dpsmagazine.com

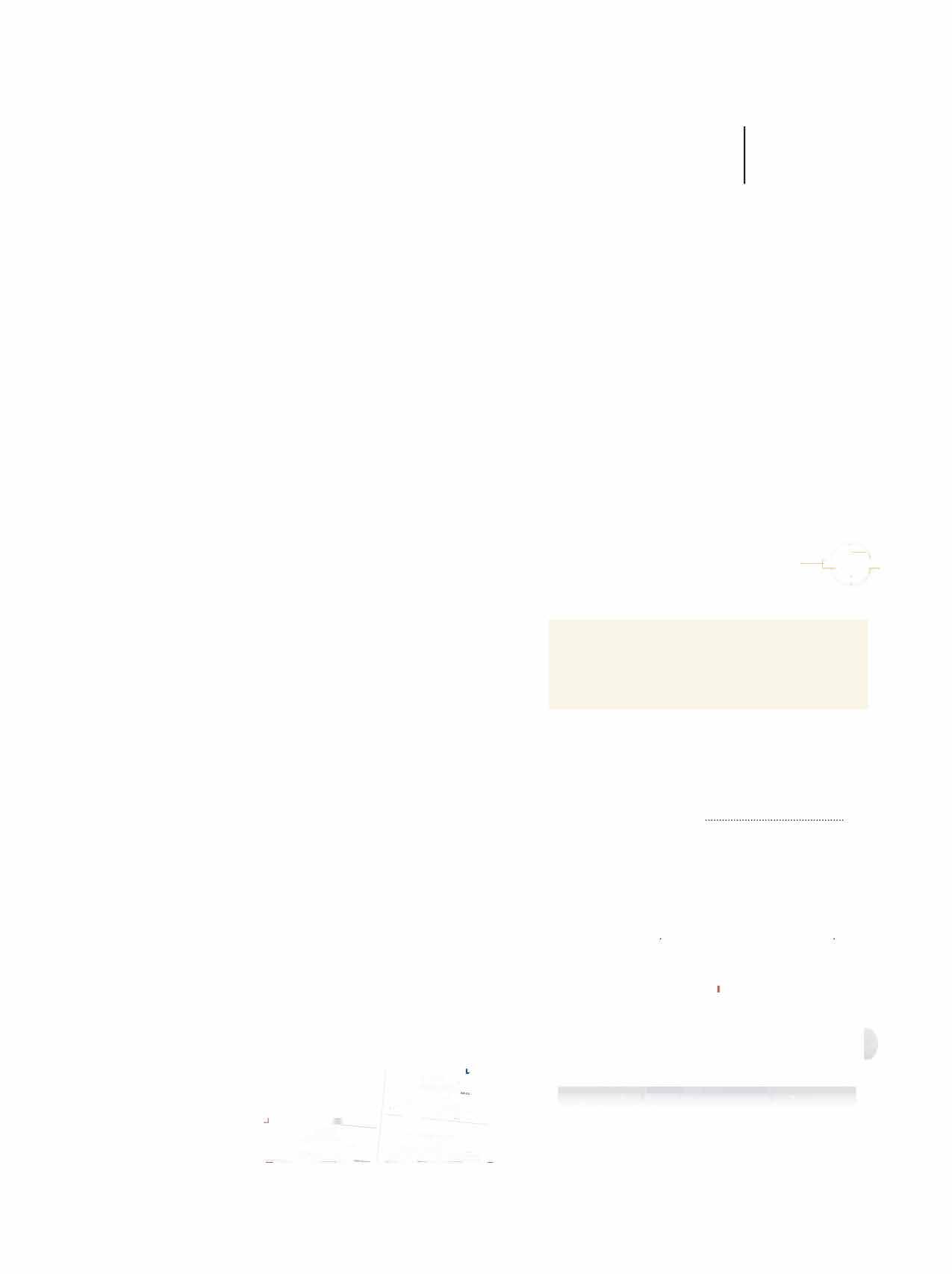

Volume 28, Number 1 • ISSN: 1529-2320

dpsmagazine.com

Volume 28, Number 1 • ISSN: 1529-2320

A new year means a fresh outlook, a good time to reset and consider future business goals. Do you want to diversify your business by adding new applications or improve productivity by revamping your production workflow?

Our January issue once again offers the printed version of our Buyers Guide. While the online guide is available online 24/7 in an interactive format, the printed version provides an easy resource for finding your next business partner.

We also look into the continued evolution of digital label production. Incorporating Automation highlights the advantages achievable with the help of automation and digital print technologies. Whether you would like to add digital label printing applications to your existing commercial print portfolio, or expand digital technologies to an active label and packaging environment, many benefits are ripe for the taking with a strategic investment in digital print technologies for label production.

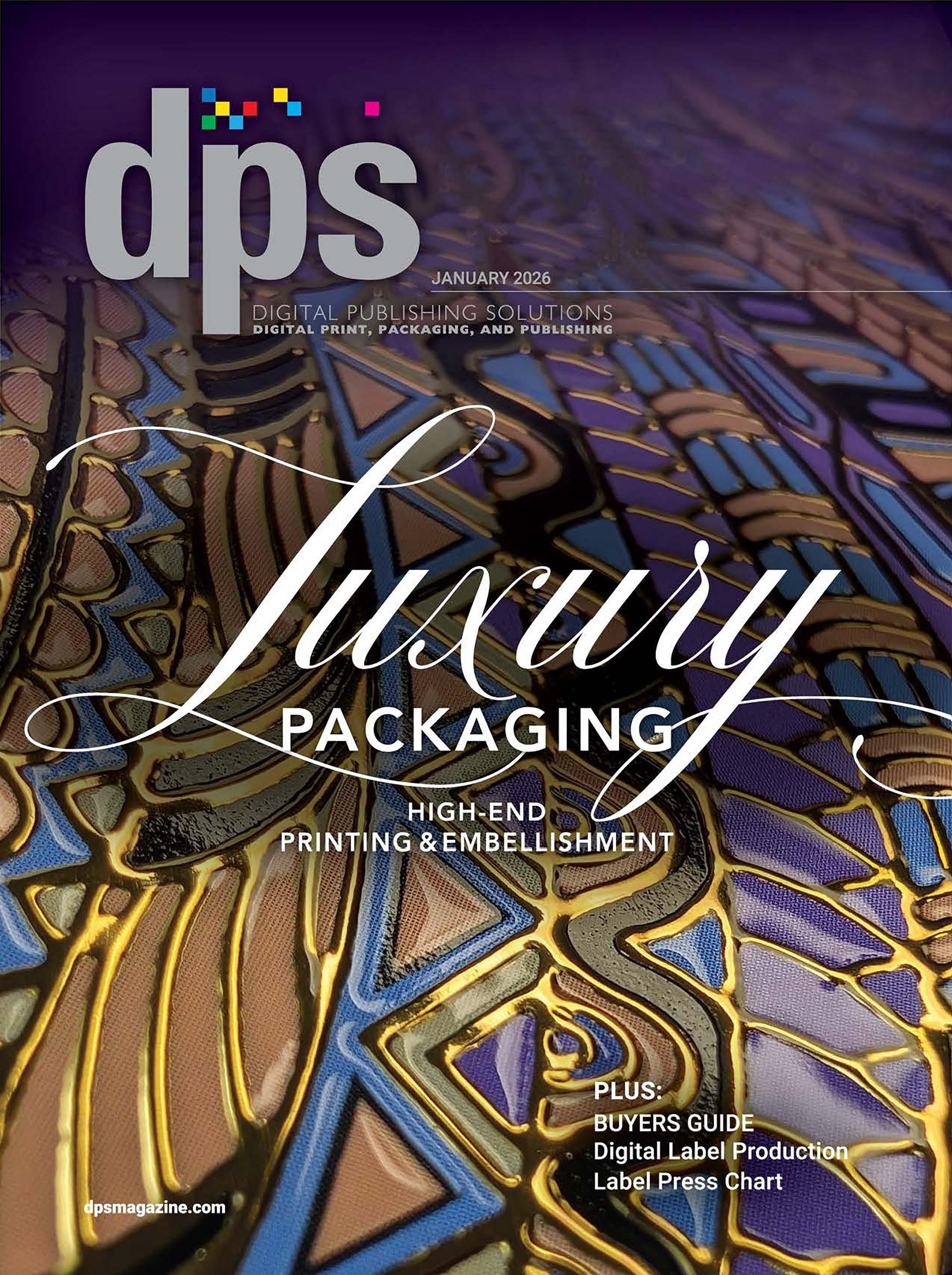

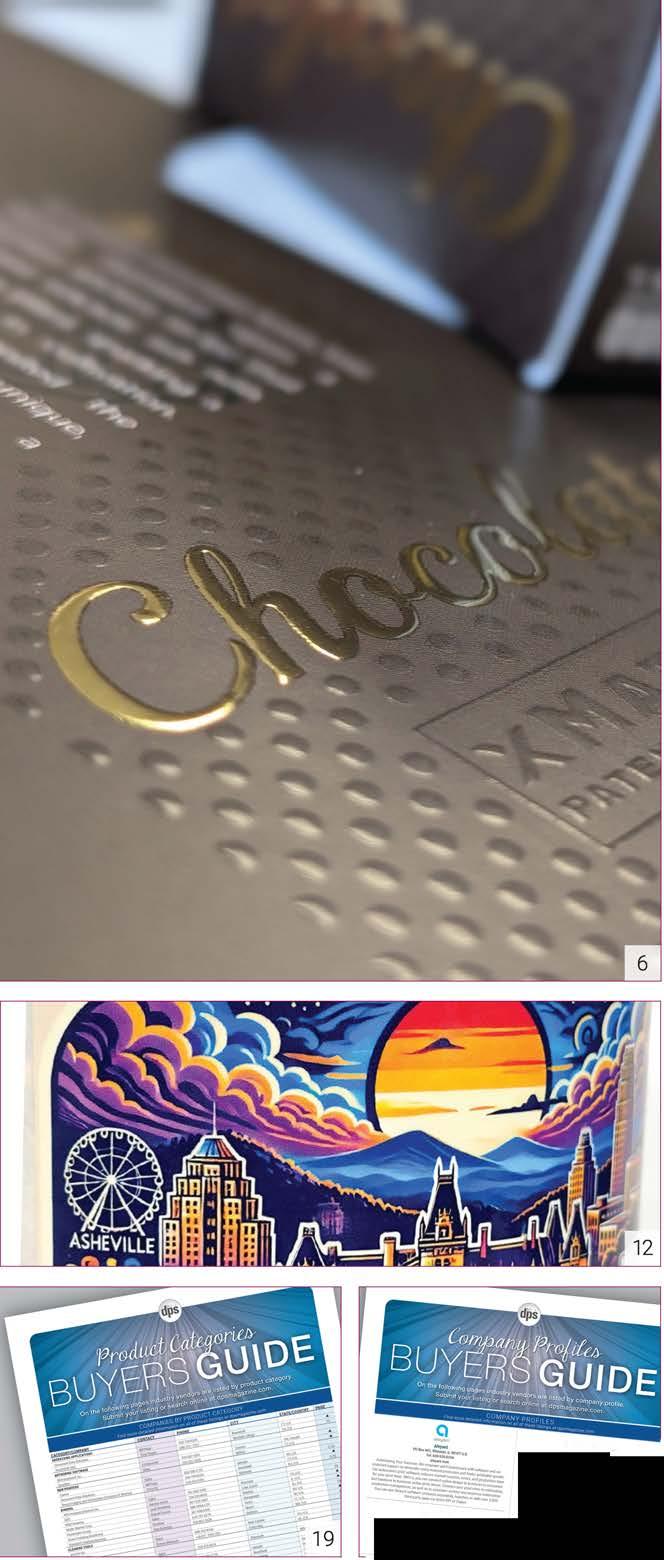

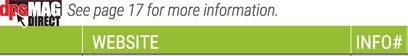

Standing on the shoulders of our partnership with LuxePack, we highlight popular finishing techniques that support luxury packaging in our cover story Eliciting Emotion. Brand owners want to stand out on the shelves with effects that look and feel opulent.

Don’t forget to visit us online at dpsmagazine.com for exclusive editorial, industry news, webinars, and more.

We look forward to bringing you unbiased, feature articles that hit on key issues and trends surrounding the digital printing industry—from transactional print to labels and packaging—throughout the year and beyond.

Keep an eye out for our online reader survey and tell us what type of content you’re looking for as we head into 2026.

Happy New Year!

Cassandra Balentine, editor cbalentine@rockportpubs.com

EDITOR IN CHIEF

Thomas Tetreault 978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Marco Boer, Kemal Carr, Olivia Cahoon, Richard Huff

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

300 Newburyport Turnpike, Ste. 11 Rowley, MA 01969

Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 300 Newburyport Turnpike, Ste. 11 Rowley, MA 01969

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

By Cassandra Balentine

remium finishing adds alue to digitally printed p . Print enhancement and embellishment tools support digital production and the creation ofluxurypackaging.

"Luxurypackagingisdefinedby theexperienceitcreates,"statesNeil

Drever,productconsultant,Skandacor."It'snotjustaboutprotectingthe productbutaboutpresentation,perception,andemotionalimpact."

Thistypeofhigh-endpackaging ischaracterizedbyexceptionalquality,distinctivedesign,andtheuseof premiummaterialsandfinishesthat

createamemorableunboxingexperience."Itcommunicatesexclusivity, craftsmanship, and brand prestige, oftenincorporatingembellishments toelevatetheperceivedvalueofthe

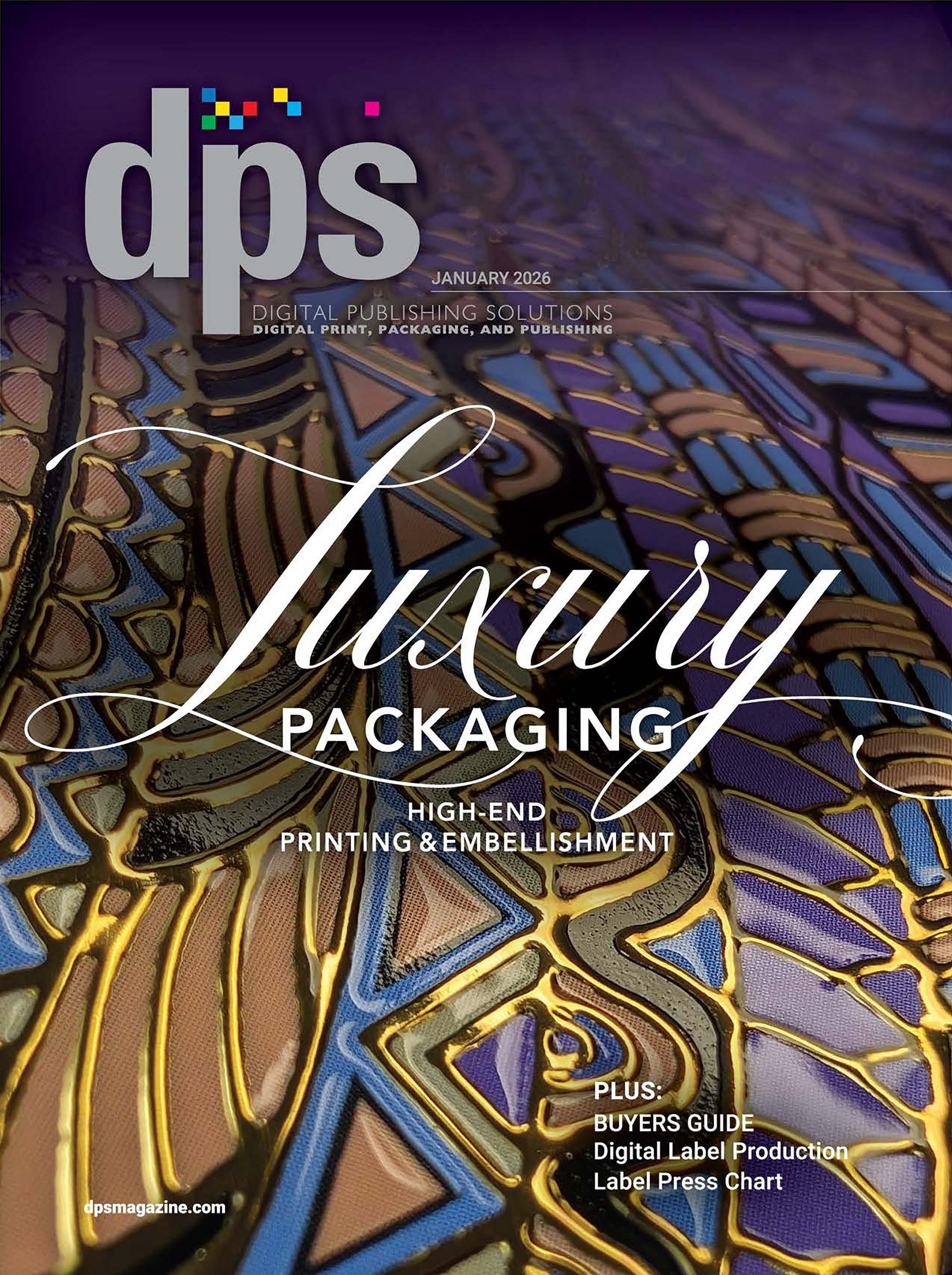

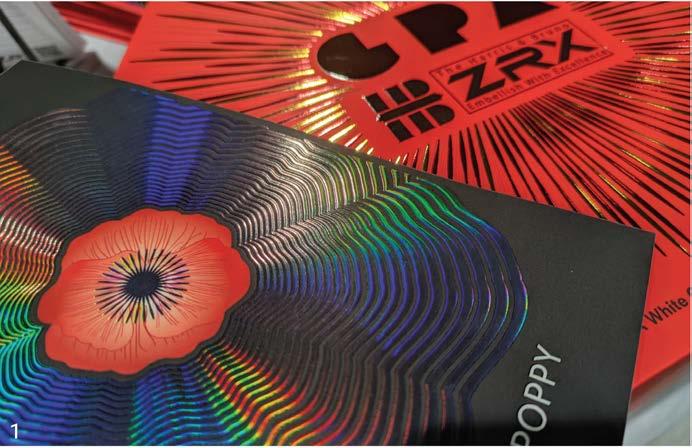

Above:The Harris&BrunoZRX Digital EmbellishmentPressdelivershigh-impacttactileandmetalliceffectswithoutdies,screens,orplates.

product," shares Mark Geeves, director of sales and marketing, Color-Logic.

Combining visual impact with a tactile experience signals quality before the product is even revealed. "The most successful examples look premium-and more importantly, feel premium-through texture and dimensional effects. It's about delivering an experience that enhances brand perception and reinforces value, before the product is even unboxed," exclaims Ryan Moskun, marketing manager, Harris & Bruno International.

When done properly, luxury packaging should elevate a product through superior sensory and emotional impact. "It communicates quality and exclusivity throughrefinedmaterials, precisefinish-

individuals. That level of agility is quickly and works beautifully with spot UV or ing, and thoughtful design. True luxury becoming part of what consumers asso- foil overlays. packagingenhancesthefirstandsecond moments of truth-capturing attention at first touch and reinforcing brand value throughout the product experience," say Ed Wiegand, CEO, and Michael Ferrari, global marketing director,JetFX.

Drever points out that high-end packaging uses premium materials and sophisticated finishes such as softtouch laminates or foiled logos tosignal quality and exclusivity. "It should create a memorable unboxing moment that connects the customer to the brand before they even see the product."

Luxury packaging must engage the consumer's sense of touch to increase the perceived value of the product in-

ciate with a premium brand experience," notesMattRaab,director, globalportfolio marketing, Xerox Corporation.

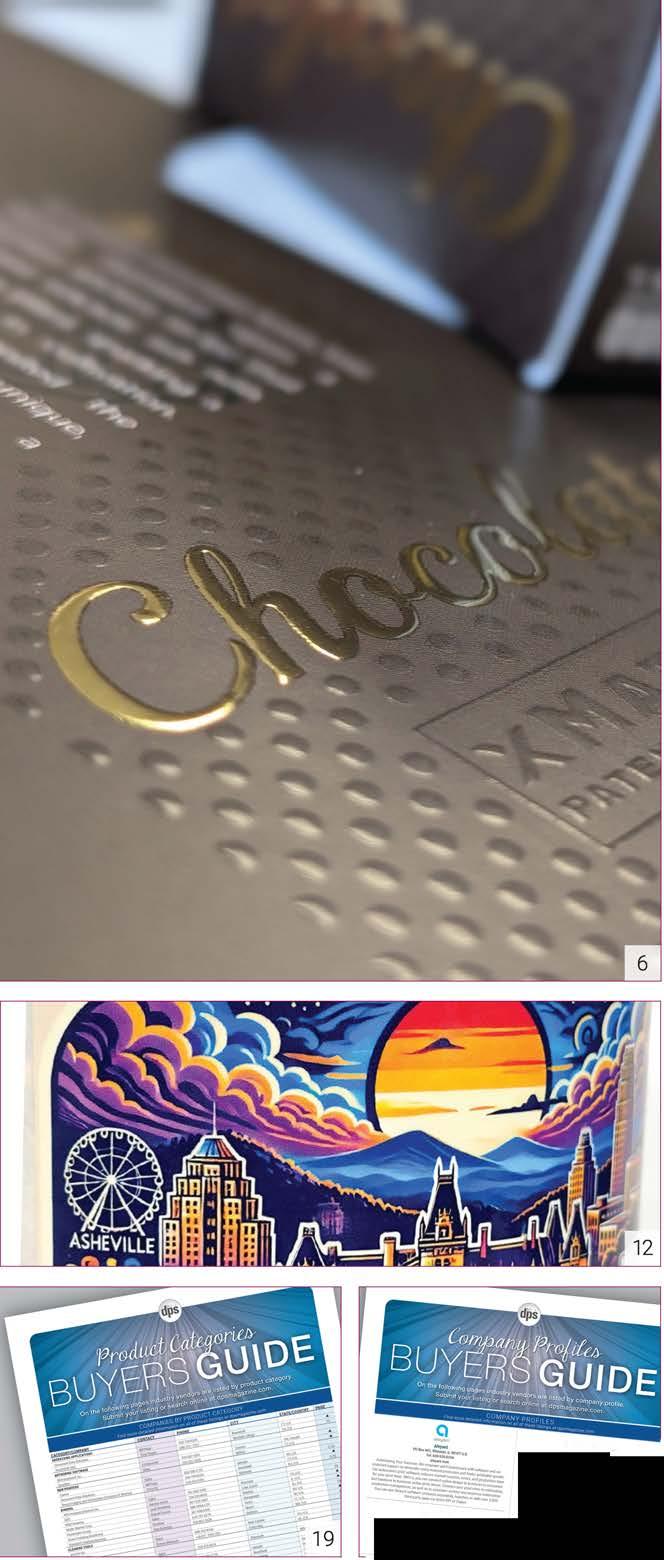

Several effects are popular on digitally printed luxury packaging, including foiling and sleeking, metallic embellishments, spot UV coating, embossing and debossing, soft touch and specialty laminations, specialty inks, white and specialtyunderlays, and die and laser cutting.

Raab sees strong demand for visually striking and tactile enhancements that help brands differentiate without com-

"Modem lamination films are available in a range of premium matte finishes, with some being smooth and others tactile. Among these finishes, many types arecompatiblewithconventionalorinkjet spot UV, hot foiling, and cold foiling. It is very hard for consumers to resist the appeal of embellishmentslayeredover atactilemattefilm;' saysNikolic.

With spot UVcoating, print providers colors, and special effects that enhance applyglossvarnishtoselectareasto ere- brand storytelling and product allure, ate visual and tactile contrast, making says Geeves. logos or patterns stand out.

"These finishes enhance both visual

While metallic foils in gold, silver, or and tactile impact-helping brands ereholographic tones add a premium look. ate premium, multi-sensory packaging.

Popular premium finishes include using white and CMYK inks on metallic stocks, silver, and CMYK inks on paper, cold foil, or sleeking, and with UV spot or flood coatings. Software like Color-Logic's system is compatible mitting to long, static offset runs. with all of these effects, and its Design Specialty inks like metallic, white, or Suite forAdobe Creative Cloud enables side, adds Dragan Nikolic, partnerships clear inks create standout visual effects, printers to provide their brands the abiland enablement lead, Nobelus. "No oth- especiallywhenpairedwithvarnishorfoil. ity to add vibrant, eye-catching metallic er sense influences a person's emotions and decision-making process more than touch. When we interact with packaging that has a haptic effect, we connect with it more strongly and hold it longer, making us far more likely to buy it."

short runs without the need for dies," comments Drever.

Soft-touch and specialty laminations addatextured surfacethatfeelsluxurious

Digital print expands the potential for "Digital foil transfer methods allow luxurious, high-end packaging. "Today, luxury is also about responsiveness and the ability to tailor packaging to seasonal campaigns, microsegments, and even

1. Designed for short runs and fast turnaround, the Harris & Bruno ZRX Digital Embellishment Press delivers excels on uncoated substrates and supportseffectslikefloodcoating, raised UVspot coating, andfoil.

What’s driving adoption now is the ability to apply these finishes inline, without tooling, and even customize them per SKU or region. The trend is moving toward high-resolution, variable embellishment that makes each package unique,” say Wiegand and Ferrari.

“Today’s packaging designers gravitate toward digital embellishments that deliver high sensory value with low setup requirements,” notes Moskun.

He feels the most popular include tactile raised spot coatings, metallic foil—including matte foil and foil-on-foil, variable-height textures for dimension, digital embellishments on uncoated media, soft touch and specialty coatings that add perceived material richness, and matte spot coating.

“With digital embellishment, these effects are applied instantly without dies or long lead times, making them ideal for prototyping, seasonal packaging, and premium short runs. Additionally, the eco-friendly benefits of not having to create the dies or use harsh chemicals are a huge draw to consumers and brands looking for more ecological packaging,” adds Moskun.

Further, die and laser cutting techniques allow for creative cutouts and shapes add dimension and distinctiveness to packaging designs.

“These enhancements make packaging both visually and physically engaging, turning a printed surface into a brand experience,” says Drever.

Short-run folding cartons, ecommerce and subscription packaging, as well as labels and branded collateral that support package segments are adopting luxury packaging effects, says Raab.

When it comes to short-run folding carton production, brands rely on embellishment to signal quality, especially in beauty, wellness, and premium brand categories. “Short runs let them test limited editions, seasonal kits, and influencer mailers at lower risk,” offers Raab.

Ecommerce encourages more products to ship directly to consumers, unboxing is the new storefront. Raab points out that embellishments help replicate that “in-store moment,” making the brand feel thoughtful and high end.

High-impact metallics or clear spot effects help unify the brand story across touchpoints—boxes, inserts, and point of sale materials. “Digital embellishment shines here because it lets brands refresh

designs quickly, localize campaigns, and personalize packaging, all without excess inventory and the costs and waste often associated with inventory,” comments Raab.

In Geeves’ experience, most embellishment is occurring on cartons, labels, and sleeves. “These areas are prime real estate for visual impact making them ideal for showcasing intricate designs, metallic colors, and effects that draw consumer attention and differentiate premium products on the shelf. We are also seeing a growing trend with accent pieces like tags on the bottle or marketing pieces inside the box.”

Growth in embellishment is happening in beauty and cosmetics, wine and spirits, and premium retail and gift packaging. “These markets depend heavily on visual appeal and brand differentiation,” shares Drever.

For example, cosmetics boxes often feature soft-touch coatings with gold foil, while wine labels use embossed crests and foil borders to reflect tradition and quality. Drever adds that premium retail packaging—from jewelry to electronics—use embellishments to elevate the unboxing experience.

Even niche sectors like gourmet foods are adopting tactile coatings and foils to attract attention and convey exclusivity. “In every case, embellishment is used to create impact and emotional connection, even before the consumer takes it off the shelf,” comments Drever.

Nikolic adds collectible cards, nutraceuticals, cannabis, personal care, specialty foods and confectionary, as well as craft beers and spirits as key market recipients for embellishment.

Short-run premium packaging is a growth area. “Brands are moving away from mass-produced static designs toward shorter runs that allow for frequent updates, targeted campaigns, and limited collector editions. Digital embellishment supports this shift by eliminating the need for tooling or dies, giving brands the freedom to prototype and test various designs

as well as bring concepts to market faster,” explains Moskun.

Personalization and versioning is also trending, where packaging is tailored by region, retailer, or customer.

“Campaign-based packaging, influencer collaborations, and product unboxings on social media increasingly demand fast turnaround with premium finishing. With digital embellishment, brands create multiple design variations within a single run, combining tactile effects like raised UV or foil with variable data to produce high-end, customized packaging at scale,” shares Moskun.

Packaging is experiencing rapid growth in the use of embellishments across labels and flexible and folding carton packaging, extending beyond beauty into nutraceuticals, wine and spirits, and home fragrance,

confirm Wiegand and Ferrari. “Brands adopt digital embellishment to differentiate and justify premium pricing—especially in short- to mid-volume runs where converters add high-value effects efficiently. As digital embellishment costs decline, adoption is accelerating across new verticals, making luxury-quality packaging more accessible and scalable.”

Digital embellishment offers a strong return on investment (ROI) for both printers and brands.

“Customers are willing to pay more for premium packaging, often allowing brands to charge 15 to 30 percent higher prices for the same product. For print providers, these jobs deliver better margins because the cost of finishing is

small compared to the perceived value it adds,” offers Drever.

Digital embellishment helps teams avoid thousands of dollars in die costs while improving the ability to prototype, test, and adapt. “It enables A/B testing, design variations, and cost-effective upgrades that would otherwise be impractical using traditional embellishment methods,” states Moskun.

Embellishments also increase engagement. Tactile finishes invite customers to touch and interact with the packaging, which boosts purchase intent. “Beautifully finished packaging encourages repeat purchases and often becomes shareable content on social media. That kind of organic promotion strengthens brand image and amplifies the return far beyond the initial sale. For

manyprint providers, theabilitytotransform an ordinary print into a premium, high-margin product means the equipmentinvestment pays back quickly," suggestsDrever.

Moskun adds that when packaging looks and feels elevated, consumers assign higher worth to the product before even opening it. "It also significantly reduces time to market. Because digital embellishment does not require dies or tooling, designers can iterate quickly and move from concept to production without delay. This speed is especially impactful in competitive markets where rapid response to trends or product launches is critical."

Digital embellishments often result in a significant ROI by increasing perceived value, enhancing brand recognition, and driving consumer engagement, admits Geeves. "The ability to produce eye-catching, high-end finishes cost effectively at the design stage on digital presses allows brands to create limited editions, localized or personalized versions, test new designs rapidly, and respond tomarkettrends-all contributing

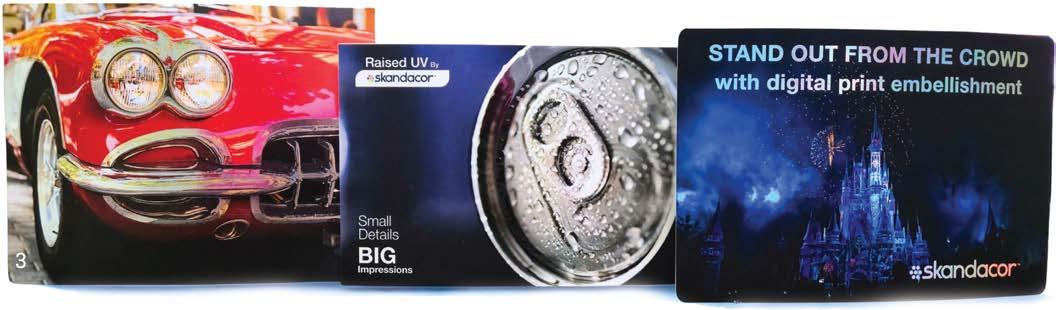

3.TheSkandacor FINISHpro3D 1623featuresamaximumprinting widthof 16inches.

COMPANIES MENTIONED Color

to increasedsalesandbrandloyalty. Color-Logic promotes return on responseor ROR-as well as ROI. The key for any brand is to provide an experience that makes such an impression they come back for more," he adds.

Embellishments and haptic finishes are more effective in signaling quality to consumers than written descriptions, which immediately demonstrates the value of premium packaging. "In competitive consumer markets, premium embellishments and tactile packaging outsell plain finishes ten-fold. If a brand wants to sell more than the competition, theyshouldinvestinthepackagingexperience that leads to greater brand loyalty," says Nikolic.

Another major advantage is shortrun viability. "Brands can economically produce premium packaging in smaller quantities for seasonal releases, luxury sampling, customization, or influencer campaigns. This reduces risk and aligns with the growing demand for personalization and targeted engagement," shares Moskun.

Raab indicates that print providers tend to see ROI show up in three clear ways-higher margins, reduced waste

and inventory, and faster time to market and greater agility.

To achieve higher margins, he explains that embellished packaging commands premium pricing that is often 30 to 60 percenthigherbecausebrandssee it directly influencing perceived value and sales lift.

For reduced waste, Raab points out that digital "white paper-in" workflows eliminate many analog processes and minimum order quantities. "Providers only print what's needed, when it's needed, improving cash flow and reducing storage and associated costs."

As previously noted, more flexibility allows brands to launch micro-runs, A/B test visual treatments, and personalize without setup delays. That agility drives repeat orders and positions the provider as a strategic partner.

"Xerox clients using beyond-CMYK technologies consistently report that embellishment has become a differentiator that attracts new clients, strengthens loyalty, and expands into adjacent applications like direct mail, labels, and promotional kits," concludes Raab.

Embellishment elevates the visual appeal of luxury packaging and is now used strategically to support personalization and market reaction speed.

"Digital technologies empower brands to be continuously agile, refine theirdesigns, create exclusivitywith limited runs, and build emotional connections through packaging that looks and feels elevated," concludes Moskun. dps

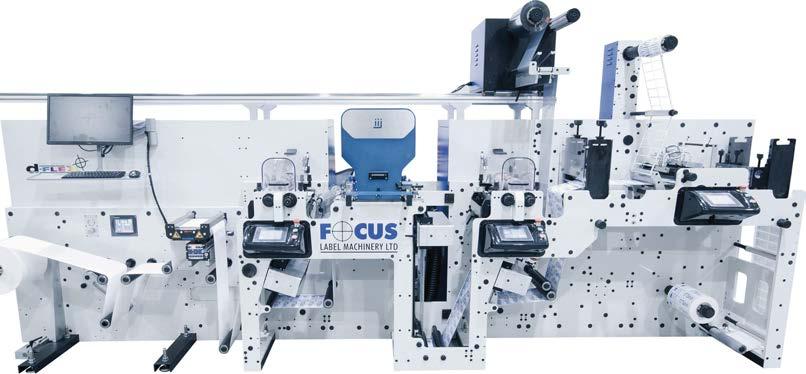

flexography, printers can reduce waste, minimize setup times, and achieve exceptional print quality across diverse substrates,"sharesJamesThomas,head of sales and business development, FocusLabel.

Advantages of digital and hybrid label production add up with trends like automation, whichenableprint providers to produce jobs in minutes that once took hours to prepare-with no guesswork, no wasted material, and no "call the specialist" moments. "We like to say it's automation that feels humansimple, intuitive, and margin-making," shares Amanda Bacon-Davis, VP, ink andinfluence, SnapPress.

Across the industry, automation is a key differentiator in digital label production. "Modern presses are designedtoreduceoperatortouchpoints, streamline job setup, and minimize waste. Automation now extends beyond print-encompassing prepress workflow, color management, and even post-press finishing. Integration with digital front ends (DFEs) enables automated job queuing, variable data handling, and consistent color output across devices," explains Taylor Buckthorpe,directorofsalesandmarketing, ColordyneTechnologies.

Automation is taking shape in two forms-hardwareandsoftware.

Many digital label presses incorporate automation within the hardware of the printer. "Designed to enhance printqualityandprolongthelifeofthe

printer, these features simplify maintenance and ensure it's happening at regular intervals," notes Mike Pruitt, senior product manager, professional imaging, EpsonAmerica, Inc.

Canon's LabelStream LS2000 offers these elements while also helping to make a positive impact on sustainability goals. This is achieved through its water-based ink system and the reduction of materials typically required intheanalogprintingprocess, particularly for short- and medium-run length converting applications, shares KatsuhiroMatsufuji, VP, marketing strategyUnit, CanonU.S.A., Inc.

Calibration, profiling, andquality/inspectioncheckscannowbeperformed inline with cameras and measuring devices at the touch of a button within the hardware. "This speeds up the printing device for label production substantially. The inline cameras and spectrophotometers provide important informationsuchaswhetherornotthe targetedcolorspaceiswithintolerance and that no defects are present. This ensures quality and color-accurate labels are produced right after warming up," shares Russell Doucette, product marketingmanager, KonicaMinolta.

John-Paul Burton, managing director, EclipseLabelEquipment, feelsthat it's not so much about how the digital presses incorporate automation, but rather whatautomation is available to enhanceproductionandreduce costs.

Within the solutions side, easyto-use label imposition and hot folder management allow companies

to streamline workflow into a dragand-drop environment, simplifying prepress for both operators and customers. "Additional options such as preflight checks, template creation, embellishment/die plate creation, and web to print (W2P) storefronts can be added, simplifying the process further. KonicaMinoltahashelpedperfectthis for sheet-fed customers and the ability tomigrateittolabelcustomersisawelcomedaddition," saysDoucette.

Juan Kim, CEO, Valloy Incorporated, sees a general trend towards end-to-end workflow automation that follows the general steps of W2P to RIP, preprint, processprint, post-print/ embellishment, and finishing. He says barcode/quick response (QR) codejob calling, closed-loop color, substrate presets, predictive maintenance, and in/nearlinefinishingarealsotoolssupported by workflow automation in a digitallabelenvironment.

Overall, automation improves processefficiencyandreducesthelaborintensity forthetask oflabelproduction. "Due to its relative maturity, there are some great examples of digital label presses that have implemented a substantial amount of automation," notes Paul Edwards, VP, digital division, INX InternationalInk Co.

Edwards explains that the implementationofall-in-oneworkflowsallow a roll of label stock fed into a printer to exit as finished rolls of labels and 1. Konica Minolta offerstheAccuriolabel400, a dry toner based digital label press that features a fifth stationforwhitetoner.

-------ready to be put on a box or envelope. The process of label production can include printing processes as well as embellishments suchas gloss effects, foils, and more through various finishing and converting processes like die cutting, laminating, coating, andmatrix removal.

For example, the introduction of digital processes such as real-time quality inspection and workflow optimization can significantly enhance the automation and efficiency of the system, offers Edwards. ''A good example of an all-inone workflow is the SEI Laser Labelmaster. It offers high efficiency and provides digital label converting, as well as many automated processes including automatic workflow integration, missinglabel detection, motorizedautomatic slitting, and on-the-fly job changes-to namejust a few."

Fiery Focus

INX

Konica

SnapPress

Valloy

and sustainable solutions without thesetup costs of flexography. "The rise of ecommerce packaging, personal

izedbranding, and on demand production is fueling the digital label boom.

Add to that a new generation of buyers who want data-driven designs, variable

content, and made-local agility, and

Evolving market trends, shifting trade digital becomes notjust an advantage, conditions, and tariff fluctuations are all driving factors towards digital label production, as brands seek greater flexibility to manage unstable product variations and order volumes.

''As businesses face increasing pressure from time, labor, and material costs, digital technology offers faster setup and cleanup, improved productivity, and shorter turnaround times. While still requiring specialized skills, digital printing can be learned quickly, allowingaccess to a broaderlabor pool than traditional analog processes. Additionally, automated maintenance and self-monitoring features reduce manual intervention, enabling operators to focus on workflow efficiency and print quality," suggests Pruitt.

Bacon-Davis sees brands looking for more SKUs, faster turnarounds,

usa.canon.com

colordynetech.com eclipselabelequipment.com epson.com fiery.com focuslabel.com inxinternational.com kmbs.konicaminolta.us makelabels.com valloy.com

but a necessity. The conversation isn't 'should we go digital?' anymore. It's 'how fast can we get there?'"

Companies also want product to stand out more, and like to try new looks andapproaches for different markets. "Digital embellishments on labels canprovidethis, andcompaniesarebeginning to take notice of it. Companies want to try new concepts and digital makes it much easier. The simplicity of digital technology and the ability to show a client three to six different versions of a new label, whether it be a simple two-dimensional spot varnish or a more complex, multiple-pass foil/ varnish combo enables companies to test and create new ideas and products much easier," shares Doucette.

From fully variable, personalized content through to interactive features such as QR codes, labels now have greater value as differentiators. "Brand owners are aware of the differentiation that can be achieved via the implementation of digital content. Short run and digital content has made the digital production process more valuable

2 The LabelStream LS2000 is Canon's first digital inkjet label press. It utilizes water-based inks.

3. Colordyne Technologies' 3800 Series inkjet engines, powered by Kyocera Mechanical Piezo printheads, integrate seamlessly with Fiery Impress DFEs, whichprovide advanced jobautomation, intelligent color profiling, and simplified job submissionfrom designtoprint.

Additionally, as inkjet technology continues to advance in the areas of speed, color gamut, as well as substrate versatility, converters find that digital print solutions can now handle a larger share of their traditional flexographic or offset work. "At Colordyne, we see strong interest in hybrid and retrofit models, where converters maintain their flexo capabilities while adding full-color digital capability inline. This hybrid model gives converters flexibility without a complete process overhaul," offers Buckthorpe.

The trend towards decreasing the average run length of a production job isa clear one, andimpacts pretty much all packaging applications to some extent. "Havingtheabilitytomakemoney on the shorter run length jobs fits nicely with the ability of the digital printer to create short-run jobs efficiently, with ever-increasing automation and the ability to provide all kinds of embellishments in asinglemanufacturing line. To some extent, this driver also dovetails with the sustainability drive as the digital process provides less waste and a more efficient process," says Edwards.

"Digital label production is following the same path that so many mechanical printing technologies have

4. Focus Label Machinery's hybrid platforms, such as the DFlex Digital Hybrid Press, integrate high-speed inkjet technology in both UV/LED and water-based with traditional fiexographic units and full finishing.

taken over the decades. From publishing to desktop publishing, from silkscreen printing to direct to garment and direct to film, and from analog plate-based commercial presses to modern inkjet and toner presses in the print shop," notes Burton.

In each case, he says the shift is driven by the same core demandsfaster turnaround times, short run and variable data capability, reduced setup and labor, customization and on demand production, and greater flexibility to pursue new products and new niches withoutcapital investment. ''And where brands once needed long runs and high volumes to justify plate and screen setups, they now need flexibility, versioning, and the ability to react to customer demands immediately. All of those motivations apply to both printing and finishing."

Kim notices several digital capabilities serving trends towards digital label production. For shorter turnarounds and SKU proliferation, plate and dieless agility wins. For faster turnaround and on demand label output, web to label and same-day service is ideal. Mass customization and variable data print enables serialized and market-ofone labels. Wider media/flexible packaging with films and foils benefit from low-temperature fusing and broaden media compatibility. Sustainability and waste reduction is also achieved through digital without plates and dies

as well as a focus on right-sized runs.

"We're seeing increased adoption todigitalwithmore of a focus on sustainability. Furthermore, intelligent automation capabilities that digital has to offer can help offset challenges in the traditional label market," shares Matsufuji.

Moving to digital label productionwhether from a traditional converting business or adding labels as a digital service offering to additional commercial business-should take into account several considerations.

Edwards feels that increasing the volume of jobs for short-run digital content requires a few strategies. "Implementing highly automated and efficient digital printers and workflows, providing a competitive product and pricing, and then highlighting the ability to do this to customers and brands is vitally important. A clear message must be communicated for the customers to understand the potential product opportunities."

The second consideration is related to pure volume, rather than the volume of jobs itself. "It requires digital equipment with the capacity for efficient high-volume manufacture and a workflow to support it. This will provide the best and most economical product for the longer print runs. It also boils down to communicating the advantages of the digital product and implementation of the correct technology-or blend of technology-required to deliver it," suggests Edwards.

Bacon-Davis suggests starting with the low-hanging fruit-repeat short runs, private labels, or variable data

jobs that flexographic shops avoid. “Build success stories around them. Then, streamline your workflow with automated color management, built-in RIPs, and integrated finishing.”

Most importantly, educate your customers. “Once they understand that they can get ten designs for the price of one setup, they start rethinking how they order labels—and that’s when your volume grows naturally,” stresses Bacon-Davis.

Pruitt feels that when moving to digital technologies, its essential to know your customers and their priorities. If they are looking for the lowest print cost and have no need for artwork changes, or quick turnaround—then they might not be the best fit for digital. The best opportunities lie with customers who require versioning, design changes and regional labeling—all are key selling points and areas where digital printing provides clear advantages in speed, flexibility, and customization.

requirements when stepping into the digital world for the first time, the cost of digital printing can be a little higher than traditional, which matters when we are looking at those high supermarket volumes,” notes Burton.

Buckthorpe says that the most successful converters treat digital as an extension of their production ecosystem, not a standalone device. “This means automating job entry, proofing, and color management, and using data analytics to identify jobs ideally suited for digital—typically those with multiple SKUs, short runs, or frequent artwork changes.”

Modern digital printing brings great flexibility and easier setups. “A key factor is understanding the volume

Standardizing file formats, color profiles, and substrates also accelerate digital throughput. “Many converters increase digital volume by offering flexible pricing models and educating customers about the benefits of digital— like faster lead times and versioned artwork. Customers can rapidly grow digital volume when they align internal workflows and customer expectations around speed, flexibility, and reduced waste,” adds Buckthorpe.

Finishing is another consideration. Kim says digital printers are getting faster, but the speed of digital finishers has been “an adventure.” He points out that while laser cutting is fast, the quality may not meet commercial labels, while knife cutters tend to be slow but give substrate-independent good quality. “Valloy overcomes disadvantages of knife cutters—speed and automation. Valloy’s digital finishers can run in high speed with automatic depth adjustment as well as automatic job change and head distance control between multiple cutting heads.”

Today’s digital label presses are getting smarter. “Automation is about confidence and control. From auto-webbing and intelligent job queuing to direct help desk links and remote monitoring, automation is making label production more seamless, consistent, and operator friendly,” concludes Bacon-Davis.

Read more on digital label printing advancements online at dpsmagazine.com, including a webinar on the topic. dps

1Canon U.S.A., Inc. 2canonproductionprint.com

2Eastman Kodak Company 5kodak.com/go/dpsmagazine

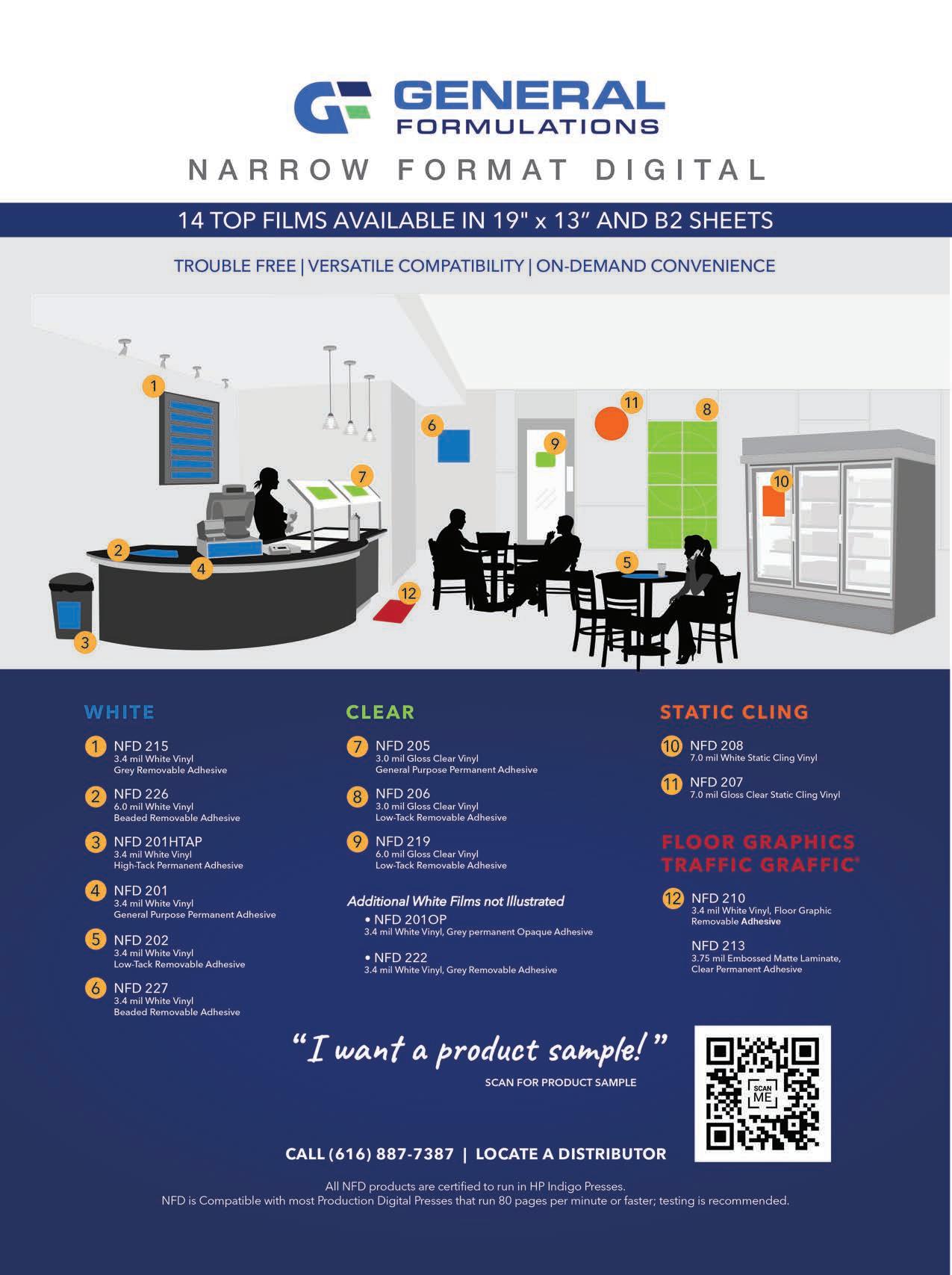

3General Formulations 27generalformulations.com

4InfoPro Digital 11luxepacklosangeles.com

COMPANIES MENTIONED

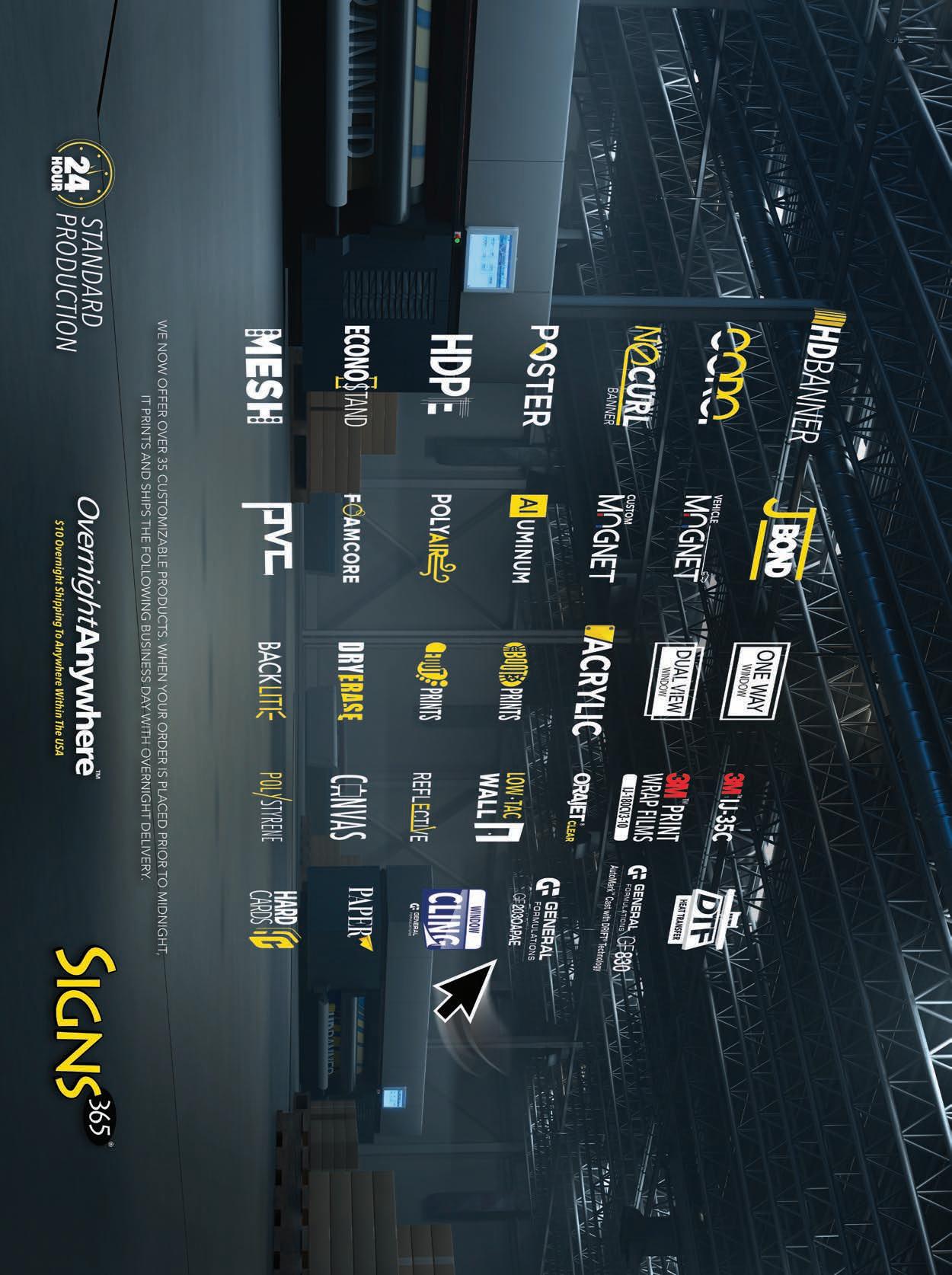

5Komori America 15komori-america.us 8Sharp Production Print 9business.sharpusa.com 6Signs365 28signs365.com 7Tecnau 25tecnau.com

300 Afinia Label afinialabel.com

301 Anytron anytron.com

302 AstroNova - QuickLabel astronovaproductid.com

303 AstroNova - TrojanLabel astronovaproductid.com

304 Bobst bobst.com

305 Canon usa.canon.com

306 Colordyne Technologies LLC colordynetech.com

307 Dantex Group dantex.com

309 Dilli dilli.co.kr

309 Domino Printing Sciences domino-printing.com

310 Durst Image Technology US LLC durstus.com

311 Epson epson.com

312 Focus Label Machinery focuslabel.com

313 Formax formax.com

314 FUJIFILM NA Corp., Graphic Communication Div.

print-us.fujifilm.com/about-fujifilm

315 Gerber Technology gerbertechnology.com/signage

316 HAPA AG hapa.ch

317 Heidelberg heidelberg.com

318 HP Inc. hp.com *

319 InkJet, Inc. inkjetinc.com

320 iSys Label isys-label.com

321 Konica Minolta kmbs.konicaminolta.com

322 Mark Andy markandy.com

323 Miyakoshi miyakoshi.co.jp

324 Monotech Systems Limited monotech.in

325 Mprint mprint.biz

326 MPS Systems North America mps4u.com

327 MTEX mtexns.com

328 NEOS neoslab.it/em

329 NeuraLabel Printing Solutions neuralabel.com

330 Nilpeter nilpeter.com

331 Primera Technology, Inc. primera.com

332 SCREEN Americas screenamericas.com

333 SnapPress (company of Allen Datagraph Systems, LLC) makelabels.com

334 UniNet icolorprint.com

335 Uteco uteco.com

336 Valloy Incorporation valloy.com

337 Xeikon xeikon.com

KEY: *HP Indigo ElectroInk

F,nd more detailed ,nformat,on on all of these /1st,ngs at dpsmagaz,ne com

Find more detailed 1nformat1on on all ofthese listings at dpsmagazine com

technologies

aleyant

Aleyant

PO Box 641, Wheaton, IL 60187 U.S. Tel: 630-929-0104

aleyant.com

Automating Your Success. We empower print businesses with software and unmatched support to eliminate costly manual processes and foster profitable growth. Our automation print software reduces manual touches, errors, and production time for your print shop. With it, you can connect online design to business to consumer and business to business online print stores. Connect your print store to estimating, production management, as well as to customer service and prepress automation. You can use Aleyant software products separately, together, or with over 2,000 third-party applications via direct API or Zapier.

APS Imaging Solutions, Inc.

14120 Meridian Pkwy., Bldg.1, Riverside, CA 92518 U.S. Tel: 951-653-1343

apsimaging.com

Establishedin 1999 our many years of distributing andsupportingour top-quality book binding manufacturing partners have taught us what successful printers need-trusted, reliable, and committed knowledgeable technology partners.

Aurigma Inc.

66 Canal Center Plz., Ste. 505, Alexandria, VA 22314 U.S.

Tel: 800-661-8190

customerscanvas.com

Aurigma, Inc. is a vendor of image composition, design personalization, and prepress automation software for print service providers and marketing companies. Our software development team specialized in the image processing area and web to print related tasks for more than 20 years and we gained a lot of software developing experience in these fields.

Canon

1 Canon Pk., Melville, NY 11747 U.S.

Tel: 800-815-4000

usa.canon.com

Canon U.S.A., Inc. is aleadingproviderofconsumer,business-to-business, and industrial digital imaging solutions to the U.S., Latin America, and the Caribbean markets. Canon U.S.A., Inc. is committed to helping ourcustomers grow by providing an integrated array of automated, productive, user friendly, and profitable solutions. With one of the broadest portfolios in the industry we develop hardware, such as digital inkjet and toner presses and wide format printers, workfiow software, andprofessionalservices to assist a commercialprinteringrowingtheirbusinessand profits. Canon isdedicatedto its Kyosei philosophy of social and environmental responsibility. See our ad, page 2.

ColordyneTechnologies LLC

3275 lntertech Dr., Ste. 100, Brookfield, WI 53045 U.S. Tel: 262-784-1932

colordynetech.com

Colordyne Technologies manufactures high-performance, open-architecture inkjet engines and retrofits for labels, packaging, and commercial print. Our scalable Mechanical Piezo platform transforms fiexographic and analog equipment into digital systems, offering fiexible ink compatibility, advanced workfiow integration, and high-speed, high-quality production.

CrawfordTechnologies Inc.

20 Bay St., Ste. 1105, Toronto, ON M5J 2N8 Canada Tel: 866-679-0864

crawfordtech.com

Crawford Technologies is an award-winning, global provider of solutions and services, leveraging over 30 years of experience helping communication providers optimize the secure and accessible delivery, presentment, and storage of high-volume customer documents. Our software reduces costs, simplifies processes, and streamlines mission-critical production (e.g., bills and statements) across all channels and formats. We enable clients to meet rigorous demands for instantaneous information access and compliance, supporting all outputs-print (laser/inkjet), digital (PDF, responsive HTML, XML), and a full range of accessible formats (braille, large print, PDF/UA, audio, e-text).

DirectMail2.0

DirectMail2.0

600 Cleveland St., #480, Clearwater, FL 33755 U.S. Tel: 800-956-4129 dm20.com

DirectMail2.0 is a leading omnichannel marketing platform that enhances direct mail campaigns with digital technologies and real-time attribution. Who's Mailing What! offers the largest archive of direct mail creative for competitive intelligence, research, and inspiration. DM20.ai compiles years of campaign engagement to show marketers the steps they can take to lift response rates. Three powerful services as one seamless ecosystem for smarter, faster, and higher performing campaigns.

No.18, Rd. No 2, Dawohengfeng, Changping Tn., Dongguan, Guangdong, China 523000 Tel: +86 755 28225550

dtfstationglobal.com

DTF Station is a leading provider of direct to film (DTF) printing solutions worldwide. Ourcomprehensiverange includes A4, A3, A2, and 60cm DTF solutions, along with cutting-edge UV DTF printers and heat press machines, empowering you to unleash your creativity and achieve exceptional results in the world of digital textile printing.

Find more detailed information on all of these listings at dpsmagazine com

FINISHING MACHINERY -1-••····.....__

Shark Finishing Machinery

7745 NW 56 St., Miami, FL 33166 U.S.

Tel: 619-797-6278

sharkmachinery.com

Shark Finishing Machinery manufactures and distributes digital print finishing solutions. The Shark line offers a variety of equipment such as creasers, perforators, paper cutters, corner rounders, business card cutters, stitchers, UV coaters, perfect binders, paper joggers, and much more. Sharkdistributes through a global network of dealers and distributors and aims to become the most trusted name in the digital print finishing Industry.

Sharp Imaging and Information Company of America

100 Paragon Dr., Montvale, NJ 07645 U.S.

Tel: 800-BE-SHARP

business.sharpusa.com

Sharp Imaging and InformationCompany of America (SIICA) helps businesses achieve simply smarter work by assisting in workfiowmanagement,creatingimmersive environments and increasing productivity. SIICA offers secure production printers, office printer and copier solutions, commercial displays and projectors, Dynabook laptops, management, and productivity software and fully managed service. See ourad, page 9.

51245 Filomena Dr., ShelbyTownship, Ml 48315 U.S.

Tel: 800-265-8830

signs365.com

Signs365 is a grand format, trade only wholesale printer.We offer a wide variety of full color, high-quality printed products all produced in 24 hours. $10 Overnight Anywhere shipping is available on all products. Visit signs365.com for more details.

Signs365-We Are Only Trade Only1 See ourad, page 28.

Solimar Systems Inc.

1515 SecondAve., San Diego, CA 92101 U.S.

Tel: 619-849-2800

solimarsystems.com

Solimar Systems is an award-winning workfiow software provider specializing in production print and digital communications since 1991. The Solimar Chemistry platform delivers enterprise print management, PDF security, and industrial optimization, along with visibility dashboards for print service providers, in-plants, and commercial printers globally. Solutions integrate seamlessly across environments, supporting legacy and modern data streams, including AFP, IPDS, PCL, Postscript, and PDF.

Standard Finishing Systems

10 Connector Rd., Andover, MA 01810 U.S.

Tel: 978-470-1920

standardfmishing.com

Standard distributes a broad line of feeding and finishing products including Horizon perfect binders, collators, folders, saddlestitchers, die cutters, slitters/creasers, and bookletmakers; and Hunkeler unwinders, rewinders, cutters/slackers, dynamic per/orators, and inspection systems for continuous-feed printers. Standard has applied its knowledge of the conventional offset print finishing industry to engineer effective solutions for the expanding digital and inkjet print markets.

Skandacor

545 Basket Rd., Webster, NY14580 U.S.

Tel: 888-820-9020

skandacor.com

Skandacoroffers high-quality print-finishingsuppliesand equipment, coupledwithyears of expertise. Our goal is toenhance our clients'brandsandreturnsbyaddingvalue to print. By continuously improving and developing our own products, we allow our clients to stay ahead of their competitors by expanding their product offerings.

Tecnau

60 Willow St., North Andover, MA01845 U.S.

Tel: 978-608-0500

tecnau.com

Tecnau and Sitma USA deliver innovative, integrated solutions that help customers in printing, packaging, and fulfillment do more with less. Tecnau is a global leader in paper handling,monitoring, processing, and finishing systems for the digital printing industry. Serving transactional, direct mail, publishing, graphic arts, book-on-demand, and short-run markets, Tecnau provides feeding, cutting, folding, quality assurance, and inline finishing modules compatible with the most advanced digital printers. With decades of industrial automation expertise, customized engineering, and a worldwide support network, Tecnau empowers customers to reduce production costs, expand application possibilities, and improve operational efficiency. Sitma, a pioneer in packaging and sortation solutions since 1965, serves industries from consumer goods and frozen foods to graphic arts, direct mail, and e-commerce fulfillment. With a strong focus on sustainability, Sitma develops rightsized, eco-friendly packaging to minimize material use and optimize transportation. Operating in more than 70 countries with over 9,000 installations, Sitma's product portfolio spans automated identification, order fulfillment, e-commerce automation, and sortation equipment. Together, Tecnau and Sitma USA bring customers a unique combination of print finishing, packaging, and logistics expertise enabling streamlined production, sustainable operations, and new revenue opportunities across the print and e-commerce value chains. See our ad, page 25.

THERM-0-TYPE Corp.

509 Church St., Nokomis, FL 34275 U.S. Tel:800-237-9630 thermotype.com

Therm-0-Type digitalfinishing products include the Glue-TechSheet-to-Sheetgluer, the NSF Elite, Excel & Ultra die cutting/foil stamping/embossing presses, RDC-Flex rotary die cutter, Zip cutter/slitter/creaser/finisher models, RAS-me right angle slitters, and traditional business card slitters. Therm-0-Type also produces foil !users and handled thermography equipment. Therm-0-Type has been supporting the printing industry with equipment, supplies, and technical expertise since 1977.

Ultimate TechnoGraphics

300 Leo Pariseau, Ste.2120, Montreal, QC H2X 4B3Canada Tel: 514-938-9050 imposition.com

Ultimate TechnoGraphics develops anddistributes cutting edge software to automate and facilitate imposition and post-press finishing for the graphic arts.

Valloy Incorporation

Rm 410,Woorime-Biz Center 35, Gwangnaru-ro 6-gil, Seongdong-gu, Seoul 04799 Korea Tel: +82-2-6082-5022

valloy.com

Valloy is a global digital printingsolution company. Rollio Xpress with professional RIP software is a performance roll label press and DUOBLADE NXB is a new,automatic multiblade roll digital label finisher. Knife depth can be adjusted automatically with DUOBLADE NS and NX series during high speed operation. DUOBLADE FX is an intelligent sheet-fed finisher, which produces various kiss cut, full cut, creasing, perforation, and pen-drawing design goods in unmanned environments.

Xerox Corp.

401 Merritt 7, Norwalk, CT 06851 U.S. Tel: 888-242-9098

xerox.com

Xerox has been redefining the workplace experience for over a century. As a services-led, software-enabled company, we power today's hybrid workplace through advanced print, digital, and Al-driven technologies. The 2025 acquisition of Lexmark expanded our global reach and capabilities. We continue to deliverinnovative,client-centric solutions that help organizations thrive in an evolving business landscape.