is paving a plastic free future...with onion skins.

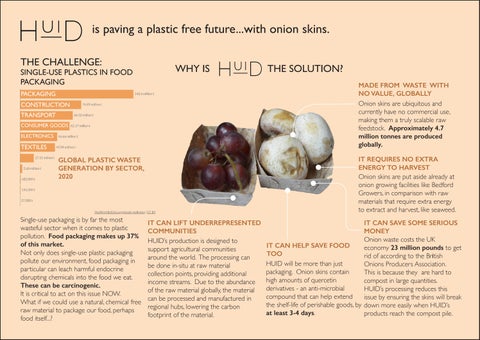

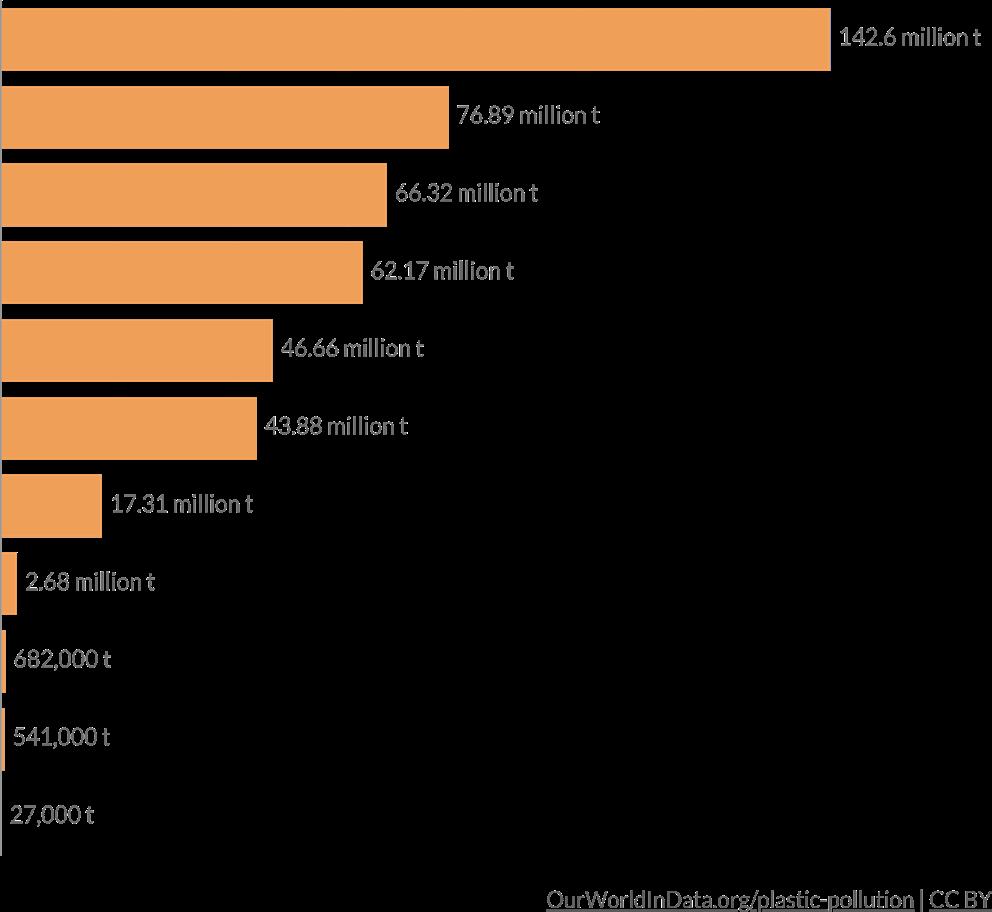

THE CHALLENGE: SINGLE-USE PLASTICS IN FOOD

PACKAGING

PACKAGING

CONSTRUCTION

TRANSPORT

CONSUMER GOODS

ELECTRONICS

TEXTILES

Single-use packaging is by far the most wasteful sector when it comes to plastic pollution. Food packaging makes up 37% of this market.

Not only does single-use plastic packaging pollute our environment, food packaging in particular can leach harmful endocrine disrupting chemicals into the food we eat. These can be carcinogenic. It is critical to act on this issue NOW.

What if we could use a natural, chemical free raw material to package our food, perhaps food itself...?

WHY IS THE SOLUTION?

IT CAN LIFT UNDERREPRESENTED COMMUNITIES

HUID’s production is designed to support agricultural communities around the world. The processing can be done in-situ at raw material collection points, providing additional income streams. Due to the abundance of the raw material globally, the material can be processed and manufactured in regional hubs, lowering the carbon footprint of the material.

IT CAN HELP SAVE FOOD TOO

MADE FROM WASTE WITH NO VALUE, GLOBALLY

Onion skins are ubiquitous and currently have no commercial use, making them a truly scalable raw feedstock. Approximately 4.7 million tonnes are produced globally.

IT REQUIRES NO EXTRA ENERGY TO HARVEST

Onion skins are put aside already at onion growing facilities like Bedford Growers, in comparison with raw materials that require extra energy to extract and harvest, like seaweed.

IT CAN SAVE SOME SERIOUS MONEY

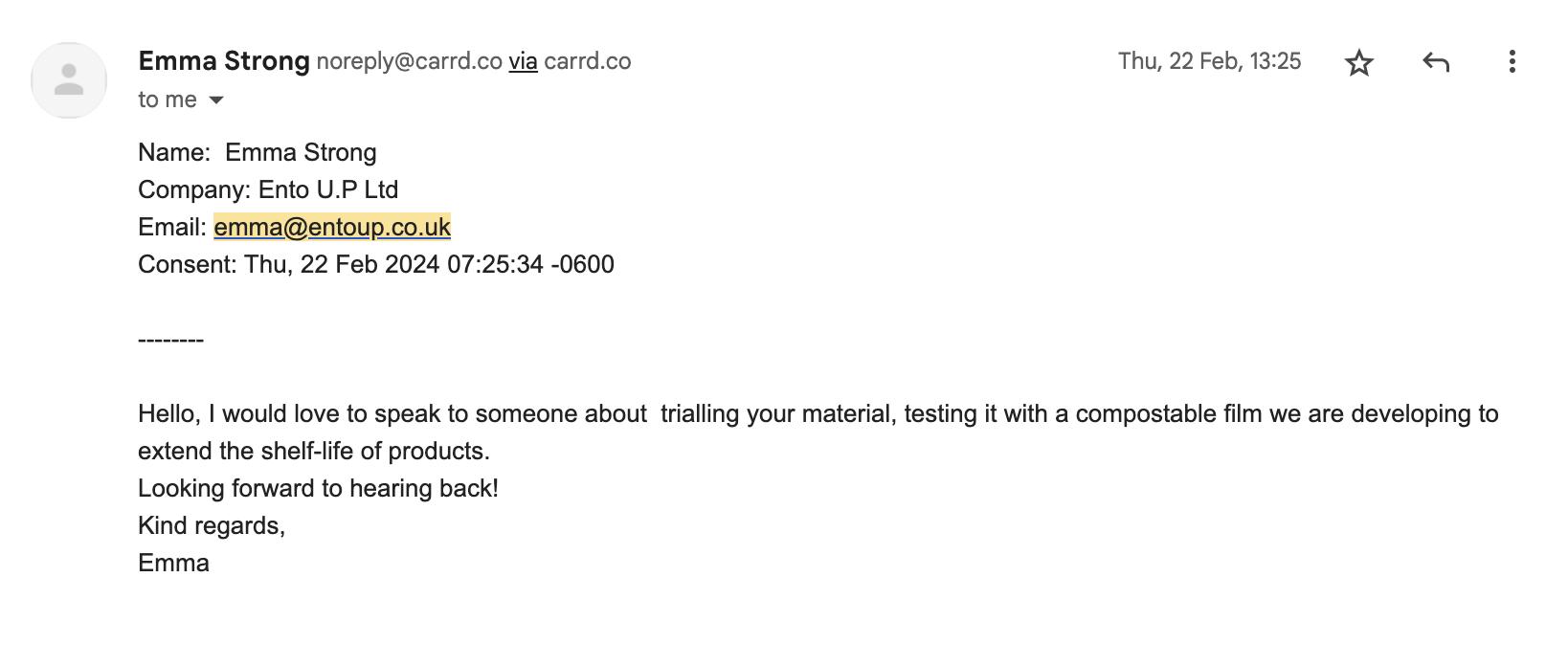

HUID will be more than just packaging. Onion skins contain high amounts of quercetin derivatives - an anti-microbial compound that can help extend the shelf-life of perishable goods, by at least 3-4 days.

Onion waste costs the UK economy 23 million pounds to get rid of according to the British Onions Producers Association. This is because they are hard to compost in large quantities. HUID’s processing reduces this issue by ensuring the skins will break down more easily when HUID’s products reach the compost pile.

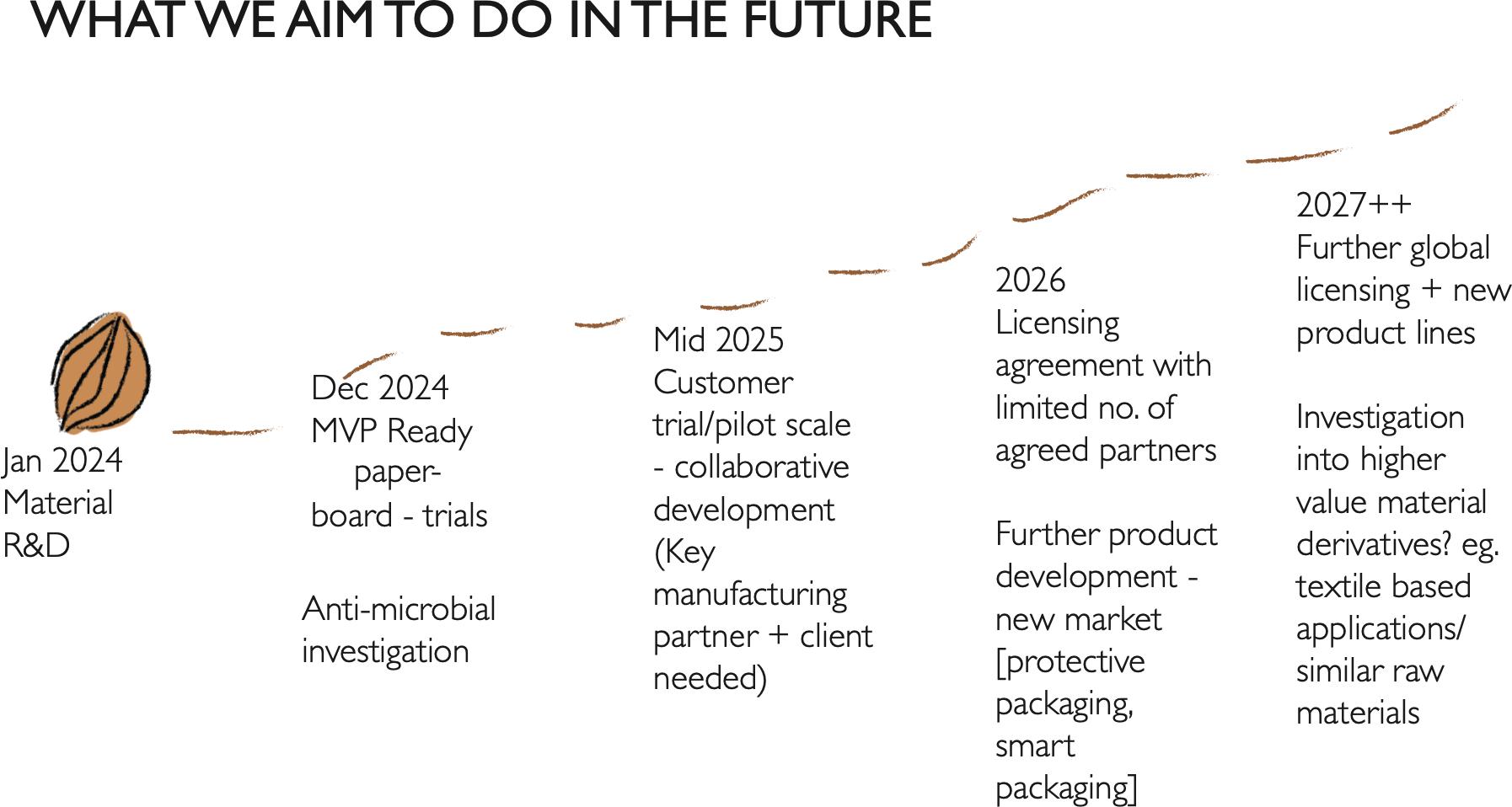

WHAT WE HAVE DONE SO FAR

Changed formulation from a composite to a cellulosic mono-material in both a film and rigid quality

Started 3D material tests with surface texture and casting objects

Exploring enzymatic treatments for raw material processing to reduce CO2 by up to 37kg/ton

Funding

has been supported by:

Business Support

Technical Support

Exhibiting Opportunities

WHAT WE WILL DO THIS YEAR: OUR DREAM

ANTI-MICROBIAL EXTRACTION PRODUCT DEVELOPMENT

A key USP for HUID, phenolic compounds in the onion skin like quercetin are of interest for their anti-microbial properties.

HUID hopes to hone an extraction technique and find a method to insert this into its cellulosic material.

HUID wants to use existing manufacturing processes in industry to create a refined, replicable prototype that is ready to go to market. This includes trialling coating applications.

CERTIFICATION IP PROTECTION

In order to ensure HUID is the best it can be for the market, HUID will undertake:

- rigorous mechanical testing (working to ISO 9001)

- compositional analysis

- LCA reporting (ISO 14040/44)

- Food Contact Material Compliance

- Biodegradation (EN13432)

In order to keep developing solutions with confidence, HUID will embark on a strategic IP roadmap to ensure that it is protected through:

- Concentrated FTO review pre-patent

- Patent filing

HUID would like to partner with food waste charities, soup kitchens and circular economy initiatives to help move the cause of municipal food waste collection, and educate the public on materials, recycling and composting.

Partner with businesses that could use our by-products/ waste and us theirs. Gills Onions uses onions to create electricity to power their plant. They have solid onion ‘cakes’ as left over that have been partially processed that could improve HUID’s LCA.

PROTOTYPE MATERIALS

PYBER is a card-like material made from onion skin fibres.

Made from an abundant source of waste, Pyber presents a sustainable alternative to wood fibre paper for secondary packaging products.

Pyber can be made in a range of natural shades and weights.

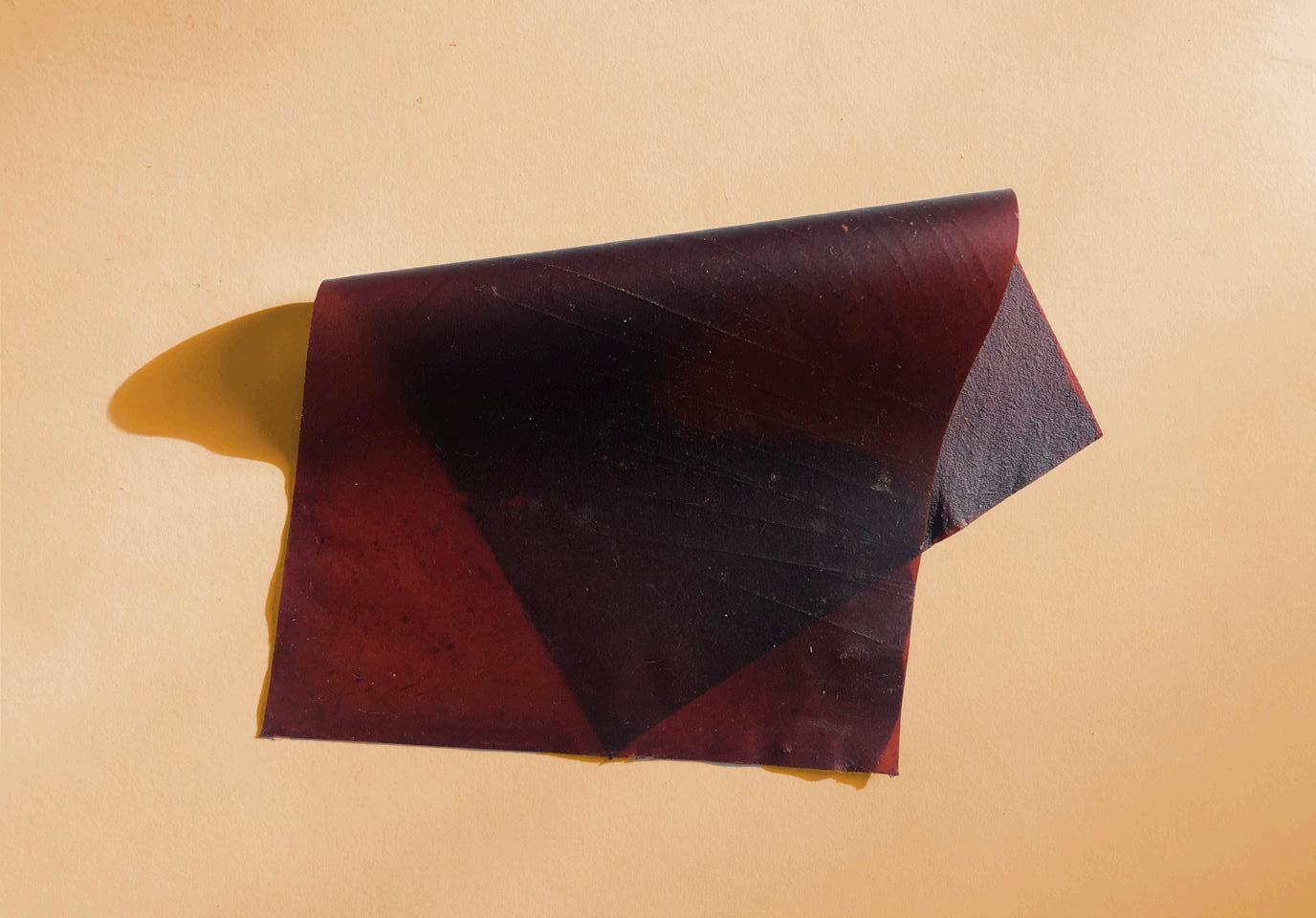

CELLOFIL is a flexible film material made from biologically processed onion skin.

The film offers an alternative to LDPE and PE films for a variety of packaging applications, including food contact materials.

It is translucent with visible fibres - you can be sure this is made from plants.

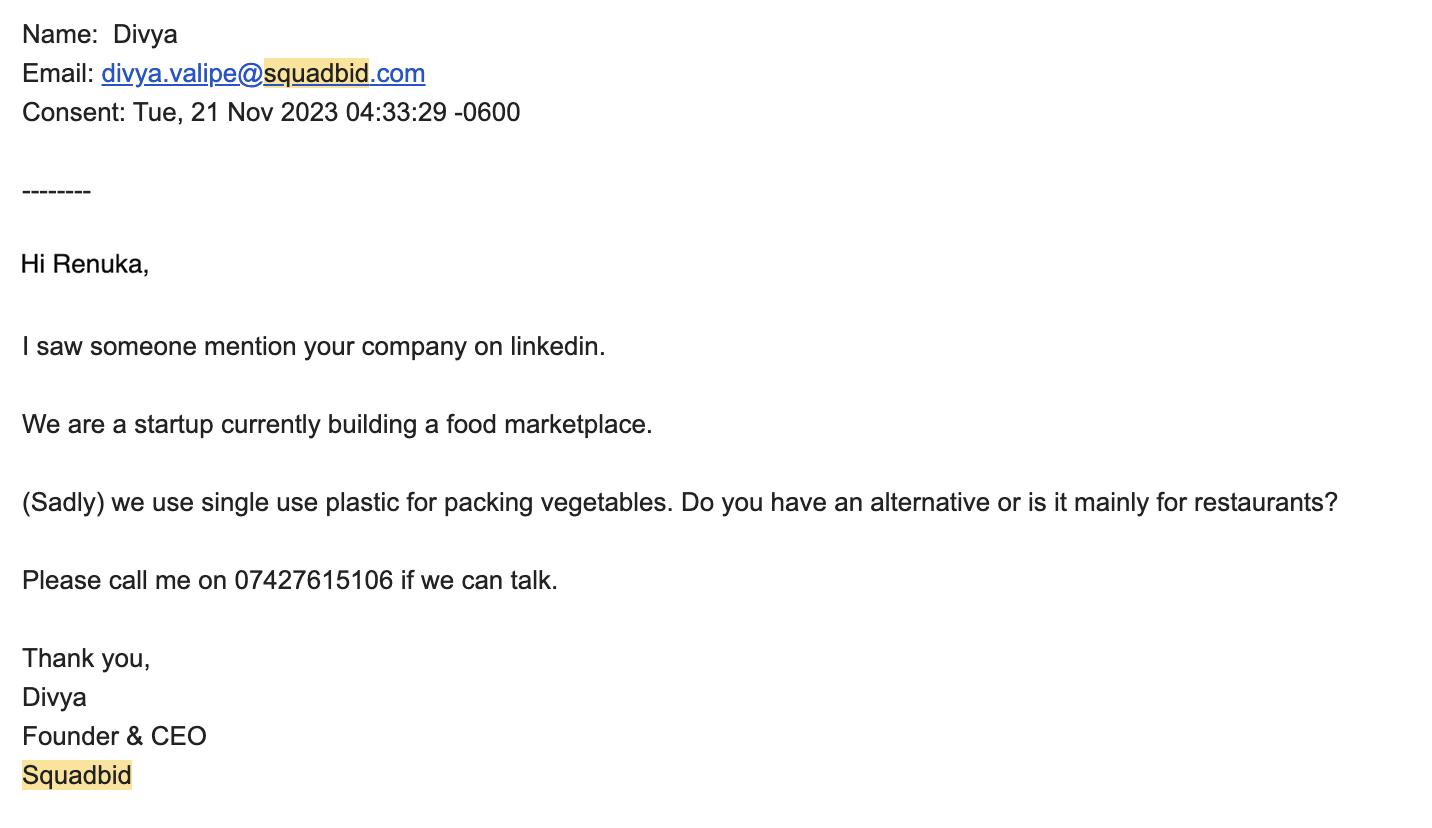

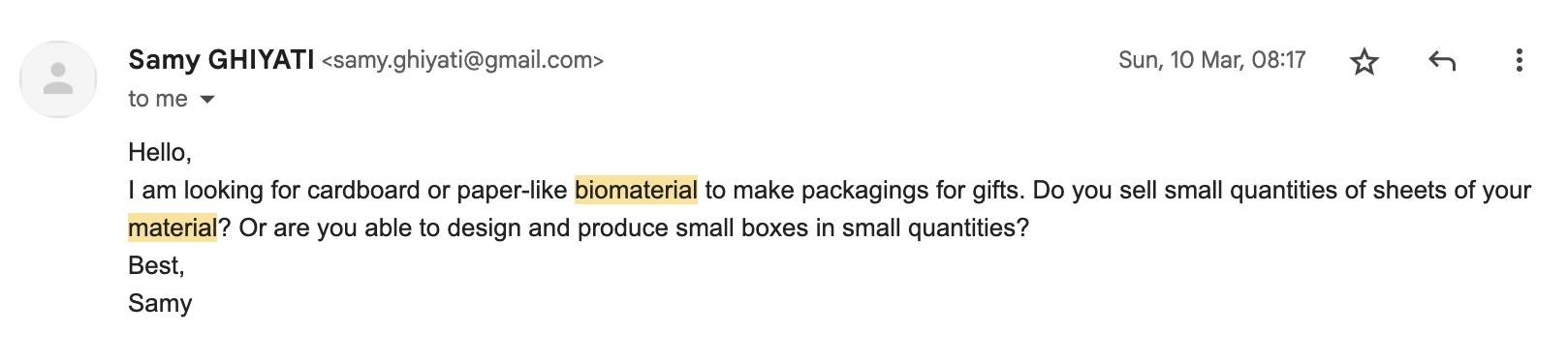

EXPRESSIONS OF INTEREST