• Miksad: a time for BCI celebrations!

• Full details of BCI activities over the year

• Amplify challenge for marketing success

• Innovation award, best responses ever

• A century of achievements remembered

• Don’t miss the great BCI Centennial Book

Battery Council International’s Convention and Power Mart Expo, looks yet again to be the hottest meeting of the North American lead (and more) battery community this year. With an exciting agenda covering many issues that urgently need to be discussed. The 600 plus delegates heading to Fort Lauderdale, Florida should find much to talk about.

A hundred years ago today you could walk into a car showroom and pick up a Model T Ford with $300 in your pocket and still get $10 change; a little punch-card firm decided to rename itself as International Business Machines although times were hard; and Calvin Coolidge gave that new-fangled radio a live broadcast from the White House.

Interesting facts perhaps.

But they pale in the light of a back-room meeting that year that resulted in the formation of Battery Council International (first created as the National Battery Manufacturers Association).

BCI was created by a small coterie of US electrical and battery firms keen to create a trade body capable of lobbying government to help the industry and achieve some form of standardization across the US.

So, 100 years on from that first meeting in a grey overcast morning in January in Chicago, we find ourselves now in the bright Florida sunshine celebrating a 100 years since BCI’s creation.

The elderly men that sat together that first meeting have been replaced by another more liberated and less formal generation of batterymen and women.

Gone are the black tie, the dinner jackets and the rigid seating arrangements that characterized BCI convention dinners even up to 30 years ago.

Instead, the centennial dress instructions for Fort Lauderdale were simplicity itself — “Come in sandals or a sundress… and get ready to party! … it’s going to be a once-in-a-lifetime convention experience!”

In any event only the heartiest of congratulations can come from this magazine to the leadership of Battery Council International — and not just the present figures at the top but those of previous years too.

In the past decade or so we’ve seen the metamorphosis of the Convention into not just a meeting of the great and the good of the lead battery industry but also as a forum with greater power and influence.

The technical presentations have increased in quality and number, the focus, via awards and ceremonies, on parts of the industry — think the Innovation Award, the Amplify Award and the Poster Research competition — have emphasised the need for our ability to come up with ideas and market them. Core values of any vibrant industry.

BCI itself has transformed itself too in the last 15 years.

Its policy approach is far wider and assertive than ever before. It’s also in closer rapport with federal government, in particular with its collaborations with the Department of Energy as well as US National Laboratories.

Internationally, BCI has been the dominant figure working with the International Lead Association, EUROBAT and the ABR in speaking with a common voice on aspects as diverse as battery recycling or blood lead levels.

Perhaps more importantly the present leadership has understood the need for greater communication of what lead batteries are, can do, and where they have real value.

The result has been campaigns that have attracted national newspaper headlines, and representations to senate and house committees on key topics.

Among a host of other things, BCI’s dealings and acceptance by the Californian authorities — widely recognized as the most difficult state to discuss environmental issues — have forged a successful pathway for other states, and another nations, to follow.

Roger Miksad, president and executive vice president of BCI, talks warmly about the industry’s future and that of the association, over the next 100 years. He is rightly proud of its expansion into alternative chemistries and its relationship with those at the cutting edge of lead battery technology.

His optimism isn’t misplaced if BCI continues to push on, in the way that it has for the past century. Mike

Glorious beaches, golden sun and fun things to do — in sum an extraordinary place to celebrate BCI’s centennial! By Julia Berg.

Fort Lauderdale — dubbed “the Venice of America” {if almost certainly by itself] — can certainly live up to much of its claim. There are an incredible 300 miles of scenic inland waterways weaving through the Greater Fort Lauderdale area with 165 miles of those running through Fort Lauderdale itself.

With a nod to Venice — that’s the other one in Italy — these waterways are often called canals that offer yes, wait for it, gondola rides.

There are water taxis too which serve 20 stops with an onboard guide pointing out everything from the historic area, mostly established in the 1920s and the 1930s, to the best shopping opportunities.

Not to disparage this but why not enjoy sunset cruises when the sky streaks red and a happy-hour drink is included in the ticket price?

If short of downtime, conference delegates would do well to hop on a water taxi even for just one trip during their stay in Fort Lauderdale.

Despite these canals meandering under some 117 bridges in the city alone, the tourist office claims that this watery canvas is not the main attraction of Fort Lauderdale.

The number one attraction is the beaches, or rather the nine long beaches stretching for seven miles located in Fort Lauderdale. One is perfect for families, another for an eclectic dining scene on the boardwalk, another for water sports.

One big suggestion is to explore

the Fort Lauderdale Riverwalk. It’s a two-and-a-half mile trail that winds its way along the banks of the New River, past historic homes, gleaming condo towers and waterfront homes, some of famous people.

There are 10 parks on the scenic route and plenty of cafes and restaurants along the trail.

If you’re short of time or prefer a seated experience, the Riverfront Water Trolley (20 seater bus) is the way to go. It’s free, covers all of the Riverwalk experience and works from 10am-10pm.

Fort Lauderdale is home to the tallest dive tower in the western hemisphere: 27 metres tall and nine levels of platform to dive from.

Be there or be square (and put something on your feet too)

Coconuts at 429 Seabreeze Boulevard, an upscale seafood restaurant with a cool beach vibe and fantastic views across the water.

Dress code: shirt and shoes required, no beach/fitness tops.

YOLO at 333 East Las Olas Boulevard, an upscale place serving New American menu, with a happening bar and an outdoor lounge with a fire pit.

Dress code: no beach/fitness wear.

After a day of business sessions, networking and slipping off to the bar, why not nip off to Las Olas Boulevard in the heart of Fort Lauderdale? It’s the beating heart of the city. Everything can be found on Las Olas: fashion boutiques, art galleries, memorable restaurants from burgers to Balinese, sidewalk cafes and bars together with some serious eclectic shopping opportunities.

If you plan a little additional celebration of the 100th anniversary of BCI, this is the place offering wine bars, cocktail bars and craft brewery lounges. It stretches from the beach along highway A1A.

Two places here for great food and live music popular with locals are Wild Sea and The Wharf.

There are many more. Much, much more.

The Greater Fort Lauderdale area boasts 25 miles of golden sandy beaches, reckoned as some of Florida’s finest, with some 300 days of sunshine per year (and not forgetting an average temperature 24°C (75°F) year-round).

Casa d’Angelo at 1201 N Federa Highway, just north of Las Olas Boulevard, founded by Angelo Elia 25 years ago and a regular award winner, this is an upscale restaurant serving Italian food with a modern twist. Dress code: no beach/fitness wear

Reservations are usually needed for all three.

Leslie Nielsen, he of Naked Gun fame and much more, is buried in Fort Lauderdale’s Evergreen Cemetery. As a final bit of humour — he had a long standing joke with his friends using a so-called fart machine he carried with him — he chose “Let ‘er rip” as his epitaph.

Indigestion or gestion? The founder of the Subway franchise Fred DeLuca lived in Fort Lauderdale until his death aged 67 in 2015. A few years before Dave Thomas founder of the Wendy’s the fast-food chain died aged 69.

1970s pop idol David Cassidy, lived in Fort Lauderdale for 15 years until his death in 2017. An extraordinary man in many ways he struggled with dementia and alcoholism in his final years.

• The Seminole Indians who first appeared in modern-day accounts in Broward County in the 1820s are the only unconquered tribe in the US — and the only tribe to never have signed a peace treaty.

• There is a three-tiered living coral reef system and more than 75 artificial reefs in the sea around Fort Lauderdale, making it one of Florida’s most popular dive destinations.

• Fort Lauderdale claims to be the yachting capital of the world with over 50,000 yachts registered there, some 100 marinas and some of the biggest boating events around the globe.

• Staying on after the conference? Bee Gees NOW!, one of America’s top tribute bands is performing on April 27 at the Broward Center for the Performing Arts.

• Shopping as only in USA — try The Galleria at Fort Lauderdale, an upscale experience with more than 100 fashion stores, Silver 925 and Southport for more of a mall experience and The Flamingo Flea, Fort Lauderdale’s own flea market and emporium of vintage, memorabilia and things boho-chic.

• In the 1970s, two million tires were dumped into the ocean to help build up an artificial reef. Unfortunately, The tires quickly became disconnected and scattered, causing damage to the environment and marine life.

• The concept of Spring Break where college students flock to the sun and hooliganise in the Easter holidays began in Fort Lauderdale.

• Fort Lauderdale is home to Butterfly World, the largest butterfly-centred park in the world.

• Fort Lauderdale’s beaches are some of the busiest nesting sites for sea turtles in the world.

• On January 19, 1977, it snowed in Fort Lauderdale for the first time in recorded history.

• Port Everglades is the third busiest cruise port in the world.

• The oldest section of the city is the Himmarshee Historic District dating to the Florida land boom of the 1920s.

When Batteries International announced that we were compiling a special centennial issue celebrating BCI’s 100 years of service to the industry, many of our subscribers and advertisers contacted us asking if they could add their best wishes and thanks …

The MAC Engineering team would like to thank the BCI team for their unending support and putting on some rather spectacular events for us! Congratulations on your first 100 years – we are looking forward to the event and meeting all our friends and colleagues form across the globe.

This event and the team that build and guide this are invaluable to us, we wouldn’t have missed a minute of it.

Looking forward to the next 100 years.

Congratulations to the Battery Council International on 100 years of leadership and success! We are proud to have celebrated many of our own milestones with you and we look forward to many more together in the future.

Cheers, Your Friends and Family at Atomized Products Group, Inc

STRYTEN ENERGY

Celebrating 100 Years of Industry Leadership

Congratulations, Battery Council International! You have led the way in advocating for the lead battery industry, promoting the world’s most successful circular economy, and calling for greater investments to unlock the tremendous potential of lead batteries.

The next generation of energy storage is here, and you’re leading

Congratulations to Battery Council International on a century of powering progress! Wirtz Manufacturing is proud to celebrate your 100 years of leadership and innovation in the battery industry. Here’s to continuing our shared journey toward a brighter, more energized future.

FROETEK congratulates Battery Council International on its 100th anniversary.

We would like to say thank you for many years of co-operation and look forward to the future in which batteries will play an even more important role than today.

FROETEK wishes all members success, health and all the best. We all work together to electrify the world we are living in.

The team at Advanced Battery Concepts would like to congratulate BCI on its 100th birthday. BCI’s continued fostering of innovation within a mature industry is a motivation for companies like ours that are pushing lead technologies

the way by embracing new battery technologies that will support the growing need for sustainable energy solutions.

Stryten Energy is proud to be a contributing member of this impactful organization, and we’re excited to be a part of the next 100 years!

to the next level and opening new and larger markets for all members to participate within. We look forward to BCI’s next 100 years!

CAM SRL

CAM sends warm wishes to the Board and all of the members of Battery Council International for the 100th anniversary of this important organization. The BCI is one hundred years old, but Lead Batteries are still young!

We are proud to participate in the celebrations that BCI has planned for the Convention in April.

Looking forward to meeting Battery Manufacturers and other Suppliers to this vital industry in Fort Lauderdale!

See you soon!

STTS BRAZING SOLUTIONS

“Congrats for your 100th anniversary, your event is precious for all companies involved in batteries field.

Our good wishes from your French subscriber: STTS Brazing solutions, the worldwide supplier of soldering flux for battery manufacture with COS process.

Cordial congratulations to the Board and all the members of Battery Council International to the 100th anniversary of the organization. We appreciate so much your support for keeping the sustainable lead acid battery so successful. Equally bfs does its very best to simplify the maintenance of these batteries.

We wish everyone attending the celebrations an amazing time with great moments.

We hope to see you soon, your bfs team.

Happy 100th birthday! Congrats. Let’s go for the next 100 years!

Christophe Pillot, Avicenne Energy

Thank you BCI for a century of innovation and leadership! Power Sonic Batteries proudly celebrates BCI’s 100 years of driving excellence in battery technology. From empowering industries to enhancing everyday lives, BCI’s legacy of innovation has illuminated pathways for progress. Here’s to a hundred years of powering the world forward.

Happy 100th anniversary, BCI, from your friends, Power Sonic Batteries.

I would like to take this opportunity to congratulate the Battery Council International on the celebration of its 100th anniversary! The BCI has worked tirelessly to connect and inform industry members as well as educate the public on important issues related to advancements within the lead battery industry. Focusing on issues like recyclability and environmental wellbeing have been key issues that they continue to promote. Working with government agencies, they are continuing to shine a positive light on this very valuable energy resource.

Donald Wallace – COO

U.S. Battery Manufacturing Company

We at ENTEK would like to congratulate the Battery Council International (BCI) on achieving this historical milestone of 100 years supporting the world of energy storage. ENTEK is proud to be a BCI member and shares in their commitment of educating people on the critical role of batteries that power our communities, our daily lives, and our future.

On behalf of the Institute of Electrochemistry and Energy Systems

“Academician Evgeni Budevski” at the Bulgarian Academy of Sciences, we would like to extend our heartfelt congratulations on the BCI 100-year anniversary. Throughout this century, your dedication to uncovering the inseparable connection between technology, innovation, and industry in the field of energy storage has been commendable.

And on behalf of the Lead-Acid Battery Department team of the Institute of Electrochemistry and Energy Systems at the Bulgarian Academy of Sciences I extend greetings to all BCI members on the occasion of the 100th anniversary of BCI and our sincere wishes for success in their endeavours to support future prosperity and wellbeing of the battery society.

Best regards,

Assoc.Prof. Dr. Plamen Nikolov Director of IEES-BAS

SORFIN YOSHIMURA

Sorfin Yoshimura has been a proud member of BCI since our inception almost 40 years ago. We are so grateful to BCI for their consistent support of the US Battery Industry bringing us all together to drive targets for the betterment of our collective future. BCI has been an integral part of the battery industry for the last 100 years

As ENTEK and battery manufactures across the nation focus on a cleaner, more sustainable future, BCI’s support of its members is even more critical today than it

impactful body as the global energy revolution evolves. We are grateful to the BCI for steadfast industry support and look forward to the next 100 years!! Congratulations BCI!!

Eagle Oxide are proud to be supporting and supported by the BCI and hope the next 100 years can be just as fruitful.

Congratulations BCI on your stellar work educating and supporting the industry for 100years!

From all of us at Hammond Group, congratulations BCI on 100 years of leadership! We are proud to be part of this vibrant organization that is promoting and connecting the nation’s battery industry. We support your unwavering advocacy in favor of federal policies that advance the critical role of domestic battery manufacturing, encourage investment in research and development, and inform policymakers on the growing demand for energy storage and supporting a low-carbon future.

The expander may be negative, but your experience will be entirely positive.

The job of negative expander is to reduce strain, maintain capacity and improve performance. In a way, that’s our job, too.

At APG, we deliver the best products and customer satisfaction in the industry through unwavering focus and personal relationships.

We offer the best pre-blend negative expander on the market, brought to you by a certified Women’s Business Enterprise and family-owned company you know and trust.

Find out more at atomizedproductsgroup.com info@atomizedproductsgroup.com

Sunday, April 21, 2024: Networking and anticipations of the convention ahead

6:00 –

Anyone who is anyone in the lead battery industry will be there at the opening reception of each BCI convention. All the senior figures in BCI — that’s to say the heads of pretty much every battery manufacturer of note in the North Americas as well as many of the key supplier firms — will arrive early to attend the Saturday afternoon BCI board meeting ahead of the following night’s reception.

A strange comment from a senior figure in BCI to Batteries International many BCI moons ago said this: “The average delegate doesn’t realise that these senior people who seem so aloof to those who don’t know them actually want to meet the attendees and gauge the opinions of others in the industry and to do it in a sociable way. Some of the most extraordinary friendships have come from these dialogues.”

That said the most important part of the reception is as much about introducing delegates together as setting the scene for the following convention days. Some of last year’s pictures below.

The old BCI saying, “When two or three of the US battery industry are gathered together, golf must be played” still hangs true. Or at least a little.

BCI’s annual golf tournament provides an exceptional opportunity to play competitive golf — and it IS very competitive as everyone who plays it always remarks — with business friends, rivals and total unknowns, all part of the battery industry.

Monday April 22, 2024: Opening keynotes, presentations and Power Mart Expo

9:00 – 9:35 Opening remarks

Chris Pruitt, CEO East Penn

9:35 – 10:15

A century of power: Celebrating 100 years of low voltage batteries in automobiles and a vision for the future

James Martin, S&P Global

10:15 – 10:40 Innovation Award presentation

10:40 – 11:00 Beverage break + Meet the Expert

James Martin

11:00 – 11:30

Resilient lead’s role alongside other battery metals in the ‘green’ energy transition

Neil Hawkes, CRU

The great news for exhibitors this year is that the Power Mart has been extended to a second day. This year the Expo has been opened up further, and as ever — see the photos of before and during the event — this period of the convention is fascinating as the hall transforms from the set-up of empty booths, to the quiet ahead of the storm as delegates work the aisles looking for new products, technologies and business partners.

11:30 – 12:30

12.30 – 5.00

4.00 – 5.00

5.30 – 6:30

Inaugural Fireside Chat with industry CEOs

Power Mart Expo opens with lunch and cocktails

Poster Research Showcase

Women in the Global Battery Industry (WGBI) Networking Reception

Sponsored by Hollingsworth & Vose, Stryten (open to potential WGBI members)

The Women in the Global Battery

Industry reception has become an important talking point of the BCI conventions since its inaugural first drinks gathering in the BCI convention in Tucson Arizona in 2018. Since then, the WGBI has gone from strength to strength capturing the changing business temperature of an industry where fresh management is no longer limited by age or gender.

Membership of the WGBI has grown rapidly within the battery business and the group is now looking towards increasing its membership and extending, in a positive way, its powers of influence.

Hal Hawk, Crown Battery; and Roger Miksad as moderator.

The Innovation Award

One of the most talked about features of recent BCI meetings has been the Sally Breidegam Miksiewicz Innovation Award. This was set up in 2016, as a tribute to East Penn’s CEO following her untimely death in June 2014.

Forget about the fireside, five of the top figures in the US battery space reveal — candidly — their thoughts about the direction of the lead and battery storage energy now and in the future. This is a must-attend session for all delegates.

Panel: Chris Pruitt, East Penn; Dave Shaffer, EnerSys;, Mark Wallace, Clarios;

It has now become one of the most watched features of the convention not just to learn who the independent judging panel deems a winner but also to see the variety of innovations submitted and how some have become standard within parts of the battery business. The award celebrates innovation in equipment, processes, services and products that advance the lead battery industry. (Last year’s winners, Gopher pictured below). This year 12 firms were contestants: Black Diamond Structures, CAM, Clarios, Daramic, ENTEK, GS Yuasa Energy Solutions, Li-Metal Corp, Midtronics, OPTIMA, Servato Corp, Wirtz Manufacturing and distinguished academic Mészáros Tamás.

Tuesday April 23, 2024: General session

8.00 – 1.15 Power Mart Expo is extended (coffee and lunch)

8:45 – 9:00 Amplify Marketing Award presentation

9.00 – 9:30 BCI regulatory & advocacy update

Roger Miksad, BCI

9:30 – 10:00 Charting the course for US battery manufacturers in the age of electrification

Melissa Floyd, Stryten

10:00 – 10:30 Beverage break + Meet the Expert (Melissa Floyd)

10:30 – 10:45 Looking to the next 100 years

Jeff Reeves, BCI

10:45 – 11:15 European battery legal frame, market and inspiration

Marc Zoellner, Hoppecke

11:15 – 11:45 Industrial battery market forecast 2024

Nick Starita, Hollingsworth & Vose

11:45 – 12:15

The Clarios perspective on the future of vehicles and their low voltage architectures

Federico Morales-Zimmermann, Clarios

12.15 – 1:15 Lunch break

1:15 – 1:45

The evolution and outlook of APAC lead battery markets

Dong Li, Leoch International

1:45 – 2:15 Transportation market update 2024

Rebecca Conway, Clarios

2:15 – 2:30

2:30 – 3:00

3:00 – 3:30

3:30 – 4:00

Beverage break + Meet the expert (Rebecca Conway)

Powering South America: the Moura story

Tiago Tasso, Moura

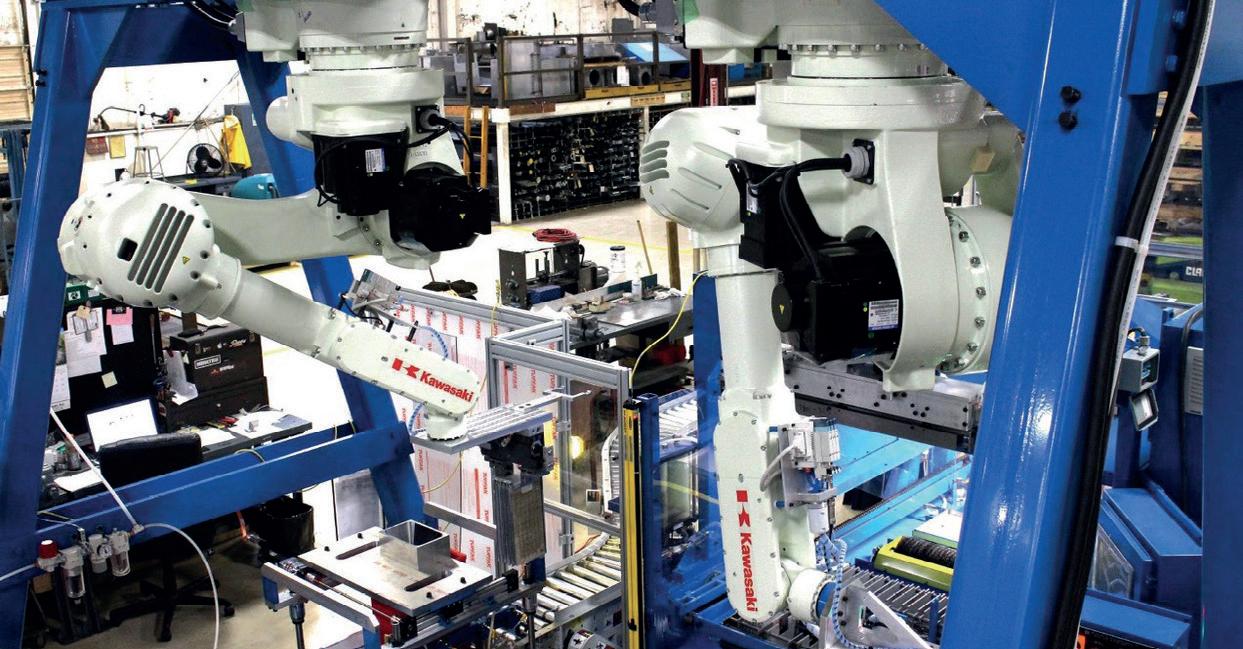

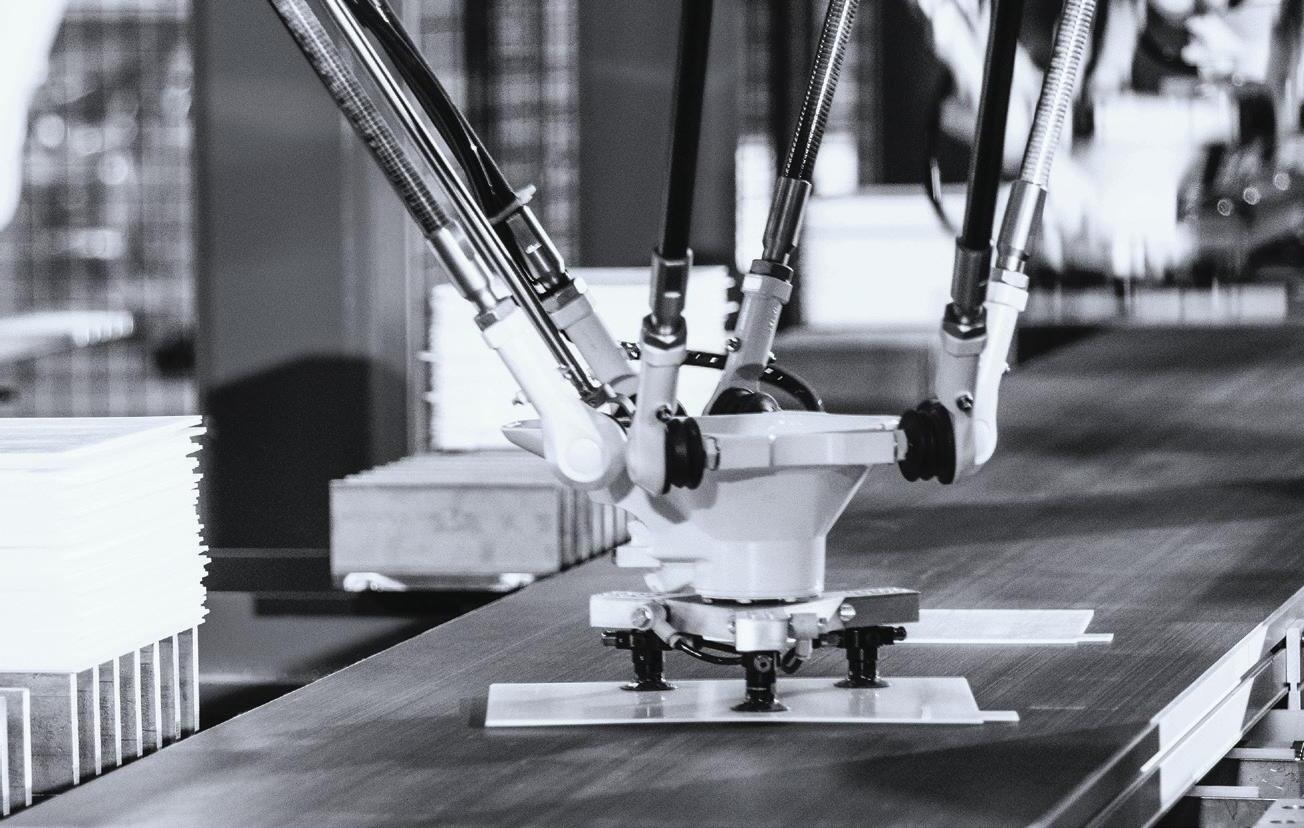

Supplier Showcase: Removing the worker from lead environment using robots and automation

Jimmy Stewart, MAC Engineering, Mark Gardiner, TBS Engineering

Supplier Showcase: Separator innovation and advances

Fabio Trigo, Daramic, Clint Beutelschies, ENTEK

programs important to the lead battery industry

5.00 – 9.00 BCI centennial celebration and party — a night to remember

A night to remember Roll of the drums, momentary silence and yes the BCI Centennial Celebration will start smack on the hour of 5pm.

So … be part of BCI’s oncein-a-lifetime celebration honoring the legacy and future of the battery industry — with live entertainment, door prizes, dinner, drinks and more.

And if you’re looking for a more laid-back vibe, skip the cocktails and band and hang out at the BCI Block Party on the Ocean Terrace behind the Marriott Fort Lauderdale Harbor Beach Resort & Spa for yard games and craft brews with friends and colleagues. Come in sandals or a sundress… and get ready to party!

‘90s rock icons to headline the birthday bash!

The Gin Blossoms (pictured), the iconic rock group, will be headlining BCI’s 100th Centen-

nial Celebration with a live concert.

The band, which has sold over 10 million records, remains one of the most in-demand live artists from the 1990s.

The 75-minute set is exclusive to BCI conference attendees!

You’ll hear popular tunes including the Gin Blossoms’ Top 25 smash “Hey Jealousy” along other hits “Found Out About You,” “Follow You Down,” “As Long as it Matters” … and more!

Amplify awards

The BCI Amplify Awards recognizes a highly effective and top-rate internal or external campaign, program or communication that serves to inform, educate and promote battery products, components, services for industry as a whole on the basis of four key pillars: innovation, sustainability, essentiality and safety. (Last year’s winners C&D Technologies receiving their award below).

Wednesday, April 24, 2024: Technology and Innovation summit

7.00 – 8.30 Quarter Century Club

8.30 – 9.15 Prospect battery innovations to market by 2030

Ray Kubis, Gridtential Energy

9:15 – 9:40 Renewed interest and new approaches to sodium as an energy storage resource

John Howes, Redland Energy, Joseph Liedhegner, Clarios, Xiaolin Li, Pacific Northwest National Laboratory

9:15 – 9:40 Storage innovations 2030 technology lift-off, DE-FOA 0003020: a DOE opportunity

Tim Ellis, American Battery Research Group, Matthew Raiford, CBI, Alyssa McQuilling, CBI

10:15 – 10:40

10:15 – 10:40

10:55 – 11:20

10:55 – 11:20

A bright future for lead battery research with the APS upgrade

Tim Fister, Argonne National Laboratory

US DOE funding awards to Flow Battery Industry Group (FBIG) members

Russ Weed, CleanTech Strategies

Top developments in the US stationary energy storage market

Scott Childers, Stryten

9:45 – 10:10

Successful engagement strategies for DOE support

Samuel Gillard, Strategic Marketing Innovations

What is it with the US obsession with crack-of-dawn meetings? And power breakfasts at 7am as the sun comes up?

Was a whole nation raised on farms in the mid-West?

“6.49am is sunrise for the Wednesday so we’ll all have milked our cattle, ploughed a couple of acres and caught up on our emails by then. It makes sense for a late-start at 7am,” says an insider. “It’ll give the East Coast softies a bit longer in bed.”

And is the press allowed in?

“Absolutely not. The only people allowed to attend are BCI veterans of 25 years’ standing. Besides, — isn’t 7am closer to their bedtime rather than breakfast?”

The Quarter

Century Club:

This meets up every last day of the convention and was set up to honor the battery heroes who have had already spent 25 years working in the industry and also for those venerable veterans who have spent half a century in the business.

It also reminds us of those that are no longer with us, the faces that once were a regular part of the committees, the conventions and the life of BCI. This year we particularly remember Bill Brecht who died last summer.

William Brecht, a stalwart of the BCI and a regular supporter of its numerous working groups for many years, particularly the Battery Standards Committee, died at his home in Rio Rancho, New Mexico on June 3, 2023.

Bill was a much-liked, largerthan-life figure in the battery business for over four decades, making huge contributions to the advancement of the industry’s engineering and technology and even occasionally nicknamed “a rogue genius” for the originality of his thinking.

Bill was born in Philadelphia, Pennsylvania on March 14, 1948. After college he joined Exide Battery. Hard work and innovative thinking helped him climb the corporate ladder and in the early 1980s to become vice president of technol-

11:25 – 11:50

11:25 – 11:50

11:55 – 12:20

Fundamental limits of discharge reactions in lead batteries — from well-defined interfaces to molecular design of expander molecules

Pietro Lopes, Argonne National Laboratory

Material supply considerations for lithium-ion batteries

Linda Gaines, Argonne National Laboratory

Behind-the-meter storage

Anthony Burrell, National Renewable Energy Laboratory

Lead-acid batteries in small and medium-sized LDES for behind-the-meter applications

Shawn Peng C&D Technologies/Trojan, Kimber Staub, Trojan

11:55 – 12:20

Major components and integration of flow batteries

Nate Kirchhofer, BioZen Batteries

The breakfast meeting consists of a reading of the members’ names and a short talk by one of the veterans of the club.

ogy. During his time there his research led to step-change performance increase of an industrial forklift battery — he was later dubbed ‘The Father of the Load Hog” for this quite remarkable work.

He subsequently was VP for C&D, Evanite Fiber Corporation, and CTO at Trojan Battery Company. On retirement he was widely sought after as a consultant for companies in South Korea and China. He was also a co-founder of bipolar firm Advanced Battery Concepts.

A full roll of honor of the club — both extant and departed — can be found in the BCI’s Centennial book, Leading the Charge.

Bill was a highly respected technologist and an enthusiastic electrochemist with 53 US and foreign patents to his name.

He invented the Single Point Watering system. He developed battery separators and a sealing technology for lead acid batteries as well as working with telecoms around the world with telecommunications, and back-up power systems.

He leaves behind Laura, his wife of 49 years. His ashes were committed to the ocean off Long Beach, California on October 13, 2023.

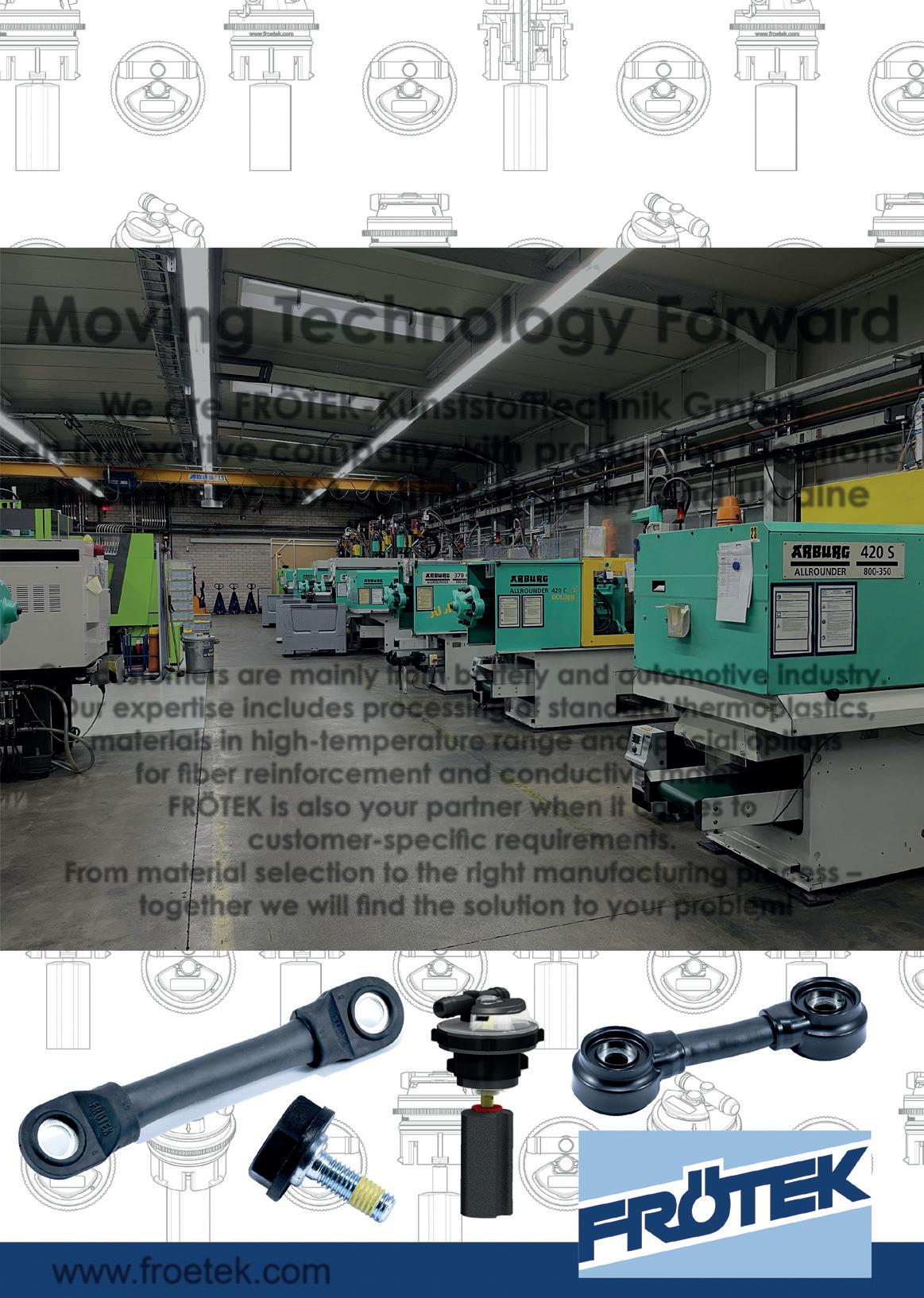

We are FRÖTEK-Kunststofftechnik GmbH, an innovative company with production locations in Germany, USA, China, Hungary and Ukraine

Our customers are mainly from battery and automotive industry. Our expertise includes processing of standard thermoplastics, materials in high-temperature range and special options for fiber reinforcement and conductive materials.

FRÖTEK is also your partner when it comes to customer-specific requirements. From material selection to the right manufacturing process –together we will find the solution to your problem!

Raise a

toast and look forward to the next hundred years!

As delegates gather for BCI’s celebratory convention of the century, Roger Miksad says the best is yet to come…

As BCI gathers in Florida for its 100th birthday celebrations delegates could be forgiven for putting on their shades, kicking back on the beach and taking in the Florida sunshine — not that anyone would want to miss a second of the packed program and specially-extended Power Mart.

It’s not every day that any family gets to celebrate a centenary, let alone the family of professionals that are an integral part of the global lead battery market.

Talking to Batteries International for this convention publication,

BCI president and executive director Roger Miksad acknowledged this year’s event would rightly be a mix of work and play, but stressed the event was not just a victory lap. It will be an important opportunity to look to the future too as he believes the brightest days of the industry have yet to dawn.

Looking ahead, Miksad says one of the major shifts over the next 10 to 15 years is going to feature stationary storage applications, grid-connected ESS and localized backup power.

“That’s an area where traditional low-voltage battery designs really have a place to play if those designs

can meet the performance requirements of the users, but we see that market exploding and everybody has to be prepared to meet those demands.”

In the battery market in general, the transition from ICE vehicles to EVs continues to be a talking point and also the role traditional low-voltage manufacturers have to play.

“It’s clear this is something that is not going away. Those applications require fundamentally different electrical services than in a standard SLI battery and the industry has to adjust to changing demand.”

This will require changes in manufacturing techniques and capacities and a look at where the industry as a whole is going to invest.

On the question of investment, how much focus there should be on exploring advances in bipolar tech looms large, so what is BCI’s take on that? Some industry observers might argue there have been a few false dawns, but is that a fair assertion?

Miksad is clear: “People are trying to figure out whether and how to deploy bipolar manufacturing because it’s a fantastic technology and a solution that requires a signifi-

The quest for constant improvement is a hallmark of our industry. The innovation award demonstrates that we are continuing to innovate in terms of product and technologies

cant investment to take from concept to high-volume production.

“But it’s also important to say that it requires a step-function change in the way you make a battery and let’s not forget that some of the advantages of bipolar have already been partially delivered through AGM, TPPL and other advanced traditional design batteries.”

Another battery chemistry, and one that has been around longer than BCI itself in a variety of iterations, is the flow battery. These systems are going through a renaissance of their own, particularly in terms of their potential to play a part in future long duration energy storage.

Lead and lithium player Stryten Energy is among companies that have also embraced flow battery technology and, just over a year ago, BCI launched its Flow Battery Industry Group to maximize synergies with the lead battery industry in boosting energy security in North America.

“The work of the group is going very well. Our goal for the group is to provide a home for interesting technology to support collaboration among a community that has a lot of new players and to bring them into the BCI fold,” says Miksad.

Flow battery technology is very cohesive in terms of markets and tech that also involve lead batteries.

Since BCI’s founding in 1924, the ubiquitous and too-often underappreciated automotive batteries that have long formed the backbone of the battery industry have reliably powered nearly one billion cars and trucks in the US alone.

Advanced lead-based batteries are supporting the growth of reduced-mission and EVs and supporting 21st century industrial applications.

Meanwhile new and growing applications such as grid-storage, EV fastcharge support, vehicle auxiliary power, and other areas are opening markets and unprecedented opportunities.

“Batteries of all types including lead-based, lithium ion, flow, sodium ion, and emerging battery chemis-

tries are supercharging this transition to renewable energy sources and a more sustainable global economy.”

Among the enduring success stories of the lead battery industry is its virtual 100% record on recycling, but can there possibly be room for further advances in that sector?

Miksad’s view is that the job is never completely done. Miksad points to the formal launch in 2022 of the ‘LeadBattery360°’ program to help reduce sub-standard and informal lead battery recycling in LMICs, an initiative supported by the ILA, BCI, EUROBAT and the Association of Battery Recyclers.

He also praises the industry’s work with the UN Basel group and engagement with government agencies and NGOs worldwide.

BCI is particularly interested in sharing lead battery recycling’s core strategies with stakeholders in other battery chemistries so they can learn from lead’s success. These include practices such as consistent labeling standards, widespread free consumer collection opportunities, prohibitions on improper disposal and industry-funded transportation and processing networks.

“These are all some of the ways in which our industry is doing its part to deliver sustainable energy.”

Nevertheless, pressures from the regulatory environment abroad and in the US continue and BCI has to stay alert to actions that could impact the industry.

“In the US, on occupational standards for lead, BCI has been very clear, for almost a decade now that we support employers seeking lower blood lead levels.

Frankly, right now we agree with the blood lead levels in California and other regulatory proposals that are out there. That said the rules writ large have a significant impact on the ability of the employers to continue to operate in high regulatory environments when they deal with operational requirements as opposed to worker health requirements.

“We see that in California and know the US federal Occupational Safety and Health Administration is

working on potential changes to the nationwide rules, so from a regulatory perspective that’s the biggest issue out there that we are dealing with.”

Miksad will give an update on the regulatory picture when he addresses the convention, but he also wants the event to celebrate the industry’s achievements — not least in showcasing the breadth of expertise that the industry has to offer during BCI’s annual Innovation Award.

In terms of submissions for the award, this centenary year has been one of BCI’s biggest.

“The quest for constant improvement is a hallmark of our industry. The innovation award demonstrates that this is ongoing and the industry is continuing to innovate in terms of product and technologies from suppliers and battery manufacturers. It’s important we keep on doing just that.”

Miksad is also setting the bar high for generations to come.

“This year’s convention is not just a victory lap because we are not going to be satisfied with our achievements for the first 100 years. We’re looking ahead to 200 and 300 years as an organization supporting an industry that is going strong and has everything to look forward to.”

Industry leaders sharing their vision for the future will be in abundance in Florida, with more CEOs and top executives lined up to address the convention than any other battery industry event.

“We are definitely going to enjoy the moment. Tuesday night especially is going to be a memorable one, taking a pause to recognize the longevity of our organization as the oldest battery industry trade group in the world.”

Miksad says the state of the battery nation as delegates gather to raise a toast for BCI’s 100th birthday is “fantastic”.

The industry is in the midst of a dynamic period for energy storage that requires nimbleness, imagination and action from battery manufacturers to make sure they are staying relevant in terms of changing technology, applications and demands, but it is an exciting time.

“Energy storage demand is only going up, so it’s a great time to be in the battery industry. There can be no single technology winner in terms of battery storage — there is room for everyone.”

“There are probably three key things that as an industry we have to do. One is continuous improvement in performance. We have to get even better on what we do today — not because we have a problem as such but to reaffirm our commitment to continually improving processes and safety.

“Second is being able to share successes with new market entrants and work to see how the industry can use the incumbent lead battery recycling supply chains and expertise to bring the same level of sustainability to new

markets and new technologies that our industry is investing in, such as flow and lithium.”

He says the third priority is to share technological success in the sector with the rest of the world because high-performing lead recycling systems really only exist in a few regions — North America and the EU being two of the key ones.

“We owe it as an industry to help other regions, in particular lowand middle-income countries that have historically been unable to afford a high level of performance, to improve their own systems.”

We owe it as an industry to help other regions, in particular low- and middle-income countries that have historically been unable to afford a high level of performance, to improve their own systems.”

Hammond-Engineered to Reduce Acid GravityGuard®

High-Quality Staples of Battery Manufacture, Tailored & Processed Red Lead & Oxides

Technical Assistance

Hammond is A Leading Global Developer of Lead-Acid Battery Chemistry for Advanced Energy Storage Applications with Production Facilities in the U.S, the United Kingdom and Malaysia.

Hammond-Engineered to Reduce Acid GravityGuard®

High-Quality Staples of Battery Manufacture, Tailored & Processed Red Lead & Oxides

Technical Assistance

Hammond is A Leading Global Developer of Lead-Acid Battery Chemistry for Advanced Energy Storage Applications with Production Facilities in the U.S, the United Kingdom and Malaysia.

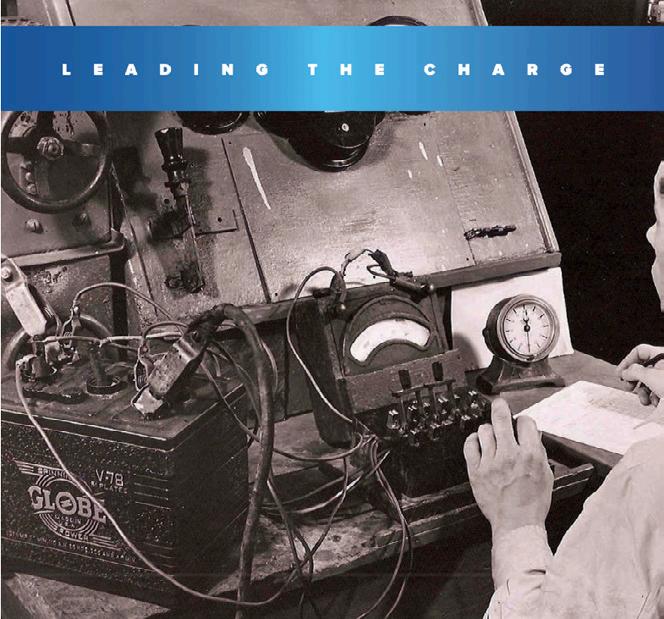

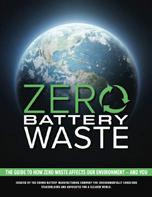

Every delegate at this year’s special Centennial Anniversary event will be given a copy of a specially commissioned book by BCI celebrating the first 100 years of the association’s history.

Leading the Charge traces the history of BCI from its earliest years to its present day, charting its many successes over the years and influences that extend far beyond that of the United States and the Americas. Within the book there is a spectacular set of photos showing how the industry used to be and what it has become.

From that very first meeting held on a chilly January 1924 in Chicago to the BCI celebrations today: the changes, which this book so excellently documents, goes far beyond the steady march of technology.

As one looks through many of the photos in the book one notices the growing changes in the workplace, the assortment of ages, clothing, and of course the growing representation of women at all levels of industry.

As the industry has moved forward, the book illustrates how BCI has helped shepherd the investigation of new battery chemistries and technologies through an array of research and development efforts.

It also details some of the milestones over the years — one particularly significant achievement being the group numbering system for batteries — a seemingly mundane cataloguing with huge implications for the battery industry.

Another achievement with huge implications was the BCI Model Battery Recycling Legislation, the first model regulation to protect the environment and to encourage recycling of batteries by promoting the industry-managed reverse-logistics system for the collection and recycling of batteries.

Yet another interesting section in Leading the Charge looks at BCI’s steady commitment and success in reducing blood lead levels well ahead of federal or state legislation.

All in all, Leading the Charge is a great read, and an informative one too. Highly recommended.

“Innovation is the thing that gives you the opportunity. It’s the promise of our future.”

Sally Breidegam Miksiewicz

One of the most talked-about features of recent BCI meetings has been the Sally Breidegam Miksiewicz Innovation Award. This was set up in 2016, as a tribute to East Penn’s CEO following her untimely death in June 2014.

The award celebrates innovation in equipment, processes, services and products that advance the lead battery industry.

The range of innovations set up as candidates for the award has been startling. Some have been as simple as a better design shape for a marine battery; others have embraced the latest technological advances in our understanding of the lead battery.

Some of the nominations have been breakthroughs in the laboratory but struggled to be commercialized. And yet others — think of advances in EFBs — have been quickly embraced as a new standard in an emerging marketplace that continues to grow exponentially.

But, be they large or small, these innovations matter. All advances are worthy of note.

For the last decade a tonne of investment has been flung at developing better lithium batteries while lead research has been side-lined.

The revamp of the ALABC and its replacement by the Consortium for Battery Innovation is putting the lead battery back in the spotlight. Clear advances are on their way and credit must go to CBI for helping to put some of this together.

That said credit must also go to a generation of lead researchers that have remained in the background — think RSR, Hammond, East Penn, Daramic and many others — that continue to shape the lead battery industry.

This year 12 firms put their hat in the ring to win the award. They were: Black Diamond Structures, CAM, Clarios, Daramic, ENTEK, GS Yuasa Energy Solutions, Li-Metal Corp, Midtronics, OPTIMA, Servato Corp, Wirtz Manufacturing and distinguished academic Mészáros Tamás. Please note, for space reasons, not all the entrants are listed in the following pages.

This year’s judging panel consisted of six well known battery luminaries: George Brilmyer, Tim Ellis, Bob Flicker, Don Karner, Geofrey May and Boris Monahov

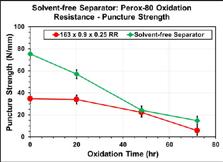

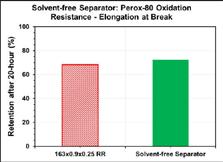

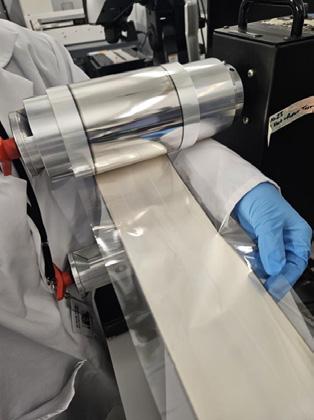

International lead and lithium separator firm last year introduced solvent free separators in its customer armoury.

Most flooded lead acid batteries include polyethylene separators. The term “polyethylene separator” is a misnomer because these microporous separators require large amounts of precipitated silica to be sufficiently acid wettable.

The volume fraction of precipitated silica and its distribution in the separator generally controls its electrical properties, while the volume fraction and orientation of polyethylene in the separator generally controls its mechanical properties. The porosity range for commercial polyethylene separators is generally 50%-65%.

During the manufacture of polyethylene separators, precipitated silica is typically combined with a polyolefin, a process oil, and various minor ingredients to form a separator mixture that is extruded at elevated temperature through a sheet die to form an oil-filled sheet. This sheet is calendered to its desired thickness and profile, and the majority of the process oil is extracted with an organic solvent.

Hexane and trichloroethylene have been the two most common solvents used in separator manufacturing.

The solvent-laden sheet is then dried to form a microporous polyolefin separator and is slit into an appropriate width for a specific battery design.

In response to environmental pressures, government regulations, and health concerns related to organic solvents such as hexane and trichloroethylene, there is a need for a new approach to manufacture microporous membranes that can meet the performance and process requirements for production of a Pb-acid battery separator.

This innovation involves the extrusion of isotactic-polypropylene (i-PP) in combination with a nucleating agent, silica, plasticizer, and surfactant to form a non-porous sheet that is wound into rolls. The extruded sheet is then stretched mono-axially or biaxially to form a microporous film as a result of cavitation and/or beta-crystal to alpha-crystal transformation.

Next, ribs are extruded and bonded to the surface of the microporous sheet to form Pb-acid separators in roll form. Battery manufacturers can their use this separator product

within their existing capital equipment and manufacturing processes (e.g., enveloping).

ENTEK is a global materials science and engineering company that produces and markets lead-acid separators, lithium-ion separators, extruders, and engineering services on six continents. We combine bestin-class equipment with our pursuit of continuous improvement and innovation to give our customers industry-leading performance and reliability.

In response to environmental pressures, government regulations, and health concerns, there is a need for a new approach to manufacture microporous membranes that can meet the performance and process requirements for production of a Pb-acid battery separator.

Making flooded lead batteries achieve the performance of their more expensive AGM counterparts has been a long-held ambition of battery makers. But also improving VRLA performance to reduce costs is a double win.

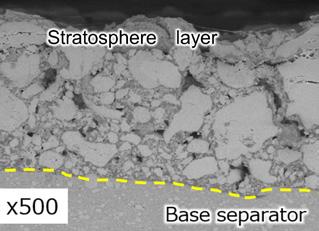

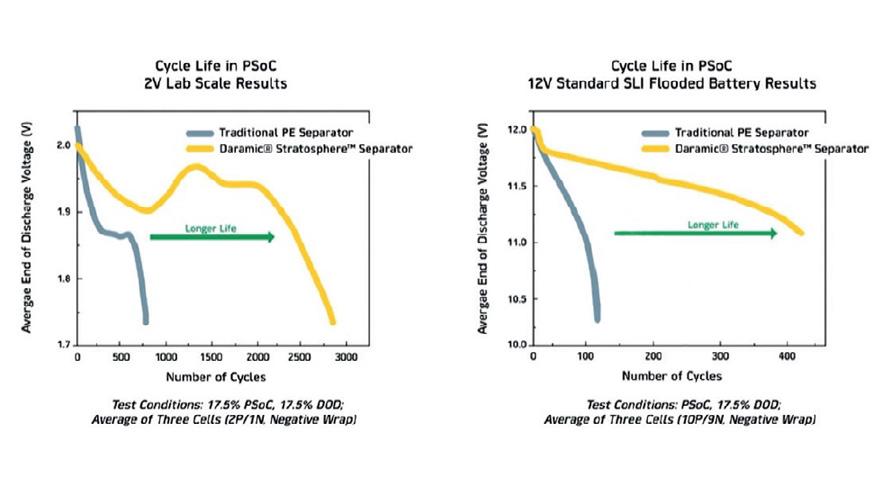

Daramic’s latest innovation — Daramic® Stratosphere™ — is a revolutionary new approach that increases battery performance and reduces costs for both flooded lead batteries (FLB) and VRLA ones.

Stratification of the electrolyte has challenged lead-acid batteries since their earliest days. This is particularly the case for flooded batteries used in applications such as energy storage systems and in auxiliary batteries for hybrid and electric vehicles, and other uses where extreme temperatures and partial state of charge conditions can accelerate the stratification process.

The variability of stratification exacerbates open circuit voltage excursions and discharge voltage fluctuations, which result in battery sulfation. That increase ultimately affects the charge acceptance and cycle life of the battery.

The typical functions of a traditional flooded battery separator involve managing <10% of the electrolyte in the system, but unfortunately the separator does not regulate the distribution of the acid in each cell.

Advanced absorbent glass mat (AGM) separator technology provides a solution to these stratification issues, improving the efficiency of battery management systems.

However, this comes at the expense of increased complexity and cost of more than double in battery design and manufacturing.

Daramic’s innovative Daramic Stratosphere technology, featuring a proprietary gelation composite substrate, controls the electrolyte by absorbing the electrolyte and expanding into the void space by 50%.

For flooded batteries, this evolution in technology retards stratification ensuring reliable sulfate ion trans-

port and communication with the battery management system (BMS), improving the battery’s Partial State of Charge (PSoC) cycle life by at least 2x, and all while maintaining affordability of FLB.

For VRLA batteries, Daramic Stratosphere separator technology can replace AGM, increasing filling and formation speeds, and negating

§

§

the need for vacuum systems, high battery compression (>5%), or intricate and expensive manufacturing processes that are usually required.

The introduction of Daramic Stratosphere technology represents a huge step forward for lead-acid batteries. Whether enhancing the performance of a flooded system, or improving the cost structure of AGM/VRLA

The introduction of Daramic® Stratosphere™ technology brings significant advancement to both flooded and VRLA systems, reinforcing the position of lead-acid batteries as one of the most cost-effective and reliable battery technologies available today.

— Daramic Stratosphere technology enables the next evolution of leadacid batteries.

Daramic says its Daramic Stratosphere technology features a proprietary gelation composite substrate, and so controls the electrolyte by absorbing the electrolyte and expanding into the void space by 50%. The introduction of Daramic Stratosphere technology brings significant advancement to both flooded and VRLA systems, reinforcing the position of lead-acid batteries as one of the most cost-effective and reliable battery technologies availa-

Validation of the technology has been proven by research in two Daramic facilities, one in the US and the other in Japan. This has allowed the next leap forward, taking 2V performance enhancements to be scaled up to the 12V level with realtime testing with battery manufacturing partners.

Margaret Roberts, patent liaison; Kevin Whear, vice president strategic marketing; Juri Iwama, development & evaluation; Susmitha Appikatla, R&D electrochemical engineer; Eric Miller, director of lead-acid battery R&D; , Abel Sy, senior research scientist.

PbLite increases

plate production per batch of lead-oxide

up to 4%, decreases waste production up to 70%, and increases battery-to-battery uniformity at a net negative cost, says Black Diamond Structures.

PbLite is a novel process additive, based on MOLECULAR REBAR carbon nanotube technology, which acts as a rheology modifier for leadacid battery paste to improve its application to the grid, simplify line operations, decrease waste, and increase plate output, to improve a battery maker’s manufacturing capacity, revenue, and quality at a net negative cost.

PbLite is a tool that can help battery manufacturers improve throughput and increase process capability indexes.

PbLite increases plate production per batch of lead oxide (PbO) by 0.2-4.0%, decreasing waste production >25%, and improving line efficiency to help foremen and plant managers exceed their quotas.

PbLite marks the first in a potential series of MOLECULAR REBAR products targeting process improvements, rather than performance enhancement. Since the first industrial-scale deployments of MOLECULAR REBAR products, line operators routinely told Black Diamond Structures of not just the ease of implementation of our material versus advanced carbons, but the unexpected improvements to production the material had elicited.

For a decade, our commercial team focused on improving dynamic charge acceptance, partial state of charge cycling, and deep discharge resistance, without highlighting process improvement as a key value proposition of the technology because the cost/benefit ratio was imbalanced,” the firm says.

“Now, thanks to process improvements in our own 130 tonne facility and extensive reformulation of our MOLECULAR REBAR product, we have been able to separate process improvement from performance improvement to offer a product which is essentially free to use and capable of generating additional profit for the battery maker.”

The production efficiency increase provided by PbLite is between 0.5% and 3.0%. This is equivalent to producing an additional 25 to 500 automotive plates per 1000 kg of lead oxide (PbO). The increase in production efficiency is achieved through two processes. First, PbLite decreases waste production by reducing the number of plates that need to be discarded due to incomplete paste coverage, out-of-spec weight, or thickness. Most manufacturers have reported a reduction in waste of approximately 25-30%, with some achieving up to 73% less waste compared to reference pastes.

Second, PbLite improves the pastability of the oxide batch by altering its material properties, allowing more plates to be extracted from it before it becomes unusable. The mechanism behind these processes is the ability of MOLECULAR REBAR to retain water and heat, reducing evaporation and extending the paste’s pot life. This results in a more efficient production process and increased plate output.

Safety is important too. By converting raw, tangled, solid-form carbon nanotubes into purified, de-tangled, liquid-form MOLECULAR REBAR, much of the inherent hazard of working with such material is removed. The chief concern with nanomaterials relates to its inhalation, which in our products is near impossible.

PbLite directly reduces waste (25-73%) and recycling costs by increasing the capture of plates from a batch of lead oxide, improving the efficiency of the Pb-Acid battery building process. Energy costs are reduced over time by decreasing the number of mixer, flash dryer, and curing oven since fewer batches are required to meet a manufacturer’s monthly quota of plates.

In most cases, PbLite pays for itself immediately after pasting in the form of extra plates. The cost of 2-2.5 L of material is paid back to the customer in additional plates within an hour of its introduction to the mixing chamber.

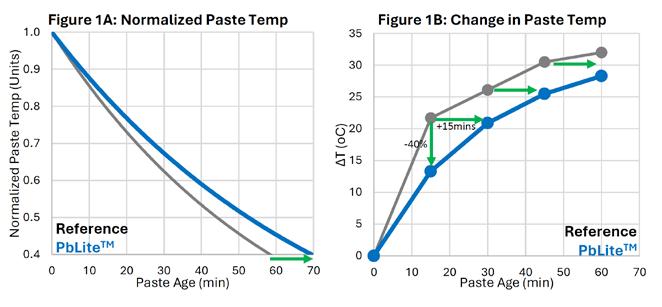

Figure 1A indicates an elongation of PbLite’s heat loss trendline resulting in a 17% increase in duration to reach the same normalized paste temp as reference.

Figure 1B shows that PbLite pastes lose around 40% less heat than Reference pastes in the critical first 15-20 mins post-mix when the plate thickness/weights get dialed-in on the production line. An additional 15 min is required for PbLite pastes to lose the same amount of heat as Reference. A warmer paste is a more pastable paste, and cooling delays are valuable to the production team. Extra heat is retained in PbLite pastes because evaporative heat loss has been impacted by the material.

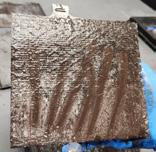

Italian engineer firm CAM last year released FASMELT, adapting and refining an existing technology to lead furnace need.

FASMELT is a no-gas melting pot, with rapid melting time, extremely low dross production, and most of all, roughly 60% lower energy costs by using magnetic induction. This clean system allows immediate production, and no need to maintain temperatures when not producing. It requires roughly 20 minutes liquify lead, ready to be fed to the rolling mill.

Today, the most important mission for this industry is to reduce the environmental impact of the production chain. One of the most difficult things to adapt to this mission is the need to melt lead for various processes. If you consider the cost of controlling CO2 emissions, special waste disposal, and energy consumption, the impact of melting is significant.

The concept of the oven is basically the same as a classic gas or electrical melting oven: It is equipped with an automatic ingot conveyor designed specifically for this application. The ingot is lowered into the melt when the set parameters of bath temperature and level are reached.

FASMELT is a magnetic induction oven, so there is a high frequency generator which heats the center of the melting pot by means of copper coils, generating a magnetic field which quickly melts the lead ingot It reaches the melt temperature of around 400° in just 20 minutes.

The magnetic field created by the induction system is safe for operators because FASMELT has been designed to isolate the magnetic field thanks to a shield. CAM has done exhaustive testing to measure the magnetic field and has values lower than 10 microT, which is the magnetic field threshold for humans.

Molten lead output is done by a classic CAM lead pumping system, with an extraction pump and a joule effect heated pipe regulated by inverter. The molten lead is then sent to the grid production system.

FASMELT is equipped with an automatic system to remove dross based on an extraction system that channels and deposits it into a container for disposal. FASMELT is completely closed, thus has a smaller diameter than a classic melting oven. This means the melt surface contact with oxygen is reduced, and consequently less dross is produced. This means greatly reduced special waste treatment costs.

FASMELT doesn’t only mean lower gas consumption costs – there is also less maintenance. Also, there is no flaking of the refractory material or risk of breaking the crucible.

It is well known that in traditional production, costs are just one aspect of maintenance operations. There is also the issue of production stops that create back-ups and matters regarding operators, etc.

With FASMELT, there is no flame pointing directly on the crucible, or bricks which are sensitive to temperature variations. The crucible is made of the same material as a gas oven and it is insulated with rock wool.

The melt temperature of around 400° for the lead is reached in just 20 minutes

With magnetic induction, the heat is distributed uniformly instead of just on one point as with gas heating. So, CAM expects a long life of the crucible. The payback on this system is incredible. Taking an example of a gas cost of €1 per m3. A gas oven would consume an average of 600,000 euro per year compared to about 90,000 for FASMELT at the same production rate. That annual saving of about €500,000 per year means the payback is around six months. This represents only the energy saving.

FASMELT is a game changing system for the entire lead battery industry, because this is the first induction system for this purpose in this industry. This innovation was designed, engineered, and implemented by the company’s R&D team. Economic funding was awarded through Italy’s National Plan to implement The European Union’s 4th industrial revolution.

Clarios, the automotive battery giant has come up with an all-in-one package combining the best features of a robust AGM battery and the best in real-time diagnostics for safety-critical applications.

The Clarios Smart AGM is an innovative lead-acid battery designed for real-time cell level diagnostics for preventative replacement and safety-critical applications, supporting all forms of mobility – passenger through commercial vehicles.

Clarios Smart AGM offers firstof-kind integration which measures critical attributes at cell level and processes through diagnostics with connected communications in an AGM type battery. Smart AGM is precision-engineered to enhance diagnostic accuracy on battery health and functionality.

This product identifies potential issues before they occur, enabling preventive replacement before failure. Additionally, it offers emergency power crucial for electric vehicles and autonomous vehicles, contributing to optimized vehicle system performance.

Smart AGM offers OEMs and consumers a choice between lead acid and lithium-ion. OEMs have many critical factors to choose in vehicle design and must be considerate of overall cost. Lithium-Ion technology has embedded electronics for diagnostic capability enabling function safety, but comes at a higher price point and has challenges with recyclability.

“The Clarios Smart AGM will be a game changer for the industry, providing a reliable, safety-critical battery with real-time communications,” said Mark Wallace, Clarios CEO. “It combines the proven reliability, inherent safe chemistry and sustainability of AGM with the realtime intelligence of our Smart technology.

“Also, it will extend our Clarios xEV portfolio, a range of advanced low-voltage batteries specifically designed to maximize EV performance, safety and reliability.”

Smart AGM offers an alternative solution to leverage the existing benefits of lead acid technology while offering similar tech/moni-

toring that lithium-ion offers, and more mature recyclability.

The implementation of Smart AGM was truly a cross-functional effort with company leadership support, including engineering, “Our team went above and beyond the technology boundaries, to revolutionize this innovated lead-acid technology,” the firm says.

Clarios says it is the only battery manufacturer to successfully integrate monitoring at the cell level delivering real-time diagnostics in an AGM format making SMART AGM a true innovation. Notably, the Smart AGM represents a novel concept in the low-voltage battery industry.

“The Clarios Smart AGM will be a game changer for the industry, providing a reliable, safety-critical battery with real-time communications. It combines the proven reliability, inherent safe chemistry and sustainability of AGM with the real-time intelligence of our Smart technology”

— Mark Wallace, CEO

This product identifies potential issues before they occur, enabling preventive replacement before failure. Additionally, it offers emergency power crucial for electric vehicles and autonomous vehicles, contributing to optimized vehicle system performance.

Clarios creates the most advanced battery technologies for virtually every type of vehicle. The firm says: “We are a global leader in advanced energy storage solutions, powering one in three of the world’s vehicles. We produce more than 150 million batteries — one-third of the industry’s output — every year, and we continue to build and expand our capacity to meet our customer’s future demand.

“Clarios is recognized as a global leader in low-voltage systems. The firm plays a pivotal role in driving innovation within the automotive industry.

“By closely collaborating with automakers, the company leverages its prominent position to introduce cutting-edge technologies that support advancements in powertrain technology and vehicle autonomy. Partnering with our customers, Clarios continues designing cost-effective energy storage solutions tailored to meet environmental, safety and electrification requirements, to add value to our customers.”

Fleet charging for EVs using lead batteries has developed a long way in recent years. Advances in technology make these BESS suitable for a wide range of functions.

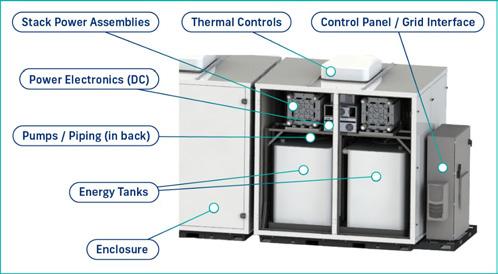

GS Yuasa’s product is a 1.5MWh battery with a 500KVA power conversion system contained in one 40ft battery container and one 10ft container for balance of system including BMS/EMS, Power Conversion System, and UPS for black start and house loads.

This application is for EV fleet charging using a system consisting of two 922Vdc strings of 384 GS Yuasa Advanced Lead-Nano carbon SLR cells deployed in a 40-foot ISO container providing 1.5MWh storage.

A second 10-foot container houses:

• State of the art BMS/EMS which monitors cell voltages and temperatures, string currents, and manages battery charge/ discharge and equalization profiles,

• EPC PD500 Power Conversion System providing power,

• System modularity enables battery size or required power to scale easily,

• An 15KVA UPS System provisioned for black start operation and for house back-up power. The enabling technology that makes the GS Yuasa BESS effective is the advanced lead-nano carbon SLR battery technology. The SLR battery provides 5,000 cycles to 70% DoD performance and in third party testing has passed 19 macro cycles of the IEC 61427 standard and is a standout for VRLA battery technology.

GS Yuasa says:

• The SLR technology is a game changing technology which provides a platform for VRLA batteries to contribute to the growing energy storage demand in North America.

• The 5000 cycle capability opens the door for VRLA technologies with a pathway to approach the

LCOS (Levelized cost of storage) for energy storage.

• The SLR EV Charging BESS is a definite example of how VRLA batteries can participate in providing solutions to support the grid.

The design features that increase the performance of the SLR product are: the nanocarbon enhanced negative active paste material for higher capacity retention; a proprietary grid design to inhibit grid growth by retaining the grid’s integrity; an increased density of the positive active paste material to increase the number of battery cycles; a proprietary PP-X additive to prevent

premature capacity loss; and, a HT X Alloy to minimize grid corrosion in high heat temperatures.

The SLR battery technology was developed by GS Yuasa Engineering in Japan and is manufactured at GS Yuasa’s main manufacturing campus in Kyoto, Japan.

For the BESS Balance of Plant GYES selected additional parties to support the turkey system design and fabrication. GYES partners with: Greentech Renewables for the system electrical design; Nuvation Energy for the BMS/EMS; EPC Power provides the Power Conversion System; and the containers are fabricated by Module X Solutions.

•

•

•

•

•

• Nano carbon additive in negative plate: increases charge efficiency; reduces sulfation, improves capacity retention over life

The combination of these technologies allows SLR batteries to achieve up to 5000 cycles at a 70% depth of discharge, enabling them to compete with Li-ion and other chemistries in battery energy storage systems.

For the first time at BCI and given that many of its members already manufacture lithium as well as lead batteries, there were two new submissions for the Innovation Award.

Li-Metal’s lithium on metalized polymer anodes is the company’s second-generation lithium metal anode technology and can be leveraged in battery cells for next-generation battery applications including eVTOL (electrical vertical take-off and landing).

Li-Metal is one of the only next-generation anode technology developers to successfully produce these lithium metal anode products using physical vapour deposition technology. Li-Metal’s second-generation anode technology expands the company’s ability to support current EV battery customers and aviation customers.

Li-Metal’s ultra-thin lithium on metalized polymer anodes should reduce the need for copper in next-generation batteries anodes, resulting in improved costs by up to 25% and lighter weight batteries,

metalized polymer anode products. Li-Metal and Mustang Vacuum Systems plan to together produce these second-generation products at commercial-scale.

while delivering better gravimetric and volumetric energy densities.

Currently, battery developers utilize lithium metal anodes that use 6-10 microns of copper foils, on average, which results in energy densities of less than 400Wh/kg. Next-generation battery developers, particularly those targeting electric aviation markets, are seeking to produce batteries with more than 450 Wh/kg and energy density of more than 1000 Wh/kg.

Li-Metal’s second-generation anode products utilize metalized polymers with 0.5-1 microns of copper, which enables the light-weighting of anodes and should enable next-generation battery developers achieve their targeted battery performance metrics.

Li-Metal has continued to execute with process performance and product quality by producing lithium metal anode products with lithium thickness of between 3 and 20 micrometres.

In the 1970s, OPTIMA Batteries introduced the first maintenance-free lead acid batteries for commercial and military use and the first high-performance AGM automotive batteries.

Over the past two years, the firm has introduced two lines of OPTIMA Orangetop LiFePO4 batteries — Powersports (six battery models) and Marine/RV (two battery models) — as well as three new chargers/ maintainers.

The firm says: “The Orangetop is a game-changing product that has the scale to fit over 95% of powersports vehicles. It brings the power, strength and performance of OPTIMA to a powersports market that had struggled with shoddy replacements for years.

“This battery comes equipped with a patented system, which provides a

convenient connection for battery charging as well as a state of charge indicator that allows users to see what issues a battery may be experiencing at any time.”

The Orangetop features a first-of-its-kind built-in jumpstart that reserves enough power in the battery to start it even if its dead.

CUSTOM AND CONVENTIONAL AUTOMATED SOLUTIONS FOR: AUTOMATED ADDITIVES, FIBER EXPANDERS

LEAD HANDLING

MONITORING LOADING, INGOT CASTING

PASTE MIXING

RFID, SERVOS, EQUIPMENT SETTINGS

SORTING - STACKING

VISION RECOGNITION SCANNING, HIGH-SPEED SPIDER ROBOTS

OFF LOADING - PALLETIZING

PALLETIZING ROBOTS, CUSTOM GANTRY SYSTEMS

Discover the benefits of robotic and automated solutions for increased production and productivity by calling +1.810.987.7600 or emailing sales@wirtzusa.com.

Applying artificial intelligence to battery testing is a new field of endeavour for the lead battery industry — with many positive outcomes expected.

Midtronics, founded in 1984, develops and produces battery management equipment and services for the global automotive industry. It says its “advancements in testing, diagnostic charging, monitoring, and analytics have provided value across the entire battery lifecycle in automotive, heavy truck and motor sport industries”.

Midtronics says the MVT handheld battery tester is powered by MDX-AI, and showcases diagnostic capabilities never thought possible in handheld battery testing. MVT makes battery testing fast while delivering professional accuracy.

With the MVT, Midtronics says one can:

• Accurately diagnose discharged batteries in-vehicle, without having to charge them.

• Get instant test results with no user input on most quick lane testing scenarios.

• Accurately diagnose batteries when the CCA rating can’t be seen.

• Accurately diagnose batteries when faced with vehicle system noise interruptions.

In addition to new diagnostic capabilities, the MVT features: an intuitive user interface, over-the-air data transmission and update-ability and the ability to email test results.

Midtronics says, “MDX-AI uses algorithms and AI machine learning models to enable specific diagnostic features, however it is more than just Artificial Intelligence. That is why when we refer to AI, we mean Applied Innovation. MDX-AI applies not only Artificial Intelligence machine learning but also our 38 years of experience, expertise, and innovation.

“So, for example, the start event diagnostics feature in the MVT. Over the years, we have amassed millions of diagnostic charge records in BMIS. In this data are key parameters, including data about the battery captured during a starter/alternator

test. We used this data to create and feed a machine learning algorithm capable of predicting battery diagnoses using the battery data collected during a start event.”

The MVT handheld battery tester is powered by MDX-AI, and showcases diagnostic capabilities never thought possible in handheld battery testing

Depending on the problem feature with MDX-AI, the technology may leverage AI machine learning models to improve speed and accuracy of our diagnostics. For example, in the MVT, when a battery can start the car, but is too discharged to be diagnosed with a handheld tester, Midtronics uses an AI machine learning model which can diagnose the battery’s health by monitoring key parameters during a start event.

Machine Learning

Learn to learn Decision trees / algorithms

MDX-AI

Battery diagnostics using our experience, expertise, and applied innovations

Leverages a machine learning model fed with millions of battery and system diagnostic records

Logistic / Linear regression

Clustering & Classification

Uses decision trees / algorithms

Combines above with our experience and expertise to create diagnostic features

Generative AI

Create new content from previous learning

Language mastery across context, sentiment, emotion etc

More autonomous than other technologies

Leverages many Artificial Intel methods and technologies

Wirtz Manufacturing has been involved in lead acid battery manufacturing equipment since 1935 and has supplied grid casting equipment since 1955. Its new Gravity FlowCaster takes this experience to a new level.

While offering the same performance advantage of traditional gravity cast grids, the Gravity FlowCaster delivers a continuous web of grid material in a complete reel-to-reel solution. Each grid is produced with an adjoining frame and is spooled for storage and subsequent downstream processing.

The firm says: “With the Gravity FlowCaster, battery manufacturers can now take full advantage of continuous manufacturing, which brings benefits including, but not limited to, lower scrap rates, higher production speeds, less demanding operations, and overall improved process control—lending itself to total industry sustainability.”

The Wirtz Gravity FlowCaster is also the first continuous grid casting machine capable of handling difficult-to-process alloys such as lead-antimony. With its alloy segregation and wide freezing window, products requiring antimonial grids have been relegated to piece-by-piece and batch manufacturing processes. These processes are labor intensive, place considerable strain on operators, increase lead-in-air emissions and operator exposure, and bottleneck production.

The patented Wirtz Gravity FlowCaster (US Pat. 10,981,218) is based around a continuous rotating mold, whereby half of the mold is comprised of a wheel with an engraved grid cavity and the other half a thin steel belt that is forced into engagement with the wheel surface via multiple temperature-controlled shoes.

Molten lead or lead alloy is delivered to a gate, or runner system, at the top of the mold. The molten material then fills the cavity via gravitational force, and it will subsequently solidify while continuing to pass under the temperature-controlled shoes but while still encapsulated between the wheel and belt.

Both mold halves will eventually disengage and the now solidified web of lead grid may be released from the

mold cavity. Once free, the interconnected grids can be wound on to a spool. Any flashing present on the grid can be addressed with a standard deflash unit common to the industry. Further, the remaining sprues left at the foot frame of the grid can be trimmed at the reeler, where all scrap is recycled immediately back into the original melt furnace.