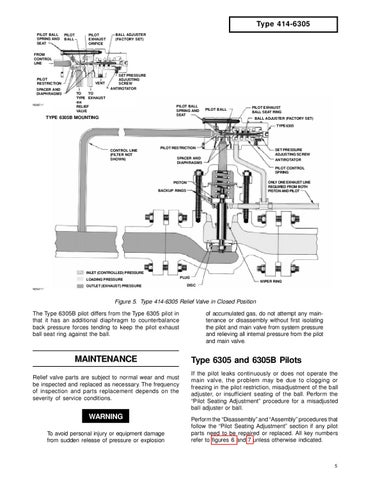

Type 414-6305 PILOT BALL SPRING AND SEAT

PILOT BALL

PILOT EXHAUST ORIFICE

BALL ADJUSTER (FACTORY SET)

FROM CONTROL LINE

PILOT RESTRICTION SPACER AND DIAPHRAGMS W2897-1*

VENT

SET PRESSURE ADJUSTING SCREW ANTIROTATOR

TO TO TYPE EXHAUST 414 RELIEF VALVE

PILOT BALL SPRING AND SEAT

TYPE 6305B MOUNTING

PILOT BALL

PILOT EXHAUST BALL SEAT RING BALL ADJUSTER (FACTORY SET) TYPE 6305

CONTROL LINE (FILTER NOT SHOWN)

PILOT RESTRICTION

SET PRESSURE ADJUSTING SCREW

SPACER AND DIAPHRAGMS

ANTIROTATOR PILOT CONTROL SPRING ONLY ONE EXHAUST LINE REQUIRED FROM BOTH PISTON AND PILOT

PISTON BACKUP RINGS

INLET (CONTROLLED) PRESSURE LOADING PRESSURE OUTLET (EXHAUST) PRESSURE

PLUG WIPER RING DISC

W2547-1*

Figure 5. Type 414-6305 Relief Valve in Closed Position The Type 6305B pilot differs from the Type 6305 pilot in that it has an additional diaphragm to counterbalance back pressure forces tending to keep the pilot exhaust ball seat ring against the ball.

MAINTENANCE Relief valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection and parts replacement depends on the severity of service conditions.

WARNING To avoid personal injury or equipment damage from sudden release of pressure or explosion

of accumulated gas, do not attempt any maintenance or disassembly without first isolating the pilot and main valve from system pressure and relieving all internal pressure from the pilot and main valve.

Type 6305 and 6305B Pilots If the pilot leaks continuously or does not operate the main valve, the problem may be due to clogging or freezing in the pilot restriction, misadjustment of the ball adjuster, or insufficient seating of the ball. Perform the “Pilot Seating Adjustment” procedure for a misadjusted ball adjuster or ball. Perform the “Disassembly” and “Assembly” procedures that follow the “Pilot Seating Adjustment” section if any pilot parts need to be repaired or replaced. All key numbers refer to figures 6 and 7 unless otherwise indicated.

5