryer.

De Lautour believes demand for butter is strong because the world now understands that natural fats are good for you. “Natural protein and fats are good, and they are in demand in almost every market in the world,” he told Dairy News

The hype around manufactured dairy alternatives and plant-based proteins is also waning rapidly, he adds.

De Lautour says the Waharoa site has had quite a bit of work done to it in the last 12 months.

SUPPLIERS GROW

THE COUNTRY’S second largest milk processor now has around 1100 suppliers, with 70 farmers signing new contracts for the season.

Open Country Dairy chief executive Mark de Lautour says the new suppliers come from all three regions: Waikato/ Bay of Plenty, Manawatu/Taranaki and Southland/Otago.

Competition among processors remains fierce but de Lautour says it helps to have 20 years of experience under their belt.

“We’re in a good position from a brand position with farmers,” he told Dairy News

“The whey processing plant upgrade will allow it to make higher grade whey proteins and capture more value from

“We’re not new, we’re not small and we’re therefore very secure.

“There are always some nerves when farmers move to a new processor; during our early years, it was the same for us. The industry was saying, ‘oh, they’re not going to make it’. But we’re well past that now.”

Open Country, which pays its farmer suppliers in full four times during the year, is confident it will exceed $10/kgMS for milk supplied last season.

The company’s fourth and final period payout has a forecast mid-point of $10.70/kgMS, highlighting the strength of the markets at the end of last season.

the existing cheese manufacturing. Waharoa is where our cheese plant

is already: the butter plant’s there to deal with the fat, so you’ve got a

good protein-fat mix. And then, obviously, from the cheese, you get the whey.”

More stainless steel means the need for more milk, and Open Country is actively recruiting farmers in all its three regions: Waikato/ Bay of Plenty, Manawatu/ Taranaki and Southland/ Otago.

De Lautour says a milk processor cannot wait until it has got all the milk to make the investment.

SAME AS US

ASKED TO comment on Fonterra’s divestment plan –which includes either selling or floating its consumer brands – de Lautour says the co-operative is turning its focus on core nutrition and bulk ingredients.

“That’s what we’ve always done,” de Lautour says.

“So, getting rid of the consumer brands division is probably the right thing for them to do.

“I’d be a hypocrite if I didn’t agree with the decision given that’s our business strategy.”

“You’ve got to have the capacity. So, it’s a leap of faith to some extent each time, and you must back yourself and farmers in the region to support the investment.”

Open Country is also investing in plants at Whanganui and Awarua.

At the Whanganui site, the company is putting in separators and a reverse osmosis facility and is also looking at boosting milk processing capacity. Plans for the Awarua site in Southland include continued planning for a new cheese plant.

Thriver Calf Teats deliver a natural feeding experience, helping calves feed instinctively from day one. Made in New Zealand, the soft yet strong, rubber material makes them the perfect solution for calves of all ages.

The unique end geometry prevents leaking, while the two-piece valve ensures a steady one-way milk flow. Infused with a light vanilla scent to encourage faster latching for efficient, stress-free feeding.

Open Country Dairy chief executive Mark de Lautour says entering the butter market is an exciting time for the company.

Fonterra’s unique hub of excellence, innovation

products from the more than five million NZ cows.

COMMON SENSE and

good human judgement

are still a key requirement for the super highly qualified staff working at one of New Zealand’s largest and most important research facilities –Fonterra’s R&D Centre at Palmerston North.

The centre employs more than 350 staff from 46 countries of whom nearly a third have PhD’s. It’s a unique hub of excellence and innovation which had its beginning in 1927 and now, nearly a century later, continues to discover new ways to produce world-class

The innovation from this establishment is legendary and it continues to produce new products and or ingredients that meet the demands of customers and consumers.

Professor Jeremy Hill is Fonterra’s chief technology officer who has a role in recruiting staff and says it won’t always be those with PhDs but for those who have what he calls ‘trade craft’ with excellence in science and engineering.

“That’s a starting point or prerequisite. We also want people who have the right ability to work both on their own and collegially in teams and those teams are not

just your immediate colleagues, but obviously

across different organisations in our case different countries because we must operate way beyond the confine of NZ to do our work,” he says.

Hill says people who work at the Fonterra R&D facility have got to have broader skill sets than just science, technology, engineering and relationship skills. He says they need people who are truly innovative who can think beyond where we currently are and put disparate pieces of information together.

“Like, put one and one together and come up with a lot more than two. We don’t need all our staff to be like this, but we need enough of them to drive our innovation,” he says.

All this begs the question, how do you find such people? Hill says track record – what they have done in the past – is a good predictor of the future. He says they

look at people who have been innovative early in their career. He says young people obviously bring the latest, greatest skills in terms of their education and development. And they are ‘digital natives’ so ICT-based technology is second nature to them.

“But we are also looking for people who are mid-career onwards who… had the opportunity to create a track record, and people from other countries. I once did the A to Z count here and we had someone from Zimbabwe here. We do even allow Australians to work here,” he joked.

Hill says Fonterra’s R&D centre’s close proximity to Massey University and the Riddett Centre is a bonus.

He is an adjunct professor there himself and says not many people are doing PhD’s or ‘post docs’ and it is very easy to move between the two.

He says the ability of staff to be good collaborators with other scientists, engineers and technologists is essential.

The advent of AI is of course now on the agenda and Hill likens this to arrival of the internet, when people weren’t sure what that would bring.

He says what they do know is that AI is a very powerful tool and, provided good data is fed into it, there is the opportunity to do things that are beyond the capacity of individuals or even groups to do.

But even with all this technology and the results it creates, Hill says the human factor still has a role to play.

“We need to be careful about the answers that technology provides and step back and apply common sense and make sure that the answer is actually the right one,” he says.

Jeremy Hill, Fonterra’s chief technology officer

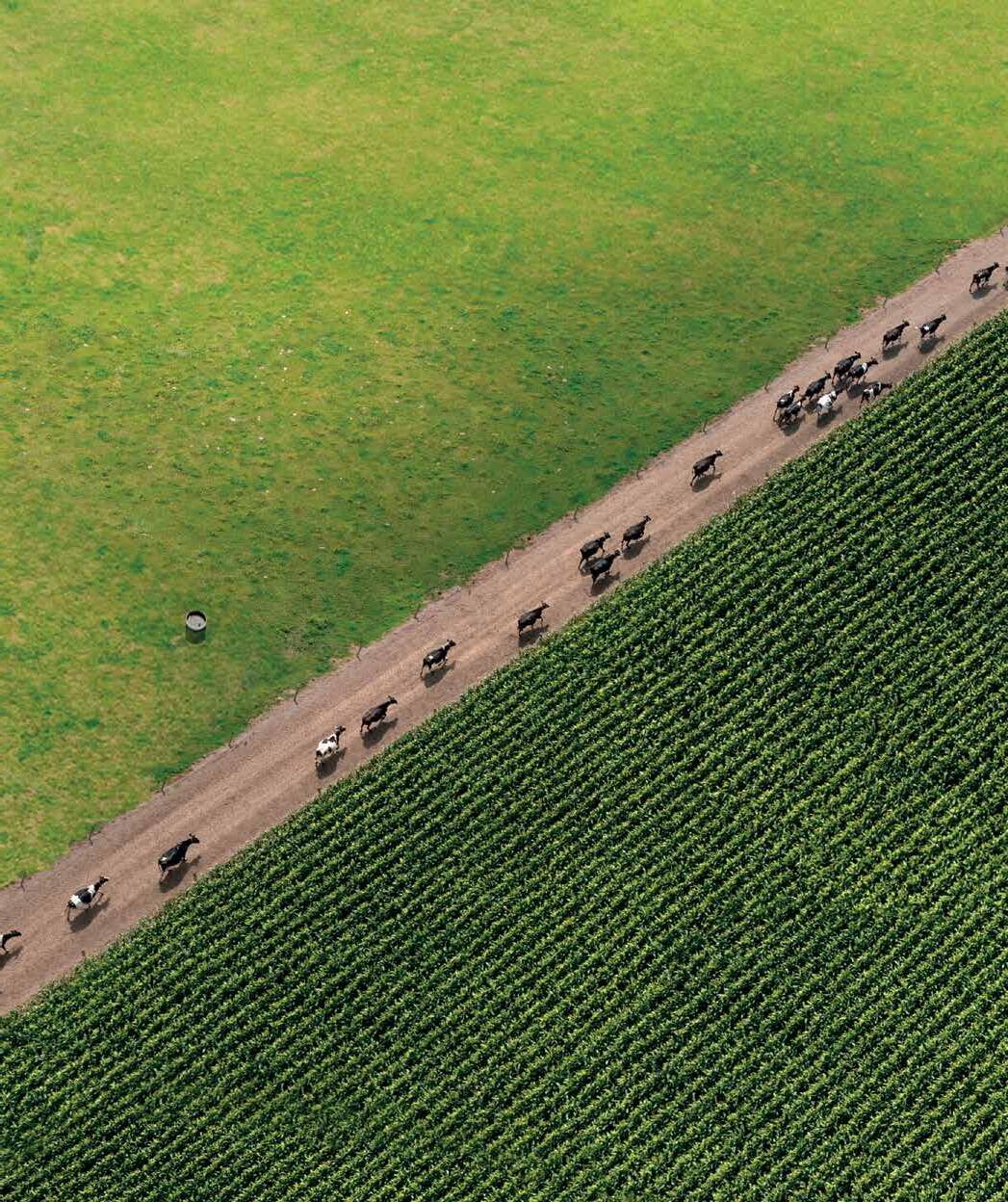

Dairy exports reach new heights

THE PROFITABILITY of dairy farmers is likely to increase in the coming year, according to the latest report by the Ministry for Primary Industries (MPI) on the outlook for the primary sector.

It says global dairy prices are likely to increase and farm expenses will stay static and it’s predicting that dairy farmers will on average receive a record $10/kgMS farmgate milk price.

This comes on top of what the Director General of MPI, Ray Smith, is describing as a blockbuster year for the primary sector with dairy exports for the year ended June set to reach

$27 billion – up 16% on the previous year. This is due, he says, to strengthening demand among traditional dairy importing countries such as China and a slight weakening in global supply.

Overall, primary

export returns for the year are close on a record $60 billion and this is due mainly to the performance of the dairy industry. What’s more, dairy exports are expected to hit $30 billion by 2029. For dairy it’s been an

amazing turnaround, says Smith.

“These global dairy prices have been well above the long-term averages and that’s driven a lot of the value,” he told Dairy News.

“Full cream related products – cheese and so on –have been fetching incredible prices because in Europe and the US there’s been a bit of decline in production. In China, very good prices have been achieved in the food service sector, especially with high value products such as cream and butter doing particularly well. There has even been a pickup of infant formula sales there,” he says.

Smith says a combination of global factors have worked in NZ’s favour. The exchange rate is one, but a significant factor is

the decline of milk production in China and in the US where avian influenza has gone through their cattle herd.

He says in Europe an outbreak of foot and mouth disease in Hungary has affected production and volumes have also been down in Argentina.

Smith says overall on the home front it’s been a bumper season and NZ has got through the droughts reasonably well – producing more milk. He says the good spring and summer were key factors and grass growth has been good, with a lot of feed stored.

“To me, what is phenomenal is that there’s been a two per cent productivity growth in dairy farming alone, which is quite an achievement,” he says.

‘AMAZING YEAR’

THE MPI outlook report paints a picture of an amazing year for the dairy sector.

It notes that on 6 May 2025, Global Dairy Trade (GDT) prices were 18% more than they were a year ago. Figures for some of the individual products, show that the average whole milk price was up 20%, AMF 27% and butter 25%. The report goes on to point out that against their five-year average, butter was up 42% and AMF 31%. SMP prices, while better, are however still below their five-year average.

Back on the farm in NZ, MPI is forecasting a modest 2.2% increase in milk production to the end of June and just a 1% increase for the coming season. Droughts and the early drying off cows in some regions have put something of a handbrake on production.

Some other good news is the prediction that interest rates are likely to continue their decline into the new season.

While there is cause to celebrate this year, Ray Smith warns there are still headwinds to conquer in the future, with the report showing that growth in the coming years will be incremental – around 2%, not the super 16% of 2025.

“I think there is uncertainty in the environment and outlook, and you can’t deny that. Among other things we have yet to see the full effect of tariffs play out across the world,” he says.

fonterra.com/next-gen-co-op

MPI director general Ray Smith says it’s been a blockbuster year for primary exports.

Councils told to hold fire until new rules are ready

SUDESH KISSUN sudeshk@ruralnews.co.nz

“WE’RE TRYING to get to the promised land but we’re still in a bit of a swamp at the moment.”

That’s Associate Agriculture Minister Andrew Hoggard’s response to ongoing farmer frustration around implementation of regional plans.

Hoggard says the Government is working to get better regulations in place, but the situation isn’t helped by some regional councils ploughing ahead under the old system.

He says these councils don’t recognise the work being done by the coalition Government to change the rules.

“I don’t know – do they feel too afraid that environmental activists and lawyers would take them to court if they don’t keep pushing this stuff through?” Hoggard told Dairy News

Getting consent renewals remains a big issue for many farmers. Hoggard says some renewals were just not being issued for unknown reasons, and a small group of extensive farmers risked being placed into a costly notified consent, just so they could carry on farming.

The costs that some of these landowners are being put through is eye watering, he adds.

He says changing the rules takes time and he hopes that regional coun-

cils can hold fire and wait until the new rules and regulations are in place.

“Let us get the new

rules and regulations in place and then you can start moving on this stuff again, knowing that in

all likelihood a lot of the heavy-handed rules and regulations will be gone.”

Federated Farmers

local government spokesperson Sandra Faulkner says councils can save money by sticking to their lane and leaving climate policy to central government.

“Councils should stop duplicating effort, and wasting ratepayer dollars, by setting climate policies.”

Federated Farmers supports RMA and local planning reform that reduces delays, costs and uncertainty, and utilises tools like farm plans rather than consents, she says.

Meanwhile, Hoggard says he was happy to see the positive vibe among farmers at Fieldays.

He says dairy farmers are buoyant with a $10/kgMS milk price last

season and a potential consecutive $10 payout this season.

However, he adds that farmers have concerns around geopolitical issues like wars and spats around tariffs.

“We’ve got a really volatile world at the moment, so things could change, but I’m hoping that common sense will prevail and we can keep doing well in the agriculture sector,” he says.

“Because it’s almost a universal positive story across the board for a wide range of our agricultural products: that’s what this country needs - strong agricultural performance to move the economy forward.”

@dairy_news facebook.com/dairynews

GUIDE TO CREATE RESILIENT PASTURES

A NEW publication has been launched that offers a comprehensive and up-to-date resource on commercially available grazing pasture species in New Zealand.

The publication, unveiled at Fieldays, has been produced to help farmers confidently select the best pasture plants based on their location, farming system, and management practices.

Resilient pastures for a changing climate is the result of a collaboration between Massey University and the Ministry for Primary Industries (MPI), separate to but in collabora-

tion with the seven-year governmentfunded Whenua Haumanu program.

Whenua Haumanu programme lead and booklet principal author Professor Danny Donaghy says this publication represents a first in New Zealand.

“Not all pasture plants are created equal, but until now, there has been a lack of accessible knowledge about which plants are best suited to specific outcomes or how and when to mix species,” Donaghy says.

“The Whenua Haumanu programme seeks to fill these knowledge gaps. This booklet is a result

of that research and ensures that vital information reaches the farmers who need it.

“By writing this guide, we wanted to create a resource that not only brings science to the farm sector, but also invites their input so that it’s truly a collaborative effort to enhance New Zealand’s farming practices.”

As the most comprehensive programme on regenerative and standard pastoral agriculture in New Zealand, Whenua Haumanu aims to bridge the gap between academic research and practical on-farm applications.

“The booklet is intended to be a practical tool for farmers and rural professionals to help them make informed decisions about selecting pasture species,” Donaghy says.

“It also provides a clear approach

for evaluating whether diverse pasture mixes can help achieve a farmer’s goals.

“The booklet includes a step-bystep guide for farmers to select the right location for planting, identify most suitable plant species for regional conditions and land-use capabilities, and outlines necessary management practices for successful establishment.

“It also contains information to help highlight any potential animal health issues and how to avoid incompatible plant species to prevent poor outcomes.”

• Ideal for Cattle Troughs

• High Flow

• Side/Bottom Mount

• Detach to Clean

• Compact/Robust

• Up to 50mm Inlet

• Flows up to 600L/min

• For Storage Tanks

• Easy Access to Valve

• Inlets Upto 50mm

• Avoids Starting & Stopping of Pump When Tank is Filling

Danny Donaghy

Biosecurity Minister Andrew Hoggard with a MPI detector dog at Fieldays.

Gongs for co-op’s Whareroa site

FONTERRA WHAREROA

wrapped up a successful season with a recording-breaking cheese production volume and several gongs at the coop’s annual Best Site Cup awards.

The site won the Best Large Site Award, which recognises excellence across all areas of operations.

Fonterra Whareroa was celebrated for its commitment for continuous improvement. The site has not only significantly lifted its quality standards and customer engagement but also started leading the way in building talent capability, while maintaining a sharp focus on sustainability.

Hayden Baylis, site operations manager for Whareroa South, say this is due recognition for the team’s hard work.

“Success is best when

TALE OF THE TAPE

■ Established in 1972, Whareroa is one of Fonterra’s largest manufacturing sites.

■ With 11 plants, the site produces a wide range of products, including milk powder, cheese, protein, butter and lactic casein.

■ Products from Whareroa are exported to more than 85 countries worldwide.

■ With more than 1000 staff, the site can process up to 12.5 million litres of milk every day during peak season.

it’s shared. I am incredibly proud of our team’s achievements and the strong culture we’ve cultivated together. It’s our dedication, unity, and shared values that drive us forward and make us truly exceptional,” Baylis says.

Fonterra Whareroa also won the Japan Cheese Award for the strong performance of its cheese plants, making the site the second larg-

est supply factory to the Japan market. The plant produced over 95,000 metric tonnes this season – exported across North and Southeast Asia markets in countries such as China, Japan and Korea.

Ryan Bernhardi, Whareroa cheese plant manager, says it always starts with the great work Fonterra farmers are doing on farms.

“We rely on our farmers’ milk. There have

been some dry weather conditions in the North Island this season, so we acknowledge and really appreciate their hard work to enable our success,” he says.

A portion of Whareroa’s cheese is sent to its neighbour site in Eltham to be processed into billions of cheese slices, while the rest is exported

all over the world.

“Our cheese like cheddar and mozzarella are mainly used as ingredients for cheese snacks, processed cheese mix and in some local dishes,” Bernhardi says.

Apart from topping pizzas and burgers, consumers in these markets are using cheese in local dishes such as cheese

Production....Great Location

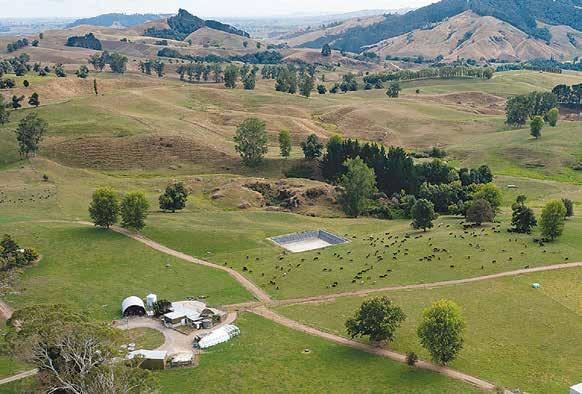

An outstanding opportunity to secure a high-performing 313ha (774 acre) dairy farm in four titles, located in a sheltered valley beside the Pelorus River, right in the heart of Marlborough’s dairying country.

'Dalton Downs' has a history of strong production with 296,000kg MS recorded in 2020 from 662 cows. The current season has achieved production of 278,591 kg MS from 600 cows. Farm records indicate a reliable season average of 284,000kg MS. With a milking platform of 242 ha and an irrigated area of 188 hectares, plus the region's reliable annual rainfall of over 1750mm, it is easy to see how production can be maintained through the season. The land is mostly flat with gentle slopes and excellent access via an extensive track network.

Infrastructure includes a 44-bail ASHB shed with recent upgrades, four quality sheds, a 30T silo, and a compliant effluent system. Accommodation includes a modern 286sqm five-bedroom, two-bathroom homestead with double garage, plus two staff cottages.

Dalton Downs delivers the rare combination of scale, profitability, and lifestyle, offering a proven dairy operation in a stunning rural setting, just minutes from the Marlborough Sounds and bathed in New Zealand’s most sunshine hours.

Whether you're looking to diversify your portfolio or invest in a proven performer, now is the perfect time to harness the strength and stability of the dairy industry.

gyudon (Japanese beef rice bowl).

Dubbed the ‘Oscars of Manufacturing’ the Best Site Cup awards are held annually in Auckland to celebrate the successes of Fonterra’s manufacturing sites across the country.

Now in their 19th year, the awards spark a bit of friendly competition with the opportunity to win

in a range of areas, from sustainability and innovation to efficiency. Other manufacturing sites in Taranaki: Eltham also took home two awards, including the Best Specialty Site Award and Customer Cup, while Kapuni was the runnerup for Best Specialty Site.

@dairy_news

facebook.com/dairynews

Greg Lyons M 027 579 1233

E greg.lyons@pggwrightson.co.nz DEADLINE PRIVATE TREATY Plus GST (if any) (Unless Sold Prior) Closes 1.00pm Thursday 17 July 20 Westwood Ave, Blenheim VIEW By Appointment Only

Joe Blakiston M 027 434 4069

E jblakiston@pggwrightson.co.nz

Fonterra Whareroa staff celebrate their wins at the annual Best Site Cup Awards.

On the go

AFTER HOPPING from one event to another at Fieldays, Associate Agriculture Minister Andrew Hoggard would have been hoping for a rest.

But on Monday last week, he found out at the last minute that he was needed at Hamilton Airport, not too far from the Fieldays venue, to cut the ribbon and welcome the first international flight to Hamilton in 13 years.

Part of the welcome was the unveiling of a plaque. As Hoggard pointed out in a social media post: “Will have to get some twink and a vivid to fix the plaque.”

This is because the plaque Hoggard unveiled read ‘Our international terminal was officially opened by Hon James Meager, Acting Minister for Transport’.

Hoggard, also the Biosecurity Minister thanked the Biosecurity NZ team for a smooth operation clearing international passengers on day one.

Suitors line up

AS FONTERRA’S divestment of its Oceania and global consumer businesses progresses, clear contenders are emerging.

And it seems interest is strong across the ditch, not surprising when Fonterra Oceania owns some of Australia and New Zealand’s top milk, cheese and dairy dessert brands. Bega Cheese last week informed the market that it was making a bid for Fonterra’s Oceania business. French company Lactalis has also confirmed that its Australian business unit is in the hunt for Fonterra Oceania. And media reports say A2 Milk, with around $1 billion cash reserves, is eyeing manufacturing assets in New Zealand.

Sticky situation

THE FEDERATED Farmers rural advocacy hub at Fieldays has been touted as a great success.

However, not every visitor to the site was left impressed.

One social media post referred to the language and sentiment towards sustainability, and included a photo of car stickers stating, ‘Quit Paris’ – obviously from farmer group Groundswell.

The sticky posting attracted one quick rebuttal from a media company which stated that ‘those stickers were from one group in particular in the advocacy hub, not necessarily a reflection on the rest of the groups represented’.

Some farmers would be wondering where the hub actually stands on the Paris Agreement.

110,000 visitors!

IT’S official, Fieldays 2025 clocked 110,000 visitors over the four days.

Kudos to the organising committee and new chief executive Richard Lindroos. The weather may not have been fully on side, but the vibe was positive. Confidence in the rural sector was apparent with exhibitors reporting good sales across a range of products and services.

Lindroos has already made it clear he is looking for primary sector support.

“Our call is not for handouts, but for hands joined together to take advantage of the opportunities and meet the challenges of the next five, ten, and twenty-five years.”

Bring it on!

Agri’s mojo is back

GOOD TIMES are coming back for the primary industries. From sentiment expressed at Fieldays to the latest rural confidence survey results, all indicate farmer confidence at a near-record high.

The quarter two Rabobank Rural Confidence Survey, released last week, shows farmers across all sectors looking favourably at the 12 months ahead.

The latest Ministry for Primary Industries (MPI) Situation Outlook Report predicting export returns for the year will be almost $60 billion – 12% up on last year – and that these will hit $65.8 billion by 2029. Leading the charge is dairy which is picked to be a record $27 billion (up 16%).

And banks, often seen in a bad light by farmers for charging high interest rates, are getting back in farmers’ good books. In a Federated Farmers survey, 61% of farmers rated their bank’s communication as good or very good – the best result since 2020.

Just on 18% of farmers said they were feeling undue bank pressure, down from 24% six months earlier and the lowest rating recorded since 2018.

Rabobank’s report shows farmer confidence in the broader agri economy was unchanged at a net reading of +44%. Alongside last quarter, this is the second-highest net reading recorded across the past decade, with only quarter two 2017 higher (at +52%).

The latest survey, completed early this month, found 48% of farmers were now expecting the performance of the broader agri economy to improve in the year ahead (down from 52% in the previous quarter).

There’s no doubt that sentiment is high among producers of all our major agri sectors. It’s largely driven by strong commodity prices – led by dairy.

However, the world markets are beyond the control of farmers. Geopolitical shocks can easily overtake the current positive. But for now, the agri sector’s mojo is back. Let’s hope no one spoils our party.

Head Office: Lower Ground Floor, 29 Northcroft St, Takapuna, Auckland 0622

Phone 09-307 0399.

Postal Address: PO Box 331100, Takapuna, Auckland 0740

by: Inkwise NZ Ltd Contacts: Editorial: sudeshk@ruralnews.co.nz

: davef@ruralnews.co.nz Rural News on-line: www.ruralnews.co.nz Subscriptions: subsrndn@ruralnews.co.nz

Publisher: Brian Hight Ph 09-307 0399

General Manager: Adam Fricker Ph 021-842 226

Editor: Sudesh Kissun Ph 021-963 177

Machinery Editor: Mark Daniel Ph 021-906 723

markd@ruralnews.co.nz

Reporters: Peter Burke Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech Ph 021-190 3144

Production: Dave Ferguson Ph 027-272 5372

Becky Williams Ph 021-100 4831

Digital Strategist: Jessica Marshall Ph 021 0232 6446

AUCKLAND SALES CONTACT: Stephen Pollard Ph 021-963 166 stephenp@ruralnews.co.nz

Farmers are quietly solving one

ish fellow Kiwis.

AS FOOD insecurity deepens across New Zealand, a powerful solution is quietly unfolding in our rural communities — and it starts at the farm gate.

At Meet the Need, our 2025 Impact Report shows what’s possible when farmers take the lead in feeding our nation. In the past year, over 1.1 million meals were made possible — including more than 655,000 servings of meat and 540,000 servings of milk — all thanks to donations.

Farmers are already feeding the world. Now they’re helping feed their own backyard. But this is about more than numbers. It’s about a model that puts manaakitanga into action — connecting rural generosity with real need in our towns and cities, all without creating extra supply chains or waste.

Meet the Need was founded by farmers, for communities. We work within existing industry systems and organisations, making it easy for farmers to donate livestock and milk. Those donations are processed by partners like Silver Fern Farms, Miraka and Fonterra, then distributed to over 130 foodbanks, community organisations and social supermarkets around the country.

Protein is one of the most sought-after and least available items for families facing food insecurity. What we’re providing isn’t just calories, it’s nutrition, dignity, and hope. Every donation makes a tangible difference to families doing it tough.

This isn’t charity in the traditional sense. It’s a practical communityled solution to a growing national problem, powered by the people who produce the food in the first place. For many farmers, donating through Meet the Need is a simple decision: one cull cow, one bobby calf, or a few litres of milk that would have been sold can instead be used to nour-

Over 1.1 million meals were delivered this year — all powered by rural generosity.

It’s also good business for the heart. In a time where rural wellbeing is under pressure, we constantly hear from farmers that being part of Meet the Need gives them purpose. It’s a way to give back, to stay connected to the communities beyond the farm, and to lead change in a way that feels authentic and impactful.

We’re incredibly proud of the partnerships behind this work. From our processors to every one of our partners, supporters, grant funders and beyond, this is a team effort. Everyone involved shares a common belief: that no one in Aotearoa should go hungry, especially in a country that produces more than enough to feed our own.

And while we’ve come a long way, the demand is growing. The foodbanks we work with are seeing more working families, more elderly people, and more children going without. Food insecurity isn’t something happening “somewhere else”it’s everywhere. And it’s urgent.

Protein is the most needed, least available item in foodbanks. That’s where Meet the Need steps in.

That’s why we’re calling on even more farmers to get involved. Donating through Meet the Need is straightforward and fully transparent. You know where your donation is going, and the impact it’s having. Whether it’s one animal or a few litres of milk, your contribution will feed real people; no waste, no middlemen, just direct support where it’s needed most.

You don’t have to be a farmer to get involved. If you’re not on the land but want to help, you can donate directly — every dollar goes toward getting protein to the families who need it most.

To the farmers who’ve supported us already: Thank you. Your generosity has made a difference to thousands of families.

And to those who haven’t yet joined: we’re here, we’ve made it easy, and your support has never mattered more.

At a time when many feel disconnected from solutions, Meet the Need offers something differ-

ent – a way for rural New Zealand to lead with compassion, pride, and purpose.

The food is already here.

The systems are in place.

All we need now is

your help.

• Zellara Holden is General Manager of Meet the Need, a farmer-founded, nationwide charity delivering meat and milk to foodbanks across NZ. Learn more or get involved at www. meettheneed.org.nz

ZELLARA HOLDEN

Zellara Holden is general manager of Meet the Need.

Global dairy prices rising but risks emerge – report

WHILE GLOBAL dairy commodity prices continue to climb in most key exporting countries, the second half of the year is expected to bring increased downside risks.

That’s according to Rabobank’s latest Global Dairy Quarterly report, which says modest production growth in the first few months of 2025 has underpinned firm dairy commodity prices, with output from the ‘Big-7’ dairy exporting regions (New Zealand, Australia, the EU, Argentina, Uruguay , Brazil and the US) expanding 0.5% year-on-year (YOY) in Q1.

Report co-author RaboResearch senior analyst Emma Higgins says while this modest increase aligns with recent price strength, outlooks are shifting.

“Growth is projected at 1.1% in Q2 and 1.4% in Q3, marking the strongest quarterly increase since Q1 2021. The US and EU are expected to contribute to this growth with additional support from South America – granted, against weak prior-year comparisons.”

However, signs of stress are emerging on the dairy demand side, including near recordlow consumer confidence in the US, indicators of economic struggles in China and declining sales data from restaurants and consumer packaged goods companies across many regions.

Meanwhile, global trade conflicts remain elevated, with volatility and rapidly changing tariffs influencing dairy trade flows.

Nevertheless, Higgins says dairy product prices have surged to multi-year highs, with

a $10.00/kgMS forecast Fonterra price for the 2025/26 season, positive signs at the Global Dairy Trade Auction and US dairy commodities showing bullish trends and strong Q1 exports, albeit prior to the implementation of retaliatory tariffs by China and Canada. Higgins explained while Rabobank does anticipate risks emerg-

ing in the second half of the year due to expanding supply and demand uncertainty; this was expected to be a “recalibration” rather than a sharp downturn.

“[This is] a natural correction following a period of strong performance. Fonterra’s highest on-record milk price forecast positions farmers for a likely second

consecutive season of double-digit payouts and sustained profitability.”

However, uncertainty around the macroeconomic backdrop to the 2025/26 season remains. Fonterra’s forecast ranging from $8.00-11.00/ kgMS highlights potential market volatility, with similar ranges in other dairy companies potentially cause for concern.

Higgins explains that while RaboResearch sees the $9.50-$10.00/ kgMS range as sensible to kick off a new production season, firm dairy markets and weaker currency over a sustained period could see a higher figure, whilst winter volatility and commodity price shocks could bring it down.

New Zealand dairy

RED DAIRY COW CONFERENCE

Red Dairy Cow conference will be hosted by New Zealand in March.

The conference, held every three years, is part of the International Red Dairy Breed Federation. The federation’s two NZ members - Ayrshire NZ and NZ Milking Shorthorn Association will host the event.

The programme runs between March 2 and March 15th and includes the three-day conference in Palmerston North, 10 farm tours and postconference tours.

A trip to Fonterra’s R&D centre in Palmerston North is also on the itinerary. Federation board member and

farmer Russell Tocker says they will be hosting international delegates from other red dairy breeds as part of the event.

Four federation youth scholarship recipients, two from Denmark and one each from Scotland and Australia, will also attend.

“As part of this we’re organising

a NZ-wide tour programme to help our visitors build up their knowledge, skills and network and learn about our country.

“The overall goal for the upcoming IRDBF conference is to facilitate a platform for red dairy breeders, farmers, stakeholders and industry to share knowledge, discuss research,

export volumes for Q1 rose 5% year-on-year, with shipments to China up 10% and increased demand also seen from Indonesia, Korea, and Sri Lanka.

This was driven by a weaker New Zealand dollar and stronger commodity prices, contributing an additional $1.5 billion in export value over the same period 2024.

The report says New Zealand dairy farmer confidence remains high, with dairy production for next season expected to rise.

Sentiment was particularly elevated in the South Island, where land conversions to dairy are being discussed.

Higgins said while the scale of new conversions remains uncertain, any resulting milk growth is likely to materialise from the 2026/27 season onward.

network with their peers, learn and address challenges.

“We believe this will ultimately improve efficiency and quality of red dairy breeds and enhance growth and co-operation worldwide.”

• For more information visit the conference website: www.reddairyconference2026.co.nz

SOFT UNDERFOOT STRONG OVERHEAD

THE 2026

Manawatu

RaboResearch senior analyst Emma Higgins says outlooks are shifting.

Understanding and tackling Serratia

WAIKATO FARMER

Craig Clausen had an unpleasant experience after an outbreak of mastitis cases on farm, suspected to be caused by the pathogen Serratia.

Bacteria don’t need much in the way of nutrient to proliferate. Serratia is a mastitis pathogen which generally results in a failed mastitis treatment, often leading to a 3-teater or a cull.

From Ministry for Primary Industries (MPI) surveillance testing, the prevalence of Serratia in mastitis cultures has been increasing.

“We have farmed here for years and never had any issues like this before,” says Clausen.

“For us the water clarity and colour had always been an issue, but we’d never had issues with Serratia. We’d put in a water treatment system in 2003 to remove iron and manganese, which it did.

some Serratia in the milk samples taken from cows with mastitis.

“A year later, however, a pink slime appeared in both post filtration water storage tanks and has been there ever since. Since the slime appeared, my mastitis rates went up. I hadn’t changed any of my routines with milking; I had always used blanket dry cows, so I was rather puzzled.” Milk tests confirmed

“Oddly, I decided to stop teat spraying for the whole season and my mastitis rates went down.”

Clausen saw an article in Dairy News about Serratia from Farm Medix in 2024 about surveillance testing for Serratia in chlorhexidine teat sprays. He was a chlorhexidine user and used the filtered

water to dilute his teat spray.

“It just hit me,” he says, “In the article it said Serratia is often seen as an orange slime, and that’s what I saw.”

Clausen spoke to his FIL area manager, Mark Mohring, who confirmed it could indeed be something in the water and switched him to an iodine-based teat spray, as it is more effective for Serratia and isn’t at risk of being contaminated by Serratia.

Mohring says diluted chlorhexidine can be source of Serratia. “We were surprised to find how it can grow to high levels in diluted teat spray from Farm Medix

testing.”

Clausen had his water storage tanks cleaned out, serviced the water treatment system and began testing his water every five weeks for Serratia via his vet, noting that as the temperature rose, so too did the presence of bacteria.

Farm Medix’ chief scientific officer, Natasha Maguire, agrees warmer water brings more risk.

After cleaning the tanks in winter, Pseudomonas, a common biofilm in water reservoirs, was detected in January. Once the water tank temperature reached 20 degrees in February, Serratia was detected again.

Clausen says he wondered whether it was the length of time after cleaning or the temperature.

He decided to sample water from a further 18 farms in the Whitikahu area from Woodlands to Orini, testing them all at his own cost.

REDUCING RISK

YOU CAN help reduce risk of Serratia outbreak by following these steps:

Maintain a clean water supply

Seal and cover any tanks (lids on, cut way any branches and leaves above tanks to prevent bird poop being an issue. Make sure bores are protected from surface water getting in — they should be built higher than the surrounding ground).

Clean water tanks and troughs out before summer, avoid water use around cows with cups off, clean areas like drains and under the bridge at the platform exit.

Use Farm Chlor in water tanks to prevent bacterial proliferation.

Avoid water splashing and hosing off cows.

Use best practices for teat spray preparation.

Make up teat spray using dedicated buckets, and use water cooled from the hot water cylinder to avoid high levels of bacteria.

Keep teat spray tanks and vessels sealed and clean them out weekly, rather than topping them up continuously.

Do not make up too much diluted teat spray at a time.

It’s best to seek advice based on pathogen profile, generally speaking, use iodine teat spray if you have a Serra -

Water quality is an issue on many farms worldwide, especially those not on a drinking water compliant supply.

“Iron and manganese can cause issues with water, including compliance with milk processing, but high iron and manganese can cause other issues, including metallic taste, oxidative stress for cows as well as blocking pipes,” says Maguire.

“The presence of iron, manganese, or the low water pH associated with

tia issue where possible, as most iodine actives are effective against Serratia, and will not support its growth in diluted teat spray products. (growth of Serratia in teat spray can make your situation worse).

Farm Medix do not recommend stopping teat spraying. Teat disinfection after milking is a critical part of mastitis control on all farms.

Chlorinate or use peracetic acid for tank or wash down water. Products like Farm Chlor are registered for dairy use and very effective against water born pathogens. Test the water for chlorine (Farm Source have chlorine test strips) at the final point of use (tub) at least weekly to ensure proper chlorine content. 1ppm of chlorine is sufficient.

Lastly, if you are considering chlorination of your water supply, ensure that a carbon block filter is fitted for the entire house supply, this way all shower water, drinking water is not going to smell of chlorine. Since chlorine breaks down, stock water to troughs is fine so long as levels at the point of use are below 5ppm.

Test your farm and cows for subclinical and clinical mastitis.

Test mastitis cases or high SCC cows with Fresh Cow Dry Cow. This will tell you what pathogens are involved so any patterns will be picked up quickly.

them can slow down the growth of some bacteria, but it’s important to remember that any water source can still be easily contaminated.”

Farm Medix testing throughout the farm system found Serratia only in a pit hose.

This season, thankfully, has seen 30-50% fewer mastitis cases on Clausen’s farm with the changes he has made. He has also had no cases of Serratia mastitis from samples tested.

“We have changed teat

spray active, cleaned out the tanks, and we plan to have the tanks cleaned regularly to avoid issues,” he says. “It is more cost effective than ionizers or UV lights, and I wanted other farmers to know about this issue and be aware of how water can cause issues with mastitis.” Clausen will also use Farm Chlor tank tablets to help control the problem, since chlorinated water reduces the growth of bacteria and algae.

@dairy_news

Waikato farmer Craig Clausen (left) with FIL area manager Mark Mohring.

Serratia is a mastitis pathogen, mostly resulting in a failed mastitis treatment.

Pact to tackle FMD breakout

potential foot and mouth outbreak.

SIX INDUSTRY organisations, including DairyNZ and the Dairy Companies Association (DCANZ) have signed an agreement with Ministry for Primary Industries (MPI) to prepare the country for a

The Foot and Mouth Disease Operational Agreement confirms how government and industry will jointly prepare for, and respond to, a possible outbreak – including how costs will be shared.

Under the deal, industry will contribute 40%

of readiness costs and 15% of response costs –capped at $450 million.

The dairy sector will contribute over 60% towards these costs.

Dairy farmers will meet 41.85% of costs and dairy processors 18.85%.

Sheep and beef farmers will foot 20% of the costs with sheep and beef pro-

cessors 16%.

Biosecurity Minister Andrew Hoggard says the agreement marks a major milestone in New Zealand’s readiness for a potential FMD outbreak.

The deal takes effect from 1 July 2025 for five years.

“An outbreak could cost up to $3 billion to

WHAT IS MILK FEVER COSTING YOUR FARM?

Animate: the palatable solution for transition cows.

eradicate but doing nothing would be far worse; potentially slashing export values by $14.3 billion per year until it’s controlled,” says Hoggard.

“Through this agreement, we’re locking in a truly collaborative approach. Industry will contribute 40% of readiness costs and 15% of response costs - capped at $450 million - and in return, they’ll have a formal seat at the decision-making table.”

Hoggard says the agreement reflects years of work and a shared commitment to protecting New Zealand’s vital livestock sector.

“This is a significant and practical step forward for our national biosecurity system.”

DairyNZ chief executive and inaugural chair of the Foot and Mouth Disease Council Campbell Parker welcomed the signing.

“Biosecurity is a key priority for DairyNZ as it helps us to power more productive and resilient farms – with dairy farmers the biggest sector investors in the biosecurity system,” he says.

“Dealing with an outbreak of FMD would cost the livestock sector billions, and we want to be involved in deciding how those costs would be best spent.”

Dairy Companies Association of New Zealand Executive Director

Kimberly Crewther says the agreement is a major milestone after over a decade of engagement to establish the foundations for partnership in addressing this most significant biosecurity risk for the livestock sectors.

“Recent overseas FMD outbreaks, including in Europe, reinforce the importance of getting to this point and ensuring government and industries’ combined resources, knowledge, and capability can be deployed in the most efficient and effective way to reduce risk and impacts.”

The Crown’s reference exposure is $2.5 billion million; however, its liability is uncapped, meaning it may spend more in the very unlikely event of multiple responses during the FMDOA’s term.

The industry contributions are split between the different sectors based on their relative size in terms of value, with a further adjustment to account for any market access agreements that allow product to be traded, even if FMD is present in New Zealand.

Value is calculated on what different sectors add to the value of a product. The value of the farming sector is calculated on farm gate sales, and the value of processors is the difference between farm gate value and export value.

Biosecurity Minister Andrew Hoggard says the agreement marks a major milestone in New Zealand’s readiness for a potential FMD outbreak.

SUDESH KISSUN sudeshk@ruralnews.co.nz

Digital upgrades for JD’s round baler offerings

MARK DANIEL markd@ruralnews.co.nz

JOHN DEERE have recently announced upgrades to its round baler offerings, with all models of this latest generation equipped with advanced ISOBUS capabilities, allowing them to be fully integrated into the John Deere Operations Center.

While some digital innovations might appear frivolous for everyday farming, it would appear that some upgrades do add some utility to the machines.

Anyone who has spent time on a tractor seat will know the importance of a well-formed swath – ideally box-shaped and flattopped – ahead of the pick-up assembly. If the swath is significantly narrower than the pick-up, the operator will have to “weave” to fill the cham-

ber uniformly.

JD’s innovative weave automation feature was first introduced in the US in February. Rather than driving to the left or right of the windrow for several metres, before

switching to the other, a flexible drawbar automatically guides the baler left and right along the windrow, depending on how the chamber is filling,

The automated weaving feature is said to

No-nonsense calf feeder

CELEBRATING 50 years of being in business in 2025 and specialising in the design and manufacture of an extensive range for the rural industries, Feilding-based McKee Plastics was at Fieldays highlighting a range of feeding products.

The Black and White 50-teat Open Trough Feeder features a host of design details making the unit practical and easy to use, alongside durability and an extended service life.

At the heart of the unit, a heavy-duty chassis and subframe offers a low centre of gravity for improved stability, an integral chassis tilt mechanism for machine levelling and an easily extendable towbar, making it suitable for towing by quads or side by sides, compact tractors or utes.

Manufactured in-house, a 550-litre milk res-

ervoir incorporates a large diameter lid for filling and cleaning, with access via a robust rear step assembly. The moulded plastic open trough style manifold delivers simplicity, with the biggest benefit being ease of cleaning. Equipped throughout with quality Hansen fittings, the unit is supplied with 50 McKee touch teats.

Director Logan McKee says, “This is a nononsense heavy-duty product offered at an extremely competitive price. Of course, we have an extensive range, right up to 100-teat units to suit a wide range of requirements. The key point is that they all incorporate our five decades of experience in designing and building these types of machines, in what is still a family business – with Pops still working on the factory floor every day”. www.mckeeplastics.co.nz

ensure consistently shaped bales, while also enabling the machine to accurately follow curved windrows, even at the field corners as it tracks the cut grass, eliminating missed crop and reducing

tractor shunting. Additionally, the tighter turning radius makes general manoeuvring easier.

Two variable chamber models – the V452R and V462R – have been given a 15% increase in driveline power intake, offering a claimed 8% increase in productivity in the paddock, while the double-belt system has been upgraded to give 7% more compression.

The fast bale release system also allows for unloading a bale and closing the gate in just three seconds.

An optional moisture monitor can measure the average moisture per bale in real time and alerts the operator on the trac-

tor display if the moisture content deviates from the pre-defined setting.

For those being asked for production and crop data – typically contractors – the ability to track each bale’s size and drop location data can be documented in the cloud, delivering the ability to record total bales per field and create dry-matter maps.

Combination baling and wrapping models, the C442R, C452R, and C462R, can be specified with a built-in bale weighing system, using strain gauges on each of the four transport table rollers, allowing on-thego measurement of individual bale’s weights.

All models are equipped with advanced ISOBUS capabilities, allowing them to be fully integrated into the John Deere Operations Centre.

The Black and White 50-teat Open Trough Feeder features a host of design details.

Non-polluting wrap that animals can munch on

WRAPPED BALES

arrived in the 1980s offering a viable alternative to clamp silage, and they remain a solution for those not wishing to invest in expensive clamps – a solution for smaller farms and a means to clearing excess grass at the end of the season.

On the downside, disposing of the net wrap used to secure the bale and the external plastic film required to make the package airtight has been problematic, although in the last half decade, the film has been collected for recycling.

The inner plastic net wrap has become more of a problem, accounting for approximately 2.5 million tons of waste per year, at least half of all plastic waste in agriculture. It typically ends up in landfill or is burned – both creating harmful consequences for the environment.

Plastic net wrap can be left in paddocks, contaminating soil and water, or become entangled in machinery such as bale feeders, manure spreaders and seeding equipment, causing downtime and repairs.

Perhaps worse, it can be ingested by cattle and wildlife. When that happens, it can

cause weight loss

and death.

outer bark which is jute. Initially hand woven at home with Lightfoot’s partner Colleen, the first 50m of the 1.25m wide net was woven at around one metre per evening.

Trials in a baler showed it worked straight from the get-go, followed up by a win in the opensection of the Southern Rural Life Farm Innovation Awards, followed by calls from around the world over the following days.

It seems that farmer ingenuity has come

up

with the answer at either end of the globe.

Here in New Zealand, Southland deer farmer, Grant Lightfoot has invented a non-polluting baleage wrap that animals can eat, made from jute yarn, which is similar to flax fibre.

Working as a commercial diver who spent many hours in a decompression chamber, Grant had a eureka moment when thinking about the farm at home and

came up with the idea of Econet bale wrap.

Initially, the idea was to use hemp fibre, but legal restrictions in the United States relating to THC – a psychoactive substance found at low levels in hemp –prevented its use and its byproducts in livestock feed.

This evolved into the use of jute, which grows like a bamboo plant, that after cutting is soaked, then beaten, to leave the

Lightfoot has gone on to partner with an Indian living in America and an ex-Kiwi living in Oklahoma, with the former using his connections in India to create more samples for testing and the eventual move into commercial production. The rolls of baler netting are made in Kolkata in 525m or 775m lengths. With stocks available in NZ, it costs slightly less than $4 to net wrap a bale with Kiwi Econet compared with $2.40 for conventional net. Despite the extra cost, Lightfoot says he has already got farmers and contractors knocking on his door.

WORLD’S FIRST COMPOSTABLE BALER WRAP

IN WESTERN Canada, rancher Larry Ruud and son Austin are co-inventors of the world’s first certified compostable baler wrap, that has been on sale for a year, saving farmers’ time, cutting repair costs and avoiding enviromental damage. Nature’s Net Wrap decomposes naturally, so removes the problems currently associated with burning or burying plastic net wraps.

The Ruud’s came up with the idea for Nature’s Net Wrap in 2015, after becoming increasingly frustrated with removing net wrap wound around machinery parts.

Nature’s Net Wrap is made from a blend of biopolymers and natural fibers that have been tested both in the field and in laboratories, evolving into a product that is strong enough to meet farmers’ typical storage needs, yet is compostable and fully consumed by microorganisms and enzymes in the soil, leaving behind no microplastics.

If inventing a strong, compostable non-toxic bale net wrap wasn’t hard enough, the Ruuds also wanted to ensure their product reached the largest possible market and has the biggest possible impact. Making it compatible with any baler model from any manufac-

turer was as high a priority as strength and degradability.

During the development phase, they worked with multiple universities and private testing facilities, including the University of Alberta by 2022, had a prototype ready to do field testing. Two years of testing looked at performance through multiple brands and various models of balers, over a wide range of climatic zones.

A contact, who realised the potential of the product, contacted CNH Ventures, CNH’s venture capital fund, which took a minority stake in Nature’s Net Wrap in January 2024. By May, with CNH’s help, the product was launched onto the North American market. Its arrival to market resulted in multiple calls and emails from around the world. They also took calls from farmers who grow tomatoes, flowers and vine crops, and others who use plastic netting and webbing, as well as from people looking to use the product apply to stop soil erosion.

Currently, Nature’s Net Wrap is solely available through CNH’s Case IH and New Holland dealer network in North America, with plans to extend into Europe later this year.

MARK DANIEL markd@ruralnews.co.nz

The non-polluting baleage wrap is made from jute yarn, which is similar to flax fibre. Inset: Grant Lightfoot.

Tractor Pull celebrates milestone

MARK DANIEL markd@ruralnews.co.nz

DESPITE THE rain and a liberal coating of mud, engines roared, the 50th Fieldays Tractor Pull Competition, drew crowds of spectators across the four days of the annual event.

Contestants put their machines to the test in the challenging conditions, competing in categories determined by tractor and load weight, age and modifications. For the first time in many years, the competition welcomed a South Island competitor all the way from Gore, along with a group from the Bay of Plenty.

The wet and muddy track conditions added an

extra layer of difficulty to the competition. Organiser Dan Reymer said that this year was one of the wettest years they’ve had

for a long time.

“We lowered the kilowatt-per-kilo ratio just to get the tractors through the mud. There was still

some seriously good racing out there, and it’s as much about the driver’s skill as the tractor’s performance. The win-

ners can come down to fractions of a second,” said Reymer.

In the Weight Transfer class, with the aim to pull a tractor mounted sledge down the track, to which weight transfer is gradually added, the winner was contractor Trent Hickford.

Thomas Fare took out the Weigh-Adjusted competition, where two tractors race side by side pulling a concrete block, with its weight adjusted following a measure of horsepower on a dynamometer.

The winner of the Modified Tractor competition went to

Wally Sinton, and the Pre-85 Class to Andrew Reymer. The Brent Garrett Sportsmanship Award went to Rowland Ambler and the First Time Entrant Award went to Fergus Goodwin, with the latter commenting, “I‘ve been volunteering for Tractor Pull for over 10 years, and it’s the first time I have entered, after peer pressure made me get in the cab”. Helping to power this year’s golden anniversary celebrations was new Major Sponsor PTS Logistics, who joined returning Sponsors, Corson Maize and Giltrap AgriZone.

TOP INNOVATORS WIN GONGS

HOSTED BY ginger dynamo Te Radar, the Fieldays Innovation Award Winners Event put the spotlight on the agricultural industry’s most promising ideas

Steve Chappell programme manager, New Zealand National Fieldays Society, said, “This year, we have seen entries that combine impact, innovation, and industry leadership; there are some true standouts”.

With 63 participants across Prototype, Early-Stage, and Growth & Scale highlighting those shaping the future of the rural sector, five shortlisted finalists in each category had their entries judged by a panel of 18 sector experts on the first day of the annual event.

Ruminant Biotech from Auckland was the winner of the Prototype Award for its slow-release bolus called Emitless, which delivers over 75% methane reduction in cattle for 100 days from a single treatment.

Head judge Peter Dowd said, “The winner has not only demonstrated strong underpinning science and a thorough product development process but also a solid understanding of the market and regulatory environment that their product will be entering. Their IP is well considered, and effective implementation of their

solution will have a drastic impact on New Zealand’s emissions profile”.

Oamaru’s Alps2Ocean Foods Tapui Ltd won the Early-Stage Award with its product Mīti, which transforms surplus dairy calves into a world-first, shelf-stable, functional protein snack.

Head judge Shane Dooley stated that this idea provides a game-chang-

ing solution, transforming bobby calf waste from the dairy industry into a high-value, low-carbon protein product.

“By addressing a long-standing social license challenge, they’re helping reshape the wellbeing narrative around calf management in New Zealand,” said Dooley. “It creates value from waste, reduces emissions, and offers a commercially viable path forward for a more circular and ethical agri-food sector.”

CropX, from Wellington won the Growth & Scale Award, with judges noting that CropX stood out for its exceptional ambition, strategy, and execution.

They were also impressed by the development and introduction of the Evato1 evapotranspiration sensor, a transformative addition to the CropX platform.

Head judge Brendan O’Connell said, “This innovation significantly

enhances the insights available to global growers, positioning CropX at the forefront of agritech solutions that enable smarter, more sustainable farming”.

Not to be outdone, Hamilton’s St Paul’s Collegiate School’s KiwiPrune team won the Fieldays Young Innovator Award for entrants 19 years old and under. KiwiPrune was designed and developed as part of coursework for the AgriBusiness in Schools program to simplify the labour-intensive task of removing the plastic clips used to secure the Kiwi fruit vine.

The device is designed to remove clips from kiwifruit vines on orchards, improving productivity, reducing strain, and enhancing sustainability.

Head judge Jenny Cameron said, “The judges saw significant potential for use in kiwifruit orchards both in NZ and overseas, as well as in other horticulture and viticulture applications”.– Mark Daniel

The wet and muddy track conditions added an extra layer of difficulty to the competition at Fieldays.

The Ruminant Biotech team were, from left, head of research studies Kirsty Bardoul, senior business development manager Ian South and head of intellectual assets and strategic partnerships George Reeves at Fieldays.

PERFECT PARTNER PASTURE’S