The Re:Tool-Kit for Detroit

project began with the question, “what can get made in Detroit?” The objective of the research has been to gather insights about the skills and services available in the city today by conducting interviews with people who make things, resulting in this handbook for good communication practices between designers and fabricators. Our goal to better understand how fabrication in Detroit is evolving, and to facilitate collaboration between the design and fabrication communities has informed this effort, which begins with this book, and continues into the future with an on-line version at www.retoolkitdetroit.org.

This project is made possible by a grant from Alan and Cynthia Berkshire at Taubman College at the University of Michigan. The principal investigators are Heidi Beebe, Seth Ellis, John Marshall, and Julia McMorrough.

EDSELFORDFWY

18 05 19 41 34 44 36 28 29 PONYRIDE 40 42 47 39 RUSSELL INDUSTRIAL CENTER 17 33 35 31 24 MEXICAN TOWN, SOUTHWEST DETROIT VIRGINIA PARK PETOSKY OSTEGO BRIGGS CORE CITY EASTERN MARKET WEST SIDE INDUSTRIAL LAFAYETTE PARK ELMWOOD PARK FOREST PARK WAYNE STATE UNIVERSITY WAYNE STATE UNIVERSITY CCS MCFARLAND SPRINGWELLS 1 1 3 375 53 10 10 10 5 94 94 94 94 75 12 CHRYSLER FWY CHRYSLER FWY WOODWARD AVE WOODWARD AVE OUELLETE UNITEDSTATES CANADA GRATIOT AVE GRANDRIVERAVE FORDRD FORDRD JEFFRIESFWY MICHIGAN AVE MICHIGAN AVE FISHER FWY WVERNORHWY EVERNOR FISHERFWY ELAFAYETTEST MACK EJEFFERSONAVE MC DOUGAL ST MT. ELLIOTT ST DIX AVE CENTRAL ST LIVER NOIS ST EDSELFORDFWY

75 75 96 96 HOLBROOK TIREMAN ST W. WARREN AVE EWARRENAVE EWARRENAVE NORTH END www. retoolkitdetroit. org

Re: Tool-Kit for Detroit

Heidi Beebe

McMorrough Re:Tool-Kit for Detroit Beebe, Ellis, Marshall, McMorrough University of Michigan 2013

Seth Ellis John Marshall Julia

Re:Tool-Kit for Detroit_INTRODUCTION

1 18 05 19 41 34 44 36 28 29 PONYRIDE 40 42 47 39 RUSSELL INDUSTRIAL CENTER 17 33 35 31 24 TOWN, BRIGGS EASTERN MARKET WEST SIDE INDUSTRIAL LAFAYETTE PARK ELMWOOD PARK FOREST PARK WAYNE STATE UNIVERSITY WAYNE STATE UNIVERSITY CCS 1 1 3 375 53 10 10 10 94 94 75 CHRYSLER FWY CHRYSLER FWY WOODWARD AVE WOODWARD AVE OUELLETE UNITEDSTATES CANADA GRATIOT AVE MICHIGAN AVE FISHER FWY HWY FISHERFWY ELAFAYETTEST EJEFFERSONAVE MC DOUGAL ST EDSELFORDFWY 75 75 EWARRENAVE EWARRENAVE NORTH END Re:Tool-Kit for Detroit A Study of Making Principal Investigators Heidi Beebe Seth Ellis John Marshall Julia McMorrough This project is made possible by a grant from Alan and Cynthia Berkshire at Taubman College at the University of Michigan.

The Re-Tool-Kit for Detroit set out to assess what is being made in Detroit, today. In the summer of 2012, we conducted 50 interviews with Detroit area fabricators. What we captured was a fleeting moment. Old shops are evolving or closing while new shops are opening, and new types of makers are moving in. Although every attempt has been made to ensure that the information in this book is accurate to the best of our knowledge at the time of printing, it is subject to change. The way things are made and the tools that are used do not amount to a static data set; shops can expand, shrink or move.

This book is a record of that fleeting moment, and while it cannot accommodate changing input, an accompanying website (retoolkitdetroit.org) has been established to move forward with an expanded database of shops, and the ability to track an evolving landscape.

Re:Tool-Kit for Detroit_INTRODUCTION 2

RESEARCH TEAM

PRINCIPAL INVESTIGATORS

Project Management and Research Coordination: Heidi Beebe, Taubman College of Architecture and Urban Planning Project Direction: John Marshall, Penny W. Stamps School of Art and Design Graphic Design: Julia McMorrough, Taubman College of Architecture and Urban Planning Digital Analysis: Seth Ellis, Penny W. Stamps School of Art and Design

RESEARCH ASSISTANTS

Historian: Michael P. McCulloch Project Assistant: Erika Lindsay Graphics Assistant: Pooja Dalal

Student Researchers: Melissa Ablin Casey Carter Hannah Hunt Moeller William Martin

UROP Students: Anna Buzolits Mariah Gardziola

Except as noted, all illustrations and photographs are those of the Re:Tool-Kit team

copyright © 2013 by Heidi Beebe, Seth Ellis, John Marshall and Julia McMorrough ‘Made in Detroit’ essays copyright © 2013 by Michael P. McCulloch All rights reserved

3

ACKNOWLEDGMENTS

Re:Tool-Kit for Detroit_INTRODUCTION 4

SPECIAL THANKS

Donors

Alan and Cynthia Berkshire

University of Michigan

Taubman College of Architecture and Urban Planning

Monica Ponce de Leon, Dean

John McMorrough, Chair, Architecture Program

Penny W. Stamps School of Art and Design

Gunalan Nadarajan, Dean

To all the makers and fabricators who graciously offered their time and insights to this project, we offer sincere gratitude. In addition to those in this book, thanks go to the following:

Michael Coleman, College for Creative Studies

Mariana Nakashima, University of Detroit Mercy

Robert Hutchinson, University of Detroit Mercy

Albert Young, Michigan Hot Glass Workshop

Andre Sandifer, Ali Sandifer

Andrew Zago, Zago Architecture

Andy Kem of Kem3D

Anthony Reale, AReale Detroit

Bill Massie, Cranbrook Academy of Art Architect in Residence

Cathlyn Newell, Alibi Studio

Cezanne Charles, ArtServe Michigan

Cheryl Baxter, Cranbrook Academy of Art M.Arch

Chris Gordon, Wilson Student Team Project Center, UMich College of Engineering

Chris Palmer, Cranbrook Academy of Art MFA

Dana Nelson at All Hands Active

Dale Grover, Maker Works

Doug Skidmore, Beebe Skidmore Architects

Francesco Reale AReale Detroit

Gail Hohner, Multidisciplinary Design Team, UMich College of Engineering

Jason Burton, Tech Shop Dearborn

Jodi Burton, Tech Shop Dearborn

Jeff Baxter, Borrough Furnace

Jeff Sturges, Mt. Elliot Makerspace

Malik Goodwin, Detroit Economic Growth Corporation

Maria Nicanor, BMW Guggenheim Lab

Matt Clayson, DC3 Detroit Creative Corridor Center

Michael Lee, Wilson Student Team Project Center, UMich College of Engineering

Scott Berels, Tech Shop Dearborn

Thea Augustina Eck, Maker Works

Tom Root, Maker Works

Will Brick, Tech Shop Dearborn

5

Re:Tool-Kit for Detroit_INTRODUCTION 6

CONTENTS

Introductions

What Can You Get Made in Detroit? - Heidi Beebe Post-Industrial Futures - John Marshall

Made in Detroit: Ten Stories From the Early Twentieth Century - Michael P. McCulloch Pictures Unite - Julia McMorrough Google Narratives - Seth Ellis

Symbol Guide

“Research Through Making” at Pewabic Pottery Precision and Interchangeability Maps of Shops

Casting, Rolling and Smelting: Diversity in Metalwork The Automobile as Art

Directory of Shops

Craftwork and Commerce: Symbolic Ornament at the Guardian Building Craft Multiculturalism

Timeline Morris in Detroit: Selling and Exhibiting Craftworks Kiln Sharing at Flint Faience Case Studies

Re:Tooling for War Production A New Spirit to Lead Us: Art and the End of War and Consumerism Bibliography

“Made in Detroit” essays by Michael P. McCulloch]

7

08 10 12 14 16 19

34 36 62 64 66 174 176 178 180 182 184 244 246 248

32

[all

What Can You Get Made in Detroit?

Heidi Beebe

Making is the identity of Detroit. Even before the rise of the automotive industry, Detroit was already a city that made many things. The phrase “You can get ANYTHING made in Detroit” is still heard often, even today in the face of an eroded population, rampant outsourcing and the decline of the American automotive industry. The Re: Tool-Kit for Detroit research project questions the veracity of this claim. What is really being made today? Who is making it? Where are they making it? And how is the landscape of making evolving at this moment in response to urban, economic, and technological changes?

Research for this project centered around 50 hour-long interviews with Detroit area fabricators, conducted in their workshops during the summer of 2012 by a team of five University of Michigan graduate students. Participants were drawn from a working database of 400 fabrication shops collected via internet directories, driving around the city, and recommendations from local fabricators and other Detroiters who make things and get things made. Interviewers were asked 35 questions along 8 themes: 1) what is made 2) what tools and skills are required, 3) how does the business work - number of employees, batch size, scale and finish of products, and customer base, 4) when did the shop start and how has it changed over time, 5) does the shop “collaborate,” 6) is the shop capable of making something different than they make today, 7) how does one find the right fabricator for a job in Detroit, and 8) how does being in Detroit affect the work.

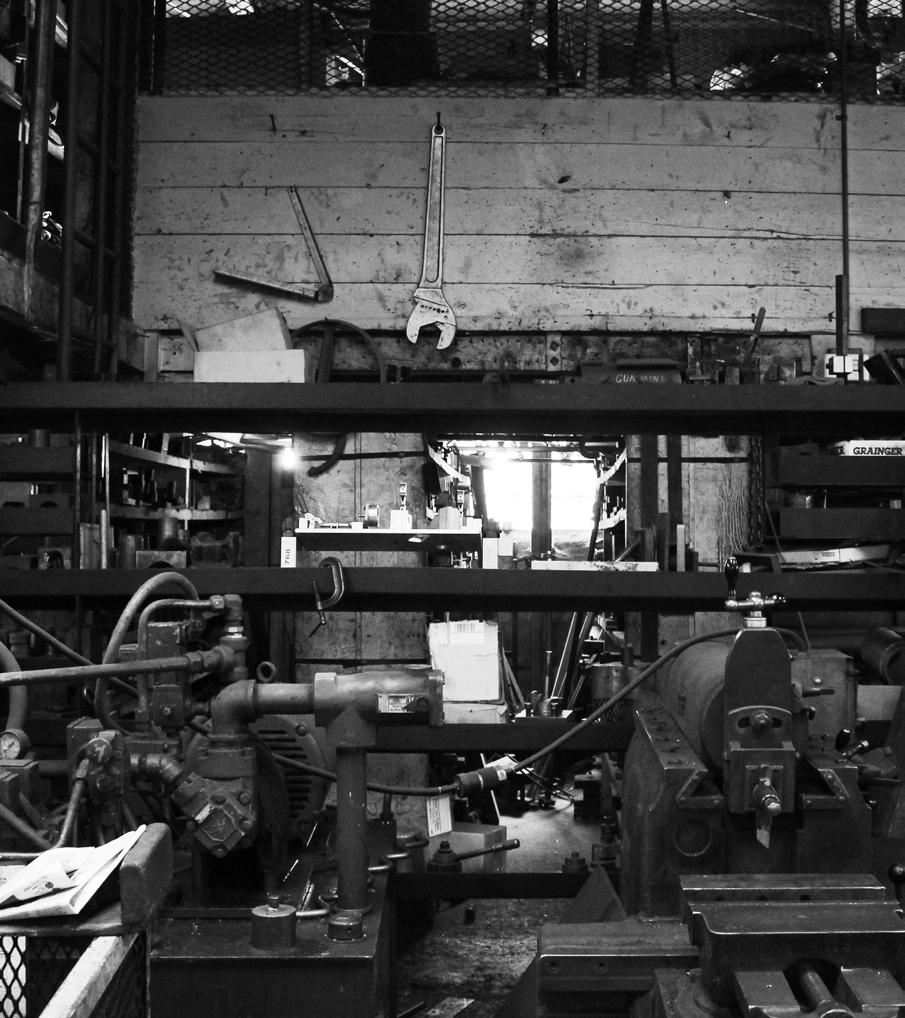

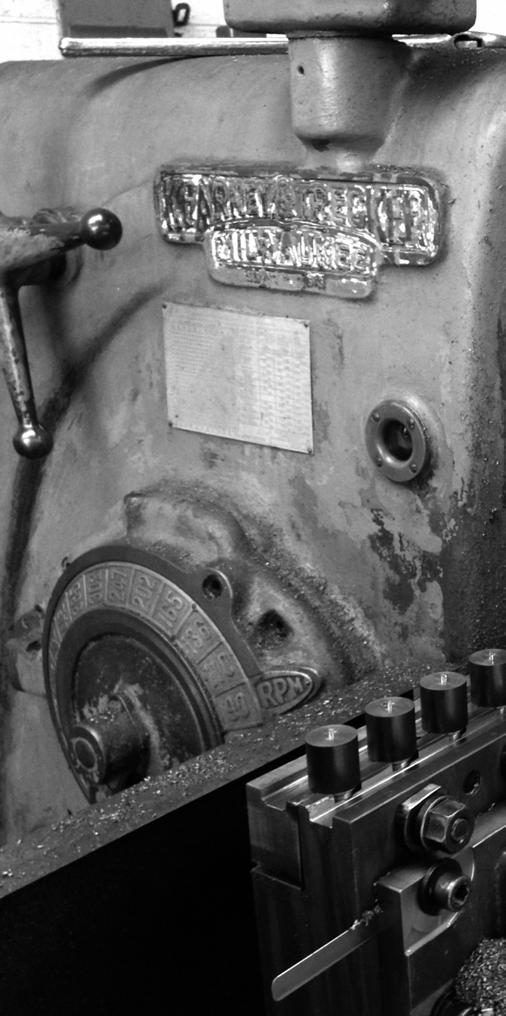

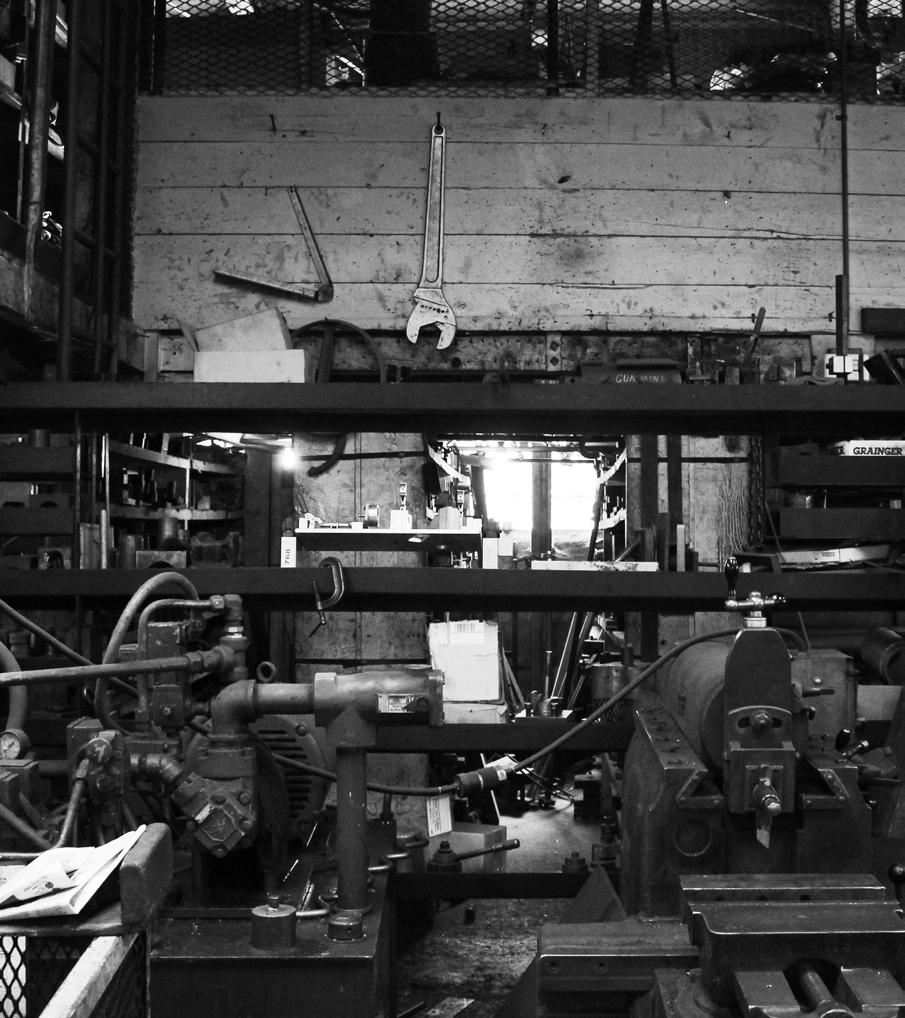

The team interviewed shops that had been in business for over a century –started in a garage before the invention of the automobile and then passed on from grandfather to son to daughter. Several shops interviewed are newly established by craft-based entrepreneurs who moved here to participate in the city’s revival through making. Some shops use state-of-the art tools and specialize in prototypes and low volume production or high-tech work for aerospace and defense. Other shops had not purchased a new machine

Re:Tool-Kit for Detroit_INTRODUCTION 8

INTRODUCTION

in 43 years. Many were working at less than 20% capacity. Data gathered assesses the state of making in Detroit at this fleeting moment. Within the sixmonth span of our research, one shop caught on fire and another relocated outside of city limits. The interviews provide insights into the people that make things here, and the great impacts -- both positive and negative -- that the city of Detroit has had upon their work and business.

Although the Re:Tool-Kit was in part motivated by skepticism about the notion that one could still get anything made in Detroit, it was also driven by curiosity and a desire to better understand both the city of Detroit and the world of fabrication. Fabrication networks, and the city itself, are somewhat illegible to outsiders. Façades are closed to the street. Entrances are through the back door. Buildings are spread far apart on wide and fast moving streets. Many shops are completely barricaded by security fencing. It is possible to see where buildings are missing or in a state of disrepair, but its much harder to see any clue as to what is going on inside these buildings, not to mention what is being made there. As in most American cities, fabrication businesses concentrate along transportation corridors in light industrial areas populated with durable workshop buildings, often windowless. The invisibility of making and fabrication may not be unique to Detroit, but it might be argued that the culture of fabrication has added to the illegibility of Detroit. In the heyday of the automotive industry, many small-scale fabricators produced specialized products in large batches for recurring clients. Business was, and still is, conducted within well-established networks.

From the outset, the Re:Tool-Kit assumed that despite the state of the economy, there is a wealth of knowledge, know-how and human capacity in Detroit. If the existing fabrication capacity and making network can be rendered visible to a larger audience, a new generation of designer/makers, and a developing movement toward craft-based entrepreneurialism, making could become not only the identity of Detroit, but also its future.

To complement the ethnographic, interview-based study, and in an effort to encourage new forays, collaborations, and relationships by making fabrication shops and products findable, the Re:Tool-Kit is creating two primary products—an online map and this book. The map is web-based, interactive and open to new information. The tool-kit is a book that can be downloaded or printed on demand. It is designed to demystify fabrication for non-fabricators and contains stories, histories, a map, and a directory that explain what is made in the 50 shops we interviewed, how they make it, what tools and materials they use, and other interesting observations about their trades and the city. It is intended to both inspire design students about what is possible in Detroit and encourage the uninitiated to engage with Detroit’s current fabrication capacity.

9

Post-Industrial Futures

John Marshall

Detroit is known around the world for three things: automobiles, great music and (unfortunately) industrial collapse. Both of the former are connected to the American Dream, the latter is as yet unresolved and will likely determine the future of the richest society on earth. Within this only one thing is certain - that the future will be discontinuous with the past.

The impact of technological developments on manufacturing is changing the way products are designed, produced, and distributed. Many of these developments are founded on the integration of disruptive technologies and means of distribution via the Internet - just ask Kodak, Blockbuster, Yellow Pages or any former ‘record label’ (the term itself is outmoded). Networked technologies can connect ideas, designs and people to revolutionize the process of production and innovation. Supply-chain manufacturers and individual makers may now operate in the same market space and can cooperate, or compete. Consumers are no longer merely passive but can actively participate and drive the product development processes of big business. The cost of tools is decreasing almost as fast as their capabilities are increasing. As the use of digital technologies has become more widespread, new companies and indeed new business models have been established to meet the manufacturing needs of diverse industries.

The crumbling auto plants of Detroit are stark signifiers of the changes that have taken place over recent decades. However, throughout the making of Re:Tool Kit for Detroit we have discovered that it is still possible to get (almost) anything made in Detroit, today. There may be fewer people working in manufacturing but the industrial heart of Detroit is still beating. The military and biotech industries are more sought-after as clients than the ‘Big-3’ automakers - past transgressions and future insecurities play a part in this. Industrial manufacturing historically compelled a separation of design and production which resulted in producing large numbers of standardized prod-

Re:Tool-Kit for Detroit_INTRODUCTION 10

INTRODUCTION

ucts displaying minimum variation. More recently, digital technologies have afforded alternatives to this model. Through adopting these technologies, the processes of design and production have been brought closer together. This is the model of production used by a new generation of hipster-makers that are electing to stay on in the city or move there after college. Organized in collectives, these multi-disciplinarians eschew traditional entry-level job descriptions and are repurposing the industrial fabric of the city to their own ends.

Perhaps the greatest threat to Detroit’s post-industrial revival is its residents’ instinctive autoimmune response to non-natives, outsiders and transplants. The culture in Detroit is based on word-of-mouth and an insistence on personal endorsement. The worst an outsider can do is express missionary zeal to “help” Detroit. Inevitably, there will be cultural opportunism and some of those that come will make the mistake of thinking that the city represents a tabula rasa. Detroiters can, and should be more tolerant of this - the future might depend on it. The most positive change would be to embrace ‘Detroitbased’ initiatives, even by non-natives.

Both Glasgow and Manchester in the UK are examples of cities that learned this lesson to great effect. Between the 1960’s - 1980’s both UK cities experienced more than 30% population loss. This was mainly from manufacturing decline and by the 1980’s both experienced threats from the increasing globalization of key traditional industries (steel-based and textile-based, respectively). Both cities have engaged in culture-led urban regeneration to achieve more sustainable development (for example: Glasgow European City of Culture, 1990; Glasgow City of Architecture and Design, 1999; Commonwealth Games, 2002; new regional arts infrastructure (North West Development Agency), 1999; and the relocation of 2,300 BBC jobs to Salford, 2012).

Although it can be argued that the costs of these cultural projects were often borne by those who could least afford it, Glasgow and Manchester have successfully transformed the perception of themselves to culturally-driven, cities capable of attracting and sustaining citizens from around the world without abandoning their heritage or distinctiveness. Detroit can also do this.

Detroit - and by that we mean heavy manufacturing - is not ‘coming back’ anytime soon. The world has moved beyond that model of production. The potential for the present is for Detroiters to remake their city in the image of the values its citizens hold dear. Then Detroit will be known for three things: automobiles, great music and being the world’s first 21st Century city.

11

Made in Detroit: Ten

Stories from the Early Twentieth Century

Michael P. McCulloch

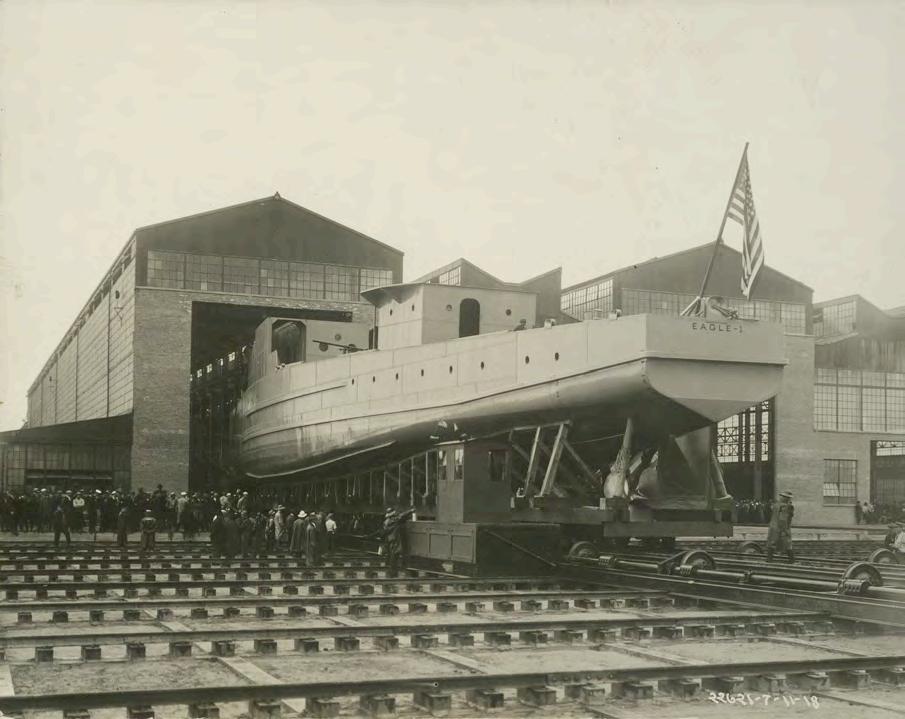

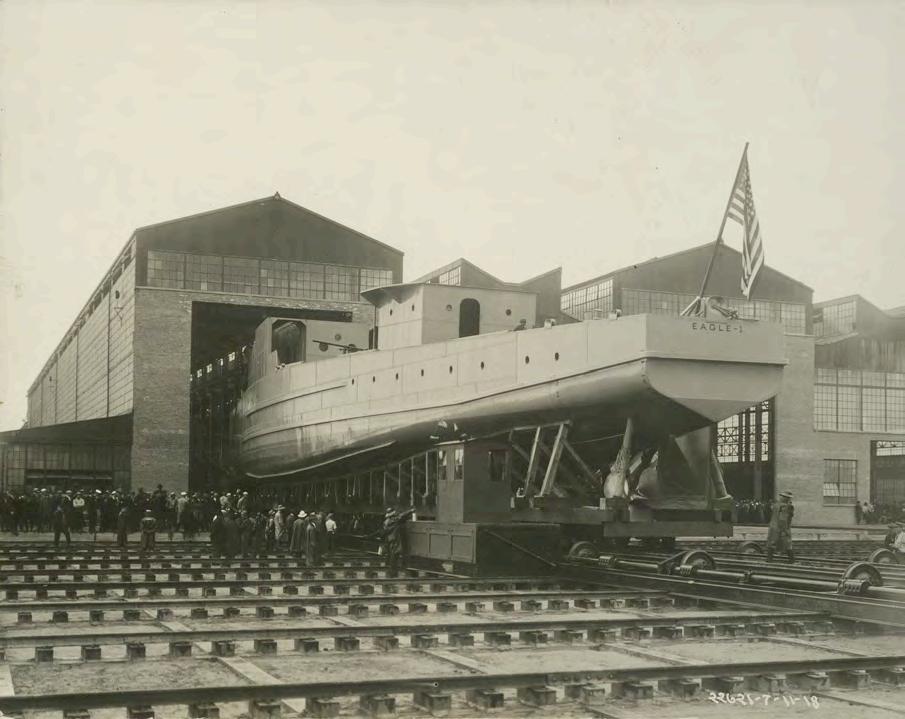

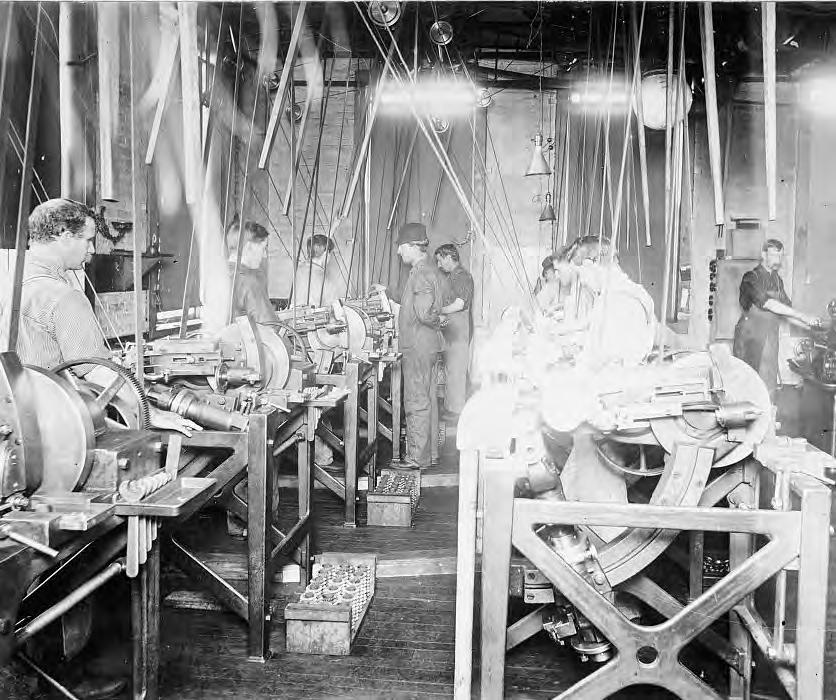

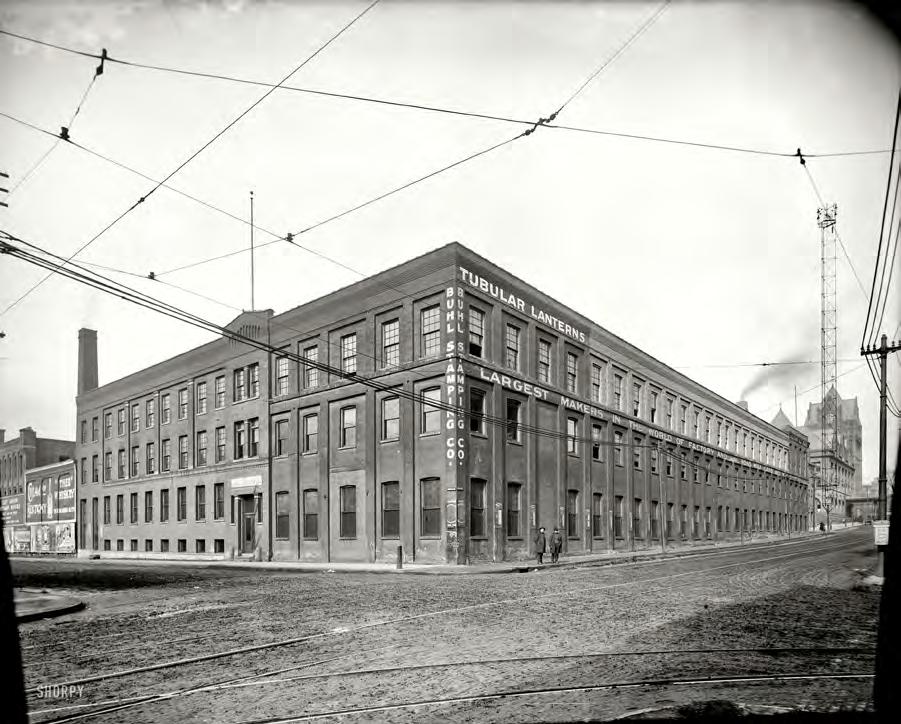

Black-and-white photographs appear as occasional interlopers in this volume. They are accompanied by makers’ stories from early twentieth century Detroit, and stand in parallel with the Kit’s contemporary investigations. But can one inform the other? What can the culture of making in “Model T Era” Detroit teach us in the de-industrialized present, where production seems to be flourishing at a smaller-scale, with nimbler processes and customizable outcomes? I will suggest two useful outcomes of this dialogue with the past: a new perspective on the past and a provocation for the future.

These stories from the city’s “old” culture of making call our common historical narratives into question. They suggest that readings of boomtown Detroit as a rigid one-industry center, or alternatively, as a birthplace of industrial genius, conceal as much as they reveal. On the contrary, we find that Detroit benefitted greatly from industrial ideas developed elsewhere, such as the drive toward interchangeability that Henry Leland and other mechanics brought from New England. The city was also more diverse and more flexible in its capabilities than is often acknowledged. Detroit produced dozens of products and components from stoves to beer and pharmaceuticals to railcars. In metalwork, Detroit was a place where raw materials could be shaped into a seemingly endless range of forms. The vast majority of mass production workers experienced mind-numbing routinized work after 1914, which must be borne in mind, yet at the same time many artists and craft workers engaged Detroit commerce and industry in creative and critical ways.

These relationships between makers and the industrial/commercial power structure of Fordist Detroit raise questions about the politics of making today. They can provoke thought and action in the present. Ceramicists at

Re:Tool-Kit for Detroit_INTRODUCTION 12

INTRODUCTION

Flint Faience found a symbiosis with the auto industry, sharing kiln-time with a sparkplug-maker. Others worked for the automakers directly, developing a modern aesthetic for the automobile. Craftspeople gave form to the rhetoric of the giant Union Trust Bank at the Guardian building, and also introduced well-made and “ennobling” objects to the homes of middleclass Detroit through the DSAC (Society for Arts and Crafts) showroom. The Society provided a unique countervailing voice in the mass-production city. While automakers pressed their campaigns to Americanize immigrant workers, the society attempted to cultivate a multi-cultural craftwork market as a means of preserving the diverse craft-knowledge of new arrivals. Finally, in the dark days of World War I, in whose violence Detroit industry was deeply implicated, the Society’s president called for art as the basis of a “new spirit,” capable of transcending violence and consumerism.

These stories, while suggesting possible affinities between Detroit’s “cultures of making” past and present, pose questions about the possibilities and politics of our work. How can artists, designers and craftsmen take advantage of seemingly-unrelated people, facilities and processes? How should Detroitbased making engage with commerce and with its publics? In this archetypal “rust-belt” city at the beginning of the twenty-first century, anything “Made in Detroit” sounds like a victory; but as it was in the early twentieth century, it is up to the city’s makers and users to decide what this trademark will stand for.

image left, based on the city’s trademark, c. 1915

13

Pictures Unite

Julia McMorrough

The subjects of ‘Detroit’ and ‘fabrication’ are sufficiently complicated and nuanced, and as this study has proposed, effectively invisible, at least as perceived by one coming from outside the city, or outside the fraternity of making – or both. These are two communities that are properly wary of interlopers and place high value on commitment and sincere engagement. Such issues were not lost on our efforts, which took a systematic approach to scratching the surface of making in Detroit, one person at a time. From countless hours of an accumulation of personal connections came a valuable collection of data delivered via first-person narrative: descriptions of materials, tools and processes, candid interviews, and illuminating photographs.

Having thus established this data, the challenge became the creation of an effective means for cataloguing and disseminating it in a manner that might be simultaneously useful and engaging, while providing the featured shops a range of possible exposures from very public to very private.

The Re:Tool-Kit has taken shape as a method for distilling and making accessible information that might otherwise become too overwhelming to consider. Drawing inspiration from the ideals of the ISOTYPE (International System Of TYpographic Picture Education) picture language developed in the early days of the 20th century by sociologist Otto Neurath and others, the Re:Tool-Kit book takes the opportunity of having too much complex information to share and determining which ‘invisible’ moments might be brought into sharper focus by a simple, clear and engaging collection of navigational symbols. In extolling the virtues of his own picture language, Neurath famously stated that “words divide, pictures unite.” With that in mind, Re:Tool-Kit has developed a collection of symbols that work to efficiently telegraph pertinent details of a

Re:Tool-Kit for Detroit_INTRODUCTION 14

INTRODUCTION

particular shop or maker, such as the type of production, materials used, and the scale of what is produced. Taken together and within the unique context of any one shop, they form a graphic narrative that, contrary to appearances, is not reductive, but expansively legible and personal.

The Re:Tool-Kit book takes seriously the ways that graphic design can facilitate the compelling dispersal of information, and has set for itself a series of ambitions. Namely, that the book’s content (including historical context, an illustrated shop directory, navigational maps, and in-depth case studies) will provide multiple avenues for engagement by a wide variety of readers. By navigating the interconnections of the book, whether to gain a clearer understanding of the geography of the city, to have a design fabricated, or to uncover a history, readers of all types are invited to make highly personal discoveries about the content of Detroit.

Taken altogether, Re:Tool-Kit offers up a cross-section of generations and human capabilities in Detroit at this moment, operating simultaneously as field guide, travel brochure, and chapter in a Detroit novel. Most significant, however, is not the book as a finite effort that ends once printed, but the structure now in place that can grow (on-line and elsewhere) in its ability to receive and share – in the spirit of connection and the type of useful unity that could allow willing outsiders in, to the benefit of all.

15

Google Narratives

Seth Ellis

When we asked the people featured in this project how to go about getting something made in Detroit, the most common response was, “ask someone.” Word of mouth, knocking on doors, physical conversations and personal networks: these are the things that make up Detroit’s manufacturing culture, historically and currently. Why, then, try to summarize these social interactions online, where they aren’t taking place? What role can a digital map serve in trying to show this complicated network? Why even try to superimpose a generic virtual structure on such a proudly local, idiosyncratic culture?

Maps have two functions: to locate, and to direct. We think of online maps first and foremost as a tool for the second function, an interface that generates a set of directions towards a simple goal, a phone book with built-in GPS. But when we use maps this way we often remain in ignorance of the places we’re moving through, as we follow contextless instructions towards our end point.

We intend our map to locate some of the people who make up manufacturing culture in Detroit. We want to locate these shops not just in space, but in time; we want to locate them within the web of relationships within Detroit fabricators, engineers, and makers. And we want to locate ourselves relative to all of these people, and to the work they do, and the work that Detroit has done for many years. Collecting information and stories into an online map, a now-familiar interface that travels with us in our computers, isn’t a way of replacing or supplanting the deep physical and social culture that exists in Detroit; that would be antithetical to the nature of a living, productive city. Digital culture has value to the degree to which it supports and informs physi-

Re:Tool-Kit for Detroit_INTRODUCTION 16

99 INTRODUCTION

cal culture. But the physical culture of Detroit needs to imagine new ways to re-invigorate itself and to grow. The continuing online presence of Re:Tool-Kit, the expanding database of shops, and the map that locates them for future interested users, is a guide that allows us to imagine and shape the future of making in Detroit.

17

Re:Tool-Kit for Detroit_INTRODUCTION 18 SYMBOL GUIDE

Symbols

To make a picture is a more responsible work than to make a statement, because pictures make a greater effect and have a longer existence.

-Otto Neurath

The symbols described on the following pages were created for telling stories about Detroit, specifically the ways that making is about more than what is made, but about who makes it, how it is made, and to whom it will go.

The topic is a big one, and the symbols act as a friendly guide through the material, in much the same manner that familiar pictograms help us navigate foreign places. The symbols in the Re:Tool-Kit offer distillations of complicated arrangements - easy to recognize and easy to recall, they are the bread crumbs that mark a trail through the book and through the city. Though inherently reductive form, in spirit they aspire to reach out and pull viewers into an evolving story already in progress.

19

Re:Tool-Kit for Detroit_INTRODUCTION 20 SYMBOL GUIDE SHOP TYPES WOOD SHOP METAL SHOP SHEET METAL SHOP MACHINE SHOP CONCRETE FABRICATION METAL FOUNDRY GLASS BLOWING INJECTION MOLDING ACRYLIC PRODUCTION SCULPTURE STUDIO CUSTOM FABRICATION STUDIO DIY MAKER SPACE (COLLECTIVE)

21 SCREEN PRINTING LETTERPRESS STUDIO SIGN & AWNING SEWING STUDIO UPHOLSTERY BLACKSMITH FACILITY TYPES MULTIPLE BUILDINGS OR LOCATIONS SHARED BUILDING WITH STOREFRONT COLLECTIVE FULL BUILDING

Re:Tool-Kit for Detroit_INTRODUCTION 22 MATERIAL TYPES WOOD METAL SHEET METAL CAST METAL CONCRETE ACRYLIC PLASTIC FABRIC LEATHER VENEER PAPER GLASS SYMBOL GUIDE

23

FOAM WIRE WAX PAINT POWDER COATING SOLVENT/LIQUID EPOXY/ADHESIVE CHALK SAND CLAY FIBERGLASS METAL FINISHING GOLD LEAF

VIDEO CERAMICS

Re:Tool-Kit for Detroit_INTRODUCTION 24 CLIENT TYPES INDIVIDUALS ARCHITECT BUILDER / CONTRACTOR ARTIST / DESIGNER MEDICAL SYMBOL GUIDE HOME BUILDER COMMUNITY FABRICATOR SHOP OWNERS STUDENT DEVELOPER HOMEOWNER

25 ENGINE REPAIR NEW ENERGY CASINOS HOUSE CONSTRUCTION ROAD CONSTRUCTION BUSINESS REPAIR HVAC MACHINING TOOL & MACHINING FABRICATION CONVEYOR STOPS

Re:Tool-Kit for Detroit_INTRODUCTION 26 CLIENT TYPES HOSPITALS RETAIL INSTITUTIONS GOVERNMENT MUNICIPALITY MICHIGAN NATIONAL GLOBAL EDUCATION SCHOOLS SHOPS & COMMERCIAL HOTELS

27 OIL PIPELINE AUTO INDUSTRY AIR INDUSTRY MILITARY SMALL BUSINESS AEROSPACE OIL INDUSTRY SCIENCE MOTION CONTROL INDUSTRIAL ELECTRONICS MOBILE ELECTRONICS ROBOTICS

Re:Tool-Kit for Detroit_INTRODUCTION 28 SYMBOL GUIDE CLIENT TYPES PUBLIC ART AGRICULTURE MARINE MINING LIGHTING RESTORATION FOOD SERVICE WEDDINGS FILM INDUSTRY CELEBRITIES GALLERIES ART

29

FIRE SUPPRESSION HYDRAULICS D ENERGY PRODUCTION NATURAL GAS FIRE TRUCKS MUSIC DIESEL

CAR WASH

Re:Tool-Kit for Detroit_INTRODUCTION 30 CNC_ HANDHELD FURNITURE AUTO ARCHITECTURE SCALE CNC CAPABILITIES COLLABORATION COMPONENT WHOLE FINISHED ROUGH PRODUCT OTHER

31

“Research through Making” at Pewabic Pottery

Pewabic Pottery was opened in 1903 by two researchers and makers who were driven to experiment: ceramicist Mary Chase Perry and kiln-maker Horace Caulkins. The later created innovative “Revelation” kilns that were designed to provide a safer, cleaner and more reliable firing for china-making. As architectural tile became a part of their business the partners developed an experimental tunnel kiln. Its internal rollers exploded during the first test, but undeterred, they fixed the problem in their second attempt. Chase Perry researched novel ceramic glazes. With various material compositions and firing temperatures she could create a range of effects such as transparency, glossiness and color. Copper glazes fired in an oxidizing atmosphere could give a range of green hues for example, or provide red hues if subject to a reducing temperature. The height of Perry’s achievement in these pursuits was her signature iridescent glaze. A 1909 columnist described it lyrically, “Through the misty surface from beneath its veil-like texture there was a hint of purpling sky…a star breaking through the cloud…a pinkish glow of sunrise, gone before it was caught and slipping off in a gray monotone.”

Re:Tool-Kit for Detroit_INTRODUCTION MADE IN DETROIT: Stories

Early Twentieth Century 32

from the

32

©DSAC Archives, College for Creative Studies. Used with permission.

©DSAC Archives, College for Creative Studies. Used with permission.

33

Mary Chase Perry (Stratton), potter, in the original Pewabic Pottery, at the time of the opening exhibition in 1904.

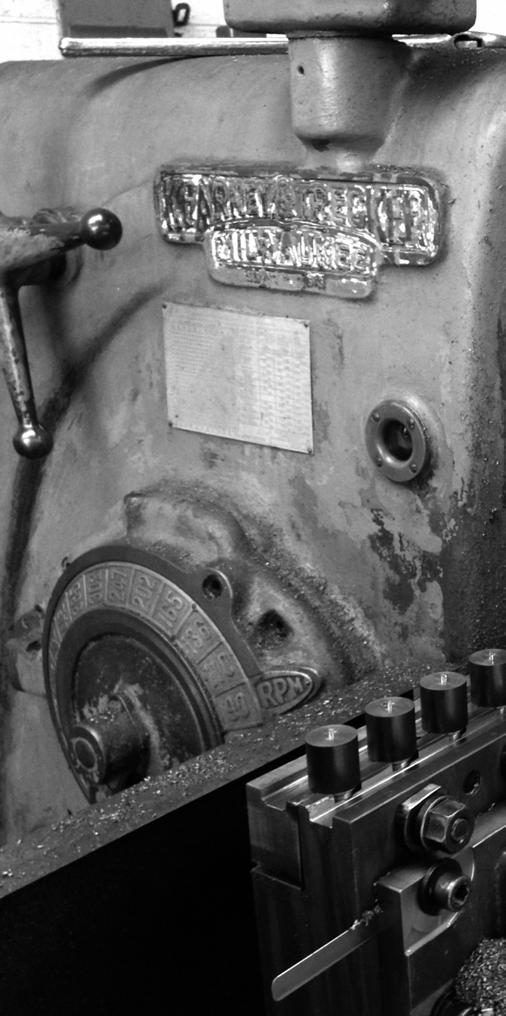

Precision and Interchangeability

What do sewing machines, firearms and Cadillacs have in common? All are composed of precisely-made interchangeable parts, and all were influenced by the life of machinist Henry Leland (1843-1932). Leland built tools at Colt’s Hartford armory and sewing machines for Brown and Sharpe in Providence before moving to Detroit in the late nineteenth century. He developed a more precise grinding lathe which allowed greater precision and interchangeability of parts. Precision meant efficiency. If identical parts could be reliably produced assembly times could be substantially reduced. Hand-fitting and re-grinding could be eliminated, a prerequisite for the kind of mass-production that would emerge in Detroit. Leland went on to establish the Leland and Faulconer Manufacturing Co. in Detroit, providing engines to the automaker Ransom Olds, and ultimately became an automaker in his own right by developing the Cadillac and Lincoln brands.

Re:Tool-Kit for

INTRODUCTION

34

Detroit_

MADE IN DETROIT: Stories from the Early Twentieth Century

IN DETROIT: Stories the Early Century

35

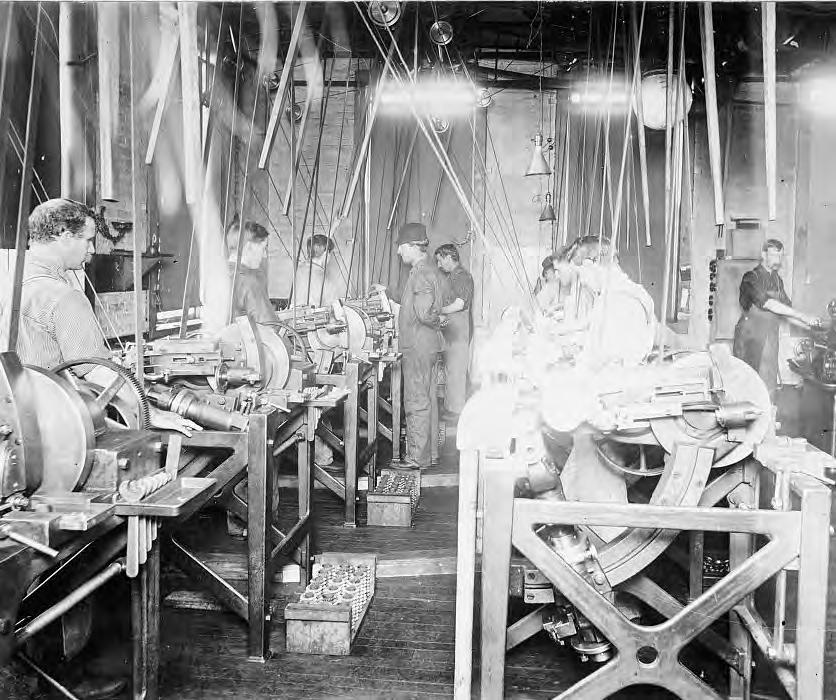

Factory workers assembling engines at Leland & Faulconer Manufacturing Co., Detroit, Mich. Ca. 1903.

Library of Congress, Prints and Photographs Division, Detroit Publishing Company Collection

Re:Tool-Kit for Detroit_MAPS 36 A B 13 22 26 27 10 01 04 06 23 37 25 47 39 08 14 MEXICAN TOWN, SOUTHWEST DETROIT VIRGINIA PARK HIGHLAND PARK BAGLEY PETOSKY OSTEGO BRIGGS CORE CITY DELRAY FORT WAYNE ZUG ISLAND BOYNTON OAKWOOD HEIGHTS RIVER ROUGE FORD CHALDEAN TOWN FITZGERALD LITTLEFIELD MARTIN PARK UNIV. DISTRICT W. MC NICHOLS RD PALMER PARK PALMER PARK PALMER WOODS SHERWOOD FOREST GREEN ACRES STATE FAIR GROUNDS E. MC NICHOLS RD W. MC NICHOLS RD GNIMOYW DAOR R NHOJ UNIVERSITY OF DETROIT MERCY OAK PARK RIVERDALE BRIGHTMOOR WEATHERBY BARTON MCFARLAND DEARBORN FISHKORN FRANKLIN PARK DEARBORN HEIGHTS SPRINGWELLS WARRENDALE 5 5 10 39 39 1 1 8 8 1 85 39 39 153 153 102 102 153 39 10 10 5 94 94 94 75 75 24 24 24 24 12 12 12 Y DLEIFHTUOS WOODWARD AVE WOODWARD AVE WOODWARD DETROIT RIVER TELEGRAPH RD HPARGELET SOUTHFIELD FWY JEFFRIES FWY JEFFRIES FWY PLYMOUTH RD ELIZA HOWELL PARK RIVER ROUGE PARK ROUGE RIVER FAIRLANE TOWN CENTER ROUGE GOLF COURSE PLYMOUTH RD W CHICAGO ST W OUTER DR W OUTER DR NEERGREVE TELEGRAPH RD EVA NEERGREVE SOUTHFIELD HWY SOUTHFIELD HWY GRANDRIVERAVE GRANDRIVERAVE GRANDRIVERAVE FORD RD HUBBARD DR FORD RD FORDRD FORDRD JEFFRIESFWY JOHN C LODGE FWY JOHNC LODGEFWY EDSEL FORD FWY MICHIGANAVE MICHIGAN AVE MICHIGANAVE FISHER FWY FISHERFWY FISHER FWY WVERNORHWY WJEFFERSONAVE WFORTST WVERNORHWY WFORTST DIX AVE SDIXST CENTRAL ST LIVER NOIS ST SPRINGWELLS ST W END ST EDSELFORDFWY W 8 MILE RD W. 7 MILE W 5 MILE W 8 MILE RD W 8 MILE RD TO TROY TO MADISON HEIGHTS W. 7 MILE W. 7 MILE W. 7 MILE W. 7 MILE TO LIVONIA TO BELLEVILLE 96 96 96 75 75 96 96 TIREMAN ST TIREMAN ST JOY RD JOY RD FORD RD W. WARREN AVE W. WARREN AVE EWARREN D R DLEIFNEERG DLEIFNEER G D R ESAHC REFAHCS NORTH END 16 30 UNIVERSITY OF MICHIGAN - DEARBORN D E C F

37 18 07 12 09 05 19 03 15 21 11 20 02 41 34 44 43 45 46 36 28 29 PONYRIDE 40 42 47 39 RUSSELL INDUSTRIAL 17 33 35 31 24 38 MEXICAN TOWN, SOUTHWEST BRIGGS CITY EASTERN MARKET WEST SIDE INDUSTRIAL LAFAYETTE PARK ELMWOOD PARK GROSSE POINTE SHORES GROSSE POINTE FARMS GROSSE POINTE JEFFERSON CHALMERS MORNINGSIDE CHRYSLER HARPER WOODS HAMTRAMCK COLEMAN YOUNG INTL AIRPORT VAN STEUBEN LA SALLE COLLEGE PARK EAST ENGLISH VILLA PULASKI FOREST WAYNE STATE UNIVERSITY WAYNE STATE UNIVERSITY CCS REGENT PARK 8 1 1 85 102 102 102 53 3 3 3 3 375 53 10 10 10 94 94 94 94 94 94 75 GRATIOT AVE CHRYSLER FWY CHRYSLER FWY CHRYSLER FWY WOODWARD AVE WOODWARD AVE OUELLETE AVE HURON CHURCH ROAD UNITEDSTATES DETROITRIVER UNITED STATES CANADA CANADA GRATIOT AVE GRATIOT AVE GRATIOT AVE EVA EKYD NAV EVA EKYD NAV EVA EKYD NAV TOILLE TOILLE OUTER DR E YRETEMEC MICHIGAN AVE FISHER FWY VERNORHWY EVERNORHWY FISHERFWY ELAFAYETTEST EVERNONHWY MACKAVE MACKAVE MACKAVE EJEFFERSONAVE EJEFFERSONAVE MC DOUGAL ST MT. ELLIOTT ST EDAVISONST EDSEL FORD FWY EDSELFORDFWY EDSELFORDFWY E 8 MILE RD TO ROSEVILLE E 8 MILE RD 7 MILE 75 75 OUTER DR E DOOWR EHS E. MC NICHOLS RD E. MC NICHOLS RD CANIFFST HOLBROOKST CONANT ST E. 7 MILE E. 7 MILE E. 7 MILE MOROSSRD E. 7 MILE E DAVISON ST EWARRENAVE EWARRENAVE NORTH END BELLE ISLE G J L F H K I Maps N

10

Contractors Steel 48649 Schooner Dr. Belleville, MI 48111

26

Glass Academy LLC Furnace Design, LLC 25331 Trowbridge Dearborn, MI 48124

Re:Tool-Kit for Detroit_MAPS 38

39 A 26 10 DEARBORN HEIGHTS 153 153 24 24 12 HPARGELET ROUGE RIVER MICHIGAN AVE TO BELLEVILLE FORD RD (off map 13 miles) DEARBORN N

13

Welk-ko Fabricators, Inc. 11885 Mayfield Livonia, MI 48150

16

Tolerance Tool & Engineering, Ltd. 20541 Glendale St. Detroit, MI 48223

Re:Tool-Kit for Detroit_MAPS 40

41 B 13 W. MC NICHOLS RD RIVERDALE BRIGHTMOOR WEATHERBY 24 JEFFRIES FWY ELIZA HOWELL PARK RIVER ROUGE PARK ROUGE GOLF COURSE PLYMOUTH RD W CHICAGO ST W OUTER DR W OUTER DR NEERGREVE TELEGRAPH RD EVA NEERGR E GRANDRIVERAVE W 5 MILE TO LIVONIA 96 JOY RD 16 N

04

L.A. Martin Co., Inc. Screw Machine Products & CNC Milling 14400 Henn Street Deaborn, MI 48126

06

Thiry Machine Company, Inc. 6500 Chase Rd. Dearborn, MI 48126

23

Jim’s Ornamental Iron & Steel Co., Inc. 7555 Greenfield Rd. Detroit, MI 48228

30

Jim’s Awning 7555 Greenfield Rd. Detroit, MI 48228

Re:Tool-Kit for Detroit_MAPS 42

43 23 06 04 DEARBORN FISHKORN FRANKLIN PARK WARRENDALE 39 39 153 12 JEFFRIES FWY PLYMOUTH RD FAIRLANE TOWN CENTER SOUTHFIELD HWY SOUTHFIELD HWY FORD RD HUBBARD DR MICHIGANAVE 96 96 TIREMAN

JOY RD W.

DLEIFNEERG DLEIFNEERG ESAHC REFAHCS 30 UNIVERSITY OF MICHIGAN - DEARBORN C HENN ST DIVERSEY N

ST

WARREN AVE

08

Truchan Tool & Machine 7446 West Fort St. Detroit, MI 49209

25

Vulcanmasters Welding Co., Inc. 374 Fordson St. Detroit, MI 48217

Re:Tool-Kit for Detroit_MAPS 44

45 25 08 DELRAY ZUG ISLAND OAKWOOD HEIGHTS RIVER ROUGE SPRINGWELLS 75 DETROIT RIVER FISHERFWY WJEFFERSONAVE WFORTST WVERNORHWY WFORTST DIX AVE SDIXST CENTRAL ST LIVER NOIS ST SPRINGWELLS ST W END ST D N

27 New York Designers

8450 McNichols Road West Detroit, MI 48221

Re:Tool-Kit for Detroit_MAPS 46

FITZGERALD

MARTIN PARK

47 27

BAGLEY PETOSKY OSTEGO

PALMER

GNIMOYW

5 10

W.

96 E

N

LITTLEFIELD

UNIV. DISTRICT W. MC NICHOLS RD PALMER PARK

WOODS SHERWOOD FOREST

UNIVERSITY OF DETROIT MERCY

JOHN C LODGE FWY

7 MILE

MARYGROVE COLLEGE

14 Carlson Metal Products, Inc. 2335 Alger Dr. Troy, MI 48083

Acrylic Specialties & Plastics 32336 Edward St. Madison Heights, MI 48071

37 i3 Detroit 1481 Wordsworth St. Ferndale, MI 48220 34 Origins Concrete Design 515 Woodward Heights, suite A Ferndale, MI 48220 36 Aaron Blendowski 39221 Woodward Ave. Bloomfield Hills, MI 48303

Re:Tool-Kit for Detroit_MAPS 48

22

49 22 37 14 HIGHLAND PARK CHALDEAN TOWN MARTIN PARK UNIV. DISTRICT PALMER PARK PALMER PARK PALMER WOODS SHERWOOD FOREST GREEN ACRES STATE FAIR GROUNDS E. MC NICHOLS RD DAOR R NHOJ UNIVERSITY OF DETROIT MERCY 1 1 8 102 WOODWARD AVE WOODWARD AVE JOHN C LODGE FWY W 8 MILE RD TO TROY TO

W. 7 MILE W. 7 MILE W. 7 MILE 75 75 F (off

7 miles)

36 (off map 10 miles) TO

(off

TO

34 N

MADISON HEIGHTS

map

(off map 5 miles)

BLOOMFIELD HILLS

map 1 mile)

FERNDALE

11

Crankshaft Craftsmen 13505 Joseph Campau Street Detroit, MI 48212

17

AK Services

Russell Industrial Center 1604 Clay, suite 137 Detroit, MI 48211

24

Wooden Graphics, LLC

Russell Industrial Center 1600 Clay St. Detroit, MI 48211

26

Arts and Crafts Hardware

Russell Industrial Center

1610 Clay St., suite 221 Detroit, MI 48211

31

Chido Johnson

Russell Industrial Center 1600 Clay Street Detroit, MI 48211

35 Andrew Thompson

Russell Industrial Center 1600 Clay Bldg. 1A West, 3rd floor Detroit, MI 48211

38 Detroitus 13169 Moran St. Detroit, MI 48212

Re:Tool-Kit for Detroit_MAPS 50

51 11 RUSSELL INDUSTRIAL CENTER 17 24 35 31 26 38 VIRGINIA PARK HIGHLAND PARK HAMTRAMCK E. MC NICHOLS RD DAOR R NHOJ 1 8 8 1 10 94 WOODWARD AVE CHRYSLER FWY WOODWARD AVE EDAVISONST W. 7 MILE 75 75 E. MC NICHOLS RD CANIFFST HOLBROOKST CONANT ST E. 7 MILE NORTH END G E.GRAND N

01

Detroit Tube Products 300 S. Junction St. Detroit, MI 48209

19

Richard Bennett & Associates 470 Brainard Street Detroit, MI 48201-1718

39

Detroit Denim

Ponyride Detroit 1401 Vermont St. Detroit, MI 48216

40

The Empowerment Plan

Ponyride Detroit 1401 Vermont St. Detroit, MI 48216

43

Stukenborg Letterpress Studio

Ponyride Detroit 1401 Vermont St. Detroit, MI 48216

45

Detroit Fashion Collective 2431 4th St. Detroit, MI 48201

48

Smith Shop

Ponyride Detroit 1401 Vermont St. Detroit, MI 48216

Re:Tool-Kit for Detroit_MAPS 52

53 01 19 45 PONYRIDE 40 43 48 39 MEXICAN TOWN, SOUTHWEST DETROIT BRIGGS CORE CITY WEST SIDE INDUSTRIAL DELRAY FORT WAYNE WAYNE STATE UNIVERSITY WAYNE STATE UNIVERSITY 1 85 10 10 94 75 12 CHRYSLER FWY WOODWARD AVE HURON CHURCH ROAD UNITEDSTATES CANADA GRANDRIVERAVEJEFFRIESFWY MICHIGAN AVE FISHERFWY FISHER FWY WVERNORHWY FISHERFWY WFORTST 75 96 EWARRENAVE G H COLLEGE OF CREATIVE STUDIES N

05

Addison Iron Works, Inc. 3449 East Vernor Highway Detroit, MI 48207 18

C.A.N. Art Handworks, Inc. 2264 Wilkins St. Detroit, MI 48207 29

Dormouse Fabrication 6447 Mack Ave. Detroit, MI 48207 33 Cyberoptix Tie Lab 1440 Gratiot Ave. Suite 2A Detroit, MI 48207

41

OmniCorpDetroit 1501 Division St. Detroit, MI 48207 42

Signal Return Press 1345 Division St. Detroit, MI 48207

Re:Tool-Kit for Detroit_MAPS 54

55 18 05 42 33 41 29 EASTERN MARKET LAFAYETTE PARK ELMWOOD PARK FOREST PARK WAYNE STATE UNIVERSITY CCS 1 3 375 10 94 CHRYSLER FWY CHRYSLER FWY WOODWARD AVE OUELLETE AVE UNITEDSTATES CANADA GRATIOT AVE MICHIGAN AVE EVERNORHWY FISHERFWY ELAFAYETTEST MACKAVE EJEFFERSONAVE MC DOUGAL ST MT. ELLIOTT ST 75 EWARRENAVE I N

07

Do-All Plastic

1265 Terminal St. Detroit, MI 48214

44

The Collective 8325 E. Jefferson Ave. Detroit, MI 48214

Re:Tool-Kit for Detroit_MAPS 56

EVERNORHWY

MACKAVE EJEFFERSONAVE

57 07 44 JEFFERSON CHALMERS MORNINGSIDE CHRYSLER 3 94 DETROITRIVER

EVERNONHWY

MACKAVE BELLE ISLE J N

McNichols Rd. Detroit, MI 48212

Engineering 6350 E. Davison Detroit, MI 48212

5431 E. Davison St. Detroit, MI 48212

Re:Tool-Kit for Detroit_MAPS 58

12

15

20

47 Chocolate Cake Design Collective 17501 Van

46 Talking Dolls

21 J&N

03 Federal Pipe & Supply Co., Inc. 6464 E.

Eutectic

Soley Metal Fabricating 20506 Sherwood St. Detroit, MI 48234

Allied Manufacturing Technologies, Inc. 6000 Caniff St. Detroit, MI 48212

Dyke St. Detroit, MI 48234

17501 Van Dyke St. Detroit, MI 48234

Industries

59 12 03 15 21 20 46 47 COLEMAN YOUNG INTL AIRPORT VAN STEUBEN LA SALLE COLLEGE PARK PULASKI 3 53 94 GRATIOT AVE EVA EKYD N A V EVA EKYD N A V TOILL E T M ILLE E R D RETUO YRETEM E C EDSELFORDFWY E 8 MILE RD DOOWREHS E. MC NICHOLS RD E. 7 MILE E DAVISON ST K N

02

National Bronze Manufacturing Company 28070 Hayes Road Roseville, MI 48066

09

Wolverine Bronze Company 28178 Hayes Road Roseville, MI 48066

Re:Tool-Kit for Detroit_MAPS 60

61 09 02 COLEMAN YOUNG INTL AIRPORT VAN

PULASKI REGENT

102 3 3 94 GRATIOT AVE

GRATIOT AVE EDSELFORDFWY

E

L

N

STEUBEN LA SALLE COLLEGE PARK

PARK

GRATIOT AVE

TO ROSEVILLE

8 MILE RD E. 7 MILE E. 7 MILE

(off map 5 miles)

IN DETROIT:

Stories the Early Century

Casting, Rolling and Smelting: Diversity in Metalwork

for

INTRODUCTION MADE IN

Century 62

Re:Tool-Kit

Detroit_

DETROIT: Stories from the Early Twentieth

In Detroit raw ore was transformed into a world of metal parts and products for consumption. It was shaped into wire, sheet and pipe, and cast as stoves, fans, radiators, sprocket chains and railcar wheels. The blending of metals was an essential service as well. The Michigan Smelting and Refining Co. produced bulk metal alloys such as brass and bronze in ingot, billet, and slab form. Babbit, which the company also produced, is described in an 1885 issue of The Manufacturer and Builder as an alloy of tin, antimony and copper, with perhaps a bit of lead for softening. It was considered to be excellent for use in fast-running machinery. As the auto industry expanded Detroit’s metalworkers became a parts-supply network for large assemblers such as the Ford Motor Company. The J.W. Murray Manufacturing Co., for example, produced hoods, fenders and gasoline tanks while the Kelsey Wheel Co. created wheels, hubs, brake drums, rims and bodies. These suppliers represented a diverse metalworking culture that belies the assumed simplicity of a “one industry town.” 62

Library of Congress, Prints and Photographs Division, Detroit Publishing Company Collection

63

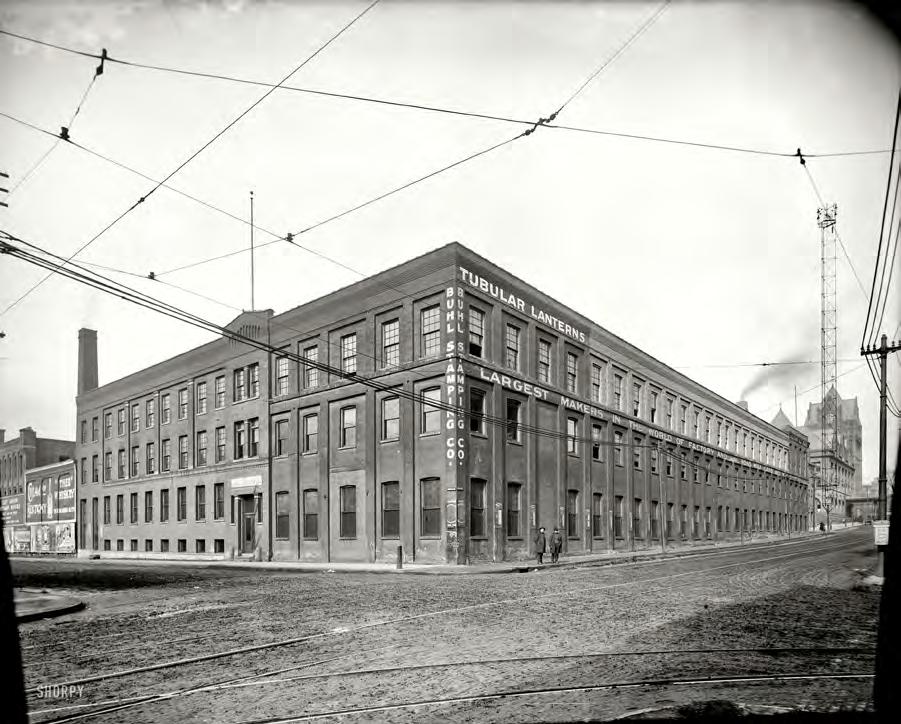

Buhl Stamping Co. around 1900. In addition to making tubular lanterns the company claimed to be the “largest makers in the world of factory and rail road milk cans.”

63

The Automobile as Art

Nearly a decade after Le Corbusier praised the engineering aesthetic of the automobile in Towards an Architecture, Detroit’s Society of Arts and Crafts became the first gallery in America to present the automobile as an art form. Their public exhibition Art in the Automobile Industry (1933) was conceived as a response to public perception that the car was primarily the creation of engineers. Rather, its curator asserted that the designing artist was the author of “the beautifully proportioned motor car of today,” and that ”due credit has not been given to his genius and its effect upon the industry about which Detroit life centers.” The exhibition included “dream” models for future automobiles with clean aerodynamic lines as well as photographs and advertisements from past designs. The evolution of hubcap, radiator, and instrument panel styling was on display with these objects mounted upon black velvet.

original caption: STYLING UP - The artist as well as the engineer makes a contribution to modern merchandising. In New York, the annual show of art in industry is on at the Art Center. In Detroit, the Society of Arts and Crafts offers an exhibit featuring the role of design in the automobile industry. Here is 26 years of Packard development. Right, with arm around the 1907 radiator, is Alvan Macauley, president of Packard; left, behind the 1933 radiator, is Edward Macauley, his son.

64

Re:Tool-Kit for Detroit_INTRODUCTION MADE IN DETROIT: Stories

from the Early Twentieth Century

MADE IN DETROIT: Stories from the Early Twentieth Century

Local news coverage of the Detroit exhibit Art in the Automobile Industry, 1933.

©DSAC Archives, College for Creative Studies. Used with permission.

Local news coverage of the Detroit exhibit Art in the Automobile Industry, 1933.

©DSAC Archives, College for Creative Studies. Used with permission.

Re:Tool-Kit for Detroit_DIRECTORY 66

Directory of Shops

The pages that follow provide assorted data about each of the shops in the initial interview set. Each shop is identified by type (metal shop, machine shop, letterpress studio, etc.) and a number. The number represents its place in the chronology of these original shops - so number 1 is the oldest and higher numbers are newer. These numbers also identify the shops on the maps and in other areas of the book.

The graphic language that describes each shop is meant to be equally informational and engaging, and acts as a shortcut into the depth of information that could be shared about any one shop.

67

Re:Tool-Kit for Detroit_DIRECTORY 68

01

Detroit Tube Products 300 S. Junction A ve. Detr oit, MI 48209

02 National Bronze Manufacturing Co. 28070 Hayes Rd. Roseville, MI 48066

03 Federal Pipe & Supply Co., Inc. 6464 E. McNichols Rd. Detr oit, MI 48212

04

L.A. Martin Co., Inc. Screw Machine Pr oducts & CNC Milling 14400 Henn St. Dearbor n, MI 48126

05

Addison Iron Works, Inc. 3449 E. Vernor Highway Detr oit, MI 48207

06

Thiry Machine Company, Inc. 6500 Chase Rd. Dearbor n, MI 48126

07

Do-All Plastic 1265 Terminal St. Detr oit, MI 48214

69

Truchan Tool & Machine 7446 W Fort St Detr oit, MI 48209 09 Wolverine Bronze Company 28178 Hayes Road Roseville, MI 48066 10

Contractors Steel 48649 Schooner Dr Belleville, MI 48111 11

Crankshaft Craftsmen 13505 Joseph Campau St. Detr oit, MI 48212 12

Eutectic Engineering 6350 E. Davison Detr oit, MI 48212 13

Welk-ko Fabricators, Inc. 11885 Mayfield Livonia, MI 48150 14

Carlson Metal Products, Inc. 2335 Alger St. Troy, MI 48083

Re:Tool-Kit for Detroit_DIRECTORY 70

08

15

Soley Metal Fabricating

20506 Sherwood St. Detr oit, MI 48234

16

Tolerance Tool & Engineering, Ltd. 20541 Glendale St. Detr oit, MI 49223

17 AK Services

Russell Industrial Center 1604 Clay St., suite 137 Detr oit, MI 48211

18 CAN Art Handworks, Inc. 2264 W ilkins St. Detr oit, MI 48207 19

Richard Bennett & Associates 470 Brainar d St. Detr oit, MI 48201 20

Allied Manufacturing Technologies, Inc. 6000 Canif f St. Detr oit, MI 48212 21

J & N Industries 5431 E. Davison St. Detr oit, MI 48212

71

22

Acrylic Specialties & Plastics 32336 Edwar d Ave, Madison Heights, MI 48071

23

Jim’s Ornamental Iron & Steel Co., Inc. 7555 Gr eenfield Rd. Detr oit, MI 48228

24 Wooden Graphics, LLC

Russell Industrial Center 1610 Clay St. Detr oit, MI 48211

25

Vulcanmasters Welding Company, Inc. 374 For dson St. Detr oit, MI 48217

26

Arts and Crafts Hardware Russell Industrial Center 1604 Clay St., suite 221 Detr oit, MI 48211

27 New York Designers 8450 McNichols Rd. W est Detr oit, MI 48221

28

Glass Academy, LLC Fur nace Design, LLC 25331 Trowbridge St. Dearbor n, MI 48124

Re:Tool-Kit for Detroit_DIRECTORY 72

Dormouse Fabrication

6447 Mack A ve. Detr oit, MI 48207 30

Jim’s Awning

7555 Gr eenfield Rd. Detr oit, MI 48228 31

Chido Johnson

Russell Industrial Center 1600 Clay St. Detr oit, MI 48211

Cyberoptix Tie Lab

1440 Gratiot AVe., suite 2A Detr oit, MI 48207

Origins Concrete Design

515 Woodward Heights Suite A Ferndale, MI 48220 35 Andrew Thompson

Russell Industrial Center

1600 Clay St., Bldg 1A, W est 3rd Floor Detr oit, MI 48211

73

29

32 Context Furniture 33

34

36

Aaron Blendowski

39221 W oodward Ave. Bloomfield Hills, MI 48303 37 i3 Detroit

1481 W ordsworth St. Fer ndale, MI 48220

38 Detroitus

13169 Moran St. Detr oit, MI 48212 39 Detroit Denim

Ponyride Detr oit 1401 Vermont St. Detr oit, MI 48216 40

The Empowerment Plan

Ponyride Detr oit 1401 Vermont St. Detr oit, MI 48216 41

OmniCorpDetroit

1501 Division St. Detr oit, MI 48207 42

Signal Return Press

1345 Division St. Detr oit, MI 48207

Re:Tool-Kit for Detroit_DIRECTORY 74

43

Stukenborg Letterpress

Ponyride Detr oit 1401 Vermont St. Detr oit, MI 48216

44 The Collective

8325 E. Jef ferson Ave. Detr oit, MI 48214

45 Detroit Fashion Collective

2431 4th St. Detr oit, MI 48201

46

Talking Dolls 7 17501 Van Dyke St. Detr oit, MI 48234

47

Chocolate Cake Design Collective 17501 Van Dyke St. Detr oit, MI 48234

48 Smith Shop

Ponyride Detr oit 1401 Vermont St. Detr oit, MI 48216

75

How to Use This Directory:

indicates whether shop is housed in its own building (or buildings), or is part of a larger collective

SHOP

Shop Name Shop Address Detroit, MI Phone Number web address

TOOLS

Interviewee name e-mail address

FACILITY MATERIALS PROCESSES

combination of symbols gives indication of the product’s nature - such as if it’s a part that must go into a larer whole, or if it needs further finishing, or if it’s completely finished once it leaves the shop

Re:Tool-Kit for Detroit_DIRECTORY 76

FINISHED PRODUCT PART WHOLE ROUGH FINISHED

77

* ESTABLISHED year = PRODUCT BATCH SIZE: CONNECTION CLIENTS

SCALE

this is the type of shop shop number (for map and other keying)

typical

Description of shop’s history, specifically related to Detroit gives general size parameters of typical products made in the shop

past and present clients descriptions of collaborative efforts number of employees

Re:Tool-Kit for Detroit_DIRECTORY 78 CONNECTION

MATERIALS

FACILITY < All metals Metal tube fabrication & tooling design. Making the tools that are used to machine. PRODUCT Components with close tolerances. FINISHED PRODUCT

End-forming machines Mandrel bending 3-roll bending Flaring devices Expanding machines Welders

& robot Drills Work with clients to make the best product, which is usually done with client input and design. CLIENTS PART WHOLE ROUGH FINISHED D heavy duty diesel power generation walter filtration & irrigation commercial food service The design work that happens here is tooling design. The customer gives us a design for the tubing. We would have to design the tools to make that happen, but we don't design their products.

Detroit Tube Products 300 S. Junction Avenue Detroit, MI 48209 (313) 841-0300 www.detroittubeproducts.com

SHOP M. Therese Bellaimey therese@detroittubeproducts.com

TOOLS

- TIG, MIG

*

The shop was founded by Therese’s grandfather to build metal tubing required to convert ship engines from steam to gasoline. Many of the tools they have in the shop today are the same tools that were built by the shop during WWII. The tools get updated, rebuilt and improved gradually over time.

ESTABLISHED 1911 = 22

Drill presses

Swaging machines

Toolroom equipment: lathes, mills, shapers, grinders

PROCESSES

BATCH SIZE:

Up to 1,000 per month of a unique part

SCALE

Tube bending, forming, shaping Assemblies

Finishing is available (paint, powder coating, e-coat, electroplating, bright annealing)

Swage Punch Weld Crush Expand Drill/punch Flare

All scales and gages (1/2” - 6” outside diameter bending)

car wash systems fire suppression mining

The shop loves the challenge of making new things.

79 01

interior design

architectural &

SHOP

National

MATERIALS

SCALE

Bronze (copper and tin-based alloy)

(

PROCESSES

Cutting and shaping of bronze CONNECTION

Re:Tool-Kit for Detroit_DIRECTORY 80

Outside customers look to Detroit because they know they can get a part made and then have it heat treated down the street.

Bronze Manufacturing Company 28070 Hayes Road Roseville, MI 48066 (586) 791-2000 www.nationalbronze.com Michael Russo mike.russo@nationalbronze.com

1” - 20” round FACILITY

work

together in Detroit because they

to be competitive against companies

and

business

Copper brass

copper and zinc-based alloy) BATCH SIZE: larger parts: 100s smaller parts: 100,000s Collaboration occurs when working on assemblies as one part of many that will fit into a given assembly for a customer.

Businesses

well

want

overseas

keep

here.

PART OR WHOLE

The shop began over 100 years ago as a foundry on the lower east side of Detroit. It has re-tooled twice (for both world wars), and has added bearings, bushings, and washers. The foundry was sold in 1990 and moved to Clinton Township in 2002, then moved to current location in 2011.

PRODUCT

ESTABLISHED 1911 = 30

Bronze bearings, washers, and bushings - of which the end use is not always known. Some known uses include refrigerator parts and exercise equipment. Notably, parts for Olympic weightlifting bars product is finished component also sell raw materials to other shops

The shop can make other things - as long as the machine can handle it and there is a demand for it, they’ll do it.

81

Saws

Bar

02 *

TOOLS CNC Lathes Mills

Welders

feeders for machines (proprietary)

CNC_

PART WHOLE ROUGH FINISHED Fastener companies Industrial manufacturing companies CLIENTS

MATERIALS

SHOP

Federal Pipe & Supply Co., Inc. 6464 E. McNichols Rd. Detroit, MI 48212 (313) 366-3000 fax: (313) 366-6466 www.federalpipe.com sales@federalpipe.com

Leon Saperstein

leon@federalpipe.com

TOOLS

FACILITY

Re:Tool-Kit for Detroit_DIRECTORY 82

Components CLIENTS

for racks and railings; columns; lintels; cut and threaded

weldments. Cutting and fabricat-

for the

industries.

product

PRODUCT FINISHED PRODUCT

steel

Copper

Many small-scale artisan projects. The number of small-scale artisan projects has increased, but you can't base a city, county, or state on it. PART WHOLE ROUGH FINISHED commercial jobbers local shop owners auto industry

fabricators Shop sells structural and bar sizes of steel, and is a pipe, valve, and fitting distributor.

Components

pipe; general

ing

construction and communications

Often the end

is not known.

< Low-carbon

Aluminum

Hydraulic shear Hydraulic press brake Hydraulic ironworker Mechanical ironworker Dual column saw

(on 3 acres)

The shop was originally located in Detroit for proximity to customers and easy access in all directions - now customer base is here and nearby. Current owner bought the shop in 1985 after being a long-time employee.

Metal Cut to size Braking, Welding, Punching, Notching Pipe and Bold Threading Twisting metal PROCESSES

Work is customer-driven. They don’t do design work, but help and make suggestions.

83 CONNECTION 03

COLLABORATION

* ESTABLISHED 1920 = 20

SCALE

1” to over 20’ (varies)

BATCH SIZE: 1 - 10,000 depending on job.

individuals No order is too small! film industry artist community

Cold saw Abrasive saw Pipe threaders Bolt & pipe threaders Drill press ARC and MIG welders

SHOP

FINISHED PRODUCT

ESTABLISHED 1928 = 20

PROCESSES

Precise machining of hard metals - removing of material to precision.

FACILITY

Paul Martin

pjmartin1965@yahoo.com

L.A. Martin Co., Inc. Screw Machine Products & CNC Milling 14400 Henn Street Deaborn, MI 48126 (313) 581-3577 (313) 581-3444 www.lamartincompany.com

MATERIALS

PART WHOLE

Milling, turning, super finishing, prototyping, repairs. “precise components”

ROUGH FINISHED

all metals

PRODUCT

This is a job shop, meaning they make parts that make parts - in the form of jigs, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes.

INTERFACE

Because small batches are often too epensive to have made overseas, they frequently fill such orders.

The shop can machine anything that is machine-able - but no stamper or bender. Because small batches are often too expensive to have made overseas, they frequently fill such orders.

Re:Tool-Kit for Detroit_DIRECTORY 84

The business was founded by Paul's father, who came to Detroit to work for Ford in Hamtramck, until the Great Depression, when he left. At one point, his father operated

the largest distillery in Michigan. Current shop is not in Detroit, because the city does not give support to small businesses, and security concerns that accompany Detroit would lead to additional operating costs.

TOOLS

CNC Lathes (19)

Automatic screw machines (7) CNC Mills (11) Micrometers

Laser cutter Shop tools of all varieties (see website)

85

from tiny screw valve to 500 lb. pieces for oil pipeline. CONNECTION

1- 100,000 CLIENTS

out

ing and plating to shops

the

* SCALE Ranges

BATCH SIZE:

The shop sends

grinding, hon-

in

area.

CNC_ 04

Gov’t contracts Dept. of Defense

oil

US

Alaskan

pipeline

Re:Tool-Kit for Detroit_DIRECTORY 86

Hand tools Mitering Welding Mig and Tig welders Arc welder

Iron Works, Inc. 3449 East Vernor Highway

MI

(313)

MATERIALS SHOP

TOOLS

Addison

Detroit,

48207

923-0520

FACILITY SCALE 8’ X 12’ and large jobs (ranges from custom cheese grater to large welding commission for US Navy) < Iron Steel Custom metals CONNECTION CLIENTS Collaboration happens with outsourcing of certain processes such as bending, forging and cutting of heavy metals. BATCH SIZE: Mostly custom, one-of-a-kind work. artists & creative people individuals

Joseph Bommarito

The Addison company has been in business for 80 years, and is in its third location in Detroit. Joe has owned the company since 1998, and was born and grew up here. He prides himself on doing unconventional jobs that many other fabricators turn away.

PRODUCT

Specialty ironwork, welding, and metal fabrication. Notably, windows of downtown skyscaper.

The shop can make other things if a client requests it and the work limits allow it.

Finished parts and wholes. End products include both components that go into products assembled by other shops, and complete projects. Everything is finished in house to 1/8” to 1/4” precision (no grinding).

87

05

Mitering Soldering Cutting [outsources

* ESTABLISHED 1930s = 2 Welding

big metal cutting, forging, and heavy metal bending] PROCESSES

WHOLE

FINISHED FINISHED PRODUCT

PART

ROUGH

Re:Tool-Kit for Detroit_DIRECTORY 88

Thiry Machine Company, Inc.

FACILITY

6500 Chase Rd. Dearborn, MI 48126 (313) 584-3730 TOOLS SHOP Dave Thiry

MATERIALS

lathes Milling machines Saws Shapers Vertical milling machine PROCESSES Cutting of material FINISHED PRODUCT PART WHOLE ROUGH FINISHED Finished parts (components of things assembled

that are very precise. repair for manufacturing HVAC manufacturers machine builders

The shop could add more machines (most recent purchase was 1969), and if economically feasible, the shop can make anything the tools are equipped to make.

Engine

by others)

Dave, 81, plans to close the shop when he retires.

The shop was started by Dave’s grandfather, who left the family farm in the 1920s to come work for Ford at $5 a day. Originally located at Livernois and Michigan, the shop moved to Dearborn in 1991.

PRODUCT

This is a jobbing machine shop, which services replacement parts and does machine repair for various industries.

notably: blower shaft for air conditioning units

up to 28” dia. and 20’ long

SCALE

Collaboration happens in various ways, for instance, if the shop can’t do all the work for a job, they’ll do just the small part grinding. They also seek out welders if necessary for a job.

There are currently far fewer large production jobs in Detroitmostly small jobs.

35 years ago, much of their business was from steel mills.

Dave has extra stock on hand so he can do a job on demand if needed.

89 06

ESTABLISHED 1936 = 5

*

CONNECTION CLIENTS

BATCH SIZE: 1-12

plastic mold injection

SHOP

Do-All Plastic

1265 Terminal St. Detroit, MI 48214 www.doallplastic.com (313) 824-6565

Gary LaDuke doallplastic@aol.com

<Plastics (synthetic, nylon, polyethylene, polypropalene, vinyl, pvc)

Rubber

End product is often a component, but doesn’t have to be. Products are dimensionally precise. No surface finishing is done after molding process is complete.

(would like to work domestically, but will work for anyone)

Collaboration with mold makers, inventors, and material makers.

Re:Tool-Kit for Detroit_DIRECTORY 90

FINISHED PRODUCT PART WHOLE ROUGH FINISHED

FACILITY MATERIALS

inventors

anyone

The shop has the capacity to do much more than it does currently.

The shop began with the production of a small part made of fabric, that sits between the leaf springs of the back wheel of a car. In 1950, Gary’s grandfather figured out how to make the same part out of plastic.

91

07

ESTABLISHED 1950 = 4

from dime size to pool steps; up to

lbs or 2’x2’ Injection machines (9) Molds (100s) PROCESSES Heat plastic pellets in hopper and squirt through small tube and screw into mold PRODUCT Injectionmolded plastics. CONNECTION CLIENTS BATCH SIZE: 1- 1,000 auto industry

TOOLS SCALE *

3.5

MATERIALS

SHOP

Truchan

7446 West Fort St. Detroit, MI 49209 (313) 841-4025

Cutting tools Inspection tools

FACILITY

Surface grinding

Turret lathe Lathe tool room TOOLS

Outside Diameter grinding

Collaboration happens with the hydraulics company of Richard’s son. FINISHED PRODUCT PART WHOLE ROUGH FINISHED Industrial compainies Construction companies

Re:Tool-Kit for Detroit_DIRECTORY 92

Tool & Machine

Richard G. Truchan BATCH SIZE: 3 - 10 pieces

Inside Diameter grinding

*

PROCESSES

Grinding and machining material away from larger pieces of metal.

Richard is from Detroit, and was born two miles away, and has been machining since he was a child.

[all machines are handoperated, which are increasing in value due to demand for them as backup for CNC models that do the same thing]

SCALE

The shop has the capacity to do much more production than currently.

CLIENTS

PRODUCT

ESTABLISHED 1955 = 4

Precision parts that go into bigger parts of machines. Usually secondary or tertiary parts that are custom-designed to the piece.

CONNECTION

Tool makers are a trade - few and far between, although there is still demand for it.

93

08

Hydraulics

“We are subcontractors”

Timothy E. Griffin tgriffin@wolverinebronze.com

Re:Tool-Kit for Detroit_DIRECTORY 94 CONNECTION

MATERIALS

Wolverine Bronze Company 28178 Hayes Road Roseville, MI 48066 (586) 776-8186 www.wolverinebronze.com

SHOP

PRODUCT

processcast to

net shape”; critical surfaces must be machined FINISHED PRODUCT CLIENTS ESTABLISHED 1956 = 35 Aluminum Bronze Copper alloy Commercialgrade, nonferrous sand castings PART WHOLE ROUGH FINISHED automotive machine & tool aircraft welding conveyor stops

Crude

“near

TOOLS

Located in Roseville, just north of Detroit. The company started when the road was dirt and the surrounding area was still countryside. It was a manufacturing center, and still retains the remnants of that time. Shop is centrally located for their client base. It’s a family business. CNC

Create molds and patterns for holding poured metal. Made the largest aluminum casting in North America for the aircraft industry Created a Michigan product that is sold in China PROCESSES

95 09

Machining centers

Boring mills

sand mixing machines Furnaces (induction & gas) SCALE 1 lb. - 500 lb. (copper alloy) 1 lb. - 50,000 lb. (aluminum) BATCH SIZE: 1 - 1000 COLLABORATION

The shop is capable of making something different. * CNC_ Alliances with other pattern and tooling manufacturers, as well as with chemical companies

CNC

No-bake

FACILITY

Contractors Steel 48649 Schooner Dr. Belleville, MI 48111 (734) 464-4000 www.contractorssteel.com lisales@contractorssteel.com

FACILITY

Structural roll Rotary shear tee splitter Saws Plate shear Punch press

Shop occupies whole buildings in multiple locations: Livonia, MI Van Buren, MI Grand Rapids, MI Twinsburg, OH East Chicago, IN

* In Belleville (323 companywide)

shipments are made daily from each location with fleet of 85 trucks

Carbon steel: Beams up to 36’, Plates from 3/16” to 16” thick, Sheet from 16 gauge to 11 gauge, Hot Rolled Bars, Cold Rolled Bars, Square & Rectangular Tubing up to 60’, Pipe up to 60’ lengths, Channels/Angles up to 60’ lengths, Coil leveling

Beam cambering machine Drill press MAG drills

-Flame burning -Plasma burning -Hi-Def plasma burning -Laser cutting -Sawing PROCESSES

Pre-fab products can be finished inhouse to either rough or highly refined state. Most often components that will go into assemblies made by other shops.

Re:Tool-Kit for Detroit_DIRECTORY 96 CONNECTION

MATERIALS SHOP

CLIENTS < Machine shops Job shops

ESTABLISHED 1960 = 64*

FINISHED PRODUCT

WHOLE ROUGH

PART

FINISHED

fabricators ‘anybody’

The shop was started in the back of a lumber yard by the father of the current owner. He traded his car for a truck that could haul steel, and began with 25 tons of material. They stay in the area because that’s where they’re from, but they ship products to New York, Pennsylvania, West Virginia, Illinois, Wisconsin, and Canada.

Press brake

TOOLS

Leveling/blanking for roll steel

60” Grinder 25-ton Cranes

Fleet of 85 trucks (next day delivery)

Oxy-fuel burn machine

Laser burning machine

Hi-def plasma burning machine

Plasma/contour beveling machine

Plate roll

PRODUCT

-Beam splitting

-Cambering

-Structural and plate rolling

Anything the customer wants. Pre-fabrication from beam to tube to angle, roll and plate

BATCH SIZE: 1 - 1,000,000 whatever the customer wants

SCALE

8’ dia. cylinders to 80’ long plate - limitations only by the size of the material

The shop never makes the same thing twice, so every job is unique and lots of things are possible.

May have a finishing process done elsewhere and shipped back, or may ship pieces to a fabricator working for the same customer.

97

10

* CNC_

13505 Joseph Campau Street Detroit, MI 48212 (313) 336-0140 www.crankshaftcraftsmen.com

Timothy P. Taylor crankcraft@comcast.com

Re:Tool-Kit for Detroit_DIRECTORY 98

Crankshaft Craftsmen

MATERIALS

TOOLS

SHOP ESTABLISHED

Crankshaft grinders Crankshaft welders

1960 = 2 steel SCALE 1” to 24” diameters BATCH SIZE: Average is three.

Sometimes other crankshaft repair shops send them welding they aren’t able to do. They also work with Moldex Crankshaft Manufacturing and auto builders.

FACILITY

Shop was started by former Chrysler workers - remains in Detroit because it doesn't make sense to move. The rent is cheap, but within their hyper-local environment, hiring is difficult because few in the

PROCESSES

Grinders are built specifically for grinding down crankshafts.

Welders are built specifically for evenly applying continuous layers of new metal along cylindrical surfaces.

neighborhood have the capacity to do the work. The blighted neighborhood and the perceived security issues discourage customers from visiting the shop, and can make working with other shops difficult.

PRODUCT

There is no fabricating from scratch - they repair crankshafts and camshafts, mostly for larger-scale engines in industrial machinery.

CLIENTS

The production of the shop is pretty specific and can't really make other things, although one could use the crankshaft welders to build up the diameter on a generic cylindrical surface.

99

11

CONNECTION

*

PART WHOLE ROUGH FINISHED (Repair) FINISHED PRODUCT

crankshaft repair shops

MATERIALS

SHOP

Eutectic Engineering

6350 E. Davison Detroit, MI 48212 (313) 892-2248 www.eutecticeng.com

Charles Baer cebco123@aol.com

FACILITY

Fe + non-Fe

PROCESSES

Creating tools and the forms used to make the parts. Finishing work for cast parts. Melting alloys, baking ceramics, melting wax.

140 different metal alloys Steel, Aluminum, Bronze, Brass (no Titanium)

PRODUCT

The people who work here are the best, smartest, most conscientious and hard-working employees.

Precision castings (investment castings) - examples: stainless steel replacement knee and golf club heads. Precision casting is suitable for lower volume runs of complex parts that need to withstand high temperatures and corrosive environments. Finished castings (often components of another assembly)

CLIENTS

defense industry

The shop has the capacity to make assemblies again (used to)

Re:Tool-Kit for Detroit_DIRECTORY 100

PART WHOLE ROUGH FINISHED FINISHED PRODUCT

Eutectic was founded in 1961, and before the signing of NAFTA they had 120 employees. It's hard for the city of Detroit to be competitive because of safety issues, inconvenience of city services, and the cost of doing business here.

TOOLS

ESTABLISHED

101 12

*

12

1961 =

(was 120) SCALE

BATCH

100

1,000 Capable

100,000

1,000 currently largest Ceramic + Wax (for castings)

Wax presses Grinders Ovens Conveyors Crucible Pneumatic tools Band saw

SIZE:

to

of

(when had more employees)

CONNECTION aircraft industry food service medical Texas oilfield companies new energy companies 2 oz. to 40 lbs.; 14” X 16” matrix

Chop saw Wheel abrator Sand blasters Machining tools

Re:Tool-Kit for Detroit_DIRECTORY 102 CONNECTION

Fabricators, Inc.

Mayfield

MI

425-6840

Shearing CNC Forming Welding Painting PROCESSES MATERIALS SHOP

P. Karaisz

FACILITY PRODUCT Custom sheet metal fabrication and structural metal fabrication. CLIENTS The shop can make something different. ESTABLISHED 1967 = 25 Aluminum Stainless steel Carbon steel The names of the six original shop owners each contributed a letter to the Welk-ko name. Timothy's father took over the business in 1971, focusing at the time on electrical enclosures. Timothy took over the business in 1999. PART WHOLE ROUGH FINISHED High precision - tight tolerances government contracts FINISHED PRODUCT End products are often components finished in house. front office & shop

Welk-ko

11885

Livonia,

48150 (734)

www.welk-ko.com

Timothy

welkko@aol.com

SCALE

has been with WELK-KO for 15-30 years, and they wish to keep the business close to home for the employees. *

Up to 4,000 lbs.

The shop moved from Detroit to Livonia when they outgrew their facility. Livonia made sense, as it is close to family. The average employee Press brake CNC Turret press Powder-coating Welding tools CNC punch press

TOOLS

Maintain

BATCH SIZE: 1 - 1,000 pieces

103 13

CNC_

Local businesses in Michigan, Ohio, Pennsylvania, and Illinois

working relationships with other shops in the area, with whom they will trade jobs depending on which shop is better equipped to handle it. Have signed non-competitive agreements with several other companies in order to foster cooperative relationships.

powder coat

Re:Tool-Kit for Detroit_DIRECTORY 104

Metal Products, Inc.

MATERIALS SHOP

W. Martin

PRODUCT Medical enclosures Industrial machinery Electronics enslosures Computer control boxes Cabinets ESTABLISHED 1971 = 10 <Stainless steel Aluminum Copper Brass Formwork (for concrete) Automotive test equipment PART WHOLE ROUGH FINISHED FINISHED PRODUCT Makes component parts and finished whole assemblies. Fabrication, assembly, and finishing. CLIENTS medical marine construction food service robotics motion control powder coating some plastic

Carlson

2335 Alger Dr. Troy, MI 48083 (248) 528-1931 www.carlsonmetal.com

John

johnmartin@carlsonmetal.com

FACILITY

The company began in Detroit and was moved to Troy in 1987 by original owner Ed Carlson. John Martin purchased the shop in 2000, after working there for 20 years. Press

TOOLS

SCALE

105 14

Turret

Shear Welding

Spray-

brake

press

tools

and powder-coating equipment

Shaping Finishing

CONNECTION BATCH SIZE: 25 - 100 (prior to 2000, was closer to 500-1000) Cutting Bending

(of sheet metal) PROCESSES

* 1/4”X1/4” up to 2-1/4”X3’X4’

Work with a few outside processes, for plating, anodizing, laser cutting, and silk screening.

in with bar napkin sketches.

work with

to resolve confusion, and

offer basic engineering consultation. military automotive mobile electronics industrial electronics

The shop can make something different.

Clients have come

They

all clients

also

20506 Sherwood St. Detroit, MI 48234 (313) 893-2170 www.soleymetalfab.com

David E. Soley dave@salessoleymetalfab.com

Brass Stainless steel (304L, 309, 301, 316)

Exotic Metals

Iconel Halstoloy Titanium

Custom stainless steel fabrications. Precision manufacturing and restorations. Notably: fabricated brass ceiling for DIA; current work with Kresge fellow for 2012 Art Prize installation.

Soley Metal has recently worked with artists to fabricate large-scale artworks in Binmingham, Ann Arbor, and Grand Rapids.

Re:Tool-Kit for Detroit_DIRECTORY 106

CONNECTION

Soley Metal Fabricating

circular steel

edges Punching steel Welding PROCESSES MATERIALS

Bending

Notching

SHOP

PRODUCT Craft-oriented, not super tight tolerances FINISHED PRODUCT CLIENTS ESTABLISHED 1978 = 5

Collaboration with companies that do larger work - sending work back and

with others.

and

and

services to

PART WHOLE ROUGH FINISHED defense/military

forth

Has a diverse clientele

sends out grinding

finishing and other

nearby shops.

*

Overhead costs in Detroit are low. The shop moved to its current location in 1981. In the 1980s Detroit was a lively manufacturing city with shops open all night. The location used to be central to the customer base. Now there are safety concerns and no more walk-in customers.

FACILITY

TOOLS

Heim 120 ton X 144” press brake

Acupress 60 ton X 60”

Niagra 45-ton Minster 4” stroke

Niagra 10 ft. X 3/16” capacity shear

Peck & Stowe shape cutter

Miller Syncrowave 300 & 250 heli-arc

SCALE

From hand-held to large sculptural pieces.

Wiedemann 24-station thick turret 60-ton punch 48” X 120” sheet to 1/4” S/S plate Miller XMT304 multi-process inverter 35KVA spot welder Hand benders

BATCH SIZE: 1-2 at a time

The shop can make something different, and the only restriction they face is space.

107 15

national

municipal/government automotive artists architects

clientele

SHOP

Tolerance Tool & Engineering, Ltd.

20541 Glendale Ave. Detroit, MI 48223 (313) 592-4011 www.toltool.com

TOOLS

CNC