Instruction Manual

DVC6200 Digital Valve Controller June 2011

D103409X012

Travel Calibration Field Communicator

Configure / Setup > Calibrate > Travel Calibration (1‐3‐1)

If a double‐acting relay is used, you will be prompted to run the relay adjustment when auto or manual calibration is selected. Select Yes to adjust the relay, select No to proceed with calibration. For additional information, refer to Relay Adjustment in this section.

Note Relay Adjustment is only available for the double‐acting relay (Relay A).

Auto Travel Calibration Field Communicator

Configure / Setup > Calibrate > Travel Calibration > Auto Tvl Calib (1‐3‐1‐1)

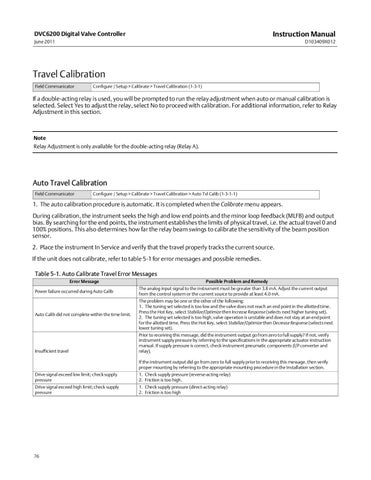

1. The auto calibration procedure is automatic. It is completed when the Calibrate menu appears. During calibration, the instrument seeks the high and low end points and the minor loop feedback (MLFB) and output bias. By searching for the end points, the instrument establishes the limits of physical travel, i.e. the actual travel 0 and 100% positions. This also determines how far the relay beam swings to calibrate the sensitivity of the beam position sensor. 2. Place the instrument In Service and verify that the travel properly tracks the current source. If the unit does not calibrate, refer to table 5‐1 for error messages and possible remedies. Table 5‐1. Auto Calibrate Travel Error Messages Error Message Power failure occurred during Auto Calib

Auto Calib did not complete within the time limit.

Insufficient travel

Possible Problem and Remedy The analog input signal to the instrument must be greater than 3.8 mA. Adjust the current output from the control system or the current source to provide at least 4.0 mA. The problem may be one or the other of the following: 1. The tuning set selected is too low and the valve does not reach an end point in the allotted time. Press the Hot Key, select Stabilize/Optimize then Increase Response (selects next higher tuning set). 2. The tuning set selected is too high, valve operation is unstable and does not stay at an end point for the allotted time. Press the Hot Key, select Stabilize/Optimize then Decrease Response (selects next lower tuning set). Prior to receiving this message, did the instrument output go from zero to full supply? If not, verify instrument supply pressure by referring to the specifications in the appropriate actuator instruction manual. If supply pressure is correct, check instrument pneumatic components (I/P converter and relay). If the instrument output did go from zero to full supply prior to receiving this message, then verify proper mounting by referring to the appropriate mounting procedure in the Installation section.

Drive signal exceed low limit; check supply pressure

1. Check supply pressure (reverse‐acting relay) 2. Friction is too high.

Drive signal exceed high limit; check supply pressure

1. Check supply pressure (direct‐acting relay) 2. Friction is too high

76