In a test scenario where a carbide bit is used to cut titanium rod, a known challenge due to titanium's toughness and heat resistance, Duravi-treated bits delivered five successive flawless cuts. Normally, a single cut would dull or destroy the bit. Duravi facilitated a surface hardening process that maintained bit sharpness and cutting edge integrity, resulting in a mirror-like finish and exceptional repeatability.

Click to View Video

Click to View Video

Boron steel, often used in automotive applications, is exceptionally difficult to drill due to its hardness. Conventional approaches avoid drilling in favor of cutting and welding. After application of Duravi, a handheld Snap-On drill with a carbide bit successfully drilled clean holes in boron steel, with no evidence of overheating or tool chipping. This demonstrates Duravi's potential to unlock new processes and eliminate specialized machining constraints.

In this test, Duravi was sprayed onto a coupler made from 4140 pre-heat-treated steel (Rockwell C 28-32). The insert cutter performed a full dry cut with a single Duravi application. Compared to untreated cuts, the Duravienhanced process yielded cooler cuts with no discoloration or burning, preserving the material’s springiness and internal strength. The insert cutter remained in serviceable condition for additional use, supporting extended tool life. Click to View Video

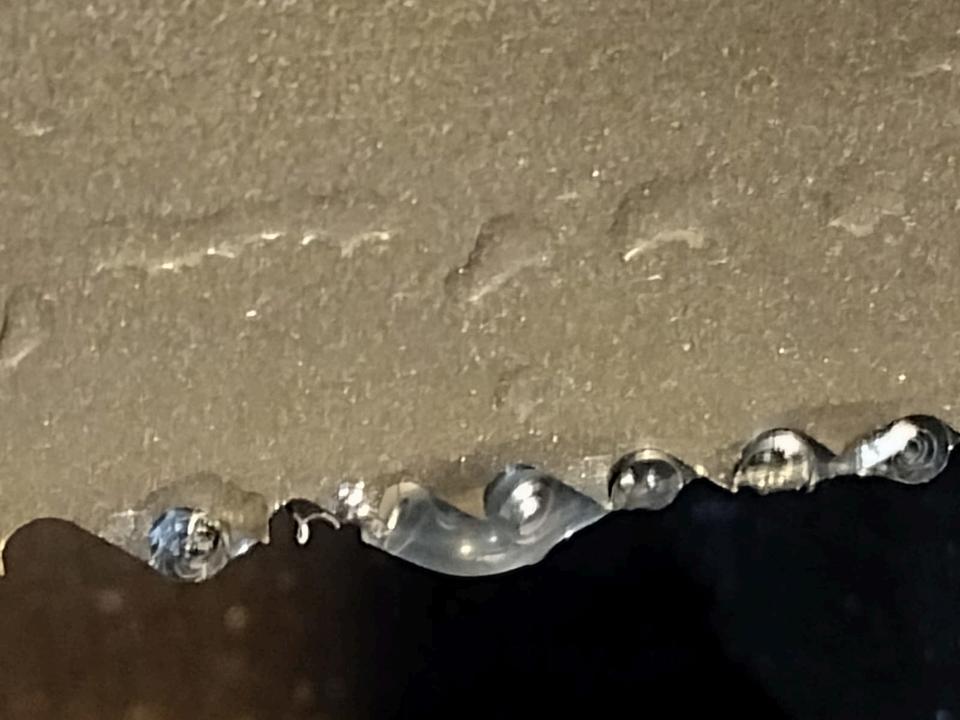

In this scenario, a 10% Duravi blend was added to water coolant during the cutting of a hardened hydraulic cylinder rod. The results included increased tool life, a smoother surface finish, and reduced tool loading. The chip morphology shifted significantly — rather than breaking or splintering, the chips curled uniformly and maintained ductility, indicating controlled heat management and reduced surface tension.

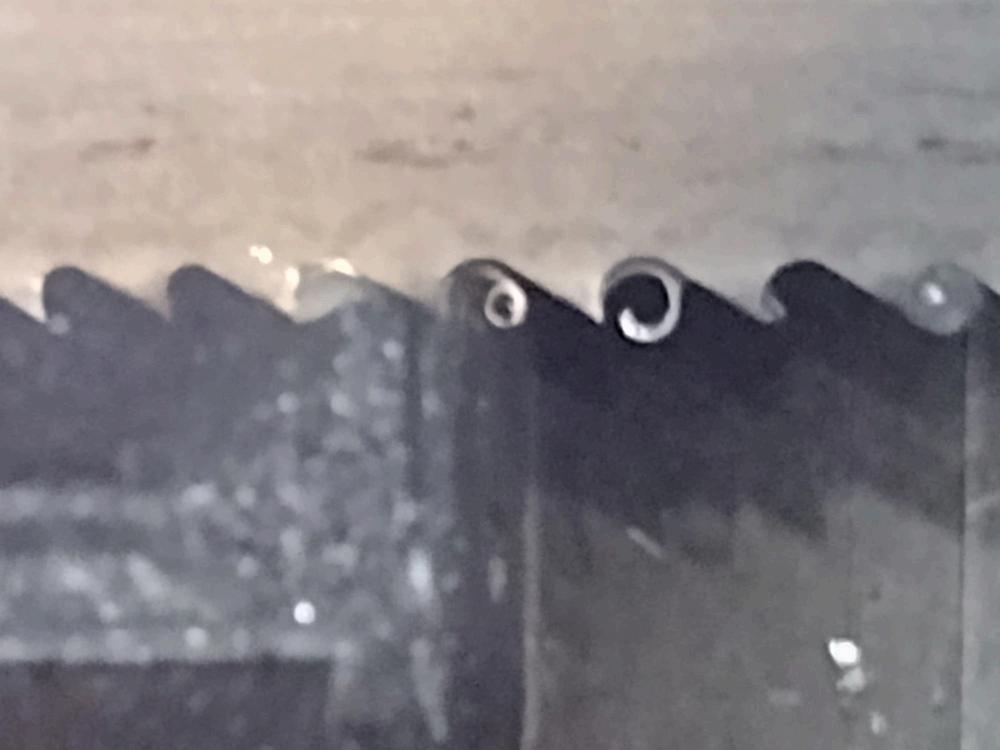

A standard metal cutting band saw blade was compared before and after Duravi treatment. The untreated blade cut a 1" x 1" steel block with standard chip adhesion and heat buildup. After Duravi treatment, the same cut was completed 16 seconds faster with no chip sticking to the blade and lower surface temperatures. This improvement highlights Duravi’s ability to enhance chip clearance and minimize blade fatigue.