PROTECTION, DISTRIBUTION & CONTROL

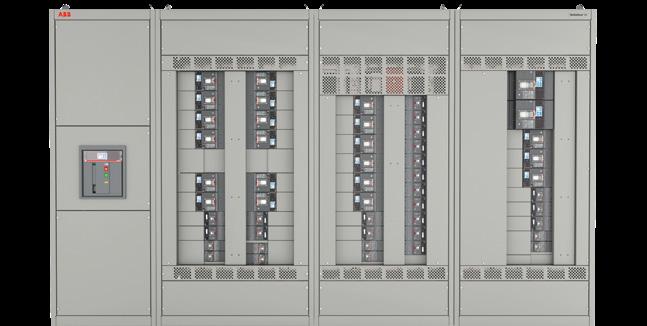

ReliaGear® SB switchboards feature a safer, more reliable design and groundbreaking SACE® Emax 2 power circuit breakers or SACE® Tmax® XT plug-in MCCBs to save time, labor, and cost while helping ensure greater energy efficiencyandreliability.

ReliaGear SB switchboards are available up to 6,000 A and 600 VAC. Plug-in group mounted distribution sections allow for devices, such as circuit breakers, to be installed anywhereonthebusstack.

ReliaGear SB switchboard is a safer, smarter, and more sustainablesolutionforprojectsofanysize–with2newfast shippingoptionsavailable.

Ready to dramatically speed up field modifications and eliminate labor-intensive bolt-on components? Plug into what’s next in switchboards: ReliaGear SB.

01

ReliaGear SB features a safe, reliable design that dramatically saves time, labor and cost while helping to ensure greater energy efficiency and reliability.

02 Finger-safe bus stack that meets IP20 standards in select models

03 Spring-loaded circuit breaker plug-in connectors

SAFE

The next level of protection

ABB is passionate about safety. From the largest piece of arc-resistant switchgear down to the smallest arc fault and ground fault sensing circuit breaker, ABB is always designing ways to help keep personnel out of harm’s way. ReliaGear panelboard and switchboard designs come with an improved finger-safe bus stack that meets IP20 standards. Thanks to the circuit breaker integrated Bluetooth® technology, it is also possible to set parameters and check measurements directly from your smartphone from an arc-free zone.

Modular, flexible, fast

The ReliaGear® SB features plug-in, single-tool simplicity enabling easy, fast component installation or replacement in the field. For even greater flexibility, circuit breakers can be installed anywhere on the bus stack. Hinged gutter doors allow quick, convenient access for wiring of circuit breakers. Captive splice plates between sections allow for quick assembly.

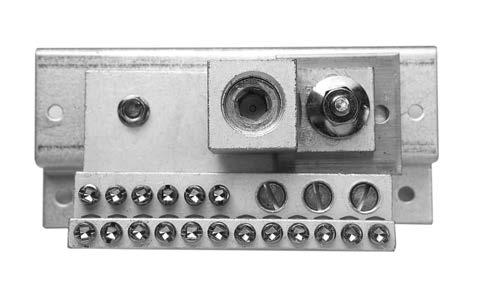

Dependable connections

Spring-loaded circuit breaker plug-in connectors have plating that is durable enough to withstand repeated insertion and removal. Levering features further reduce installation and removal forces. The plug-in connector design uses the magnetic forces generated by a short circuit event to help make the connection even stronger and more reliable. Fewer bolted joints mean fewer potential loose connections to check and retorque.

SACE® Tmax® XT plug-in circuit breakers feature springloaded primary disconnects, enabling fast installation, easy replacement and reliable connection to maximize uptime.

When reliability matters, count on ReliaGear® SB. To learn more, contact your ABB representative or visit electrification.us.abb.com/products/switchboards/ reliagear-sb-switchboard.

05 Angled lifting brackets for fast placement

06 Remote access to accurate information anywhere, anytime

07 Components can be installed in as little as 20 seconds

Set in place

With ReliaGear® SB, angled lifting brackets enable switchboard sections to be placed together without having to remove the brackets, allowing for faster, more precise placement of switchboard sections next to each other.

Link to data analysis in real time

With ABB Ability™ cloud connectivity, multiple communication options and built-in metering, SACE® Emax 2 and SACE® Tmax® XT circuit breakers put facility managers in control. Precise measured data allows users to access accurate information anywhere or anytime, making it easier to monitor resources and identify savings opportunities.

Speed up your project

Reducing labor and saving time is crucial for electrical contractors. In fact, an 8% savings in labor costs for a typical large project can mean 133% more profit for the contractor.* ReliaGear SB's intuitive installation enables components to be installed in as few as 20 seconds, dramatically saving skilled-labor costs, reducing downtime and lowering the risk of mistakes.

*From “How to Make a Good Estimate Even Better” by Don Kiper, |EC&M, 2017.

ReliaGear® SB can be equipped with circuit breakers from 15 to 6000 A. The maximum short circuit rating is equal to 150 kAIC at 480 V AC or the lowest current interruption rating of any device installed.

ReliaGear SB can be used on the following system voltages:

• 240 V AC; 3-phase, 3-wire

• 480 V AC; 3-phase, 3-wire

• 600 V AC; 3-phase, 3-wire

• 208Y/120 V AC; 3-phase, 4-wire

• 480Y/277 V AC; 3-phase, 4-wire

• 600Y/347 V AC; 3-phase, 4-wire

Available environmental enclosure types

• NEM A 1

• NEM A 3R

Section depths

• 25– 60" in 5" increments

• (50 00 to 6000 A - 30" minimum depth)

ReliaGear SB is available with multiple options

• Fee d location: Top or bottom

• Inco ming type: Main lug only (MLO), main circuit breaker (MCB, either vertically or horizontally mounted) and with feed-through lug pads

• Bus stack material: Copper or aluminum, heat-rated or density-rated

ReliaGear SB group-mounted distribution sections come in three bus stack configurations: center, offset and one-sided. The bus stack configuration and width of the switchboard section determine the maximum ampacity circuit breaker allowed on the side(s) of the bus stack.

Power circuit breaker – SACE® Emax 2

The SACE Emax 2 product line is a multifunctional platform able to manage the next generation of electrical plants such as microgrids, evolving into a true power manager.

case circuit breaker - Power Break® II Power Break II insulated case circuit breakers are highly compact, heavy-duty circuit breakers that combine ease of use and state-of-the-art performances up to 4000 A frame sizes.

The Record Plus FB line features true one- and two-pole construction, has a double-break contact system for fast response and current limitation to help with arc flash and coordination.

The SACE Tmax XT range offers higher performance, better protection and more precise metering than equivalent units, and can handle from 15 A up to 1200 A.

Combined with precise electronic trip units in small frames, the new range delivers significant time savings and helps to enhance installation quality. Reliability is further increased, and speed of installation improved, thanks to Bluetooth® and Ekip connectivity for mobile devices.

Ekip trip units represent a new benchmark for circuit breakers, able to satisfy any performance requirement. These complete, flexible protection trip units can be adapted to the level of protection required, independently of the complexity of the system. The range is available for three levels of performance to meet any requirement, from simple to advanced applications.

An easy solution for protection against overloads and short circuits. Available in both fixed and adjustable versions depending on the circuit breaker frame size.

As the first level of electronic trip units, Ekip DIP trip units are based on microprocessor technologies designed for high reliability and tripping precision.

The Ekip Touch/Hi-Touch trip units provide a complete series of protections and high accuracy measurements of all electrical parameters. They are intended to integrate seamlessly with most automation and supervision systems. With a common and intuitive user experience between the SACE® Emax 2 and SACE® Tmax® XT circuit breakers, Ekip Touch/Hi-Touch offer class 1 active energy measurement compliance with IEC 61557-12 and embedded Bluetooth® technology, allowing for fast interaction within a safe distance from the equipment.

Several communication protocols allow users to remotely supervise electrical systems and control the circuit breaker.

Thanks to the maximum flexibility guaranteed by these packages, the Ekip Touch/Hi-Touch trip units are completely customizable and field upgradeable. Depending on the specific trip unit version, different packages are available by default, but all of them can be added to the trip unit.

Table

Default functionalities and upgradeability of the trip units:

• • Available by default

↑ Upgradeable

↑ Some functions available. Upgradeable with the full package.

units

Fast lead time and great flexibility with 3000+ preconfigured options available in empower, ABB Reliagear SB – EXcelerate uses a configure-to-order approach that allows the customer to easily combine pre-engineered sub-assemblies to build switchboards up to six sections, thanks to the streamlined configuration option in empower. The switchboards are sent to manufacture at the moment of the order, eliminating the need for engineering, and the drawings are immediately available in empower, making the process easier and turnaround time faster.

EXcelerate highlights

• 2X faster lead times than standard switchboards

• 300 0+ configurations of simple and midcomplexity switchboards available

• Configured-to-order (CTO) sub-assemblies reduce project cycle times

• Simple selection process results in no engineering interaction, immediate manufacturing and faster delivery

• Available in empower quote

Features and benefits

• 120 0 to 4000 A 3P 4W

• 208 V, 480 V

• Indoor and outdoor enclosures (NEMA 1, NEMA 3R)

• Cop per and aluminum bussing up to 100 kA

• Tma x® XT1 to XT7 distribution breakers (TMA and Ekip DIP, Touch for XT7 1200 A only)

• Fixed section width (determined by amperage) and depth (front and rear aligned)

• Opt ional SPD Type 1 and 2, 125 kA and 200 kA individually mounted

• Opt ional RGM meter 2200, 6000, 6010 and 7000

• Single section shipping split

• Cab le in / cable out for main option

ABB's On Demand program provides customers the opportunity to easily order and quickly receive ReliaGear SB Switchboards, with product ready to ship in as few as two weeks.*

The On Demand program can potentially reduce project cycle times, helping customers gain a competitive advantage wherever 24/7 reliability is an absolute necessity.

On Demand program highlights

• Pro duct shipment in as few as two weeks

• Seven pre-configured designs with flexible breaker settings

• Cat alog-number driven for easy ordering

• Potentially reduces project cycle times

Features and benefits

• Main bus, 2000 A or 4000 A, copper bus

• Ema x 2 main device with GF and RELT

• 480/277 V AC maximum at 100 kAIC

• ReliaGear plug-in panel type for easy installation of breakers

• Fully rated bus with provision for future extensions

• Front access only with hinged doors

• Front and rear alignment for splicing sections

• Features XT DIP trip units for maximum flexibility

• RGM 2 200 (2000 A) and RGM 6000 (4000 A) digital power meter provided

• Qualified for seismic ratings per publication

9AKK108466A5933 and OSP-0044-10

• Enclosures available in NEMA Type 1 and 3R

* Items must be in stock to meet two-week delivery timeframe. Pl ease check empower Flow for current availability. 10-week mid cycle also available.

ABB Inc.

305 Gregson Drive Cary, NC 27511 USA

electrification.us.abb.com

We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB Inc. does not accept any re sponsibility whatsoever for potential errors or possible lack of information in this document.

We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents – in whole or in parts – is forbidden without prior written consent of ABB Inc.

2024 ABB

The ReliaGear® SB EV Grid-to-Charger switchboards from ABB allows customers to meet deadlines, mitigate supply chain risks, and adapt easily to future EV charger growth demands.Withfastleadtimes,thisstandardizedEVGrid-toChargerofferingtakestheguessworkoutofdeployments.

The program offers six pre-configured designs with flexible breakersettings,helpingcustomersgainacompetitiveedge by reducing project cycle times with cost-effective designs. Future-proofdesignsgivecustomerspeaceofmindtoeasily accommodateadditionalchargerexpansion.

• Reduced project cycle time

• Flexib le

• Future-proof design

• Eas y to order

The new EV Grid-to-Charger program for ReliaGear ® SB low voltage switchboard from ABB allows customers to meet deadlines, mitigate supply chain risks, and adapt easily to future charger growth demands.

With fast lead times, this standardized EV Grid-to-Charger offering takes the guesswork out of deployments. The program offers six pre-configured designs with flexible breaker settings, helping customers gain a competitive edge by reducing project cycle times with cost-effective designs. Future-proof designs give customers peace of mind to easily accommodate additional charger expansion.

The EV Grid-to-Charger program for the ReliaGear ® SB switchboard offers customers fast lead times and the option to choose among six pre-configured switchboard designs.

Reduced project cycle time

• Onsite delivery significantly faster. Helps to meet deadlines and mitigate supply chain risks.

Future-proof design

• The f lexible design easily accommodates future charger changes/upgrades by allowing for easy expansion of the feeder section.

• The d esign allows easy adding/changing of feeder breakers to the existing frame and/or adding an additional feeder frame in the future.

Flexible

• Six standardized engineering designs with flexible breaker settings.

• Utility designed for EUSERC applications with door kits.

Easy to order

• Cat alog-number driven for easy ordering.

• Uni versal design.

The flexible design of SACE® Emax2 and Tmax® XT breakers allows for simple field adjustments to meet a wide variety of applications for today and tomorrow.

With an installed base of thousands of units worldwide, the ReliaGear ® SB switchboard sets the standard for functional, flexible and rugged, durable construction.

The EV Grid-to-Charger program from ABB builds on this reputation by providing customers the opportunity to easily order and quickly receive delivery of ReliaGear SB switchboards significantly faster. The EV Grid-to-Charger program can potentially reduce project cycle times, helping customers gain a competitive advantage wherever 24/7 reliability is an absolute necessity.

The universal design of the ReliaGear

switchboard allows substantial flexibility for a wide variety of customer applications. The modular assembly of the plug-in style connections helps reduce maintenance and assembly while allowing for easy future expansion.

The future-proof design allows the customer to plan ahead to easily accommodate future EV charger additions and expand the feeder section by adding another frame to the existing unit.

The flexible design of SACE® Emax2 and Tmax® XT breakers also allows for simple field adjustments to meet a wide variety of applications. Combined with the ReliaGear plug-in style distribution section bus stack, customers can quickly and easily move breaker locations for maximum flexibility.

Features and benefits

• Main bus 1200 A, 2000 A, 3000 A or 4000 A

• Aluminum bus

• 480/277 V AC maximum at 65 kAIC

• NEM A 3R with rodent barriers

• Space heaters with thermostat

• Large hinged covers with DIN rail backplate to allow for easy field upgrades such as communications and remote control

• SACE Emax2 main device with touch trip unit, GF and RELT

• Tma x XT DIP trip units on feeders for maximum ampacity flexibility

• ReliaGear SB plug-in panel type for easy breaker installation and removal

• Fully rated bus with provision for future extensions

• Front access only with hinged doors

• Front and rear alignment for splicing sections

• Qualified for seismic ratings per publication 9AKK108466A5933 and OSP-0044-10

• Surge protection included in each board (SPD Type 2, 200 kA)

EV G2C switchboard

Main characteristics

Configurations available on demand

The EV Grid-to-Charger program offers six preconfigured ReliaGear ® SB designs:

• ReliaGear SB 1200 A

• ReliaGear SB 2000 A

• ReliaGear SB 3000 A

• ReliaGear SB 4000 A

• ReliaGear SB 2000 A EUSERC

• ReliaGear SB 4000 A EUSERC

Pages 7 through 13 show detailed drawings of these six configurations.

• DIN rail backplate to allow fo r easy field upgrades such as communications and remote control

Ordering

ReliaGear EV Grid-to-Charger switchboard catalog numbers have been added to both empower Flow and empower Quote. If adding in empower Quote, it is important to ensure there is adequate stock at the time of quotation and order entry.

• Ant i-rodent barrier

• Pre -installed heaters to protect in cold and/or damp weather

• NEM A 3R outdoor rated enclosure

• Pre -selected feeders to meet popular EV charger sizes

• Ele ctronic breakers with a wide range of settings to accommodate project variations

• Surge protection included in each board

18 Dev ice furnished with EKIP DIP (LSI) programmer.

19 Dev ice furnished with PLL fixed padlock–open.

20 Prov ision for future extension.

21 Dev ice is furnished with RELT-Ekip signaling 2K3 module. 22 Dev ice is furnished with measuring package.

Configuration covers the following number of chargers:

For switchboards requiring EUSERC utility sections there are two preconfigured options available.

• ReliaGear ® SB 2000 A — EUSERC

• ReliaGear SB 4000 A — EUSERC

Each option offers the utility section hard bussed, and it is delivered with pre-mounted Group 1 door kit (see page 14). If the required utility is in Groups 2, 3 or 4, then the customer can purchase a dedicated door kit and replace the factoryinstalled Group 1 door kit.

For non-EUSERC utility, the utility section can be cable connected to the Grid-to-Charger switchboard. When paired with an order for an EV G2C switchboard, a special fast track cycle can be requested when a single utility section is ordered. The process is as follows:

1. Design the utility section desired in empower Quote.

2. Add the Reference Sales Order # of your ReliaGear EV G2C switchboard in the Drawing Notes section of empower.

3. Sel ect Short Cycle or “S” in the drop-down menu in the pricing tab to activate the fast cycle.

If a utility section is ordered together with an EV Grid-toCharger switchboard, skip step 2 and select the Short Cycle as per step 3.

between sections; each section ships separately. 25 Swi tchboard furnished with Type 2 TVSS/SPD HE 200 kA per mode / 400 kA per phase, 200 kAIC. TVSS

• EUSERC catalog numbers RSBG4206A3RBBE (2 000 A) and RSBG4406A3RBBE (4000 A) ship with door kit Group 1 as the standard.

• See t able below for alternate door kits for other specific utilities to be ordered separately.

• Simple and fast field installation by removing the pin from the hinge and replacing with the door kit that matches the specific utility required.

ABB Inc.

305 Gregson Drive

Cary, NC 27511 USA

abb.com/contacts

abb.com/lowvoltage

We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB Inc. does not accept any re sponsibility whatsoever for potential errors or possible lack of information in this document.

We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents – in whole or in parts – is forbidden without prior written consent of ABB Inc.

2024 ABB

GenTower is a stand-alone, permanent solution. It easily connects a mobile generator to feed the main power system without modifications to the building or the electrical system. This saves costs forbothlaboranddowntime.

Rated up to 4000 amps, it connects either by cabling to the lugs on the main switchboard (if tap connections are in place), with hard bus connection to approved GE switchboards,orthroughafeederbreaker.It'salsoavailable asasectioninanewSpectraSeriesline-up.Thestand-alone version's NEMA 3R enclosure installs in any location accessibletoamobilegenerator.

Thisisalogical,cost-efficientsolutionforanyonewhoneeds to quickly and easily connect a portable generator during a power outage - especially retail, commercial, health care, educationalandmanufacturingfacilities.

Restore power quickly and efficiently with GenTower® How to be prepared for anything!

imagination at work

Power outages are unpredictable. And they can bring your facility to a halt –for an unknown length of time.

Be ready. With the new GenTower generator connector from GE, you’ll be ready to get the power –and your operation – back up and running quickly.

GenTower is a stand-alone, permanent solution. It easily connects a mobile generator to feed the main power system without modifications to the building or the electrical system. This saves costs for both labor and downtime.

The stand-alone version’s NEMA 3R enclosure installs in any location accessible to a mobile generator.

This is a logical, cost-efficient solution for anyone who needs to quickly and easily connect a portable generator during a power outage – especially retail, commercial, health care, educational and manufacturing facilities.

Key Features

•Connection via color-coded, cam-lock quick connects and traditional lugs

•Supports help maintain proper connection of cables to quick connects

•Hinged trap door maintains NEMA 3R protection when cables are connected

•Sequence of operation clearly displayed on front cover

•Provisions for mounting key interlocks (Kirk lock and key ordering and coordination with existing/separate equipment is customer’s responsibility)

•UL Listed (UL 891, Switchboards)

• Advanced configurations integrated into switchboard lineups are available with factory support or via Speedi

Selection

*Requires double section configuration

Panelboards

Key Features

• Side entry offers quick and easy generator connection and allows for bottom load exit if required

• Spectra RMS breakers deliver greater flexibility and quicker, more accurate reaction to faults than thermal magnetic breakers

• Two Kirk Key interlocks offer more security than mechanical interlocks, since keys are needed to transfer power

• Top and bottom lugs expand load exit options and reduce cable/wire bending

• Storage compartment allows all compatible connectors can be purchased and stored for quick access

GenTower helps you prepare for situations that knock your utility power out.

GE helps you recover from emergencies that damage your electrical equipment.

Our emergency response team is prepared to work around the clock to serve you. The program includes the following elements:

• In addition to your local sales representatives, our Customer Service team has the capability to answer calls 24x7 and will add a “natural disaster” prompt, within hours of an emergency situation, that will direct affected callers to this dedicated team.

• We review inventory levels on key component items to ensure sufficient stock for expedited deliveries.

• The factories are prepared to ramp up production on stock items that are typically ordered in your area as well as freeing up short cycle capacity for non-stock equipment items.

If you need information following a disaster, call 1-800-GE-1-Stop 24/7, email emergencyresponseteam@ge.com, or visit www.geindustrial.com/emergencyresponse

Want to get ready? Ask GE about GenTower.

GenTower is a registered trademark of the General Electric Company.

Information provided is subject to change without notice. Please verify all details with GE. All values are design or typical values when measured underlaboratory conditions, and GE makes no warranty or guarantee, express or implied, that such performance will be obtained under end-use conditions.

GE Energy 41 Woodford Avenue, Plainville, CT 06062 www.geindustrial.com

© 2011 General Electric Company

ABB's industrial-duty switchboard product line Power Break® II ---features individually-mounted breaker compartments for ABB's complete product family of insulatedcasebreakers.

Power Break II (PB) switchboards can house insulated case circuit breakers as mains, ties, and feeders; and low voltage powercircuitbreakersasmainsandties.

Both switchboard product lines feature protective devices that can be provided with communications capability for connection to ABB's Power Management Control System. Thisswitchboardlinealsofeaturessimpledesignsthatallow for rapid field modification and maintenance - a must for use in applications where system downtime is absolutely unacceptable.

ABB's industrial-duty switchboard product lines Power Break II and AV-3 Access feature individually-mounted breaker compartments for ABB’s product family of breakers

Power Break II (PB) switchboards can house insulated case circuit breakers as mains, ties, and feeders; and low voltage power circuit breakers as mains and ties. AV-3 Access (AV3) provides individual compartments for molded case breakers serving as mains, ties, or feeders.

Both switchboards lines offer an outstanding cost effective, alternative to the more robust switchgear constructions.

ABB switchboards feature:

• Rugged construction - specially designed bus structure enabling them to withstand the damaging effects of a short circuit for at least 30 cycles - a feature normally found only in switchgear

• Fast cycle times – ABB has a competitive switchboard manufacturing cycle times in the industry

• Broad functionality - similar overall functionality to comparable ANSI-rated switchgear

• Cost effective design - ABB switchboards save you money as functional alternative to switchgear

Both switchboard product lines feature protective devices that can be provided with communications capability for connection to ABB Ability. Both switchboard lines also feature simple designs that allow for rapid field modification and maintenance - a must for use in applications where system downtime is absolutely unacceptable.

Product scope

• Up to 6000A main bus

• 150kAIC @ 480V, 100kAIC @ 600V

• EntelliGuard G mains and ties only up to 6000A

• Power Break II (ICCB) breakers up to 4000A

• Designed, built, and tested in accordance with NEMA PB-2, and listed under UL-891

• AV3 utilizes individual mounted Spectra (MCCB) breakers

Optional features

• Rear extensions to 60, 64 and 74 inch deep frame

• Infrared scanning window in rear doors

• Lockable T-handles on circuit breaker cubicle door

• Lockable T-handles on rear doors

• Overhead breaker lifting hoist

• Section barriers and shutters

• Individual breaker compartments, including 100% rated molded case breakers

• Rear cable compartment

• Trip unit display through the breaker escutcheon with metering and trip information

• Industry-exclusive 30-cycle short circuit withstand bus rating up to 85kA

• Standard tin-plated copper main bus

• Standard full-height 2000 amp silver-plated copper vertical bus in AV3

• Compact, modular design allowing 5-high breaker stacks in most cases

• Optional epoxy-coated, insulated/isolated bus with rear and side barriers

• EntelliGuard TU trip unit

• ABB design approach also facilitates field reconfiguration

• Flexibility, reliability, simplicity and safety

• Coordinated to ABB sub-assemblies

• Cycle time to support your needs

1. Meets UL 891 and NEMA PB-2 standards for switchboard construction

2. Industry-exclusive 30 cycle short circuit withstand bus rating eliminates need for instantaneous tripping

3. Standard tin-plated copper bus

4. Drawout or stationary breakers

5. Indoor and outdoor (walk-in and non-walk-in) enclosure available

6. Individual breakers isolated (top, bottom and rear) from adjacent breaker compartments and main bus/rear cable compartment

7. Drawout breaker can be tilted providing easy inspection and maintenance of primary contact finger assembly

8. Fully equipped solid state MicroVersaTrip Plus™ or PM™ trip

9. New, compact, 100%-rated Power Break II insulated case circuit breaker combines ease of use and state-of-the-art performance in 800A, 1600A, 2000A, 2500A, 3000A, and 4000A frame sizes

10. Smaller Power Break II breaker design, allowing up to 5 breakers to be mounted in the same switchboard stack (some restrictions apply)

11. Convenient access to breaker controls and trip unit

12. Standard hinged doors with quarter-turn latches

1. Compact, lightweight design

2. 36-point pre-wired, dedicated secondary terminal block standard (see item 16)

3. Optional mechanical counter

4. Padlock device standard

5. Easy-to-reach ON/OFF buttons

6. EntelliGuard© TU trip units - field upgradable, UL Listed, CSA certified, IEC 947-2 certified

7. Sealable door provides added security

8. Drop-in shunt trip, undervoltage release and bell alarm (with and without manual lockout) modules

9. Flush-mounted pump handle

Power Break II insulated case circuit breakers are highly compact, heavy-duty breakers that combine ease of use, asethetics and state-of-art performances in 200 through 4000-Amp frame sizes, rated for up to 200,000 Amps RMS symmetrical for 240Vac, in drawout and stationary versions.

Available with EntelliGuard TU trip unit with the built-in flexibility required to match your system's needs, whether for optimum safety, optimum system reliability, or both at the same time. Whether you're using all circuit breakers or a mixed system of breakers and fusible devices, the EntelliGuard TU will accommodate your needs with minimal compromise and maximum functionality.

Features and benefits

Power Break II insulated case circuit breakers

• Modular, drop-in accessories common to all frame sizes

• Flush-mounted pump handle

• Manually and electrically operated versions in same compact envelope

• Double insulated ON/OFF buttons

• 72-point pre-wired, dedicated secondary terminals

• Modular, field-installable motor operator

• EntelliGuard TU trip unit featuring reduced energy let-through (RELT) setting

• Modular auxiliary switches with up to 12 NO/NC set of contacts

• Charge-after-close mechanism

• Manual discharge of springs without closing

• Suitable for reverse feed

ABB low-voltage air circuit breakers designs rated from 400A to 6000A, with fault interruption ratings up to 200kAIC. Integral to the EntelliGuard G breakers with state-of-the-art EntelliGuard TU trip units, which provide superior system protection, system reliability, monitoring and communications. The breaker-trip unit system delivers superior circuit protection without compromising either selectivity or arc flash protection.

Features and benefits

EntelliGuard G air circuit breaker

• ANSI/UL1066, UL489, carries a UL, cUL and CE label

• Multiple short time bands under 100ms optimally fit above the Instantaneous clearing times

• Alternate instantaneous setting (RELT) mitigates arc flash hazard

• Adjustable ST and GF zone selective Interlocking optimizes restrained and unrestrained bands

• Zone selective instantaneous protection, multiple zone protection, 3 cycle clearing and selectivity are provided simultaneously

• Instantaneous trip adjusts up to 30X trip plug rating

• In addition to arc flash protection and selectivity features, the EntelliGuard TU

• Motor operators

• Closing devices

• Shunt trip for ground fault

• Uvr with fixed time delay

• Second shunt trip or UV release

• Auxiliary switches and contacts

• Bell alarm / trip annunciation

• Breaker mounted key interlock

• Mechanical interlocks – fixed breakers

• Mechanical interlocks – drawout breakers

• Network interlock

• Mechanical operation counter

• Pushbutton padlock device

• Ready-to-close switch

• Secondary disconnect block

• Spring charged contact

EntelliGuard TU

• Instantaneous - zone selective interlocking (I-ZSI) builds on the short time and ground fault interlocking by now providing the ability to overlap the Instantaneous setting on the main and feeder breakers. Now I-ZSI can be used for selectivity

• Instantaneous - waveform recognition instantaneous trip is based on the amount of energy and duration versus a threshold current setting (MVT). Improves coordination with current limiting devices by discerning whether a downstream breaker/fuse is clearing the fault. Provides ability to set the Instantaneous pickup below the peak let thru of a downstream current limiting device while maintaining selectivity

• RELT- reduced energy let through with positive feedback two independent instantaneous settings selectable via an external switch or modbus communications with positive indication via an output contact. Commonly referred to in the industry as an "arc flash switch" or "maintenance switch"

• Additional features and benefits:

- Large backlit LCD screen with detailed descriptions***

- LED health status indicator***

- Status and event log with date/time stamp (10 events)***

- Free set-up software

- Full metering and relaying***

- Thermal memory

- Universal rating plugs

- Programmable input and output relays***

- Meets and surpasses all applicable UL, ANSI, NEMA and IEC standards

- WaveForm capture (4 cycles prior, 4 cycles after, 40 samples/cycle)

- Open communication protocols: Modbus

485 RTU and Profibus (EntelliGuard G breaker Only)***

- Plug and play replacement without breaker rewiring for RMS-9, MVT, MVT+, EPIC, MVT M/PM trip units legacy

***Some options require additional 24 VDC.

1. Selections adjacent to a 4000 A device or EntelliGuard breaker must be a minimum of 30” wide. Add 2” for non walk-in outdoor construction.

2. Feeder devices can be located in the same section with mains rated 3000 A and lower.

3. Horizontal main bus available up to 6000 A.

1. Feeder devices can be located in the same section with mains rated 3000A and lower.

2. Requires 7” blank at top to meet 6’7” rule.

Applications:

• Critical power facilities

• Medium to large commercial and industrial applications

Segments/Industries:

• Data center

• Food and beverage

• Industrial processes

• Waste water

• High/Medium commercial

— ABB Inc.

305 Gregson Drive Cary, NC 27511

abb.com/lowvoltage

GE is a trademark of GE. Manufactured by ABB Ltd under license from General Electric Company.

The information contained in this document is for general information purposes only. While ABB strives to keep the information up to date and correct, it makes no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the information, products, services, or related graphics contained in the document for any purpose. Any reliance placed on such information is therefore strictly at your own risk. ABB reserves the right to discontinue any product or service at any time.

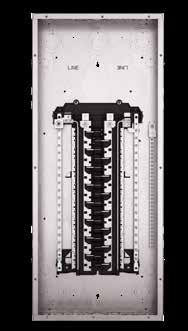

ABB's Commercial Metering Switchboard line offers a full line of metering products for the commercial construction market. Ourmodularconstructiontakesuplessspace,isavailablein anfractionofthetimeversusstandardswitchboards,iscost competitive, and can be delivered and installed without specialequipment.

• UL Listed, EUSERC, Non-EUSERC Lever Bypass

• 208Y/120V, 240Y/120V or 480Y/277V

• 100 kAIC, 150 kAIC up to 4000A, 200 kAIC at 3000A and 4000A

• 400, 600, 800, 1000, 1200, 2000, 3000, 4000A

• 100 kAIC

• Bottom feed

• Cu or Al bus

• NEMA 1 or 3R

• NEMA 1 or 3R enclosure

• Bottom feed, center feed, and top busway

• Cu or Al bus

• Refer to Speedi for all sizing

• 400A-4000A

• NEMA 1 or 3R

• 400A-2000A

• G, K and PBII circuit breakers

• HPC and BPS fused switches

• Device padlocking

• SE Barriers

• Equipment ground fault protection on 1200A-2000A (optional on 400A-1000A)

• Front access

• Hot Sequence Metering

• SG, SK, PBII, BPS, HPC

• Bottom or top exit

• Device padlocking

• Equipment ground fault protection

• Mounting provisions for CTs

• Isolating barriers

• Hinged sealable cover

• Transformer rated meter socket (EUSERC only)

• Front access

• Middle or bottom mounted neutral

• Lever bypass meter sockets available (Non-EUSERC only)

• Submains

• Rear load wire way spacing 8” minimum

• Cold and hot sequences (hot is default)

• Tenant disconnects SF, T-fuse pullout J fuse constructions:

- SF (100A, 200A)

- T-fuse pull out (100A, 200A)

• 3Ph 4W Service

• 3 pole, 2 pole disconnects

• 600A-4000A horizontal bus

• 25” minimum depth for top or bottom exit - to 60”

• Provisions for field installable socket and breaker additions

• Front access

• 100% rated neutral; standard ground rating

• Middle (EUSERC only) or bottom (Non-EUSERC only) mounted neutral

• Interior 2000A, Cu bus, 100 kAIC

• 13, 18x distribution space

• Bolt-on and plug-in

• 3Ph 4W

• Spectra main breaker or main lug only interior

• CT compartment up to 2000A

• Front neutral access

• Submains

• Ringless style sockets, cover contains ring

• Lever bypass meter sockets available (Non-EUSERC only)

• Service entrance barriers (Non-EUSERC only)

• 100 kAIC

• Top and bottom feed exit

• Test bypass block meter socket available

• 5, 7, 13 locking jaw sockets

• Flash shields

• Line lugs at top, customer load connection at bottom

• All disconnects lockable in OFF position

• Rear load wire way spacing 3” minimum

• 3-pack (20” wide) available for both EUSERC and Non-EUSERC

• 6-pack (35” wide) available for EUSERC only

• 15” minimum width, copper or aluminum bus

• Copper or aluminum bus

• Available in Speedi

• In most cases a 15” section will be added on each side of the corner

UL Approved Field-Installable Small Tenant Kits

Prewired section meets UL

If Meter Socket exists (chose ST-200A or ST-100A in Speedi) choose the following:

If Meter Socket does not exist (chose ST-200A Space or ST-100A Space in Speedi) choose the following:

GE RESOLve ensures your satisfaction by giving you fast and reliable responses to warranty issues, field service requests, missing parts problems or product returns. GE’s national network of factory authorized service operations is ready to meet all your installation, start-up, testing and maintenance needs. 1-888-GE-RESOLve

www.geindustrial.com is where you’ll find complete, easy-to-use information on the power of the GE Energy package: products, services, support, and solutions.

Contacts

Pro-stock unassembled panelboards R-Series panelboards

ReliaGear neXT power panelboards

Retrofit kits for Spectra panelboards

Molded case circuit breakers

Circuit breaker enclosures

Disconnect and safety switches

Dry type transformers

Lighting contactors

SPDs/TVSS

Load centers and circuit breakers

Electrical distribution contacts

ABB Distributor customer service

Stock, price and availability

Order status

Expedite requests

Order changes

Order cancellation

E-mail: us-el.distributorsales@abb.com

Phone: 1-800-431-7867, prompt 1

ABB new order entry

Use empower or E-mail us-elgmusorders@abb.com

ABB component support

Technical support product/application inquiries

E-mail: epis.component.support@abb.com

Phone: 1-800-431-7867, prompt 4

ABB post sales and warranty

Defective product warranty issues and inquiries

Use empower or phone 1-800-431-7867, prompt 5

ABB empower help desk

empower technical issues

E-mail: empoweru@abb.com

ABB training

empower training: https://empoweru.lessonly.com/signin

Product training: https://mylearning.abb.com

Buylog and Control Catalog

Please refer to the Buylog and/or Control Catalog for further product information and details. Reach out to your local ABB account manager with any questions

Buylog: https://electrification.us.abb.com/buylog

Control Catalog: https://electrification.us.abb.com/control-catalog

Adding breaker to circuit breaker enclosure

1. Select CB enclosure from CB enclosure tab

2. Select breaker from CCB tab

3. Select lugs from MCCB tab

Adding breaker to Spectra bolt-on panel

1. Select mounting hardware from Retrofit kit for Spectra panelboards tab

2. Select breaker from MCCB tab

3. Select lugs from MCCB tab

Adding main breaker or subfeed breaker to a ReliaGear prostock panel

. Select breaker from Pro-stock tab

Adding breaker to ReliaGear neXT panelboard or ReliaGear switchboard group mounted section

. Select breaker from ReliaGear neXT tab

ReliaGear lighting panelboards

Pro-Stock, unassembled lighting panels

100-600A (600A main circuit breaker not available)

240 Vac 1 or 3 phase or 480y/277 vac 3 phase

Order by product number from the customer service center

1. Select interior

Select the interior by bus type, panel rating and number of circuits.

Identify the box/front height for use in Steps 2 and 3.

1 For TGL20 ground lug quantities, see TGL20 Ground Lug Quantities table above.

2 For isolated ground, use EGS12. When using the EGS12, 3, 5 and 7 ground lugs (TGL20s) are required for 18, 30 and 42 circuits respectively.

2. Select box

Select a box of the correct height (see Step 1). Boxes come with blank endwalls. If endwalls with knockouts are required, also order knockout endwall kit AKEW2.

Note: This is only available for NEMA 1 20" wide enclosures.

3. Select front

Select a front of the correct height (see Step 1).

4. Select main and/or sub-feed circuit breaker kit

Select main circuit breaker kit appropriate for your interior type (see Step 1), amp rating and kAIC rating. If a sub-feed circuit breaker is required, repeat the selection process.

Note: 400A circuit breaker kits cannot be used for sub-feed applications in Pro-Stock panelboards.

For additional details, see Section 6 of the BuyLog.

MBM124WB XT5NU340ABFN000XXX

MBB13WB XT4NU3225AFJ000XXX

MBB16WB XT4NU3225AFJ000XX²

MBM134WB XT5NU340ABFN000XXX

MBC33WB XT1HU3125AFD000XXX

MBB33WB XT4HU3225AFJ000XXX

MBB36WB XT4HU3200AFJ000XXX²

MBM334WB XT5HU340ABFN000XXX

MBM324WB XT5HU340ABFN000XXX

– (x2) XT4N – – –

MBM334 400 3 – XT5NXT5SXT5HXT5L

MBM134WB 400 3 – XT5N – – –

MB423 100 3 – TEY – – – –

MB426 100 6 – (x2) TEY – – – –

MBC33 125 3 – XT1N XT1S – XT1H – – –

MBC33WB 125 3 – XT1H – – –

MBB33 150 3 – XT4NXT4S – XT4HXT4LXT4VXT4X

MBB33 225 3 – XT4NXT4S – XT4HXT4LXT4VXT4X

MBB33WB 225 3 – XT4H – – –

MBM124WB⁵ 400 2³ – XT5N – – –AEU3; 480/277 VAC, 3 phase

MBB36⁶ 400 6⁶ – (x2) XT4N (x2) XT4S – (x2) XT4H – – –

MBB36WB⁶ 400 6⁶ – (x2) XT4H – – –

MBM334⁷ 400 3 – – XT5NXT5SXT5H – – –

MBM334WB⁷ 400 3 – XT5H – – –

MBM324WB⁵ ⁷ 400 2⁶ – XT5H – – –

¹ Circuit breaker not included except for “WB” kits (where product number ends in “WB”). “WB” kits include a circuit breaker, mounting kit and load-side lugs.

² Actual Circuit breaker Short Circuit Rating is 25kAIC

³ Use 2 outer poles for 3 pole applications.

⁴ Can use (2) 3 pole devices only, no 2 pole allowed

⁵ For Subfeed application only

⁶ 6 poles of subfeed applies only to 400A and 600A interiors.

⁷ Only compatible with standard fronts with a quarter turn lock. Order front part number with suffix “T” at the end of the SKU.

5. Typical main circuit breakers

-Skip Step 5 if you selected a main circuit breaker kit ending in “WB” —no circuit breaker is required.

-To correlate circuit breaker types with the kAIC rating in specific panelboards, see the table for Step 4. For more rating details, see ReliaGear Lighting Panels Rating Series Labels (1TQC173100E0001).

-Use 2 outer poles for 3 pole applications

-For TEY and THQB main circuit breakers, see branch circuit breakers tables in Step 7.

Tmax XT Circuit breakers (3-pole) For use with appropriate main circuit breaker kit (see Step 4).

Main or subfeed circuit breakers for use with RQ panels (208/120 Vac 3-phase or 240 Vac single phase). See Step 4.

2-pole

Pro-Stock, unassembled lighting panels

6. Select main lug kit and accessories

Select lug kit(s) for main lug and/or feed-thru applications, if required. (All lugs are suitable for interiors with either copper or aluminum bus.) Also select any accessories required.

Main lug kits

³

² For 200% neutral feed-thru, order NKA4FT, (GO-101P). Wire range (2) 2/0 – 600 MCM or (4) 4-250 MCM.

⁴ 3 pole XT breakers can be used in 2 pole applications

⁵ Kits include 3pcs lug

⁶ External solution: lugs to be mounted on EF terminals in the kit

⁷ ProCare Kit includes: (5) filler plate hardware kits, (9) bus stud nuts, (5) MLA1 filler plates, (2) 225A phase barriers, (2) feed-thru barriers, (1) 400/600A phase barrier, (50) directory cards/rating books, (50) circuit number strips (1-48), (50) circuit number strips (43-84), (5) standard locks and keys, (50) deadfront screws, (10) RQ/RE front

Main breaker service entrance lug cover kit

Breaker

ReliaGear lighting panelboards

Pro-Stock, unassembled lighting panels

7. Typical bolt-on branch circuit breakers

These tables show typical branch circuit breakers, but do not include all branch circuit breakers that can be used with Pro-Stock panelboards.

Enclosure options

Box extensions—For additional end gutter space or conduit skirt applications–see page 11-21.

Equipment grounds—factory supplied with panelboard

Optional equipment grounds

THQB/THHQB/THQL/THHQL/TEY filler plates

TED4/SE/FB filler plates

Circuit breaker mounting¹ hardware kits

¹ Use to mount circuit breaker in existing space.

² Includes screws, washers and ReliaGear panelboard connectors.

Field installed kits/replacement parts

Order by product number from factory

Endwall kits

Field installed. For standard 20"w x 5.81"d boxes.

Panelboard locks

¹ The quarter turn kits are only compatible with factory-built quarter turn fronts. They cannot be used to convert other locks (standard, Corbin, etc.) to quarter turn. Keys are interchangeable with standard, Corbin, etc.

Tmax

Tmax

Tmax

Tmax

Handle Locking (nonpadlocking) Q

Q/E

CorbinField installed kits/replacement parts

Order by product number from factory

Panelboards parts

in factory assembled panels—AD panels with Spectra branch circuit breakers.

to ReliaGear box with or without box endwall in place. Extensions can be combined to obtain lengths greater than 18 and 24 inches.

Types

Service information:

1P, 3W-120/240 Vac

3P, 3W-240 Vac

3P, 4W-240/120 Vac, 208/120 Vac

Fully rated: 65kAIC at 240V

Series rated: 200kAIC at 240V

Main circuit breakers:

100A-THQB, THHQB, TEY

125A-XT1

225A-A2

250A-XT4

400A-XT5

600A-XT5

800A-XT6¹

Main lug: 125-800A

Branch circuit breakers (plug-in): Amperage-15-100A

Poles-1, 2, 3

Types-THQL, THHQL, TXQL

Subfeeds:

Amperage-15-600A

Poles-2, 3

Types- A2, XT1, XT4, XT5

Enclosures

Depth-5.81”

Service information:

1P, 3W-120/240 Vac

3P, 3W-240 Vac

3P, 4W-240/120 Vac, 208/120 Vac

Fully rated: 65kAIC at 240V

Series rated: 200kAIC at 240V

Main circuit breakers:

100A-THQB, THHQB, TEY

125A-XT1

225A-A2

250A-XT4

400A-XT5

600A-XT5

800A-XT6¹

Main lug:

125-800A

Branch circuit breakers (bolt-on):

Amperage-15-100A

Poles-1, 2, 3

Types-THQB, THHQB, TXQB

Subfeeds:

Amperage-15-600A

Poles-2, 3

Types- A2, XT1, XT4, XT5

Enclosures

Length-25.5, 31.5, 37.5, 43.5, 49.5, 55.5, 64.5, 76.5, 82.5, 88.5

Width-20”

Depth-5.81”

Types

Type RE

Service information:

1P, 3W-120/240 Vac, 125/250 Vdc

3P, 3W-240 Vac

3P, 4W-480/277 Vac, 208/120 Vac, 240/120 Vac

Fully rated: 18kAIC at 480Y/277V, 65kAIC at 240V

Series rated: Reference panel configuration in empower or DET-008

Main circuit breakers:

100A-TEY, TEYF

125A-XT1

250A-XT4

400A-XT5

600A-XT5

800A-XT6¹

Main lug: 125-800A

Branch circuit breakers (bolt-on): Amperage-15-100A

Poles-1, 2, 3

Types-TEY, TEYF

Subfeeds: Amperage-15-600A

Poles: 3*

Types: XT1, XT4, XT5

*3 poles can be used as 2 poles

Enclosures

Width-20”

Depth-5.81”

Type RS

Service information:

1P, 3W-120/240 Vac, 125/250 Vdc

3P, 3W-240 Vac

3P, 4W-480/277 Vac, 208/120 Vac, 240/120 Vac

Fully rated: 65kAIC at 480Y/277V, 100kAIC at 240V

Series rated: Reference panel configuration in empower or DET-008

Main circuit breakers:

100A-TEYD, TEYH, TEYL

125A-XT1

250A-XT4

400A-XT5

600A-XT5

800A-XT6¹

Main lug: 125-800A

Branch circuit breakers (bolt-on):

Amperage-15-125A

Poles- 1, 2, 3

Types- TEYD, TEYH, TEYL

Subfeeds:

Amperage-15-600A

Poles: 3*

Types: XT1, XT4, XT5

*3 poles can be used as 2 poles

Enclosures

Length-25.5,

Width-20”

Depth-5.81”

Type RD

Service information:

3P, 3W-480 Vac, 600 Vac

3P, 4W-208/120 Vac, 480/277 Vac, 600/347 Vac

Fully rated: 42kAIC at 240V, 42 kAIC at 600Y/347V, 42kAIC at 480V

Series rated: Reference panel configuration in empower or DET-008

Main circuit breakers:

150A-XT4

225A-XT4

400A-XT5

600A-XT5

Main lug:

150-800A

Branch circuit breakers (bolt-on):

Amperage-5-100A (FB 1P, 2P)

15-125A (XT2 eKIP DIP Hi-Touch 3P)

220A Max. double branch

Types: FB, XT2 eKIP DIP Hi-Touch

Enclosures

Width-20”

ReliaGear neXT panelboard interiors feature plug-in and bolt-on (when vertical main circuit breakers are selected) technology, IP 20 “ finger-safe” features (on clean bus only) and center or offset mounting positions within the enclosure. Main lug, feedthrough lug and clean bus options exist. X-height or X-space refers to the space occupied by individual (plug-in) components on the interior bus. One X-space for ReliaGear neXT equals 1.385 inches.

Standard interior heights

• 16X05

• 24X05

• 32X05

• 40X05

Interior materials

• Tin- and silver-plated aluminum (heat rated)

• Tin- and silver-plated copper (heat rated or 1000 A per sq. in. density rated)

X-space requirements for plug-in devices

See table below for the X-space requirements of plug-in components.

XT1 circuit breaker assemblies — panelboard densitiy and mounting hardware

The small footprint of XT1 allows this panel to offer multiple options to improve circuit breaker density. As you configure and order ReliaGear neXT panelboards, you'll notice that XT1 are grouped in quantities of one, two or five. As part of this feature, unique mounting brackets are required when adding XT1 breaker assemblies to existing installations. See below for X-space and mounting brackets required.

Select horizontal main and feeder circuit breakers (80% rated only)

S = Ekip Touch Measuring LSIG

T = Ekip Hi-Touch LSI

U = Ekip Hi-Touch LSIG Interrupting rating

Line-side terminals (top)

Y = Line-side connectors

Load-side terminal (bottom)

D = XT1 10–2/0 AWG

G = XT4 14–1/0 AWG, 100 A

N = XT5 2x2/0 AWG-500kcmil

U = XT6 3x2/0 AWG-400kcmil

J = XT4 4 AWG– 300 kcmil, 225 AW = XT7 4x4/0 AWG-500kcmil

L = XT4 3/0 AWG–350 kcmil, 250 AX = XT7 3x500-750kcmil

Additional certifications

X = None

Advanced functionalities

X = None

Key locks

X = None

A = Ronis key lock – A type key

K = Castell key lock XT5-XT7 Accessories

E = Ronis key lock – Different keys

G = Kirk key lock XT5-XT7

BB

Tmax ® XT Retrofit Kits for Spectra™ Panelboards

Extending the life of your installation

You consider what you need. We will show you what's possible

The world of electrical distribution is a complex one, yet choosing the right device for your individual needs has never been simpler thanks to this Tmax ® XT retrofit01 offering for Spectra™ Panelboards and Switchboards. Maybe you are looking for a basic protection device for a standard distribution system.

Or perhaps you need something more complex, such as a locking mechanisms or devices that integrate protection, automation, measuring and communication into a cloud-based supervision system. Follow the flowchart when placing an order. All mounting kits, filler plates and hardware required are included under a single part number. Circuit breakers are ordered separately.02

Possible combinations within the range Legacy Spectra™ breaker

The parts you might need for your installation Neutral

Renewal parts

Mounting hardware

Order from the customer service center

Mounting hardware with filler plate, straps and brackets bolt-on Spectra™ - Mounting kit with filler plate includes hardware straps, brackets and filler plate. - Filler plate kit includes filler plate and associated hardware only.

Please note that Spectra, TED, FE, and FG breakers are obsolete

Renewal parts

Mounting hardware

Order from the customer service center

Filler plates bolt-on Spectra™

- Filler plate kit includes filler plate and associated hardware only.

Notes: 1X = 1 3/8" vertical space. THLC 1/2/4 breaker no longer available.

Filler plates plug-in or bolt-on Spectra™

Use to cover unused spaces.

Includes filler plate support brackets and hardware.

Please note that Spectra, TED, FE, and FG breakers are obsolete

240V Class

Bolt-on Circuit Breakers

240V Class THQB,

Industrial Circuit Breakers

15-100A

Thermal Magnetic Trip

Type TEY/TEYF

Noninterchangeable Trip

Bolt-on

480Y/277V Class

TEY and TEYF breakers are one-inch wide per pole, compact, bolt-on circuit breakers for use on grounded 480Y/277 Vac systems. Short circuit ratings at that voltage for TEY and TEYF are 14 and 18kA, respectively. TEYF also offers higher selectivity ratings with upstream devices (See DET-537 for details). The bolt-on mounting base (TEY3B) shown on page 6-217 makes TEY and TEYF suitable for various lug-lug applications.

TEY/TEYF (UL/cUL File E-11592)

1Solid or stranded for 14-10 AWG.

2Single-pole, 15 and 20 ampere breakers are also UL listed as switching duty breakers, suitable for switching 120, 240, or 277 Vac.

3UL listed HACR (Heating, Air Conditioning, Refrigeration).

4UL listed for HID (high intensity discharge), all 50A or less.

The TEY family of circuit breakers (TEY, TEYF, TEYD, TEYH, and TEYL) are one-inch wide per pole, compact, bolt-on circuit breakers for use on grounded 480Y/277 Vac systems, and are typically installed within Lighting Panelboards, including ABB A-Series. Short circuit ratings at 480/277 Vac are shown in the tables that follow. Ratings at other voltages are shown in the Quick Reference Guide at the beginning of this section. Bolt-On mounting bases TEY3B (page 6-66) and TEY3B125 (page 6-66) make these frames suitable for unit mount / lug-lug connected applications. Handle tie kits, suitable for use with multiple single pole breakers used on shared neutral circuits (page 6-66) are available for TEYD/H/L circuit breakers.

1Solid or stranded for 14-10 AWG.

2Single-pole, 15 and 20 ampere breakers are also UL listed as switching duty breakers, suitable for switching 120, 240, or 277 Vac. 3UL listed HACR (Heating, Air Conditioning, Refrigeration).

4UL listed for HID (high intensity discharge), all 50A or less. ;

A2 ordering information

* Lugs not included. Please refer to page 31-32 for lug information.

Tmax XT molded case circuit breakers

XT2 stocked base breakers

XT2 125A - Fixed (F) - 3 poles - Front terminals (F) - UL/CSA

125 (100% rated) XT2NQ3125EFF000XXXXT2SQ3125EFF000XXXXT2HQ3125EFF000XXX

Ekip LSIG trip unit

XT2NU3125GFF000XXX

XT2HU3060GFF000XXX

XT2HU3125GFF000XXX No trip unit (MCS) In

XT2HU3125DFF000XXX

* Lugs not included. Please refer to page 31-32 for lug information.

* Lugs not included. Please refer to page 31-32 for lug information.

XT4 250A - Fixed (F) - 3 poles - Front terminals (F) - UL/CSA

* Lugs not included. Please refer to page 31-32 for lug information.

Ordering codes for Tmax XT4

Circuit breakers

Distribution circuit breakers

Tmax XT, XT4, 250A Frame, Ekip DIP LS/I, LSI, LSIG, and LIG protection trip units with Front Terminals

Amps

Ekip DIP LS/I

N (25kA) S (35kA) H (65kA)

U.S. Ordering Code U.S. Ordering Code U.S. Ordering Code

40 XT4N040EFF000XXX XT4S040EFF000XXX XT4H040EFF000XXX

60 XT4N060EFF000XXX XT4S060EFF000XXX XT4H060EFF000XXX

100

040FFF000XXX XT4S040FFF000XXX XT4H040FFF000XXX

60 XT4N060FFF000XXX XT4S060FFF000XXX

Ekip DIP LSIG 40

60

150 XT4N

XT4H040CFF000XXX

60 XT4N060CFF000XXX XT4S060CFF000XXX XT4H060CFF000XXX

100

150 XT4N150CFF000XXX

150CFF000XXX XT4H150CFF000XXX

225 XT4N225CFF000XXX XT4S225CFF000XXX XT4H225CFF000XXX

250 XT4N250CFF000XXX XT4S250CFF000XXX XT4H250CFF000XXX

U for UL 80% rated or Q for 100% rated 3 for 3-pole or 4 for 4-pole

Tmax XT, XT4, 250A Frame, Ekip DIP LS/I, LSI, LSIG, and LIG protection trip units with Front Terminals

Amps

Ekip DIP LS/I

L (100kA) V (150kA) X (200kA)

U.S. Ordering Code U.S. Ordering Code U.S. Ordering Code

40 XT4L040EFF000XXX XT4V 040EFF000XXX

040FFF000XXX XT4X040FFF000XXX

60 XT4L060FFF000XXX XT4V 060FFF000XXX XT4X

60

250

Ordering codes for Tmax XT5 Circuit breakers

Tmax XT, XT5 Ekip DIP LS/I, LSI, LSIG, and LIG protection trip units with Front Terminals

N (35kA)

Frame Size Amps

Ekip DIP LS/I

400

S (50kA) H (65kA)

U.S. Ordering Code U.S. Ordering Code U.S. Ordering Code

250 XT5N25AEFF000XXX XT5S25AEFF000XXX XT5H25AEFF000XXX

300 XT5N30AEFF000XXX XT5S30AEFF000XXX XT5H30AEFF000XXX

400 XT5N40AEFF000XXX XT5S40AEFF000XXX XT5H40AEFF000XXX

600 600 XT5N60BEFF000XXX

Ekip DIP LSI 400

250 XT5N25AFFF000XXX

400 XT5N40AFFF000XXX

U for UL 80% rated or Q for 100% rated 3 for 3-pole or 4 for 4-pole

60BEFF000XXX XT5H60BEFF000XXX

Tmax XT, XT5 Ekip DIP LS/I, LSI, LSIG, and LIG protection trip units with Front Terminals

U.S. Ordering Code

Tmax XT molded case circuit breakers

XT5 stocked base breakers

XT5 400/600A - Fixed (F) - 3poles - UL

Thermal magnetic adjustable (TMA)

300A TMA

400A TMA

400A TMA 100% rated

600A TMA

Ekip LS/I trip unit

300A LS/I

400A LS/I

400A LS/I 100% rated

600A LS/I

Ekip LSI trip unit

400A LSI

600A LSI

Molded case switch (MCS)

400A MCS

600A MCS

Ekip I trip unit

400A I

500A I

XT5NU330ABFF000XXXXT5SU330ABFF000XXXXT5HU330ABFF000XXX

XT5NU340ABFF000XXXXT5SU340ABFF000XXXXT5HU340ABFF000XXX

XT5NQ340ABFF000XXX

XT5NU360BBFF000XXXXT5SU360BBFF000XXXXT5HU360BBFF000XXX

XT5NU330AEFF000XXX

XT5NU340AEFF000XXX

XT5NQ340AEFF000XXX

XT5NU360BEFF000XXX

XT5NU340AKFF000XXX

XT6 800A - Fixed (F) - 3poles - UL

In Ordering code

Thermal magnetic adjustable (TMA)

800A TMA

Ekip LS/I trip unit

600A LS/I 100%rated

800A LS/I

800A LS/I 100% rated

Molded case switch (MCS)

800A MCS

XT5HU340AEFF000XXX

XT5HQ340AEFF000XXX

XT5HU360BEFF000XXX

XT5SU340AFFF000XXXXT5HU340AFFF000XXX

XT5HU360BFFF000XXX

XT5HU340ADFF000XXX

XT5HU360BDFF000XXX

XT5LU340AKFF000XXX

XT5LU350BKFF000XXX

Ordering code

XT6NU3800BFF000XXX

XT6NQ3600EFF000XXX

XT6NU3800EFF000XXX

XT6NQ3800EFF000XXX

XT6HQ3800EFF000XXX

XT6HU3800DFF000XXX

* Lugs not included. Please refer to page 31-32 for lug information.

Tmax XT molded case circuit breakers

XT5 stocked base breakers

XT7 1200A - Fixed (F) - 3poles - UL

* Lugs not included. Please refer to page 31-32 for lug information.

Ordering codes for Tmax XT7

Circuit breakers

Tmax XT, XT7 Ekip DIP LS/I, LSI, LSIG, and LIG protection trip units with Front Terminals

Ekip DIP LSIG

800 800 XT7S80CGFF000XXX

10001000 XT7S10DGFF000XXX

12001200 XT7S12EGFF000XXX

Ekip DIP LIG 800

12EFFF000XXX

XT7H80CGFF000XXX XT7L80CGFF000XXX

XT7H10DGFF000XXX XT7L10DGFF000XXX

80CCFF000XXX XT7L80CCFF000XXX

10001000 XT7S10DCFF000XXX XT7H10DCFF000XXX XT7L10DCFF000XXX

U for UL 80% rated or Q for 100% rated

3 for 3-pole or 4 for 4-pole

Tmax XT, XT7 Ekip TOUCH LSI and LSIG, protection trip units with Front Terminals

10001000

12001200

U for UL 80% rated or Q for 100% rated

3 for 3-pole or 4 for 4-pole

kits

terminals

Front terminals for MCP KXT1F3PCMCP

Extended front terminals

Extended spread terminals

Multi cable for Cu cables, 6x14-2 AWG

Cu cables, 14-1/0 AWG

Cu cables MCP, 14-1/0 AWG

CuAl cables, 14-1/0 AWG

CuAl cables w/Control Tap, 14-1/0 AWG

FC CuAl terminals for CuAl cables 102/0 AWG

FC CuAl terminals AuxV for CuAl cables 10-2/0 AWG

Cu cables, 10-250 kcmil

CuAl cables, 4 AWG -300 kcmil

CuAl cables w/Control Tap, 4 AWG-300

kcmil

CuAl cables, 4 AWG -300 kcmil

CuAl cables w/Control Tap, 4 AWG -300

kcmil

CuAl cables, 250-350 kcmil

KXT1EF-3PC KXT2EF-3PC

KXT1CU-3PC KXT2CU-3PC

KXT1CUMCP-3PC

KXT1CUAL1-3PC

KXT1CUAL1C-3PC

KXT2CUAL1-3PCKXT3CUAL1-3PC

KXT3CUAL1C-3PC

KXT2CUAL2-3PC

KXT2CUAL2C-3PC

KXT3CU-3PC

KXT3CUAL2-3PC

KXT3CUAL2C-3PC

KXT4EF-3PC

KXT4CUAL1-3PC

KXT4CUAL1C-3PC

KXT4CU-3PC

KXT4CUAL2-3PC

KXT4CUAL2C-3PC

KXT4CUAL3-3PC

FC CuAl terminals AuxV for CuAl cables 3/0 AWG-350 Kcmil KXT4CUAL3C-3PC

Tmax XT accessories

Terminal kits, insulating kits and phase barriers

Terminal kits

Front terminals

Front terminals for MCP

Extended front terminals

FC CuAl 1x6AWG-350kcmi

FC CuAl 1x250-500kcmil

FC CuAl 1x500kcmil AuxV K

FC CuAl 2x250-500kcmil

FC CuAl 2x500kcmil AuxV

FC CuAl 3x2/0AWG-400kcmil

FC CuAl 3x400kcmil AuxV

FC CuAl 4x4/0 AWG – 500 kcmil

FC CuAl 3x500-750kcmil

2X500-750MCM

Insulating terminal covers

LTC low terminal covers

HTC high terminal covers

HTC_BS High terminal covers with back shield

Phase barriers

PB height 25mm/0.98in

PB height 100mm/3.94in

PB height 200mm/7.87in

XT5

XT6 XT7

KXT5F-3PC KXT6F-3PC

KXT5EF-3PC KXT6EF-3PC

KXT5CUAL350K-3PC

KXT5CUAL500K-3PC

KXT5CUAL500KC-3PC

KXT5CUAL2X500K-3PCKXT6CUAL2X500K-3PC

KXT5CUAL2X500KC-3KXT6CUAL2X500KC-3

KXT6CUAL3X400K-3PC

KXT6CUAL3X400KC-3

KXT5CUAL2X750KC-3

XT5

XT6

KXT5LTC-3 KXT6LTC-3

KXT7CUAL4X500K-3PC

KXT7CUAL3X750KC-3

XT7

KXT5HTC-3 KXT6HTC-3 KXT7HTC2pcs-3

KXT5HTCBS-3

XT5

KXT5PB25UL-3

XT6

KXT5PB100UL-3KXT6PB100UL-3

KXT5PB200UL-3KXT6PB200UL-3

PS – Rear phase separators for FP KXT5PBFP-3

Cable Rack

KXTFACCRCK KXTFACCRCK

Product Features

-Suitable for use as service equipment (SE) as noted.

- 60°C/75°C conductor ratings

-Short circuit ratings are equal to the rating of the installed breaker.

To order enclosed or accessorized circuit breakers, a configurator is available at: empower.abb.com

5

(Table continued on next page.)

(continued)

1 cUL Listed - Suitable for use as service equipment.

2 Enclosures with blank end walls (no Knockouts) and a feature to adjust the instantaneous setting on Spectra Circuit breakers.

3 Neutral for ground fault required to mount neutral sensor in enclosure.

4 For 250A rating, use copper cable only.

* 1200A Circuit Breaker enclosure code requirements may require Relt. Consult with an ABB representative before quoting.

Product Features

-Suitable for use as service equipment (SE) as noted.

- 60°C/75°C conductor ratings

-Short circuit ratings are equal to the rating of the installed breaker.

To order enclosed or accessorized circuit breakers, a configurator is available at: empower.abb.com

(150A DIP) 1SDA081987R1 (225A DIP) 1SDA066979R1 (250A DIP) 1SDA101973R1 (Touch) 1SDA107408R1 (Touch V) 600

NEMA Type 3R

NEMA Type 3R (continued)

1 cUL Listed - Suitable for use as service equipment.

2 100-250A devices have removable closing cap. Larger ampere devices require field cut openings. Order hubs separately. See page 7-10.

3 3-Pole breakers with an accessory can not be installed in these enclosures.

4 Service rated equipment only.

NEMA Type 12

Product Features

-Suitable for use as service equipment (SE) as noted.

- 60°C/75°C conductor ratings

-Short circuit ratings are equal to the rating of the installed breaker.

To order enclosed or accessorized circuit breakers, a configurator is available at: empower.abb.com

NEMA Type 12

1 cUL Listed - Suitable for use as service equipment.

2 Neutral for ground fault required to mount neutral sensor in enclosure.

3 For 250A rating, use copper cable only.

* 1200A Circuit Breaker enclosure code requirements may require Relt. Consult with an ABB representative before quoting.

(100A

1SDA081986R1 (150A DIP) 1SDA081987R1 (225A DIP) 1SDA066979R1 (250A DIP) 1SDA101973R1 (Touch) 1SDA107408R1 (Touch V)

1SDA105152R1(300ADIP)

1SDA105154R1(400ADIP)

1SDA105155R1(600ADIP)

1SDA101974R1(Touch)

1SDA107409R1(TouchV)

Product Features

-Suitable for use as service equipment (SE) as noted.

- 60°C/75°C conductor ratings

-Short circuit ratings are equal to the rating of the installed breaker.

To order enclosed or accessorized circuit breakers, a configurator is available at: empower.abb.com

NEMA Type 4/4X

1 cUL Listed - Suitable for use as service equipment.

2 Neutral for ground fault required to mount neutral sensor in enclosure.

3 For 250A rating, use copper cable only.

* 1200A Circuit Breaker enclosure code requirements may require Relt. Consult with an ABB representative before quoting.

1SDA081985R1 (60A DIP) 1SDA066977R1 (100A DIP) 1SDA081986R1 (150A DIP) 1SDA081987R1 (225A DIP) 1SDA066979R1

1 800A and 1200A non-double throw safety switches also use the C Duty Level nomenclature

Note: This information is provided for interpreting numbers. It should not be used to build product numbers.

All ABB Spec-Setter safety switches carry the following certifications:

-UL Listed and cUL Listed (UL98 Enclosed Switches/CSA-C22.2 No. 4-04)

- Federal Specification WS-865C

-NEMA Enclosed Safety Switch Standard KS1-2013

- Seismic Certified

- Service Entrance Rated (unless otherwise noted)

*1200A Switch code requirements may require relt. Consult with an ABB representative before quoting.

All Spec-Setter safety switches are horsepower rated with the following exceptions:

-800A single throw type TC switches

-1200A single and double throw type TC and TDT switches

For specific HP ratings by part number, see DET845 or specification sheets found on https://empower.abb.com

The viewing window is a polished surface, UV stabilized, polycarbonate product. A flame-retardant grade that meets UL 94, high-temperature resistance, and high clarity properties. It has been impact and strength tested. It has not been approved for use with infrared thermography.

AC disconnect, NEMA type 3R

30 -60 amperes

240 volts AC 50/60 Hz

UL/CUL listed

GE by ABB's general purpose single-phase dry type transformers are step-down transformers designed for installations that require a 3-wire secondary voltage for 120/240 V systems. These units can also be used in 2-wire, 120x240 V applications. Their primary voltages are 240x480.

Optional wall mount brackets are available for most models. lug kit and copper ground bar are included.

Technical characteristics

• Connection: 3-wire or 2-wire secondaries

• Voltages: (P) 240x480 (S) 120/240

• Temperature rise: 150 °C; 220 °C insulation class; IEC 60085 Class R

• Frequency: 60 Hz

• Ambient temperature: 40 °C

• Standard single-phase tap arrangement

• Painted, ANSI #61 gray NEMA 2 enclosure

• Type QL

• Audible sound level: NEMA ST-20 Standard

• Seismic qualifications – CBC 2019 and IBC 2018; ASCE 7.05-2016

• UL 1561

• UL & cUL listed (XQNX, XQNX7:E323777)

• Energy efficiency: DOE 2016 (10 CFR Part 431)

• Energy efficiency: NRCan (CSA 802.2)

• UL energy verification – for US and Canada (ZXPC:EV519886) (ZZED:EV23760)

¹ See page 10A-45 and 10A-46 for wiring diagrams.

Please Note: This catalog number nomenclature is for illustrative purposes only. Not all catalog number combinations are available for production. Please reference the ordering tables beginning on page 10A-12 for Three-phase DOE 2016 Efficiency transformers currently available for ordering. For additional assistance, please contact your ABB Account Manager.

* Standard factory lug kits are included with 150KVA transformers and below

¹ See page 10A-45 and 10A-46 for wiring diagrams.

¹Seepage10A-45and10A-46forwiringdiagrams.

¹ See page 10A-45 and 10A-46 for wiring diagrams.

Basic contactor

Combined with other appropriate components, basic contactors allow configuration into any available electrically or mechanically held model. Includes two power poles.

Replace * in the product number with the appropriate digits from the Coil Voltage table. The resulting product number will be for an assembled contactor with no additional auxiliary contacts, pilot devices, pilot lights, control circuit fuses or CPTs.

Power poles

CR460 series basic contactors accept up to 6 single- or double-pole power poles. These can be used to form up to:

-12 NO poles when 6 double-poles are used in the NO positions (1-6) or -8 NC poles with 4 double-poles in the NC positions (1-4) + NO poles with 2 double-poles in the 2 NO positions (5-6)

Conversion kits for mechanically held contactors

Kits for converting electrically held contactors to a mechanically held version. Kits include control module, latch, latch cover and auxiliary contact(s) plus installation instructions.

Conversion kits are suitable for coil voltages 277V and below. Use CPT to reduce coil voltage if line voltage is higher than 277V.

Each contactor may use one single or one double auxiliary contact block on eacch side of the base. When installed on the left side the contacts are NO, when installed on the right side the contacts are NC. This allows a total of 2NO +2NC contacts maximum.

See additional auxiliary contacts tables on pages 3-15 and 3-19 for contact selection data.

Electrically held contactors

Follow the diagram and tables below to select the options and corresponding product number digits for your modified contactor.

Modified assembled forms - electrically held (continued)

CR463L Electrically held contactors

Follow the diagram and tables below to select the options and corresponding product number digits for your modified contactor.

6: Enclosures

7: Pilot devices

•

•

•

•

•

• -

holding interlock is included in pilot device digit and pricing.

Heavy-duty, 30mm pilot devices. Contactor supplied in oversize enclosures with these options. Not available in Type 1 flush enclosure.

8: Pilot

Heavy-duty 30mm pilot lights with interchangeable red and green lenses. See the additional auxiliary contacts table above for contact limitations. OFF light includes extra auxiliary contact. Not available in Type 1 flush enclosure.

Mechanically held contactors

Follow the diagram and tables below to select the options and corresponding product number digits for your modified contactor.

Each side of the contactor base will accept one single- or double-pole auxiliary contact block, for a maximum of 2NO-2NC contacts. The 2-wire control module uses 1NC contact and the 3-wire uses 1NO-1NC for feedback and control. The table above indicates the additional auxiliary contacts available for customer or field use when factory-assembled forms are supplied. For open forms, this is the final digit.

Modified assembled forms - mechanically held (continued)

CR463M Mechanically held contactors

Follow the diagram and tables below to select the options and corresponding product number digits for your modified contactor.

7: Pilot devices

•

•

•

•

•

Heavy-duty, 30mm pilot devices. Oversize enclosure required for field installed pilot devices, pilot lights and control power transformers. Not available in Type 1 flush enclosure.

8: Pilot

* New Load Center offering coming soon

PowerMark Gold load centers lower your costs by making installation faster and easier, increasing application flexibility and reducing inventory requirements. At the same time, they deliver obvious and significant advances in design, function and quality.

-UL Listed (Panelboards No. 67)

-Service Barriers included for factory installed main circuit breaker and main circuit breaker kits (required to meet UL67 for service entrance applications)

-Suitable for Use as Service Entrance Equipment when i nstalled in accordance with National Electrical Code

- 60°C/75°C Conductor Rating

-Single phase, 40-225A, 2-42 circuits

-Main lug models field convertible to main breaker

-Main breaker 22kAIC standard - factory installed

-All load centers top or bottom feed

- Indoor and outdoor rated enclosures

- Indoor fronts combination surface/flush

- Copper bus with tin plating standard1

-Split neutrals extend the full length of the interior for ease of wiring

- Entire main lug line converts easily to main breaker

- Combination surface/flush front with springreinforced pan

- Combination slotted/Robertson square-drive screws on neutral, 2 ground, front and breaker lugs

-Front packed in inner carton for added protection

-Field installable feed-through lugs up to 200A

- Straight-through main wiring

-Main breaker is clearly marked and circuit numbers are stamped on front

- Isolated ground bar is available

One-piece interior removes and reinstalls easily

Main breaker configuration allows top or bottom feed without modification

Full-length neutrals are easier to wire,2 reducing installation time and cost

Combination slotted/Robertson square-drive speeds screw wiring

All holes rated for 14-4 wire

Minimum 100% neutral terminations

100% rated split neutral on each side2

Tie bar may be removed to split neutral/ground

Sturdy copper bus and galvanized box increase durability and reliability Accepts ABB Q-Line branch circuit breakers, including ABB’s exclusive 1/2" THQPs

Accessories and Options

- Door lock and handle

-Equipment ground kits

- Sub-feed and feed-thru lugs

- Front filler plates

- Handle lock and ties

- Compact box maintains optimum wire-bending space 1 Three-phase

- Hardware kits

- Main breaker retainers

- Neutral kits

- Universal raintight hubs

Packaging features comprehensive selection and application data. Fronts are packed in inner cartons for added protection during shipment and at the job site.

A complete family of meter socket load centers — ring style and ringless, wide and narrow, meter mains, farm panels and more — deliver specialized solutions for special situations.

Main lug load centers offer an economical solution for subpanels and similar applications. All main lug units 125A and above convert easily to main breaker.

ABB’s residential load centers reach into commercial applications as well, with riser panels, auxiliary gutters, three-phase units with standard 22kAIC ratings, and all the accessories needed to complete the job.

The PowerMark Gold line includes a wide range of outdoor as well as indoor units.

Safety accessories – convenient and easy to install

-THQLSURGE whole house surge protector