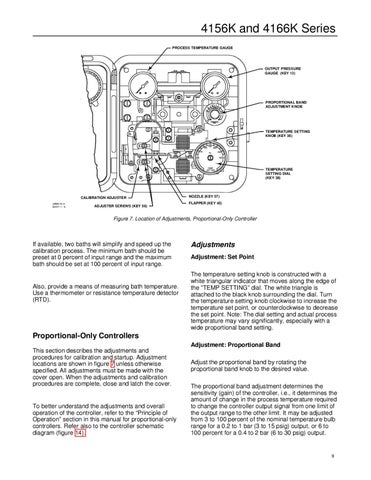

4156K and 4166K Series PROCESS TEMPERATURE GAUGE

OUTPUT PRESSURE GAUGE (KEY 13)

PROPORTIONAL BAND ADJUSTMENT KNOB

TEMPERATURE SETTING KNOB (KEY 36)

TEMPERATURE SETTING DIAL (KEY 38)

CALIBRATION ADJUSTER 48B6016-A B2431-1 / IL

ADJUSTER SCREWS (KEY 56)

NOZZLE (KEY 57) FLAPPER (KEY 45)

Figure 7. Location of Adjustments, Proportional-Only Controller

If available, two baths will simplify and speed up the calibration process. The minimum bath should be preset at 0 percent of input range and the maximum bath should be set at 100 percent of input range.

Also, provide a means of measuring bath temperature. Use a thermometer or resistance temperature detector (RTD).

Adjustments Adjustment: Set Point The temperature setting knob is constructed with a white triangular indicator that moves along the edge of the ”TEMP SETTING” dial. The white triangle is attached to the black knob surrounding the dial. Turn the temperature setting knob clockwise to increase the temperature set point, or counterclockwise to decrease the set point. Note: The dial setting and actual process temperature may vary significantly, especially with a wide proportional band setting.

Proportional-Only Controllers Adjustment: Proportional Band This section describes the adjustments and procedures for calibration and startup. Adjustment locations are shown in figure 7 unless otherwise specified. All adjustments must be made with the cover open. When the adjustments and calibration procedures are complete, close and latch the cover.

To better understand the adjustments and overall operation of the controller, refer to the “Principle of Operation” section in this manual for proportional-only controllers. Refer also to the controller schematic diagram (figure 14).

Adjust the proportional band by rotating the proportional band knob to the desired value. The proportional band adjustment determines the sensitivity (gain) of the controller, i.e., it determines the amount of change in the process temperature required to change the controller output signal from one limit of the output range to the other limit. It may be adjusted from 3 to 100 percent of the nominal temperature bulb range for a 0.2 to 1 bar (3 to 15 psig) output, or 6 to 100 percent for a 0.4 to 2 bar (6 to 30 psig) output.

9