A(BouT) Building Technology periodical for the Building Technologist

featuring

MANUFACTURA, NPSP BV, Veena Sahajwalla, Dr.Faidra Oikonomopoulou & Dr.Telesilla Bristogianni , Sam Lonis and ROTOR

BT Spotlight featuring CORE Studio - Dr. Serdar Așut ,Project RED, DSS SARO & SeismoSolve, User centered sustainability StudioDr. Craig Martin & Designing together

85. Waste Streams

Cover page

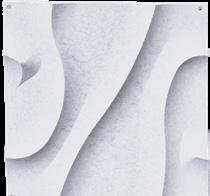

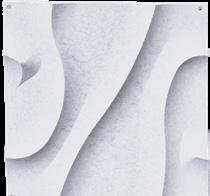

NABASCO® 8010

The cover image shows a bio-composite material by NPSP BV made from reed and Recell® (recycled cellulose) fibers, which are recovered by the Dutch water boards and would otherwise be burned or composted.

NPSP develops and supplies innovative environmentally friendly composite materials and products for public space, construction, design and mobility. They use biobased and circular raw materials as much as possible, which can be reused after a long life cycle.

https://www.nabasco.nl NPSP BV

RUMOER 85 - WASTE STREAMS

3rd Quarter 2024

29th year of publication

RuMoer

RuMoer is the primary publication of the student and practice association for Building Technology ‘Praktijkvereniging BouT’ at the TU Delft Faculty of Architecture and the Built Environment. BouT is an organisation run by students and focused on bringing students in contact with the latest developments in the field of Building Technology and with related companies.

Every edition is covering one topic related to Building technology. Different perspectives are shown while focussing on academic and graduation topics, companies, projects and interviews.

With the topic 'Waste Streams', we are publishing our 85th edition.

Praktijkvereniging BouT

Room 02.West.090

Faculty of Architecture, TU Delft

Julianalaan 134 2628 BL Delft

The Netherlands

www.praktijkverenigingbout.nl rumoer@praktijkverenigingbout.nl instagram: @bout_tud

Printing www.printerpro.nl

Interested to join?

The Rumoer Committee is open to all students. Are you a creative student that is eager to learn about the latest achievements of TU Delft and Building Technology industry?

Come join us at our weekly meeting or email us at rumoer@praktijkverenigingbout.nl

Circulation

The RuMoer appears 3 times a year, with more than 150 printed copies and digital copies made available to members through online distribution.

Membership

Amounts per academic year (subject to change):

€ 10,- Students

€ 30,- PhD Students and alumni

€ 30,- Academic Staff

Single copies

Available at Bouw Shop (BK) for :

€ 5,- Students

€10,- Academic Staff , PhD Students and alumni

Sponsors

Praktijkvereniging BouT is looking for sponsors. Sponsors make activities possible such as study trips, symposia, case studies, advertisements on RuMoer, lectures and much more.

For more info contact BouT: info@praktijkverenigingbout.nl

If you are interested in BouT's sponsor packages, send an e-mail to: finances@praktijkverenigingBouT.nl

Disclamer

The editors do not take any responsibility for the photos and texts that are displayed in the magazine. Images may not be used in other media without permission of the original owner. The editors reserve the right to shorten or refuse publication without prior notification.

The Eggshell Project

-Dinorah Schulte, Edurne Morales & Montserrat Ayala,MANUFACTURA

Project Article

Nabasco biobased and waste-based composites

-Willem Böttger, Mark Lepelaar & Dimitra Tsoli , NPSP BV

Company Article

Waste as a resource for Sustainability & Decarbonisation

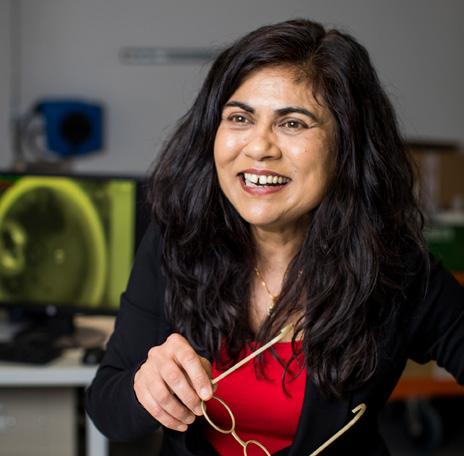

-Veena Sahajwalla

University of NSW

Academic Article

Use of Aerospace Thermoplastic Composite Material

-Sam Lonis

TU Delft - Faculty of Industrial design engineering

Graduate Article

Rotor/ Rotor DC

- Emmanuel Cortés Garcia & Arne Vande Capelle ROTOR

Company Article

Re3 Glass

-Dr. Faidra Oikonomopoulou and Dr. Telesilla Bristogianni, ReStruct group,TU Delft

Academic Article

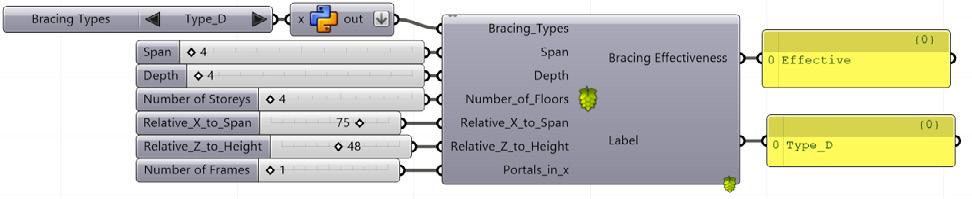

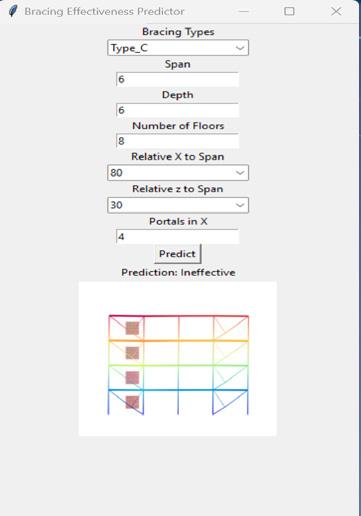

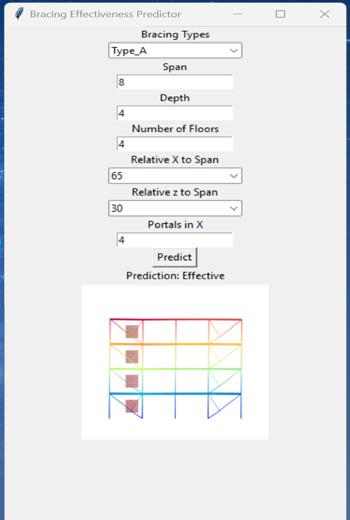

CORE Studio

- Dr Serdar Așut BT Spotlight article

- Ramya K umaraswamy & Sofia Markson

Spotlight article

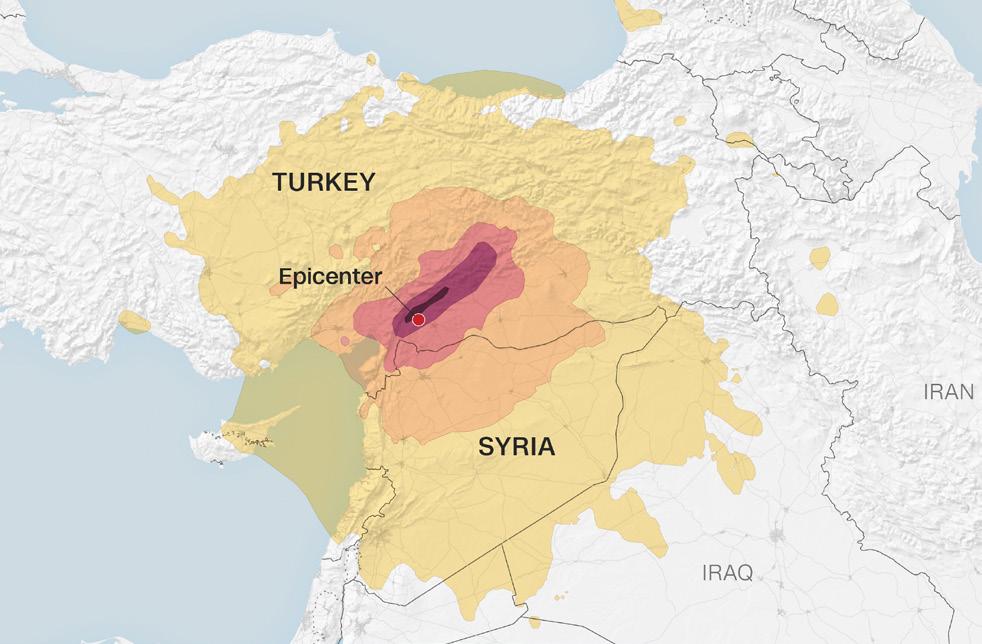

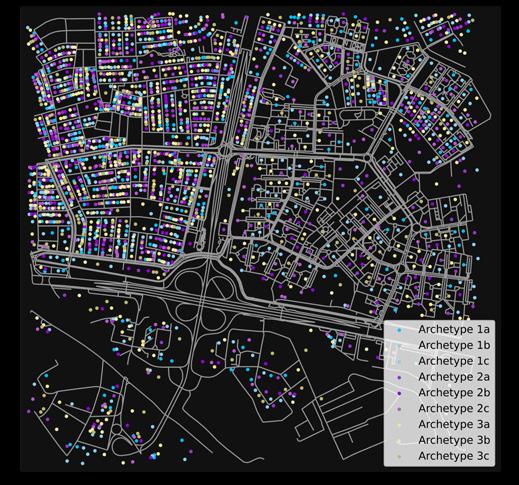

DSS for search 7 rescue resource allocation for earthquakes

- Bo Valkenburg, Brent Smeeks, Pavan Sathyamurthy & Shreya ejriwal

BT Spotlight article

SeismoSolve

- Zahra K hoshnevis & Aron Bakker

BT Spotlight article

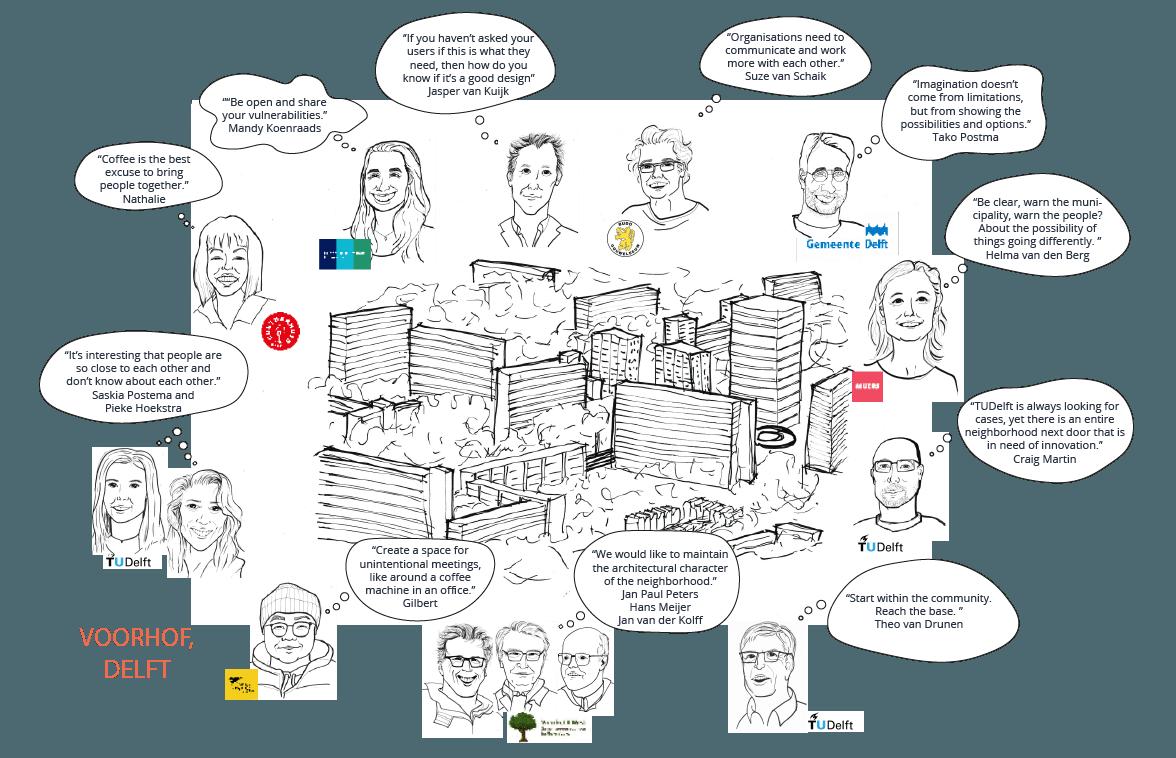

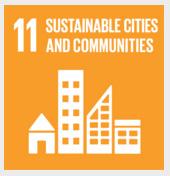

User centered sustainability studio

- Dr. Craig Martin

BT Spotlight article

Designing together

- Madevi Sewnath, Melissa Campos, K immy On and Juan Carlos Prazmowski

BT Spotlight article

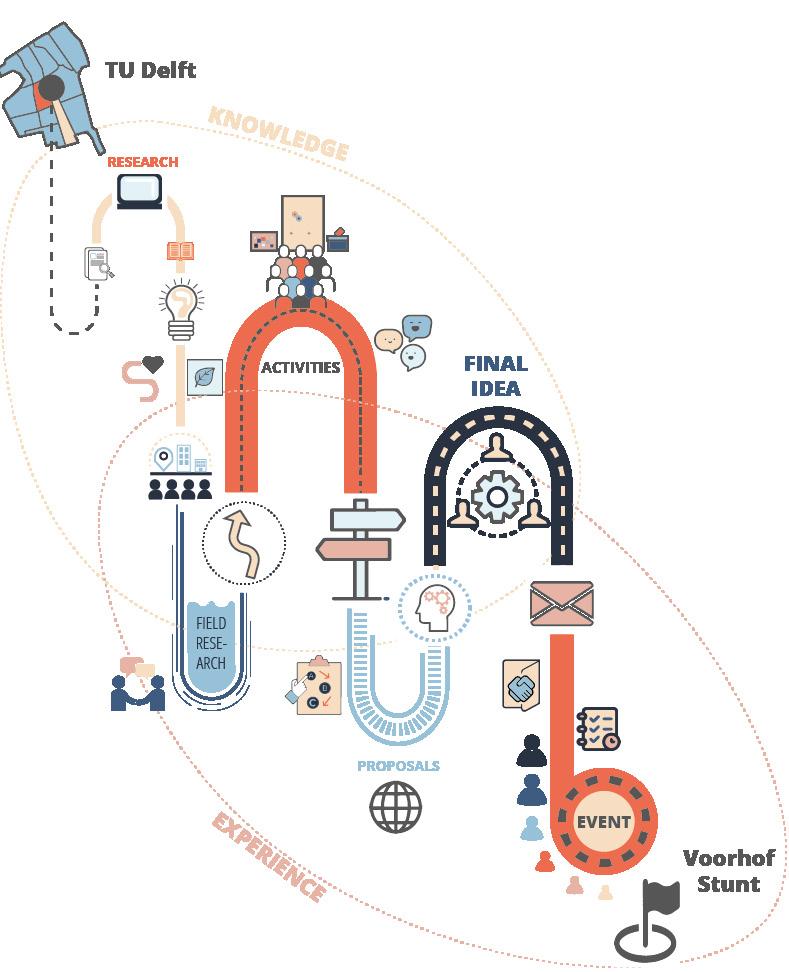

BouT's get-away to Czech Republic

- Aron Bakker, Chair of study trips, Praktijkvereniging Bout

Bout Events and Trips

- Praktijkvereniging Bout

TU Delft

Board 29 Signing off

- Ece Sel

Praktijkvereniging Bout

TU Delft

CONTENT

56

RED

Project

BT

60

64

86

88

68

72

76

82

14

22

36

28

48 06

EDITORIAL

Dear reader,

It is with great pleasure that I present to you the 85th edition of RuMoer: Waste streams. Repurposing waste streams into construction materials not only fosters innovation and drives cost-efficiency but also contributes significantly to a more environmentally responsible construction industry, paving the way for a sustainable future. Exploring the current possibilities in construction utilizing waste streams allows us to understand the economic, environmental, and social implications associated with embracing waste as a primary resource. By delving into these multifaceted dimensions, in the 85th edition, we aim to provide a comprehensive understanding of strategically integrating waste into construction practices.

With the 29th year of publication, we introduced the BT Spotlight section in the periodical.This issue’s BT Spotlight section features projects from the design studio electives CORE (COmputational REpertoire for Architectural Design and Engineering) and User-centered sustainability studio from quarter 5 of the MSc programme.

As this edition also marks the end of my tenure as editorin-chief, I would like to thank all the contributors and sponsors for the wonderful collaborations over the past year. Working with this exceptional editorial team the past 2 years has been a privilege, and I look forward to seeing this committee grow larger and stronger.

I would also like to congratulate Swornava Guha and wish him good luck in his new role. Having worked with him the past year, I believe that RuMoer will evolve and reach larger audience under his leadership. Lastly, I would like to acknowledge the dedicated members of the RuMoer committee who consistently work towards enhancing the quality of the periodical.

We hope you enjoy this edition.

Ramya Pushpalatha Kumaraswamy

Editor-in-chief

| RuMoer 2023-2024

5

Editorial

RuMoer committee 2023-2024

Fieke

Ramya

Swornava

Bryan

Mauritz

Rossella

Daniel Pavan Shreya

THE EGGSHELL PROJECT

MANUFACTURA

Materials of the future and new possibilities.

A third of the production of food intended for human consumption is lost or wasted worldwide, which is equivalent to approximately 1,300 million tons per year. An estimated 17% of all food available to consumers in 2019 ended up in landfills at households, retailers, restaurants and other food services, according to new UN research conducted as part of global efforts to reduce waste. of food in half by 2030. The weight is equivalent to approximately 23 million fully loaded 40-ton trucks, enough to circle the Earth seven times (Food and Agriculture Organization of the United Nations, 2019).

Instagram

Fig. 1: Eggshell project © Zara Arroyo

QR1: manufacturamx

Mexico is a hungry country that wastes tons of food. Total waste in Mexico, a country with 53.4 million people in poverty, reaches 20.4 million tons per year (37.98 percent of what is produced in the country). (Do you know how many tons of food Mexico throws away? El Universal, 2018). Mexico is also considered the main consumer of fresh eggs worldwide; the per capita consumption of the Mexican is 28.0 kg per year, considered the fourth largest producer of eggs worldwide and is responsible for 1/27 eggs produced in the world (Sader).

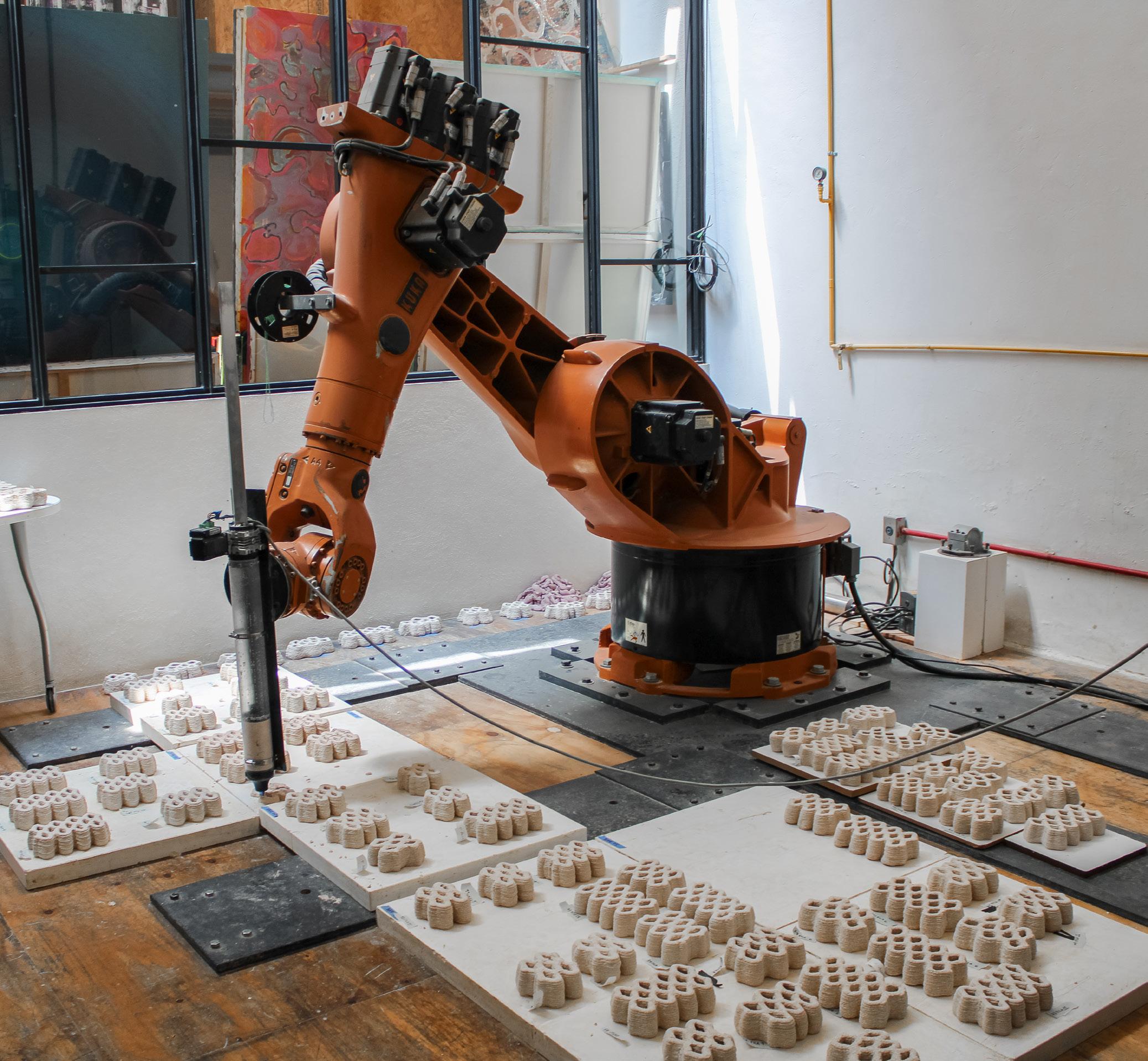

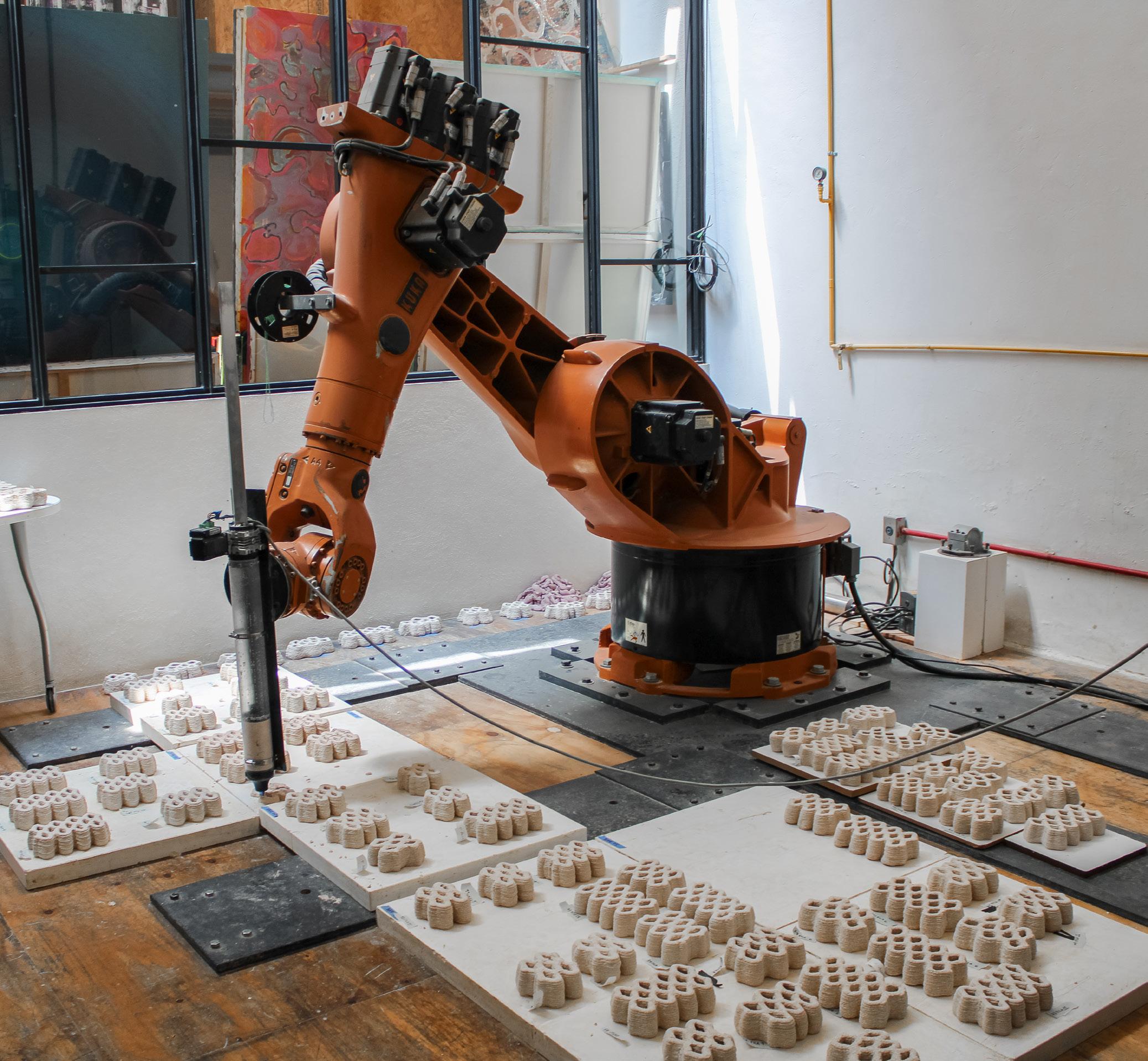

workspace is certainly not a clean/green environment.”. Gas emissions, waste management, transportation and energy consumption are just a few of the characteristics that turn this process into one that can negatively impact our environment. We decided to reevaluate the potentials of ceramics, keeping the connection between materiality and nature, extensive access to raw materials, geometrical freedom and strength. But reducing some of the harmful traits by using a locally sourced extensively found lightweight waste product: egg, together with biobinders that allow the mix to solidify without the need of firing and an additive fabrication process based on 3D printing with a robotic arm. Our process allows less

We tend to think of ceramics as an environmentally friendly industry, and a beloved hobby for many of us. But, is this claim real? Robert Harrison in his book Sustainable Ceramics mentions: “Ceramics with all its necessities for manufacturing, materials, firing, fuels and

8 85 | Waste streams

Fig. 3: 3d-printing an eggshell brick © Zara Arroyo

Fig. 2: Eggshells © Enrique Aquilar

9 Project

Fig. 4: a kuka kr-150 robotic arm in MANUFACTURA's atelier workshop © Zara Arroyo

waste production, geometrical freedom, precision and repeatability.

THE EGGSHELL PROJECT / UN PROYECTO DE HUEVO

is a research project that seeks to take advantage of and transform our waste to turn it into a buildable material and open up a new possibility to create our living in an environmentally responsible way. In this project we create a bioceramic made from eggshell and combine it with sustainable aggregates, resulting in a new materiality, which seeks to reduce food waste and generate new opportunities.We decided to reevaluate the potentials of ceramics, keeping the connection between materiality and

nature, extensive access to raw materials, geometrical freedom and strength. But reducing some of the harmful traits by using a locally sourced largely found lightweight waste product: egg, together with bio-binders that allow the mix to solidify without the need of firing. Our process is based on 3D printing with a KUKA KR-150 robotic arm, an extruder and additive fabrication process, which allows us to shape our blocks with different geometries and project them into different architectural applications. allows efficient use of material (less waste), geometrical freedom, precision and repeatability, project them into different architectural applications.

In this research we have made two applications: A wall (Eggshell Bricks, presented in the INÉDITO collection by Design Week Mexico 2022) made of a total of 105 different blocks that are assembled based on their geometry, and a column (Eggshell Column, presented in the DISEÑO EMERGENTE collection by ZONA MACO 2023) made of 26 pieces that embrace each other and create stability through their shape. Each brick is made in a 100% sustainable and circular way since the raw material was obtained through the collection and donation of waste from more than 2 months of production from various restaurants in Mexico City such as Rosetta, Rosetta Panadería, LARDO and Rancho Rio Blanco. From the cultural perspective, this project frames a new material that does not exist in the current market, which generates added value as a construction material, since it cannot be found or produced in any other way. Technology allows us to innovate in the current markets in terms of construction, which economically and culturally has a great weight in society because it opens up new possibilities for construction and materiality in our habitat,

10 85 | Waste streams

Fig. 5: Another 3d-printed bio-ceramic application with eggshell waste © Enrique Aquilar

generating a circular system from where it is obtained to its use, by giving a new life to our waste.

This project was achieved thanks to the mixture of computational design and the opportunities offered by digital manufacturing, technology and materials innovation to transform our waste and raise awareness, questioning our manufacturing methods and creating centuries of circular life, generating new sources of employment since you recycle it, sanitize it, until its manufacturing with robotic 3D printing and its placement on site; having to look for new talents to produce this material and product in series and opening up new opportunities in the construction of future architectural spaces, creating a new dialogue between machines and humans.

Bibliography

Harrison, R. (2013). Sustainable ceramics: A practical approach. Bloomsbury.

Home | Food and Agriculture Organization of the United Nations. (n.d.). Retrieved February 13, 2023, from https://www.fao. org/3/i2697s/i2697s.pdf

¿Sabes Cuántas toneladas de Comida Tira México a la basura? El Universal. (2018, January 2). Retrieved February 13, 2023, from https://www.eluniversal.com.mx/nacion/sociedad/ mexico-desperdicia-20-millones-de-toneladas-de-comida

11 Project

Fig. 6: wall of eggshell bricks © Design week

12 85 | Waste streams

Fig. 7: collection of eggshell bricks © Arturo Arrieta

@MANUFACTURA

Dinorah Schulte is a mexican architect/researcher

graduated in Architecture from Universidad Iberoamericana, Mexico City. She completed her postgraduate master’s program, MASDFAB Master of Advanced Studies in Architecture and Digital Fabrication, at ETH Zurich in Switzerland.In 2019, she participated as a scholar in the Robotic Atelier hosted by the Norman Foster Foundation. Currently based in Mexico City, is a Co-Founder and CEO of MANUFACTURA. She is an adjunct professor at Universidad Iberoamericana and Universidad La Salle and member of the editorial board of CEMEX México 2023.

@MANUFACTURA

Edurne Morales obtained a Bachelor of Architecture from Tecnológico de Monterrey and studied the Master of Advanced Studies in Architecture and Digital Fabrication at ETH Zurich. Morales has contributed to multiple international projects, amongst them, the New International Airport of Mexico City (Foster+Partners and FREE), Clay Rotunda (Gramazio Kohler Research), Magic Queen (MAEID - Venice Biennale 2021), the GRAM certification for space applications (European Space Agency). Currently based in Switzerland, she is part of a research project focused on developing a constructive system around large-scale unfired clay printed modules at ZHAW Zurich University of Applied Sciences.

@MANUFACTURA

Montserrat Ayala is a plastic artist with a great interest in materials. She founded Sumario Tierra, a platform dedicated to the dissemination of ceramics and she’s co-founder of CAL VIVA. Currently dedicated to research and material design, always having as a main focus the sustainability of materials. The center of her research is the observation of natural processes, from the material’s birth to their death and the aesthetic relationship that exists in that is. Currently, Montserrat is studying for her master degree at ELISAVA Escuela Universitaria de Diseño e Ingeniería de Barcelona in Design Through New Materials.

13 Project

Montserrat Ayala

Edurne Morales

Dinorah Schulte

NABASCO BIOBASED AND WASTE-BASED COMPOSITES :

NPSP turns waste resources into valuable products

Willem

Böttger, Mark Lepelaar and Dimitra Tsoli at NPSP BV

Introduction

The challenge for the upcoming decades is the material transition. Industrial revolution initiated the shift from local and organic resources to fossil fuels, which due to their affordability have allowed us to develop and trade specialty materials on a large scale, worldwide. Overtime, the overuse of fossil fuels has resulted in many negative side-effects. Specifically, their use in the construction sector is responsible for more than 30% of total CO2 emissions. At the same time, raw materials for products used in construction such as floor coverings, solar panels, fire-resistant additives and fibreglass, are coming under increasing economic and environmental pressure.

QR1: website

Fig. 1: Innovatie Paviljoen Marineterrein © Boom

This is where NPSP targets to create impact, by using locally sourced bio-based and waste-based resources to develop materials that are processed as little as possible and used in products that can be easily taken apart, reused and recycled. In other words, are part of the circular economy.

At the moment, NPSP is a leader in making bio-based composites. Since its founding in 2003, NPSP has been engaged in the research, development and production of composite products for outdoor use that have as little environmental impact as possible. This is done by taking concrete steps, with our vision and mission as a guideline.

Mission: “Making an impact with highly bio- and wastebased composite materials and products and positioning them as a viable alternative to less sustainable conventional materials such as glass composites, aluminium and tropical hardwood.”

Vision: “To keep the world liveable in the long term, the demand for bio-circular products with a truly low environmental impact will have to grow dramatically. NPSP is committed to leading the way in the development and application of composite materials, ultimately using only bio-based, waste-based and circular raw materials, which are also extracted as locally as possible and which demonstrably replace the use of less sustainable outdoor materials."

Nabasco® materials

The bio-composites developed by NPSP carry the Nabasco® label. Nabasco® circular bio-composite products are made from bio-based and waste-based

materials. NPSP uses local, natural fibres such as flax, hemp and increasingly residual materials such as roadside grass, reed and recycled toilet paper as much as possible combined with bio-based fillers and resins. The products are durable and maintenance-free, so very suitable for demanding outdoor use such as façade cladding.

The fibres and fillers used for Nabasco® require significantly less energy to produce and fewer chemicals to adhere to the binder. As a filler NPSP uses chalk that is a by-product, extracted from the water of drinking water companies, instead of virgin chalk from mines. The drinking water companies filter this chalk from the water to make it softer and to give washing machines and dishwashers a longer lifespan. The resins we use are also based on residual flows from other industries. For example, resins are made from residual flows from biodiesel production, sugar production, paper production and even sewage treatment.

16 85 | Waste streams

Fig. 2 (a): waste-based resources from the water authorities (waterschapen) that are used in Nabasco®: Reed, Recycled toilet paper – Recell® © NPSP

100% bio-based and 100% based on residual materials does not mean that the product is also recyclable at the end of its lifespan. NPSP works together with its strategic partners on various forms of recycling. At this point, the materials can be ground and completely reused as a functional filler material in new composites. In addition, we are working on higher-quality chemical recycling with which we expect to be able to separate the fibres and resin and reuse both. We are also working on optimal recycling from the perspective of bio-based circularity, where we allow micro-organisms to break down the biobased composites into nutrients for agriculture.

We ensure that our bio-composite materials and products keep improving by measuring and analysing the environmental impact via the Life Cycle Analysis (LCA) method. The LCA of our materials Nabasco8012, Nabasco8012F and Nabasco8040 is currently being validated by an external party. We have determined the CO2 emissions of our materials (A1-A3) according to the LCA methodology: cradle-to-gate. The NET CO2 range of our materials is between [1,296] and [-1,519] kg CO2 eq / kg of material.

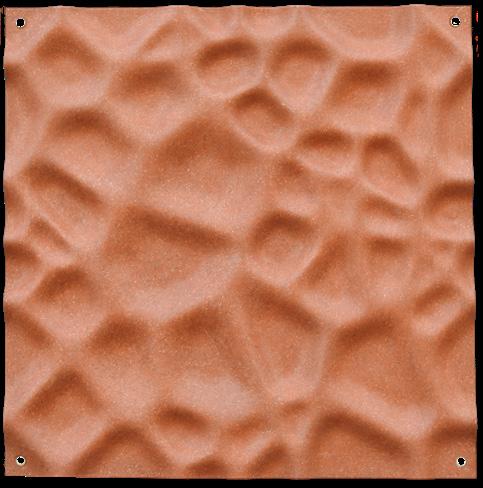

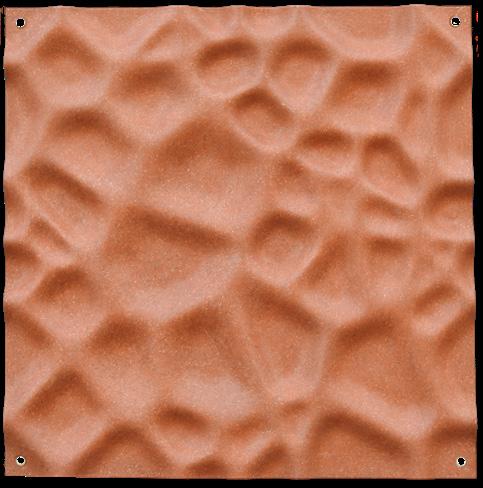

Nabasco® Products

Nabasco® products are produced by the application of high pressure and heat on the material while it is secured and shaped in a mould. Unlike sheet materials, this offers the possibility of creating three-dimensional, double bended products without material loss or additional processing costs. This allows designers to create façades with a completely unique identity.

Nabasco® bio-composite is maintenance-free. It requires no coating and is pigmented within its mass, so minor damage does not affect its quality or appearance. The technical lifespan of Nabasco® bio-composite is at least 50 years. It is highly suitable for extreme conditions:

17 Company

Fig. 2 (b): waste-based resources from the water authorities (waterschapen) that are used in Nabasco®: De-calcination chalk © NPSP

Fig. 3 (a): Amsterdam Tectural © NPSP; Fig. 3 (b): Dune Tectural © NPSP

resistant to large temperature differences and suitable for ‘wet’ applications. Currently, applications of Nabasco® are among other things, level gauges and other signs.

Next to traffic signs, the largest product application at this moment is façade panels. Nabasco® Tectural is a collection of 3D-shaped architectural façade panels. The façade panels are offered in either a homogeneous colour scheme or in a playful hue. The panel system is also fire safe according to building regulations.

“Amsterdam Tectural” is developed in collaboration with Studio Marco Vermeulen for the ‘Innovatie Paviljoen Marineterrein’ in the heart of Amsterdam, a project initiated by the municipality of Amsterdam. The design is inspired by the mathematical diagram Voronoi. This panel showcases the ability of forming complex detailed panels with multiple depths and shapes. The most recent panel of this line, “Dune Tectural” is developed inhouse by Frank Bleeker for ‘Pompstation 34’ in the ‘Amsterdamse Waterleidingduinen’. The design is inspired by the sand dunes. This panel showcases the possibility of forming sharp edges and thin curves along the surface of panels.

Our latest innovation is the application of the 100% biobased and 100% waste-based Nabasco® 8040 material on the Dune Tectural façade. While this innovation is still under development, it shows a lot of promise as a carbon negative material.

Another innovation in the portfolio of NPSP is Nabasco® New Habitat. Nabasco® New Habitat are nature-inclusive façade elements for utility buildings such as warehouses,

18 85 | Waste streams

Fig. 4: Pompstation 34 in de Amsterdamse Waterleidingduinen © NPSP

Fig. 5 (a): Dune Tectural with Nabasco®8040 © NPSP; Fig. 5 (b): Nabasco New Habitat © NPSP

6: Nabasco New Habitat © NPSP data centres, pumping stations and hospitals. It was developed in collaboration with Studio Marco Vermeulen, ecologists and research institutes. This product is a solution to the increasing demand from customers and inhabitants for both practical building materials and nature inclusive products, without compromises on safety and scalability. Nabasco® New Habitat elements in buildings aim to enable biodiversity to thrive. The products consist of waste reed for the insect housing and fire safe biocomposite for the overall structure.

Except for the standard products that NPSP offers, we work closely with our clients for the development of custom-made projects. Examples are; the façade panel developed together with Marco Vermeulen for ‘Prorail’, the “Exploded view” tile showcased in Dutch Design Week and the “Natuurhuis”, a collaboration with Common Affairs Architects.

19 Company

Fig.

Fig. 7: Prorail Façade (a project for Prorail in collaboration with Marco Vermeulen)

Fig. 8: Exploaded view façade (shown at DDw)

20 85 | Waste streams

Fig. 9: Natuurhuis (collaborations with Common Affairs Architects)

Willem Böttger @ NPSP

Willem Böttger @ NPSP

Willem is a bio-material entrepreneur and a cofounder of NPSP BV. He initiates research projects with valuable partners and is invested in developing 100% bio-based and 100% wastebased Nabasco® materials. He has more than 30 years of working experience in the field of renewable energy and bio-based materials. He is also owner of four patents, of which two are composite related. His background is experimental physics at the University of Amsterdam.

Mark is an entrepreneurial specialist in bio-based and circular materials and products and a co-founder of NPSP. He brings the material innovations of NPSP to the market by leading the product development team. He has professional experience in Europe and Asia that varies from renewable energy to sustainable technology and bio-based composites. At NPSP, he has received awards for innovation (AVKInnovation, Products/ Applications) and business development (NRK Prima Ondernemen). He is a graduate of the Industrial Design Department of TU Delft.

Dimitra is a creative engineer and researcher of bio-based materials and products at NPSP. Her work at NPSP revolves around color implementation on the façade panels, the effects of environmental exposure on the material through time and the development of fire safe products. She studied mechanical engineering in Greece and then pursued her masters in the Industrial Design Department at TU Delft, where she discovered her interest for circular and innovative materials.

21 Company

Mark Lepelaar @ NPSP

Dimitra Tsoli @ NPSP

WASTE AS A RESOURCE FOR SUSTAINABILITY & DECARBONISATION

Veena Sahajwalla

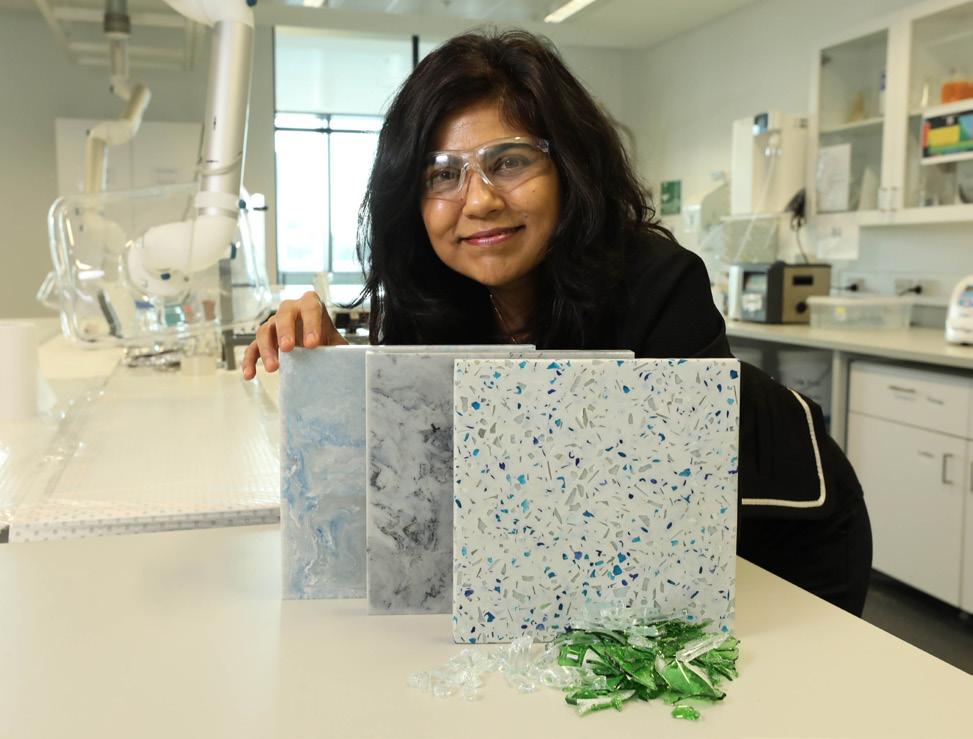

Recovering valuable materials from wastes not only creates greater sustainability but introduces new capability to support wider manufacturing (and sovereign) needs. It also creates more skilled jobs, and delivers overall economic, social and environmental benefits, compared to only using virgin materials.

Our current overconsumption of resources is more than planet Earth can sustain in the medium to long term. Making sure that our actions today do not have an adverse effect on the potential of present and upcoming generations to exist comfortably on this planet is the essence of sustainability.

QR1: SMaRT @ UNSW

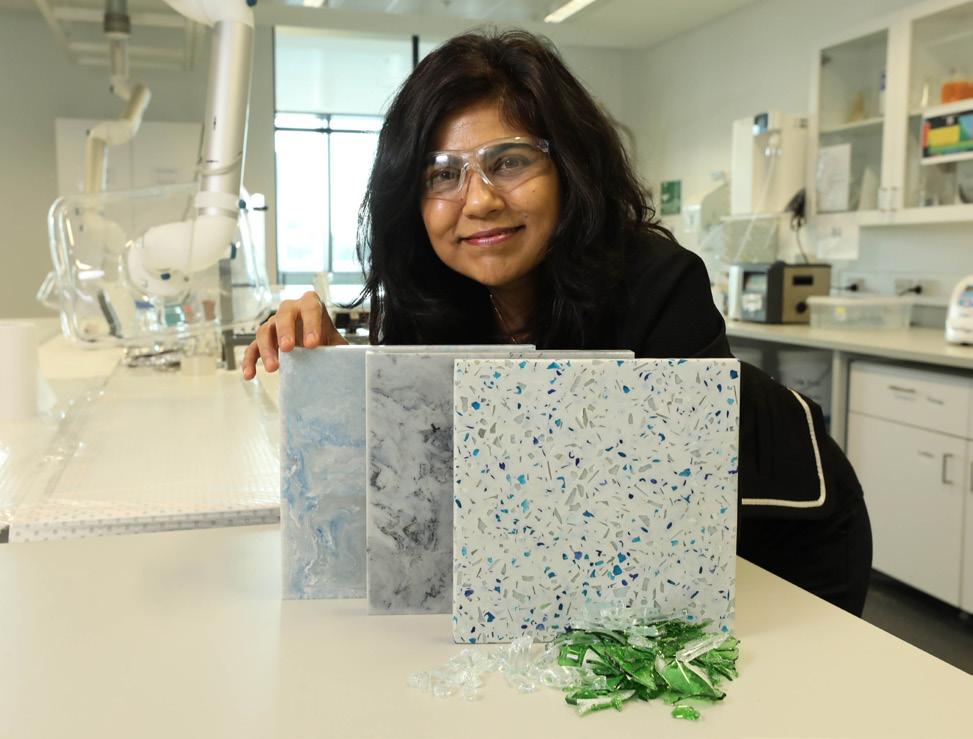

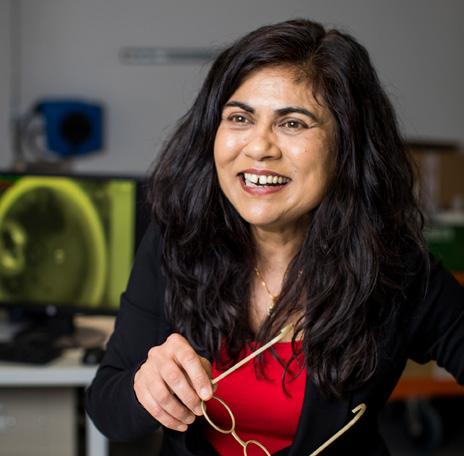

Fig. 1: Professor Veena in the UNSW SMaRT Centre's E-waste MICROfactorie.

© Anna Kucera

The challenge is very much one of incorporating emerging recycling technologies, like the various ones developed by our UNSW Sustainable Materials Research and Technology (SMaRT) Centre, into future manufacturing challenges to help make sure we can fulfill our requirements in ways that are financially viable, environmentally responsible and benefits communities.

A wasteful society

Statistically, Australia is one of the most wasteful developed nations, second only to the United States of America in terms of per capita plastic bags consumption.

On average, each Australian consumes over 24kg of plastic and uses over 230 plastic bags every year. In 2020, only 13% of the plastic waste was recycled and 84% going into landfill. The rest ends up in waterways and the oceans, which the 2021 The National Plastics Plan (NPP) estimates to be at 130,000 tonnes every year. This is equivalent to 1,280 kilograms of plastic being dumped every hour in Australia’s ocean.

Australia is also increasingly challenged by complex e-waste. Australian Bureau of Statistics’ latest waste estimate figures show the Australian economy generated 539,000 tonnes of e-waste in 2019, with more than 50% going to landfill and only 17.4% being ‘claimed as recycled’. Although much of the ‘claimed as recycled’ product goes offshore where outcomes are unknown.

Australian traditional recycling facilities are limited to pre-processing or partial mechanical processing which can separate, dismantle or shred only. There are limited decentralised technologies for the effective isolation of the valuable metal alloys, REEs (rare earth elements) and critical metals contained in e-waste.

24 85 | Waste streams

Fig. 3: Chairs and a table made from SMaRT's Green Ceramics.

Fig. 2: Veena with Green Ceramic tiles made from waste textiles and glass.

Valuable and much needed materials going to landfill

Many materials needed for future electrification and manufacturing components are subject to supply and price constraints, not to mention the environmental impacts of virgin mining, transporting and processing raw resources.

Yet we are landfilling waste containing many of these valuable materials needed.

We know that over the coming decades all of our global natural resources will not be sufficient to supply future manufacturing needs, including to electrify the world.

So, it is clear we urgently need advanced solutions to supply recycled waste materials as feedstock resources for future manufacturing needs, thus helping to truly create circular economies and sovereign capability.

Reforming complex waste to manufacturing feedstock

There are emerging technologies that can reform various hard to recycle or complex wastes into new value-added products and manufacturing feedstock, and our various UNSW SMaRT Centre-designed technologies attest to this.

Best known of these technologies is SMaRT’s Green SteelTM Polymer Injection Technology, which is well known for using millions of waste rubber tyres destined for landfill as an alternative source for partial replacement coke and coal (carbon) in electric arc furnace steel making.

The next generation of Green SteelTM research now shows waste plastics and bio-waste like coffee grounds are also effective and contain hydrogen which improves the efficiency of steel making. This technology locks the carbon from waste resources into the steel, hence causing no emissions and delivers a form of carbon capture while diverting millions of tyres from landfill.

SMaRT’s various MICROfactorieTM Technology modules are now in various stages of R&D and commercialisation, tackling hard to recycle wastes through small but scalable MICROfactoriesTM that can recover the valuable materials of these waste and reform them into new products or as feedstock for new manufacturing.

The Green Ceramics modules reforms waste textiles and problematic glass, plastics and other materials into a wide range of ceramics for the build environment, while the Plastics Ecofilament modules which reforms toner cartridges, and a range of e-waste plastics not being recycled, into filament for 3D printing and manufacturing.

The E-waste module recovers valuable E-materials

Some recent work has involved developing a new module to create a demonstration battery recycling MICROfactorieTM capable of dismantling spent batteries, including those made of alkaline and lithium for re-use. And in a new partnership we have with a regional metal can manufacturer for our Green Aluminium MICROfactorieTM technology.

25 Academic

The UNSW SMaRT Centre’s aluminium recycling technology will be used to enable our partner become one of the first aluminium aerosol can producers in the world to make aerosol cans from waste currently not recycled because it contains mixed materials including plastics.

In another SMaRT Centre scientific breakthrough, a new process has been developed that could pave the way for the manufacturing of a new breed of batteries to help meet decarbonisation goals. Results from a UNSW SMaRT Centre scientific paper demonstrate that recovered carbon from automotive waste can be used as a vital ingredient (anode active materials) for sodium ion batteries.

Finding a sustainable purpose

Diverting waste so it can become a resource for future manufacturing needs, particularly that related to making all of the electrical components needed for electrification, will help Australia and the world achieve its ambitions around decarbonisation, clean energy and creating circular economies.

With the right will, society can find a purpose for most waste by understanding the elemental value inherent in it. This can only be done through rigorous scientific analysis and active collaboration with industry, the community and governments to ensure innovations are taken up and used.

By better valuing our waste materials and creating circularity for their reuse, we can help the world be more sustainable and tackle our big global challenges.

26 85 | Waste streams

Fig. 4: Veena undertaking metallurgical reactions in a laboratory furnace.

Veena Sahajwalla

Veena Sahajwalla

@ University of NSW

Professor Veena Sahajwalla is a material scientist, engineer, and inventor that is revolutionising recycling science. She is the Director of the UNSW Sustainable Materials Research and Technology (SMaRT) Centre, and the inventor of polymer injection technology Green SteelTM; an eco-friendly process for using recycled tyres and other wastes in steel production. Veena launched her MICROfactoriesTM, the first of it's kind, in 2018 and is the Director of the ARC Microrecycling Research Hub, as well as Leader of the National Environmental Science Program’s Sustainable Communities and Waste Hub, and the 2022 NSW Australian of the Year.

27 Academic

USE OF AEROSPACE THERMOPLASTIC COMPOSITE MATERIAL

Sam Lonis, Faculty of Industrial Design Engineering, TU Delft

Designing new applications

The aviation sector's CO2 emissions, which currently account for approximately 2.4% of global emissions, require immediate attention for reduction. Composite materials offer crucial weight reduction potential, key to decreasing aircraft fuel consumption and emissions. Yet, these materials require significant resources during production and offer limited re-use possibilities, challenging circular economy ideals. Repurposing this waste into valuable new applications aligns with circular economy principles, prioritizing resource efficiency. This project explores this approach by utilizing composite production waste from the aerospace industry in the design of a new application:

QR1: Repository

Fig. 1: Prototype exhibited at Dutch design week 2023 © Sam Lonis

Fig. 2: Representation of material exploration process © Sam Lonis aligns with circular economy principles, prioritizing resource efficiency. This project explores this approach by utilizing composite production waste from the aerospace industry in the design of a new application: a bridge.

Exploring the material

The initial stages of the project focused on exploring the various types of composite waste materials from the aerospace industry and selecting a suitable waste material for the project. During the manufacturing process of composite materials, waste is avoided as much as possible, but some material is still discarded due to the stringent requirements posed by the aerospace industry.

The distinct types identified in the project include single ply-off-cuts, laminate off-cuts, blank cutting remains, post forming trim-offs and milling remains as shown in (Fig.2). Laminate off-cuts, for instance, are generated during the trimming of a larger consolidated laminate, often exhibiting defects along their edges resulting from the consolidation process. One of these defects is the squeeze out of resin from within the layers, which is shown in (Fig.3).

These laminate off-cuts were deemed suitable for the project as they were a recurring waste material from the composite manufacturing process, readily available within the timeframe of the project and had little contamination

30 85 | Waste streams

of other materials. As these off-cuts are discarded late in the manufacturing process, embodying the energy of the previous process steps, they present in a multiply consolidated form that can be readily processed. In terms of geometry, the laminate off-cuts are very consistent and similar, making it easier to utilise a large amount in for a single design.

With the type and form of composite production waste defined, the received material for the project was studied in further detail. This more material oriented exploration covered the defects in the material and how they affect the mechanical properties, its aesthetic properties and how the material can be perceived. These explored properties would form the basis for the development of the style of the final design.

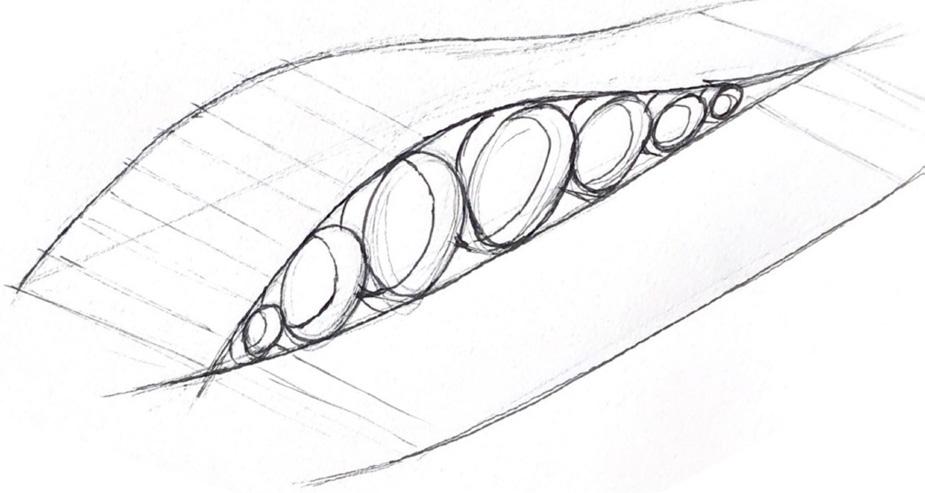

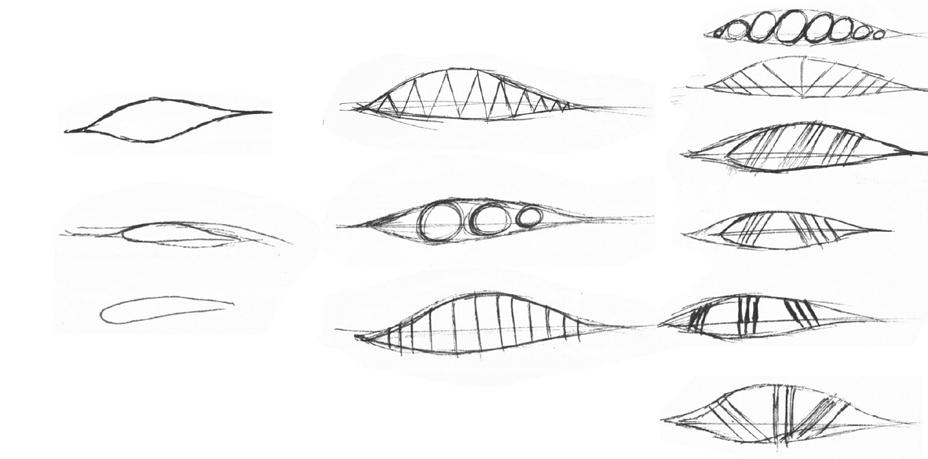

Design of the bridge

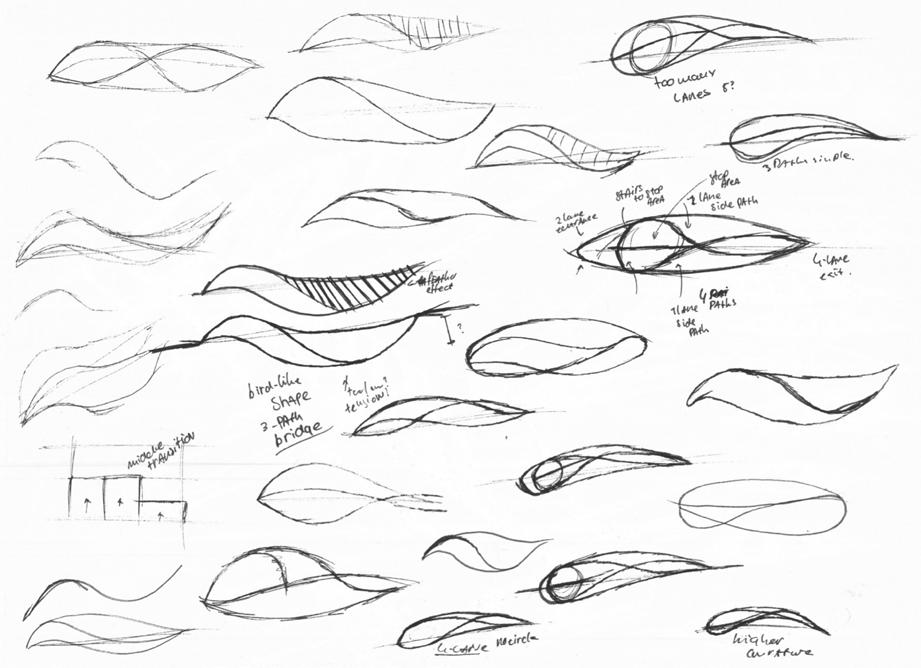

With the design of the bridge, the goal was to create a design from the laminate off-cuts that would stimulate creative thinking by designers and engineers about the use of the laminate off-cuts in new applications. This process

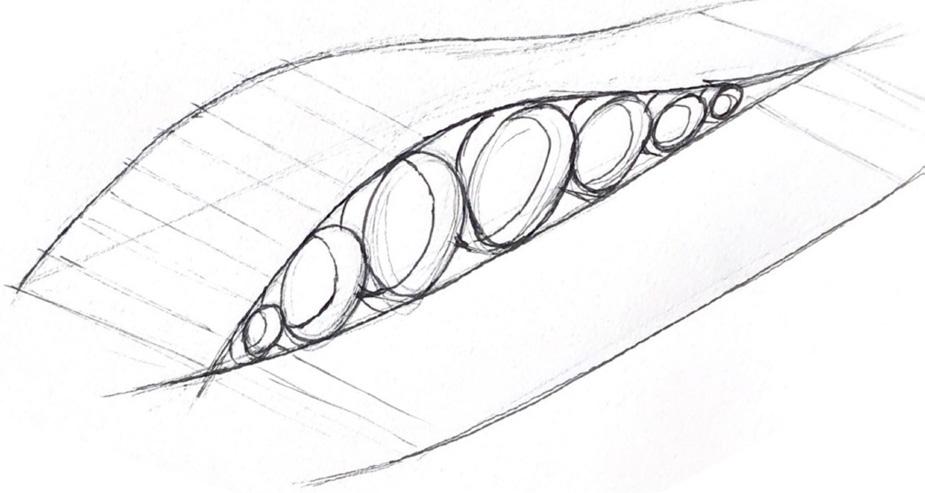

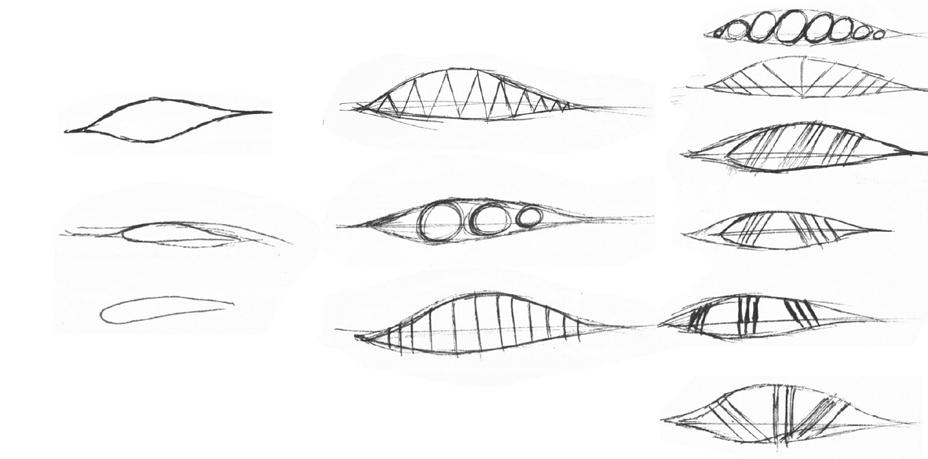

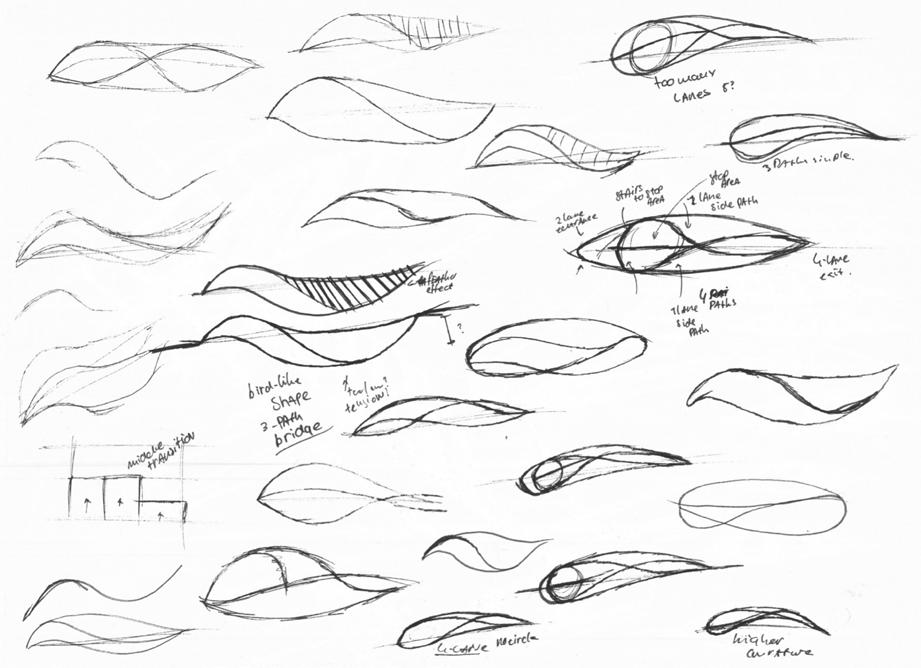

created a shift of focus from the material and processing side, to envisioning an application which would allow for a creative and novel use of the material and provide a strong message about the value and functional use of the material. From an initial ideation session, a bridge structure was determined the best fit, as this allowed for ample design and shaping freedom, whilst portraying the properties of thematerial. Through a form exploration, the initial form of the bridge is created as shown in (Fig.4).

To create a strong link back to the origin of the material, and highlight its unique nature, the shape and form of the bridge were related to themes from the aerospace industry. The chosen design style for the bridge is characterized by sleek, streamlined lines reminiscent of the aerospace industry's aerodynamic shapes. It aims to capture an exclusive and futuristic aesthetic, with minimal decorative elements to maintain focus on the bridge's message and efficiency. The shape and form of the bridge are characterized by streamlined and sleek lines inspired by the airfoil of an aircraft. The design envisions pedestrians becoming part of the airflow, with two paths along and below the airfoil shape, emphasizing asymmetry and creating a sense of direction.

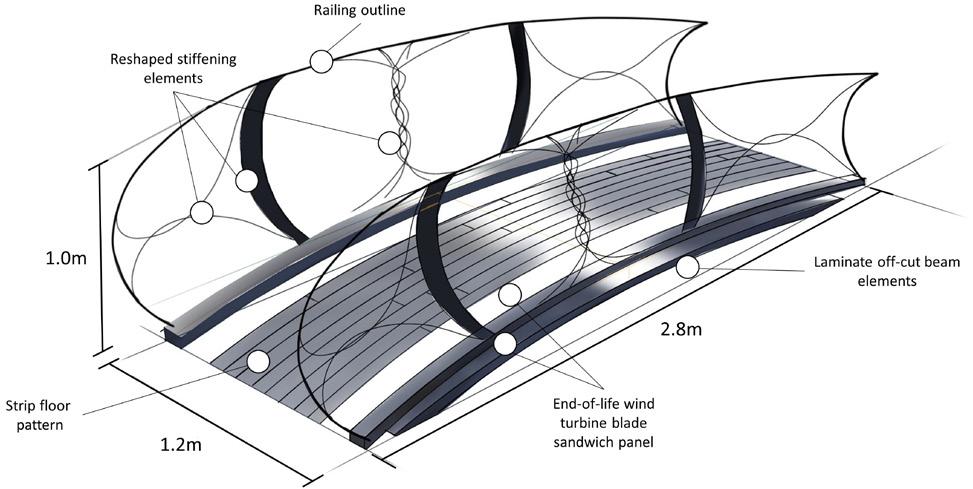

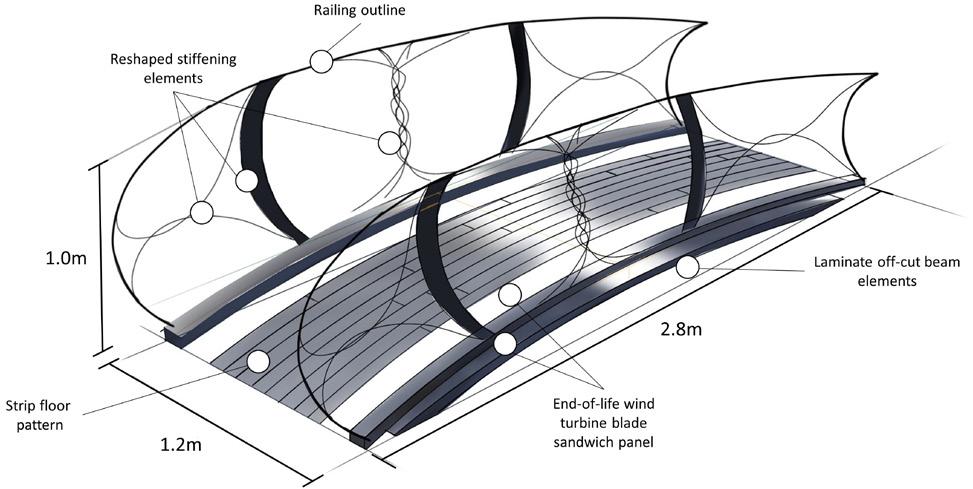

For the materialization, the bridge is divided into two parts: the deck and the railing. For the deck, endof-life wind turbine blade (WTB) sandwich panels in combination with beams made from laminate off-cuts are used, which not only enhance its functionality by providing a curved lightweight and stiff panel, but also add value to the message of the design. By repurposing these materials, the design extends the theme of re-using end-of-life composite material beyond the initial scope

31 Graduate

Fig. 3: Edges exhibiting defect © Sam Lonis

of the aerospace industry at the beginning of the project, demonstrating the synergy of combining composite waste streams from different sources.

The railing, serving as both a support and visual element, features an asymmetric, sleek, and streamlined form with minimal decorative elements, stiffened by vertical balusters and horizontal elements. Despite material defects, shaping methods such as single bend forming, coil forming, twisting, and in-plane bending are employed to create functional and aesthetic elements, demonstrating the versatility of the material. The final concept of the bridge is shown in (Fig.5).

Prototyping manufacturing

The prototype building started with a set of replica sections of end-of-life wind turbine blade material, which was cut to match the dimensions of the bridge design. This resulted in four sections, one for each end and two in the middle of the bridge, which were set in place temporarily whilst the beams made from stacked laminate off-cuts were prepared. (Fig.6).

The initial idea was to use an adhesive to manufacture the beams, but due to time constraints simple fasteners were used. Using glue clamps, the beams made from the laminate off-cuts were attached to the deck sections, through which holes for the fasteners were drilled. Using

32 85 | Waste streams

Fig. 4: Form exploration © Sam Lonis

Fig. 5: Visual of final concept © Sam Lonis

a carriage bolt in combination with a nut and fastener at the bottom of the deck, the beams were secured to the deck sections. (Fig.7)

To showcase the use of the bridge, a mannequin was introduced in the middle of the bridge. For the attachment of this mannequin a threaded insert was used in the glass fibre sandwich panel, which held the mannequin upright

for the duration of the exhibition. (Fig.8). The railing was made by shaping the laminate off-cuts using simple MDF tooling and a heat-gun. The laminate off-cuts were heated locally until the glossy shine of the material disappeared, after which these were formed using the MDF tooling. For additional stiffness a cross member was introduced in the railing, and each section was again attached using a carriage bolt. (Fig.9 and Fig.10).

33 Graduate

Fig. 6: Preparation of stacked laminate off-cuts © Sam Lonis

Fig.7: Picture showing beams secured to dark sections © Sam Lonis

Fig.8: Picture showing threaded insert to support mannequin © Sam Lonis

Dutch design week exhibition

The bridge design was a part of the Dutch Design Week 2023 exhibition: Designing with composite waste material. Together with two other graduation projects, the goal was to present the opportunities in designing with composite waste material. This included an overview of the design process, small prototypes from processing experiments, shown in (Fig.11), and three designs that demonstrate the value of composite waste material in new applications (Fig.12). The exhibition was very well received, attracting over eight thousand people over 9 days, and hopefully contributed to furthering the more sustainable design using composite materials.

34 85 | Waste streams

Fig.9: Picture showing additional reinforcements © Sam Lonis

Fig.10: Picture showing the final prototype © Sam Lonis

Fig.11: Picture from Dutch design week © Sam Lonis

Fig.12: Picture from Dutch design week © Sam Lonis

Sam is a Design Engineer at PAL-V in the Netherlands, discovered his passion for composite materials while gaining experience at Delft Aerospace Rocket Engineering (DARE) in 2016.

As a composite teaching assistant at the D:Dreamhall, he contributed to various student projects, sparking his interest in designing and manufacturing composite products further. Sam pursued a unique path by completing Individual Double Degrees in Aerospace Engineering and Industrial Design Engineering, culminating in a combined thesis project. His passion lies in the intersection of design and manufacturing with composite materials.

35 Graduate

Sam Lonis

ROTOR / ROTOR DC

Urban Mine Inc.

Emmanuel Cortés Garcia and Arne Vande Capelle

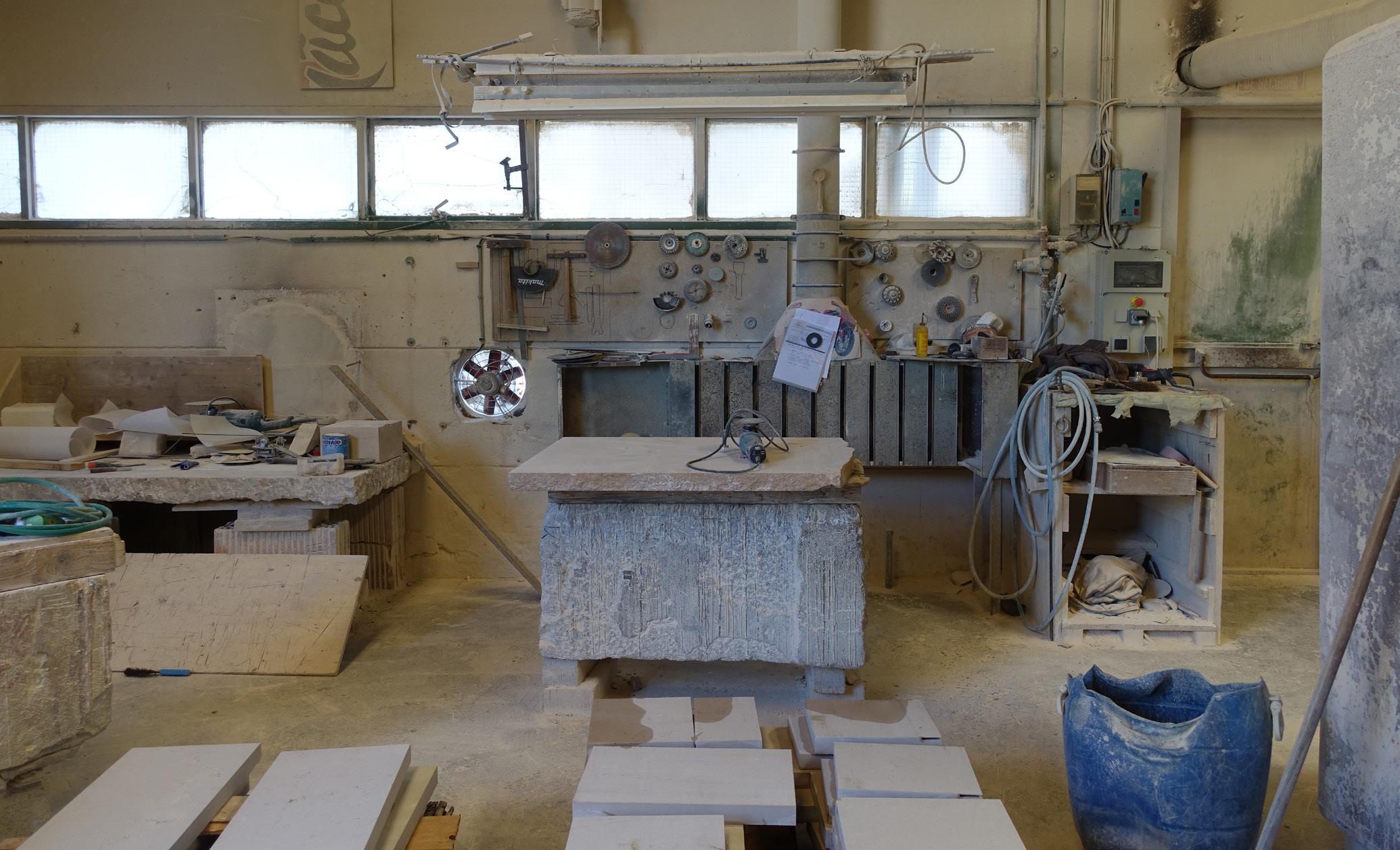

In its purest, conceptual sense the circular economy promises an endless cycle of reusable resources. With regard to the construction industry, the concept often revolves around the central metaphor of the urban mine, which understands the city as an accumulation of valuable materials and reusable elements. Through our work at Rotor and Rotor DC, we are continuously engaging with multiple actors on many levels within the reuse sector. The following text aims to demystify the urban mine metaphor by looking at a set of concrete situations, and by describing the framework wherein reuse is currently practiced, since both main elements of the somewhat romanticized term – the urban and the mine – need a more nuanced understanding in order to offer a clear understanding on circularity.

QR3: Rotor website QR2: Rotor DC website QR1: Opalis website

Fig. 1: Everheide © Rotor DC

1. A short history of reuse in construction

First and foremost, the characteristics of an urban mine differ significantly from mines in the more conventional understanding of the term. Contrary to geological raw material supplies, which can be found concentrated by type within confined areas, the urban mine is by default heterogeneous and so far unpredictable, consisting of a wide variety of different materials in small quantities at any given location. Specific types of building elements are often dispersed and, in many cases, ownership varies between various kinds of private actors, making the exploitation of an urban mine very different from the exploitation of a geological mine. [1]

This is not a small difference. In fact, the current economic context highly favors regular mining with big investments resulting in even bigger returns. Urban mining on the other hand inevitably consists of a large number of small investments with uncertain returns. The responsible factors for the current situation become obvious when comparing two symbolic moments in the history of demolition: The demolition of the Palais de Tuileries in Paris in 1882 and the demolition of the Gillender Building in New York in 1910 – separated by only 28 years. [1,2]

During the grand urban renewal operations in Paris coordinated by Baron Haussmann at the time of Napoleon III., a lively reuse scene was thriving in the city. By order of Haussmann himself, reclaimed materials from demolitions had to be sold at public auctions. Archived reports still attest to the fact that these elements found their way to a whole series of small enterprises and craftsmen who directly benefited from the cheap resource. At the same time, deconstruction companies were able to profit from

the sale of reclaimed materials. They even bid against each other for the right to deconstruct buildings.

Achille Picart was probably the most notable and active deconstructor and reseller of reclaimed materials in Paris at the time. In 1882 he received the commission to deconstruct the ruins of the Palais des Tuileries in the heart of the city, one of the largest remaining symbols of the monarchy. The contract specified a demolition time of just six months, a fact that deterred most of Picart’s competitors from participating in the tender and thus awarded him the contract at very low cost. As a deconstruction specialist, he was able to conclude the immense task in the relatively short time frame by mobilizing and coordinating enough manpower to effectively disperse the reclaimed stones in a continuous flux across his entire network of customers.

In 1910, Jacob Volk, another important actor in the history of the demolition became famous for the demolition of the Gillender Building in New York City. With a height of 83 meters, it was not only the tallest building ever razed, but Volk also succeeded to do so within an astonishing time limit of 45 days. The building was only 12 years old, fully functional and equipped with the latest technologies. However, in a growing city it had to make place for a bigger and more advanced building. The demolition marked one of the first modern encounters with the concept of obsolescence, [3] and as shown below, the beginning of the decline of reuse as a common practice in construction.

The construction industry naturally is part of the accelerating and globalizing economy. During the 20th century, deconstruction practices gradually dwindled

38 85 | Waste streams

due to aspects such as the rising real estate pressure, which turned to be demolished buildings quickly into expensive worksites: On the one hand, ever-rising land prices and rental income made profits from reclaimed material resale negligible compared to profits from realestate operations. On the other hand, forced by delay penalties and speed bonuses for demolition contractors, deconstruction or demolition contracts needed to be fulfilled at an increasing speed. This in turn then resulted in growing insurance costs due to an increasing number of demolition related accidents, while a significant rise in worker’s wages occurred around the same time. Put together, these influences drastically shortened the amount of time a worker could spend economically on reclaiming and cleaning a material, before the operation turned into a financial loss. Adding aspects such as workforce mechanization, and the continuing diversification of building materials to the equation, it becomes obvious why organizing profitable salvage operations became extremely difficult and unpopular.

A New York Times article from 1928 illustrates how quickly the shift to a decline of reuse took place. It describes how new bricks still hot from the ovens were being delivered to building sites. The ovens were operating at full capacity to keep up with the sudden rise in material demand. Brick manufacturers were completely surprised by suddenly having to take over the market segment, which until then was occupied by reclamation dealers. [1]

2. Challenges of reuse in today’s construction industry

Almost overnight, the economic framework which had rendered the reuse of building elements feasible had disappeared. The building industry started evolving, and continues to do so today, shaped by forces prompting ever- increasing levels of consumption. New materials, freshly mined, cut and/or manufactured started to be introduced into construction processes in ever growing quantities year after year, which ultimately caused the construction world to lose touch completely with the specificities of reclaimed materials.

The desire to introduce new elements to the market quicker and in bigger volumes has supported the development of new legal frameworks, leading to a highly codified and bureaucratic construction sector. The process is based on clearly defined tasks for different actors, with formalized documents to mediate between them. Instructions from the architect considering a project and its use of materials are formulated into tendering documents, defining a series of legally binding obligations to which the contractor subscribes by accepting the job. There are good reasons for this divide between architect and contractor such as identification of liabilities and

39 Company

Fig. 2: Wallstra © Opalis

transparency of construction costs, however the mode of building production that is the result of it often neglects the way in which reclaimed materials are managed. A professional brick dealer does have a continuous supply of bricks, however, that doesn’t mean that every kind of brick is always available. Neither will he be able to provide proof of origin of the clay of which the bricks were made, or the exact test results about their pressure strength at the time of making. He will however be able to provide for exactly the right type of brick needed for the purpose of a specific project, but this kind of organic process where material identification influences the design and vice versa is very difficult to organise and requires a lot of effort for the different parties involved.

This results in the following revealing statistic: Only an estimated 1% of all materials implemented in new constructions today are reclaimed resources. [4] And they are distributed within a few types of construction where reuse is still common, such as industrial warehouses, landscaping and certain types of private housing. In big construction projects, reuse is a practice long lost.

3. Successful reuse in today's construction industry

The described historic developments did not make the practice of reuse disappear completely, but reduced it to increasingly smaller proportions. Those businesses that are still operational did so by means of specialization. Either they identified different types of reclaimed materials that are still able to compete price-wise with their equivalents from virgin resources, or they focused on materials that generated an added value beyond purely economic aspects, such as cultural or historic sentiment. Within its practice, Rotor has focused largely

on such businesses and has been documenting them on its website Opalis.eu since 2011. These businesses prove that reuse is not only a great hope for the future, but that there are feasible business models being executed in the present already with a wide range of reclaimed materials to work with.

Even though the dealers had to undergo a gradual process of specialization, the variety of dealers and materials remains remarkably high. One may find contractors who started stocking roof tiles from their demolition sites in the yard behind their office; resellers of very high-quality timber floors, with an impeccably maintained showroom; and dealers featuring cavern- like stocks filled with beautiful antiques and marble chimneys. Rotor has met with small, one-person businesses, having started, for example, as the owner’s personal hobby for antique floor tiles. Other dealers jumped on a market opportunity and started selling doors out of a warehouse on an industrial zone and yet others are family businesses that exist

40 85 | Waste streams

Fig. 3: Gebroeders Sleeuwenhoek © Opalis

for generations and operate enormous outdoor stocks ranging up to 30.000m2, filled with 15-meter tall piles of cobblestones or bricks.

These companies have a long track record and ample experience. Throughout the years they have established a strong network of specialized suppliers, and know exactly

how to deconstruct and clean a specific element with ease and minimal loss while maintaining material quality. A brick dealer can estimate before beginning a job, the amount of bricks which will be lost during deconstruction, how many during the cleaning, and for what purposes they can be used afterwards. Often the building elements sold by these dealers are provided with a lot of necessary information to assess their “fitness-for-reuse.”

Paradoxically, the most circular actors in the field of construction today are the ones that are advertising it the least. After decades of finding ways to survive, their marketing focus instead lies on the unique aesthetic of their material’s patina and the history behind its acquisition. They advertise the superior quality of their reclaimed product as opposed to a new one, or the fact that it is cheaper. Or they focus their energy on small scale private projects that still offer some space for a reciprocal

relationship between material and design. The ecological benefits of using reclaimed elements has little commercial viability in the construction industry (yet).

" By the 1970s most tiles had become so thin, and they were glued to the floor so strong that they couldn’t be salvaged anymore without breaking. Bricks were being placed using cement mortar instead of lime mortar, which is easier to work with during construction, but impossible to remove. "

At the same time, the manufacturing and installation of construction materials also evolved, under the influence of the same mechanisms that drastically reduced reuse practices. Both were becoming faster and cheaper. By the 1970s most tiles had become so thin, and they were glued to the floor so strong that they couldn’t be salvaged anymore without breaking. Bricks were being placed using cement mortar instead of lime mortar, which is easier to work with during construction, but impossible to remove. Additionally, production prices for these materials had become so low, that salvaging such products was and is simply not feasible. The construction sector wasn’t interested in reclaimed materials, and dealers weren’t interested in new construction materials anymore. Luckily, the first exceptions to this rule started to appear around the beginning of the 21th century. Heightened floor tiles,

41 Company

Fig. 4: LV Trading © Opalis

technical installations, ceiling lights and selected window types are among the elements produced from 1970s onwards that are currently available on the reuse market. Although not all of these market opportunities have been discovered yet, the general offer of reclamation dealers today reflects more or less what the sector is capable of doing within the limits of a competitive market-based economy. All things considered, it’s still a lot.

4. Locating reuse within the urban context

We don’t have to change our point of view much for an analysis of the urban element of the metaphor. Let’s return to 19th century Paris: Located at the 12th Arrondissement, not far from Place de la Nation, Achille Picart’s warehouse had a very strong presence in the city. His stock of salvaged stones, ironwork, and decorative elements was clearly visible from the street, and one could hear the sound of tools and see workers busy reconditioning items when passing by. After successfully deconstructing the

42 85 | Waste streams

Fig. 5: Maris © Opalis

Palais de Tuileries in under six months, Picart kept one of its pediments, known as "the one with the watch," and used it to decorate his warehouse façade. This heightened his presence in the city even more.

Similar scenes are hard to find nowadays. Because of the same rising land prices that prevent a lot of reuse in the first place, most reclamation dealers have left the inner cities. While some of them might still have a small showroom in the city center, warehouses are very rarely a part of the urban fabric. In Rotor’s experience, visiting a reclamation dealer equals getting into your car and driving to an anonymous industrial zone or a plot somewhere along a busy road in between two cities. On opalis.eu, Rotor has documented stacks of reclaimed windows located just in the open surrounded by fields. Sometimes the plot of a reclamation dealer presents itself through a mountain of cobblestones competing for sunlight with the surrounding trees, or through a set of tiles or architectural antiques displayed strategically at the end of their land, facing the road next to it. But in all these cases, they have become more a part of the Zwischenstadt and even the countryside, rather than the urban fabric. This does not mean that they are absent though. The urban mine would be nothing without their capacity to stock and prepare.

While this might seem arbitrary, the disconnection between city and dealer goes beyond this geographical disconnection. Although the extent of this phenomenon is difficult to assess, it is not uncommon for dealers in Belgium to sell reclaimed materials to customers in Australia, America, Russia, and other parts of the world. These clients are looking for authentic Belgian materials to furnish for example a Belgian-themed bar,

or to distinguish their terrace or kitchen interior from their neighbors’. Because global transport costs are rarely an issue for clients looking to add an “authentic” or “ecofriendly” label to their project, there is a clear separation between locally sourced materials and the now global market. Rotor DC often receives international shipping requests for elements, which used to cycle within a very small radius - a trend that increased spectacularly after the opening of the online shop in 2017. Via the world wide web, reclamation dealers are now part of a highly globalized world, in the same way manufacturers of new products are. Today, the pediment from the Palais de Tuileries would probably be promoted online, with the implicit possibility to be shipped all over the world.

And not only are locally sourced European materials sold around the world, materials sourced around the world are being sold in Europe, or more generally, in the West. Sometimes, these operations are nothing short of cynical, appropriating the mechanism of a globalised neoliberalism. In the 1990s, the New York Times published

43 Company

Fig. 6: Neerhof © Opalis

an article about a company active in the repurposing of wood reclaimed in Asia for the American market.

The demand for this type of “guilt-free” wood skyrocketed so quickly that it became a market force, encouraging the dismantling of existing Asian houses that were still being used, and greatly disrupting local economies. [5]

5. Scalability

The complexity of reuse raises interesting questions about the standards of the existing material economy. As described, reclaimed materials are often quite different from what today's construction industry is accustomed to. They demand a more reciprocal design process where materials and design influence each other, and where there is time to draw up project specific solutions, specific ways in assessing their fitness-for-reuse, and general room for flexibility. Reclaimed materials often reject in one way or another the easy scalability of their application. [6]

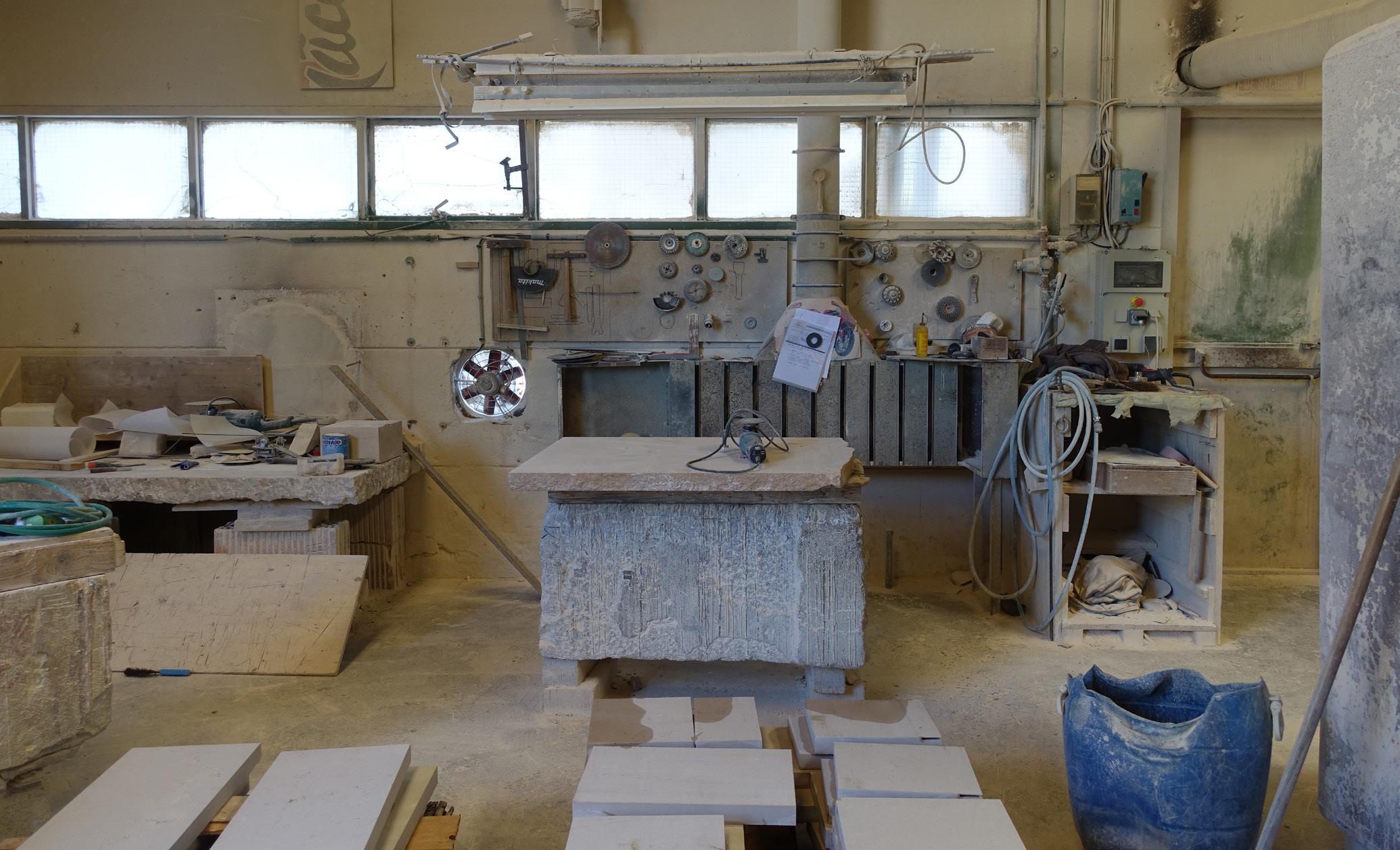

Similarly, the preparation of reclaimed materials remains a predominantly manual and variable task. Preparing them is, in many cases, quite different from working along a mid20th century industrial assembly line. The preparation of reclaimed materials, which is really the essence of what a reclamation dealer does, include the cleaning of bricks; preparing of parquet or wooden beams for reinstallation;

dismantling and cleaning of radiators; deconstructing different kinds of partition walls on the 20th story of an office building before transporting them down to a truck waiting on a busy street. As every building, and every batch of used materials is different, and often relatively small, the majority of tasks related to reuse requires a significant level of knowledge, autonomy, flexibility, and a good understanding of the tools and methods that are being used. [1]

" (...) the preparation of reclaimed materials remains a predominantly manual and variable task. Preparing them is, in many cases, quite different from working along a mid-20th century industrial assembly line."

Up until now, this meant that reuse was local work. For a majority of dealers, any preparation work is done inhouse or outsourced only on a very local scale. The logistics combined with material knowledge necessary to carry out all reclaim and reuse operations result in reclamation dealers being predominantly small to medium scale businesses, commonly family-owned and employing their third or fourth generation. Very few of them have scaledup beyond this level. Seen as a part of the complete

44 85 | Waste streams

Fig. 7: Europort © Opalis

material economy, this forms a remarkable alternative to our contemporary business culture.

6. Opportunities and the future of reuse

But we find ourselves at a tipping point. Similar to other economic fields, small to medium scale businesses are slowly disappearing. [7] Their owners have trouble finding successors. A considerable share of the reclamation dealers is currently run by people that already have surpassed their 50s. Some companies have started selling off certain parts of their stock after years of decline, and others simply stop existing, without new traders to replace them. Interestingly however, in parallel to this decline of companies in the reuse sector, interest in circularity and reclaimed materials is significantly increasing at the moment. But the significant rise in demand of reclaimed materials that would be needed to revive the sector is not seeping through.

This prompts the question: what kind of circular economy is it that is currently being promoted, and is it the circular economy that we should want?

Because what makes reuse interesting for Rotor is exactly what makes it difficult in the current construction world. We could approach circularity as a way to rediscover alternative practices and narratives. First by acknowledging the current qualities of the existing reuse market, such as for example local and unalienated labour in small scale companies, often organised around the needs of the workers. These qualities are key in working towards a truly sustainable future on more than only a metabolistic level. Rather than shaping reuse solely for the

needs of the contemporary construction world, rethinking these needs to the particularities of working with reuse is an equally important part of the equation. If we succeed in doing so, there certainly are unexplored opportunities waiting to be attained: different types of materials could be salvaged and/or cleaned more efficiently, new categories of contemporary materials that are currently still being overlooked could be reclaimed, missing links between contractors and dealers could be restored, and reversible ways of installing materials might again be applied.

In the midst of the endlessly multiplying realities of our current world, regarding closely and attentively might be the guidance we need to form new, maybe counterintuitive alliances and reintroduce some of the logic of Achille Picart in Jacob Volk’s construction world. What that will look like we have no idea, but we hope it will be radically different than the Urban Mine Inc

45 Company

Fig. 8: reclaimed heater © Opalis

This article has been written within the framework of and funded by the Interreg NWE FCRBE project. At the time of writing, the authors, Emmanuel Cortés Garcia and Arne Vande Capelle, were respectively employed by Rotor DC and Rotor. The text appeared first in German in: Heisel, F., & Hebel, D. (Red.). (2021). Urban Mining und kreislaufgerechtes Bauen: Die Stadt als Rohstofflager. Fraunhofer IRB Verlag.

46 85 | Waste streams

Fig. 9: Lapierre Rofani © Opalis

Bibliography

[1] Ghyoot, Michaël; Devlieger Lionel; Billiet Lionel; Warnier, André: Déconstruction et réemploi: Comment faire circuler les éléments de construction. Lausanne: Presses Polytechniques et Universitaires Romandes, 2018

[2] Byles, Jeff: Rubble: Unearthing the History of Demolition. 1st ed. New York: Harmony Books, 2005

[3] Abramson, Daniel M: Obsolescence: An Architectural History. Chicago; London: The University of Chicago Press, 2016

[4] Salvo: BigREc Survey. A Survey of the UK Reclamation and Salvage trade. 2007; This research has been conducted for the UK and Ireland only, but there are no reasons to believe that the situation is different on continental Europe.

[5] Rotor; DogA; Dansk arkitekturcenter, eds: Behind the Green Door: A Critical Look at Sustainable Architecture through 600 Objects. Oslo, Norway: Oslo Architecture Triennale, 2014

[6] The concept of the ‘non- scalable’ is derived from: Tsing, Anna L.: The mushroom at the end of the world: On the possibility of life in capitalist ruins. Princeton NJ: Princeton University Press, 2015.

[7] Tourdjman, Alain; Le Dret, Thomas: La cession –transmission des entreprises en France. Les Carnets de BPCE L'Observatoire, 2019; The article does not specifically target the reuse sector, but the findings of the authors align well with our experience.

Rotor has been founded in 2005 by Maarten Gielen, Tristan Boniver and Lionel Devlieger. It is a cooperative design practice that investigates the organisation of the material environment. They develop critical positions through research and design. Besides projects in architecture and interior design, they also produce exhibitions, books, economic models and policy proposals. In 2016, they launched the spin-off project Rotor DC, a place to buy salvaged building components.

47 Company

Rotor

RE3 GLASS Glass up-casting

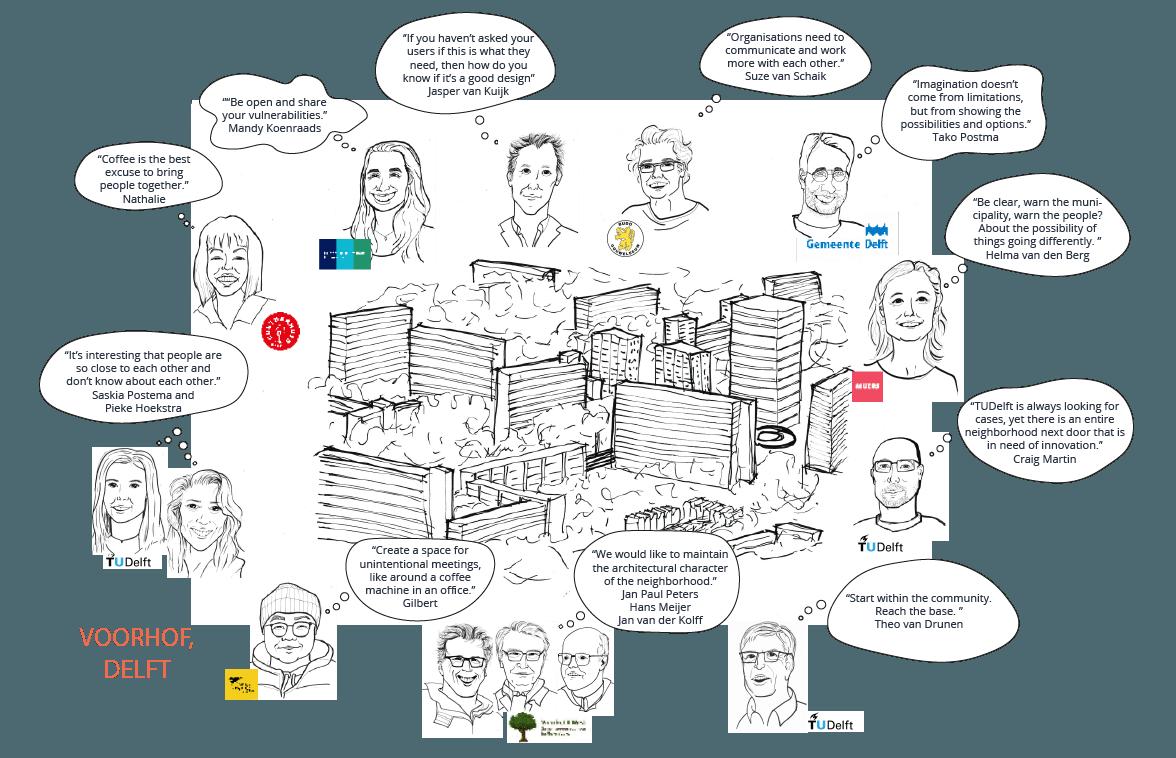

Dr. Faidra Oikonomopoulou and Dr. Telesilla Bristogianni from ReStruct group at TU Delft in conversation with Pavan Kumar Satyamurthy from RuMoer

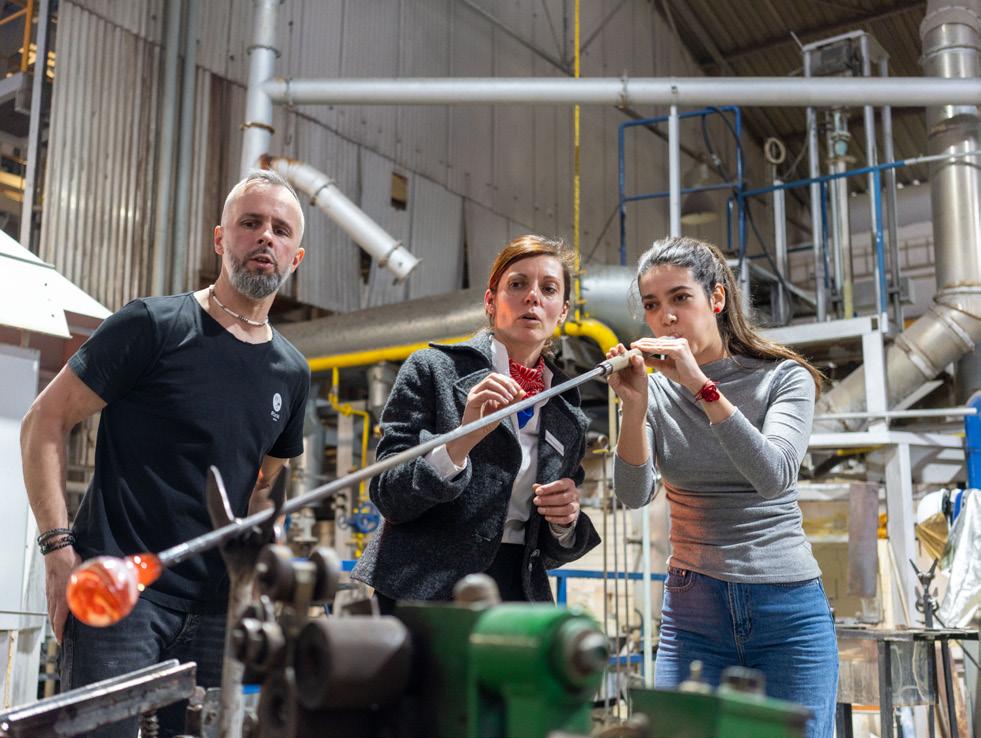

RuMoer: Your work in the past few years on the topic of recycling and the ideas of volumetric casting has clearly revealed the aesthetic and structural potential of the product for construction and other industries. Where did the inspiration for this come from?

Faidra: The inspiration with the recycling of glass via casting? So, we started doing research on Cast Glass via the Crystal houses project in Amsterdam, where we dealt with soda lime glass. And while we were on site supervising its construction, we thought that the cast glass blocks truly make for a beautiful façade. But what happens at its end of life? The connections were glued and irreversible. And you cannot recycle this glass conventionally because of its contaminants. So,

QR1: ReStruct webpage

Fig. 1: Glass interlocking systems © ReStruct group, TU Delft

can we do something to make it more circular? And together we came up with this idea of a dry assembly system. And furthermore, can we make these glass bricks out of waste?

Telesilla: And when we got funding or further exploration, we went to the Southern Illinois University to work with Prof, Jiyong Lee. Coincidentally, it was Halloween, and they were blowing a lot of glass pumpkins, and we saw an opportunity there! With the glass waste, which we hammered down and started our first trials, we started experimenting with various casting temperatures, making marbles. We were soon picking up glass from antique stores, glass waste from the other departments at TU Delft- television screens, CRT’s (Cathode Ray Tubes) and what not! We were mainly driven by curiosity at this point, but we were growing aware of how little of these forms of glass waste are being recycled. It seemed like there was unexplored potential here.

RuMoer: So what are the different kinds of glass waste streams that you have explored?

Faidra: Too many to list! Architectural glass, of course, with coatings with no coatings, laminated windscreens, phone screens, old television screens, crystalware, Broken traffic light glass from around the campus, Pyrex, oven doors, microwave glass, to name a few. It’s almost easier to name what glass we haven’t tried to melt!

RuMoer: The ingenuity of your work seems to lie, in part with the departure from the paradigm of glass as a sheet or panel, (which dominates a lot of the industries like the construction industry) and moving towards volumetric

components where the castings are bulkier. So, can you maybe elaborate on this and what the advantages could be?

Faidra: Several reasons! There are structural, aesthetic, manufacturing and practical reasons.

Structural reason- the volumetric blocks resist loads better than flat sheet of glass. Glass in theory is exceptionally strong in compression. However, mechanically loaded glass always fails in tension. This has to do with flaws on its surface, where stresses accumulate. Material failure begins at these points. With typical sheets of glass, the high surface area means that there are a lot of surface level flaws that make the glass vulnerable. Further, these thin sheets are of course more vulnerable to buckling under loads due to their own slenderness.

Conversely, when you have a volumetric component, the flaws are dispersed in the bulk. And our research, particularly Telesilla’s PhD work, shows that these flaws are far less likely to trigger material failure.

Telesilla: So one thing is indeed the structural argument. There are also the aesthetic argument. Right now the industry is focused on making perfect, transparent glass with absolutely no distortion. And we must question this. A lot of glass is now being rejected because it has a slight tint, slight colour in there, but it's often really good quality glass without contamination. We must ask- Can we make attractive products that embrace the imperfections of glass- the bubbles, the colouration? It is also possible to cast with ‘contaminated’,‘compromised’ glass,and achieve very interesting mechanical, but also aesthetic results.

50 85 | Waste streams

Faidra: The third argument relates to manufacturing. Casting is a more flexible and versatile process that the float glass one. It lets us experiment with many ‘recipes’.

The float glass process is literally continuous- a 24/7 process where we float an uninterrupted ribbon of glass. It is very expensive to interrupt the float line, and we cannot change batch properties (E.g: Color) without incurring a lot of waste and expense. Casting, on the other hand, is more comfortable. You can take any glass and melt it. You

have freedom to scale up or down your process, and try different glass recipes and temperatures, as each casting is essentially ‘discrete’. It’s like how, if you have the ingredients, you can make many kinds and sizes of pizza with the same oven!

Telesilla: And then there is the practical reason. Some industries have very high standards with glass products. You can imagine- a vaccine bottle after use, is categorized as hospital waste, and will never be recycled into a new

51 Interview

Fig. 2: Casting contaminated glass sources © Faidra Oikonomopoulou, Telesilla Bristogianni

vaccine bottle. It’s the same with phone screens and so on- they do not get recycled into the same products, so there is a need to find a new way to use this waste. To transform them into architectural, interior or even engineering products, is a solution.

RuMoer: How do you envision these volumetric products to feature in these industries? Do you see potential to use beyond the building industry?

Faidra: At the moment we have mainly tried applications for the building industry, but we think there is potential to use it in many different industries. We could have chemically and thermally resistant tableware, for example. Or load bearing furniture.

Telesilla: We have been contacted by an expensive automotive company to use recycled glass for some of their interiors. There is also the idea of making a foam out of some glass, which could be used in prosthetic applications! I think there are several ideas to explore. The more the merrier!

RuMoer: This cast glass technology is a great idea in that it almost sequesters or glass waste, but energy goes into recycling. From the performance versus cost/energy point of view, what are your remarks? How does it compare with other building materials?

Telesilla: We still need to solve the economics. Right now, like with many recyclable materials, the recycling of glass is still expensive and takes effort, and we need to advance both the science and the legislation to make this pathway more attractive. This is absolutely necessary.

Can you imagine for the next upcoming 30 years, another material than glass, that can have the same performance in our buildings? That has all these propertiestransparence, strength, weather resistance, chemical inertness... We may have to accept the fact that large volumes of glass are something we need for various industries in the coming future. So the question is about

52 85 | Waste streams

Fig. 3: Crystal house Amsterdam © MVRDV

Fig. 4: Closer view of the Crystal house © ReStruct group

making glass products in a responsible way. Does it all really have to be make the way it is? And creating so much waste that is landfilled? We need to maximise how much of the glass we use is made from recycling, and improve the way we recycle. This requires advance in science and policy.

RuMoer: This cast glass technology is a great idea in that it almost sequesters or glass waste, but energy goes into recycling. From the performance versus cost/energy point

of view, what are your remarks? How does it compare with other building materials?

Faidra: This has to do with a very practical aspect of things. It is necessary to nudge industries to recycle more. The Netherlands has some of the strictest policies for glass waste, for example. We have the highest percentage of float glass recycling, which is very good. We hope that with our current 4-year project funded by the Dutch Research Council (NWO), we will be able to further inform policy. There are limits to how much glass waste can go

53 Interview

Fig. 5: Mirage at Apple park © Iwan Baan, Archdaily

into landfills, with penalties for exceeding. Glass that can be safely recycled is not allowed for landfilling.

There could also be better management at industry level. A big logistical challenge is that glass suppliers often cannot take back their own glass due to the mixing of glass from various sources. Recycling this glass could compromise the glass as the nature of this cullet is not fully traced or known. There could be systems developed to improve trackability of glass waste, perhaps a QR code or something! Some way for industries to identify their glass so they don’t have throw away a theoretically very recyclable material because of a practical uncertainty.

Telesilla: and there is the matter of market perception of the product. A lot more recycled glass can be used if we are more tolerant to colours and other material variability, and begin to question some of our aesthetic and perceptual preconceptions.

Faidra: The Mirage project was an interesting step it this direction. It was a collaboration with Zeller and Moye where we made an art sculpture for Apple at their Cupertino headquarters. For this we cast several 1.8m tall glass pillars using 70 different desert sands from around the world. These pillars have a lot of different colours, bubbles and inconsistencies, and this was appreciated by Apple, who even with their rigorous design ethic and aesthetic, embraced this nature of glass.

RuMoer: What is next for you both? What are you researching in the domain of glass, as well as waste streams?

Telesilla: Several things! We want to dive even more into the fundamentals of glass flaws, and how we can engineer them- for example, a glass product that has different properties on its surface and its core. We want to research on the 3D mechanical testing of glass. But in addition to glass we are also researching plastic waste and how to engineer products from plastic wastes.

It is also important for us to research the applications of the technologies and products we are developing, so we have tangible actionable solutions for the industry for the next few years.

54 85 | Waste streams

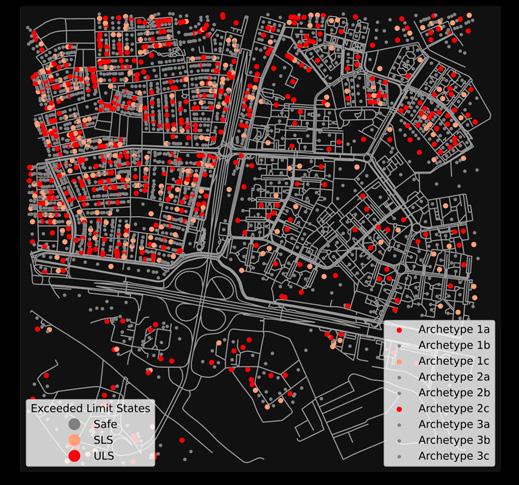

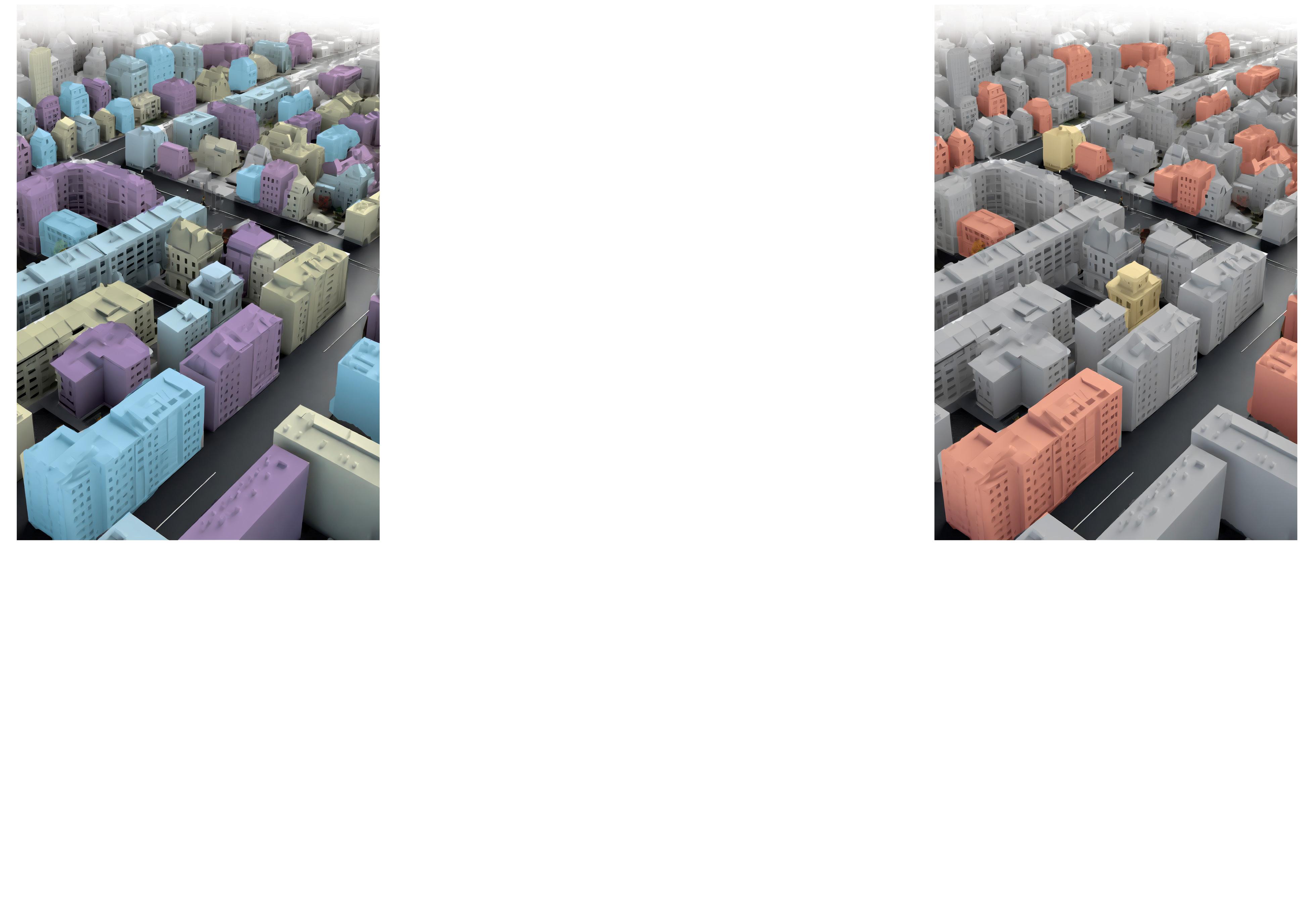

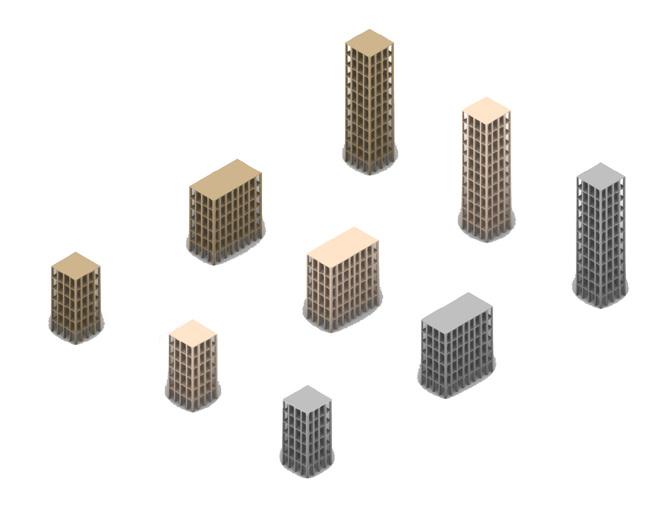

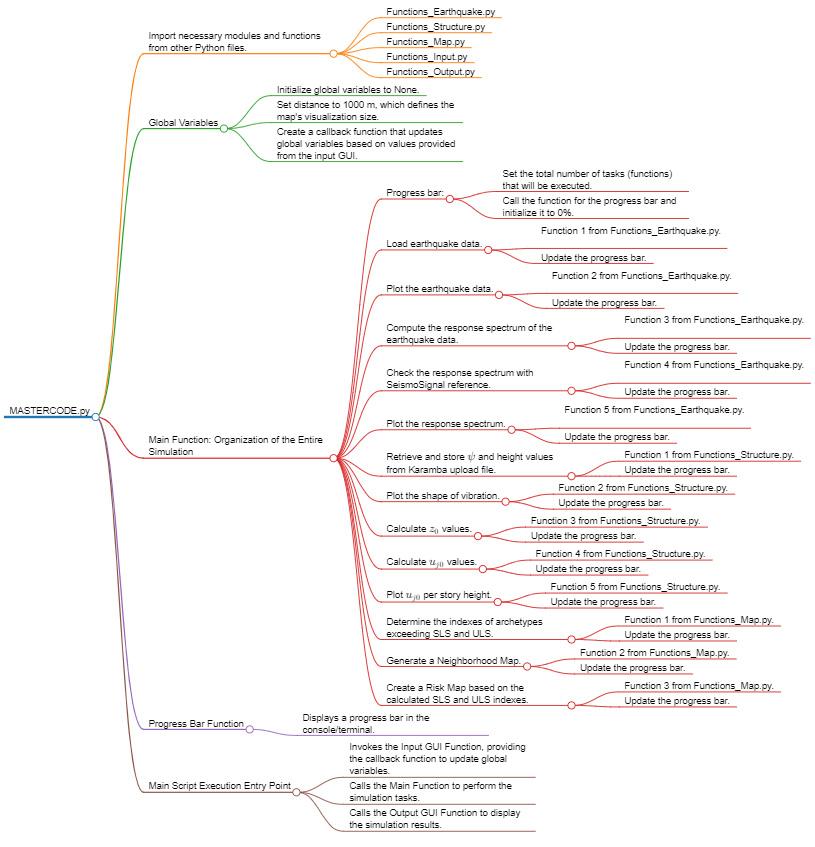

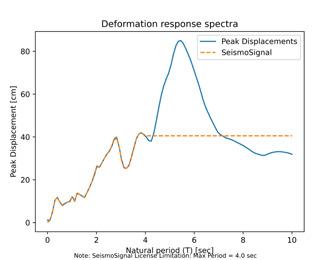

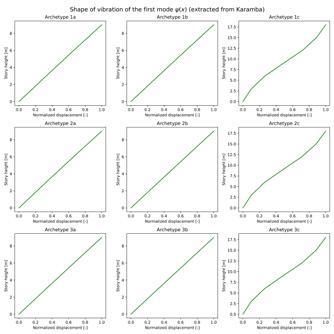

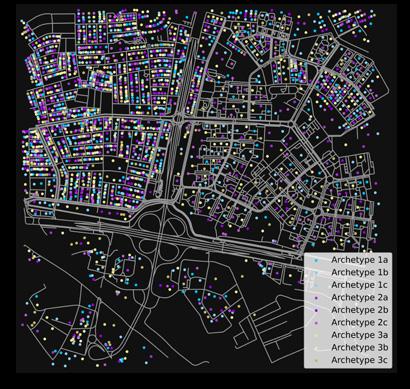

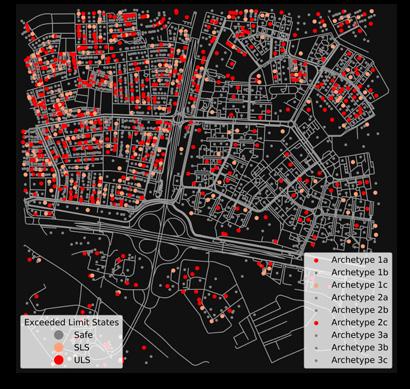

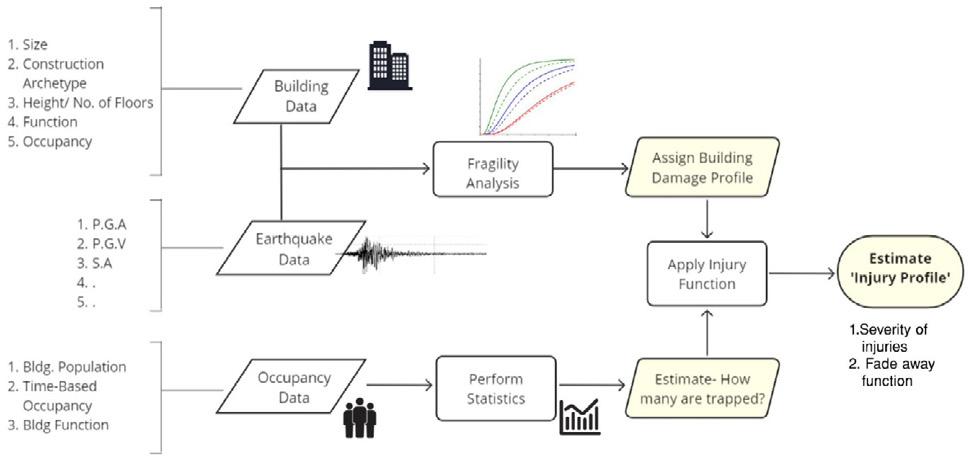

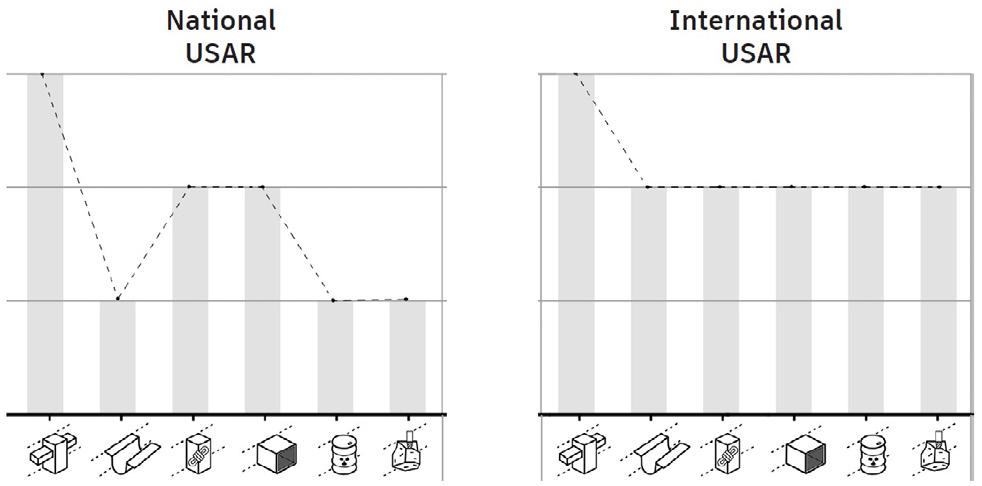

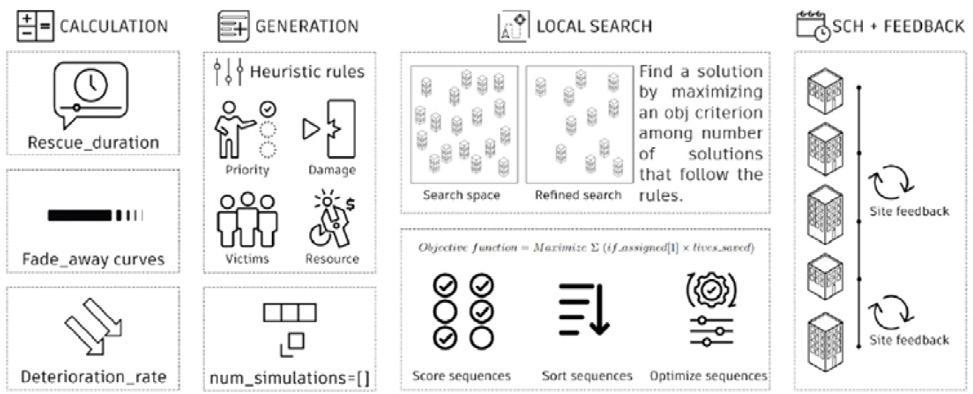

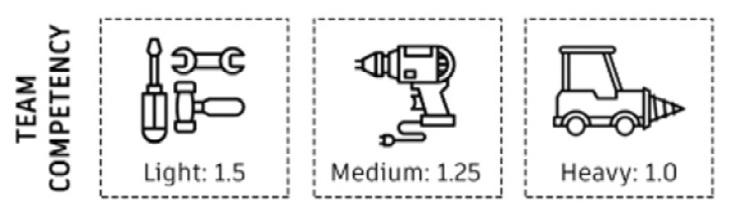

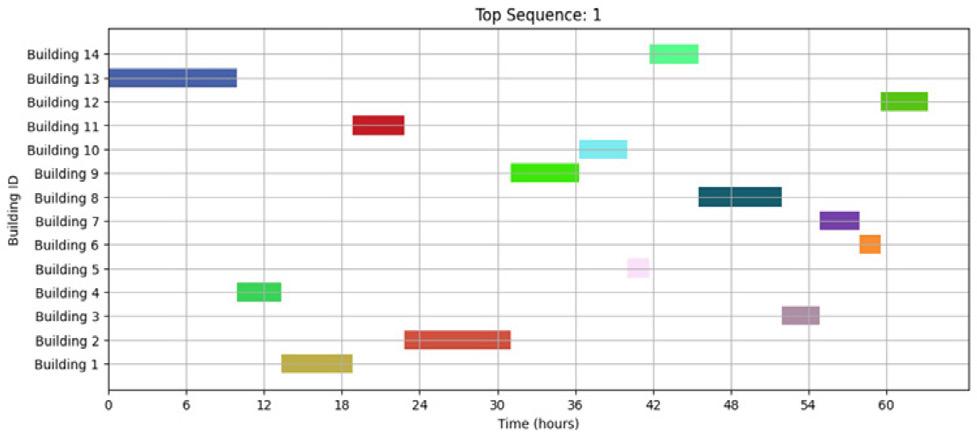

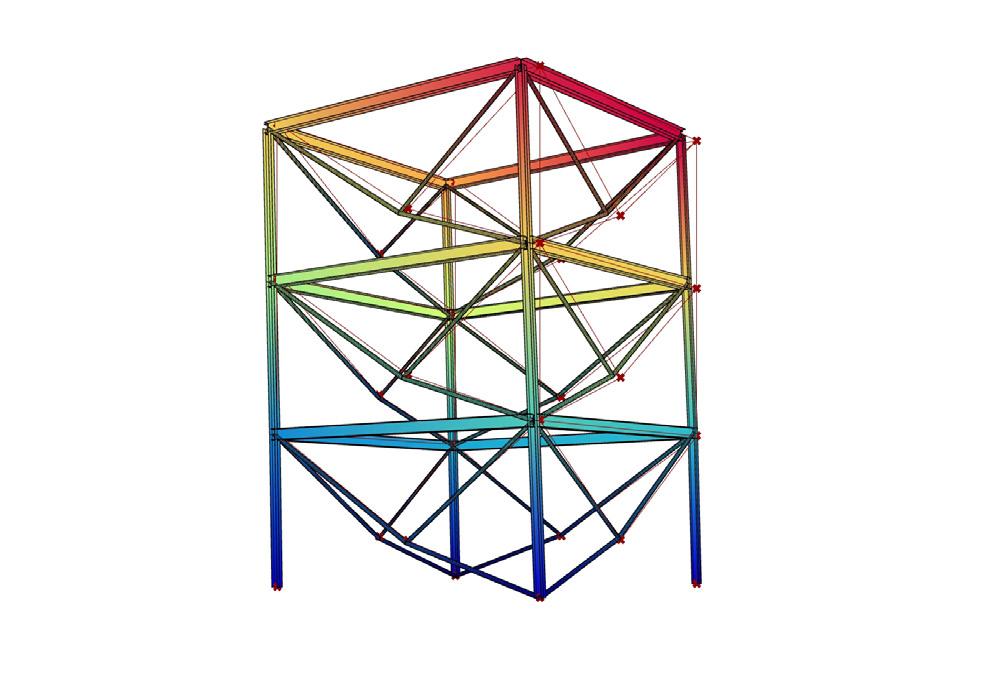

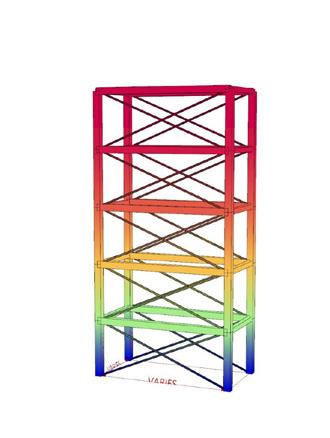

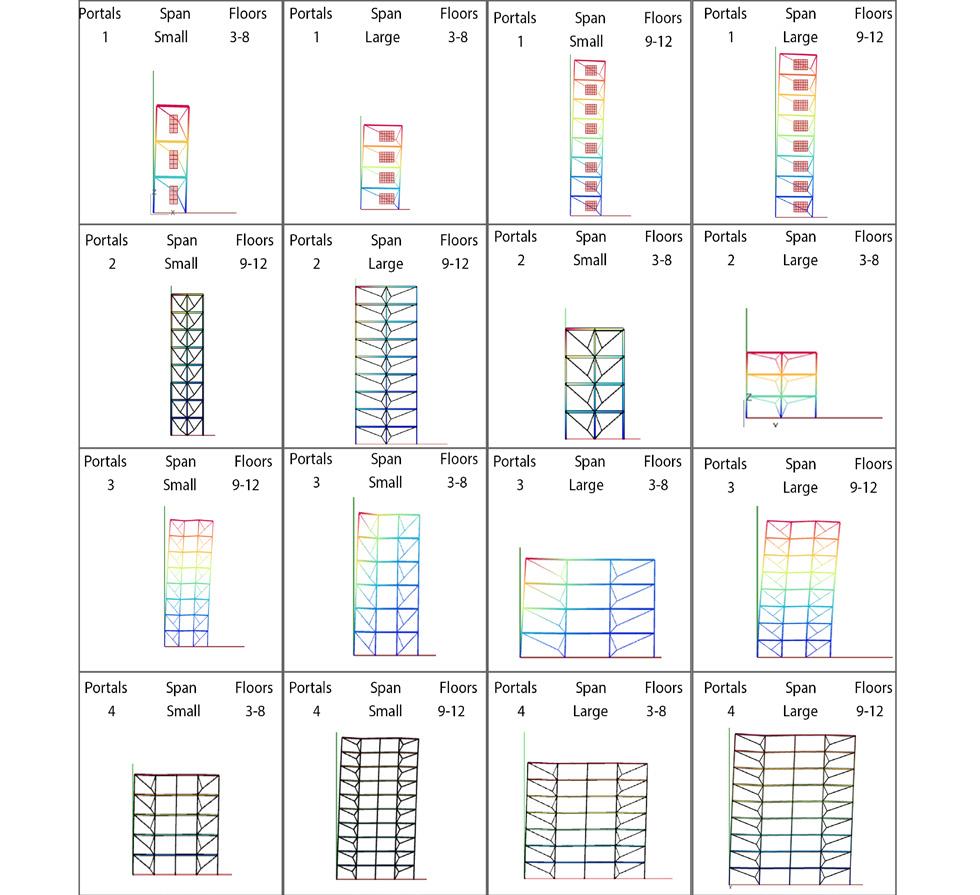

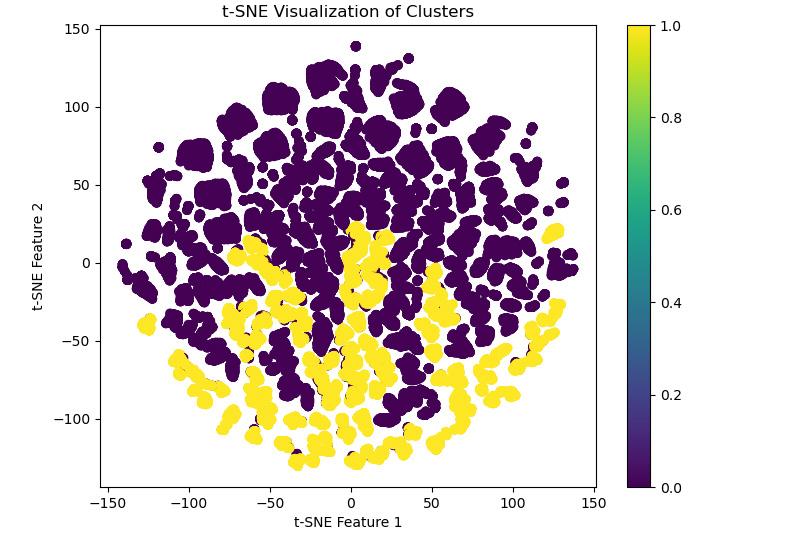

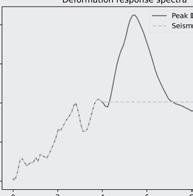

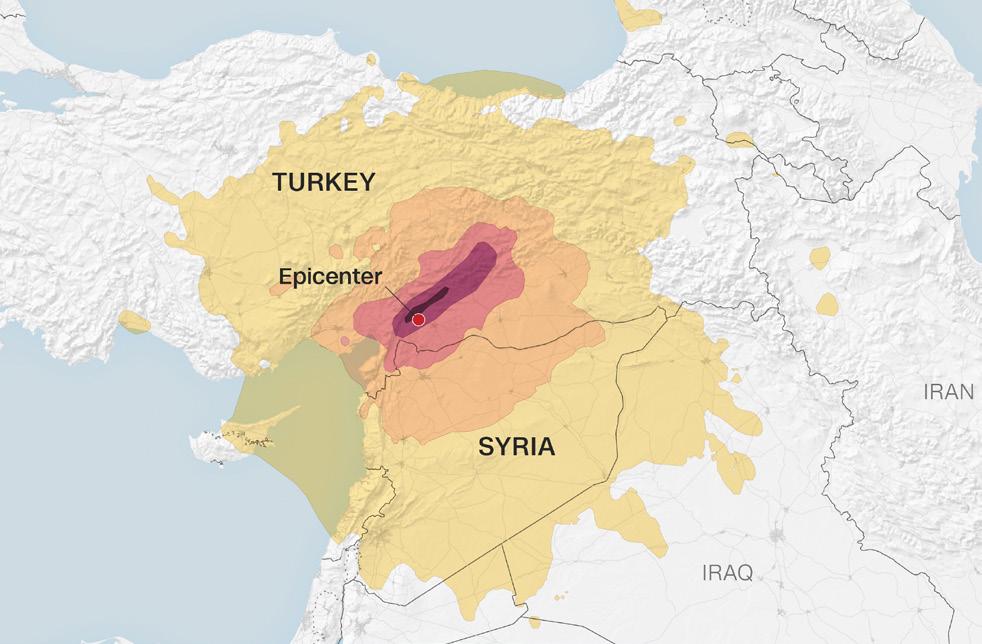

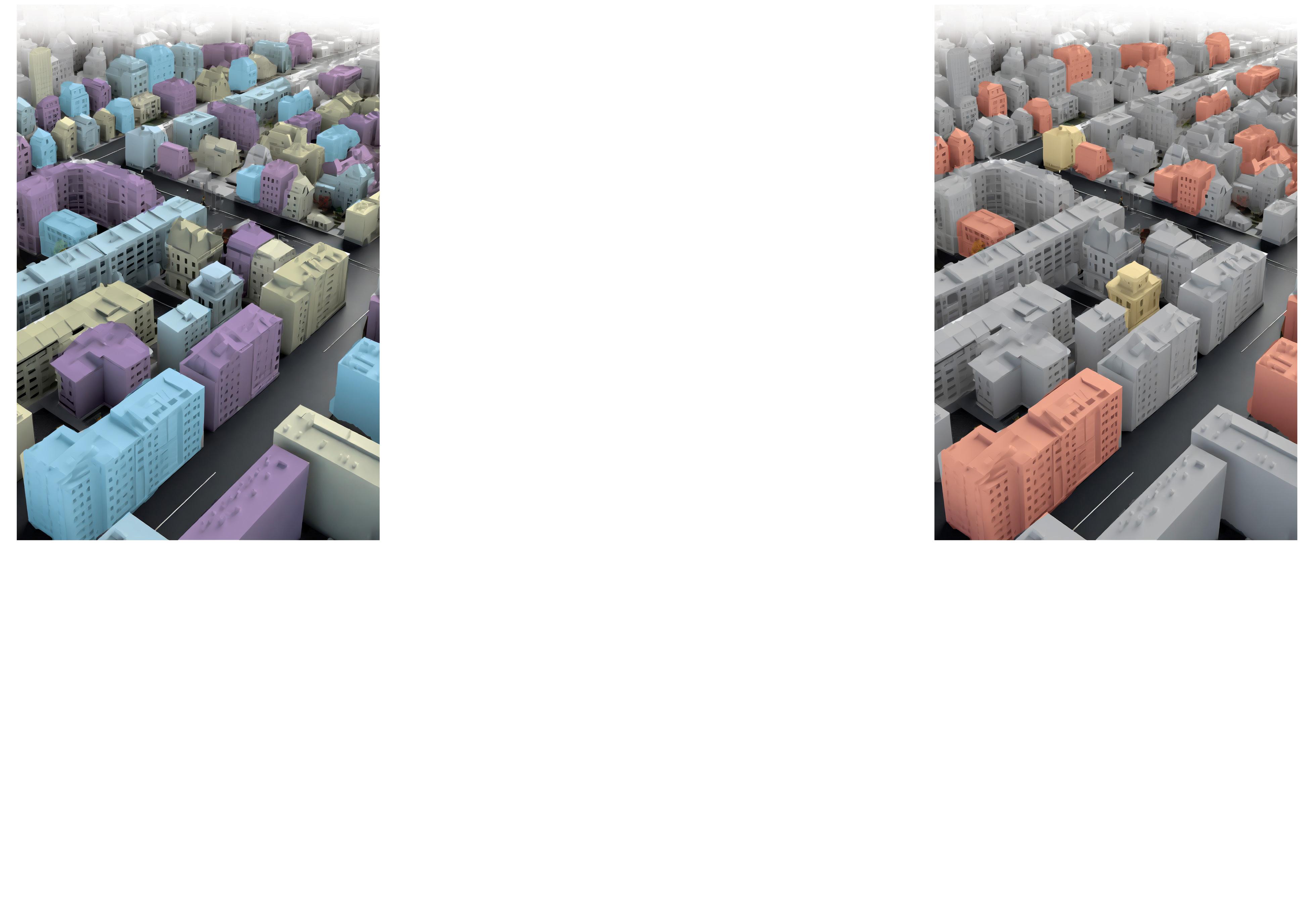

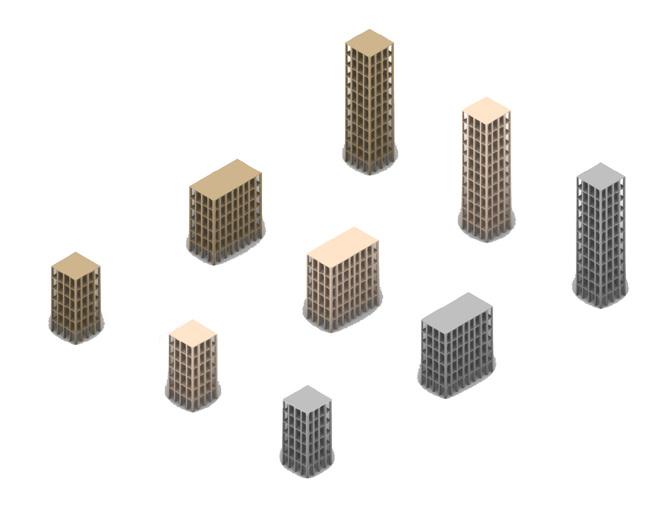

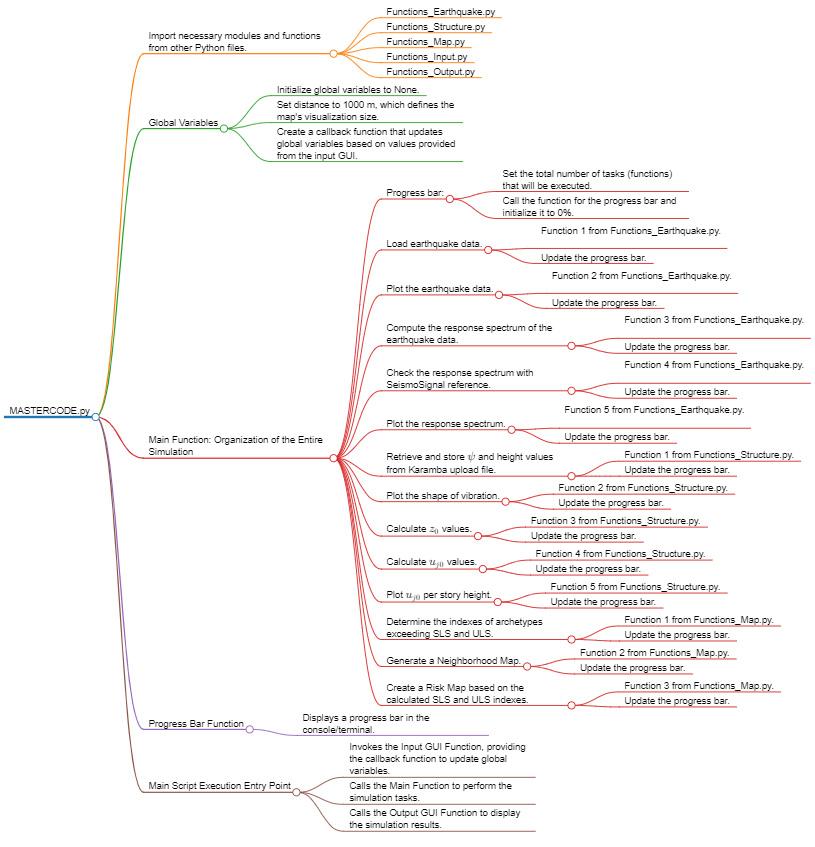

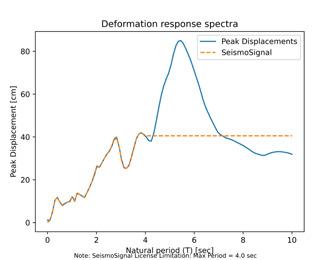

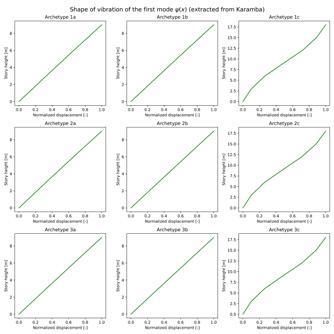

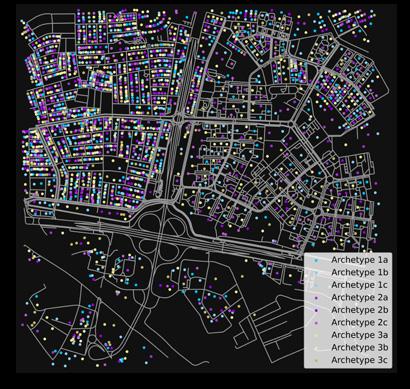

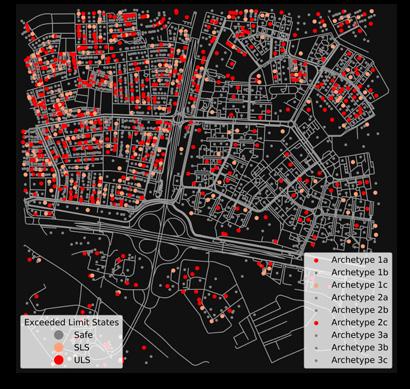

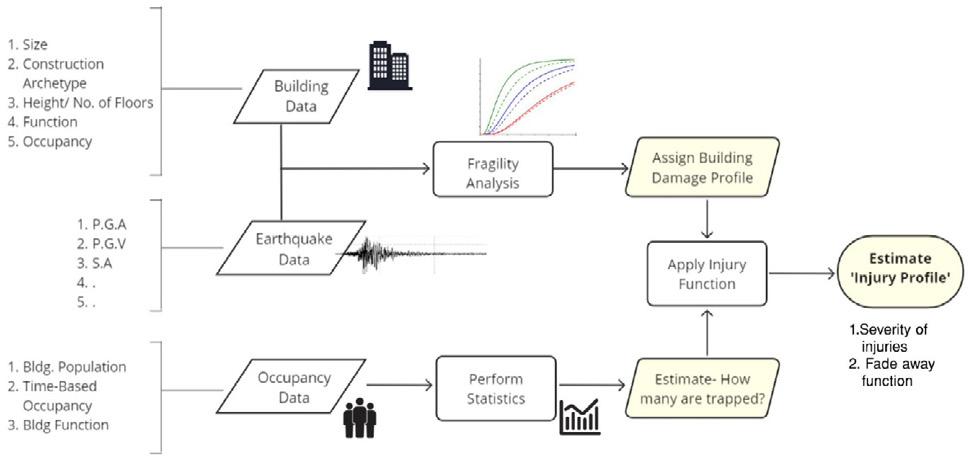

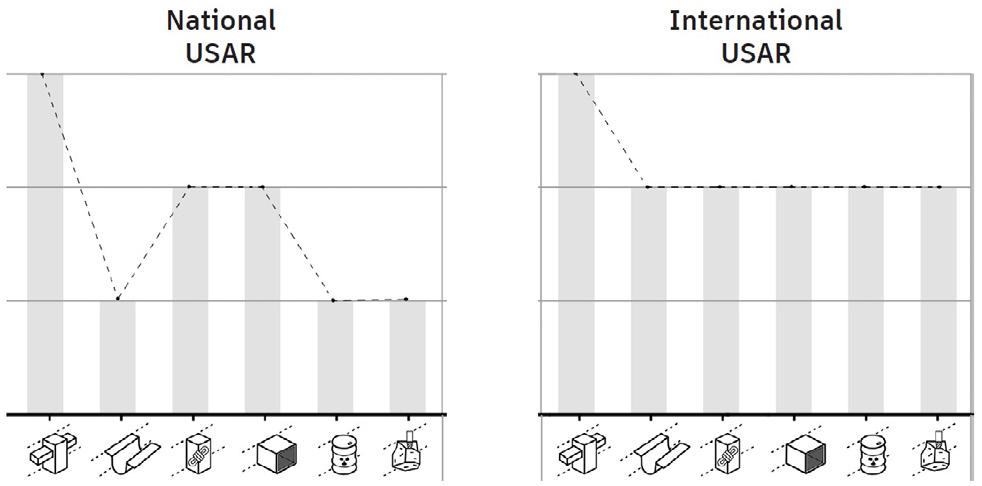

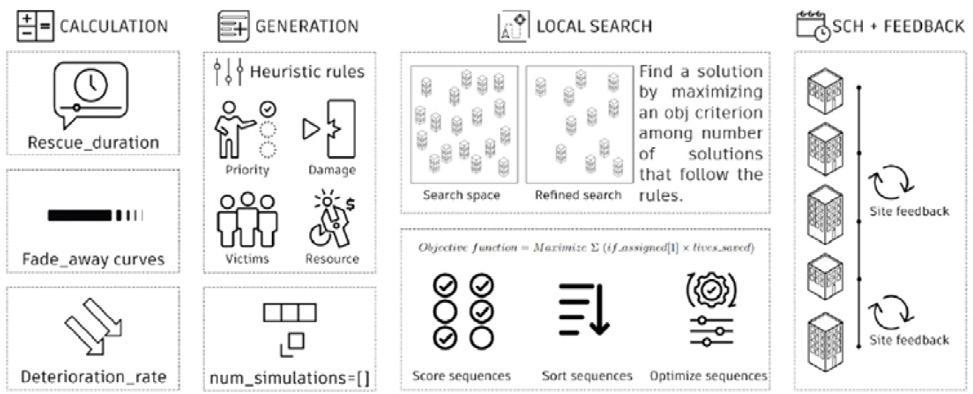

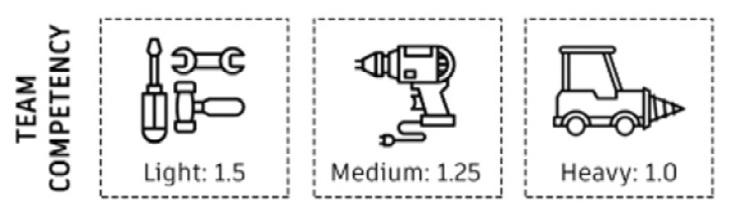

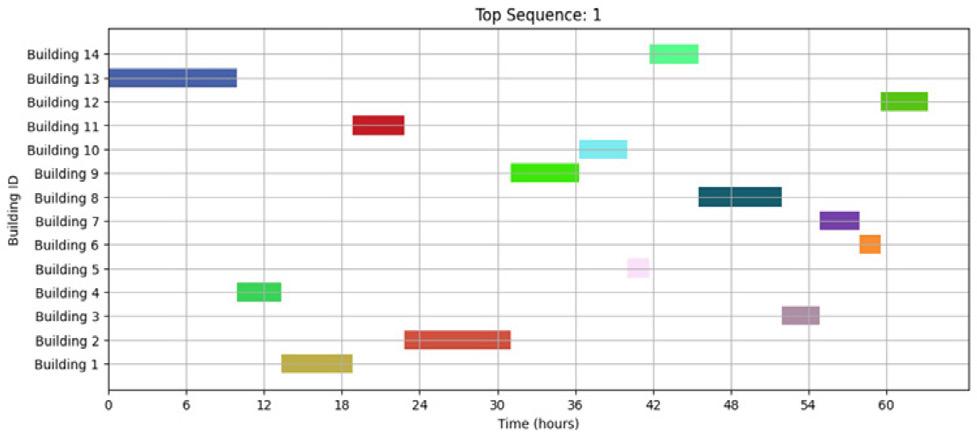

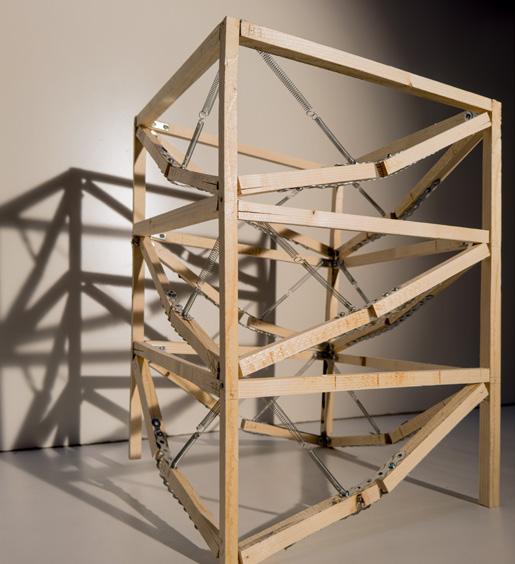

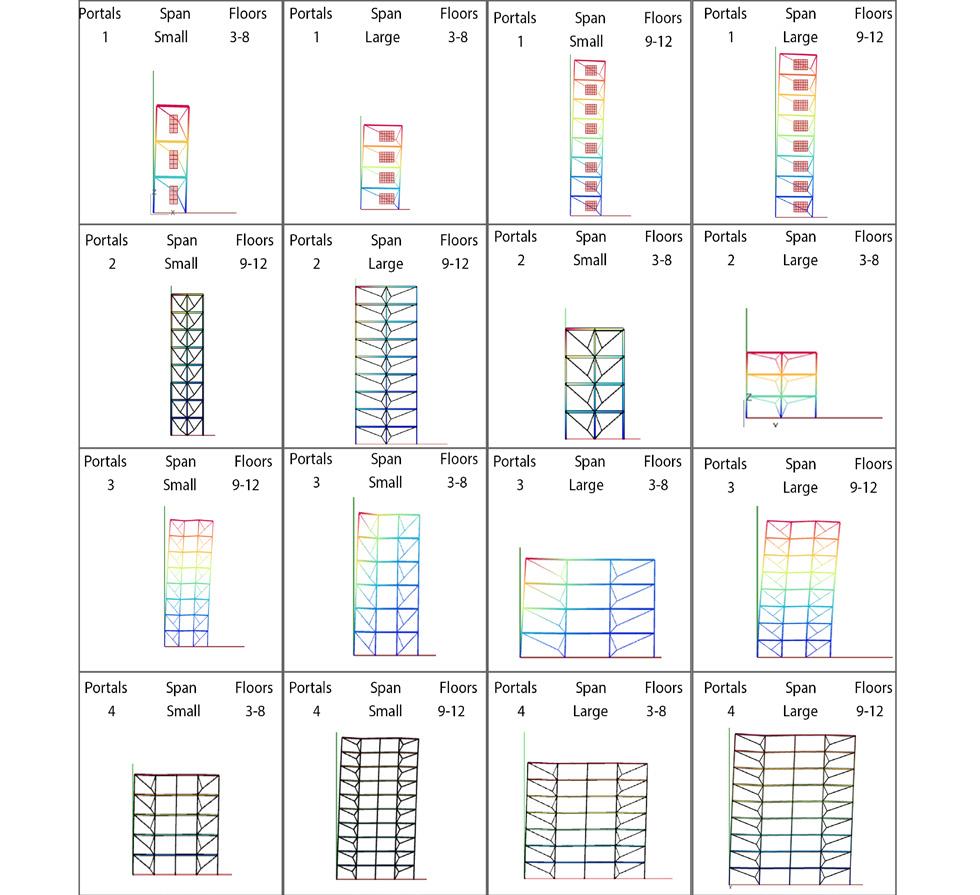

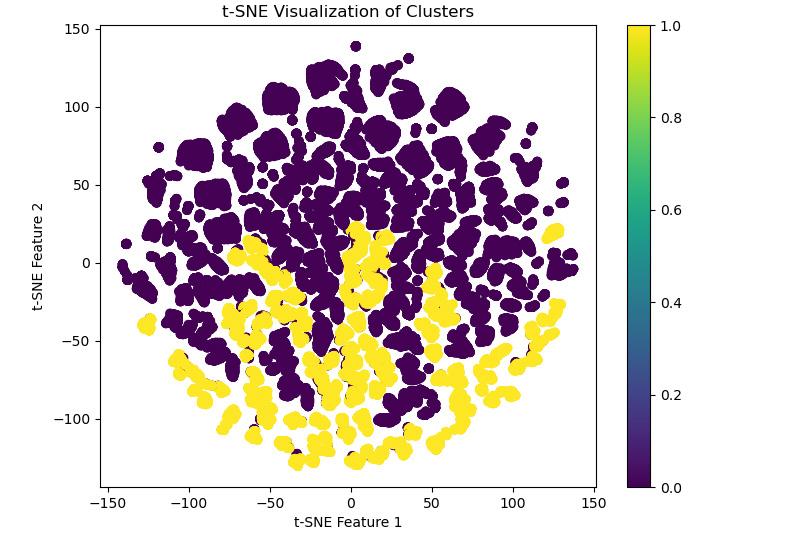

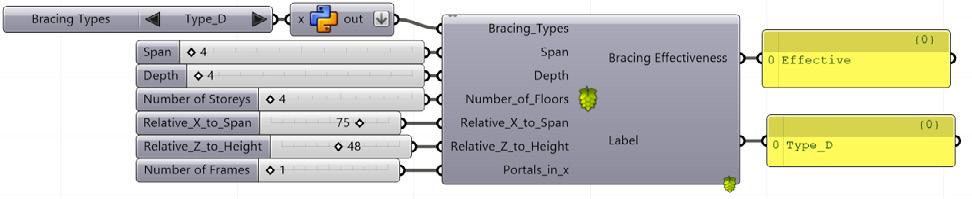

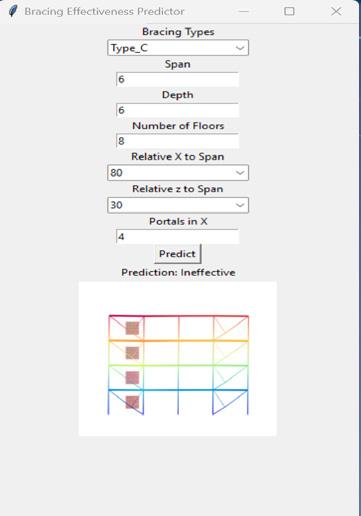

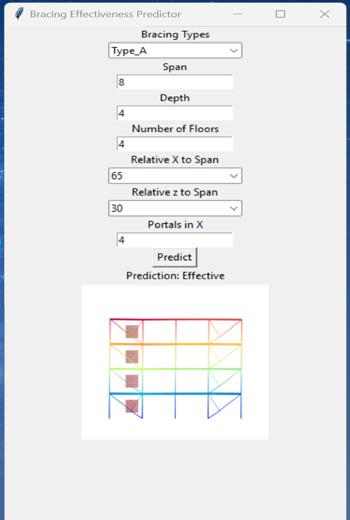

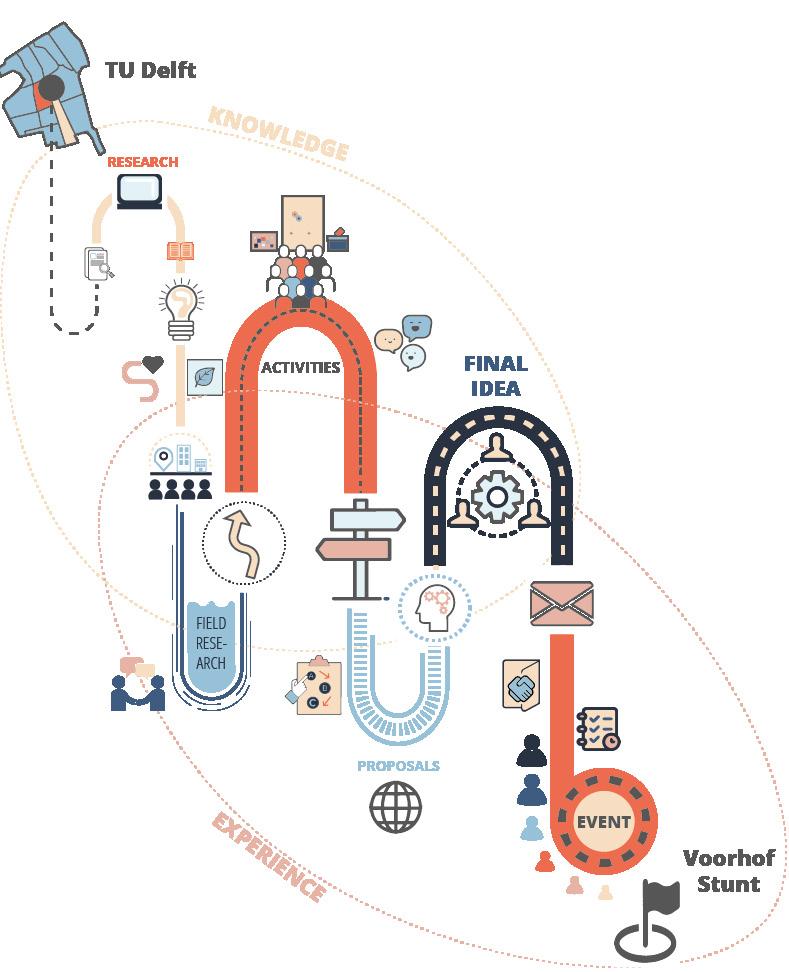

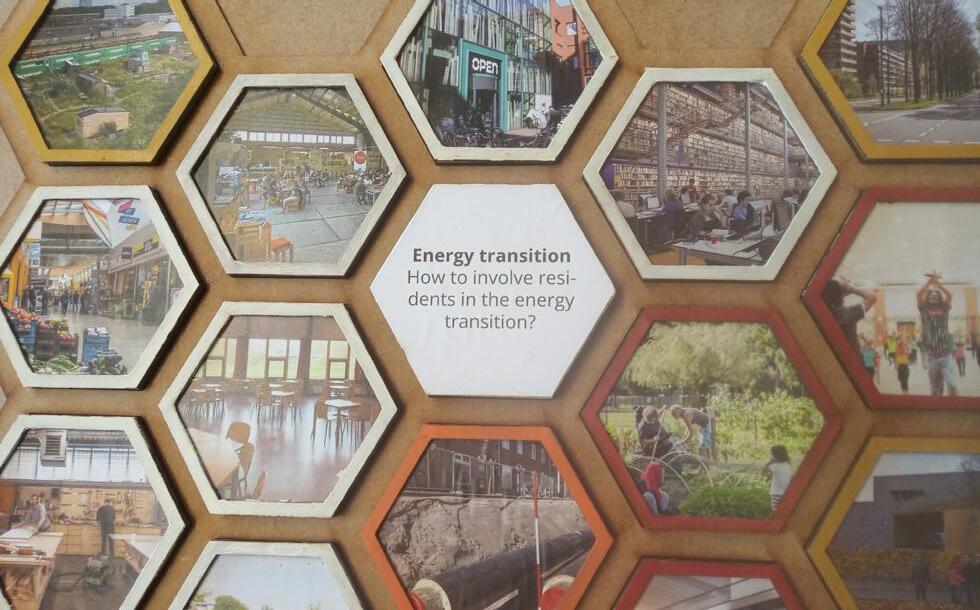

Faidra is Assistant Professor at the Structural Design & Mechanics Group in the Faculty of Architecture at TU Delft. Her research focuses on structural glass and particularly on innovative structural applications of cast glass components and on the design of full-glass load-bearing structures and components.Faidra holds two MSc degrees, in Architectural Engineering by the National Technical University of Athens (NTUA) and in Building Technology by TU Delft. She completed her PhD at TU Delft on the topic of “Unveiling the Third Dimension of Glass. Solid Cast Glass Components and Assemblies for Structural Applications”.