As the bit cuts the titanium rod in this video, the DURAVI activates and penetrates the bit. This makes the surface of the bit stronger, and harder without being brittle, allowing the bit to perform better and make more cuts than normal.

Normally in this process of cutting a titanium rod with the bit, only one clean cut is usually performed before the bit must be replaced.

This bit performed five flawless cuts that provided a smoother, mirror-like finish on the titanium rods. Click to View Video

Because of its hardness, boron steel is used as a structural component of cars to maintain cabin integrity and keep occupants safe.

When performing body work on automobile cabins, parts are usually cut and then welded together (vs drilled) because of the difficulty and cost associated with drilling into boron steel (time, broken drill bits)

After spraying with Duravi, these holes were drilled into the boron components using only carbide bit and a snapon handheld drill. This was done with minimal effort, producing little heat and almost no wear on the drill bit.

Click to View Video

PSL was sprayed on top of a blow off preventor coupler used for offshore drilling.

The material is 4140 PHT (Pre Heat Treat). Rockwell “C 28-32”

The entire bore was dry cut with a single spray of the Duravi PSL.

In the second video you can see the Duravi treated cuts vs non Duravi treated.

The treated cuts were much cooler, non discolored, still had ductility (springiness). In addition, the insert cutter was still viable and used to cut additional parts.

Click to View Video

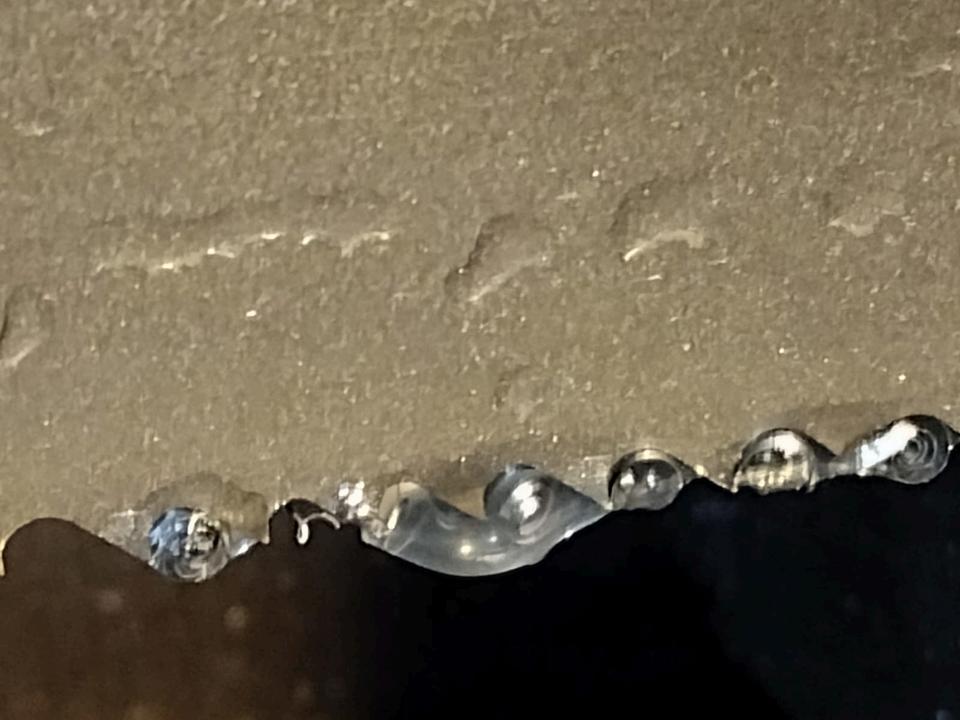

Duravi was added to the water coolant (at 10% concentration) running on the hydraulic cylinder rod (Rockwell C 67) cutting surface and the cutting tool was a high-speed steel insert.

As a result, the tooling lasted significantly longer, and the cylinder rod finish was significantly smoother and generated less heat on the tooling.

In addition, the chips did not fracture or fly off, instead they curled away and remained ductile.

to View Video

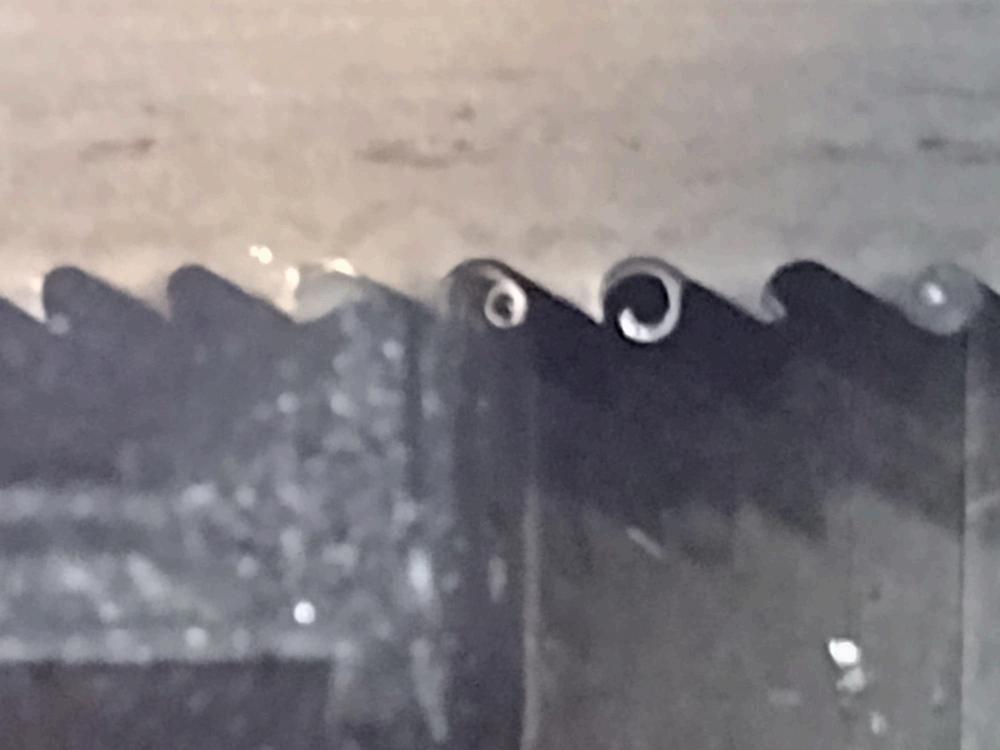

The first image is a standard metal cutting band saw blade untreated with Duravi. It was used to cut a 1x1 square block of 1020 Hot Roll Steel.

In the second image, the same blade was sprayed with Duravi. Again, a 1x1 square block cut made into 1020 Hot Roll Steel.

As evidenced by the images, there we no chips sticking to the treated blade, the blade and chips generated less heat, and the cut time was reduced by 16 seconds.