Choosing the Right Air Cavity Package for Your Electronic Components

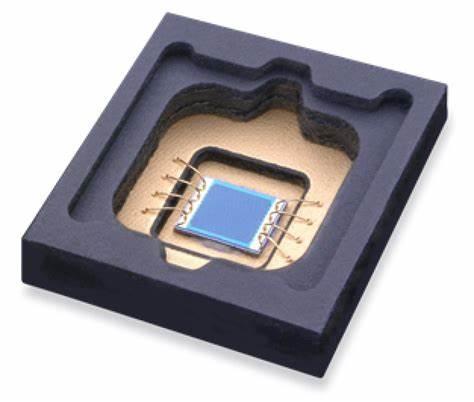

Particularlyinapplicationssuchasradiofrequency,microwave,andhigh-frequencycircuits,air cavitypackagesareessentialforguaranteeingthefunctionality,dependability,anddurabilityof electronic components. These packages provide heat dissipation and protect signal integrity whileofferingasealedenvironmenttosafeguardsensitiveelectronics.Foroptimumperformance, selectingtheappropriate air cavity package isessential.So,whenchoosinganaircavitypackage foryourelectroniccomponents,keepthesefivethingsinmind.

Understand Your Application Requirements

Finding the precise needs of your application is the first step in choosing the best air cavity package. High-frequency equipment like satellite communications, optical sensors, and RF amplifiersfrequentlyrequireaircavitypackaging.Determinethepowerlevel,frequencyrange, andenvironmentalcircumstancesthatyourcomponentswillexperience. The performanceofa packagemadeforalow-frequencyapplication,forinstance,canbehamperedbyitsinabilityto handlehigh-frequencysignals.Compatibilityanddependabilityareguaranteedwhenthepackage iscustomizedforyourapplication.

Prioritise Thermal Management Capabilities

Excess heat can be effectively managed by air cavity packages with sophisticated thermal management features, such as incorporated heat sinks or materials with high thermal conductivity. The enhanced thermal characteristics of materials like metal composites and ceramics make them popular choices. Effective heat management prolongs the life of your components,lowersthechanceoffailure,andavoidsoverheating.

Evaluate Signal Integrity Needs

Keeping the signal intact is crucial for components that operate at high frequencies. Signal performanceisgreatlyimpactedbythearrangementandmaterialsusedintheaircavitypackage design.Tofacilitatehigh-speeddatatransfer,lookforpackageswithlowparasiticeffectsandlittle signal loss. Achieving the intended performance depends on a number of factors, including materialdielectriccharacteristics,leadinductance,andpackagegeometry.Customdesignsmay benecessarytomeetspecificsignalintegrityrequirements.

Consider Material and Environmental Compatibility

The component's specifications and the operatingenvironment should be met by the material utilized in the air cavity package. Due to their strength and capacity to withstand harsh environments,ceramicandmetal-basedpackagingarewidelyused.Makesurethepackageisalso resistant to environmental stresses including moisture, vibration, and temperature changes. Sturdy and hermetically sealed packaging are frequently necessary for use in industrial or aerospacesettingsinordertopreserveoperationinchallengingconditions.

Collaborate with Experts for Custom Solutions

Off-the-shelfaircavitypackagescannotalwayssatisfyyourdemandsbecauseeveryapplication hasdifferentrequirements.Partneringwithexperiencedmanufacturers orsuppliersallowsfor customizationtailoredtoyourspecifications.Customsolutionsguaranteeoptimalperformance, frompackagesizetomaterialselectionandthermaladvantages.Collaboratingwithprofessionals alsogivesyouaccesstohelpfuladviceandtestingtoolstoconfirmthepackagedesignbeforeitis deployed.

In the end

In order to guarantee the effectiveness and dependability of your electronic components, choosing the appropriate air cavity package is essential. You can make informed choices by keepingthesetipsinmind.Purchasingtheappropriateaircavitypackage improves the overall performanceofyourdevicesandprotectsyourcomponents,enablingthemtofunctionflawlessly indemandingapplications.