Equally strong and attractive, these metal roofing panels are available in Florida in our full line of PAC-CLAD painted steel, aluminum and Galvalume Plus coatings, ensuring that your roof will endure whatever comes its way. All panels are Miami-Dade County and Florida Building Code approved.

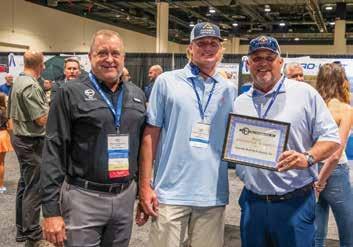

S.T.A.R. Awards Recipient Davis Roofing & Sheet Metal Craftsmanship in Roofing

MFM introduces IB-3™ StormStopper Plus, designed specifically for the Florida roofing market. Stop storm damage in its tracks and offer your customers a qualified FORTIFIED PROGRAM product for years of worry-free service. This 50-mil, self-adhering roofing underlayment features a granulated surface and a non-removable selvedge edge for a secure seal on overlaps for whole roof protection.

IB-3 StormStopper Plus meets ASTM D 1970 and Florida Building Code FL# 41919.1.

FRSA-Florida Roofing Magazine Contacts:

For advertising inquiries, contact: Skip Heymann at: skip@floridaroof.com (800) 767-3772 ext. 127

All feedback and reprint permission requests (please include your full name and address) contact: Lisa Pate, Editor, at: lisapate@floridaroof.com (800) 767-3772 ext. 157

Florida Roofing Magazine PO Box 4850 Winter Park, FL 32793-4850

View media kit at: www.floridaroof.com/ florida-roofing-magazine/ #FRSA #roofingprotects

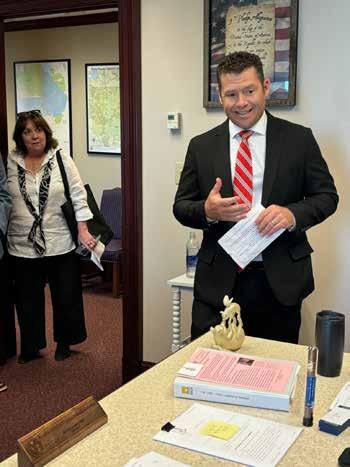

FRSA President Manny Oyola, Jr., Eagle Roofing Products

My wife, Arlene, and I personally invite you to attend FRSA’s 103rd Annual Convention & Expo, June 4-6 at Gaylord Palms Resort and Convention Center. Events are planned for everyone, so bring your team and your family.

The Educational Foundation is offering 26 seminars that include 31 hours of continuing education (CE) credit. There are three advanced (ADV) credit seminars, along with wind mitigation (WMM), workplace safety (WPS), workers’ comp (WC), laws & rules (L&R), business practice (BSP) and general requirement (G) seminars. We’re also offering business courses that do not provide CE credit. FRSA members receive a 20 percent discount on all seminars. There’s also a seminar for Foremen and Superintendents – Safety and Housekeeping – offered at a special rate.

There will be three tournaments offered – Golf at Falcon’s Fire, Clay Shooting at Tenoroc Shooting Range, Lakeland, and Fishing at Sunrise Marina, Port Canaveral. Tournaments sell out each year, so you’ll want to register as soon as possible.

Events are also planned for the family. There are Ladies’ Program events on Thursday and Friday morning and Kids’ Program events beginning on Wednesday evening that include meals, activities and adult supervision.

Join us on Wednesday evening as we kick off the Convention and Expo with a Welcome Reception held in the Gaylord Atrium. The Business Lunch will take place on Thursday and the San Juan Casino Party on Thursday evening. For the Casino Party, come dressed in tropical and casual attire and enjoy gambling, dancing, dinner buffet and an open bar.

FRSA’s Expo is the largest regional roofing show in the industry. This year’s event is the largest in FRSA’s history with 251 exhibiting companies, taking up 130,000 square feet of space. Expo attendees receive free vouchers for lunch on Thursday and Friday.

I’m honored and humbled to serve as FRSA’s 103rd President and look forward to seeing you at Convention & Expo!

If you haven’t registered, please visit www.floridaroof.com/convention to register in advance or onsite beginning Wednesday, June 4.

Best wishes,

Manny Oyola, Jr. FRSA President manuelo@eagleroofing.com

Commercial Roofing Specialties Inc. (CRS), Atlanta, has expanded its Board of Directors. The initiative to expand the Board and add outside Directors began in 2024, was initiated by its Founder, Larry Dale Burns, who passed away unexpectedly in December while still serving as the company’s CEO.

"The establishment of the expanded Board sets in place a governance structure that ensures CRS remains a privately held, family-run entity in the future,” said Brett Burns, CRS President. “Dad started this company in 1981 and we are moving forward with the intent to continue his mission and vision of being the finest independent roofing distribution company in the Southeast."

The Board of Directors will set the long-range financial and strategic objectives of the business and provide critical counsel to the Burns family as the business transitions management from its founder. Each Board member brings top level board and business experience and expertise to CRS.

Independent Board members include TJ Coombs, President of Coombs and Associates, LLC, who is serving as the Board Chair and David Brush, former CEO and President of Richard’s Building Supply, a family-owned roofing and building supply distributor

based in Chicago. The other three members of the Board are Brett Burns, who will continue to serve as President of CRS, Ann Burns and Caroline Burns Richmond. Caroline Burns Richmond will take the position of Executive Director of Strategy and Planning, reporting to the Board Chair and will also serve as Board Secretary.

“Larry was so pleased to have both of his children working in the business with him,” said Ann Burns. “He would be proud today to see them work together to map a path forward for CRS in a way that ensures his vision for the company is solidified for future generations of customers and employees.”

CRS, Inc. was built on a foundation of quality products, a knowledgeable staff, unmatched service and continues to be the go-to supplier for commercial and residential roofing materials and supplies in the Southeast. The company has more than 520,000 square feet of warehouse space and acres of outdoor storage, stretched out over nine locations in major Southeast markets. CRS also offers an extensive e-commerce service that sells roofing supplies and equipment to customers across the U.S.

Bill Mosienko joins Premium Roofing Products (PRP) as the new Vice President of Sales. He is a dynamic addition to the Premium Roofing Products team, arriving in Land O’ Lakes in May 2024 with a rich history of business leadership. Hailing from Oshawa, Ontario, Bill spent two decades in the Pittsburgh, Pa. area before heading west to Phoenix, Az. in 1996.

In Phoenix, he turned his entrepreneurial vision into reality, founding and operating a successful company for 27 years. With a deep understanding of the demands businesses face today, Bill has always prioritized exceptional service, believing that small details make a big difference – a philosophy he brings to PRP.

Beyond his professional life, Bill is passionate about the outdoors and dedicates time to coaching youth hockey, traveling nationwide for competitions. He’s a proud father of three adult children and he’s eager to apply his energy and expertise to strengthen PRP’s customer relationships and contribute to the company’s continued growth.

If you haven’t connected with him yet, now’s the perfect time. Whether you’re a contractor, distributor or property owner, Bill is ready to support your roofing needs with experience, insight and a genuine commitment to service.

FRM

Joe Sorrentino, RRO, Region Account Manager of the GEOCEL Kool Seal Brands for The Sherwin-Williams Company Roofing Solutions Group is retiring after 47 years in the low-slope commercial roofing industry. Joe joined the Sherwin-Williams team in March 2015 as Government and Public Sector Sales Manager, Special Projects. He previously served as Commercial Roofing Trainer and Development Manager supporting the owner, property manager and design community (architect, engineer, roof consultant) for sustainable, renewable, labor and material warranty programs for the service life of the facility.

His role includes participation in IIBEC, NRCA, AIA, CSI, FRSA and RCMA. Joe has been responsible for the development and delivery of comprehensive training programs for SW Roofing Solutions team members (existing and on-boarding), independent sales representatives, SW TAG employees, professional roofing contractors, building owners, specifiers, influencers and independent distribution employees, as well as other external and internal stakeholders. Joe received his Bachelor of Science Degree in Economics from Florida Southern College, Lakeland in 1977.

Since 1985, Joe has been working in the field of sustainable roofing and industrial coating systems. He started his roofing career as a Commercial Roofing Sales Representative for Owens Corning Fiberglass in Charlotte, NC in 1977. During his years in the roofing industry, he has held positions of Regional and National Technical Manager for

single-ply and modified bitumen roofing systems, Regional Sales Manager for a leading protective and maintenance coatings products manufacturer and Business Development Manager for a national facilities engineering and roof consulting firm. He works closely with owners, property managers, contractors and specifiers nationwide.

Joe earned the Registered Roof Observer designation (RRO) from RCI (now IIBEC) and in June 2016 and has been active in IIBEC as a participant for the Mentoring Program since 2017. The Florida Chapter of IIBEC awarded Joe the 2023 Mentor of the Year Award.

Joe will continue to be active in roofing industry associations such as FRSA, NRCA and IIBEC. His new firm will support the roofing industry in the areas of education and marketing.

In the next chapter, Joe will travel more and enjoy time with family and friends. We wish Joe all the best in his retirement!

APOC Polyset AH-160 has been reformulated with a low global warming potential (GWP) blowing agent to meet the nationwide regulations while staying true to the features and benefits you are familiar with.

This two-component, polyurethane foam adhesive adheres each individual tile in place with superior holding power compared to nails, screws, mortar and wire tie systems. Depending on roof pitch, it can be used without mechanical fasteners so it won’t puncture the waterproofing membrane or the roof deck.

www.apoc.com | www.icpgroup.com info@icpgroup.com

Lisa Pate, FRSA Executive Director

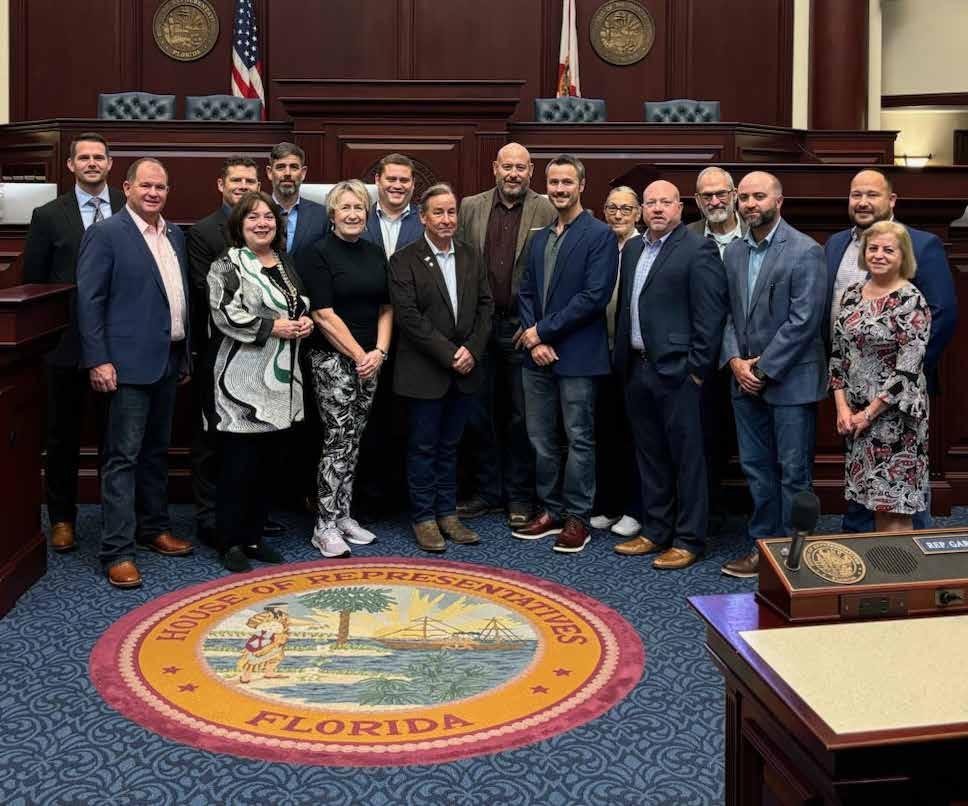

At the end of March, FRSA held its third annual Roofing Day in Tallahassee, where a small group of members visited the Capitol to speak with legislators. The event mirrored NRCA’s successful Roofing Day in D.C. Spearheaded by Governmental Affairs Committee Chairs, Ralph Davis, Streamline Roofing & Construction Inc., Tallahassee and Tammy Hall, CFS Roofing Services LLC, Ft. Myers and organized by FRSA Legislative Counsel, Chris Dawson, the group held several successful meetings over the three-day event.

With the legislative session only a week in, some of the topics we addressed were just being presented to members of the legislature and were new to our group as well. Chris was able to schedule meetings with several key legislators who focused on business, education, building codes, workers’ comp and contractor fraud.

In order to cover as many meetings as possible, attendees broke into two groups. Meetings were held with Representatives Taylor Yarkosky, Dan Daley, Tom Fabricio, Jennifer Canady, Griff Griffitts, James Buchanan and Mike Redondo. Senators included Tom Leek, Stan McClain and Kristen Arrington. Top legislative priorities for the team included:

■ Supporting HB 715 and SB 1076 – Roof-to-Wall Connections – which has since passed both the House and Senate and is headed to the Governor to sign. If signed by the Governor, it will allow roofing contractors to perform roof-to-wall connections when reroofing. Currently, that function is outside the scope of a roofing contractor’s license. The bills also clarify the length of a State of Emergency for roof repair contract cancellation window available to consumers and limits the

amount of time up to 180 days following the triggering event. Meaning that even if the Governor extends a State of Emergency, the cancellation contract language will only be required for 180 days per qualifying event.

■ Advocating for Protecting Consumer Choice and asking for support to keep asphalt shingles an approved roofing system. All roofing systems that meet the rigor of the Florida Building Code should be available to consumers without undue market influence from Tallahassee (Office of Insurance Regulations Commissioner Yaworsky). Premature roof tear-offs should be avoided to promote

long-lasting, resilient roof systems of all types. Homeowners should be incentivized to invest in resilient roofing systems without fear of an arbitrary life span being imposed.

■ Support for HB 681 and SB 1458 – Apprenticeship and Preapprenticeship Program Funding. Early exposure to career opportunities in the trades

will help students evaluate all postsecondary and career planning options. CTE dollars should be delivered in a student-first model, cutting down on bureaucratic waste.

topics

■ Support for HB 1461 and SB 1452 – DBPR to Provide True Oversight of Employee Leasing Companies.

The meetings were all very productive and the team had the opportunity to provide additional language for consideration on some bills.

Chris was able to keep us on task, focused and on time – no small feat. Special thanks to our sponsors Eagle Roofing Products and the Southwest Roofing Florida Roofing Contractors Association (SWFRCA) for underwriting the expense.

I recently had the privilege of attending the third annual FRSA Roofing Day in Tallahassee. As a member of FRSA and a newer member of the Codes Committees, I attended the event interested to see just how the process works and to learn about the involvement of our legislators in the things that are important to us as professionals in the roofing industry. We had a schedule of events put together for us by Chris Dawson. We broke up into two small groups led by a couple of our Committee Chairs and visited the offices

of several legislators and had real discussions with Florida House of Representatives, Senate members and staff. We went into each meeting with a list of key talking points on issues that we wanted to get support on or request changes to. I was pleasantly surprised to see that our legislators had direct knowledge and could speak in depth about the items that we brought to them.

Aside from the meetings with legislators, we also had a few meetings with some other very interesting

business professionals. The first was Tim Cerio, CEO of Citizens Insurance Company. We discussed several topics concerning insurance and the roofing industry. We also had a meeting with Herbie Thiele from Sachs Media who gave us an informative presentation on what Sachs does for ARMA and FRSA on the media and marketing front. We also heard from Andrew Wiggins from the Florida Chamber of Commerce who gave a detailed political update on the State of Florida. I enjoyed

hearing updates from people who are directly involved in all of it s. Overall, the entire experience was educational and enjoyable.

Trent Cotney, Partner, Adams & Reese

In workplaces where multiple employers operate simultaneously, ensuring safety compliance can be a complex challenge. OSHA enforces a Multi-Employer Citation Policy, which holds multiple parties accountable for workplace hazards, depending on their roles and responsibilities. There have been updates and clarifications that impact roofing contractors, subcontractors and other employers working on shared sites. Understanding these updates is essential to maintaining compliance and preventing costly citations.

A multi-employer worksite is any location where multiple employers have a presence and contribute to workplace conditions. Construction sites, manufacturing plants and large-scale industrial projects often fall into this category. OSHA’s policy applies broadly, ensuring that all employers who affect workplace safety are responsible for upholding regulations, even

if their own employees are not directly exposed to the hazards.

OSHA uses a two-step process to determine which employers can be held accountable for safety violations on a multi-employer worksite:

■ Identifying the Employer’s Role –Employers are categorized as either a creating, exposing, correcting or controlling employer based on their level of involvement in a hazard.

■ Assessing the Employer’s Efforts to Comply – OSHA examines whether an employer took reasonable measures to address and correct safety hazards in accordance with their specific role.

To clarify responsibilities, OSHA recognizes four distinct types of employers on a shared worksite:

Creating Employer: This employer is responsible for introducing a hazardous condition. If an employer’s actions or inactions create a workplace hazard, they can be cited, regardless of whether their own workers are directly affected.

Exposing Employer: If an employer’s workforce is exposed to a hazard – regardless of who created it – they must take steps to protect their employees. Failure to do so can result in citations if OSHA determines that the employer had knowledge of the risk and did not act appropriately.

Correcting Employer: Employers tasked with correcting hazards (such as safety contractors or those responsible for equipment maintenance) must take immediate steps to mitigate risks. If they neglect this duty, they can be cited under OSHA’s regulations.

Controlling Employer: This category applies to employers with general supervisory authority over the worksite. General contractors and site managers often fall into this role and are expected to take reasonable

steps to prevent and correct safety violations among subcontractors and workers under their oversight.

Legal interpretations and OSHA enforcement policies have evolved, influencing how citations are issued on multi-employer worksites. Key updates include:

Expanded Accountability for Controlling Employers: Courts have reinforced that controlling employers have an active duty to enforce safety compliance, even if they do not directly supervise subcontractor employees.

Greater Focus on Documentation: Employers now face increased scrutiny regarding their safety records. A subcontract should have provisions in it which require the subcontractor to be responsible for their own safety.

Increased Citations for General Contractors: Recent case law has upheld citations against general contractors who failed to address known hazards, even if subcontractors were primarily responsible for the unsafe conditions.

Emphasis on Training and Communication: OSHA has stressed that all employers on a multi-employer worksite should conduct safety meetings and document hazard communication efforts to prevent accidents. However, it is important to reinforce that the subcontractor is responsible for managing its own safety.

To minimize liability and enhance workplace safety, employers should adopt proactive measures, including:

Strengthen Subcontractor Agreements: General contractors should develop subcontract agreements that explicitly assign the burden of safety management to the subcontractor. These agreements should include specialized provisions requiring subcontractors to implement their own safety programs, conduct training and bear responsibility for OSHA compliance on their portion of the project.

Avoid Branding Subcontractors with Prime Contractor Logos: To reduce the risk of being seen as a direct employer of subcontractor workers, prime contractors should avoid allowing subcontractors to wear company-branded apparel. This can help prevent legal arguments that subcontractor employees are actually under the control of the prime contractor.

Enforce Safety with Top-Down Measures: When safety violations are found, address them immediately by notifying the head of the crew or the subcontractor’s management, rather than individual workers. Make it clear that they are in breach of contract and will be back-charged administrative time for the violation.

This approach reinforces accountability at the management level and encourages subcontractors to enforce safety compliance within their own teams.

Conduct Regular Site Inspections: Frequent safety audits help identify and address hazards before they lead to violations or accidents.

Document Everything: Maintaining detailed records of safety meetings, inspections and corrective actions can serve as critical evidence in the event of an OSHA investigation.

Employers operating on multi-employer worksites must remain vigilant about their safety responsibilities. Understanding OSHA’s Multi-Employer Citation Policy and staying updated on recent legal developments can help businesses mitigate risks, avoid citations and create a safer work environment. We anticipate future legal challenges and changes from the Trump administration may also impact the doctrine.

By implementing strong safety practices, maintaining thorough documentation and fostering communication among all employers on a worksite, companies can ensure compliance and protect both their workforce and their bottom line.

FRM

The information contained in this article is for general educational information only. This information does not constitute legal advice, is not intended to constitute legal advice, nor should it be relied upon as legal advice for your specific factual pattern or situation.

Trent Cotney is a partner and Construction Team Leader at the law firm of Adams & Reese and FRSA General Counsel. You can reach him at trent.cotney@arlaw.com or 866-303-5868.

Adams & Reese is a full-service law firm dedicated to serving the roofing industry. FRSA members can contact Trent Cotney to discuss and identify legal issues and to ask general questions through access to specialized counsel. They offer free advice (up to 15 minutes) for members. If additional legal work is required, members will receive discounted rates. This is a pro bono benefit provided to FRSA members only. Contact Trent at 866-303-5868.

John Kenney, CPRC, CEO, Cotney Consulting Group

In the roofing industry, your workforce is more than labor; it’s your reputation, productivity and the foundation of your future success. As we’ve covered in previous articles – on mastering cash flow, business excellence, quality control and bid-hit-win ratios –having solid systems in place are essential. At the core of every excellent roofing business is a great team. Without the right people, systems break down, quality suffers and growth stalls.

The labor shortage in roofing isn’t going away anytime soon. That means forward-thinking contractors must be diligent about recruiting, training and leading. Building a high-performance team isn’t luck, it’s strategy. This article provides a practical roadmap broken down into three phases: attracting talent, developing and retaining that talent and leading your team for long-term growth.

Recruitment: Hire for the Long Term, Not Just the Job In today’s tight labor market, roofing contractors can’t afford to be reactive. Instead of hiring when you’re short, develop a proactive pipeline of candidates who align with your values and work ethic. This means contacting local trade schools, technical colleges and vocational programs early and often. Internships or job-shadowing experiences can introduce young workers to the trade and your company.

Don’t underestimate the power of your current team. Employee referral programs tap into a trusted network and encourage team members to take ownership of who joins the crew. And when interviewing, go beyond experience. Ask behavioral questions that assess reliability, coachability and fit. Culture trumps experience every time.

Onboarding: Set the Tone Early

How you bring people into your company determines how long they’ll stay. A structured onboarding program with checklists, safety training, company expectations and a clear point of contact builds confidence and reinforces professionalism. Assigning a mentor or team lead during a new hire’s first 90 days encourages faster integration and creates camaraderie.

Too often, roofing companies throw new hires into the field with little preparation, hoping they’ll “figure it out.” This leads to frustration, mistakes and early turnover. Invest the time up front and you’ll see returns in retention and job performance.

High-performing crews don’t just happen – they’re built through continuous training. Whether it’s proper shingle nailing patterns, metal roofing installation or understanding new code updates, your team should always be learning. Invest in structured, hands-on training that aligns with manufacturer specifications and internal quality standards.

But don’t stop at the field. Leadership training for forepersons and supers is essential. Technical skills are one thing but managing people, resolving conflicts and planning are entirely different. Many top roofers are promoted without being equipped for leadership. That gap affects morale and productivity on the jobsite.

Office staff need growth, too. Estimators, project coordinators and admin personnel benefit from systems, communication and time management training. When your back office runs efficiently, it keeps the field running smoothly and your cash flow intact.

Retention isn't just about pay – people stay where they feel valued, challenged and connected. Culture starts at the top and is reinforced daily by how people are treated and recognized. Make recognition part of your weekly rhythm. Whether it’s a simple thank-you, a crew lunch or an “Employee of the Month” spotlight, appreciation boosts morale and loyalty.

Provide clear growth paths. Show team members what it takes to move from laborer to lead, from crew to crew chief. A job without upward mobility becomes a revolving door. Conduct quarterly check-ins to listen, coach and clarify goals. Two-way feedback is vital –employees want to be heard, not just managed.

Compensation: Think Holistically

Competitive wages are matter but they are only part of the equation. Contractors who provide predictable hours, year-round work and benefits, even modest ones, tend to attract more serious professionals. Offering PTO, tool stipends and optional retirement

plans can set you apart from competitors who rely solely on hourly rates.

Consider performance-based bonuses, project incentives or profit-sharing programs. When your team has a financial stake in the outcome of a job, they’ll care more about hitting deadlines, minimizing rework and upholding standards.

Leadership: Accountability Starts at the Top

Even the best crew members will underperform without strong leadership. Your superintendents and forepersons must model the behavior you want to see: punctuality, professionalism, jobsite cleanliness and communication. Train your leaders to coach, not command. Create a leadership development track with soft skills like active listening, conflict resolution and crew motivation.

Consistency matters. Set expectations for every role on every crew and ensure accountability systems are in place. This might include daily jobsite checklists, photo documentation or quick huddles to align on goals and standards. A leader’s ability to reinforce expectations and follow through when they’re missed creates the structure in which high-performing teams thrive.

As your company grows, systems that worked with 10 employees won’t work with 30. That’s why you must prepare your people and processes in tandem. Crosstrain team members to handle multiple roles, increasing flexibility and keeping operations running when someone’s out or leaves unexpectedly.

Start succession planning before you need it. Identify potential future leaders and provide them with the mentoring and exposure they need to be ready. Scalability also requires consistent systems, replicable onboarding, standardized training and clear communication protocols. This creates predictability, freeing owners and managers to focus on strategic growth instead of daily fires.

Bonus Insight: Create a Feedback Loop

To keep improving your team and culture, create feedback mechanisms that go both ways. Anonymous surveys, suggestion boxes or quarterly roundtables allow employees to share thoughts on what’s working and what’s not. You’ll identify trends before they become issues and build trust by showing that leadership listens and adapts.

This feedback loop also helps you stay competitive. What motivates today’s workforce changes? Understanding their needs – more flexibility, modern tools or a better path to advancement – can help you

Continued

Mike Silvers, CPRC, Owner, Silvers Systems Inc. and FRSA Technical Director

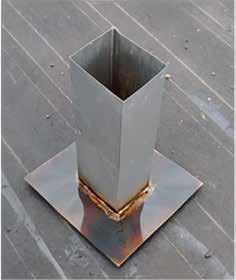

When answering calls for FRSA, I never know what the primary topic of the conversation might be. Calls come from consumers, engineers, architects, building officials and others but primarily they come from our members: contractors, manufacturers and distributors. Some are easy to address and are repeated often. Others can be complex and may be the first time the question has arisen. I took one of the latter from a contractor a few days ago. He explained that he was about to start a new low-slope roof system installation. During a walk-through, he noticed that the internal roof drainage point didn’t have a roof drain, just a PVC pipe flush with the top of the metal deck. He inquired why this was the case and asked, “where is the roof drain?” The designer said that it wasn’t required and then said, “show me where it says in the building code it’s required.” I get questions about where a specific requirement is located in the building code, often. As those who are familiar with the code know, it is not presented in a question-and-answer format and only the simplest questions can be answered in a single section. More often, the answer is found by navigating a pathway that leads you to it. That was the case here. Before diving into specific code sections, a little background information was needed. When an internal roof drainage system is routed through the interior of a building, it needs to be sealed. If there is any chance that the drain could back up, it must be sealed to resist leakage from a head of water or head pressure. The pressure is created by water building up on the roof

and in the leader as well. In cases where the seams in the drain leaders and downspout occur outside the building, a gravity seal or lap is acceptable. This arrangement was used often during mid-century construction that employed what we referred to as "porch tubes." These were typically used in buildings with overhangs and soffits. A porch tube is like a scupper except it flows straight downward – as opposed to a scupper that extends through a wall or mansard. It should be a sealed unit until it extends through the soffit. If the termination is left open and of sufficient size, blockage won’t occur. If it is run into a downspout and blockage does occur, the leakage from the laps will happen outside of the building envelope. It may only take one turn or elbow to eventually create a blockage. In a more typical drainage system routed through the building interior, there can be many reasons for the drain to stop flowing properly that including:

■ Clogging or restrictions from debris

■ Rainfall in amounts that exceed the flow rate of the system

■ Flooding that limits the outflow of the storm drainage system or outlets near the ground

■ A combination of two or more of the above often occur during hurricanes.

Most experienced roofers that provide repair services on low-slope roofs have come across the

In 2023, Fund members received $5 million in Dividends and in June another $2 million based on 2023 performance –while workers’ comp rates are the lowest in history.

inverted lead boot or other similar arrangement, stuffed into a roof drain or the roof drain leader or piping. When heavy rain or blockage occurs, head pressure is created in the system and often causes severe water intrusion and interior damage. The drain at its flashing and any connections inside the structure must be sealed to resist this pressure. With a standard cast iron or PVC roof drain, this is accomplished by a clamping ring that uses the flashing material as a gasket between the drain body and the clamping ring. Other arrangements offer a flashing flange that can be stripped-in or heat welded to. The termination of these drains or flashing arrangements inside the leader must be sealed. Some of these use an inner expansion unit that expands through different mechanisms to create a seal to the inner part of the leader. When using these, the inside of the leader must be clean and relatively smooth: again, think of a gasket effect.

In my opinion, the following code sections lead us down a path to answer the question "are drains required?" We will not address all the sizing and other drainage requirements in the code. They are

voluminous. I do hope to demonstrate that drains are required in the circumstances described and they must accommodate the ability to be flashed in compliance with the roof covering manufacturer’s installation instructions. Note: For emphasis, I have bolded some of the text in teh code paragraphs below.

Alternately tighten seal compression ring screws with U-Flow Screwdriver until hand tight.

2023 Florida Building Code, Building, Eighth Edition Chapter 15 Roof Assemblies and Rooftop Structures

1501

1501.1 Scope. The provisions of this chapter shall govern the design, materials, construction and quality of roof assemblies, and rooftop structures.

SECTION 1502 – DEFINITIONS

1502.1 Definitions. FLASHING. The roofing component used to seal roofing systems, where the system is interrupted or terminated.

Hercules ® , RetroDrain ® , OlyFlow ®, SuperDome®and U-Flow ® a Copyright © 2023 OMG, Inc. All rights reserved.

SECTION 1503 – WEATHER PROTECTION

1503.1 General. Roof decks shall be covered with approved roof coverings secured to the building or structure in accordance with the provisions of this chapter. Roof coverings shall be designed in accordance with this code and installed in accordance with this code and the manufacturer’s approved instructions such that the roof covering shall serve to protect the building or structure.

1503.4 Roof drainage.

Unless roofs are sloped to drain over roof edges, design and installation of roof drainage systems shall comply with Section 1503 and the Florida Building Code, Plumbing, Chapter 11.

1503.4.1 Secondary (emergency overflow) drains or scuppers. Where roof drains are required, secondary (emergency overflow) roof drains or scuppers shall be provided where the roof perimeter construction extends above the roof in such a manner that water will be entrapped if the primary drains allow buildup for any reason. The installation and sizing of

secondary emergency overflow drains, leaders and conductors shall comply with Sections 1106 and 1107, as applicable, of the Florida Building Code, Plumbing, Chapter 11.

SECTION 1506

1506.1 Scope. The requirements set forth in this section shall apply to the application of roof-covering materials specified herein. Roof coverings shall be applied in accordance with this chapter and the manufacturer’s installation instructions. Installation of roof coverings shall comply with the applicable provisions of Section 1507.

1507.1 Scope. Roof coverings shall be applied in accordance with the applicable provisions of this section and the manufacturer’s installation instructions.

2023 Florida Building Code, Plumbing, Eighth Edition

CHAPTER 11 – STORM DRAINAGE

SECTION 1101 – GENERAL

1101.1 Scope. The provisions of this chapter shall govern the materials, design, construction and installation of storm drainage.

1101.6 Fittings and connections. All connections and changes in direction of the storm drainage system shall be made with approved drainage-type fittings in accordance with Table 706.3. The fittings shall not obstruct or retard flow in the system.

1101.7 Roof design. Roofs shall be designed for the maximum possible depth of water that will pond thereon as determined by the relative levels of roof deck and overflow weirs, scuppers, edges or serviceable drains in combination with the deflected structural elements. In determining the maximum possible depth of water, all primary roof drainage means shall be assumed to be blocked. The maximum possible depth of water on the roof shall include the height of the water required above the inlet of the secondary roof drainage means to achieve the required flow rate of the secondary drainage means to accommodate the design rainfall rate as required by Section 1106.

SECTION

1102.6 Roof drains. Roof drains shall conform to ASME A112.6.4 or ASME A112.3.1. Roof drains, other than siphonic roof drains, shall be tested and rated in accordance with ASME A112.6.4 or ASPE/IAPMO Z1034.

1105.1 General. Roof drains shall be installed in accordance with the manufacturer’s instructions. The inside opening for the roof drain shall not be obstructed by the roofing membrane material.

1105.2 Roof drain flow rate. The published roof drain flow rate, based on the head of water above the roof drain, shall be used to size the storm drainage system in accordance with Section 1106. The flow rate used for sizing the storm drainage piping shall be based on the maximum anticipated ponding at the roof drain.

1102.6 Roof drains. Roof drains shall conform to ASME A112.6.4 or ASME A112.3.1.

ICC Commentary

ASME A112.6.4 regulates the design and construction of roof drains. Roof drains must have either a dome or grate covering the opening. This helps restrict leaves and debris from entering the storm drainage piping and creating a stoppage. Because roof drains are exposed to extreme temperatures, it is common practice to install an expansion joint between the roof drain and the storm drainage pipe.

ASME A112.3.1 provides details for Types 304 and 316L stainless steel roof drains.

Based on these passages, it seems clear that the Florida Building Code assumes that roof drains are required when part of a storm drainage system. Regardless of the type of drain used, it is imperative that the attachment of the drain and the leader prevent undue movement where they intersect with the roof assembly. Most importantly, a pressure seal is required when a head of water could possibly occur in the drainage system. The code says that all primary roof drainage means shall be assumed to be blocked, so head pressure must also be assumed. It is also clear that the roof covering shall be installed according to manufacturer’s installation instructions which include roof drain flashing.

Mike Silvers, CPRC, is Owner of Silvers Systems Inc. and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient and brings over 50 years of industry knowledge and experience to FRSA’s team.

Marcin Pazera, Ph. D, Senior Director of Technical Affairs, PIMA

As one of the largest surfaces in direct contact with the outdoor environment, a roof assembly plays a crucial role in the performance and durability of a commercial building envelope. This role becomes even more critical in Florida’s hot, humid and storm-prone climate where the assembly must withstand challenging conditions like intense heat, moisture and wind pressures. Meeting these performance criteria and delivering a resilient roof requires the right combination of system design, advanced building technology and precise installation.

The importance and challenge at hand presents opportunities for Florida roofing contractors who can leverage the proven capabilities of polyisocyanurate (polyiso) insulation products to design high-performance and durable roof systems. A rigid foam insulation, polyiso has one of the highest R-values per inch and is available as a flat stock roof insulation, tapered roof insulation and high-density (HD) cover board. Its excellent thermal resistance mitigates heat transfer between indoor and outdoor environments. In Florida, using polyiso as part of the roof system can help keep the heat out and reduce loads on the HVAC systems to maintain cool temperatures inside. Beyond its thermal resistance, polyiso’s moisture resistance capabilities, compressive strength and

fire performance can help Florida roofing contractors deliver a resilient roof system.

In hot and humid states like Florida that are subject to rainstorms throughout the year, moisture resistance is key to longevity of roofs. Moisture intrusion can compromise thermal performance, promote mold growth and undermine the structural integrity of a building. “With proper system design and installation, polyiso’s multifunctional qualities can help roofing contractors reduce moisture intrusion into the building,” notes Heather Estes, Principal Codes and Regulatory Compliance Lead at GAF.

Polyiso’s closed-cell structure naturally resists water and vapor intrusion, ensuring long-term durability. For enhanced moisture protection, contractors can utilize polyiso with a coated glass facer (CGF).

These facers consist of a multi-layer construction and a coating to impart a versatile, weather resistant outer layer. In combination with the glass mat core and polymer coating, CGF offers dimensional stability and increased resistance to water absorption.

Additionally, in projects where the roof may lack proper drainage but structural modifications are impractical or cost-prohibitive, roofing contractors can opt for polyiso tapered insulation as part of their system designs to mitigate water ponding and improve overall roof system durability. Tapered insulation products are manufactured to the desired slope and configuration in order to accommodate the existing

rooftop conditions and improve rainwater management.

Florida’s strong winds and hurricane-prone climate make wind uplift resistance a top priority for commercial roof system design. “The height of the building, location and architectural features, such as parapet walls or drip edges, all determine the wind pressures that need to be met,” explains Matt Plowman, Senior Sales Representative at Johns Manville, who has spent over a decade working in Southeast Florida.

Contractors can successfully integrate polyiso flat stock and tapered insulation boards in roof assemblies designed for Florida’s high wind conditions. In these systems, the entire roofing system, including the insulation, roof cover boards, membranes and flashings are designed to withstand these pressures. Many contractors prefer adhered membrane systems for this feature but polyiso is incredibly versatile and can also be mechanically fastened on top of the roof deck. As a result, contractors can use polyiso in a variety of common roof assembly systems. To improve overall roof system performance and durability under severe conditions, the code requires continuous roof insulation to be installed in multiple layers with staggered joints.

This installation method also minimizes thermal bridging between board joints, reducing the opportunity for air and moisture movement through the roof system and can be used to bury fasteners to further reduce thermal bridges when the top layer of insulation is adhered over a mechanically attached base layer. All of these factors are key to improving building envelope performance.

When asked about other roof installation best practices, Estes added that contractors should also pay attention to perimeter flashing to seal the roof at

the building edges in order to mitigate wind exposure. Additionally, both Estes and Plowman emphasized that applying a cover board beneath the membrane further strengthens wind resistance and enhances overall system durability.

Cover boards play a critical role in improving a roof’s resilience to wind uplift, foot traffic, extreme weather events and accommodating rooftop solar or mechan-

ical installations. HD polyiso cover boards provide a multifunctional solution, to meet Florida project targets while also contributing to the roof’s thermal performance through its rated R-value (typically R-2.5 for 0.5-inch-thick HD polyiso cover board).

HD polyiso cover boards are available as individual panels or as composite products (with the cover board adhered to polyiso roof insulation boards). They are available in three compressive strengths: 80 psi (ASTM C1289 Type II, Class 4, Grade 1), 110 psi (Grade 2) and 140 psi (Grade 3) and can be installed over flat and tapered insulation systems.

Unlike traditional gypsum cover boards, which provide little to no R-value, a 0.5-inch-thick HD polyiso cover board provides an R-value of 2.5 to the roof assembly. This contributes to the total R-value requirement of a roof, optimizes roof thickness and streamlines installation, particularly when using composite HD polyiso cover boards that come pre-adhered to polyiso roof insulation panels. A combination of polyiso insulation and HD polyiso cover board means contractors may have fewer layers of material to install to meet a project’s performance and resiliency requirements, which saves material costs, time and labor.

In addition to delivering thermal, moisture and wind performance, fire performance is another code-required factor for contractors to consider. The Florida Building Code contains several fire safety provisions and fire resistance requirements for roof assemblies.

Building codes have regulated the use of foam plastic insulations using a two-step approach. The first step establishes a minimum performance baseline for the insulation itself. The second step evaluates entire assemblies containing foam plastic insulation using full-scale tests that are representative of the intended end use. It is important to note that the code requires most roof

assemblies, regardless of insulation type, to be fire tested as fully constructed assemblies.

For polyiso roof insulation products, the code requires products to have a flame spread index of 75 or less and a smoke developed index of 450 or less when tested in accordance with ASTM E84 or equivalent tests at the thickness intended for end use. Polyiso insulation, as a thermoset plastic, can resist temperatures up to 390ºF, which is more than twice the temperature resistance of some other building insulation products. Additionally, unlike thermoplastic insulation materials (such as polystyrene), polyiso stays intact by neither melting nor dripping during fire exposure. Instead, it forms a protective surface char that enhances its fire resistance by reducing flame spread.

Owing to its tested fire performance, polyiso is the only foam plastic insulation product approved for direct application to steel decks that has earned FM Approval for Class 1 Roof systems. This means that a roof assembly with polyiso has successfully passed a series of tests that include external and internal fire exposure, wind uplift, water leakage and impact resistance. As a result, polyiso direct-to-deck assemblies can meet NFPA 276 or UL 1256 standards and can be installed without a thermal barrier. “Because of its fire performance, polyiso-integrated roof systems can help contractors deliver durable roofs designed

to meet modern fire safety standards,” says Estes. As a reminder, contractors should always verify the code-compliance of a particular assembly with the manufacturer and install according to the prescribed installation instructions.

For roofing contractors in Florida, designing resilient roof systems requires careful consideration of moisture control, wind uplift resistance, impact durability and applicable fire codes. The range of available polyiso products offers high-performance solutions that meet these challenges head-on. The insulation’s high R-value, moisture resistance, adaptability to various installation methods and proven fire performance help enhance the longevity, resilience and efficiency of the building envelope in the state’s demanding climate. FRM

Marcin Pazera, Ph.D., is the senior director of Technical Affairs for the Polyisocyanurate Insulation Manufacturers Association (PIMA). Visit polyiso.org for more information. Special thanks to Heather Estes of GAF and Matt Plowman of John Manville for contributing their expert insights to this article.

During FRSA’s Convention and Expo, we’re offering 31 hours of continuing education seminars that feature the best-of-the-best industry instructors. Many of the seminars focus on changes in the Florida Building Code presented by instructors who possess strong insight into the code and its application. They provide real-world examples and can respond to specific questions that you face in your day-to-day operations. We’re also offering eight hours of non-CE seminars that focus on business operations, sales, management and finance and are taught by experts in these fields.

Alexis Ayala

FRSA Self Insurers Fund

Alexis has over 10 years of insurance industry experience, having spent the last six years exclusively on workers’ compensation. Along with her underwriting duties at SIF, she is responsible for the Premium Audit Department and issues with the state rating organization (NCCI).

Adams & Reese

Tray works for Adams & Reese and represents clients in all aspects of construction law, including liens, bonds, construction defect litigation, OSHA defense and licensing. Previously, he worked in construction as an estimator for a multi-million-dollar structural contracting company.

Jim Brauner

Brauner Safety Services

With more than 40 years of experience in the industry, Jim understands the importance of education. He owns Brauner Safety Services offering OSHA 10/30, CERTA Torch and a full range of safety training. Jim is a Campanella Award recipient and FRSA Honorary Member.

Ben Briggs

Adams & Reese

Ben works for Adams & Reese and represents clients in all aspects of labor and employment law, including wage and hour, discrimination and retaliation claims, drafting employment contracts, restrictive covenants and more. Ben has been recognized by Florida Super Lawyers for his work.

Brian Chamberlain

Carlisle Construction Materials

Brian has been with Carlisle Construction Materials since 1987. He earned a Bachelor of Science in Architectural Design from the University of Wisconsin and assists architects, consultants and specifiers on assemblies focusing on performance, sustainability and resilience.

Gary is Vice President at Certified Contractors Network (CCN), helping small and mid-sized contractors develop a plan to increase the size or profitability of their business. He is a seasoned business executive and certified professional coach.

Bo Copeland Integrity Metals

Bo is the Business Development Manager at Integrity Metals where he manages new product development, the product approval process and oversees the Gainesville manufacturing facility. He holds a general contractor’s license and a Bachelor of Science from the University of Florida.

Carlisle SynTec Systems is dedicated to leading the industry by developing and manufacturing the most progressive and innovative roofing materials on the market. Every Carlisle product is designed to enhance building performance and contractor efficiency. Carlisle has pioneered productivity-boosting products such as SeamShield™ Technology, Self-Adhering Technology (SAT ™ ), Sure-Weld 16' TPO, 12' InsulBase with ReadyFlash Technology, and many others.

For more information on Carlisle’s productivity boosting products scan here

Trent Cotney

Adams & Reese

Trent, a Campanella Award recipient and FRSA Honorary Member, is a Partner and National Construction Practice Group Leader at Adams & Reese. He is well known throughout the roofing community and is FRSA’s and NRCA’s General Counsel.

David is an Eastern Region Technical Services representative at Eagle Roofing Products of Florida. He is a licensed Florida roofing contractor with 40 years of experience in the roofing industry, primarily with tile roofing systems, including both residential and commercial projects.

Debbie Guidry, CPCU

FRSA Self Insurers Fund

Debbie has been at the FRSA Self Insurers Fund for 35 years and serves as Administrator. SIF is a self-funded workers’ comp insurer for the roofing, sheet metal and trade industries in Florida that has paid over $200 million in dividends to members since the 1990s.

Greg Keeler

Owens Corning

Greg is the Technical Services Leader for Owens Corning Roofing and Asphalt with decades of experience in architecture and as a building official. He serves on or chairs several ASTM D08 task groups and is a member of FRSA’s Codes Committee and Codes Subcommittee.

John Kenney, CPRC

Cotney Consulting Group

John has over 50 years of experience in the roofing industry. He started his career by working as a roofing apprentice at a family business in the Northeast and worked his way up to operating multiple Top 100 roofing companies. John is CEO of Cotney Consulting Group.

With a passion for empowering businesses, Marci leads Seay Management Consultants. Her extensive experience as an executive leader has fueled success across diverse organizations. Seay Management offers FRSA members free and discounted HR consultations.

Kevin Lindley

FRSA Self Insurers Fund

Kevin Lindley is part of the SIF Safety team with 20 years of experience in the roofing industry, focused primarily on safety compliance. Kevin has a Bachelor of Architectural Design degree from the University of Central Florida. He is an Authorized NRCA CERTA Program Trainer.

Paul Oleksak

Westlake Royal Roofing Solutions

Paul serves as Technical Trainer at Westlake Royal Roofing Solutions and has worked in the roof tile industry since 1990. He holds a Florida roofing contractor license and has been active on FRSA’s Codes Committee and the FRSATRI Roof Tile Committee for over 20 years.

Michael Polizzi

A.C.T. Metal Deck Supply

Michael started in the metal deck industry selling and managing projects for eight years. He currently serves as President of A.C.T. Metal Deck Supply, a metal deck distributer with 15 locations in the U.S., where he developed distribution territories and a sales department over the past 13 years.

Dan Shurtz

Aletheia Digital

Dan is Executive Vice President at Aletheia Digital. With roofing clients across North America, Aletheia Digital has a strong knowledge of the roofing business and understands the challenges contractors face in growing their business in an ever-changing and highly competitive industry.

Mike Silvers, CPRC FRSA Technical Director

Mike is the owner of Silvers Systems, Inc. and a licensed roofing contractor with more than 50 years of industry knowledge and experience. He serves as FRSA’s Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient.

Chad Westbrook Service Alignment

Chad, Founder of Service Alignment, is a sales and service expert dedicated to building sustainable, scalable sales and service teams. Encouraging companies to challenge the status quo, he has contributed to millions of dollars in commercial sales and revenue year-over-year.

S.T.A.R. Awards – the Spotlight Trophy for the Advancement of Roofing – is an awards program designed by FRSA to recognize members’ unique and outstanding projects. A panel of four judges evaluates and selects three recipients from each category.

This year, there were 42 submissions for placement in one of four categories: Community Service, Craftsmanship in Roofing, Low-Slope and Steep-Slope. The judges – Joe Williams, RRC, AIA, A/R/C Associates Inc., Orlando; Mike Silvers, CPRC, Silvers Systems Inc. and FRSA Technical Director, St. Petersburg; Bill Boyer, CPRC, Duro-Last, St. Johns and Gary Register, Register Roofing & Sheet Metal, Jacksonville – spent a day reviewing the projects. Judging criteria included aesthetics, special circumstances, unique project design, complexity of project, workmanship, teamwork, testimonials and creative problem solving. The judges evaluated before, inprogress and completed pictures and videos to assist in the judging process.

Below are the top 11 projects by category in random order. First, second and third place will be announced at the FRSA’s Convention on Thursday, June 5 at the FRSA Business Lunch. The Shining STAR Award – the “Best of the Best” – the project the judges selected as the overall top project and will also be revealed at that time.

A Kid’s Place is dedicated to providing a safe haven for children entering into the foster care system. When Tanner of Jenkins Roofing learned the nonprofit was raising funds for the renovation of their facilities, he knew Jenkins Roofing had to step up to the plate. The safety and stability of the children’s living conditions being paramount, reroofing the main building and the five adjacent homes was identified as the key priority. Thanks to the generosity of numerous businesses, including Gulfeagle Supply, Jenkins Roofing was able to complete the renovations at a fraction of the cost.

A local 47-year-old business, Al’s Family Farms was devastated by an EF3 tornado in the aftermath of Hurricane Milton in October of 2024. That’s when the local community came

together. Neese Roofing, one of Tri County Metals’ customers, agreed to cover the roofing and wall labor and looped in Tri County Metals, who agreed to provide a 5V metal roof, accessories and materials donated free of cost. The materials needed included 26g 5V galvanized roof and wall panels. Tri County Metals was pleased to play a role in helping this local community family favorite and business icon.

This historic home in Jacksonville’s San Marco neighborhood was last reroofed in the 1970s. The owners chose Santafe Spanish “S” tile. Precision Exteriors worked with Santafe’s sales department to create a custom blend of four colors. The entire roof was mortared in place but once the tear-off started, the team from Precision Exteriors saw that some areas were actually concrete, up to 1-1/2 inches thick. The tear-off was slow, back breaking work. A rotary hammer was used to break up the concrete in places. Once the project was completed, the team from Precision Exteriors knew it was worth the effort.

This 1930s cottage exudes charm with intricate brick and stucco designs, flowering gardens and a sweeping fauxthatch roof. At the end of 2023, however, the home was hit by a terrible hailstorm that damaged almost the entire roof. The crew, dedicated to replicating the previous style, paid immense attention to detail, carefully working their way up the roof, constantly referencing photos to match the style and wave-coursing as closely as possible. The wave-coursing averaged a mere 2-1/2-inch exposure, which meant using twice as much material as a typical install.

Quality Roofing, Inc. completed a highly specialized roofing project at the University of Tampa, where the building is a national historic preservation site. Due to the building’s unique status, every aspect of the project had to be custom-fabricated.

While some components were precisely created using a laser on a tripod, other elements had to be custom fabricated directly in the field. The Quality Roofing team is extremely proud of their work on this project, which required a high level of craftsmanship and attention to detail to meet the historic preservation standards.

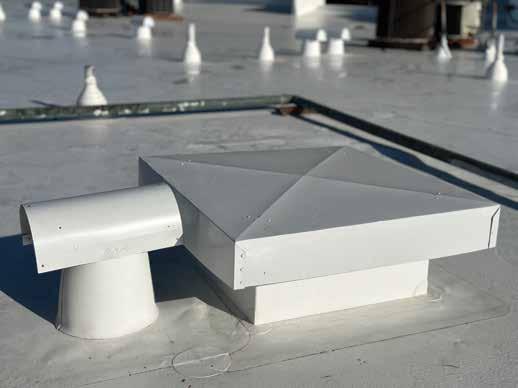

planters. The building stands 11 stories. The most challenging part of the project was transporting heavy materials, particularly the pavers, through the elevator system in the middle of the building.

The Cosmopolitan Residence is a luxury condominium with 223 units. The roof spans 44,500 square feet, covering two buildings: one four stories and the other six stories. A three-ply APP modified bitumen system was installed providing the Cosmopolitan with a new 20-year roofing system. A tapered ISO system using a modified bitumen torch and tapered insulation system with a cover board was installed directly to the concrete deck to provide adequate drainage and eliminates ponding water. The project’s success was derived largely from good communication with the condo board that allowed it to be completed without disruption to the residents.

The KLS Martin expansion was a highly intricate yet rewarding endeavor, exemplifying Register Roofing’s capabilities as a diversified and skilled roofing contractor. By successfully implementing five distinct roofing systems and managing multiple specialized crews, they demonstrated their expertise in executing large-scale, multi-faceted installations with precision and efficiency. Register Roofing’s partnership with Siplast enabled the integration of a comprehensive range of roofing solutions, ensuring optimal durability and long-term performance. The final result was a superior-quality roofing system that met the client’s expectations and contributed to the successful realization of their flagship expansion.

Following extensive hurricane damage, two Grand Isles Towers underwent a complete roofing replacement to restore durability and aesthetics across the community. The project involved installing 365 squares of Brava composite slate and Spanish tile on multiple structures. Executing a highrise roofing project of this nature required rigorous safety measures, expert coordination and technical precision. By utilizing Brava’s premium composite materials and industry-leading steep-slope roofing techniques, FL Specialty Roofing delivered a stormresistant, architecturally stunning roofing system that enhances the Grand Isles community’s resilience and aesthetic appeal.

The owner of this new construction project requested a custom blend of blue tile from Ludowici to complement the aesthetic of the house. To create a seamless look, he requested the same color for the mortar. The project also included the installation of several dormers. Together, the uniqueness of the tile color and matching mortar on a significant size custom home made this installation standout.

Quality Roofing Inc. was selected by The Beck Group for several roofing sections of this University of Tampa building, including the Skypark, which consisted of Siplast lightweight insulating concrete roof and a waterproofing system with Hanover pedestal paver system and vegetative garden

The roofing project on Harbour Island in Tampa involved the installation of a steep-slope metal roof on two seven-story buildings. It featured Polyglass MTS underlayment and Petersen SNAP CLAD standing seam panels. Due to the challenging height and steep pitch, the crew had to come up with unconventional methods of fall protection to ensure safety. Scaffolding was placed in each corner of the buildings, providing support for the crew while carrying 10 to 12-foot panels during the project. Despite the difficulties, Quality Roofing, Inc. successfully completed the project.

Kevin Lindley, Safety Consultant, FRSA Self Insurer’s Fund

Every day, thousands of people suffer eye injuries that could have been prevented by wearing proper safety glasses. Whether in industrial settings, construction sites, laboratories or even at home, protecting your eyes should be a top priority. Understanding the role of safety glasses, their different types and proper usage can help reduce the risk of eye injuries significantly.

Safety glasses are designed to shield your eyes from hazardous materials, debris, chemical splashes and radiation. Many workplace injuries involve flying objects, dust, sparks and harmful liquids that can cause serious damage to the eyes. Wearing safety glasses helps prevent blindness, corneal abrasions and long-term vision impairments.

Impact-Resistant Glasses: These are designed for high-risk environments such as construction sites, manufacturing plants and workshops. They feature durable polycarbonate lenses that can withstand heavy impacts. Impact-resistant glasses will typically have a A87.1+ stamp on either the inside of the temple near the side hinge or on the lens.

Chemical Splash Goggles: Commonly used in laboratories and chemical plants, these goggles protect against liquid splashes and fumes.

UV Protection Glasses: Designed for outdoor workers, these glasses shield eyes from harmful ultraviolet (UV) rays and reduce glare.

Prescription Safety Glasses: For individuals who require vision correction, prescription safety glasses combine protection with clear vision.

Welding Goggles and Shields: Essential for welders, these protect against intense light and sparks produced during welding processes.

When selecting safety glasses, consider the following factors:

Compliance with Standards: Ensure the glasses meet ANSI Z87.1 or OSHA regulations for eye protection. Fit and Comfort: A proper fit ensures maximum protection and reduces discomfort during prolonged use. A comfortable pair of safety glasses will encourage employees to wear them.

Lens Type: Choose lenses based on the nature of the hazard: clear for indoor use, tinted for outdoor protection and anti-fog for humid environments.

Side Shields: Some jobs require additional side protection to guard against lateral impacts, especially if the glasses being worn do not provide the required side protection.

To ensure safety, glasses provide optimal protection:

■ Always wear them in hazardous environments close enough that they will not allow flying objects to enter from above, below or from either side.

■ Keep them clean and free from scratches and damage. Safety glasses are not a single-use personal protective equipment item. Employees should take care of their safety glasses.

■ Store them in a protective case or location they will not be easily damaged or broken.

■ Replace damaged or worn-out glasses immediately. It is recommended to have workers turn-in broken or heavily damaged safety glasses. While it is the employer’s responsibility to provide mandatory personal protective equipment for their workers to use, the individual workers are responsible for taking care of the equipment, wearing the equipment, bringing the equipment back to work every day and notifying their supervisor of damaged equipment.

Investing in good-quality safety glasses is a small price to pay for protecting worker’s vision. Whether at work or home, individuals should always prioritize eye safety to prevent injuries that could have lifelong consequences. By choosing the right safety glasses and using them properly, workers will be more likely to wear the glasses when required and their eyes will remain safe and healthy for years to come.

FRM

Homeowners and roofing contractors alike are constantly seeking roofing system components that blend durability, sustainability and aesthetic appeal. Atlas has answered the call with an exceptional line of asphalt shingles, underlayments and ventilation designed to protect, perform and impress. Among the offerings, two standout products – Pinnacle Sun shingles and Pinnacle Impact shingles – are the perfect choice for Florida homeowners.

Atlas Pinnacle Sun: Cool Roofing That Works Overtime

Atlas Pinnacle Sun shingles represent a cutting-edge step forward in sustainable, energy-efficient roofing. As the only manufacturer to integrate 3M Cool Roofing granules, Atlas Roofing Corporation has created a product that does more than just look good – it performs in real, measurable ways.

These advanced shingles are engineered to reflect solar heat, reducing the temperature inside the home and thereby decreasing the demand on air conditioning systems. This not only contributes to a more comfortable indoor environment but also significantly reduces energy bills and greenhouse gas emissions. In warmer climates, this feature alone can lead to long-term savings and increased home value.

But Atlas doesn’t stop there. Pinnacle Sun shingles also incorporate 3M Smog-Reducing Granules, a revolutionary technology that helps remove smog from the air. These granules use sunlight to convert smog-forming pollutants like nitrogen oxides into water-soluble ions, which are then washed away by the rain. One roof covered in Atlas Pinnacle Sun shingles can have the smog-fighting power equivalent to planting two to three trees. This commitment to sustainability is a powerful example of how Atlas is leading the way with eco-conscious innovation.

Pinnacle Impact: Engineered for Hail and Harsh Weather

When it comes to storm protection, Pinnacle Impact shingles are second to none. Built with Class 4 impact resistance – the highest rating available – these shingles are designed to endure the most extreme weather conditions without sacrificing aesthetic appeal.

Homeowners living in high-wind and hail-prone regions understand the importance of investing in roofing that can withstand damage and minimize costly repairs. Pinnacle Impact shingles use a reinforced polymer-modified asphalt that enhances flexibility and resilience, allowing them to absorb the force of hail and resist cracking or tearing. This strength also helps protect the integrity of the roofing system as a whole, preventing leaks and other structural issues that can come unexpectedly.

Atlas Roofing Corporation’s commitment to quality and innovation is evident in the engineering behind the Pinnacle Impact line.

In addition, Pinnacle Sun and Pinnacle Impact also feature Scotchgard Protector by 3M, providing lifetime protection against the unsightly black streaks caused by algae. This ensures that homeowners not only get the rugged durability they need but also enjoy lasting curb appeal.

Both shingle lines showcase the best of what Atlas offers: high-performance products that are made in the USA and trusted by over 1.8 million homeowners. These shingles are available in a wide array of beautiful, designer-inspired colors that maintain their vibrancy thanks to the lifetime algae protection from Scotchgard Protector by 3M.

As the only manufacturer that integrates 3M Cool Roofing granules, 3M Smog-Reducing technology and lifetime algae protection into a single roofing solution, Atlas sets itself apart in a crowded market. Homeowners no longer need to choose between style and substance – Atlas delivers both, along with unmatched durability.

Atlas continues to lead the industry by combining innovative technologies with superior craftsmanship. Whether your priority is sustainability, storm resistance or stunning curb appeal, Atlas Pinnacle family of products and additional system components provide roofing solutions that meet your needs and exceeds expectations.

The Atlas Signature Select Roofing System delivers complete protection from eave to ridge with perfectly coordinated components – premium synthetic underlayments, starter shingles, hip and ridge shingles and ventilation. Featuring HighPoint and TruRidge ventilation solutions, this system helps regulate attic temperatures and reduce moisture buildup, ensuring better performance, longer roof life and maximum warranty coverage you can count on.

From the smog-reducing capabilities of Pinnacle Sun to the unmatched hail protection of Pinnacle Impact, these shingles represent the future of residential roofing. They are proof that environmental responsibility and rugged durability can go hand in hand.

Atlas is the smart choice for homeowners and contractors who demand more from their materials. Every roof installed with Atlas shingles becomes part of a growing network of homes protected by superior products backed by industry-leading warranties.

For more information on Atlas shingles, premium underlayments, ventilation and the full line of high-quality roofing solutions, please visit www.atlasroofing.com.

Lisa Pate, FRSA Executive Director

When I first began working for FRSA in 1985, we had 63 employees who worked for FRSA Services Corporation, our for-profit division. Much has changed over the years as we evolved from an Association offering services outside the scope of our founding documents to an Association focusing on the needs of our members. What originally consisted of ten different entities has been whittled in half and provides more specialized services for member companies.

Today, between the Association and the Credit Union, we’re a small staff of eight full-time employees, two consultants and one retired part-timer, each with a specific skill set that enables the whole organization to run smoothly.

“Teamwork Makes the Dream Work” is one of my favorite sayings and it embodies the spirit of our small but hardworking staff. I’m often told what a great job our team does on certain projects, events and publications and know that it takes all of us to accomplish these goals.

FRSA is the largest regional roofing association in the country, offering membership benefits, industry-specific educational programs, code and technical support, human resources and legal services, a Convention and Expo and media publications. Through the Credit Union, we offer equipment and vehicle loans, project financing, mortgage lending and in-person and online banking services. SIF offers workers’ comp insurance to members who meet their underwriting guidelines and, together, FRSA is a onestop-shop for the services and support contractors need to successfully run their businesses.

So, who makes up our team?

Mike Reed, CPA, Retired, Part-Time Accountant

Mike officially retired from FRSA two years ago after 32 years. Although he trained his replacement, she ended up leaving us for greener pastures. Mike came back last year to help us through the year-end audit and continues to work part-time as our Accountant. He prepares and oversees all aspects of the financials for the Association, Services Corp. (our for-profit

entity for Florida Roofing magazine), Educational and Research Foundation, Foundation Endowment and the Political Action Committee. Three years ago, Mike convinced the Executive Committee to consider investing in U.S. Treasury Bills and by doing so, all three of FRSA’s entities have earned considerable, consistent returns. Mike is an FRSA Honorary Member. He has a wonderfully dry sense of humor and is quick witted. He has been a great friend over the years and when he finally does retire, I will miss him dearly.

John Hellein, Director of Educational & Research Foundation

John has been with FRSA for 13 years and serves as the Educational Foundation Director. His duties include staff liaison for the Foundation, Endowment Board of Governors and the Worker Training Subcommittee. He also assists with the Codes Committee and Codes Subcommittee and works closely with Mike Silvers on many projects. John’s part-time job at FRSA? IT guru and photographer. And, although he won’t admit it, he’s also a continuous source of entertainment for the staff. John proudly boasts that he is the hardest working delegator on staff.

Alison Locklar, Convention Director

Alison has been with us just over a year, starting out as our Office Manager and then moving into the Convention Director position two months ago. She is also the staff liaison for the Convention and Ladies Committees and the Young Professionals Council. Alison is funny and extremely outgoing and known for her infectious giggle. You may have met her last year as she headed up the Registration Desk at Convention.

Rachel Zehnal, Expo Director

Kelly Sealander, Membership Director

Kelly’s been with us for 18 months. She started as our Office Manager and quickly moved into the Membership Director position, where we hit the 1,000-member mark last year. She’s done a wonderful job in bringing in new members and is on track to exceed last year’s numbers. Kelly is also staff liaison to the Membership Committee and the Affiliate Council. She has a great sense of humor and an outgoing personality with a love for hippos and New Kids on the Block.

I have known Rachel since she was 12 years old. She began working with us four years ago, originally as the Administrative Assistant for the Convention and Expo department. Last year, I split the Convention and Expo into two different positions to accommodate the growth we’ve experienced in this area. Rachel works mainly with our exhibitors but also sells sponsorships for the events, hitting an all-time record this year. She is an incredibly talented artist, has a wonderful sense of humor and an obsession with all things dinosaurs and Jurassic Park. Unfortunately, Rachel will be leaving us after the Convention, moving out of state, where she has family. She will be sorely missed.

Joshua Smith, Administrative Assistant Joshua began working with us in March and although he assists where needed, his main focus is keeping John Hellein on track and Foundation duties. He’s in charge of soliciting donations for the Foundation Auction and preparing items for Convention seminars. Joshua has a great sense of humor and quickly adapted to our “strong A personality” mostly female staff.

Amber Morris, Administrative Assistant Amber began working with us in March as my administrative assistant. For about 15 years, I’ve had a “wish list” of items I’d like to have completed and in her first two weeks, Amber completed one of the largest tasks on that list – scanning an entire filing cabinet of documents that we’ve had around for decades. After Convention, Amber will be taking over Rachel’s position as Expo Director. Amber is quiet, bubbly, glittery and extremely artistic.

Lisa Pate, CEM, Executive Director

After working with Mike as a contractor member for 30-plus years, it was a pleasant surprise when he agreed to work with FRSA as a consultant. I have worked with Mike in just about every facet of the Association, not only as a member but also when he served as FRSA President in 1994. There are very few people who know the Florida Building Code as well as Mike does and I was elated when he came on board as our Technical Director. Mike is a Life Member, Certified Professional Roofing Contractor (CPRC) and a Campanella Award recipient. He is staff liaison to the Codes Committee, Codes Subcommittee and Worker Training Subcommittee. Mike is an easy-going mentor and friend who helps me to see the other side of issues. Every year, he donates an incredible themed gift package to the Auction that brings in big bucks for the Foundation.

Skip Heymann, Ad Sales Manager