Half Studio

How to densify a climate resilience community

pg 4 -15

SuperWood Computational Design and Robotic Fabrication

pg 16 - 27

Quantifying Quality

Rethink Sydney CBD through Evolutionary Algorithm

pg 28 - 33

AAVS Kobe 2023

Re-imagining and Constructing a Japanese Pagoda 04

pg 34 - 41

Design with Dignity

Social Housing in Bomaderry

pg 42 - 45

Half Studio

How to Densify a Climate Resilience Community

Under current the Paris Agreement, we need to limit the temperature increase to 1.5ºC, by reducing greenhouse gas emission. Meanwhile, Australia are experiencing one of the worst housing crisis in the history with low supply of housing. As construction industry is one of the biggest carbon contributor, these 2 conflicting problems pose a series of questions for the future architects and all stakeholder: How can we provide more housing? How to build more efficiently? And more importantly, how to build more climate resilient housing to adapt to the future?

This project is located at Doonside, NSW, Australia, one of the most heat-prone area in the Greater Sydney. The goal of the project is to provide more housing, with the least carbon emissions.

The design process of the new housing started by investigating the material system. After researching multiple material system, Wikihouse Skylark system is found to suit the purpose as the main material system for the proposal housing, due to its modular design and low carbon material. Due to its ease to fabricate and construct without the need of special tools or skills, existing residents are able to involve in the construction process, creating more job opportunities and lowering the cost of construction. The involvement of the construction process not only build more housing, it also builds the local community at the same time.

This studio explores multi-disciplinary approach to our built environment, from material selection to urban design.

Project Data

Location | Doonside, NSW Studio Leader | Lucy Humphrey

1.

2. Keeping Existing Fences within the New Lot Boundary

4. Densifying with Modular Housing

Macro Scale Intervention

By rethinking and challenging the colonial land subdivision method, more space can be used for housing and biodiversity. Re-establishing biodiversity within housing block is crucial as it provide natural shading, passive cooling and biophilia to the resident or user.

Existing House

3BR Family House

Community Shoptop House

Shared Path for Pedestrian and Bicycle

High Trafficable Area

Low Trafficable Area

Private Outdoor Space

Shared Green Space

Shared Green Space with biodiversity

By strategically inserting new housing and opening up underutilised backyard as a shared backyard, the urban fabric become more dense in terms of number of occupants and biodiversity.

1. WikiHouse Skylark Modules

2. Vapour Barrier

3. Stud

4. External cladding with recycled timber paling shingles

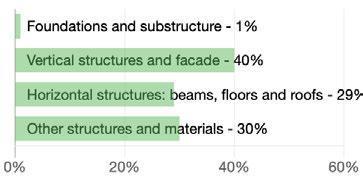

Lifecycle Assessment of New 3-bedroom Row Houses*

Wikihouse Skylark Roof Module

With 19mm Plywood

Metal Flashing

LVL Beam

50 x 150mm

Plasterboard

Loose Hemp Insulation

Vapour Barrier

Gutter

2x4 Stud Trim

Wikihouse Skylark Wall Module

With 19mm Plywood

Shingles - Recycled Timber Fence Various Size

Stud 19 x 35mm

Breather Membrane 0.15mm

Wikihouse Skylark Wall Module With 19mm Plywood

Plasterboard

Timber Skirting 90mm

Recycled Timber Floor

Recycled Timber Sleeper 250 x 150mm

Surefoot Footing

Loose Hemp Insulation Footing

SuperWood

Computational Design and Robotic Fabrication

Our given brief is to design a timber canopy. We challenge how we can reduce waste by rethinking our design process. Instead of using processed timber, we embraced the natural geometry of a tree and we decided to use natural logs as our material. During our research, we found out that tree forks are usually considered offcuts in the timber industry and are rarely used in construction due to their inconsistencies. However, tree forks have a high strength-to-weight ratio due to their wood grain, and it had high potential as a structural material.

Overall, the use of advanced digital fabrication increased efficiency in production both in terms of time and accuracy, while minimising the structural embodied carbon. It enabled opportunities for new and unique spatial properties and aesthetics compared to conventional fabrication; and ultimately allowed us to re-imagine what ‘material’ is in the construction and architecture industry.

Project Data

Location | Sydney, NSW

Team | Ling Kit Cheung, Xueying Wang, Micheal Anthony Kindica Studio Leader | David Pigram

Rethinking Design Process

Our design process begins with material extraction. We’ve used blue gum and grey gum for this project. After receiving the offcuts, we added positioners then 3D scan each log to form a digital inventory. Then, by using computational design and an optimisation algorithm, we generate 5000 iterations optimising the design’s form and structure, while minimising the material usage.

The robot arm allowed the fabrication of intricate geometries that is not possible using conventional machines.

Digital Inventory

After obtaining our material, all of the branches are 3d scanned to establish a digital inventory.

Possible Combination and Geometry

We developed a parametric script with Rhino3D and Grasshopper to create different iterations of the design, then test its structural stability and its aesthetic to determine its final form.

Activity Plan - Public Lecture

Level 4

Activity Plan - Exhibition Level 4

Activity Plan - Everyday / Cafe Level 4

Quantifying Quality

Rethink Sydney CBD through

Evolutionary Optimisation Algorithm

Sydney is recognised as one of the most livable city in the world, however the research and survey we did do not aligned with the result. With the design question of “how to make Sydney CBD more livable”, we curated a few design objectives for the algorithm to optimise and possibly find out the optimal solution. The fitness objectives include:

1. Optimise Building Typology (Commercial, Office, Residential)

2. Maximise Green spaces

3. Maximise Solar Access to Green Spaces

4. Maximise Connectivity of Elevated Green Spaces

5. Optimise Residential Density

Beside these fitness objectives, we also design 17 assessment criteria (Phenetypic Indicator) to filter out the less sucessful results. By using evolutionary optimisation algorithm, it allow us to explore more possibility and we can evaluate the design outcomes in a more quantifable and objective lens.

Project Data

Location | Sydney Town Hall, NSW Team | Jianqiang Zhang

Studio Leader | Mohammed Makki

Evolutionary optimisation engine, Wallacei result.

Grasshopper script responding to the site

Best 12 solutions based on the fitness objective given

Filtration method for filtering 36 best solution to 3 best solution with Phenotypic Indicator (PI)

Project Data

Location | Kobe, Japan

Team | Amar Mahmutovic

Amurdha Sivaprakash

Arthur Winderickx

Caitlin Wong

Ching Han Chin

Clément Taulelle

Elena Chan

Hanjie Xie

Hatsune Suwa

Iris Zheng

Julian Bracamonte

Lynda Itatahine

Mami Sakamoto

Mingming Li

Minne Chen

Mitchell Moxey

Qianyu Liu

Rei Sakurai

AAVS Kobe 2023: Re-imagining and Constructing a Japanese Pagoda

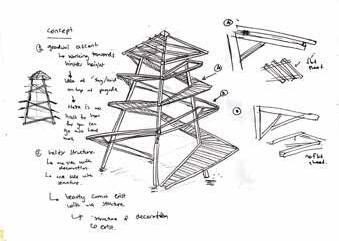

This VIsiting School to Kobe explore the relationship between Japanese traditional carpentry and advance parametric technology and digital fabrication method. Japanese carpentry is culturally significant and has been used since 12 century. However in our modern age, traditional carpentry is less celebrated in our modern structure. We design and construct aJapanese pagoda, in this workshop to explore and establish a reciprocal relationship between old and new.

Ruby Matthews

Sam Turner-Baldwin

Sari King

Sattrapattana Ruangvanish

Teddy Wang

Wentao Dai

Xinlin Lin

Yanhao Chen

Yin Teng Chin

Yuhui Cao

Studio Leader | Mohammed Makki, Masaaki Matsuoka

Structural Test

Base Model Deflection

Design process from hand sketches to parametric design and structural analysis

Final Drawing set of the pagoda

By Tom Abell and Rui Hang Yong