: India's Manufacturing Prowess on the Global Stage

Indiahas emergedasa significanthubfor themanufacturing, supply, andexport ofhigh-quality gatevalves, serving critical industriesworldwide.This document provides acomprehensive overviewof India'sstrategic role, leading manufacturers, product innovations, stringent quality controls, diverse applications, and global export capabilities in the gate valve industry.

Introduction: India9s Strategic Role in Global Gate Valve Industry

India has firmly established itself as amajor global hub for gate valve production, boastinga robustecosystem with over 600 valve manufacturers. This extensive network enables India to meet the diverse and demanding requirements of industries both domestically and internationally.

are indispensable components in numerous industrial applications. Their primary function is to startor stopfluidflow in pipelines, making them critical for regulating processes in various sectors. Indian manufacturers have skillfully blended traditional engineering expertise with cutting-edge technological advancements to produce valves that adhere to the highest global standards. This commitment to innovation and quality ensures that India remains a competitive and reliable source for worldwide.

Leading Manufacturers and Their Unique Strengths

India'sgatevalve industryis characterized by several keyplayers, eachbringing unique strengthsand specializations to the market. These manufacturers are committed to innovation, quality, and meeting diverse industrial needs, contributing significantly to India's reputation as a global valve hub.

IPC Valves

With over 20 years of experience and a 25,000 sq.ft facility, IPC offers a comprehensive range of gate, globe, check, and ball valves. They are certified to global standards and serve more than 12 industrial sectors, providing customization and automation solutions.

Rappid Valves (India) Limited

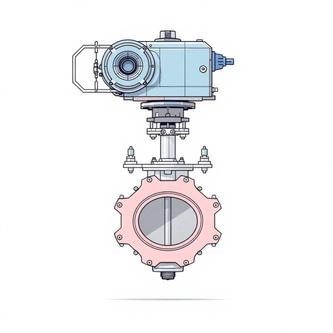

Since 2002, Rappid Valves has been a specialist in actuator-operated valves for refinery and marine applications. Their are meticulously designed to conform with DIN and ASME standards, driven by strong leadership and technological vision.

Flowtorq Engineering (Mumbai)

Established in 2012, Flowtorq is a rapidly growing entity specializing in R&D-driven custom valve solutions. Their expertise spans oil & gas, petrochemical, cement, and food processing industries, with full compliance to international standards.

4 2

Cair Euromatic excels in resilient seated gate valves, perfectly suited for water, sewage, and industrial use. They hold ISO 9001:2008 and CE certifications, known for their innovative rubberseated designs ensuring durability and drop-tight sealing. 3

Cair Euromatic Automation

Product Range and Technological Innovations

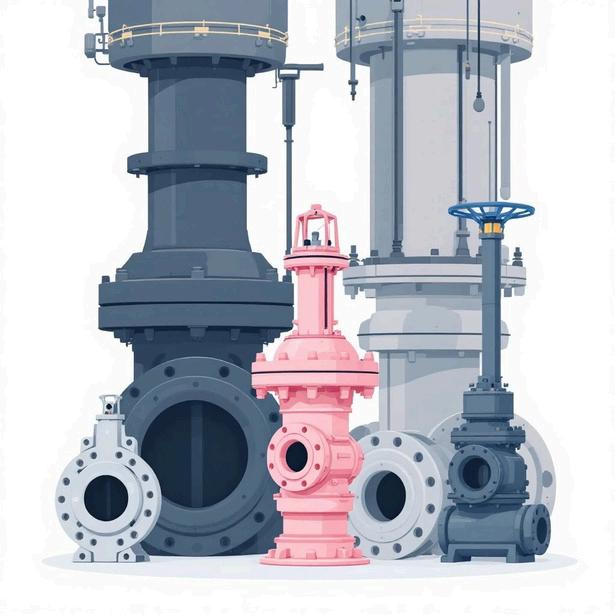

Indianmanufacturers offer anextensivearray of,characterizedby diverse types,sizes, andmaterials, alongside significant technological advancements. This comprehensive range ensures solutions for nearly every industrial application, from standard needs to highly specialized requirements.

Diverse Types & Sizes

Metal seated, resilient seated, knife-edge, and jacketed .

Sizes from 1/2 inch to 88 inches.

Pressure ratings from ASME Class 150 to Class 2500, accommodating various operational pressures.

Advanced Materials

Standard materials: Cast iron, cast steel, forged steel, stainless steel alloys.

Specialized options: Duplex steel and other alloys for corrosive and high-temperature environments.

Automation Integration

Integration with pneumatic actuators, limit switch boxes, and motorized valves.

Enhances operational efficiency, precision, and remote control capabilities.

The versatility in design and material selection underscores India's capability to deliver bespoke valve solutions.

Quality Assurance and Certifications

Qualityassuranceisacornerstoneofthe Indiangatevalve industry,with manufacturers adhering to rigorous standards and obtaining comprehensive certifications. This commitment ensures that all products meet and exceed international benchmarks for performance, safety, and reliability.

Stringent Quality Controls

Indian gate valve manufacturers implement robust quality control measures at every stage of production, from raw material inspection to final product testing.

Global Certifications International Standards

Compliance with international standards is paramount. This includes ISO certifications (ISO 9001,IEC), TUV NORD approvals, and CMRI cer tific ation.

Adherence to global specifications such as DIN, ASME,ANSI,andIBR ensures compatibility and performance across various industrial setups worldwide.

Rigorous Testing Protocols

Valves undergo extensive testing to confirm their ability to withstand high pressure, temperature fluctuations, and corrosive conditions.

Guarantees & Custom Testing

Many manufacturers provide guarantees against manufacturing defects and offer customized quality testing tailored to specific client requirements, ensuring complete satisfaction.

Industry Applications and Sectoral Reach

Gatevalves produced in India areintegraltothe operationsofa wide array of critical sectors,showcasing their versatility and reliability across diverse industrial environments. Their robust design and performance make them suitable for challenging applications

Oil & Gas

Crucial for high-pressure pipeline isolation and precise flow control in upstream, midstream, and downstream operations.

Power Generation Water & Sewage Chemicals & Fertilizers

Essential for boiler and steam applications, providing reliable shutoff in conventional and renewable energy plants.

Resilient seated valves are ideal for managing impurity-laden fluids in municipal water and wastewater treatment facilities

Corrosion-resistant valves are vital for handling aggressive media and ensuring safety in chemical processing

Marine & Shipbuilding

Specialized valves designed to withstand saline and harsh environments on vessels and offshore platforms.

Other Industries

Also widely used in Pharmaceuticals, Food Processing, Cement, and Mining industries, adapted to their specific operational needs.

Export Capabilities and Global Footprint

India's gatevalve manufacturers have successfully expandedtheir reach globally,establishingastrong presence across continents. Their robust export capabilities are underpinned by a commitment to international standards and comprehensive customer support.

Broad Export Reach

Indian are extensively exported to key markets in Asia,Europe,NorthAmerica,Africa,and theMiddleEast, serving diverse industrial needs.

Global Support Network

Leading manufacturers like G M Engineering and IPC

Valves maintain regional offices and service centers abroad, ensuring prompt support and seamless operations for global clients.

International Compliance

Exported valves rigorously meet international standards and certifications, making them suitable for critical infrastructure projects worldwide and ensuring broad market acceptance.

Custom & After-Sales Service

Indian suppliers offer custom engineering solutions and robust after-sales support, significantly strengthening India¾s reputation as a reliable and responsive global valve supplier.

Market Leaders and Notable Companies

TheIndian gatevalvemarketfeaturesseveral prominent players,each contributingtothe industry'sdynamism through their specialized product offerings and extensive experience. These companies play a crucial role in shaping the competitive landscape.

TUBOMART Amco Industrial Valves Amtech (Gujarat) G M Engineering Pvt Ltd

Though internationally headquartered, TUBOMART is a significant supplier in India, offering largescale up to 88inches with highpressure classes up to 2500, catering to heavy industrial demands.

Based in Tamil Nadu, Amco brings over 30 years of experience, specializing in robust cast iron that strictly comply with ANSI Class 150 standards.

Known for their innovative butterfly and highperformance forged steel valves, Amtech offers products with impressive pressure ratings up to ANSI Class 2500.

Located in Gujarat, G M Engineering offers a versatile range of manual, pneumatic, and electric actuated gate valves, available in sizes from 15mmto60mm, adaptable for various applications.

Challenges and Opportunities in the Indian Gate Valve Industry

Whilethe Indian gatevalve industryexhibitsrobust growth,italso faces specificchallenges.However,these challenges are balanced by significant opportunities that promise future expansion and innovation.

Challenges Opportunities

MarketFragmentation: A large number of small players leads to intense competition and can hinder large-scale strategic initiatives.

IntenseCompetition: Both domestic and international competitors vie for market share, necessitating continuous differentiation

NeedforContinuousInnovation: Rapid technological changes and evolving industrial demands require constant R&D investment.

InfrastructureGrowth: Ongoing and planned large-scale infrastructure projects, especially in water, oil & gas, and power, drive demand.

AutomationDemand: Increasing adoption of automation across industries creates a growing market for intelligent and actuated valves

ExpandingExportMarkets: Growing global demand for reliable industrial components offers significant opportunities for Indian manufacturers to expand their international footprint

SustainabilityTrends: Focus on developing valves with longer life cycles and environmentally friendly materials aligns with global sustainability goals

Conclusion: India9s Gate Valve Industry 3 A Trusted Global Partner

Indiahas firmly established itselfas a powerhouse inthe manufacturing,supply,and export ofhigh-quality gate valves. The industry's ability to tailor products for diverse industrial needs, combined with a commitment to stringent quality controls, positions India as a preferred global partner.

Through a strategic blend of skilledmanpower,advancedtechnology,andrigorousqualitystandards, Indian manufacturers consistently deliver valve solutions that are both reliable and cost-effective. This strong foundation enables them to meet the evolving demands of industries worldwide, from critical infrastructure to specialized applic ations.

For industries seeking durable, certified with comprehensive customization and automation options, India offers a mature and dynamic supplier ecosystem. Partnering with Indian gate valve manufacturers provides access to innovation, guaranteed quality, and adherence to global compliance 4 a winning combination essential for navigating today¾s complex industrial landscape.