RUBEN AGOSTINO ARCHITECTURE

PORTFOLIO

About me

Based in: Salerno, (IT) - via Francesco la Francesca 96, 84124

contact me: arch.rubenagostino@gmail.com +393664613835

my links: www.linkedin.com/in/ruben-agostino https://issuu.com/ruben.agostino https://www.instagram.com/_ben_ur_/

I’m an architect who’s also a carpenter at heart, blending digital innovation with practical craftsmanship. My work explores the intersection of parametric design and digital fabrication, supported by skills in 3D modeling, CNC milling, laser cutting and 3D printing. This enables me to seamlessly translate conceptual ideas into physical elements.

Through my work experience and the many self-construction workshops I’ve led as a tutor, I’ve deepened my understanding of the built object and construction processes. My approach combines flexibility, precision, and initiative, strengthened by computational thinking and great problem-solving skills, allowing me to adapt and deliver effective solutions in fast-paced environments.

Language Italian (native), English (fluent, written & spoken) and French (basic)

Work Experience

Studio DAZ architetti associati - The Aimes | Naples, IT - Riyadh, SA

Architect | Technical Architect

Brancaccio Costruzioni S.p.a. | Naples, IT

Technical Architect | Tender Architect

Researcher in digital fabrication

CMMKM Architects - Gridshell.it | Naples, IT

Junior Architect | Technical Architect

Architectural Intern

Tutoring Villa Pennisi in Musica, self-construction workshop | Acireale, IT MOGE, International Workshop | Ecole d’Architecture de Paris-Belleville - Paris, FR ed. 2021-2024 ed. 2021

Academic Experience

University of Naples Federico II

Academic tutor: Undergraduate thesis supervision - Prof. Sergio Pone

Adjiunct lecturer: Introduction to Parametric Design course

Teaching Assistant: Design of Building Systems course - Prof. Sergio Pone

Researcher: AURA, Green & Smart urban furniture

Publications L’industria delle Costruzioni n. 492 | Writing and sourcing

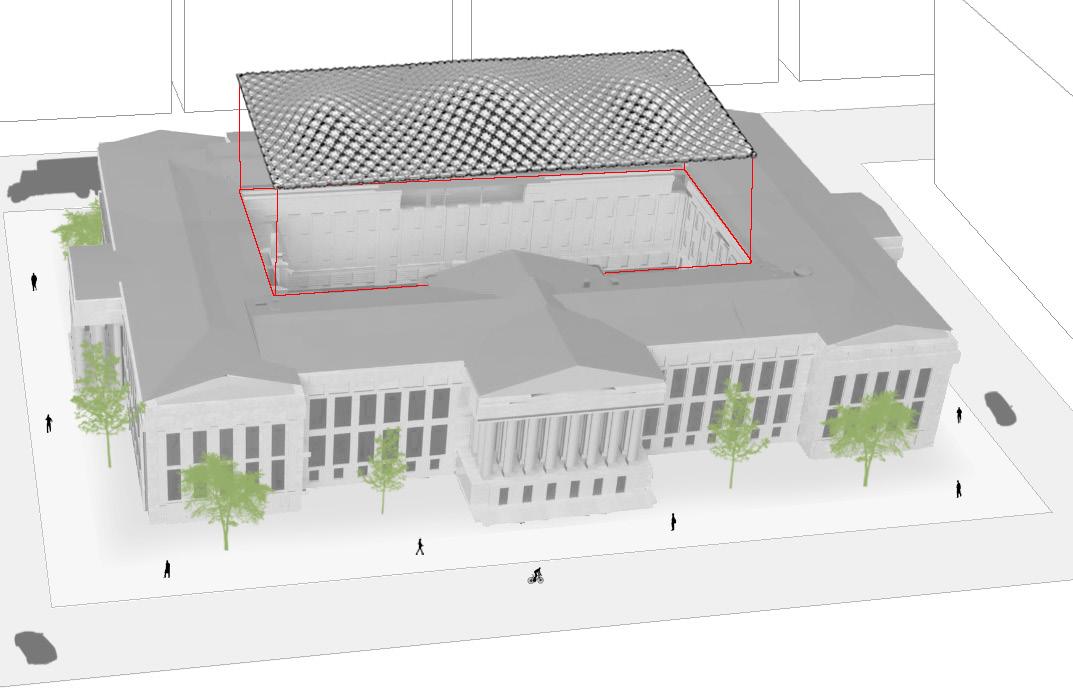

The building of Museo Gallerie d’Italia in Naples

IASS International Association for Shell and Spatial Structures vol. 2020, no. 3 | Author

Adaptive Cross-Panel System: digital fabrication for freeform architecture

Design

Rendering

Graphic Design

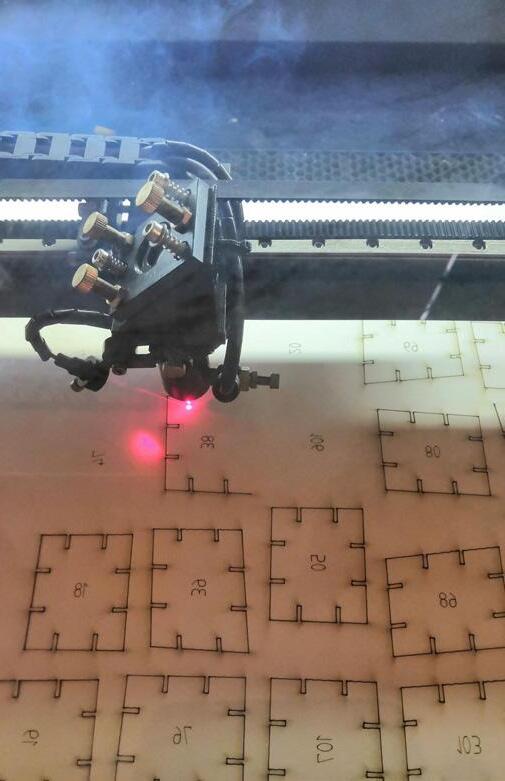

Crafting CNC milling, Laser Cutter, 3d-Print, hand/power tools

Workshops MOGE, International Workshop | Ecole d’Architecture de Paris-Belleville - Paris, FR Villa Pennisi in Music, Autoconstruction Workshop | Acireale, IT Building with Wood, Architecture Workshop | Naples, IT

Keywords

2019 ed. 2014/2017 ed. 2016

Selected Projects

Experimental approach to parametric design and innovative construction systems

Hive Cross-Panel

My role as an architectural technologist in the design and development of a real building.

Striano-shell

Research and experimentation in digital fabrication and prototyping

Mimante

CADS

A workshop experience that deepened my understanding of self-construction and architectural technology

Hive

Università Federico II | Naples, IT

Ecole d’Architecture de ParisBelleville | Paris, FR PROGRAMMATIC

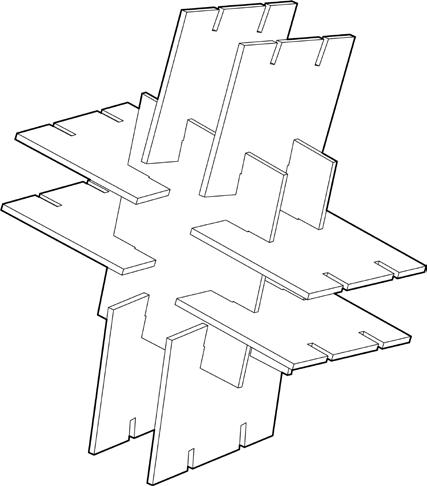

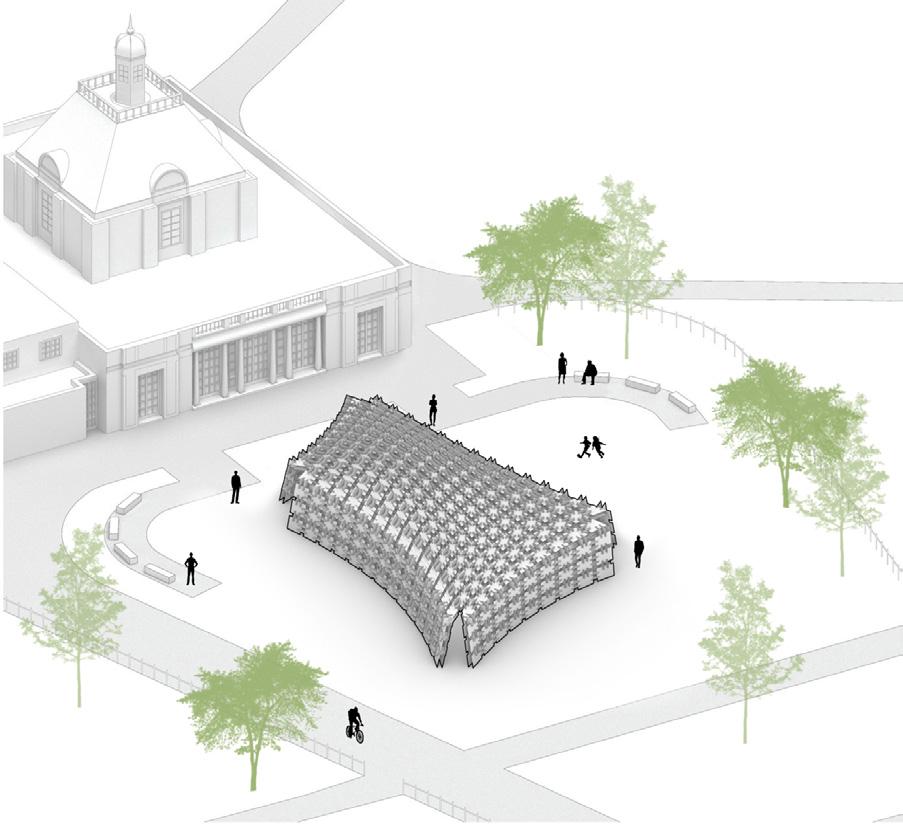

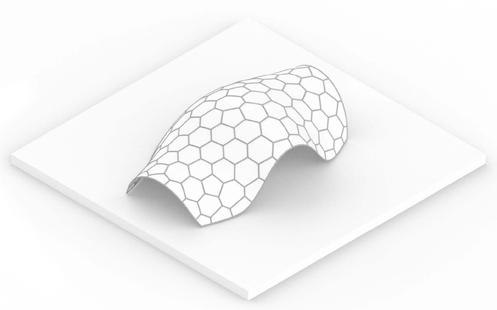

The workshop aimed to explore the principles of computational design by seamlessly integrating design methodologies with digital fabrication techniques. The final objective was the design and construction of a small pavilion using wooden panels. The project is inspired by the honeycomb structure found in nature. This geometric form represents a system of minimal material density while offering high compression and shear resistance in the out-of-plane direction — making it an ideal choice for lightweight yet robust architectural applications. PROJECT

Hive began as a research project during the MOGE International Workshop, organized by the University of Naples and the ENSA of Paris-Belleville.

Hexagon extrusion

Triangular joints on base hexa-grid

Joints destination lines

Joints destination lines

Merging overlapping surfaces

Hexagon extrusion

The individual geometric module is repeated and transformed in space to generate a complex threedimensional environment.

The assembly and the subsequent aggregation of the modules creates however a contact surface between them doubling the thickness of the sides. This results in thew use of more material, increasing the weight and therefore the overall cost of the pavilion.

Surfaces extrusion

Joints distribution and geometry extrusion

Merging overlapping surfaces

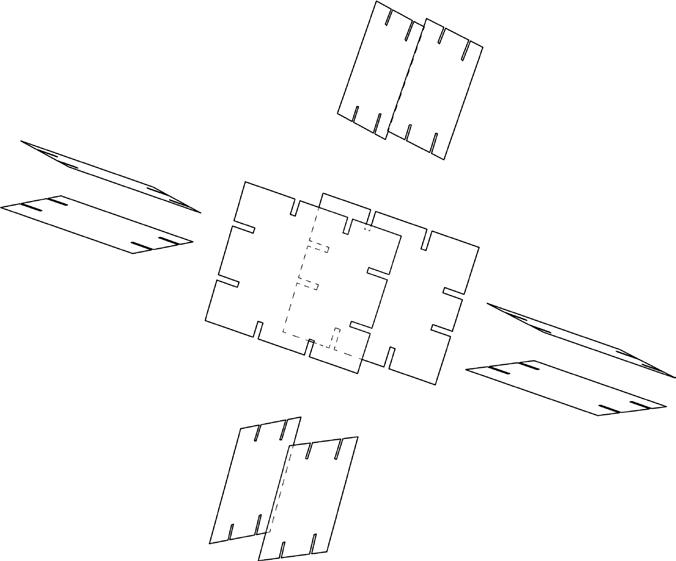

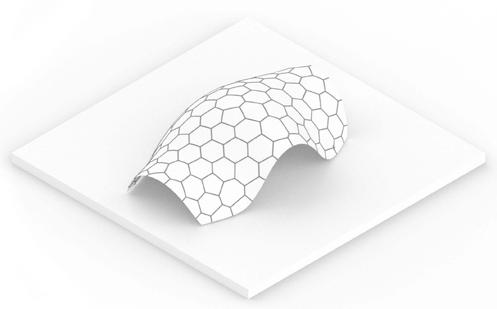

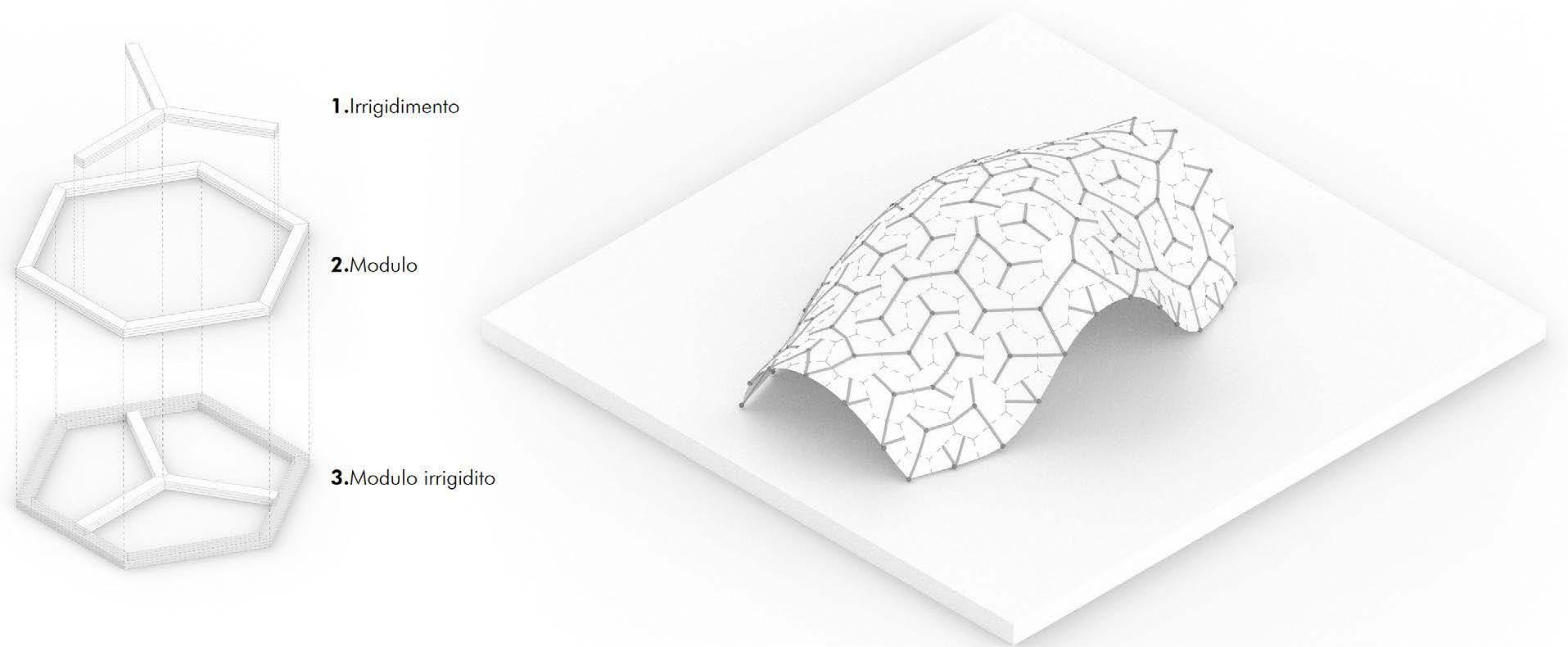

To address this issue, the hexagonal module is deconstructed into its elementary components and reconfigured to recreate the original composition—without doubling the side thickness. As a result, the construction process no longer relies on the aggregation of complete modules, but rather on the interlocking of individual panels, optimizing material use and improving overall efficiency. Consequently, modular coordination is achieved through the joints, which enable the precise anchoring of the panels.

Hexagonal subdivision

Side A

Side B

Base surface

Cross-panel

PROJECT

Adaptive cross-panel system: digital fabrication for freeform architecture

YEAR 2020-2021

LOCATION

Università Federico II | Naples, IT

PROGRAMMATIC Research

AWARDS

VII ed. Luigi Zordan Prize 1st Prize “experimental thesis”

TOOLS

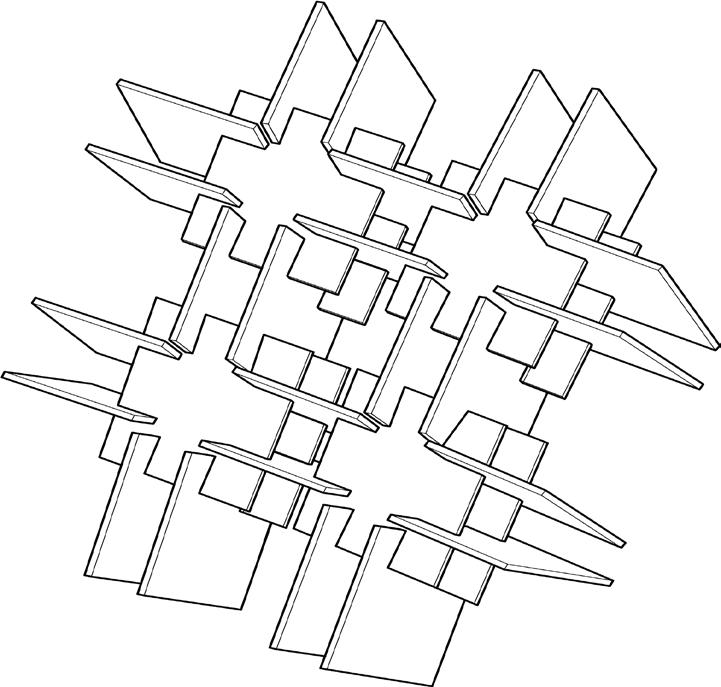

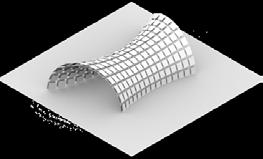

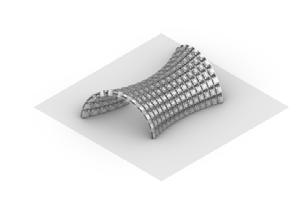

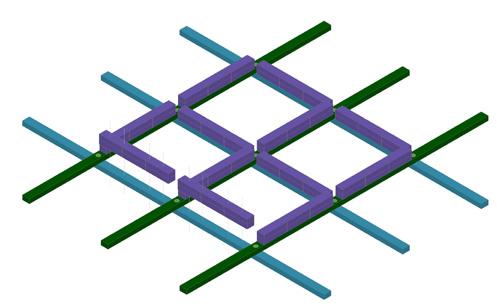

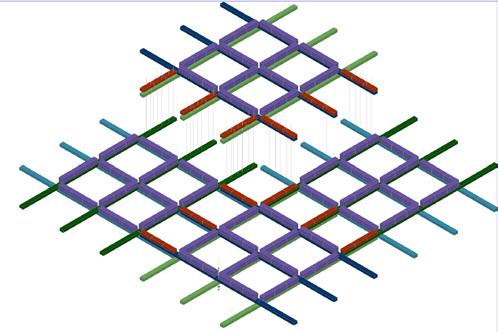

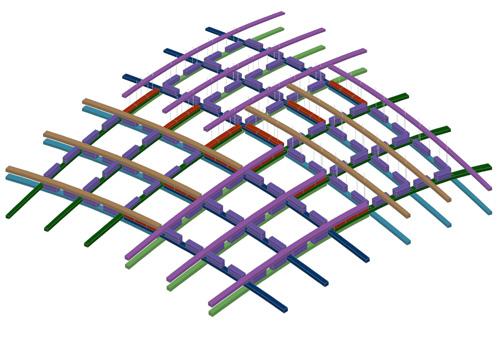

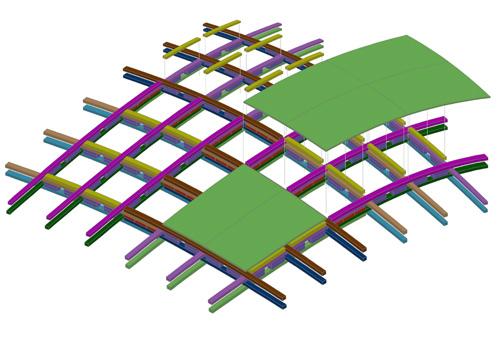

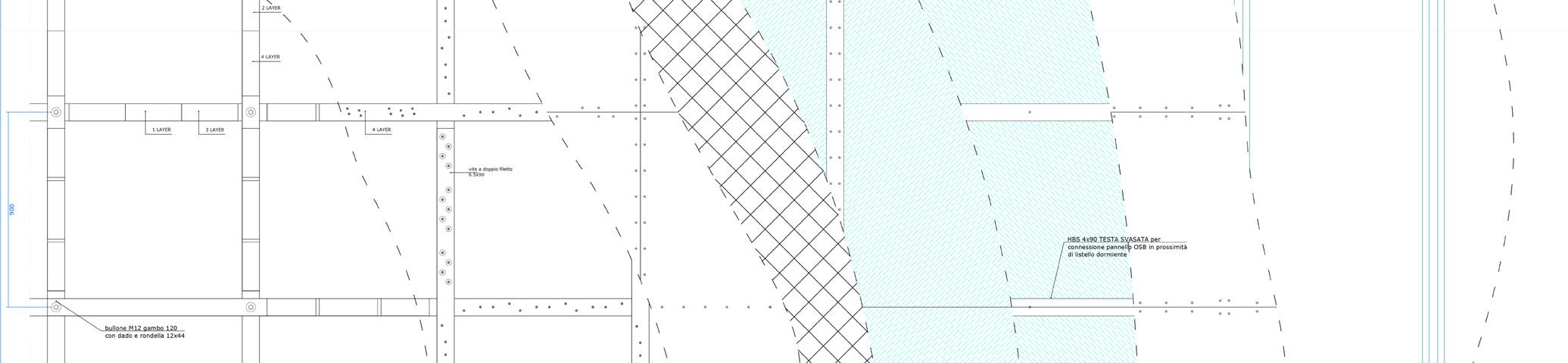

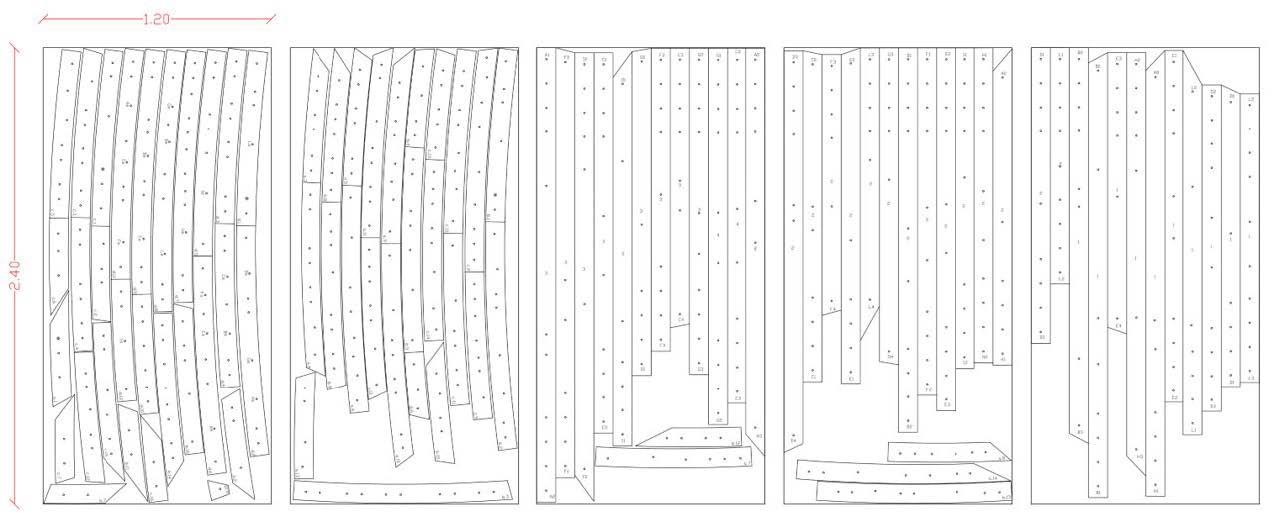

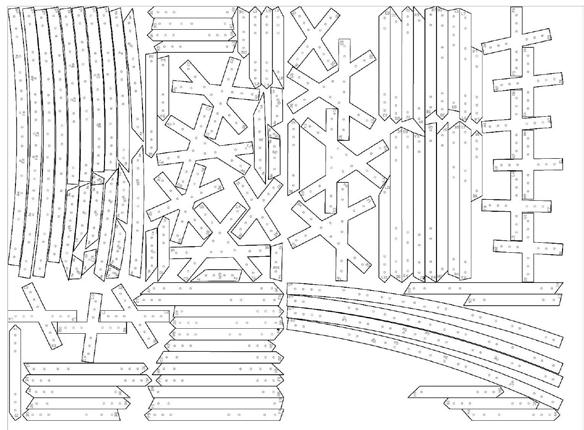

This research proposes a new construction system made of double frame crossed panels, to be used for the design and construction of free-form architectural structures. For this purpose, a parametric tool has been developed to adapt the crosspanel system to a wide number of surfaces. The experimentation went on with a case study involving a production and assembly phase using digital fabrication tools, for the construction of a temporary wooden pavilion. The study comprises three main phases:

1. Design of the construction system;

2. Creation of the parametric tool;

3. Implementation with digital fabrication.

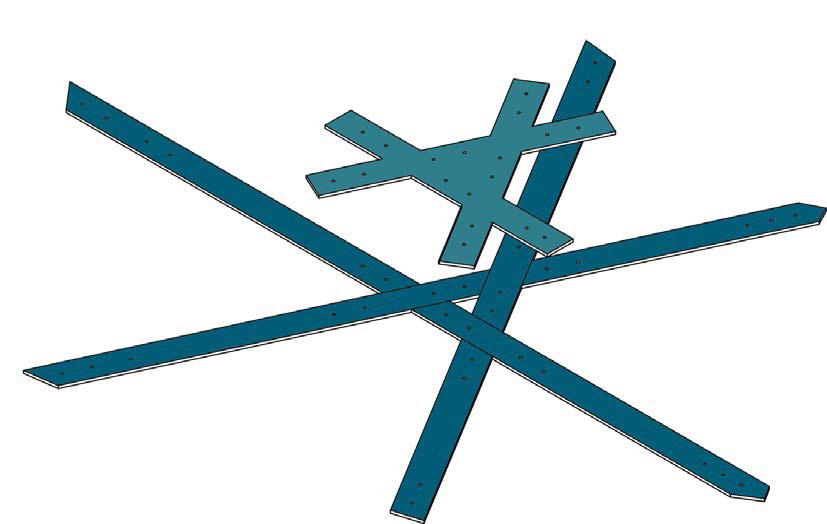

The joining method of the double cross-panel system (DCPS) takes place through halved joints, each panel is in fact both a connector and a node element. In addiction, the dubling of the panels in each directions maximizes the contact surface of the joints, increasing consequently the torsional strength and stability of the components. This solution has been chosen to avoid the use of glues or screws, in order to make the system reversible.

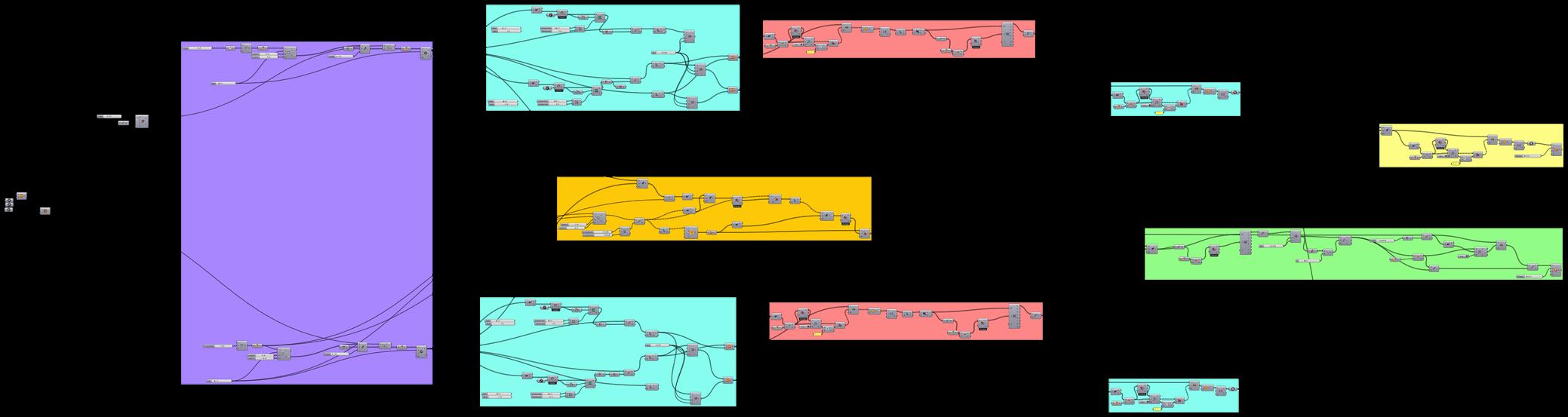

The tool, developed in grasshopper, is divided into three parts. In the first two, the system is splitted into two warps of panels generated independently on the surface:

JOIN INTERSECTIONS

˺ First frame, panels whose normals are perpendicular to the surface.

˺ Second frame, panels whose normals are rotated by 90° in the U and V directions of the surface.

Complete definition

In the third part, notches and cutting patterns are created for the digital manufacturing process. CARVINGS

Cross-panel

Once completed, the tool has been used to reproduce other architectures by replacing their structural system with the DCPS:

Serpentine Gallery 2005, Alvaro Siza – DCPS reconfiguration

Smithsonian Courtyard 2007, Foster + Partners – DCPS reconfiguration

Striano-shell

PROJECT Multipurpose Center

YEAR

2020 - Under construction

LOCATION

Striano (Naples), IT

PROGRAMMATIC Structure

PROJECT TEAM

CMMKM - Architettura e Design

TASKS

Design Development, Tecnology Development, Rendering

TOOLS

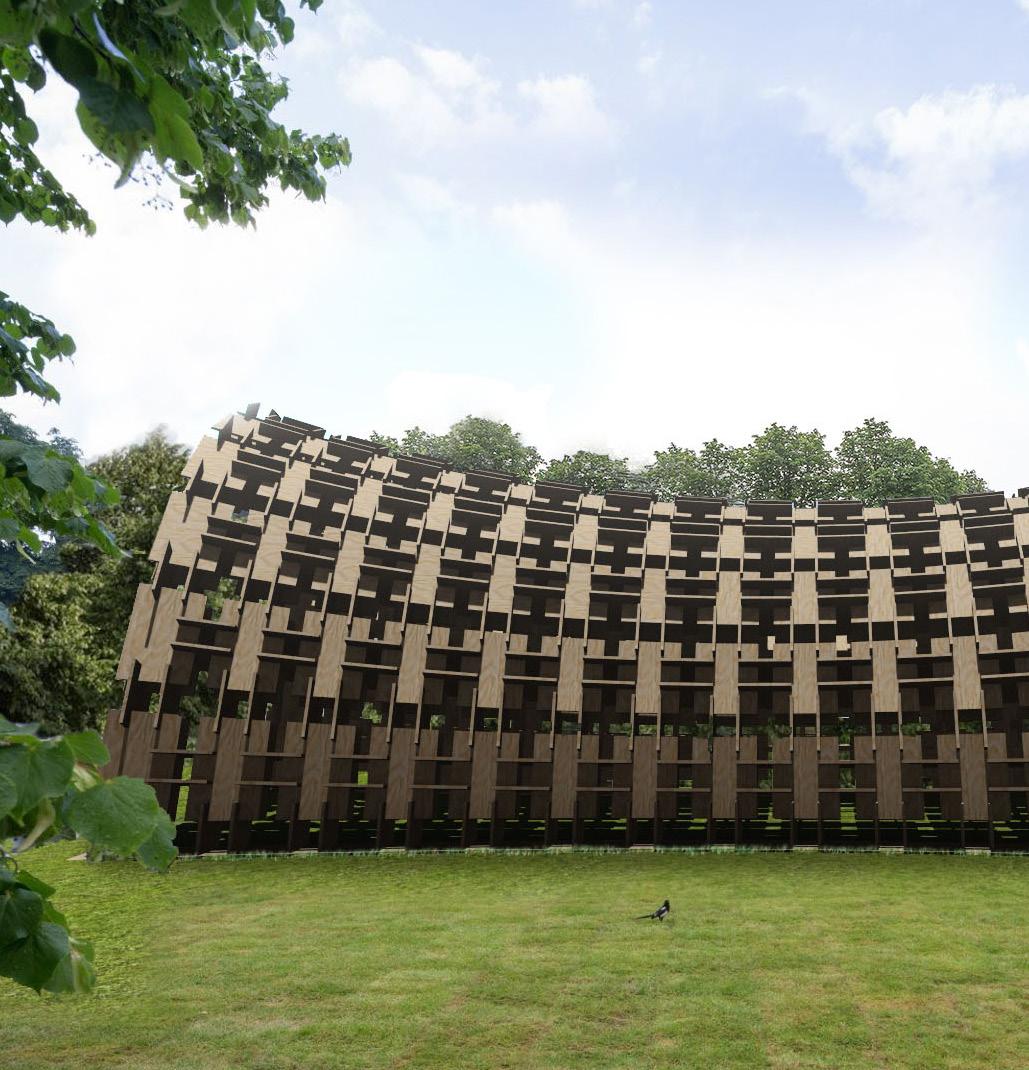

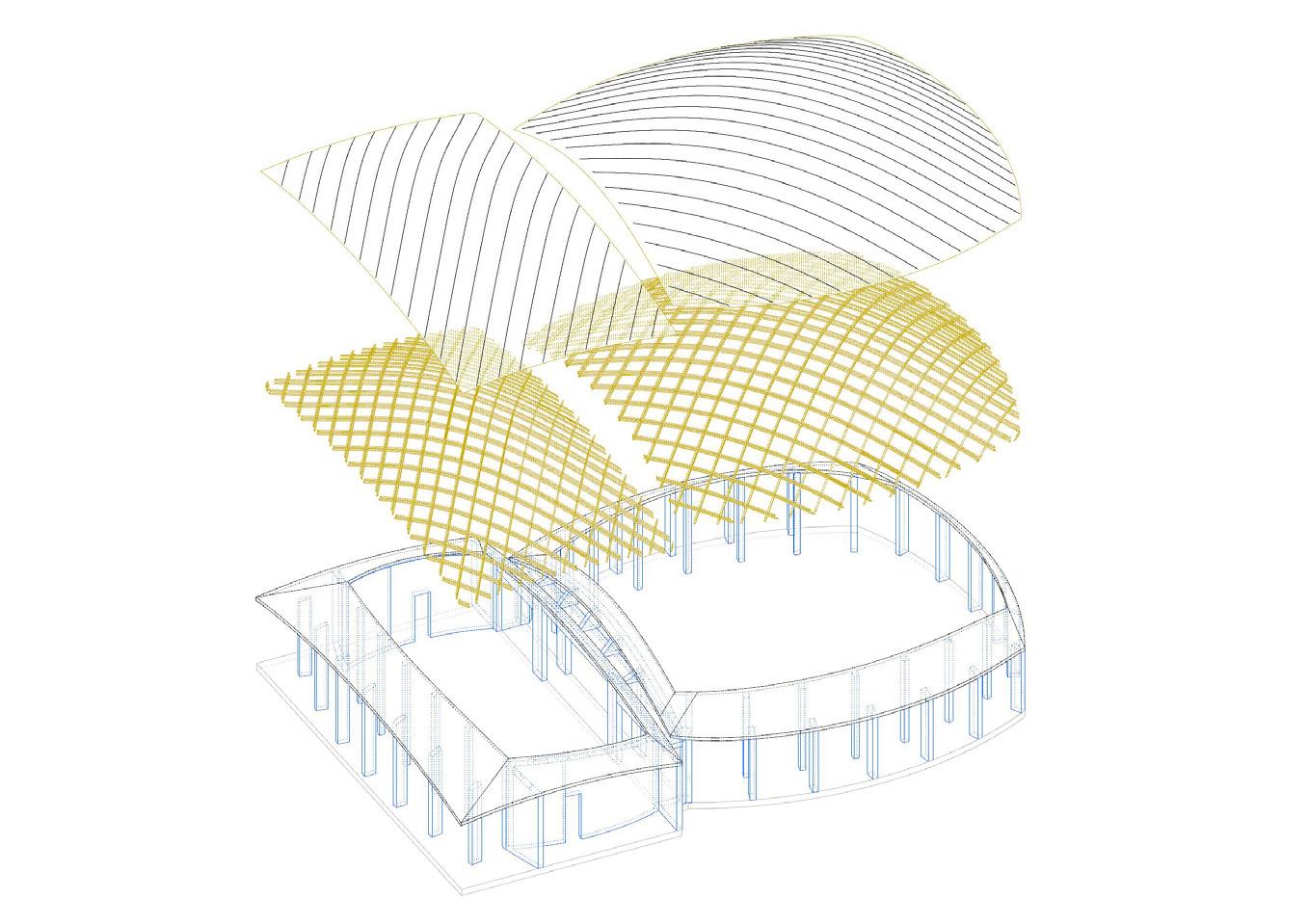

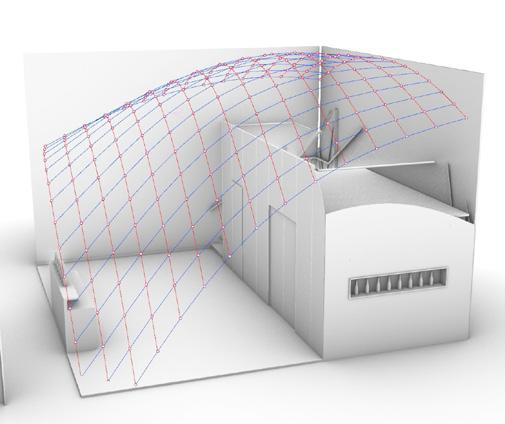

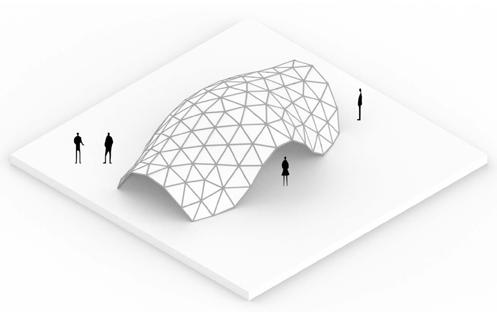

This project involves the design of a new multipurpose center for the town of Striano.

Our studio was commissioned to design, fabricate, and deliver the entire structural system of the building, conceived to support and integrate the innovative roof structure.

The key challenge was to create a structure that would perform efficiently from a structural perspective while minimizing or eliminating the need for interior columns, in order to maximize the flexibility and openness of the interior spaces.

To address this, we developed a structural system that combines a reinforced concrete base with two actively bending gridshell roofs, seamlessly integrated into the overall framework of the building.

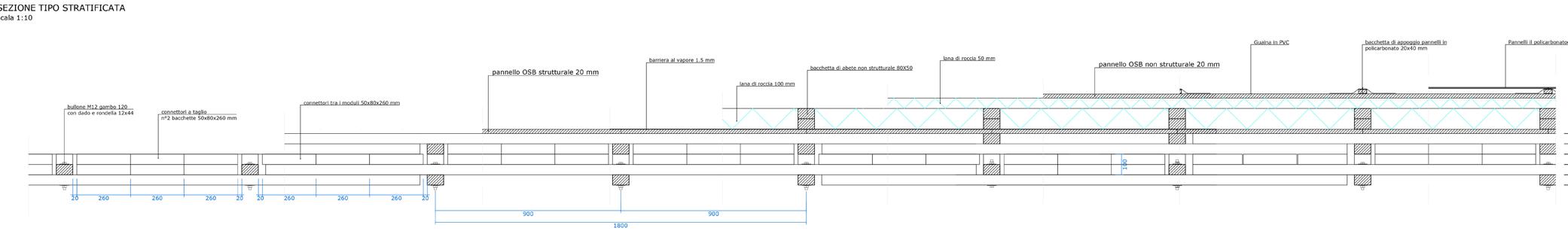

In a first phase, a flat grid of thin wooden slats is assembled; in the second phase the grid is forced to take on the expected curved shape through the bending of the wooded elements; finally, once the shape has been achieved, the deformation of the lattice is blocked by installing external constraints and braces.

The anticlastic or synclastic shape, achieved in the second phase, and the great in-plane stiffness, obtained with the stiffenings of the third phase, allow the original grid to function structurally as a shell

OSB panelling

Gridshells

Concrete slab

Striano-shell

Mimante

PROJECT

Software for the preliminary design of Active-Bending Timber Gridshells

YEAR 2022-2023

LOCATION Naples, IT

PROGRAMMATIC Research

PROJECT TEAM

Brancaccio Costruzioni Spa

TASKS

Digital fabrication, Prototype assembly

TOOLS

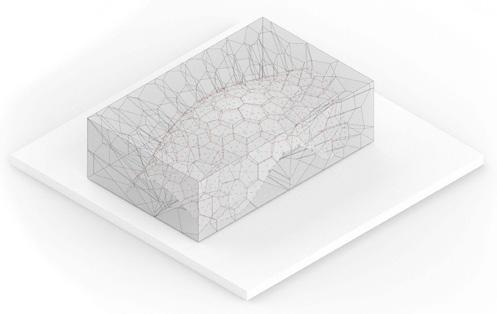

This project aimed to develop an open-source software tool for the preliminary design of Active-Bending Timber Gridshells (ABTG). The goal was to provide architects and engineers with a digital platform that facilitates the design process of this innovative structural system, which offers significant technical advantages for urban regeneration projects. Additionally, ABTG structures have the potential to be used as a tool for mitigating the urban heat island effect, supporting climate resilience strategies in cities.

The project also involved the fabrication and construction of physical prototypes, where CNC machinery was used to create the components, followed by manual assembly to bring the designs to life. This hands-on approach ensured the practical feasibility of the proposed structures and provided valuable insights into the construction process.

CADS

PROJECT

Creazione di un Ambiente

Domestico Sicuro (CADS)

YEAR 2021-2023

LOCATION Naples, IT

PROGRAMMATIC Research

PROJECT TEAM

Brancaccio Costruzioni Spa

TASKS

Digital fabrication, Prototype assembly

TOOLS

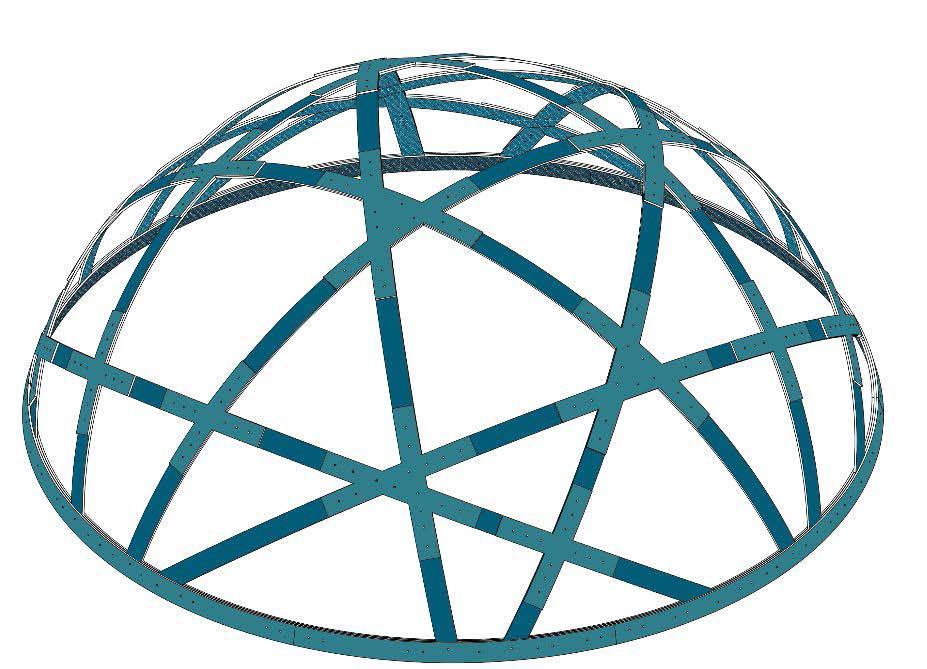

This study aimed to extend the discussion on seismic safety in residential environments, focusing on non-structural elements and external areas in the Mediterranean context.

Common installations like pergolas, canopies, and gazebos are typically made of lightweight, elastic linear elements with varying degrees of enclosure. These structures are often excluded from structural assessments under current regulations, despite functioning as actual load-bearing systems.

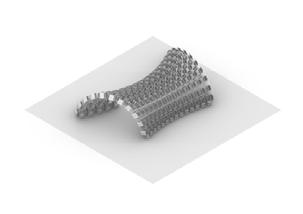

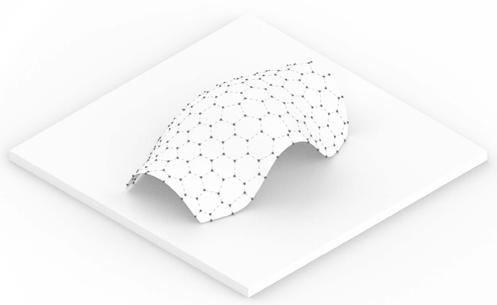

Following recent developments in architectural design and the use of advanced computational tools, the geometry of these structures is increasingly moving away from cartesian forms toward free-form shapes. For this reason, the study focused on analyzing the seismic behavior of a gridshell based on a Tiled Grid.

The subdivision was achieved through Voronoi tessellation. This allows for more structural material to be placed where it is most needed, enabling a form of natural structural optimization.

The design of the gridshell structure followed these steps:

1- Creation of a curvature-sensitive triangular mesh using Grasshopper plug-ins;

2- Extraction of triangle vertices to define the point map for the Voronoi diagram;

3- Generation of the Voronoi tessellation on the surface;

4-Identification of polygon vertices on the original surface;

5- Construction of geodesic lines connecting Voronoi points;

6-Conversion of geodesic cell edges into structural beams.

A portion of the prototype was built to verify the actual constructability, through an analysis of both structural behavior and production/assembly processes. The structure was made using 18 mm thick plywood panels, from which the beams and the nodes forming the gridshell were cut using a CNC milling machine.

NotdesignLab

PROJECT

Digital Fabrication lab

YEAR

2023 - ongoing

LOCATION Naples, IT

PROGRAMMATIC

Product - Structure

TASKS

Design Development, Tecnology Development

TOOLS

Notdesignlab is a FabLab born from the synergy of Neapolitan architects, designers, and researchers united by a shared passion for digital fabrication and selfconstruction.

More than just a makerspace, Notdesignlab operates as a research hub where experimentation and design go hand in hand. What distinguishes it within the Italian landscape is its strong involvement in academic research, particularly in projects focused on innovative structural systems. These collaborations have led to the creation of numerous experimental prototypes

Each design object developed at Notdesignlab is not only a functional piece, but also a tool for exploring new materials, fabrication methods, and construction strategies— constantly enriching the collective’s knowledge and keeping creativity at the heart of the process.

Acoustic cieling

Structure

PROJECT

Villa Pennisi in Musica - ReS

YEAR

2012 - ongoing

LOCATION

Acireale, IT

PROGRAMMATIC Research - Education

TASKS

Tutoring

TOOLS

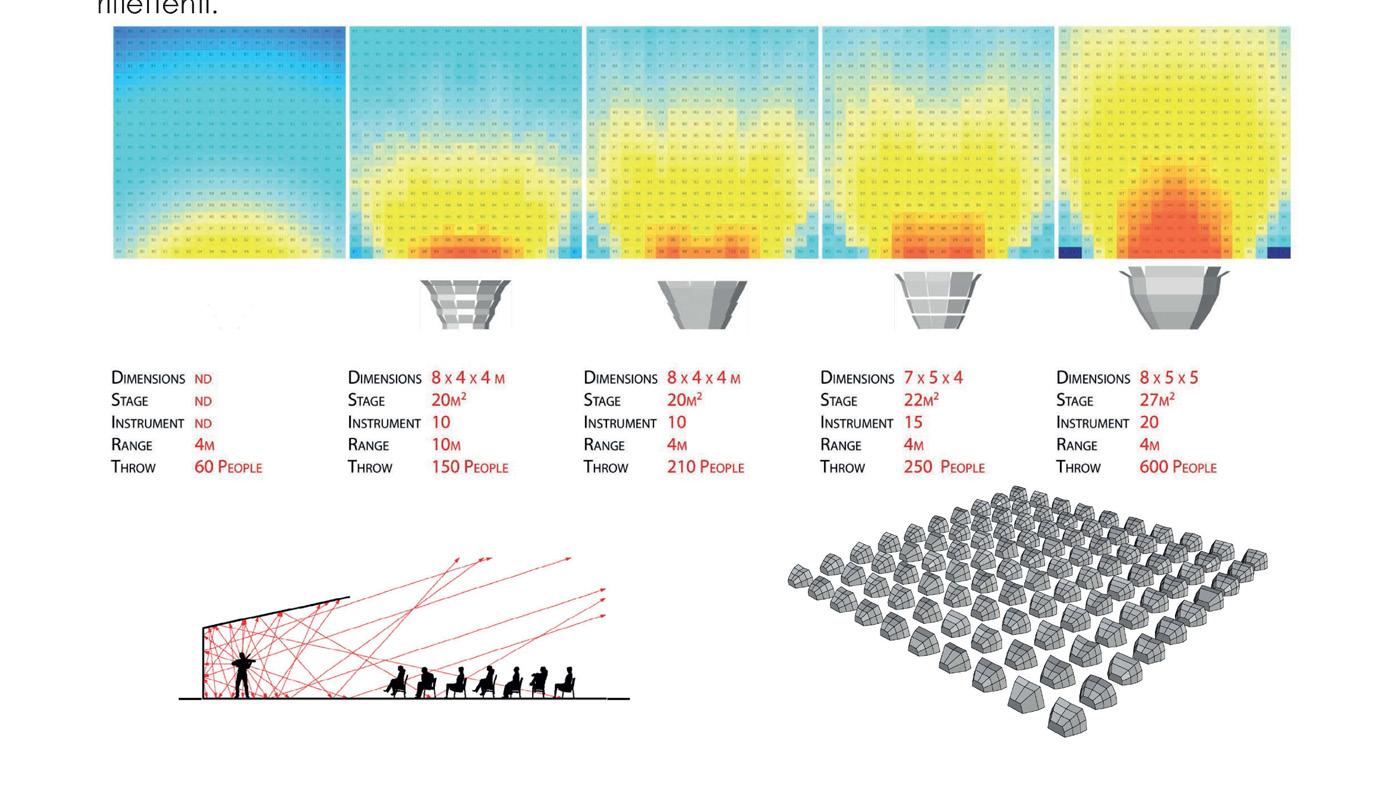

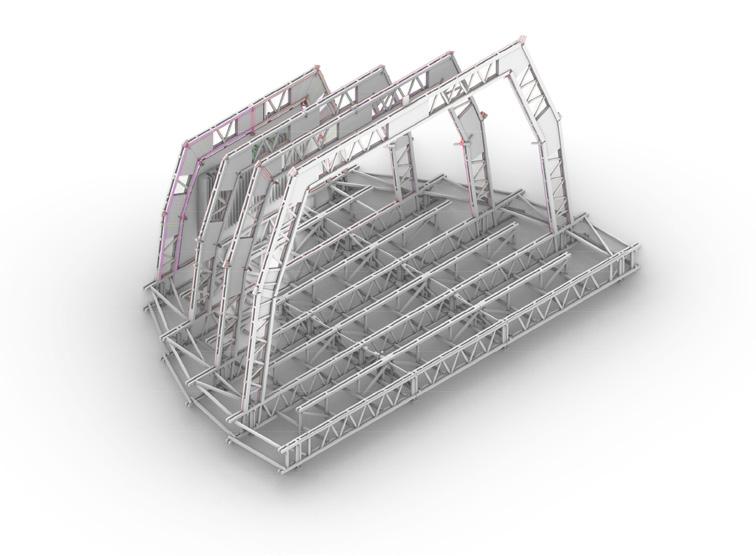

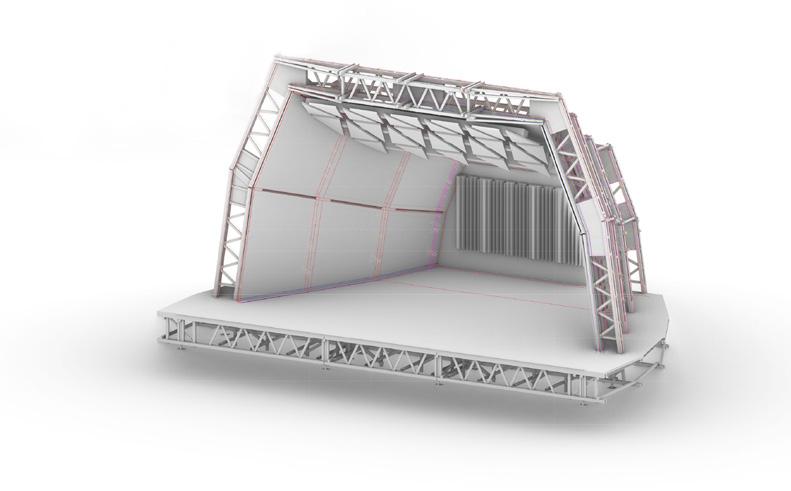

Villa Pennisi in Musica is an international summer festival that brings together classical music, architecture, and performance design. One of the core components of the festival is the ARCH LAB, an open-air design-build workshop focused on self-construction. During the lab, students and professionals collaborate to build ReS – Resonant String Shell, a temporary wooden acoustic structure designed for outdoor performances. ReS is both a stage and a sound machine, handcrafted using sustainable materials. Inspired by the form of vintage gramophones, it enhances the projection of music in open-air settings. ReS is the result of an ongoing research project launched in 2012. Each year, the structure evolves through design experimentation, combining hands-on construction with cutting-edge acoustic and architectural research.

Other project

MSC EXPLORA

YEAR 2025-ongoing

LOCATION MSC Explora - onboard

PROGRAMMATIC Retail

TEAM Studio DAZ Architects TASKS

Presentation Prep, Concept Design, Design Dev, Rendering

TOOLS Rhinoceros, Enscape

VVIP EXHIBITION

YEAR 2024

LOCATION Maraya Hall - AlUla, SA

PROGRAMMATIC Exhibition

TEAM Studio DAZ Architects TASKS

Concept Design, Design Dev, Rendering, Site Supervision

TOOLS Rhinoceros, Enscape

MSC TERMINAL

YEAR 2024

LOCATION Barcelona, ES

PROGRAMMATIC Retail

TEAM Studio DAZ Architects TASKS

Concept Design, Design Dev, Rendering, Site Supervision

TOOLS Rhinoceros, Enscape

MERGELLINA

YEAR 2022

LOCATION Naples, IT

PROGRAMMATIC Office

TEAM Brancaccio Costruzioni Spa TASKS

Design Development, Rendering

TOOLS Revit, Rhinoceros, Enscape

RUBINO B&B

YEAR 2020-2022

LOCATION Gaeta, IT

PROGRAMMATIC Hospitality

TEAM CMMKM Architecs TASKS

Concept Design, Design Dev, Rendering, Site Supervision

TOOLS Rhinoceros, Grasshopper, Enscape

LOOP

YEAR 2021

LOCATION Naples, IT

PROGRAMMATIC Cultural

TEAM Università Federico II TASKS

Design Development, Tecnology Development, Rendering

TOOLS Rhinoceros, Grasshopper, Enscape

Ruben Agostino arch.rubenagostino@gmail.com