THE FEEDER

rosendin.com/careers.

rosendin.com/careers.

“If you think you are too small to have an impact, try going to bed with a mosquito.”

Happy Fall, Everyone! We’re approaching that time of year when everyone realizes that the holidays are rapidly approaching. We wonder how the year has gone by so quickly and how we will get everything done before the year ends. For most of us, that means we will push the “easy button” and return to the tried and tested systems and processes that we use to complete our to-do lists and buy all those presents. But perhaps this is the year we shake things up and try a new approach. A little change is always fun, right?

At Rosendin, we always look for ways to improve and change our industry. Our Strategic Plan states that we are going to revolutionize the entire construction industry. To revolutionize the construction industry, we must continually change, regardless of the time of year. We must constantly focus on developing better tools, systems, and processes; this can never stop. And, when you think of our BHAG and the plan to “revolutionize the construction industry while building an unparalleled legacy of opportunity for all,” I ask that you think about the HOW and the WHY associated with accomplishing this goal. To better understand the how and the why, we must realize that to revolutionize; we must embrace change to create the future; change is inevitable.

We work in a very hands-on industry, and our strategic plan covers a lot of truths that can mean something different to everyone. From the engineers working in REVIT to the supervisors working out on the job with their iPads or the wireman with their Fluke meters, tools, systems, and processes affect us all. The first line stated in our Tools, Systems, Processes pillar is critical in understanding what we hope to achieve as we build on this pillar: “We will deliver simple, cutting-edge tools, systems, and processes that enable teams to perform seamlessly at the highest levels.” The key word in this statement is SIMPLE. We must ensure that whatever we develop or implement is simple and has a purpose!

Twenty years ago, only the most senior personnel had laptops. Now, laptops have replaced desktop computers, and the iPad is becoming as standard as a cell phone, which has been a tremendous amount of change in a short time. As we move forward, we must ensure we do not create a tool, system, or process that will bog us down. We cannot have a Foreman stuck sitting in their truck working on their iPad, adding endless data to an app so we can track production.

Look at our recent past, when supervisors had to do timesheets on a spreadsheet and fax them in. We gave them new software and a laptop, and now they have an app that only works on a mobile device. Technology has created positive change, but I feel the true revolution will come when a supervisor does not have to sit down to do an individual’s timesheet. Instead, they will use their iPhone to scan a worker’s RFID badge and a barcode on the pipe they are installing to capture both time and production.

We must be sure that every system or process we create is comprehensive and straightforward, and that the “why” we create is very clear. For example, the dual-switched band saw we developed several years ago with DeWalt had a very clear and defined “why.” We improved a proven and decades-old tool to be notably safer than ever before. The “why” is straightforward: SAFETY. The tool was a very productive and widely used product. Rosendin & DeWalt revolutionized it and made it safe.

Some innovations can be unnoticeable at the outset. In 2008, Rosendin did something briefly revolutionary: When our counterparts in the electrical industry were entrenched with AutoCAD, Rosendin switched to REVIT. We built rigid, cumbersome processes to support our growing BIM needs and were very successful. However, as time passed and technology caught up to Rosendin, the REVIT world became more user-friendly and the industry standard. It did not take long for our revolution to become an industry evolution.

The goal of developing new tools, systems, or processes is not to make our jobs more difficult. We are looking to simplify tasks, create checklists for certainty, and build in safety. A new approach could be as basic as a new way of pulling wire or coupling pipe. Or it could be AI!

We have had a team of people working with AI since 2018 on a system that would predict our projects' financial outcomes. While we are not looking at AI to replace any of our current processes, we envision AI becoming our “Check Engine” light. You know that annoying light that comes on when you think your car is running great but ends up costing you thousands in repairs? We view AI as a way to help identify issues early and address them before they become significant problems. That may require a deep dive into aging change orders or labor overruns to stop the loss. AI will support our team with identifying issues early and tell us where to look with just a few clicks of a mouse. This early warning system will allow our managers to act and limit our exposure.

Let me be clear: we are not trying to light rings of fire like they used to do for tigers in the circus, so our managers can jump through hoops every time we institute a change. We are creating change to help our people perform at a higher level. To grow, we must streamline our processes and procedures.

So, as the year begins to wind down, I encourage you all to think of ways to help streamline the processes in your own lives, not just at Rosendin. Seek ways to help YOU grow and perform at your highest level.

- Anita Roddick -

Mike

of Business Analytics

As many over the age of 40 can attest, the last 20 years in the construction industry have seen rapid advancements in construction technology, means, and methods. Simple improvements, such as power tools, are prevalent on the job site, and more complex developments, such as Building Information Modeling (BIM) software, have become standard. Once used by only a handful of contractors, many of these improvements are now industry-standard.

Rosendin has always prioritized adopting new tools, systems, and processes that will support our goal of making projects safer, more efficient, and cost-effective.

For over 100 years, beginning with the Rosendin Family, Rosendin has implemented tools, systems, and processes as technology advanced and the industry developed or discovered better and safer building methods.

The answer to this question comes in a variety of ways. First and foremost, we learn from feedback from our employees, our customers, and our results. We operate in an environment of constant change. The demands of our customers and the fluidity of the markets we serve require us to focus on continuous improvement in all aspects of our business. For these reasons, our TSPs are never a finished product but only the most current iteration. The next evolution will need to be more efficient and of a higher quality than the last, and if something isn’t working, we can’t be afraid to scrap it and create something better.

Over the last two years, Rosendin's Operational Excellence Team has presented dozens of ideas for TSPs. Six of these have been evaluated, approved, completed, and implemented. These new TSPs are constantly being reviewed to assess their effectiveness and practicality.

It is understood that no two projects are alike, so what may be an effective TSP on one project may not work for another. Personnel changes, project circumstances, and team experience can all impact how a new TSP applies across the company. Rosendin is gathering the data surrounding these new TSPs to help refine and perfect them.

As we continue to see rapid growth across the company, a solid data strategy is more critical than ever. The Technology and Analytics team collects massive amounts of data from all business areas. When using it properly, we can identify trends and gain insights into our operations and customers. In turn, we can identify inefficiencies and correct them to help reduce costs and highlight areas of opportunity that can drive top-line revenues and improved profitability. Collecting the right data, organizing it well, and displaying it in real-time allows us to make better decisions faster.

As Jad Chalhoub, Director of Business Analytics, notes, “It is important to remember that standardization in general, especially data standardization, is a tool, not a goal. Data standardization is important in allowing comparisons when repeated measurements with single variate changes are impossible, which can uniquely benefit construction. Standardization has provided several benefits for Rosendin, depending on where it was applied. For example, standardizing the data points we collect allows us to create reference

points to compare against, especially when integrating new processes or comparing performance across several projects. In construction, even with the same project, the data is rarely static and directly comparable, so standardizing the collected data points enables a way to compare a project’s outcome against its goals and with other projects.”

According to Fred Meeske, Senior Vice President, Rosendin collects a lot of standardized data for both active projects and as metrics for measuring the performance of processes. These metrics allow us to understand the performance of projects related to their stated goals.

“There are countless examples of the use of data throughout Rosendin. Within the BIM department, it has enabled the implementation and use of new conduit routing software, hanger placement processes, and interdepartmental reviews and discussions,” says Meeske. “One of the main differentiators that Rosendin pioneered is connecting multiple data sources into a single funnel, which allowed us to have insights that span multiple departments and business units, which would have previously been impossible.”

Meeske continues, describing how we gather, interpret, and apply the data. “First, Rosendin collects standardized metrics about its internal processes, especially when considering changing or updating them with new tools and software. It is easy to fall for ‘the magic trick‘ or the cool factor behind introducing new solutions. Standardized metrics allow for more direct, analytical, and objective analysis and feedback, allowing us to improve and quantify the improvement continuously.

“Secondly, for teams starting to build data standards and processes, it is essential to keep two things in mind: First, create an interdisciplinary team focusing on easily achievable goals. This will enable you to learn while still providing immediate value. More intricate questions with more effort and time requirements can have a more significant impact, but nothing beats the immediate impact when starting. The team can start tackling more challenging questions once momentum is built and the questions are well-defined.

“Second, and more importantly, build the metrics to be flexible.”

There is a misconception that data is very stringent and static, but in reality, data is very fluid, especially from where it can be collected and generated.

It is essential to connect as many distinct data pieces as possible to enable more interconnectedness and deeper insights in the future. Remember that good foundations will save you significantly more time and effort in the long run, instead of repeating things multiple times.

World Quality Week is coming November 6-10, 2023. This global campaign raises awareness of the quality management profession and focuses on the theme of “Realizing Your Competitive Potential.”

During this week, Rosendin’s Quality Department will provide information, along with lunch-and-learns, on the quality program and how each person plays an essential role in ensuring the delivery of quality projects.

Maintaining a competitive advantage requires more than just operational resilience. Daily toolbox talks will include quality improvement principles and methods to address inefficiencies and how our teams can meet changing customer expectations faster, more economically, and sustainably than the competition.

Remember, QUALITY IS EVERYONE’S RESPONSIBILITY to ensure installations are installed right the first time.

Keep an eye out for some fun swag, a video demonstrating Rosendin’s commitment to quality throughout the construction process, and level up your quality knowledge!

• Has Assisted in Reducing Costs by Being Proactive in Planning Tasks

• Has Exceeded Expectations Through Doing the Right Thing

• Is Focused on Completing Tasks Correctly the First Time

• Emulates Rosendin’s Mission and Core Values

• Is Quality-Minded

NOMINATE TODAY FOR A CHANCE TO WIN PRIZES FROM ONE OF OUR SPONSORS. THREE WINNERS WILL BE ANNOUNCED DURING QUALITY WEEK, NOV 6-10.

Trophies provided by 4 Alarm Promotions

DUAL DRILL SET

LUNCH COOLER

BLUETOOTH SPEAKER

TITLEIST GOLF BALLS

OGIO GOLF BAG

OGIO DUFFEL BAG

YETI TUMBLER

SUBMIT NOMINEES BY OCTOBER 25TH

Simply scan the QR code and fill out the form.

PADDLEBOARDS

ANYONE WORKING FOR ROSENDIN CAN PARTICIPATE IN THE PROGRAM THROUGH THE NOMINATION FORM.

BUILDING QUALITY | BUILDING VALUE | BUILDING PEOPLE®

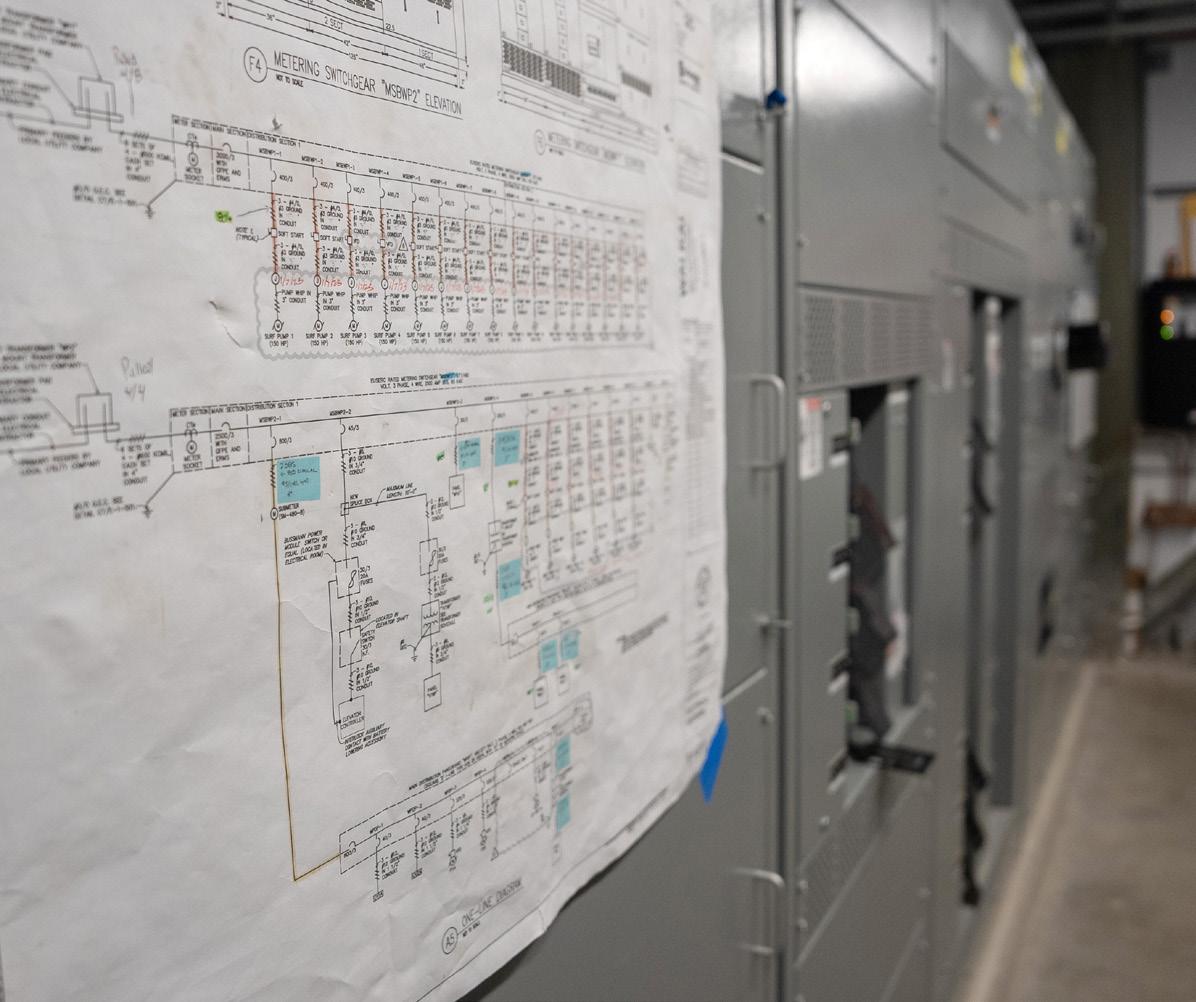

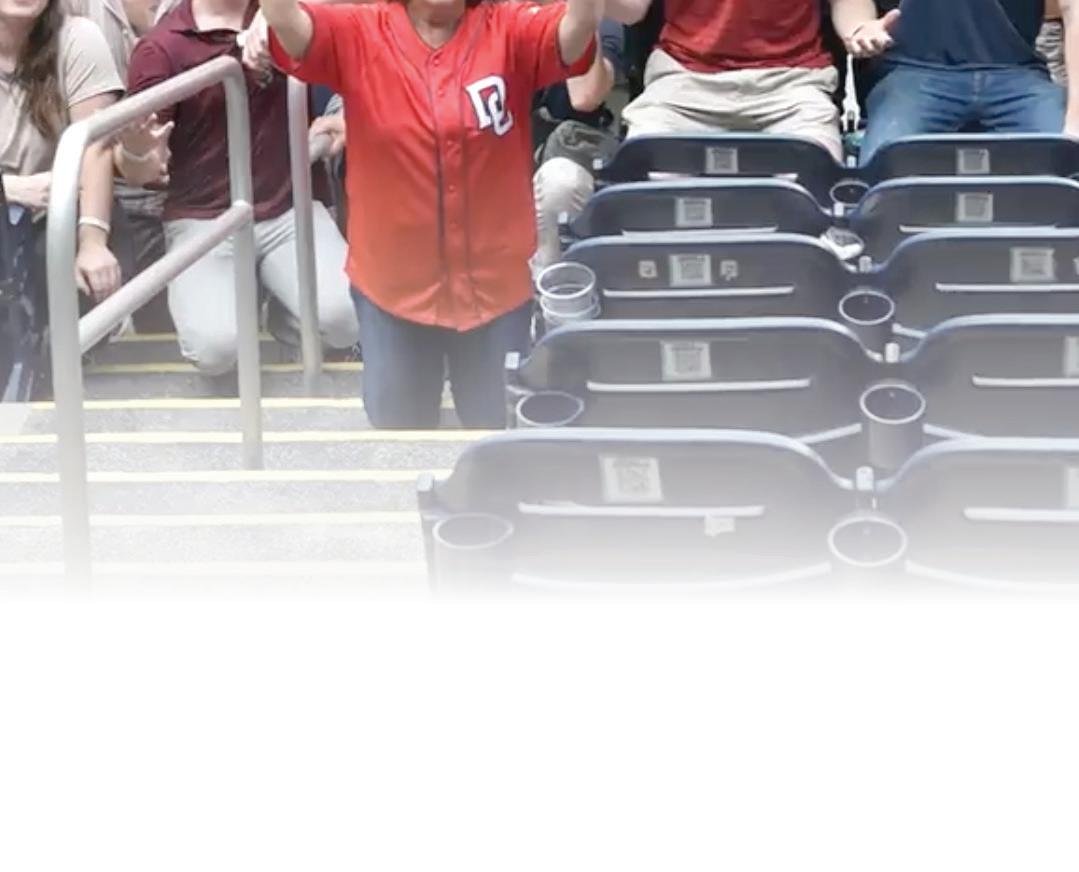

The $5 billion SoFi Stadium at Hollywood Park covers over 2.8 million square feet in Inglewood, California. Home to the LA Rams and LA Chargers, the NFL’s first indoor-outdoor stadium features a massive video display board and a sprawling roof canopy. The Rosendin-Meadows Joint Venture (RMJV) scope required approximately 1.9 million IBEW labor hours over four years to complete the project. The men and women of IBEW Local 11 reached stunning numbers, installing the following:

• 797 miles of branch raceway

• 317 miles of feeder raceway

• 1,729 miles of branch wire

• 605 miles of feeder wire

• 40 miles of HV/Med cable

• 5 miles of grounding cable

• 63,192 light fixtures

LOCATION: Inglewood, CA

CLIENT: STADCO LA LLC

GENERAL CONTRACTOR: Turner/AECOM-Hunt JV

ARCHITECT: HKS Architects, Inc.

DURATION: 43 Months

BUDGET: $343,562,721

SIZE: 2.8M SF

One of the RMJV Team's most significant achievements in the construction of the stadium is the team’s safety record and community impact. The team received the Golden Gate Partnership Award from the Cal/ OSHA Consultation Services Branch of the State of California Department of Industrial Relations. With a peak of 500 craft workers on site, the RMJV team is proud to have hired 176 local hires totaling 404,451 hours, among the City of Inglewood, Lennox, and adjacent areas. Employing local citizens and providing a safe work environment, particularly during a pandemic, provided an immediate positive economic and community impact. In the long term, SoFi Stadium will continue providing community jobs.

From a construction and design perspective, the pure complexity of the building is impressive. The roof structure and canopy extend over two additional independent structures: American Airlines Plaza and a 6,000seat performance venue. Under the LAX flight path, three venues under one roof required the construction team to dig down 100 feet to lower the stadium bowl, which presented a project challenge that the RMJV team was more than ready to accommodate.

SoFi Stadium is a seismic feat, as it features three structures: a moat wall, a roof structure, and a bowl. In the event of an earthquake, the bowl will move independently of the site and independently of the roof, lessening the effects of the earthquake on the adjacent structures. Certain blade columns have bearings that can also

absorb the shock of an earthquake, and an extensive seismic monitoring system is installed.

Arguably, the centerpiece of SoFi Stadium is the Oculus video board. Coming in at 2.2 million pounds and featuring 70,000 square feet of LED screens, it is the largest video board ever and is the only dual-sided, center-hung video board ever created.

The canopy that stretches over the stadium and beyond has led to the Rams billing SoFi Stadium as the NFL’s first indoor-outdoor stadium. The design protects attendees from the heat and allows Southern California breezes to drift throughout the structure.

Made of ethylene tetrafluoroethylene (ETFE), a lightweight and transparent plastic, the canopy sits over 200’ above the field level, consisting of 46 operable panels that, when retracted, create (16) 60’ X 60’ openings and (14) 30’ X 30’ edge panel openings. Twenty-four thousand programable LED lights provide a spectacular nighttime light show. The RMJV team installed the electrical systems that power the drivers supplying power to the lights and the operations section of the roof.

Another significant challenge in constructing the 875,000 SF roof is that the image on the roof is the same if the roof is open or closed. The way this works is that when the panel is closed, the strings are off. When the panel opens, the strings turn on and replace the image of the closed operable panel. When the operable panel opens, it covers a section of the roof. The

operable panel covers the stationary section; when this happens, it turns off, and the operable panel shifts its image to replace the stationary section. That is how the desired projected image is maintained. The RMJV team installed the LED on the stringers under the operable panel.

The challenge of installing the roof canopy offered an opportunity for the RMJV team to collaborate closely with the other partners on the roof team. The acceptable date for design completion of the roof LED lights (to not affect the construction schedule) was May 2019. However, the scope was approved in September 2019, with the final design not receiving approval until April 2020, one year after the original date and two months after the coronavirus pandemic began to impact California.

The plan was for a day-two system, meaning it would not be complete by the original occupancy date. However, the RMJV team was informed in May 2020 that both systems would need to be fully functional by the first game on August 14, 2020, since the operable roof system was in the original contract. Both systems needed be installed at the same time, or the LED lights would not be functional until a later date due to the testing and commissioning requirements. The RMJV team coordinated with all trades, revised the installation sequence to complete the roof in quadrants, and started the commissioning early. Together, the team had the LEDs working one week before opening day.

LOCATION: Ewa Beach, HI

CLIENT: Wai Kai Commercial Development, LLC

GENERAL CONTRACTOR: Layton Construction

BUDGET: $6.9 Million

SIZE: 277,356 SF

Wai Kai Recreational Facility opened in late March 2023, bringing a unique form of recreation to Hoakalei Resort in Ewa Beach. Wai Kai is a year-round facility that features the Wai Kai Wave, and an adjacent Wai Kai Lagoon.

Rosendin provided construction of all electrical, telecom, and AV rough-in for the retail, dining, and entertainment center at Hoakalei Resort in Ewa Beach. The complex comprises five one and two-story buildings totaling 277,356 SF and overlooking the resort’s 52-acre recreational lagoon. The buildings are a combination of concrete, structural steel, light gauge framing and trusses, and glulam timber construction. Rosendin’s scope included the core and shell for six buildings, wave pool buildout, power to the pool pumps, wave pool grounding, restaurant buildout, and low voltage pathways for controls.

The centerpiece attraction is the “The LineUp at Wai Kai,” the world’s largest deep-water standing surf wave. The wave pool is 100 feet wide and adjustable from two to six feet high. Up to 100 surfers per lane can enjoy waves that mimic natural standing river waves from famous locations, including Oahu’s Waimea River. The lagoon offers watersport craft rentals, Duffy boat cruises, and floating cabanas.

The facility is also focused on sustainability efforts.

The LineUp at Wai Kai is proudly working with Sustainable Surf and its Hawaii-based SeaTrees program. For every guest activity booking on the Wai Kai Wave or the Wai Kai Lagoon, one dollar is donated to the SeaTrees program to provide support for the restoration of coral reefs, coastal watersheds, kelp forests, mangroves, and educational programs. Each token purchased sequesters one ton of carbon emissions through double-certified carbon credits and restores one square foot of coastal watershed on Maui. Additionally, Wai Kai operates with a no single-use plastic policy, and all disposable products must be 100 percent BPI-certified compostable. Sustainable options for grab-and-go packaging include Sustainable Island Products and Mananalu Water.

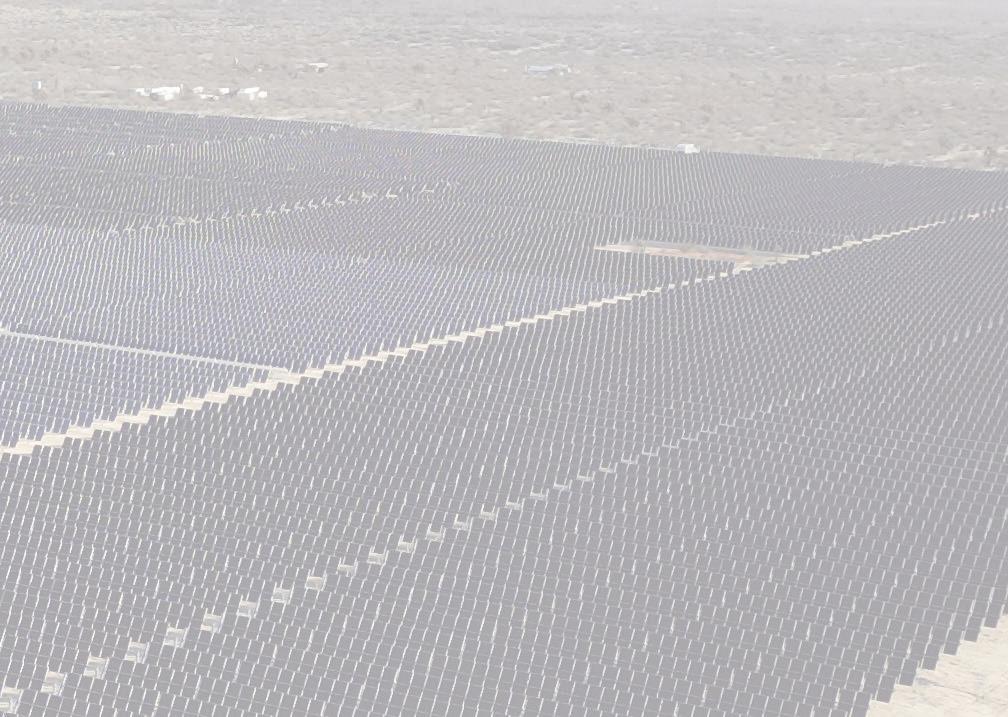

140MW Solar Energy

18,000 Households Provided with Clean Power BY THE NUMBERS

80MWh Energy Storage Systems

Rosendin’s Renewable Energy Group (RREG) received a 2023 NECA Project Excellence Award in the Design-Build Projects category Over $1 Million for the Gaskell West 2 and 3 project.

Gaskell West 2 and 3 is a solar-plus-storage project in Kern County, California. The project includes 140 MWdc (104 MWac) of solar energy and 80 MWh energy storage systems. The projects are fully contracted, holding five long-term power purchase agreements (PPA) with utilities and cities in California, and provide enough clean power for 18,000 California households. Construction on the solar-plus-storage facilities lasted nine months and reached commercial operations on May 5, 2023.

Click on the video link below to watch the construction process of this solar project in the Southern California Mojave Desert.

Top 30 Under 30 Award

Daniela Diaz, APM (TX) EC&M

Top 30 Under 30 Award

Paola Morales, APM (TN) EC&M

Top 40 Under 40 Award

Alissa Bautista, PM (HI) Pacific Business News

2023 Best Projects Award Excellence in Sustainability 1021 O Street O ce Building ENR (California)

2023 Best Projects Award Government/Public Building 1021 O Street O ce Building ENR (California)

#1 - Top Specialty Contracting Firms (Electrical) ENR (Southwest)

#1 - Top Specialty Contracting Firms (Total Value of Work Worldwide) ENR (Southwest)

#2 - Southwest Top Specialty Contracting Firms ENR (Southwest)

#6 - Top Specialty Contractor (Electrical) ENR (Southeast)

#11 - Top Specialty Contractor (North Carolina) ENR (Southeast)

#13 - Southeast Top Specialty Contracting Firms ENR (Southeast)

#2 - Top Specialty Contracting Firms (Arizona) ENR (Southwest)

In Quarter 3, 2023, Rosendin received seven awards from industry organizations including EC&M, Pacific Business News, and ENR. Daniela Diaz and Paola Morales received Top 30 Under 30 Awards and Alissa Bautista received a Top 40 Under 40 Award. Additionally, Rosendin received 10 industry rankings.

To learn more about the headlines Rosendin is making, visit rosendin.com/newsroom.

2023 Project Excellence Award Design-Build Over $1M Gaskell West 2 & 3 NECA (Orange County Chapter)

Excellence in Quality Award Sterling VA Compass Project Team Hensel Phelps

#5 - 2023 Top California

#4 - Electrical Contractors List Pacific Business News

Solar Contractors

Solar Power World

#17 - Largest Charlotte-Area Electrical Contractors Charlotte Business Journal

August marked the end of yet another successful summer intern program at Rosendin offices and project sites nationwide. The program kicked off on June 13th in San Jose, CA, with Intern Week for all first-time interns.

Students new to Rosendin’s internship program spent several days in San Jose, getting to know each other through team builders and activities while learning about Rosendin’s business. They received hands-on training, walked a few Rosendin projects in the Bay Area, and finished their time building bikes for deserving children through Odyssey Teams.

The interns then deployed across the country to Rosendin offices and project sites to meet returning interns and begin exploring a career in construction.

The intern program ran for approximately 12 weeks, with weekly lunch-and-learns providing an opportunity for students to learn about various departments and functions within Rosendin, while also gaining valuable experience, fulfilling college requirements, and expanding their professional connections. After successful program completion, first-, second-, and third-year interns were invited back for the following summer, while some fourth-year interns received offers for full-time employment.

Rosendin’s intern program is currently accepting applications and closes at the end of March 2024.

If you or someone you know may be interested in an internship, visit rosendin.com/careers/open-positi ons.

• 37 Colleges Represented

• 70 Interns Across the Country

• 17 Returning Interns

• 9 Hired as Part-Time Student Workers

• 25% Of 2023 Interns are Now Full-Time Employees

• 60+ Interns to Full-Time Employees Over the Past 5 Years

In 2021, Rosendin established a Workforce Development Team dedicated to developing the next generation of the electrical contracting workforce. Over the last two years, this team has grown to allow team members to connect with students from early middle school through college across the country.

The Workforce Development Team is integral to Rosendin's efforts to address the skilled craft labor shortage in the United States. Rosendin works locally with our International Brotherhood of Electrical Workers (IBEW) partners to inform young men and women about the opportunities and careers that await them in the electrical trade. By attending career fairs at local high schools, our teams educate students on the skilled trade training offered by an apprenticeship and how that translates to financial independence.

Since 2018, Rosendin's Arizona office has sponsored and participated in the annual Arizona Construction Career Days (AZCCD), which supports the growing need for students, teachers, and career counselors to better understand the many career opportunities available in the Construction Industry. AZCCD is the largest construction event that reaches out to high school students throughout the State of Arizona, to give students a handson construction experience.

Rosendin's Virginia office has partnered with Loudoun County Public Schools (LCPS) for nearly ten years, participating in their annual Job for a Day (JFD) program. This day-long event allows 11th-12th grade students to shadow individual(s) or a business/organization in person. Rosendin volunteers talk to students 1:1 as they learn/observe the tasks and responsibilities necessary for a particular career cluster, field, or job.

Rosendin's Oregon team partners with several high schools in the greater Portland metropolitan area to provide students with Early Learning Opportunities (ELO), while Rosendin team members also provide externships on weekends for educators to help them understand the career options available to their students. The success of these partnerships encouraged Rosendin's Maryland office to offer their first teacher externship this past summer.

The efforts to inform parents and students of career opportunities in the construction industry are for more than just high school age. The Rosendin Foundation (TRF), the charitable arm of Rosendin Holdings, launched TRF Camp Build in 2023, a construction camp experience geared to middle school students. In its inception, three Rosendin offices in Tempe, AZ, Gallatin, TN, and Austin, TX participated in week-long camps, while the Anaheim, CA office participated in a one-day camp, and Modular Power Solutions in Sherman, TX provided a two-day camp. These camps gave students the chance to learn a variety of skilled trades basics from volunteers at Rosendin and with other trade partners. These skills include:

• Personal Safety

• Electrical

• Concrete/Rebar

• Soldering, Pipe Bending

• BIM (Building Information Modeling)

• Heavy Equipment Operation

• Framing/Woodworking

• Roofing/Painting

The TRF Camp Build program will return next summer and expand to additional Rosendin offices.

In addition, Rosendin partnered with Grand Canyon University in 2022 for a Pre-Apprenticeship for Electricians program. The inaugural class included 40 students in the one-semester program. The courses included hands-on, real-world applications, and when completed, students were prepared to move into an IBEW electrician apprenticeship and begin a professional career in a growing field. From the first class, 38 students were accepted into the apprenticeship.

Rosendin's Workforce Development Team continues to work hard to discover ways to develop the next generation of construction leaders.

We continued to live our core values and fulfill our mission as we wrapped up our first season of TRF Camp Build with weeklong camps in Gallatin, Tempe, and Austin. What a transformative experience for our campers where they gained not just experience working with tools and building, but confidence and competence. Bravo to the entire TRF Camp Build committee and volunteers for a job well done! Our sponsor partners supported not just financially and with in-kind donations, but also by providing volunteers to share their knowledge and skills with this next generation of potential builders. If you are interested in reliving camp, check out our YouTube channel.

Thank you to our volunteers who continue to positively impact the community through service days. Our Rosendin and MPS teams volunteered with troubled teens, wrote letters to the military, fed the hungry, fed families with children facing critical health issues, cleaned up veteran retreat centers, collected books, and gave their own lifesaving blood. If you are interested in helping to plan a local service activity, please reach out to the local TRF Communication Committee Representative and join our local team. Join us to get out into our communities to positively impact communities, build and empower people, and inspire innovation.

In addition to serving our community, TRF's Grant Making Committee is hard at work reviewing the 262 annual grant applications that were received. We saw a 74% increase in applications over last year with a requested value of over $7.8M. The Committee is allocating $620,000 to the selected local nonprofits that positively impact our communities, build and empower people, and inspire innovation. In the Q4 newsletter, we will share information on the 2023 Annual Grant recipients. of potential builders. If you are interested in centers, collected books, and gave their own in applications over last year with a requested positively impact our communities, build and the Q4 newsletter, we will share information

In Q3, TRF's Board approved the distribution of five emergency grants to the following nonprofits:

- Children's Advocacy Center for North Texas (new school outreach about child abuse)

- RAIN, Inc. (repair carport hangout space and ensure a pathway to laundry services is safe)

- Maui Food Bank (wildfire relief efforts)

- Hawaii Community Foundation Maui Strong Fund (wildfire relief efforts)

- Arc of Maui County (relocation of disabled clients from Lahaina to Wailuku due to wildfire)

A shoutout to TRF's Fundraising Committee and Golf Tournament subcommittee who exceeded our goal for the 2023 TRF Golf Tournament. This year, TRF raised $295,580, which is $34,734 more than we did in 2022! A special thank you to the Rosendin Holdings Board Members for individually donating and supporting our fundraising efforts. We would also like to thank our generous sponsors for donating items for the tee bags: Milwaukee Tool, Herc Rentals, Chubb, Cigna, Stanley Black and Decker, Commerce Bank, and Hornito's. Also, thank you to our auction and raffle donors. Without your support, we would not have been able to raise over $20,000.

Finally, in August, the TRF Board voted to approve the 2024-2027 Focus Area of Health: Emotional, Nutritional, and Occupational. Thank you to everyone who participated in our survey and roadshows and provided feedback. The consensus was to remain in our current focus area for an additional three years.

The community of service we have developed and continue to grow leaves me in awe. Thank you for joining us in building a community of service.

Jolsna Thomas President

Interested in joining our Who Supports Us list?

Rosendin & MPS employees Visit our website donation page Visit our intranet page

to make a tax-deductible donation through your paycheck which Rosendin will match 100% for employees.

Click, or use the QR code above, to visit the TRF BetterUnite site to become a sponsor and be part of this amazing event. Sponsorships for

Annual Sponsor

Name

55

9 46

Score of the ed first-place groups. Well done to Graphic Ideals & Rosendin/McCarthy!

Number of addi onal sponsors from last year.

Date Team

Number of unique sponsors that helped to make the golf tournament a success.

82

36 104

Course We-Ko-Pa Golf Club The Rosendin Foundation 9/25/2023

The temperature at 8 a.m. tee off me, when the tournament got underway.

Number of live and silent auc on items donated.

Number of mulligan ckets sold

Number of raffle ckets sold.

Number of items in raffle.

This year's tournament was an improvement over last year's. We listened to our golfers and volunteers and excelled in making this year’s tournament an even greater success. We will continue to improve the experience for everyone who participates and strive to improve our fundraising efforts. Get ready for next year!

Foursomes sold out in less than 2 months!

Revenue was up 12% for a total revenue of $295,580! We beat our fundraising goal by 31%!

THANK YOU TO OUR 2023 SPONSORS!

World Mental Health Month aims to address mental health issues in an empathetic way. The construction industry seeks to raise awareness of the unique challenges workers face in construction that lead to suicide and what we can do to prevent it.

• Suicide is the 12th leading cause of death in the U.S.

According to the Centers for Disease Control and Prevention

• In 2020, there were 1.20 million suicide attempts.

• While women are more likely to attempt suicide, in 2020 men were 3.88 times more likely to die from suicide.

Verbal warning signs

• Talking about being a burden, or the world being better without them.

• Expressing the desire to no longer exist or die.

warning signs

• No longer able to find joy or pleasure in things they once enjoyed.

• Emotional outbursts (anger, sadness, anxiety, etc.) happen frequently or without warning.

• Sudden joy or excitement after prolonged periods of depression.

Behavioral warning signs

• Frequent mood swings.

• Giving away their belongings.

• Sleeping all the time or changes in eating habits.

• If you or someone you care for is at a really low point, help is always available. You can call or text to reach the National Suicide Prevention Lifeline's trained counselors directly.

Call or text 988 for the National Suicide Prevention Lifeline.

Open Enrollment is the only time of year (outside of a qualifying life event) that employees can:

• Enroll in plans

• Decline coverage

• Add or remove dependents

• Change between plans/insurance carriers

• Renew or waive medical, dental, vision, and/or voluntary coverages

Flexible Spending Account (FSA) and Health Savings Account (HSA) participants:

• If you are a current FSA participant and want to participate in the 2024 plan year, you must re-enroll and elect your FSA Medical or FSA Dependent contributions.

• If you are a current HSA participant and want to continue contributing to your HSA account in the 2024 plan year, you must re-elect your annual contribution.

All Rosendin ESOP Participants are encouraged to create an account with Principal. If you have not created your account, follow these simple steps:

1. Visit www.principal.com and select "Log In."

2. At the bottom of the log in screen, click "Create an Account" and complete the form.

3. Once logged in, you will have the ability to view your ESOP account at any time.

4. For assistance in reviewing or updating your beneficiary(ies), please contact your HR Representative.

October is Employee Ownership Month (EOM)—a month-long celebration of the undeniable benefits employee ownership provides to employees, companies, local communities, and the nation.

Rosendin is celebrating Employee Ownership Month all month with activities aimed at increasing ESOP awareness as well as providing employee owners a chance to enjoy some tasty treats and quality time with fellow employee owners.

Rosendin is proud to be employee-owned, and our entire team carries a sense of accountability for the successes we experience. Our employee-owners see their personal value in the company and understand their responsibility. We all have a stake in our future and are motivated and empowered to provide the very best value and service. Congratulati ons to the following individuals who became 100% vested during Quarter 3!

Project Manager

Anaheim, California

9 years

Core Clarity: Stabilizer

Hidden Talent: I have an eidetic memory

WHAT IS YOUR FAVORITE PART OF YOUR JOB?

Working with people. I love people, and I love problem solving as a team, and celebrating victories together. I love walking the jobsite and knowing almost every face that I pass by.

Managing Director/Vice President - MPS

Lewisville, Texas

18 years

Core Clarity: Force of Nature

Hidden Talent: Super Dad

‘‘

WHAT IS YOUR FAVORITE PART OF YOUR JOB?

I really enjoy building relationships. Whether that is with customers, employees, or vendors, relationships are what drive business and make work enjoyable. Building trust provides a level of freedom and confidence that is very rewarding. Working with teams to solve problems in innovative ways while being enabled to try and try again until it is perfected is something I don’t think most careers offer.

Getting to know your Rosendin family

Associate Compensation Analyst

San Jose, California

5 years

Core Clarity: Passionato

Hidden Talent: Keyboard, Guitar, Singing

WHAT IS YOUR FAVORITE PART OF YOUR JOB?

Working with data and analyzing numbers is simply amazing and fun. It's fascinating to learn about the different geographical regions where our employees are located and the unique stories that come with them. By gathering this information, we're able to provide invaluable support to our managers and help them make the right decisions when it comes to hiring, promotions, salary adjustments, and more.

Project Manager

Tempe, Arizona

5 years

Core Clarity: Illuminario

Hidden Talent: Solving license plates!

WHAT IS YOUR FAVORITE PART OF YOUR JOB?

Interacting with GC’s and Clients. Being on site and seeing the action happen!

Are you posting photos about the great work you are doing? We want to see it too! Tag Rosendin on your posts so the Marketing Team can reshare to Rosendin’s social channels, or use our hashtags #Rosendin or #LeadInspireBuild.

Follow, like, and connect with Rosendin on social media to see the projects our teams are working on and learn about how we honor and celebrate equality and diversity. Explore our services and the markets we’re in and see how our people are impacting the communities where we work and live. You can also discover job opportunities available with our teams across the country.

Maybe you don’t like to post, but you have some great photos that you would like to share. Email marketi ng@rosendin.com and the Marketing Team will take it from there.

Did you see the great things we are accomplishing through Diversity, Equity, & Inclusion? If you are interested in participating in any initiatives associated with our Culture of Care Program, please reach out to the DE&I Committee Chair at sroldan@rosendin.com.

Just ask! The Marketing Team is here to assist you with all things social media. Just email or give us a call.

If you are interested in submitting an article for the next Corporate Newsletter, please contact marketi ng@rosendin.com. The Rosendin Corporate newsletter is intended for an internal and external audience. Do not include information related to an NDA or that contains proprietary information.

ESOP Month

Hispanic Heritage Month Careers in Construction Month

Suicide Prevention Month

Oct 9

Oct 8-11

Oct 10

Oct 13

Oct 16-20

Indigenous People's Day

7x24 Exchange Fall Conference

Mental Health Day

U.S. Navy Birthday

National Construction Inclusion Week

Oct 21 Sweetest Day

Dec 13 U.S. National Guard Birthday

Dec 25 Christmas Holiday - OFFICES CLOSED

Dec 31 New Year's Eve

American Indian Heritage Month

Nov 1-3

Nov 5

Nov 6-10

Nov 8

DBIA Annual Conference

Daylight Savings Time Ends

International Quality Week

National STEM/STEAM Day

Nov 10 U.S. Marine Corps Birthday

Nov 11

Veteran's Day

Nov 13-19 Apprenticeship Week

Nov 23-24 Thanksgiving Holiday - OFFICES CLOSED

Nov 28 Giving Tuesday (TRF)