TIMBER SCREWS AND DECK FASTENING

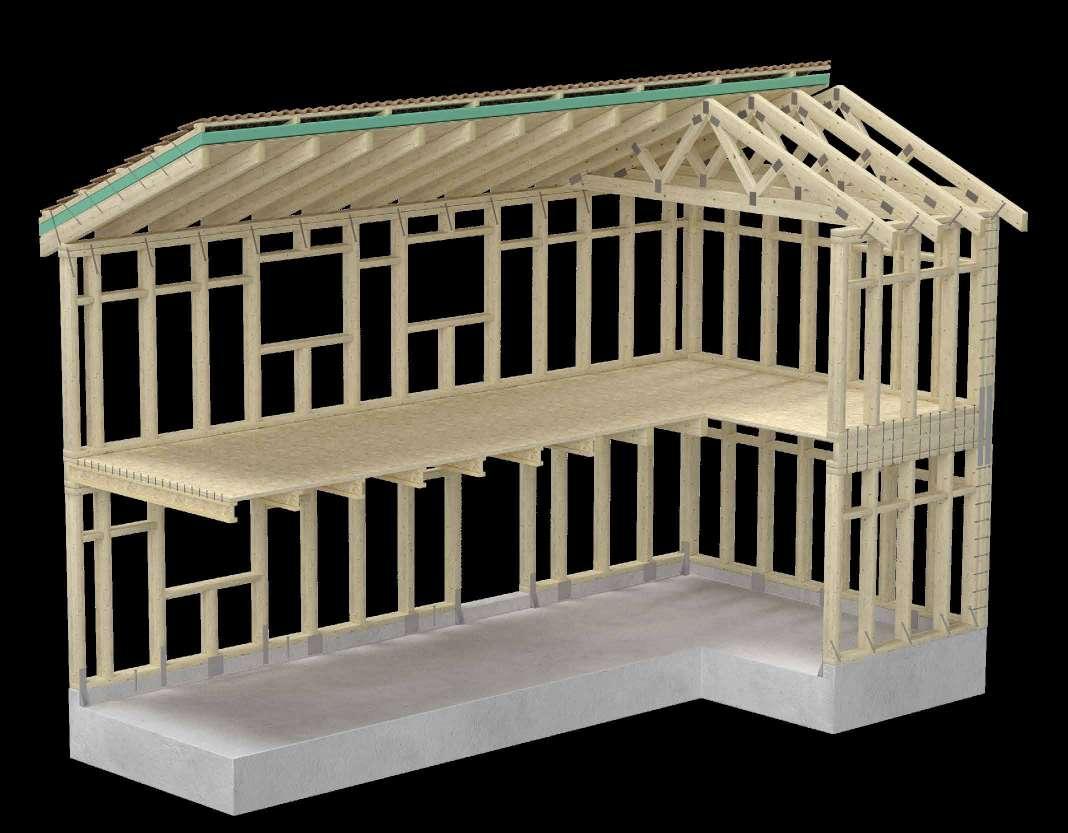

TIMBER, CONCRETE, METAL, TERRACES AND FAÇADES

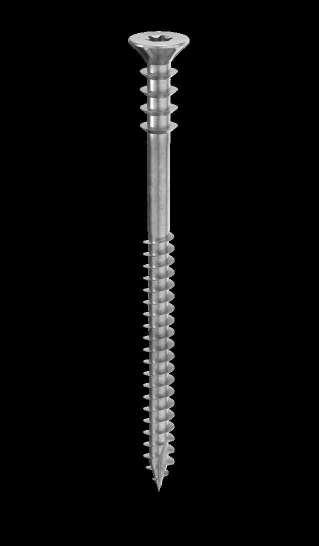

PARTIALLY THREADED - COUNTERSUNK HEAD

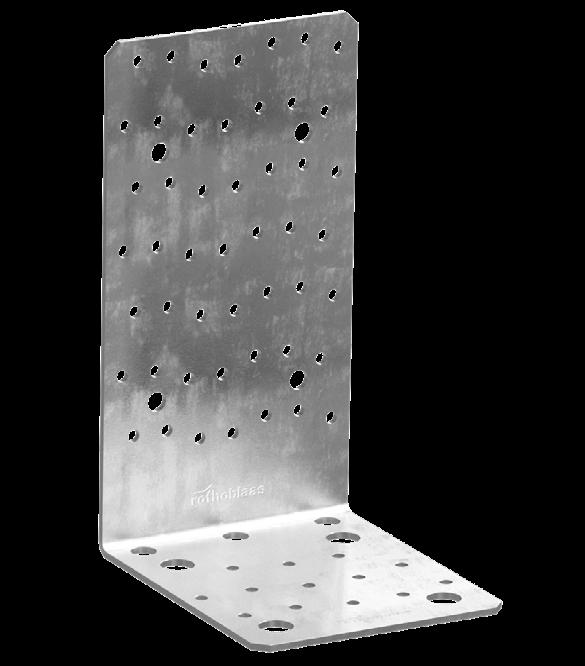

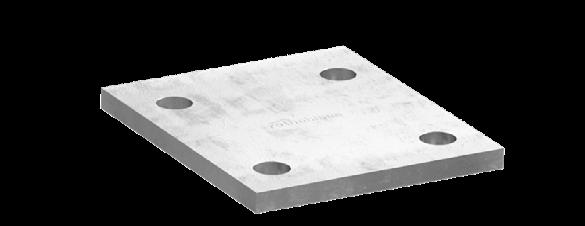

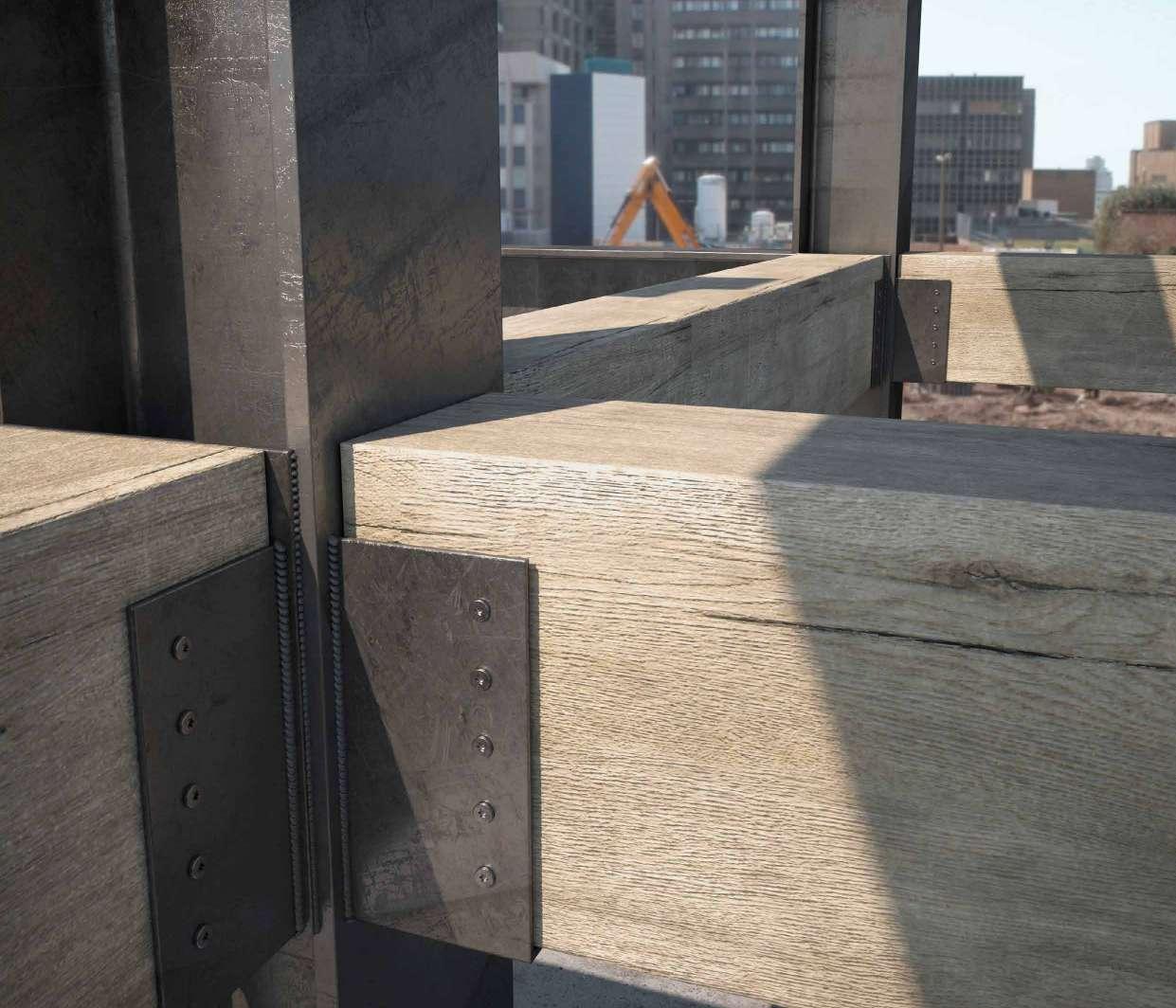

PLATE FASTENING

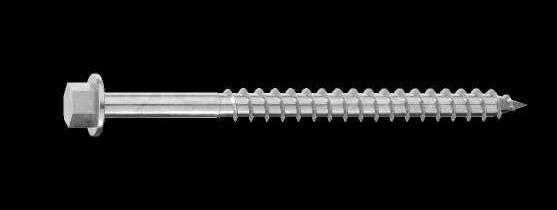

PARTIALLY THREADED - FLANGE HEAD

CONCRETE

TIMBER-TO-CONCRETE

AND MASONRY

FULLY THREADED - COUNTERSUNK HEAD FULLY THREADED - CYLINDRICAL HEAD

METAL

TIMBER-TO-METAL

FASTENING METAL SHEET

DOUBLE THREAD

DECKS AND FACADES

SCREWS

SCREWDRIVERS AND NAILGUNS ACCESSORIES AND TEMPLATES

SUBSTRUCTURE

CERTIFIED SOLUTIONS

Engineered and certified to meet the most rigorous ICC-ES safety standards.

Our screws are built to perform under the toughest conditions—reliable, strong, and tested.

ELC-4645

ESR-4645

REAL-WORLD EXPERIENCE

CLOSER THAN YOU THINK

A nationwide network of technical representatives—wherever your project is, we’re there.

Expert engineering support at every stage of your project.

Partnering with U.S. professionals since 2010—with a growing team of reps and partners.

Trusted in thousands of projects across the United States.

MOISTURE AND EXPOSURE CONDITIONS

To ensure optimal performance in various environmental conditions across the United States, we have chosen to adopt the classifications of National Design Specification for Wood Construction (NDS) and the AC257 acceptance criteria by ICC-ES.

The dry classification includes environments where humidity is limited and corrosion risk is minimal (e.g. indoor or protected spaces). The wet classification covers environments with high humidity exposure, such as outdoor areas or locations with direct water contact. AC257 also introduces specific criteria for corrosion resistance in chemically treated environments or in coastal areas exposed to salt. The summary table considers AC257 Exposure Conditions 1 through 4, ensuring that selected screws provide optimal performance and durability in diverse usage conditions.

The moisture content of wood significantly affects the mechanical properties, strength, and stiffness of structural members. In the design of wood connections, standards like the NDS (National Design Specification for Wood Construction) and CSA086 (Canadian Standards Association) provide guidance on service condition factors. These factors account for moisture content at the time of fabrication and during service. Proper evaluation of the combined service class, wood corrosivity class, and atmospheric class is essential to ensure the structural performance and durability of connections. These classifications affect decisions such as material choice and protective measures, particularly in environments with varying humidity or exposure.

MOISTURE CONDITION

According to NDS and CSA-O86

MAXIMUM MOISTURE CONTENT OF THE WOOD

DEFINITION

DESCRIPTION

NOTE

Table 11.3.3 in the NDS and Table 12.1 in CSA-086 outline the interaction of moisture content at fabrication (whether the wood is green or dried) with the in-service moisture levels. The factors vary based on the type of connection and loading conditions. Notably:

• A moisture content (MC) of ≤ 19% is the threshold for “dry service conditions.”

Wet service conditions apply to wood connections when:

1. The connection is exposed to direct wetting (e.g., rain, snow, condensation) such that drying is not effective.

2. The wood member is classified as “green” upon installation and retains a moisture content above 19% until dries.

3. The equilibrium moisture content exceeds 15% averaged annually or exceeds 19% at any given time.

In wet conditions, the need for moisture management is critical, as prolonged exposure above 19% MC can compromise the mechanical properties of wood and the long-term performance of connections.

outdoor protected environment exposed environment

If MC > 19% at fabrication or in service, adjustments using the service condition factors are applied to ensure the integrity of the structural design.

For detailed application, designers should consult NDS Table 11.3.3 and CSA-086 Table 12.1 , which provide the necessary correlations between moisture content, connection type, and loading conditions.

EXPOSURE CONDITION

According to AC257

DESCRIPTION

treated wood in dry use applications

clean untreated wood, exposed to saltwater spray aboveground with coastal salt exposure

treated wood and exposure in environments without saltwater general construction

continuous exposure to high humidity and saltwater on treated and untreated wood coastal construction

ESR-4645 certification for Rothoblaas screws permits their design and use in wet service conditions from a structural standpoint according to AC233. However, this certification does not cover corrosion resistance requirements, which must be evaluated separately.

ATMOSPHERIC CORROSIVITY

CLASSES POLLUTION

Corrosion caused by the atmosphere depends on relative humidity, air pollution, chloride content, and whether the connection is internal, external protected, or external. Exposure is described by the C category as following ISO 9223:2012. Atmospheric corrosivity only affects the exposed part of the connector. While the Exposure Conditions partially account for atmospheric corrosivity, it is possible to consider it separately for a more accurate evaluation, using ISO 9223 as a reference.

MOISTURE

WOOD CORROSIVITY CLASSES

Corrosion caused by wood depends on the wood species, wood treatment, and moisture content (see page 354). Exposure is defined by the T category as indicated. The corrosivity of wood only affects the connector part inserted in the wooden element. Although the Exposure Conditions consider wood corrosivity to some extent, it is possible to assess it separately for a more accurate evaluation according to EN 14592:2022.

DISTANCE FROM THE SEA

LEGEND:

TIMBER pH AND TREATMENT

MOISTURE CONTENT OF THE WOOD

MOISTURE CONDITION According to NDS and CSA-O86

use according to regulations

COMPLETE RANGE

HEADS AND TIPS

HEAD TYPE

COUNTERSUNK WITH RIBS

HBS, HBS COIL, HBS EVO C4/C5, HBS S, VGS, VGS EVO C4/C5, VGS A4, SCI A2/A4, SBS, SPP, MBS

FLANGE

TBS , TBS MAX, TBS EVO C4/C5, TBS S, FAS A4

FLAT FLANGE

TBS FRAME

COUNTERSUNK SMOOTH

HTS, DRS, DRT, SKS EVO, SBS A2, SBN, SBN A2, SCI HCR

COUNTERSUNK 60°

SHS, SHS AISI410, HBS H

ROUND

LBS, LBS EVO, LBS H, LBS H EVO

HEXAGONAL

KOP, SKR EVO, VGS, VGS EVO, MTS A2, SAR

CONE-SHAPED

KKT A4 COLOR, KKT A4, KKT COLOR

PAN HEAD

HBS P, HBS P EVO, KKF AISI410

REINFORCED PAN HEAD

HBS PLATE, HBS PLATE EVO, HBS PLATE A4

CONVEX

EWS A2, EWS AISI410,

CYLINDRICAL

VGZ, VGZ EVO C4/C5, VGZ H, DGZ, CTC, MBZ, SBD, KKZ A2, KKZ EVO C5, KKA AISI410, KKA COLOR

BUGLE

DWS, DWS COIL

TIP TYPE

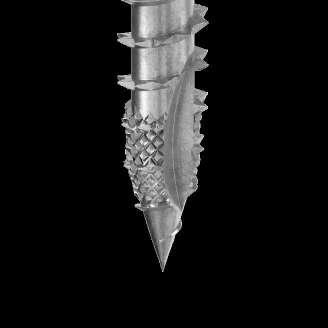

3 THORNS

SELF-DRILLING

SHARP

SHARP SAW

HBS S, TBS S VGS

SHARP SAW NIBS (RBSN)

SHARP 2 CUT

KKT COLOR

STANDARD FOR WOOD

MBS, MBZ, KOP, MTS A2

HARD WOOD TIMBER

HBS H, VGZ H

HARD WOOD (STEEL - to - TIMBER)

LBS H, LBS H EVO

HARD WOOD (DECKING)

KKZ A2, KKZ EVO C5

SKR EVO, SKS EVO

METAL (TAPERED TIP) CONCRETE

SBD

METAL (WITH FINS)

SBS, SBS A2, SPP

METAL (WITHOUT FINS)

SBD, SBN, SBN A2, KKA AISI 410, KKA COLOR

RESEARCH & DEVELOPMENT

Extensive test campaigns carried out in Rothoblaas' own laboratories and at external institutions on softwood, hardwood and LVL have resulted in the development of a performing product in every respect.

Thanks to the 3 THORNS tip, minimum installation distances are reduced. More screws can be used in less space and larger screws in smaller elements. Costs and time for project implementation are reduced.

REDUCTION OF MINIMUM DISTANCES

Featuring raised slitting elements and an umbrella thread tip ensures a quick initial grip and easy installation, reduces torsional stress on the screw and minimises timber damage. The aesthetic finish

LEGEND standard tip standard tip (with pre-drilled hole)

3 THORNS tip self-drilling tip

To be inserted, the screw must overcome the strength force of the wood. The screwing force, measured through the insertion moment (Mins), is only minimised if the tip is performing.

Thanks to its counter-threaded slitting elements, the 3 THORNS tip facilitates insertion of the screw into the grains without damaging them.

It acts as a guide hole, allowing the reduction of edge distances and screw spacing. At the same time, it prevents wooden element's cracking and mechanisms of brittle failure of the connection.

The graph shows the development of the insertion moment for screws with different geometric characteristics of the drill bit and the same boundary conditions (screw diameter, thread length and type, timber substrate material, applied force) as a function of the penetration length (Lins).

The accumulated torsional stress on the screw with a 3 THORNS tip (C) during its insertion is significantly lower than in the case of screws with standard tips (A) and is close to the screwing with pre-drilling hole (B).

The sequence represents the test procedure for the evaluation of minimum distances for axially stressed screws according to EAD 130118-01-0603.

The test is performed by tightening the screw, unscrewing it after 24 hours and filling the hole with dye to check its diffusion inside the wooden element. The portion of wood affected by the insertion of the screw is proportional to the red area.

The 3 THORNS tip (C) exhibits similar behaviour to that of the standard screw inserted with pre-drilling hole (B), tending towards the case of the self-drilling tip screw (D).

standard tip

3 THORNS tip

standard tip (with pre-drilled hole) self-drilling tip

The picture shows the insertion of screws with different tips and shows the change in pull-through depth after 1.0 second of tightening.

COMPLETE RANGE

MATERIALS AND COATINGS

CARBON STEEL WITH COATING

C5 EVO ANTI-CORROSION COATING

Multi-layer coating capable of withstanding outdoor environments classified C5 according to ISO 9223. Salt spray exposure time (SST) according to ISO 9227 greater than 3000h (test carried out on screws previously screwed and unscrewed in Douglas fir).

C4 EVO ANTI-CORROSION COATING

Inorganic-based multilayer coating with a functional outer layer of epoxy matrix with aluminium flakes. Suitability for atmospheric corrosivity class C4 proven by RISE

ORGANIC ANTI-CORROSION COATING

Colored organic-based coating that provides excellent resistance to atmospheric and wood corrosive agents in outdoor applications.

ELECTROLYTIC GALVANIZING

Coating consisting of a layer of electrolytic galvanizing with Cr passivation; standard for most connectors

STAINLESS STEEL

HIGH CORROSION RESISTANT - CRC V

Austenitic stainless steel. It is characterised by high molybdenum and low carbon content. It offers very high resistance to general corrosion, stress corrosion cracking, intergranular corrosion and pitting. The appropriate choice for exposed fasteners in indoor pools.

STAINLESS STEEL A4 | AISI316 - CRC III

Austenitic stainless steel. The presence of molybdenum provides high resistance to generalised and crevice corrosion.

STAINLESS STEEL - A2 | AISI304 - CRC II

Austenitic stainless steel. It is the most common of the austenitic steels. It offers an excellent level of protection against generalised corrosion.

STAINLESS STEEL - A2 | AISI305 - CRC II

Austenitic stainless steel similar to A2 | AISI304. This alloy contains slightly more carbon than A2 | AISI304, making it more workable in production.

AISI410 STAINLESS STEEL

Martensitic stainless steel, characterised by its high carbon content. Suitable for outdoor applications (SC3). This stainless steels offers the highest mechanical performance compared to the other available stainless steels.

LEGEND:

atmospheric corrosivity classes Rothoblaas experience Rothoblaas experience wood corrosivity classes

Atmospheric corrosivity classes defined according to EN 14592:2022 based on EN ISO 9223 and EN 1993-1-4:2014 (for stainless steel, an equivalent atmospheric corrosivity class was determined considering only the influence of chlorides and without a cleaning maintenance). Wood corrosivity classes according to EN 14592:2022.

For further information, see SMARTBOOK TIMBER SCREWS at www.rothoblaas.com.

RESEARCH & DEVELOPMENT

EVO COATINGS

Rothoblaas research projects result in coatings that meet the most complex market requirements. Our goal is to offer state-of-the-art fastening solutions that guarantee uncompromising mechanical strength and corrosion resistance.

Atmospheric corrosivity class C4: areas with a high concentration of pollutants, salts or chlorides. For example, heavily polluted urban and industrial areas and coastal zones.

Inorganic-based multilayer coating with a functional outer layer of epoxy matrix with aluminium flakes.

1440 h

Hours of exposure in salt spray test according to EN ISO 9227:2012 in the absence of red rust.

DISTANCE FROM THE SEA

RESISTANCE TO CHLORIDE EXPOSURE(1) C4 EVO anti-corrosion coating (2) C5 EVO anti-corrosion coating (2)

Atmospheric corrosivity class C5: areas with a very high concentration of salts, chlorides or corrosive agents from production processes. For example, places by the sea or areas of high industrial pollution.

Organic-based multilayer coating with a functional layer. The top-coat has a sealing function, which delays the start of the corrosion reaction.

> 3000 h

Hours of exposure in salt spray test according to EN ISO 9227:2012 in the absence of red rust carried out on previously screwed and unscrewed Douglas fir screws.

(1) C4 and C5 are defined according to EN 14592:2022 based on EN ISO 9223. (2) EN 14592:2022 currently limits the service life of alternative coatings to 15 years.

C4

JOINT TYPES OVERVIEW

HBS, TBS, SHS

TBS, SHS

TBS, SHS

TIMBER

VGS

FULLY

VGS EVO

FULLY THREADED SCREW WITH COUNTERSUNK OR HEXAGONAL

60° COUNTERSUNK SCREW

SMALL HEAD AND 3 THORNS TIP

The 60° head and 3 THORNS tip allow easy insertion of the screw into small thickness elements without creating openings in the timber.

ENLARGED BIT CAVITY

Compared to common carpentry screws, it has a larger Torx cavity: TX 25 for diameters 0.16 inch (#7) and 0.18 inch (#9), TX 30 for diameter 0.20 inch (#11). It is the right screw for users requiring strength and precision.

FASTENING ON TONGUE AND GROOVE BOARDS

For fixing beads or small elements, the 0.14 inch (#6) diameter version is perfectly suited for application in joints. LENGTH [in]

DIAMETER [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

electrogalvanized carbon steel

FIELDS

OF USE

• tongue-and-groove boards

• timber based panels

• fibreboard, MDF, HDF and LDF

• plated and melamine faced panels

• solid timber

• glulam (Glued Laminated Timber) • CLT and LVL

CODES AND DIMENSIONS

3.5 0.14 #6 TX 10 SHS3530 ( * ) 30 1 3/16 20 13/16 3/8

( * ) 40 1 9/16 26 1 1/32 1/2

( * ) 50 1 15/16 34 1 5/16 1/2 500

( * ) 60 2 3/8 40 1 9/16 3/4 500

( * ) Not holding CE marking.

GEOMETRY

in

in - Ø0.18 in - Ø0.20 in

Pre-drilling hole diameter(3)

(1)The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point.

(2) Pre-drilling applies to timber with G≤0.55 (optional).

(3) Pre-drilling applies to timber with G>0.55 (required).

SHS AISI410

60° COUNTERSUNK SCREW

SMALL HEAD AND 3 THORNS TIP

The concealed 60° head and 3 THORNS tip allow easy insertion of the screw into small thickness without creating openings in the timber.

OUTDOOR ON ACID WOOD

Martensitic stainless steel. This stainless steels offers the highest mechanical performance compared to the other available stainless steels. Suitable for outdoor applications and on acid wood, but away from corrosive agents (chlorides, sulphides, etc.).

SMALL ELEMENTS FASTENING

The smaller diameter versions are ideal for fixing beads or small elements, the 0.14 inch (3,5 mm) diameter version is perfectly suited for fastening tongue-and-groove boards.

DIAMETER [in]

LENGTH [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

FIELDS OF USE

• timber based panels • solid timber • glulam (Glued Laminated Timber) • CLT, LVL

•

and acid woods

martensitic

WINDOWS AND DOORS ON THE OUTSIDE

SHS AISI140 is the right choice for fastening small outdoor elements such as beads, façades and window/door frames.

External casing slats fixed with 0.24 and 0.32 inch (6 and 8 mm) diameter SHS AISI410 screws.

GEOMETRY AND MECHANICAL CHARACTERISTICS

Fastening hardwood and acid wood in farfrom-sea environments with SHS AISI410 0.32 inch (8 mm) diameter.

GEOMETRY

(1) The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point.

(2) Pre-drilling applies to timber with G≤0.55 (optional).

(3) Pre-drilling applies to timber with G>0.55 (required).

MECHANICAL PARAMETERS

Ø0.14

d 1 CODE L b A pcs [mm] [in] [mm] [in] [mm] [in] [in]

3,5 0.14 #6 TX 10

SHS3540AS ( * ) 40 1 9/16 26 1 1/32 1/2 500

SHS3550AS ( * ) 50 1 15/16 34 1 5/16 1/2 500

SHS3560AS ( * ) 60 2 3/8 40 1 9/16 3/4 500

4,5 0.18 #9 TX 20

SHS4550AS 50 1 15/16 30 1 3/16 3/4 500

SHS4560AS 60 2 3/8 35 1 3/8 3/4 500

SHS550AS 50 1 15/16 24 15/16 1 200

SHS560AS 60 2 3/8 30 1 3/16 1 200

SHS570AS 70 2 3/4 35 1 3/8 1 1/4 100

SHS4570AS 70 2 3/4 40 1 9/16 1 200 5 0.20 #11 TX 25

80 3 1/8 40 1 9/16 1 1/2 100 SHS5100AS 100 4 50 1 15/16 1 3/4 100 (*) Not evaluated in ERS-4645.

SHS N AISI410 - black version

4,5 0.18 #9 TX 20

SHS4550ASN 50 1 15/16 30 1 3/16 3/4 100

APPLICATION

Possible installation on acid wood but away from corrosive agents (chlorides, sulphides, etc.).

Find out the pH and density of the various wood species on page 354 “aggressive” woods high acidity "standard" timbers low acidity

FAÇADES IN DARK TIMBER

Specially designed to match façades made of charred wood, the black SHS N variant ensures perfect compatibility and offers an excellent aesthetic result. Thanks to its resistance to corrosion, it can be used outdoors, allowing to create striking and long-lasting black façades.

Douglas fir Pseudotsuga menziesii

Red oak Quercus rubra

American black cherry Prunus serotina

Maritime pine Pinus pinaster

Oak Quercus petraea

Oak or European oak Quercus robur

European chestnut Castanea sativa

Blue Douglas fir Pseudotsuga taxifolia

MINIMUM DISTANCES FOR SHEAR LOADS | TIMBER

screws inserted WITHOUT pre-drilled hole

d 1 [in]

a 1 [in] 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 3

a 2 [in]

a3,t [in]

a3,c [in]

[in]

3/8

a 4,c [in] 5∙d 11/16 7/8 1 1 3/16 1 9/16

screws inserted WITHOUT pre-drilled hole

1 [in]

[in] 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 4 3/4

a 2 [in] 5∙d 11/16 7/8 1 1 3/16 1 9/16

a3,t [in] 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 4 3/4

a3,c [in] 10∙d 1 3/8 1 3/4 1 15/16 2 3/8 3 1/8

a 4,t [in] 10∙d 1 3/8 1 3/4 1 15/16 2 3/8 3 1/8

a 4,c [in] 5∙d 11/16 7/8 1 1 3/16 1 9/16

screws inserted WITHOUT pre-drilled hole

d 1 [in] 0.14 0.18 0.20 0.24 0.32 [mm] 3,5 4,5 5 6 8

a 1 [in] 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 4 3/4

a 2 [in] 7∙d 1 1 1/4 1 3/8 1 5/8 2 3/16

a3,t [in] 20∙d 2 3/4 3 1/2 4 4 3/4 6 1/4

a3,c [in] 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 4 3/4 a 4,t [in] 12∙d 1 5/8 2 1/8 2 3/8 2 13/16 3 3/4

10∙d 1 3/8 1 3/4 1 15/16 2 3/8 3

4,5 5 6 8

1 3/8 1 3/4 1

2 3/8 2 3/16 5∙d 11/16 7/8 1 1 3/16 1 9/16 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 4 3/4 10∙d 1 3/8 1 3/4 1 15/16 2 3/8 3 1/8 10∙d 1 3/8 1 3/4 1

a 4,c [in] 7∙d 1 1 1/4 1 3/8 1 5/8 2 3/16 0.14 0.18 0.20 0.24 0.32 3,5 4,5 5 6 8 10∙d 1 3/8 1 3/4 1 15/16 2 3/8 3 1/8 7∙d 1 1 1/4 1 3/8 1 5/8 2 3/16 20∙d 2 3/4 3 1/2 4 4 3/4 6 1/4 15∙d 2 1/16 2 11/16 2 15/16 3 1/2 4 3/4 12∙d 1 5/8 2 1/8 2 3/8 2 13/16 3 3/4 7∙d 1 1 1/4 1 3/8 1 5/8 2 3/16

α = load-to-grain angle

d = d1 = nominal diameter of the screw

screws inserted WITH pre-drilled hole d

α = load-to-grain angle

d = d1 = nominal diameter of the screw

NOTES

• Values in blue are from Table 10 of ESR-4645 (REDUCED CONNECTION GEOMETRY REQUIREMENTS BASED ON TESTING);

• The minimum spacing and distances comply with ESR-4645, where d refers to the nominal diameter of the screw, and are valid for screw installed into sawn lumber, structural glued laminated timber and cross laminated timber;

• Wood member stresses must be checked in accordance with the corresponding Sections of the NDS; end distances, edge distances and fastener spacing may need to be increased accordingly.

Theory, practice and experimental campaigns: our experience is in your hands. Download the SMARTBOOK TIMBER SCREWS.

PRINCIPLES

(1) The embedded thread length does not comply with the minimum requirement of ESR-4645 (6 times the outer thread diameter for screws installed at 90° to the grain and 8 times the outer thread diameter for screws installed at an angle 0°≤ α <90° to the grain).

(2) The embedded thread length does not comply with the minimum requirement of ESR-4645 (8 times the outer thread diameter for screws installed at an angle 0°≤ α <90° to the grain).

NOTES and GENERAL PRINCIPLES on page 33

( * ) Minimum between head pull-through and withdrawal resistance

GENERAL PRINCIPLES

• Tabulated values comply with NATIONAL DESIGN SPECIFICATION FOR WOOD CONSTRUCTION in accordance with ESR-4645.

• To determine allowable loads for use with ASD, design loads for use with LRFD or both, tabulated values must be multiplied by all adjustment factors included in the NDS for dowel-type fasteners.

• As part of the connection design, the structural wood members, the steel plates must be sized and verified in accordance with the corresponding Section of the NDS and must be done separately by the designer.

• Connections with multiple screws must be designed in accordance with the corresponding Sections of the NDS and ESR-4645.

• SHS AISI410 screws must be positioned in accordance with the minimum distances.

• In case of combined axial and shear forces, the designer shall refer to the Hankinson formula, as specified in section 12.4.1 of the NDS, to evaluate the load-bearing capacity.

REFERENCE LATERAL DESIGN VALUES

• Tabulated values are determined from the yield model equations in the corresponding Section of the NDS.

• Unless otherwise noted, the threaded part of the screw is fully inserted in the main member.

• The screw penetration into the main member is minimum 6 times the outer thread diameter unless otherwise noted.

• The reference lateral design values may be determined for other connection configurations in accordance with the corresponding Section of NDS and ESR-4645.

• The reference lateral design values are calculated for screws inserted without pre-drilling hole. In the case of screws inserted with pre-drilling hole, greater resistance values can be obtained.

WOOD-TO-WOOD

• The wood main member thickness must be greater than the screw length minus the thickness of the wood side member.

• The tabulated lateral design values are based on both wood members having the same specific gravity G.

STEEL-TO-WOOD

• The steel side member must have a minimum tensile strength equal to 58 ksi (400 MPa) and comply with the minimum requirements of ASTM A36.

• The wood main member thickness must be greater than the screw length minus the thickness of the steel side member.

• In case of steel-to-wood connection with a thick plate, it is necessary to assess the effects of wood deformations and install the connectors according to the assembly instructions.

REFERENCE WITHDRAWAL DESIGN VALUES

• The reference withdrawal design values (Wref) expressed in pounds-force per inch of thread penetration into the main member for screws installed at an angle of 90° to the grain can be found in the ESR-4645.

• The values for screws installed at an angle α to the grain are determined by multiplying the reference withdrawal design values with the effective thread penetration L eff of the screw in the wood member and with the factor kα : Wα = Wref ∙ kα ∙ L eff

Where:

- Wref is the reference withdrawal design value for screws installed at an angle of 90° to the grain, as shown in the table on the left; - kα factor is calculated as:

γM 1 1.2·cos2(α)+sin2(α)

35˚ < α ≤ 90˚

0˚ ≤ α ≤ 35˚ k α =

0.3+0.7·α 45

- α is the angle between the grain direction and screw axis. Tabulated values at page 27 are valid for L eff equal to the screw thread length b minus the tip length Lt and kα = 1 for α=90°, kα = 0.91 for α= 45°, kα = 0.3 for α = 0°.

• The minimum embedded thread length is 6 times the outer thread diameter for screws installed at 90° to the grain, unless otherwise noted.

• The minimum embedded thread length for screws installed at an angle 0° ≤ α < 90° to the grain is 8 times the outer thread diameter, unless otherwise noted.

• At least four screws must be used in a connection with screws installed in the wood member with an angle between the grain direction and screw axis α ≤ 15°.

• The reference withdrawal design values must be inferior to ftens of the screw.

REFERENCE HEAD PULL-THROUGH DESIGN VALUES

While designing a connection the head pull-through values must be compared with the tensile resistance of the screw and, if necessary, thread withdrawal. The lower value is the governing one.

CONNECTIONS

GENERAL

NOTES

• Designed connections must respect all requirements on general principles and minimum distances.

• Calculations comply with the NDS in accordance with ESR 4645.

• Tabulated values, that are referred to a single fastener, are valid for Allowable Stress Design (ASD) considering a standard loading (CD = 1.0).

• Timber element specific gravity is considered as G = 0.42.

• Z : Force-to-grain angle in the shear plane is considered as 0°.

• Z : Force-to-grain angle in the shear plane is considered as 90°.

• Zm : Force-to-grain angle in the shear plane is considered as 0° for side member and as 90° for main member.

• Z s : Force-to-grain angle in the shear plane is considered as 90° for side member and as 0° for main member.

• For the connectors inserted in the panel’s face, it has been considered the same grain direction as the layer in the shear plane. For the connectors inserted in the panel’s narrow edge, it has been considered the same grain direction as the layer in which the connector is installed.

• For lateral design values the force-to-fastener angle is always considered 90°.

• Typical fastener spacings are declared considering a generic load condition; spacings should be verified and defined according to the real load conditions.

CLT | WALL-TO-WALL | FLOOR-TO-WALL

• The main grain direction of the CLT wall panel is always considered as vertical.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the wall plane.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

CLT | FLOOR-TO-WOOD BEAM

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the beam’s axis.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• Beam element can be considered both solid wood or glulam.

• Double lumber is considered as two coupled element of 2 inches thick.

• The width of the beams must comply with the minimum distance requirements.

• The proposed screw’s length does not exceed the total thickness of the connection. In configurations with no declared value (-) the fastener exceeds the main member depth.

SPLINE JOINT

• Spline thickness is considered to be thinner than the top CLT layer.

• For Root Diameter d 2 >0.25 inch, the bearing strength of the spline is conservatively considered as 3350 psi according to NDS.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the spline’s direction.

• The width of the spline and consequent machining on CLT panel must comply with the minimum distance requirements.

HALF LAP

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the machining’s direction.

• The width of half-lap machining on CLT panel must comply with the minimum distance requirements.

• The proposed screw’s length does not exceed the total thickness of the connection.

BUTT JOINT

• The screw is considered inserted with an angle of 45° between the screw’s axis and CLT plane face.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• The axis of the connector on the shear plane is considered to run through the central layer of the panel.

FULLY THREADED COUNTERSUNK SCREW

3 THORNS TIP

Thanks to the 3 THORNS tip, the screw can be installed without pre-drilling hole on even very thin joinery and furniture wood, such as melamine-faced panels, plated panels or MDF.

FINE THREAD

A fine thread is ideal for utmost screwing precision, even on MDF panels. The cavity for the Torx bit ensures stability and security.

LONG THREAD

The thread is 80% the length of the screw and the smooth part under head guarantees maximum coupling efficiency with fibreboard panels.

DIAMETER [in]

LENGTH [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

electrogalvanized carbon steel

FIELDS OF USE

• timber based panels

• fibreboard, MDF, HDF and LDF

• plated and melamine faced panels

• solid timber

• glulam (Glued Laminated Timber)

• CLT and LVL

CODES AND DIMENSIONS

3 0.12 #5 TX 10

HTS312 ( * ) 12 1/2 6 1/4 1/8 500

HTS316 ( * ) 16 5/8 10 3/8 1/8 500

HTS320 20 13/16 14 9/16 1/8 1000

HTS325 25 1 19 3/4 1/8 1000

HTS330 30 1 3/16 24 15/16 1/8 1000

HTS3516 ( * ) 16 5/8 10 3/8 1/8 1000

HTS3520 ( * ) 20 13/16 14 9/16 1/8 1000

3,5 0.14 #6 TX 15

HTS3525 25 1 19 3/4 1/8 1000

30 1 3/16 24 15/16 1/8 500

35 1 3/8 27 1 1/16 1/4 500

40 1 9/16 32 1 1/4 1/4 500

50 1 15/16 42 1 5/8 1/4 400

25 1 19 3/4 1/8 1000

30 1 3/16 24 15/16 1/8

4 0.16 #7 TX 20 HTS420 ( * ) 20 13/16 14 9/16 1/8 1000

( * ) Not holding CE marking.

GEOMETRY

Pre-drilling hole diameter(2) d V,G≤0.55 [in] -

Pre-drilling hole diameter(3) d V,G>0.55 [in]

(1)The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point.

(2) Pre-drilling applies to timber with G≤0.55 (optional).

(3) Pre-drilling applies to timber with G>0.55 (required).

HINGES AND FURNITURE

1/8

9/64

The total thread and countersunk head geometry are ideal for fastening metal hinges when building furniture. Ideal for use with single bit (included in the package), easily exchanged in the driver bit holder.

The new self-perforating tip increases the initial grip capacity of the screw.

ETA-11/0030 ESR-4645 ELC-4645

ETA-11/0030 UKTA-0836 22/6195

COUNTERSUNK SCREW

3 THORNS TIP

Thanks to the 3 THORNS tip, minimum installation distances are reduced. More screws can be used in less space and larger screws in smaller elements. Costs and time for project implementation are reduced.

FAST

With the 3 THORNS tip, screw grip becomes more reliable and faster, while maintaining the usual mechanical performance. More speed, less effort.

JOINTS WITH SOUNDPROOFING PROFILES

The screw has been tested and characterised in applications with soundproofing layers (XYLOFON) interposed on the shear plane.

The impact of acoustic profiles on the mechanical performance of the HBS screw is described on page 86

NEW-GENERATION TIMBER PRODUCTS

Tested and certified for use on a wide variety of engineered timbers such as CLT, GL, LVL, OSB and beech LVL.

Extremely versatile, the HBS screw guarantees the use of new-generation woods for the creation of increasingly innovative and sustainable structures.

DIAMETER [in]

LENGTH [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

electrogalvanized carbon steel

FIELDS OF USE

• timber based panels

• fibreboard, MDF, HDF and LDF

• plated and melamine faced panels

• glulam (Glued Laminated Timber)

• CLT and LVL

• soft woods (e.g. Spruce, Pine, Western red cedar)

• hard woods (e.g. Douglas Fir, Oak)

CLT, LVL AND HARDWOOD

Values also tested, certified and calculated for CLT, LVL and high density woods such as beech LVL.

Wall insulation boards fastening with THERMOWASHER and HBS 0.32 inch (8 mm) diameter.

GEOMETRY

AND MECHANICAL CHARACTERISTICS

Fastening CLT walls with 0.24 inch (6 mm) diameter HBS screws.

GEOMETRY

Pre-drilling hole diameter(2) d V,G≤0.55 [in]

Pre-drilling hole diameter(3) d V,G>0.55 [in]

(1) The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point.

(2) Pre-drilling applies to timber with G≤0.55 (optional).

(3) Pre-drilling applies to timber with G>0.55 (required).

MECHANICAL PARAMETERS

3,5 0.14 #6 TX 15 HBS3540 40 1 9/16 18 11/16 3/4 500

4 0.16 #7 TX 20

4,5 0.18 #9 TX 20

45 1 3/4 24 15/16 3/4 400

50 1 15/16 24 15/16 1

30 1 3/16 18 11/16 1/4

35 1 3/8 18 11/16 1/4

40 1 9/16 24 15/16 1/4

45 1 3/4 30 1 3/16 1/2 400

50 1 15/16 30 1 3/16 3/4 400

3/8 35 1 3/8 3/4 200

50 1 15/16 30 1 3/16

5 0.20 #11 TX

6 0.24 #14

140 5 1/2 75 2 15/16 2 1/2 100

150 6 75 2 15/16 2 3/4 100 HBS6160 160 6 1/4 75 2 15/16 3 1/4 100 HBS6180 180 7 1/8 75 2 15/16 4 100 HBS6200 200 8 75 2 15/16 4 3/4 100 HBS6220 220 8 5/8 75 2 15/16 5 1/2 100

HBS6240 240 9 1/2 75 2 15/16 6 1/4 100 HBS6260 260 10 1/4 75 2 15/16 7 100 HBS6280 280 11 75 2 15/16 8 100 HBS6300 300 11 3/4 75 2 15/16 8 3/4 100

HBS6320 320 12 5/8 75 2 15/16 9 1/2 100

HBS6340 340 13 3/8 75 2 15/16 10 1/4 100

HBS6360 360 14 1/4 75 2 15/16 11 100

HBS6380 380 15 75 2 15/16 12 100

HBS6400 400 15 3/4 75 2 15/16 12 3/4 100

MINIMUM DISTANCES FOR SHEAR LOADS | TIMBER

screws inserted WITHOUT pre-drilled hole

d1 [in]

[mm] 3,5 4 4,5 5 6 8 10 12

a1 [in] 15∙d 2 1/16 2 3/8 2 11/16 2 15/16 3 1/2 3 1/8 4

a2 [in] 5∙d 11/16 13/16 7/8 1 1 3/16 1 9/16 1 15/16 2 3/8

a3,t [in] 15∙d 2 1/16 2 3/8 2 11/16

[in]

[in]

a 4,c [in] 5∙d 11/16 13/16 7/8 1 1 3/16 1

inserted WITHOUT pre-drilled hole

d 1 [in]

[in] 15∙d 2 1/16 2 3/8 2 11/16 2 15/16 3

a2 [in] 5∙d 11/16 13/16 7/8 1 1 3/16 1 9/16 1 15/16 2 3/8

a3,t [in] 15∙d 2 1/16 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4 6 7 1/8

a3,c [in] 10∙d 1 3/8 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 4 4 3/4

a 4,t [in] 10∙d 1 3/8 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 4 4 3/4 a 4,c [in] 5∙d 11/16 13/16 7/8 1 1 3/16 1 9/16 1 15/16 2 3/8

screws inserted WITHOUT pre-drilled hole

d1 [in] 0.14 0.16

0.20 0.24 0.32

0.48 [mm] 3,5 4 4,5 5 6 8 10 12

a1 [in] 15∙d 2 1/16 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4 6 7 1/8

a2 [in] 7∙d 1 1 1/8 1 1/4 1 3/8 1 5/8 2 3/16 2 3/4 3 5/16

a3,t [in] 20∙d 2 3/4 3 1/8 3 1/2 4 4 3/4 6 1/4 8 9 1/2

a3,c [in] 15∙d 2 1/16 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4 6 7 1/8

a 4,t [in] 12∙d 1 5/8 1 7/8 2 1/8 2 3/8 2 13/16 3 3/4 4 3/4 5 11/16

a 4,c [in] 7∙d 1 1 1/8 1 1/4 1 3/8 1 5/8 2 3/16 2 3/4 3 5/16

α = load-to-grain angle

d = d1 = nominal diameter of the screw

3,5 4 4,5 5 6 8 10 12 10∙d 1 3/8 1 9/16 1 3/4 1 15/16 2 3/8 2 3/16 2 3/4 3 5/16 5∙d 11/16 13/16 7/8 1 1 3/16 1 9/16 1 15/16 2 3/8 15∙d 2 1/16 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4 6 7 1/8 10∙d 1 3/8 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 4 4 3/4 10∙d 1 3/8 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 4 4 3/4 5∙d 11/16 13/16 7/8 1 1 3/16 1 9/16 1 15/16 2 3/8

3,5

screws inserted WITH pre-drilled hole

[mm] 3,5 4 4,5 5 6 8 10 12 a1 [in] 10∙d 1 3/8 1 9/16

a3,t [in]

a3,c [in]

a4,c

α = load-to-grain angle

d = d1 = nominal diameter of the screw

NOTES

• Values in blue are from Table 10 of ESR-4645 (REDUCED CONNECTION GEOMETRY REQUIREMENTS BASED ON TESTING);

• The minimum spacing and distances comply with ESR-4645, where d refers to the nominal diameter of the screw, and are valid for screw installed into sawn lumber, structural glued laminated timber and cross laminated timber;

• Wood member stresses must be checked in accordance with the corresponding Sections of the NDS; end distances, edge distances and fastener spacing may need to be increased accordingly.

PRINCIPLES

REFERENCE LATERAL DESIGN VALUES (Z) | STEEL-TO-WOOD

(1) Main member loaded

(2) Main member

(1) The embedded thread length does not comply with the minimum requirement of ESR-4645 (6 times the outer thread diameter for screws installed at 90° to the grain and 8 times the outer thread diameter for screws installed at an angle 0°≤ α <90° to the grain).

(2) The embedded thread length does not comply with the minimum requirement of ESR-4645 (8 times the outer thread diameter for screws installed at an angle 0°≤ α <90° to the grain).

HEAD PULL-THROUGH (WH) | WOOD

PRINCIPLES

( * ) Minumum between head

GENERAL PRINCIPLES

• Tabulated values comply with NATIONAL DESIGN SPECIFICATION FOR WOOD CONSTRUCTION in accordance with ESR-4645.

• To determine allowable loads for use with ASD, design loads for use with LRFD or both, tabulated values must be multiplied by all adjustment factors included in the NDS for dowel-type fasteners. The design of connection with steel side plate must comply with Section 11.2.3 of the NDS.

• As part of the connection design, the structural wood members, the steel plates must be sized and verified in accordance with the corresponding Section of the NDS and must be done separately by the designer.

• Connections with multiple screws must be designed in accordance with the corresponding Sections of the NDS and ESR-4645.

• HBS screws must be positioned in accordance with the minimum distances.

• In case of combined axial and shear forces, the designer shall refer to the Hankinson formula, as specified in section 12.4.1 of the NDS, to evaluate the load-bearing capacity.

REFERENCE LATERAL DESIGN VALUES

• Tabulated values are determined from the yield model equations in the corresponding Section of the NDS.

• Unless otherwise noted, the threaded part of the screw is fully inserted in the main member.

• The screw penetration into the main member is minimum 6 times the outer thread diameter unless otherwise noted.

• The reference lateral design values may be determined for other connection configurations in accordance with the corresponding Section of NDS and ESR-4645.

• The reference lateral design values are calculated for screws inserted without pre-drilling hole. In the case of screws inserted with pre-drilling hole, greater resistance values can be obtained.

WOOD-TO-WOOD

• The wood main member thickness must be greater than the screw length minus the thickness of the wood side member.

• The tabulated lateral design values are based on both wood members having the same specific gravity G.

STEEL-TO-WOOD

• The steel side member must have a minimum tensile strength equal to 58 ksi (400 MPa) and comply with the minimum requirements of ASTM A36.

• The wood main member thickness must be greater than the screw length minus the thickness of the steel side member.

• In case of steel-to-wood connection with a thick plate, it is necessary to assess the effects of wood deformations and install the connectors according to the assembly instructions.

REFERENCE WITHDRAWAL DESIGN VALUES

• The reference withdrawal design values (Wref) expressed in pounds-force per inch of thread penetration into the main member for screws installed at an angle of 90° to the grain can be found in the ESR-4645.

• The values for screws installed at an angle α to the grain are determined by multiplying the reference withdrawal design values with the effective thread penetration L eff of the screw in the wood member and with the factor kα : Wα = Wref ∙ kα ∙ L eff

Where:

- Wref is the reference withdrawal design value for screws installed at an angle of 90° to the grain, as shown in the table on the left; - kα factor is calculated as:

35˚ < α ≤ 90˚

0˚ ≤ α ≤ 35˚ k α = γM 1 1.2·cos2(α)+sin2(α)

0.3+0.7·α 45

- α is the angle between the grain direction and screw axis.

Tabulated values at page 44 are valid for L eff equal to the screw thread length b minus the tip length Lt and kα = 1 for α=90°, kα = 0.91 for α= 45°, kα = 0.3 for α = 0°.

• The minimum embedded thread length is 6 times the outer thread diameter for screws installed at 90° to the grain, unless otherwise noted.

• The minimum embedded thread length for screws installed at an angle 0° ≤ α < 90° to the grain is 8 times the outer thread diameter, unless otherwise noted.

• At least four screws must be used in a connection with screws installed in the wood member with an angle between the grain direction and screw axis α ≤ 15°.

• The reference withdrawal design values must be inferior to ftens of the screw.

REFERENCE HEAD PULL-THROUGH DESIGN VALUES

While designing a connection the head pull-through values must be compared with the tensile resistance of the screw and, if necessary, thread withdrawal. The lower value is the governing one.

CONNECTIONS

GENERAL NOTES

• Designed connections must respect all requirements on general principles and minimum distances.

• Calculations comply with the NDS in accordance with ESR 4645.

• Tabulated values, that are referred to a single fastener, are valid for Allowable Stress Design (ASD) considering a standard loading (CD = 1.0).

• Timber element specific gravity is considered as G = 0.42.

• Z : Force-to-grain angle in the shear plane is considered as 0°.

• Z : Force-to-grain angle in the shear plane is considered as 90°.

• Zm : Force-to-grain angle in the shear plane is considered as 0° for side member and as 90° for main member.

• Z s : Force-to-grain angle in the shear plane is considered as 90° for side member and as 0° for main member.

• For the connectors inserted in the panel’s face, it has been considered the same grain direction as the layer in the shear plane. For the connectors inserted in the panel’s narrow edge, it has been considered the same grain direction as the layer in which the connector is installed.

• For lateral design values the force-to-fastener angle is always considered 90°.

• Typical fastener spacings are declared considering a generic load condition; spacings should be verified and defined according to the real load conditions.

CLT | WALL-TO-WALL | FLOOR-TO-WALL

• The main grain direction of the CLT wall panel is always considered as vertical.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the wall plane.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strenght of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

CLT | FLOOR-TO-WOOD BEAM

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the beam’s axis.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• Beam element can be considered both solid wood or glulam.

• Double lumber is considered as two coupled element of 2 inches thick.

• The width of the beams must comply with the minimum distance requirements.

• The proposed screw’s length does not exceed the total thickness of the connection. In configurations with no declared value (-) the fastener exceeds the main member depth.

SPLINE JOINT

• Spline thickness is considered to be thinner than the top CLT layer.

• For Root Diameter d 2 >0.25 inch, the bearing strength of the spline is conservatively considered as 3350 psi according to NDS.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the spline’s direction.

• The width of the spline and consequent machining on CLT panel must comply with the minimum distance requirements.

HALF LAP

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the machining’s direction.

• The width of half-lap machining on CLT panel must comply with the minimum distance requirements.

• The proposed screw’s lenghth does not exceed the total thickness of the connection.

BUTT JOINT

• The screw is considered inserted with an angle of 45° between the screw’s axis and CLT plane face.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• The axis of the connector on the shear plane is considered to run through the central layer of the panel.

SCREWING USING CATCH

Place the bit inside the CATCH screwing device and fasten it to the correct depth depending on the chosen connector.

CATCH is suitable with long connectors where the insert would otherwise tend to come out of the screw head space.

PARTIALLY THREADED SCREWS vs FULLY THREADED SCREW

Compressible elements are interposed between two timber beams and a screw is screwed centrally to evaluate its effect on the connection.

APPLICATION ON HARDWOODS

Pre-drill a hole of the required diameter (d V,H) and length equal to the chosen connector size using the SNAIL tip.

RELATED PRODUCTS

The partial thread screw (e.g. HBS) allows the joint to be closed. The threaded portion, inserted all the way inside the second element, allows the first element to slide on the smooth shank.

Install the screw (e.g. HBS).

Useful in case of screwing in corners, which usually do not allow exerting a great screwing force.

The fully threaded screw (e.g. VGZ) transfers the force by exploiting its axial strength and penetrates inside the timber elements without moving.

Alternatively, specific screws for hardwood applications (e.g. HBSH) can be used, which can be inserted without the aid of pre-drill hole

HBS COIL

HBS BOUND SCREWS

QUICK, IN SERIES USE

Quick and precise installation. Fast and safe execution thanks to the special binding.

HBS 0.24 inch

Also available in a diameter of 0.24 inch (#14), ideal for quick wall-to-wall fastening in CLT structures.

FAST

With the 3 THORNS tip, screw grip becomes more reliable and faster, while maintaining the usual mechanical performance. More speed, less effort.

DIAMETER [in]

LENGTH [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

electrogalvanized carbon steel

FIELDS OF USE

• timber based panels

• fibreboard, MDF, HDF and LDF

• plated and melamine faced panels

• solid timber

• glulam (Glued Laminated Timber)

• CLT and LVL

• high density woods

CODES AND DIMENSIONS

[mm] [in]

4 0.16 #7 TX 20

HH10600459(*) 25 1 18 11/16 1/4 - 3000

HZB430 30 1 3/16 16 5/8 9/16 167 3000

HZB440 40 1 9/16 24 15/16 5/8 167 3000 HZB450 50 1 15/16 30 1 3/16 13/16 125 2000

( * )fully-treaded screw

[mm] [in] [mm] [in] [mm] [in] [in] 4,5 0.18 #9 TX 20 HZB4550 50 1 15/16 30 1 3/16 13/16 125 1500 5 0.20 #11 TX 25

GEOMETRY | HZB

hole diameter(2) d V,G≤0.55 [in] -

Pre-drilling hole diameter(3) d V,G>0.55 [in] -

(1)The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point. (2) Pre-drilling applies to timber with G≤0.55 (optional). (3) Pre-drilling applies to timber with G>0.55 (required).

For mechanical properties and structural values see HBS on page 36

Further information on page 429.

ADDITIONAL PRODUCTS Ø0.24 inch HBS COIL APPLICATION

The adapter plates for use of 0.16, 0.18, and 0.20 inch diameter HBS COIL screws are already supplied with the respective screwdriver loaders. To use HBS COIL screws with a diameter of 0.24 inch, the adapter plates supplied must be replaced with the adapter plate HZB6PLATE. For HBS COIL screws diameter 0.24 inch it is also necessary to use the appropriate TX30 bit (code HH14001469).

We recommend using the extension HH14411591 for an easier installation of the screws on horizontal planes.

HBS EVO

COUNTERSUNK SCREW

C4 EVO COATING

Multilayer coating with a surface treatment of epoxy resin and aluminium flakes. No rust after 1440 hours of salt spray exposure test, as per ISO 9227. It can be used for exposure condition 3 outdoor applications and under class C4 atmospheric corrosion conditions tested by the Research Institutes of Sweden - RISE.

3 THORNS TIP

Thanks to the 3 THORNS tip, minimum installation distances are reduced. More screws can be used in less space and larger screws in smaller elements. Costs and time for project implementation are reduced.

PRESSURE TREATED LUMBER

The C4 EVO coating has been certified according to US acceptance criteria AC257 for outdoor use with ACQ-treated timber.

T3 TIMBER CORROSIVITY

Coating suitable for use in applications on wood with an acidity level (pH) greater than 4, such as spruce, larch and pine (see page 354).

DIAMETER [in]

LENGTH [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

FIELDS OF USE

• timber based panels

• solid timber and glulam

• CLT and LVL

• high density woods

• ACQ, CCA treated timber

carbon steel with C4 EVO coating

EXPOSURE CONDITION 3

Certified for use in exposure condition 3 outdoor applications and under class C4 atmospheric corrosion conditions. Ideal for fastening timber framed panels and trusses (Rafter, Truss).

PERGOLAS AND DECKS

The smaller sizes are ideal for securing boards and battens of decks set up outdoors.

CODES AND DIMENSIONS

4 0.16 #7 TX 20 HBSEVO440

4,5 0.18 #9 TX 20 HBSEVO4545 45 1 3/4 30 1 3/16 1/2 400

5 0.20 #11 TX 25

50 1 15/16 30 1 3/16 3/4 200

50 1 15/16 24 15/16 1 200

6 0.24 #14 TX 30

140 5 1/2 75 2 15/16 2 1/2 100

160 6 1/4 75 2 15/16 3 1/4 100

180 7 1/8 75 2 15/16 4

GEOMETRY AND MECHANICAL CHARACTERISTICS

RELATED PRODUCTS

WASHER see page 72

GEOMETRY

(1)The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point.

(2) Pre-drilling applies to timber with G≤0.55 (optional).

(3) Pre-drilling applies to timber with G>0.55 (required).

MECHANICAL PARAMETERS

HUS EVO

MINIMUM DISTANCES FOR SHEAR LOADS | TIMBER

screws inserted WITHOUT pre-drilled hole

d 1 [in]

[in]

a 2 [in]

a3,t [in]

a3,c [in]

a 4,t [in]

4,c [in]

screws inserted WITHOUT pre-drilled hole

1 [in]

a 2 [in] 5∙d 13/16 7/8 1 1 3/16 1 9/16

a3,c [in] 10∙d 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8

a 4,t [in] 10∙d 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8

a 4,c [in] 5∙d 13/16 7/8 1 1 3/16 1 9/16

screws inserted WITHOUT pre-drilled hole

d 1 [in] 0.16 0.18 0.20 0.24 0.32 [mm] 4 4,5 5 6 8

a1 [in] 15∙d 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4

a 2 [in] 7∙d 1 1/8 1 1/4 1 3/8 1 5/8 2 3/16

a3,t [in] 20∙d 3 1/8 3 1/2 4 4 3/4 6 1/4

a3,c [in] 15∙d 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4

a 4,t [in] 12∙d 1 7/8 2 1/8 2 3/8 2 13/16 3 3/4

3

4 3/4 10∙d 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 10∙d 1

<

4 4,5 5 6 8

1 9/16 1 3/4 1 15/16 2 3/8 2 3/16 5∙d 13/16 7/8 1 1 3/16 1 9/16 15∙d 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4 10∙d 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 10∙d 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 5∙d 13/16 7/8 1 1 3/16 1 9/16

a 4,c [in] 7∙d 1 1/8 1 1/4 1 3/8 1 5/8 2 3/16 0.16 0.18 0.20 0.24 0.32 4 4,5 5 6 8 10∙d 1 9/16 1 3/4 1 15/16 2 3/8 3 1/8 7∙d 1 1/8 1 1/4 1 3/8 1 5/8 2 3/16 20∙d 3 1/8 3 1/2 4 4 3/4 6 1/4 15∙d 2 3/8 2 11/16 2 15/16 3 1/2 4 3/4 12∙d 1 7/8 2 1/8 2 3/8 2 13/16 3 3/4 7∙d 1 1/8 1 1/4 1 3/8 1 5/8 2 3/16

α = load-to-grain angle

d = d1 = nominal diameter of the screw

MINIMUM DISTANCES FOR SHEAR LOADS | TIMBER

screws inserted WITH pre-drilled hole

α = load-to-grain angle

d = d1 = nominal diameter of the screw

NOTES

• Values in blue are from Table 10 of ESR-4645 (REDUCED CONNECTION GEOMETRY REQUIREMENTS BASED ON TESTING);

• The minimum spacing and distances comply with ESR-4645, where d refers to the nominal diameter of the screw, and are valid for screw installed into sawn lumber, structural glued laminated timber and cross laminated timber;

• Wood member stresses must be checked in accordance with the corresponding Sections of the NDS; end distances, edge distances and fastener spacing may need to be increased accordingly.

and GENERAL PRINCIPLES

REFERENCE LATERAL DESIGN VALUES (Z) | STEEL-TO-WOOD

(1) Main member loaded parallel to the grain.

(2) Main member loaded perpendicular to the grain.

(1) The embedded thread length does not comply with the minimum requirement of ESR-4645 (6 times the outer thread diameter for

installed at 90° to the grain and 8 times the outer thread diameter for screws installed at an angle 0°≤ α <90° to the grain).

(2) The embedded thread length does not comply with the minimum requirement of ESR-4645 (8 times the outer thread diameter for screws installed at an angle 0°≤ α <90° to the grain).

HEAD PULL-THROUGH (WH) | WOOD

( * ) Minumum between head pull-through and withdrawal resistance

GENERAL PRINCIPLES

• Tabulated values comply with NATIONAL DESIGN SPECIFICATION FOR WOOD CONSTRUCTION in accordance with ESR-4645.

• To determine allowable loads for use with ASD, design loads for use with LRFD or both, tabulated values must be multiplied by all adjustment factors included in the NDS for dowel-type fasteners.

• As part of the connection design, the structural wood members, the steel plates must be sized and verified in accordance with the corresponding Section of the NDS and must be done separately by the designer.

• Connections with multiple screws must be designed in accordance with the corresponding Sections of the NDS and ESR-4645.

• HBS EVO screws must be positioned in accordance with the minimum distances.

• In case of combined axial and shear forces, the designer shall refer to the Hankinson formula, as specified in section 12.4.1 of the NDS, to evaluate the load-bearing capacity.

REFERENCE LATERAL DESIGN VALUES

• Tabulated values are determined from the yield model equations in the corresponding Section of the NDS.

• Unless otherwise noted, the threaded part of the screw is fully inserted in the main member.

• The screw penetration into the main member is minimum 6 times the outer thread diameter unless otherwise noted.

• The reference lateral design values may be determined for other connection configurations in accordance with the corresponding Section of NDS and ESR-4645.

• The reference lateral design values are calculated for screws inserted without pre-drilling hole. In the case of screws inserted with pre-drilling hole, greater resistance values can be obtained.

WOOD-TO-WOOD

• The wood main member thickness must be greater than the screw length minus the thickness of the wood side member.

• The tabulated lateral design values are based on both wood members having the same specific gravity G.

STEEL-TO-WOOD

• The steel side member must have a minimum tensile strength equal to 58 ksi (400 MPa) and comply with the minimum requirements of ASTM A36.

• The wood main member thickness must be greater than the screw length minus the thickness of the steel side member.

• In case of steel-to-wood connection with a thick plate, it is necessary to assess the effects of wood deformations and install the connectors according to the assembly instructions.

REFERENCE WITHDRAWAL DESIGN VALUES

• The reference withdrawal design values (Wref) expressed in pounds-force per inch of thread penetration into the main member for screws installed at an angle of 90° to the grain can be found in the ESR-4645.

• The values for screws installed at an angle α to the grain are determined by multiplying the reference withdrawal design values with the effective thread penetration L eff of the screw in the wood member and with the factor kα : Wα = Wref ∙ kα ∙ L eff

Where:

- Wref is the reference withdrawal design value for screws installed at an angle of 90° to the grain, as shown in the table on the left; - kα factor is calculated as:

γM 1 1.2·cos2(α)+sin2(α)

35˚ < α ≤ 90˚

0˚ ≤ α ≤ 35˚ k α =

0.3+0.7·α 45

- α is the angle between the grain direction and screw axis. Tabulated values at page 61 are valid for L eff equal to the screw thread length b minus the tip length Lt and kα = 1 for α=90°, kα = 0.91 for α= 45°, kα = 0.3 for α = 0°.

• The minimum embedded thread length is 6 times the outer thread diameter for screws installed at 90° to the grain, unless otherwise noted.

• The minimum embedded thread length for screws installed at an angle 0° ≤ α < 90° to the grain is 8 times the outer thread diameter, unless otherwise noted.

• At least four screws must be used in a connection with screws installed in the wood member with an angle between the grain direction and screw axis α ≤ 15°.

• The reference withdrawal design values must be inferior to ftens of the screw.

REFERENCE HEAD PULL-THROUGH DESIGN VALUES

While designing a connection the head pull-through values must be compared with the tensile resistance of the screw and, if necessary, thread withdrawal. The lower value is the governing one.

CONNECTIONS

GENERAL

NOTES

• Designed connections must respect all requirements on general principles and minimum distances.

• Calculations comply with the NDS in accordance with ESR 4645.

• Tabulated values, that are referred to a single fastener, are valid for Allowable Stress Design (ASD) considering a standard loading (CD = 1.0).

• Timber element specific gravity is considered as G = 0.42.

• Z : Force-to-grain angle in the shear plane is considered as 0°.

• Z : Force-to-grain angle in the shear plane is considered as 90°.

• Zm : Force-to-grain angle in the shear plane is considered as 0° for side member and as 90° for main member.

• Z s : Force-to-grain angle in the shear plane is considered as 90° for side member and as 0° for main member.

• For the connectors inserted in the panel’s face, it has been considered the same grain direction as the layer in the shear plane. For the connectors inserted in the panel’s narrow edge, it has been considered the same grain direction as the layer in which the connector is installed.

• For lateral design values the force-to-fastener angle is always considered 90°.

• Typical fastener spacings are declared considering a generic load condition; spacings should be verified and defined according to the real load conditions.

CLT | WALL-TO-WALL | FLOOR-TO-WALL

• The main grain direction of the CLT wall panel is always considered as vertical.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the wall plane.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

CLT | FLOOR-TO-WOOD BEAM

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the beam’s axis.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• Beam element can be considered both solid wood or glulam.

• Double lumber is considered as two coupled element of 2 inches thick.

• The width of the beams must comply with the minimum distance requirements.

• The proposed screw’s length does not exceed the total thickness of the connection. In configurations with no declared value (-) the fastener exceeds the main member depth.

SPLINE JOINT

• Spline thickness is considered to be thinner than the top CLT layer.

• For Root Diameter d 2 >0.25 inch, the bearing strength of the spline is conservatively considered as 3350 psi according to NDS.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the spline’s direction.

• The width of the spline and consequent machining on CLT panel must comply with the minimum distance requirements.

HALF LAP

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the machining’s direction.

• The width of half-lap machining on CLT panel must comply with the minimum distance requirements.

• The proposed screw’s length does not exceed the total thickness of the connection.

BUTT JOINT

• The screw is considered inserted with an angle of 45° between the screw’s axis and CLT plane face.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• The axis of the connector on the shear plane is considered to run through the central layer of the panel.

HBS EVO C5

COUNTERSUNK SCREW

C5 ATMOSPHERIC CORROSIVITY

Multi-layer coating capable of withstanding outdoor environments classified C5 according to ISO 9223. SST (Salt Spray Test) with exposure time greater than 3000h carried out on screws previously screwed and unscrewed in Douglas fir timber.

MAXIMUM STRENGTH

It is the screw of choice when high mechanical performance is required under very adverse environmental and wood corrosive conditions.

3 THORNS TIP

Thanks to the 3 THORNS tip, minimum installation distances are reduced. More screws can be used in less space and larger screws in smaller elements, reducing costs and time.

DIAMETER [in]

[in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

CORROSIVITY

OF USE

• timber based panels • solid timber and glulam • CLT and LVL

• high density woods

C5 C5

CODES AND DIMENSIONS

3,5 0.14 #6 TX 15

HBSEVO3530C5 30 1 3/16 18 11/16 3/8 500

40 1 9/16 18 11/16 3/4 500

4 0.16 #7 TX 20 HBSEVO440C5 40 1 9/16 24 15/16 1/8 500 HBSEVO450C5 50 1 15/16 30 1 3/16 3/4 400

4,5 0.18 #9 TX 20

HBSEVO4550C5 50 1 15/16 30 1 3/16 3/4 200 HBSEVO4560C5 60 2 3/8 35 1 3/8 3/4 200

5 0.20 #11 TX 25 HBSEVO550C5 50 1 15/16 24 15/16 1 200 HBSEVO560C5 60 2 3/8 30 1 3/16 1 200 HBSEVO570C5 70 2 3/4 35 1 3/8 1 1/4

6 0.24 #14

TX 30

see page 72 d 1 CODE L b A pcs [mm] [in] [mm] [in] [mm] [in] [in]

140 5 1/2 75 2 15/16 2 1/2 100

160 6 1/4 75 2 15/16 3 1/4

GEOMETRY

Pre-drilling hole diameter(2)

(1)The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point. (2) Pre-drilling applies to timber with G≤0.55 (optional). (3) Pre-drilling applies to timber with G>0.55 (required).

For minimum distances and structural values see HBS EVO on page 54

TURNED WASHER

HUS

HBS HARDWOOD

COUNTERSUNK SCREW FOR HARDWOODS

HARDWOOD CERTIFICATION

Special tip with diamond geometry and notched, serrated thread. ETA-11/0030 certification for use with high density timber without any pre-drill. Approved for structural applications subject to stresses in any direction vs the grain (α = 0° - 90°).

INCREASED DIAMETER

Internal thread diameter increased to ensure tightening in the highest density woods. Excellent torsional moment values. HBS H Ø0.24 inch, comparable to a 0.28 inch diameter; HBS H Ø0.32 inch, comparable to a 0.35 inch diameter.

60° COUNTERSUNK HEAD

Concealed head, 60°, for effective, minimally invasive insertion, even in high density woods.

HYBRID SOFTWOOD-HARDWOOD

Approved in ETA-11/0030 for different types of applications without the need for pre-drill hole with softwood and hardwood used simultaneously. For example: composite beam (softwood and hardwood) and hybrid engineered timbers (softwood and hardwood).

DIAMETER [in]

LENGTH [in]

EXPOSURE CONDITION

ATMOSPHERIC CORROSIVITY

WOOD CORROSIVITY

MATERIAL

electrogalvanized carbon steel

FIELDS OF USE

• timber based panels

• solid timber and glulam

• CLT and LVL

• high density woods

• beech, oak, cypress, ash, eucalyptus, bamboo

CODES AND DIMENSIONS

6 0.24 #14 TX 30

GEOMETRY

(1)The nominal diameter of the screw is converted into imperial units and rounded up to the nearest decimal point. (2) Pre-drilling applies to timber with G≤0.55 (optional). (3) Pre-drilling applies to timber with G>0.55 (required).

HARDWOOD PERFORMANCE

Geometry developed for high performance and use without pre-drilling on structural woods such as beech, oak, cypress, ash, eucalyptus, bamboo.

BEECH LVL

Values also tested, certified and calculated for high density woods such as beech laminated veneer lumber. Certified for use without pre-drilling, for densities of up to G = 0.88.

TURNED WASHER

COMPATIBILITY

It is the ideal coupling for countersunk-head screws (HBS, VGS, SBS-SPP, SCI, etc.) when the axial strength of the connection is to be increased.

TIMBER-TO-METAL

It is the optimal choice for connections on metal plates with cylindrical holes.

HUS EVO

The HUS EVO version increases the washer's corrosion resistance due to the special surface treatment. This allows it to be used in exposure condition 3 and atmospheric corrosion class C4.

HUS 15°

The 15° angled washer is specifically designed for particular wood-to-metal applications where just a small angle is needed for screw insertion. The HUS BAND double-sided adhesive tape holds the washer in place during overhead applications.

MATERIAL

carbon steel

FIELDS OF USE

• thin or thick metal plates with cylindrical

• timber based panels

solid timber and glulam

CLT and LVL

high density woods aluminium alloy EN AW 6082-T6

CODES AND DIMENSIONS

HUS 15° - 15° angled washer

HUS BAND - double-sided adhesive for HUS washers

CODE d int d ext pcs [mm] [in] [mm] [in]

Compatible with HUS815, HUS10, HUS12, HUS10A4.

HUS - turned washer

GEOMETRY AND MECHANICAL PARAMETERS

HUS EVO - turned washer

HUS A4 - turned washer

GEOMETRY

Washer

HUSEVO8 HUS8A4

Steel plate thickness S PLATE [in] 3/16 - 11/16

(1) The choice of diameter is also linked to the diamter of the screw used.

MECHANICAL PARAMETERS

PRINCIPLES

REFERENCE LATERAL DESIGN VALUES (Z) | STEEL-TO-WOOD

(1) Main member loaded parallel to the grain.

(2) Main member loaded perpendicular to the grain.

SHEAR

( * ) Minumum between head pull-through and withdrawal resistance

SHEAR TENSION SPACING

SHEAR

floor-to-beam

STEEL-TO-WOOD | STEEL COLUMN-TO-WOOD BEAM

STEEL-TO-WOOD | STEEL SIDE PLATE CLT CONNECTION

Drill a D F = 7/8 inch diameter hole in the metal plate at the insertion point of the HUS815 washer.

Drill a guide hole with a diameter of 13/64 inch and a minimum length of 1 inch, preferably using the JIGVGU945 template to ensure the correct installation direction.

We recommend applying HUSBAND adhesive underneath the HUS815 washer to facilitate application.

Install the HBS screw of the desired length. Do not use pulse screw guns. Pay attention when tightening the connection.

STEEL-TIMBER INSTALLATION FROM BELOW

If the clearance (F) is small, the screws are installed using a long insert; both flanges must be drilled.

RELATED PRODUCTS

In this F range, there are not enough long bits and not enough free space for the operator to manoeuvre. The slight inclination of the HUS 15° allows for easy fastening.

Remove the liner and apply the washer at the hole, paying attention to the insertion direction.

Installation completed. The 15° screw angle ensures that the distance to the head of the panel (or beam) is maintained.

When sufficient free space is available for installation, a HUS washer can also be used, within the minimum distances.

GENERAL PRINCIPLES

• Tabulated values comply with NATIONAL DESIGN SPECIFICATION FOR WOOD CONSTRUCTION in accordance with ESR-4645.

• To determine allowable loads for use with ASD, design loads for use with LRFD or both, tabulated values must be multiplied by all adjustment factors included in the NDS for dowel-type fasteners.

• As part of the connection design, the structural wood members, the steel plates must be sized and verified in accordance with the corresponding Section of the NDS and must be done separately by the designer.

• Connections with multiple screws must be designed in accordance with the corresponding Sections of the NDS and ESR-4645.

• HBS screws must be positioned in accordance with the minimum distances.

REFERENCE LATERAL DESIGN VALUES

• Tabulated values are determined from the yield model equations in the corresponding Section of the NDS.

• Unless otherwise noted, the threaded part of the screw is fully inserted in the main member.

• The screw penetration into the main member is minimum 6 times the outer thread diameter unless otherwise noted.

• The reference lateral design values may be determined for other connection configurations in accordance with the corresponding Section of NDS and ESR-4645.

• The reference lateral design values are calculated for screws inserted without pre-drilling hole. In the case of screws inserted with pre-drilling hole, greater resistance values can be obtained.

WOOD-TO-WOOD

• The wood main member thickness must be greater than the screw length minus the thickness of the wood side member.

• The tabulated lateral design values are based on both wood members having the same specific gravity G.

STEEL-TO-WOOD

• The steel side member must have a minimum tensile strength equal to 58 ksi (400 MPa) and comply with the minimum requirements of ASTM A36.

• The wood main member thickness must be greater than the screw length minus the thickness of the steel side member.

• In case of steel-to-wood connection with a thick plate, it is necessary to assess the effects of wood deformations and install the connectors according to the assembly instructions.

REFERENCE WITHDRAWAL DESIGN VALUES

• The reference withdrawal design values (Wref) expressed in pounds-force per inch of thread penetration into the main member for screws installed at an angle of 90° to the grain can be found in the ESR-4645.

• The values for screws installed at an angle α to the grain are determined by multiplying the reference withdrawal design values with the effective thread penetration L eff of the screw in the wood member and with the factor kα : Wα = Wref ∙ kα ∙ L eff

Where:

- Wref is the reference withdrawal design value for screws installed at an angle of 90° to the grain, as shown in the table on the left; - kα factor is calculated as:

35˚ < α ≤ 90˚

0˚ ≤ α ≤ 35˚ k α = γM 1 1.2·cos2(α)+sin2(α) 0.3+0.7·α 45

- α is the angle between the grain direction and screw axis.

Tabulated values at page 44 are valid for L eff equal to the screw thread length b minus the tip length Lt and kα = 1 for α=90°, kα = 0.91 for α= 45°, kα = 0.3 for α = 0°.

• The minimum embedded thread length is 6 times the outer thread diameter for screws installed at 90° to the grain, unless otherwise noted.

• The minimum embedded thread length for screws installed at an angle 0° ≤ α < 90° to the grain is 8 times the outer thread diameter, unless otherwise noted.

• At least four screws must be used in a connection with screws installed in the wood member with an angle between the grain direction and screw axis α ≤ 15°.

• The reference withdrawal design values must be inferior to ftens of the screw.

REFERENCE LATERAL DESIGN VALUES

While designing a connection the head pull-through values must be compared with the tensile resistance of the screw and, if necessary, thread withdrawal. The lower value is the governing one.

CONNECTIONS

GENERAL NOTES

• Designed connections must respect all requirements on general principles and minimum distances.

• Calculations comply with the NDS in accordance with ESR 4645.

• Tabulated values, that are referred to a single fastener, are valid for Allowable Stress Design (ASD) considering a standard loading (CD = 1.0).

• Timber element specific gravity is considered as G = 0.42.

• Z : Force-to-grain angle in the shear plane is considered as 0°.

• Z : Force-to-grain angle in the shear plane is considered as 90°.

• Zm : Force-to-grain angle in the shear plane is considered as 0° for side member and as 90° for main member.

• Z s : Force-to-grain angle in the shear plane is considered as 90° for side member and as 0° for main member.

• For the connectors inserted in the panel’s face, it has been considered the same grain direction as the layer in the shear plane. For the connectors inserted in the panel’s narrow edge, it has been considered the same grain direction as the layer in which the connector is installed.

• For lateral design values the force-to-fastener angle is always considered 90°.

• Resistance values are calculated considering one single screw.

CLT | WALL-TO-WALL | FLOOR-TO-WALL

• The main grain direction of the CLT wall panel is always considered as vertical.

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the wall plane.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

CLT | FLOOR-TO-WOOD BEAM

• The main grain direction of the CLT floor panel is considered both parallel and perpendicular to the beam’s axis.

• The threaded part of the screw has been always considered inserted in the central layer of the CLT panel.

• The withdrawal capacity has been considered as the minimum between thread withdrawal, head-pull through and tensile strength of the screw.

• According to NDS, an end grain coefficient Ceg=0.67 is considered for the lateral resistance calculation due to fastener in narrow edge of CLT.

• Beam element can be considered both solid wood or glulam.

• Double lumber is considered as two coupled element of 2 inches thick.

• The width of the beams must comply with the minimum distance requirements.

• The proposed screw’s length does not exceed the total thickness of the connection. In configurations with no declared value (-) the fastener exceeds the main member depth.

HALF LAP