rh Ryan Harnish

Design Portfolio

Tulane School of Architecture

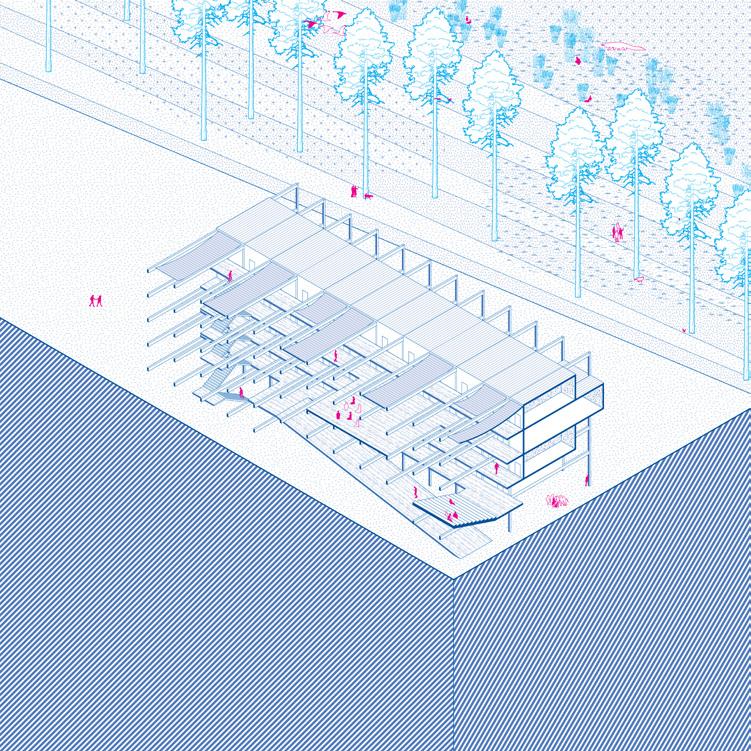

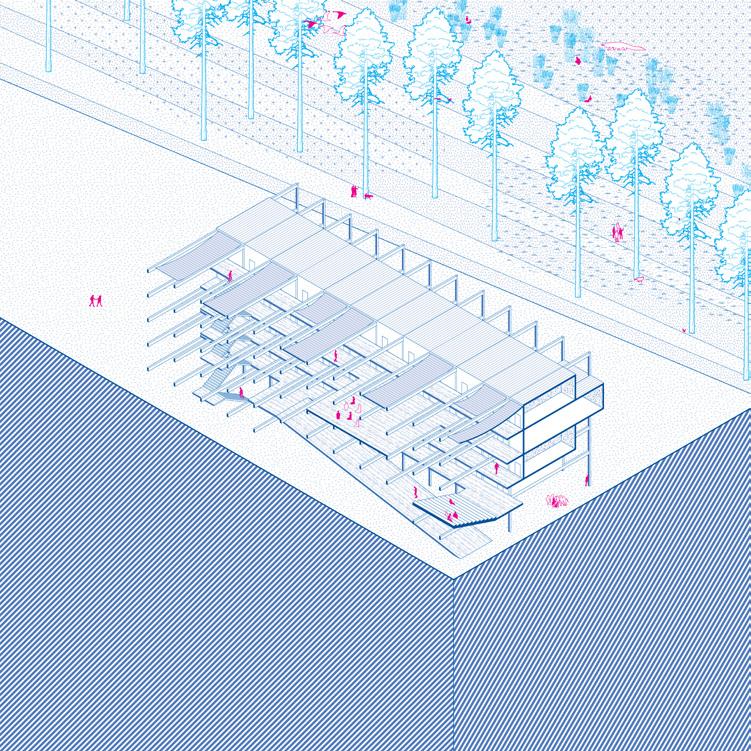

This Studio is part of an international, interdisciplinary, long-term research project led by Dr. Ruben Garcia-Rubio at the Tulane School of Architecture, as part of the Saul A. Mintz Global Research Studios program. This intervention focuses on a site at the far northern edge of Addis Ababa, in the foothills of the Entoto Mountains.

On a large scale, this project seeks to address several problems facing Addis Ababa—namely flooding and the lack of access to safe spaces to walk. While doing site research, I noticed that to reach the church, visitors walk along the shoulder of a major road. In reaction to these challenges, the project proposes a system of smaller interventions to slow, retain, and infiltrate water into the site, along with paths for walking or biking to reach the site.

At the local scale, the intervention connects an important cultural site, Entoto Kidane Merhet with the Upper Kebena River. A series of terraces work their way up the hillside, providing access to the river and a new, human-centric “gateway” to the Church. The terraces include several public spaces, along with housing for pilgrims visiting the church for healing.

Rhino was used for design and 3d modeling. The contour lines for the terrain were provided to the studio, but context and existing conditions on the site were modeled by me based on aerial imagery and gis data from the city. Once the design of the project was complete, it was exported to Adobe Illustrator to produce the finished drawings.

URBANbuild 17 is the first in a series of four houses for Bethlehem Lutheran Church, whit the intention of being used as affordable housing units, rented by the church to members of their congregation in need of housing. This iteration of Urbanbuild also marks the first time where accessibility was a major factor in the design. From the beginning, URBANbuild 17 was designed with a wheelchair-bound occupant in mind and the whole house is ADA accessible.

Each of the houses will be built in series, moving back on the lot away from the street. As the first house, 17 has to respond to the other houses on the street. This was accomplished primarily through the roof overhanging past front facade of the house. The largest one-site design decision that was made over the semester was a decision to flip the direction of the framing in this overhang.

As part of the build team I learned how an active job site operates, along with how to read construction documents. This experience has given me greater incite into how to draw details.

While everyone had some contribution to every phase of construction, my largest contributions to the project were in the shutter system and the floors. I was a part of the team that fabricated the shutters and was responsible for the aluminum frames. I was one of the few student who worked on installing the wood floors.

Process Photos

Finished Photos

The first portion of the semester focused on collecting and presenting data on climate change relating to the petrochemical industry, done in groups, and mapping using ArcGIS and Adobe Illustrator. The culmination of the studio was an individual design intervention based on this research. Each student proposed a design that would directly address an aspect of the effects of climate change on Southern Louisiana.

This project proposes a retrofit of a recently constructed liquid natural gas facility to support the offshore wind industry. The facility is located in a vulnerable location in Cameron, Louisiana along the coastal edge of the Gulf, and it is expected that it will eventually be damaged. The retrofit proposes to re-purpose the facility into a new port and a staging ground for the construction of offshore wind farms in the Gulf. Additionally, with a decline in petrochemical imports and exports into Lake Charles, the Calcasieu River will need to be dredged less frequently. This project proposes to re-purpose the dredging machinery to create wind-resistant landforms on the site to protect the new campus from future storms.

The rest of the project comprises a campus to act as headquarters for the companies overseeing the management of renewable resources. This campus will include offices and lodging for the staff charged with maintaining the offshore infrastructure. This site will act as a testing ground for the potential replication of this model along the coast.

Figure Ground, Petrochemical Industry in Lafayette Region

Figure Ground, Petrochemical Industry in Lafayette Region

This project is for multi-family affordable housing in New Orleans’ Lower 9th Ward. Two small units are mirrored across a shared, central porch. Utilizing a recent change to New Orleans building code, this project is intended to be scalable through mirroring across the property line onto an adjoining lot.

Starting at the beginning of the summer, I worked closely with the architect on design development for the project. As drawings were finished I would lay out sheets in the permit set. This layout is intended to be used as a new template file for MZ. Architecture. I also worked to clean-up the detail sections and write the code sheets and schedules.

Design Team:

Seth Laskin Lizzie Bateman

Jacob Silbermann | Jacob Taylor

Ethan Lewis Ryan Harnish

Designed and built in the fall of 2020, Sukkah 12.0 faced the challenge of following Tulane University’s Covid-19 guidelines, while also meeting strict Jewish law regarding the construction of a Sukkah.

The solution makes use of a parametric design. The undulating shape creates a variety of seating and shelving, both traditional of a Sukkah. The design was an iterative process using Rhino to model the curves of the walls, then Grasshopper was used to modify spacing and the number of divisions. The density of the fins was calibrated to allow free airflow th follow Covid-19 guidelines, while remaining dense enough to provide privacy within the Sukkah.

Each of the individual curves was cut by the Tulane Millhaus as a way to ensure precision and expedite fabrication. Once cut, the fins were held together by aluminum rods threaded the entire length of the Sukkah, with spacers to help keep the structure rigid.

Design Team:

Eric Chesebrough | Ryan Harnish Grant Jorissen

Seth Laskin | Ariel Levine | Ethan Lewis

Lauren Liroff | Josiah Ramirez Laura Rosemberg

Cole Schwabacher | Kris Smith | Dani Tirse

William Trotter

The design of Sukkah 14.0 took place over a single-day design charrette. Throughout the morning, each participant was given material to sketch or create study models. In the afternoon, the entire design team worked together to synthesize the best aspects of the individual designs. We worked between sketching by hand and digital modeling in Rhino. This final 3d model was used throughout the entire fabrication process, instead of traditional construction drawings.

Unlike previous Tulane Sukkah projects, Sukkah 14.0 was designed from the beginning to function as a permanent structure. The materials were chosen to last outdoors in New Orleans’ climate. Red Cedar was chosen for the framing and marine plywood for the walls. Like in previous years, the Sukkah made heavy use of the Tulane Millhaus, in this case in the designs in the plywood. Testing pattern options and final milling were done by me.

3d Rhino Model

Detail, joinery

Finished photo

3d Rhino Model

Detail, joinery

Finished photo

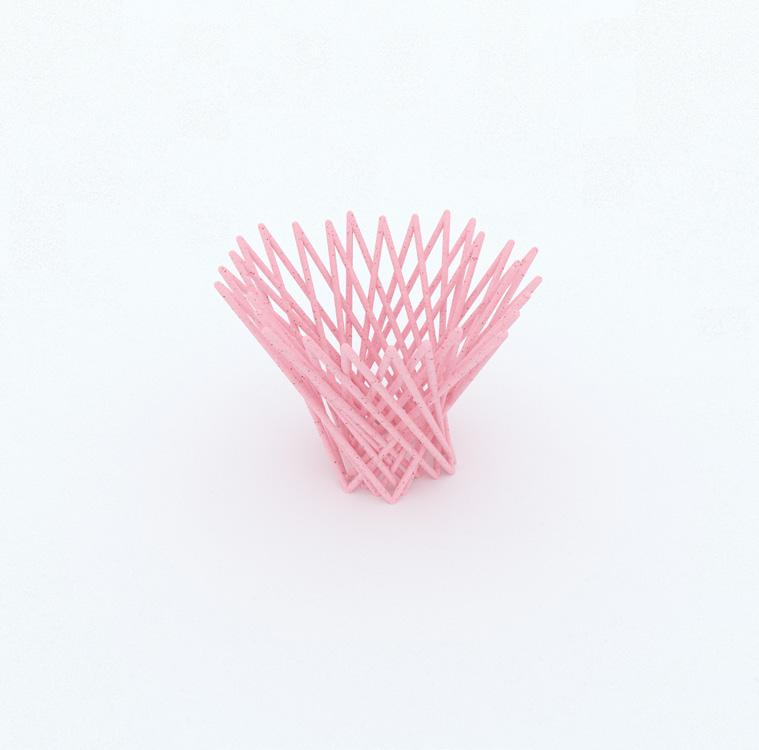

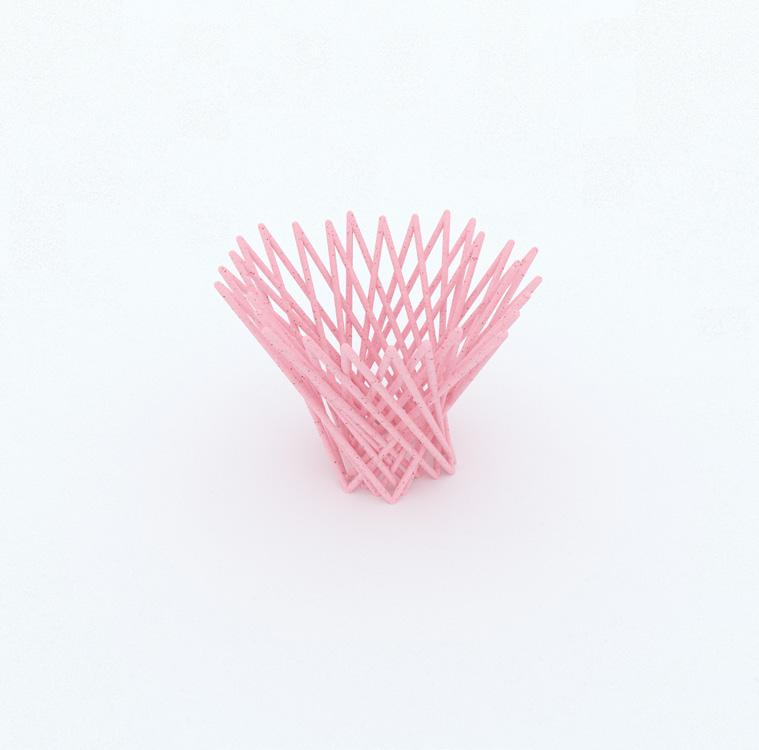

The project called for the creation of parametrically created vessels—defined as anything which could hold other objects—using a top-down workflow. Starting with an inspiration—the approximations of parabolas using a series of taught stings—this basic idea was rationalized with controllable parameters. The x and y axes of the parabola are bent into co-linear circles to yield a goblet with a parabolic profile.

The first-order parameters allow for variation in the radius of the circles, density of lines, and offset of the lines connecting the two circles. Second-order parameters were added to introduce simulated randomness. Using pseudorandom values, each point on the circle is offset, either away or toward the center of the circle. This parameter consists of the range of the random numbers along with a seed value to determine the procedurally generated list of numbers used. Using these simple parameters, a theoretically infinite number of goblets can be created.

All scripting with written in Grasshopper and used to generate 3d models in Rhino. Rendering was performed using v-ray in 3ds MAX.