Issue 168 March 2023

TB 118a: electrical safety for gas engineers

Gas Safe news

Top tips for a smooth renewal

Technical Chimney/flue locations and terminations

Controls

What’s on the horizon?

WIN: A whole home smart heating system with tado°

Issue 168 March 2023

Gas Safe news

Top tips for a smooth renewal

Technical Chimney/flue locations and terminations

Controls

What’s on the horizon?

WIN: A whole home smart heating system with tado°

16 Viewpoint

If our trade is to survive and help the UK transition to a low-carbon future, we must embrace a complete transformation of training

Issue 168 March 2023 04

36 Underfloor heating Mix and match UFH with radiators for a perfect result; top tips for hassle-free installation

39 Plumbing

The role of thermostatic mixing valves in creating a smarter, more costeffective environment

11

focus Why HHIC is encouraging you to have your say on the industry’s future by responding to the government’s consultation on improving boiler standards and efficiency

31 Controls

What could be in the pipeline as the government consults on new measures for controls with heating systems? How much do smart thermostats really save? The role that smart heating controls are likely to play in 2023

Another month, another government department reshuffle. RIP Business for Energy and Industrial Strategy and hello to the Department for Energy Security and Net Zero.

It’s encouraging to see a tighter focus on energy, with key ministers – including the Secretary of State – staying in post for a change.

The new department has set out its priorities for the year, including bringing down energy bills and ensuring the security of our energy supply.

The universal energy bills support scheme will end this month, but it may continue in some form with more targeted support. It’s been a lifeline for many during the winter and homes and businesses will be watching for further announcements.

The other half of the departmental double-act is net zero, and it’s already said that it will ensure that the UK is on track to meet its commitments, speeding up delivery of the network infrastructure and domestic energy production.

‘Governance of the energy system’ will come under the spotlight too, which could see Ofgem’s role under scrutiny, particularly in the light of its oversight of some energy companies found recently to be installing prepayment meters forcibly

Nicki Shearer, editorGas Safe Register, PO Box 631, DARLINGTON, DL1 9GD

Email: enquiries@gassaferegister.co.uk, register@gassaferegister.co.uk or technical@gassaferegister.co.uk

Managing editor: Scott Darroch scott.darroch@gassaferegister.co.uk

Editor: Nicki Shearer editorial@registeredgasengineer.co.uk

News: Jennie Ward news@registeredgasengineer.co.uk

Publisher: Peter McCreary publisher@registeredgasengineer.co.uk

Technical consultants: Carl Banister, Stephen Gallagher, Jonathan Palmer

Production: Mark Turpin

Advertising enquiries only: Ian Carter ian@rgemagazine.co.uk

Additional print subscriptions £25 per year email: wgardiner@circdata.com, Tel 01635 869 868

The views expressed in this magazine are not necessarily those of Gas Safe Register. The publishers will accept an advertisement or other inserted material only on the condition that the advertiser warrants that such advertisement does not in any way infringe copyright or contravene the provisions of the Trade Descriptions Act. All copy is subject to the approval of the publisher, who reserves the right to refuse, amend, withdraw or otherwise deal with advertisements submitted to it at its absolute discretion and without explanation. All advertisements must comply with the British Code of Advertising Practice. ABC membership approved 19 March, 2009.

Registered Gas Engineer is written, designed and published by The Team on behalf of Gas Safe Register. 30 Park Street, London, SE1 9EQ

Many businesses will soon be receiving their invitation to renew registration. Planning and doing it early will help to make it a quick and straightforward process.

There are some simple steps you can take to make renewing your registration as straightforward as possible. It’s a good idea to get everything in place as soon as you can so that any potential issues can be resolved before your ID card runs out.

You’ll receive your invitation to renew eight weeks before your registration expires so don’t forget to renew before the expiry date. If you manage your account online, you’ll receive your invitation via email.

Make sure that all your details held by Gas Safe are up to date: once you’ve logged into your account, you’ll see the ‘Renew’ option under the Account Management menu. You then have two options: Update registration details: Choose this option first if you

need to make any changes to your registration, including adding and removing engineers. Make payment to renew: If all your details are up to date, just enter the payment details and renew.

When your payment has been processed, Gas Safe Register will email you to confirm that your registration has been renewed, and you should receive your a registration certificate and updated ID cards for you and any engineers you employ within the next 10-15 working days.

For those who are already set up to pay by direct debit, your registration will be renewed automatically and you’ll receive an email to confirm when payment will be taken.

If you don’t manage your account online, you can speak

Nine in 10 homeowners reckon they could spot the signs and symptoms of unsafe gas in their homes. And almost all (98 per cent) say that their home would be up to the challenge if a gas engineer were to knock on their door and carry out a gas safety spot check.

But when Gas Safe Register put 2,000 homeowners through a nine-question Gas Safety Challenge, just four (0.2 per cent) got all the questions right.

The Register’s national survey quizzed people on the key things they should know, including how flames on gas hobs

should look, flue blockages, boiler error codes and smells, and the sounds and sights around the home that signal something could be wrong.

Against a backdrop of stretched household budgets, one-third of homeowners say they may skip their annual gas safety check. And as well as encouraging them to get their appliances checked, the Register wants them to get more clued up on the signs and symptoms of unsafe gas appliances and the simple, free ways they can make sure their home is safe.

Its Gas Safety Challenge is a

You can now set up a direct debit to renew your registration right up until your registration expiry date. When you set up a direct debit, you’ll be able to:

• Set up the direct debit to pay once a year or in interestfree monthly payments

• Save £22 if you choose the one-off payment option because you’ll pay the online fee

• Choose either the 1st or the 18th of the month to pay your direct debit

• Amend your direct debit instruction at any time. It is covered by the Direct Debit Guarantee. You may find it quicker and easier (and cheaper) to set up a direct debit using your online account rather than by phone.

to the Customer Service team on 0800 408 5577 during opening hours. You can also use 24-hour telephone system. You’ll need your telephone PIN, which is included on your renewal invitation.

Valid qualifications?

You must have a valid core qualification – CCN1 or COCN1 – to renew your registration. Make sure all your qualifications are valid before you renew and that you have up-to-date qualifications for the categories of work you carry out.

Changing your trading title

If you’re going to change your trading title, you must request this with Gas Safe Register before you renew. The Register has to carry out additional checks, so please allow enough

time for this to be completed before your renewal date.

This is so your ID card(s) and registration certificate will have your new company name, if the change can take place. Your business cannot trade under the new name until you receive confirmation of the change from Gas Safe Register.

It’s free to change your trading title, just go online to complete the request or email: Register@ GasSafeRegister.co.uk

Don’t forget

If you don’t renew your registration before your renewal date and you wish to remain registered, you will have to re-apply for Gas Safe registration and you will lose your existing registration number.

The Register teamed up with chef Miguel Barclay to create a set of recipes designed to save money and energy – and keep families gas safe.

The imaginative and topical approach to gas safety reached millions of consumers when it caught the interest of Steph’s Packed Lunch on Channel 4, featured over two pages in the Daily Star newspaper, and aired on BBC Radio 4’s You and Yours programme.

The Gas Safe Eats menu has the potential to feed a family of four for less than £1 per dish, and is designed to be cooked on a gas hob in a fuel-efficient way.

Each stage of each recipe co-created with Miguel, the original £1 chef, includes expert tips from Gas Safe Register on how people can check that their kitchen is gas safe, along with energy-saving tips and advice from price comparison site Uswitch on reducing energy consumption when cooking.

The meals showcase delicious and flavoursome charred courgette ribbons with chilli and feta, spicy chorizo and fennel seed pasta, and chocolate pots.

You can read and download the menus at:

www.GasSafeRegister.co.uk/ winter/gas-safe-eats/

new short film that invites people to refresh their knowledge – a tongue-in-cheek take on the Daz Doorstep Challenge TV ads from the 90s and 00s – highlighting the signs and symptoms that homeowners should be clued up on, and on the lookout for, in their homes.

Gas Services Director

Bob Kerr says: “There’s a

misguided confidence among the UK public: what they think they know and how that plays out in their homes is very different. We’re all feeling pressure on our finances at the moment but taking our Gas Safety Challenge is a fast, fun and free way to brush up on what you know and to check there are no dangers hiding in plain sight.”

With the Government’s decarbonisation target to achieve net zero by 20 50, we’re here to suppor t you.

We’re committed to helping you and your customers choose the right product today, while al so providing you with the necessar y training and knowledge to prepare your business for the future. Visit our website to discover the five key future technologies worcester-bosch.co.uk/future -industr y

A reminder of what needs to be reported to Gas Safe Register under the Rules of Registration.

Do I have to report unsafe work carried out by others?

Yes. Reporting unsafe work carried out by others is a requirement under the Rules of Registration, which state: The registered business, and any of its engineers carrying out gas work on behalf of the registered business, must ensure that:

• The Register is notified of any concerns about unsafe gas work carried out by others as soon as possible

• The Register is notified of any evidence of illegal gas work found.

What unsafe work should I report to Gas Safe Register?

You can find a reporting flowchart in Appendix 7 of the Gas Industry Unsafe Situations Procedure (IGEM/G/11), which provides guidance on what and when to report poor work to Gas Safe Register. If an unsafe situation has been caused by poor workmanship or design but does not meet the threshold to report under RIDDOR, you are required to notify Gas Safe Register. You can do this by signing into your online account at www. GasSafeRegister.co.uk/sign-in and choose Resource Hub. Then select Raise a Competency Concern.

When filling in the form, please include as much detail as possible and describe any actions you have taken.

If you’re reporting illegal gas work, please choose the Report Illegal Gas Work option or email: Nonreg@gassaferegister.co.uk

What does Gas Safe Register do when it receives a competency concern?

Competency concerns regarding a registered business or

Note: Photographic evidence may help in any subsequent investigtion of an unsafe situation

You can see all Gas Safe Register’s published policies at: www.GasSafeRegister.co.uk/ policies

engineer are investigated and the Gas Safe Register Sanctions policy will be applied where required. All reports of unregistered gas work are examined by the

Investigations team, which will investigate. Where evidence of unregistered work is identified, it is reported to the relevant enforcement body.

Note: Gas Safe Register cannot share the outcome of its investigation with you, although it understands that this can be frustrating.

If you’ve ever called Gas Safe, you might have already spoken to Sam Miller. She’s a member of the Customer Service team, and she’s there to help you with any and all of your queries.

Gas Safe’s Customer Service team are often the first port of call for both gas engineers and consumers who need help. If you’ve forgotten the password for your online account, or you can’t find that email about an upcoming inspection – or anything else – it might well be Sam who gets you back up and running.

The customer service advisor joined the team last summer but her previous experience in other big organisations, including the AA and Ladbrokes, meant that it didn’t take her long to learn the ropes. “I joined Gas Safe because I thoroughly enjoy customer service work, I like speaking to people and helping them,” she says.

Sam is part of a big team: there are more than 30 advisors plus senior advisors and team leaders. That means that if she can’t help you with your specific query, there will always be someone else who can.

Always busy

It’s not just gas engineers who get in touch. The team also answer queries from consumers, from finding a gas engineer because their boiler has broken down, requesting a copy of a Building Regulations certificate because they’re moving home, or raising a concern about gas work that’s been carried out.

Whether it’s dealing with queries on the phone or on email, Sam is always busy. “On average we take 50-70 calls a day,” she says. “In the winter, we’re a bit busier with consumers: they might turn on the heating to find the boiler’s not working and they need help to find someone to come and look at it.

“And in March and April, we’re really busy with registration renewals, and the calls go up to 70-100 a day.”

Sam can deal with most straightforward queries within a couple of minutes, but sometimes

she says a call might take up to 20 minutes. “Gas engineers might have been locked out of their online account because they’ve entered their password incorrectly – or forgotten it. We can get them back in quickly.

“We can also help them find the information they’re looking for in their online account. There’s a lot of information there that they can find and download.”

If Sam and her team can’t help you with what you need, they will definitely know where else to direct you. “We can put calls through to the Technical team, and we can put you through to the Scheduling team if you’ve got an inspection coming up and

For many gas engineers, the renewals period is the only time they speak to the Customer Service team, often because they may have forgotten their online user ID or password. Sam and the team can get you back up and running quickly – but did you know that you can also reset your details online at: www.GasSafeRegister.co.uk/ forgotten-login

want to find out more,” she says. With such a broad range of queries, it’s no surprise that there’s a good deal of training for the role. Initially at Gas Safe’s Basingstoke HQ, this is in the form of shadowing members of the team, listening to the queries and understanding where to find the correct information to help the caller. Then it’s time to take the calls, with a colleague listening in and helping where needed.

“But if you’re ever in doubt, there’s always a team member or team leader to ask.”

Sam says it took her a little while to get to know her way around Gas Safe because she had returned to work after a career gap during which she brought up her two children. “But everyone was very patient and understanding and went through everything as many times as I needed it.”

Now she’s confident that she can help people with almost anything and she’s eager for the busy months of March and April, when many gas engineers renew their registration and have queries. “I’m looking forward to it because it will really test my knowledge,” she says.

Although many gas engineers prefer to manage everything to do with their registration online, Sam knows that there are those who prefer to deal with a person. “Some say they’re not tech-savvy and they want to talk to someone on the phone, and that’s fine with me.” ■

“Some gas engineers say they’re not tech-savvy and want to talk to someone on the phone – and that’s fine with me.”

A Leeds plumber has been jailed for 16 months after carrying out illegal and dangerous gas work, despite having been sent to prison previously for similar offences.

Leeds Crown Court heard that Christopher Shaw, also known as Chris Parker and trading as SOS Express Plumbing, attended an elderly woman’s home on Newport Road, Headingley, Leeds, in 2019, where he was hired to carry out gas work. Mr Shaw had been assisting the woman with general plumbing needs for a number of years and told her that he fitted the water heater in her bathroom.

The 81-year-old woman

believed that Mr Shaw was qualified to work on gas appliances and asked him to remove the gas boiler and fit a new combi at a cost of £1,157. Mr Shaw had never been registered.

Gas Safe Register investigated the work he had carried out at the house and found several issues, some of which were At Risk.

The chimney/flue was not supported adequately because cardboard had been used for this purpose both inside and outside. Nor was it adequately sealed to the structure of the building. No pipework had been connected to the pressure-relief safety valve.

The winner of our January competition was Paul Bullen from Little Stukeley in Cambridgeshire. He has won a fully automatic Siemens EQ.300 coffee machine, thanks to our friends at Worcester Bosch. Congratulations!

Turn to page 43 for details of this month’s competition.

You can send faulty boiler parts from some of the most popular boiler manufacturers to Wolseley for refurbishment or recycling and receive up to £4 per part in return.

The merchant’s test scheme at a small number of branches sees faulty components, including PCBs, diverter valves and fans, sent on to a specialist company, where they will either be refurbished and put back into the market or recycled where beyond economic repair. Wolseley customers will be able to buy a selection of Kitemarked refurbished products with a two-year warranty and at a much lower cost than buying the part new.

Most faulty parts are currently recycled as other materials or go to landfill rather than being reused.

The merchant’s Emma Conroy says: “We want to help drive a more circular economy in the domestic heating sector and believe there is customer appetite for reconditioned parts as an alternative to new ones. This new service amounts to testing the water at scale, at a time when many UK households need help with reducing costs.

“Evaluating this scheme with our installer customer base, with benefits for householders, the trade and the environment, will allow us to understand the potential for developing it further and extending it to other product categories.”

Wolseley is partnering with Heating Trade Supplies Group (HTS), which has a BSI Kitemark for remanufacturing components.

A further four issues were identified plus three instances of non-compliance with the relevant Building Regulations.

Mr Shaw had already been banned from carrying out gas work by HSE and had been prosecuted for similar illegal gas work previously, resulting in a prison sentence in 2014.

Christopher Roland Shaw, of Stonegate Farm Close, Leeds, Yorkshire, pleaded guilty to breaching Sections 3(1) and 33(1)(g) of the Health & Safety at Work etc Act 1974 and Regulations 3(1) and 3(3) of the Gas Safety (Installation and Use) Regulations 1998. He was sentenced to 16 months in prison.

The Welsh Government is consulting on the installation of carbon monoxide alarms in all homes.

It is proposing to amend the current guidance in Approved Document J to include the installation of a CO alarm for the installation of all flued fixed-combustion appliances of any fuel type in all residential dwellings, including private homes.

The policy will mean that this will apply to oil, gas (including LPG) and solid fuel. Currently CO alarms are required in all homes when a solid-fuel fixed appliance is fitted.

You can find out more about the proposals and submit your views by 28 April 2023 at: www.gov.wales/carbon-monoxide-alarms

BDR Thermea Group has acquired heat network company

Fortes Energy Systems. The Baxi parent company aims to strengthen its expertise through Fortes, which specialises in collective heat and cold networks.

Its products include heat interface units, delivery stations for heat and cold distribution systems, and distributors for underfloor heating and cooling. For Baxi in the UK, the acquisition represents a strengthening of its sustainable heating expertise and technologies to support with the

energy transition in homes and commercial premises.

Karen Boswell, managing director of Baxi UK and Ireland, says: “With acquisitions such as these, we can provide our customers with the products, expertise and training they require to decarbonise heat in the UK.

“We know there is no silver bullet technology, so the stronger we can be across heat networks, heat pumps, hybrid systems and hydrogen technology, the better we can support in the energy transition.”

JG Speedfit is offering one gas engineer the chance to win £20,000 in its latest campaign.

The company’s 15mm Equal Elbows, which are often sold as single units across the counter, are now available in promotional packs of 10 from participating stockists until 31 July 2023. Each pack contains a unique code that you can use to enter the competition.

When the competition closes, one entry will be chosen to win the grand prize of £20,000 in cash. There are also monthly draws to win one of six technology bundles, each worth up to £1,000, including a MacBook Air, LG 50” TV, Xbox Series X and lots more.

JG Speedfit will be holding trade mornings at participating merchants, where visitors also have the chance to win Love2Shop vouchers. www.speedfit-giveaway.co.uk

You can now receive supermarket vouchers in return for your Stelrad Loyalty Club points. When you sign up, you’ll receive rewards when you buy Stelrad products, which can be used to get free radiators, branded clothing, tools and other rewards.

Marketing communications manager Sarah Baker says: “The supermarket voucher option seemed like a good option for installers and their families to help with the weekly shop or maybe buy a few treats.

“We are also giving the option to donate the vouchers they qualify for to charity instead. We have a few installers who are members of the Installer Loyalty Club who already do this and like to see the value of their vouchers go to Cancer Research UK for children and young people and Bluebell Wood Children’s Hospice.”

Find out more and sign up at: loyalty.stelrad.com/register

Gas engineer Ryan Mills has voiced a new animation from Resideo, aptly named The Installer. The short film shows a typical day as an installer goes about their usual business, whatever the weather, to ensure their customers’ homes stay warm. It also highlights the important role they are playing in helping customers tackle rising energy costs by ensuring that heating systems are as energy efficient as possible.

Sales director Martin Wilson says: “Through this animation, we wanted to remind installers that what they do is appreciated by homeowners across the country. They depend on installers like Ryan to ensure their home stays warm when they need it most.

“As Ryan says, this is very

much the time of the installer. And this animation is just one aspect of our campaign to ensure they have access to the support they need. We want to help professional installers make informed suggestions to customers and know that

Resideo recognises the real difference they are making.”

You can watch the animation and find energy-saving information and advice at: www.resideo.com/gb/en/ solutions/home-comfort/ every-crisis-needs-a-hero

Women Installers Together (WIT) returns for its annual event on 4 July 2023 at London Metropolitan University.

This year the headline speaker will be Sally Kettle, the first woman to row the Atlantic Ocean twice from east to west.

The event started in 2017 for women plumbers and heating

engineers but has grown since then to include all skilled tradeswomen, women trainees and a growing group of male allies.

WIT is not a trade show: it’s a full-day event with a celebrity speaker, tradeswomen talking about their lives, round-table discussions on hot topics for

HMRC wants to help you get your tax right. You are responsible for reporting your income to HMRC, via self-assessment, if you’re:

• Self-employed as a sole trader earning more than £1,000

• A partner in a business partnership

• A director of a limited company.

If you’re not already registered for Self Assessment but should be, you need to register no later than 5 October after the end of the tax year for which you need to file a tax return. For example, if you need to file a tax return for the 2022-2023 tax year, you’ll need to register for Self Assessment no later than 5 October 2023. For more information about Self Assessment and registering, go to GOV.UK and search ‘Register for Self-Assessment’.

You can set up a Budget Payment Plan if you want to make regular monthly or weekly payments towards your next tax bill using your HMRC online account. You can choose how much you want to pay and how often, so you can plan ahead for your next tax bill. Go to GOV.UK and search Pay your Self Assessment tax bill.

women working in the skilled trades, learning, opportunities to meet sponsors – and great food.

If you employ or would like to employ tradeswomen, come along and find out what will attract them to your company.

Tickets are free for all tradeswomen and trainees at: https://WIT23.eventbrite.co.uk

A new government department has been tasked with securing long-term energy supply, bringing down bills and halving inflation. The departmental reshuffle last month (February) saw the Department for Energy Security and Net Zero replace BEIS.

The government says the move recognises the significant impact that rising prices have had on households across the country as a result of the war in Ukraine, and the need to secure more energy from domestic nuclear and renewable sources as the UK moves towards net zero.

The industry is at a turning point. The government is consulting now on proposed legislation to make heating homes more efficient and less carbon-intensive, and here Stewart Clements, director of the Heating and Hotwater Industry Council (HHIC), sets out why a response from heating engineers is vital to the sector’s future.

The government’s consultation

Improving boiler standards and efficiency includes proposals around three main areas:

• Recommendations to ensure that newly installed gas boilers are performing as efficiently as possible

• Making the case for requiring gas boilers to be ‘hydrogenready’ at the point of sale to facilitate a potential switch to hydrogen heating

• The potential role of hybrid heating systems to support decarbonisation objectives.

Around these three strands, the consultation makes recommendations on potential commissioning requirements and skills and training for engineers.

Parts of the consultation seek to build on the Boiler Plus requirements and ensure that this has been effective in improving efficiency. A review of the scheme flagged several potential barriers and opportunities to go further with regulations. Some participants suggested that a lack of monitoring and oversight of the additional measures fitted alongside gas combination boilers may have diluted the impact of the standards.

In addition, consumer engagement with, and understanding of, the standards and the products they were receiving appears to have been very limited. This could explain their lack of impact, especially in terms of the benefits delivered by certain types of room thermostats, including smart controls.

The review also highlighted that the most suitable control option for each install may not have been selected. This is where plans in the consultation have been made to tighten requirements of products to comply with Boiler Plus.

This may not stop with combination boilers. Plans to extend Boiler Plus to regular and system boilers could require pipework modification between the boiler, cylinder and motorised valve. This could entail modifications to the wiring for a significant proportion of alreadyinstalled stock. Specific knowledge and qualifications will be required, and so modifications would need to be carried out by a suitably qualified heating engineer or electrician.

Aound half of homes have heat emitters at the correct size to provide comfort at a 55°C flow temperature on an average winter day – a temperature of around 4°C. As such, there is a significant opportunity to improve boiler efficiency by recommending systems to operate at these lower temperatures for the vast majority of the year.

The proposed legislation outlined in the consultation may require heating engineers to carry out room-by-room heat-loss calculations for new and replacement installations so that lower temperatures can be used: a process that the HHIC fully supports for ensuring effective installation.

To aid with effective system balancing, auto-balancing thermostatic radiator valves are recommended by the HHIC, which also proposes a requirement in the Building Regulations for such devices on all systems. This would ensure correct balancing and therefore optimal performance at all times across new and replaced heating systems.

To ensure system sizing, room-by-room calculations and system balancing are in place and work effectively, completing Digital Benchmark as a record of the work undertaken will help to

It’s important that everyone has their say when a consultation that is set to change the future of the heating industry comes to the fore. The HHIC is calling on gas engineers across the UK to respond to the questions most relevant to their views so that the government has a clear view of feedback.

The industry must move towards a more efficient, low-carbon future in line with the UK’s 2050 net zero mandate. For proposed policy like this – which could affect the everyday work of heating engineers – it is vital that decisions are made that do not make providing suitable and efficient heating and hot water provision over-complicated. Without a first-hand perspective from heating engineers, reaching decarbonisation goals will not be realistic.

You can give your response to the consultation at: www.gov.uk/government/consultations/improving-boilerstandards-and-efficiency

provide a measure of progress and a record of completion.

Correct commissioning and installation of the boiler is crucial for the system to operate efficiently and cost effectively. But ongoing maintenance and servicing are also needed to ensure that they stay safe and efficient. Lack of regular maintenance means that performance is likely to degrade over time. As suggested by the National Energy Efficiency Association, and encouraged by the HHIC, mandating servicing and using Digital Benchmark for the records would be a solution to implementing this across all homes.

The proposed mandating of hydrogen-ready boilers and potential legislation around hybrid heat pump systems are what could vastly change your work.

If hybrids are included in legislation, then our view is that an installation standard is required. Detailed product knowledge for each system will inevitably be required and so heating engineers will need to undertake manufacturers’ training courses.

If the hydrogen economy grows further, gas engineers will also need to train for 100 per cent hydrogen installations. ■ • See page 31 for more detail on the proposals for controls.

Registered Gas Engineer wants to see your pictures – whether you’ve come across some horrors or instances of really good work. Please email your stories and pictures to editorial@registeredgasengineer.co.uk or via Twitter to @RGEMag

Darren Gough was called out after recent roofing work: the roofer had re-connected the chimney/flue on a warm air heater using a sheet of rubber to join two sections of flue and then wrapped it in parcel tape. Darren made safe until the chimney/flue could be repaired.

Duncan Gordon attended a water leak at a boiler and found someone had applied silicon to the sump cover rather than using the appropriate sump cover seal. The correct seal has now been fitted.

Murat Karakas found a water isolation valve used on the gas supply to a hob. He made safe and fitted the correct gas isolation valve.

We may share some of your pictures on social media, so remember to include your contact details so we can tag you (or let us know if you’d rather we didn’t).

George Cox was quoting for a new boiler when the customer asked him to check a pipe in the lounge that was covered with bubble wrap, masking an open-ended gas pipe. The pipework has been made safe.

Scott Graham was asked to re-light the pilot on a back boiler unit after the gas mains in the street had been renewed. The BBU was badly corroded and had not been serviced in several years: a new boiler has now been installed.

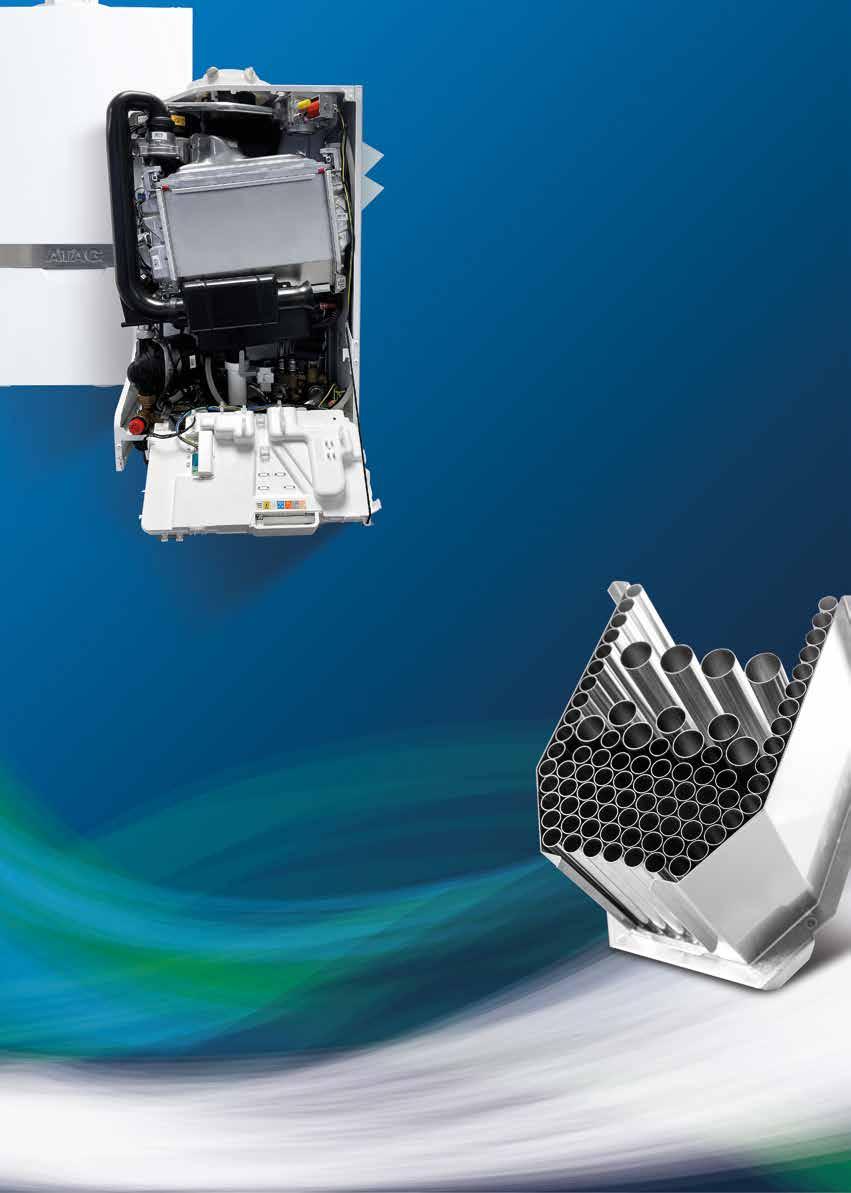

Smooth tube design delivering continuous high efficiency

0.6mm wall thickness means faster heat transfer

Angled mount to remove excess air improving performance

Easy to release burner cassette for ease of maintenance

Made from quality stainless steel for durability and longevity

BECOME AN

It’s so reliable, it comes with a lifetime guarantee!

I read with interest the letter on fast-track training (January 2023). I’m at the other end of the scale: after leaving school at 15, I completed an apprenticeship in gas fitting with North Thames Gas Board.

Now, after 57 years in the industry, I’m deemed to be unqualified to work on gas. Because my computer skills are zero, I was unable to complete an online assessment. Gas Safe said they would arrange a site inspection but I do very little gas work – the last job I did was last April. After some discussion, it was decided that I would not renew my registration in March. Gas safety comes with experience!

Geoff SandfordIn the January issue (Letters), a gas engineer made a point about “why is fast track training allowed?”

Lots of experienced engineers, including myself, are always discussing this and would love to know what the reason is. Some/most are coming into the trade with no experience but are going on the Register. We just can’t understand how this is allowed to happen.

Anthony BennettWith reference to the debate between Graham Hawkes’ letter on how the UK should make use of our own gas reserves under the ground to preserve our independence of supply to help keep costs down, versus Dan Mitchell’s view that green technology will bring reducedcost electricity to power our electric future.

I will ask the question: why is electricity the most expensive energy now? Apparently, it costs more per mile to run an electric car than a petrol car now, if charged at a charging station,

because there’s 20 per cent VAT added, whereas, if charging at home, there’s only 5 per cent VAT. That’s quite a price disparity. As people switch over to electric vehicles, the government will not have the massive amount of tax income from fuel duty and it will be added on elsewhere.

There is also the issue of exporting “dirty work” while bragging that we are environmentally clean. If we import oil, gas and coal and our green technology depends on lithium and other rare earth

materials, we’re really just swapping one source of pollution for another in someone else’s country.

Pollution can only be tackled globally and the way forward is not so simple. But I think we should do more for ourselves in this country, which would cut down on shipping goods around the world as well as cutting down on exploiting poorer countries and their people just to make goods such as mobile phones and vacuum cleaners cheaply to maximise profits.

Nigel MooreI have 45 years in the gas service engineer trade: 30 years at British Gas and 15 years contracting. However, the price to carry out a gas service and CP12 check per property has not increased in 15 years, despite more factors to check for the record.

Is this fair? The pay ratio is five times less per job than the private sector and still around £20 per property to service or inspect for CP12s.

My agency even takes a cut on standby pay and CO alarm fitting incentive on top of the mass they earn per job/hour!

Market median pay with union and HR negotiations is missing from self-employed subcontractors and inflation is not taken into account. Any ideas, fellow Gas Safe engineers?

Name withheld

We are on the cusp of a change in history: if our trade is to survive and help the UK transition to a low-carbon future, we have to embrace a complete and utter transformation of training, writes gas trainer and assessor Joshua Graves.

We have to completely change the training of new gas engineers and the upskilling of our current workforce to be able to deliver a transition to hydrogen.

Getting the training right is going to be extremely important. There are many people who are far cleverer and more qualified than me, brimming with excellent ideas, innovations, research and ways to deliver the transition to hydrogen. However, to bring those ideas to life safely, we are going to need an army of well-trained and competent gas engineers.

Very soon – within the next five to 10 years – we are going to face a large skills gap. More than one-third of gas engineers are in their late 50s to 70s. The oldest person I have personally retrained is 77 years old. Engineers such as

Joshua Graves is a gas trainer, assessor and IQA at specialist centre Southwest Peninsular Training. He has carried out research in his classroom and centre into how training for the transition to hydrogen from natural gas would be affected and how he believes it could be improved.

and its future. Where do entrants invest their time? Do they go down the heat-pump route, solar, F-Gas training for air conditioning, or do they stake their future career on gas? The choices that they make will be critical to the future of the gas industry.

Many thousands will need to be trained to replace those lost through natural attrition and to fill the gaps left by an ageing workforce. The entire current Gas Safe registered workforce will require upskilling to meet the requirements for hydrogen, all with

learning programme (MLP). The cost of a domestic MLP typically can be £2,000-£3,000 – but it can be as high as £8,000, depending on class sizes and the centre.

Colleges tend to be cheaper and account for most courses but often take far longer to train entrants because the gas option is included in some Level 3 plumbing courses, which can be four years long. A typical MLP can take up to three years to complete but has a minimum six months’ duration.

The domestic MLP has also just been made harder. Since September 2022, the hourly in-centre training requirement is now 266 hours for core, 35 hours for CENWAT and 7 hours each for CKR1 and HTR1, etc.

being made more difficult and more expensive to join.

There was a surge of online qualifications during the Covid pandemic. Now IGEM/IG/1, which covers the standards of training required for new entrants, insists that all guided learning hours need to be taken under the direct supervision of a trainer either in the classroom or online through webinars etc. This is very inflexible and creates the time commitment problem.

I believe that if we are to completely and utterly transform our industry, we need to embrace online learning and put more emphasis on enabling the student to carry out their own research.

these are on the verge of retiring and they regularly tell me that if they have to retrain for hydrogen at this stage in their career, that could be their tipping point to retire earlier than planned.

It’s not just engineers who are looking to leave. Older trainers, assessors, IQAs (internal quality assurers) and EQAs (external quality assurers) are making the same considerations, which will reduce the availability and the quality of training for future engineers.

This is in addition to another challenge facing new entrants: choice. There is a great deal of uncertainty over the gas industry

fewer and fewer training centres and trainers to accommodate the demand. Training centres and colleges will require upgrades to their equipment and assessment procedures.

Alongside the transition, regular gas work will still need to be carried out on breakdowns, repairs, upgrades and replacing faulty equipment. It all poses a very significant challenge.

But there are barriers to training. To become a Gas Safe registered engineer, you need to take a route of entry such as an initial gas qualification through a managed

If an entrant now wants to undertake the CCN1 core with boilers, cookers and fires as appliances, it will take 43 days plus an extra four days for the MLP exams and then a further five days for ACS assessment. So 52 days are required in training and assessment, which can cost tens of thousands of pounds.

As a business owner, what choice do you make? Air source heat pump courses, oil, F-Gas and electrical qualifications can all be gained as short courses delivered in far less time for less cost with fewer prerequisites. The gas industry is losing new entrants simply because it is

My proposal is this: we could take all the classroom theory (at least the first 10 days of an MLP) and turn it into an initial course that anyone can take, rather like the theory driving test. Young people are generally very IT-literate and classroom training is being viewed as less valuable: after all, it’s only as good as the trainer’s knowledge and understanding of the subject.

If the new entrant enjoys what they learn online, then they are engaged from the outset. A mixture of videos, simulations, written assignments and tests could make the training more varied and easier to absorb for a wider range of learners. Translation of the online content would also be far simpler and make learning much more accessible. Another benefit is that anyone who feels it’s not for them can abandon it without wasting the trainer’s or employer’s time.

“Classroom training is being viewed as less valuable: after all, it’s only as good as the trainer’s knowledge and understanding of the subject.”

We place a strong emphasis on continuous professional development (CPD) and engineers are required to be computer literate and able to do research for themselves. So why not train them this way from the start? They could then understand and use, for example, the IGEM Hydrogen Knowledge Centre, more effectively.

Online courses open the doors to a wider pool of people, bringing greater diversity to the industry. Upon successful completion of the online course, the learner could sit a reduced MLP with a Gas Safe registered company to gain the practical skillset, greatly offsetting the cost of training to the individual and the employer.

Personally, over the past two years, I have used online courses to gain my assessor and IQA qualifications. I am currently studying Honour’s Degree-level Health & Safety, which is all online at my own pace, time and convenience with very little interaction with my tutors and with no in-class time.

We need to move on Online learning is a powerful tool with huge benefits and we are

missing out. We must move on from traditional training and assessment mindsets and techniques if we are to recruit, retain and upskill more engineers.

The assessment process itself could benefit from online learning. Instead of the ACS burden of a series of exams and assessment every five years, why not make online learning a CPD requirement?

Here, the engineer might have to study for a regulated number of hours per year to keep up to date, but at a time and location convenient to them, and with only a smaller set of assessments every five years.

This could also bring down the costs and reduce the load on the engineer being re-assessed, as well as the training centres, which could focus more time on training new entrants. It would also ensure that there are no large gaps in an engineer’s knowledge in the five-year span: technology will have to move very quickly in this transition.

I would also recommend standardising the in-class practical training for new entrants to a set of 18 days for all core qualifications, so that every

32.5 million

engineer, regardless of how they joined the industry, receives the same level of input and supervision from the trainer.

The additional benefit of putting the theory online and minimising time on in-person training is that a smaller number of colleges and training centres can potentially train engineers far more quickly to meet the needs of the transition to hydrogen. And augmented reality could be brought in for some practical tasks such as fault-finding.

There is also the possibility of further reducing the practical elements of the cores: for example, hot works such as soldering can be replaced by pipe jointing methods such as press fitting and corrugated stainless steel tube. Some sites don’t allow

Between 1966 and 1978, 32.5 million appliances were converted from town gas to natural gas for 13 million domestic customers.

hot works so could having to train soldering be removed from the practical? Yes it could, in some instances, which could allow for further reduction of in-class time.

Embrace the new

It took 12 years for the last transition from town gas to natural gas and now we need to train a workforce capable of delivering a transition to hydrogen. We must embrace new ideas, innovation, research and training methods and step out of our comfort zones to achieve this.

It’s a once-in-a-generation change that could deliver a carbon-neutral future for years to come, and it’s an exciting time to be part of the gas industry.

Is it going to be a challenge? Yes. Is it impossible? No. ■

Safe to touch and/or safe isolation and proving electrically dead on low-voltage single-phase supplies (below 1000 volts) Date issued: 1 February 2023 Date of review: 1 February 2025

Note: This version of Technical Bulletin (TB) 118 replaces the version originally published on 30 January 2018, which is now withdrawn. This version has been reviewed and revised where appropriate to ensure that it remains both current and relevant.

This TB provides information and guidance only relating to safe-to-touch and safe isolation procedures on low-voltage single-phase supplies when carrying out gas work. A version of this TB concerning multi-phase supplies and earth loop impedance will follow. This TB should be read in conjunction with other recognised and approved guidance. This TB has been developed with a committee made up of industry members and will be reviewed periodically.

Time should be taken before attending site and before work starts to assess the risks associated with the work to ensure that those involved have the necessary competence and equipment to work safely.

The health and safety enforcing authorities in all geographical areas covered by Gas Safe Register, ie, Great Britain, Northern Ireland, Isle of Man, Guernsey and Jersey, regard the guidance in this Technical Bulletin as a best-practice requirement and would expect all Gas Safe registered businesses/engineers to apply the requirements of this TB when and where appropriate circumstances/relevant appliances are encountered.

For details of current health and safety legislation, gas safety legislation, building legislation and industry standards for the geographical areas covered by Gas Safe Register, see the Legislative, Normative & Informative Document List (LNIDL)(1) by logging into your online account at: www.GasSafeRegister.co.uk/sign-in

Check with the responsible person that it is acceptable to isolate the equipment/circuit, and that any other electrical items connected to the circuit are OK to be shut down.

Select an appropriate no-contact voltage detector. The device must be checked for damage and verified on a proving device or known live source. All test equipment should be of a proprietary design and be manufactured to BS EN 61010-31, BS EN 615572 or BS EN 61243-3.

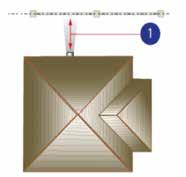

No-contact live circuit detectors (voltage sticks): Due to several fatalities over the years, it has become custom and practice in the gas industry to use a single-pole or no-contact live-circuit detectors (sometimes referred to as voltage sticks – see Figure 1). These are used prior to touching appliance casings, gas and water pipework to ensure a dangerous voltage is not present due to a fault condition.

HSE Guidance Note GS38 (Electrical test equipment for use on low voltage electrical systems, fourth edition) states that no-contact live circuit detectors (voltage sticks) should only be used for identifying live equipment, not for proving that it is dead. Therefore, further appropriate tests must be used to prove equipment is electrically dead prior to undertaking work.

In all cases, manufacturers’ instructions must always be followed when using a no-contact live-circuit indicator.

Electric shock is defined in the current version of BS 7671 (IET Wiring Regulations) as a dangerous physiological effect resulting from the passage of electric current (amps) through the human body.

Sometimes this passage of current can lead to nothing more than some small discomfort to the person receiving the shock, while at other times it can result in fatality of the person(s) receiving the shock.

The guidance in this TB should be applied in premises supplied with low voltage in a single-phase provision. The following 1-12 steps correspond to the guidance in the diagram found in Appendix 1 of the Technical Bulletin.

Two-pole voltage indicator/test lamp: Because it is vitally important to ensure that the appliance/equipment is electrically dead before any work commences, an approved voltage indicator (Figure 2) or a test lamp (Figure 3) will be required to prove this.

HSE recommends that a multi-meter is not used for proving dead (HSG85(2) ).

Before using any voltage indicator or test lamp, it is vitally important to test them on a known supply or proving unit before and after use.

Proving unit (Figure 4): This provides a reliable and repeatable means of supplying a voltage reference to check the function and serviceability of safety-critical test equipment, ie, voltage detectors and test lamps.

Due to proving units supplying lethal voltage levels, relevant manufacturers’ instructions must be followed when using these devices.

Use the no-contact voltage detector to perform a sweeping scan of all exposed surfaces of the appliance casing and all exposed metal pipework, both connected to and in close proximity to the appliance/gas meter installation.

If the no-contact voltage detector indicates the presence of voltage, stop the procedure immediately and inform the customer that the installation requires the immediate attention of a suitably electrically competent person.

If a fault is found, the follow-up actions on site to ensure the installation is electrically safe will depend on the situation. Therefore, the engineer will need to carry out a suitable risk assessment and/or obtain advice from a suitably electrically competent person. An example of a notice to leave with the responsible person is given in Appendix 2.

Where the no-contact voltage detector does not indicate any voltage on the appliance casing/gas meter and any connected/ close-proximity pipework, return the device to a known live source of power – eg, a live 13A socket-outlet – and confirm that the device indicates the presence of 230V (indicated by an audible tone and/or illumination of the device tip).

Identify the point of isolation for the appliance to be worked on. Select an approved two-pole voltage indicator (GS 38 approved) and verify it is working, either on a proving unit or known live supply.

Verify that the appliance is functional (if this is not the case, checks may be required to verify the circuit), and that it is supplied by only one power source. Once this is done, proceed to isolate the appliance:

• Turn off the circuit by the switched fuse connection unit (SFCU) (Figure 5)

• Remove the plug from the socket-outlet (Figure 6)

• Remove the fuse

• Circuit-breaker (MCB) on the consumer unit (Figure 7) Fit an appropriate locking-off device and warning label for isolation and identified work to the isolation point. The person carrying out the work should retain the key.

Plug and socket-outlets: Switch off the socket outlet (if switched) and remove the plug from the socket supplying power to the appliance/installation being worked on. Remove the plug fuse if at all practicable. If the plug and socket outlet is not adjacent to the equipment being worked on, the plug will need to be secured against inadvertent reconnection by another person. There are several proprietary devices available for this.

Switched fuse connection unit (SFCU): Switch off the SFCU (if switched) and remove the fuse. Using a proprietary locking-off device (Figure 8), secure the fuse carrier in the open position. The removed fuse (and the key to any padlock(s) used) is to be retained on the person of the individual carrying out the work. Do not leave the fuse in open view/adjacent to the SFCU.

Consumer unit MCB: Switch off the MCB controlling the circuit supplying the appliance/installation being worked on. Lock off the MCB using a proprietary lock-off device (Figures 9 and 10). The key to any padlock(s) used is to be retained on the person of the individual carrying out the work. Insulation tape must not be used to secure an MCB in the off position.

Note 1: SFCUs are not always double-pole Note 2: It is important to ensure that all other terminals, such as pump over-run, switched live and any external connections are ‘dead’

Important: The neutral coming into a property with a TT earthing system may not be at earth potential. Therefore when working on TT systems it is essential that the means of isolation being used disconnects all the live conductors (line and neutral).

Consumer units: Where fused consumer units are encountered, remove the fuse (and if applicable the fuse carrier) that controls the circuit supplying the appliance/ installation being worked on. If the fuse carrier cannot be withdrawn, a lockable fuse insert shall be used. The removed fuse (and the key to any padlocks used) is to be retained on the person of the individual carrying out the work. Do not leave the fuse in open view/adjacent to the consumer unit.

Warning notices: Regardless of the method adopted to lock off the source of supply, warning notices should also be posted to inform others that work is being carried out on the electrical system (Figure 11).

Verify the appliance is isolated. Use the approved two-pole voltage indicator device to verify the circuit is dead by testing between all conductors. Test between:

1. Earth – line

2. Earth – neutral

3. Neutral – line

Note: There can be a residual amount of voltage (up to 15V) detected between the neutral to line. This would still be deemed a dead circuit. It is good working practice to check all line terminals (permanent line, switched line, etc) for the presence of more than one power supply serving the installation.

Once the test has been carried out, and the circuit is deemed to be dead, re-check the two-pole voltage indicator is still functional on the same proving system as Step 5 of the flow diagram in Appendix 1.

Once all the above checks have been carried out, it should now be safe to carry out the work required. Always remain vigilant and re-check the circuit with the two-pole voltage indicator and proving device when moving away and returning to the appliance.

After completing the work, inspect and test to ensure that no damage has occurred. Remove the locking-off devices, locks and labels and restore the electrical supply. Once the supply has been re-energised, test the gas appliance for correct and safe operation (eg, 26/9 checks as per GSIUR). Complete and issue any appropriate documentation.

It is important that the person carrying out the work is competent to undertake the task in hand. They should also be aware of any specific requirements that may be placed upon them by the type of environment they are working in, for example, there may be a need for a permit to work in certain circumstances. Further guidance can be found at:

• www.hse.gov.uk/electricity/

• www.hse.gov.uk/pUbns/priced/gs38.pdf

• www.electricalsafetyfirst.org.uk/media/1201/BestPractice-Guide-2-Issue-3-.pdf

Note: For general information about the process behind the development of Gas Safe Register Technical Bulletins and the expectations for all stakeholders, see TB 1000(3) by logging into your online account at: www.GasSafeRegister.co.uk/sign-in

Bibliography

(1) LNIDL – Gas Safe Register Legislative, Normative & Informative Document List

(

2) HSG85 – Electricity at work - Safe working practices (HSE Books)

(3) TB 1000 – An introduction to Gas Safe Register Technical Bulletins

Appendix 2

An example of an electrical safety advice notice to be left with the responsible person:

ELECTRICAL SAFETY ADVICE NOTICE FOR YOUR SAFETY: THIS IS NOT A CIRCULAR Address:

Date:

To whom it may concern, Whilst carrying out an electrical safe-to-touch check in accordance with Technical Bulletin 118a, an unexpected result was recorded. This may indicate that the gas appliance casing/ installation pipework has electrical voltage present on the metallic parts and therefore I am/we are unable to work on your gas installation.

I/we would therefore recommend that you contact an electrically competent person to carry out further electric tests to ascertain if the electrical system at your property is safe for continued use and complies with current electrical requirements.

If your property is rented, please pass this information to your landlord/managing agent immediately.

If you should require advice on how to contact a local registered electrician, visit the Electrical Safety First website: www.electricalsafetyfirst.org.uk/find-an-electrician/ and visit the ‘Find an Electrician’ page.

I am/we are unable to proceed with any further gas safety tests/checks at your property at this time until an electrically competent person has tested and proved that your electrical system is safe for continued use.

Yours faithfully

PLEASE DO NOT IGNORE THIS ADVICE IT IS FOR YOUR SAFETY

Appendix 3

Below is a useful checklist to help you ensure that all steps have been completed:

Step Action required Pass

1 Check with responsible person that it is acceptable to isolate the circuit/equipment

2 Select an approved no-contact voltage detector. Check for damage and verify voltage detector on a known live source

3 Carry out sweep check on appliance/gas meter and any associated pipework as per no-contact voltage detector manufacturer’s instructions. If no voltage is indicated, re-check the no-contact voltage detector on known live source

4 Identify the point of electrical isolation for gas appliance that is to be worked on

5 Select an approved two-pole voltage indicator. Check for damage and verify on known live source or proving unit

6 Verify that the gas appliance is functional

7 Identify suitable means of isolation for the gas appliance

8 Isolate the gas appliance

9 Fit appropriate lock-off device and locks to isolation point. Fit warning label for isolation and identified work

10 Verify the gas appliance is isolated using two-pole voltage indictor

11 Re-check the two-pole voltage indicator is functional as per Step 5

12 Gas appliance should now be safe to work on

After completing the work, inspect and test to ensure that no damage has occurred. Remove the locking-off devices, locks and labels, and restore the electrical supply. Once the supply has be re-energised, test the gas appliance for correct and safe operation (eg 26/9 checks as per GSIUR). Complete and issue any appropriate documentation.

During the periodic review of Technical Bulletins in late 2021, it was highlighted that TB 118 – Safe isolation of gas appliances – included information that was out of date and that it should be updated.

Given the importance of the Technical Bulletin – it is the most downloaded Technical Bulletin in Gas Safe Register’s online library – a committee came together to review and update it, with a membership of experts from both the gas and electrical industry. The process involved many meetings and long discussions into exactly what information should or shouldn’t be included.

It quickly became apparent that there was too much information for a single Technical Bulletin, and so the committee agreed that TB 118 should be split in to three parts:

• Part A: Safe isolation of single-phase low-voltage supplies

• Part B: Safe isolation of multi-phase and high-voltage supplies

• Part C: Earth loop impedance. The first part of the TB should be the most commonly used section and so TB118a: Safe to touch and/or safe isolation and proving dead on low-voltage single-phase supplies (below 1000v) was set in motion.

The committee spent many hours honing and perfecting the wording to be used, drawing on the immense knowledge and experience of its members. This wasn’t always easy, and there have been many changes and corrections before getting to the final version that is now available.

Once the committee had agreed on the content of the TB,

it was decided that, for the first time, Gas Safe registered engineers should have the opportunity to give their opinion on it. Last autumn, Gas Safe Register hosted a draft version of TB 118a and invited gas engineers to view and comment on the draft, highlighting this move in Registered Gas Engineer magazine.

When all the comments had been received and collated, the committee reconvened to pore over them and updated the Technical Bulletin to reflect some of this feedback.

Finally, the Technical Bulletin was finished and ready, and on 1 February 2023, TB 118a Safe to touch and/or safe isolation and proving dead on low-voltage single-phase supplies (below

1000v) was published and uploaded to the engineer portal on Gas Safe Register’s website. But this isn’t the end of the journey. Alongside the regular Technical Bulletin, we’re trying something new. With the help of the committee member from NAPIT, an infographic style of the TB has also been produced. We are aware that the current style of Technical Bulletins can appear a little dated and so we want to know if it might be possible to update and breathe some fresh air into them.

We do need to point out that there are still considerations that need to be factored in around accessibility and that the original style may need to stay.

Look out for more detail on the infographic style of TB 118a in the next edition of Registered Gas Engineer ■

Many flue installations that don’t comply with the standards and regulations result in an unhappy customer or disgruntled neighbour. Gas Safe Register’s Technical Team set out the factors that must be considered when locating a boiler/chimney and its termination point.

When considering the installation of a new or replacement chimney/flue, you should examine the site thoroughly to prevent issues arising in the future. Similarly, when assessing an existing installation, you should do the same to ensure the safety of the installation and the customer, and to make sure that it’s in accordance with current standards and regulations.

You’ve probably encountered many flue installations that don’t meet the current installation criteria, generally resulting in an unhappy customer and/or neighbours. The majority of these situations could have been avoided if there had been more careful planning at the outset.

The chimney/flue route and its termination ensure that the products of combustion are discharged safely. We know that many an existing installation’s chimney/flue does not comply with current standards and regulations, which means that the current location is not suitable for a new boiler installation.

To start, it’s essential to make sure that when the installation is complete it will be in accordance with all the current editions of the relevant documents (see Guidance and Regulations on the next page).

BS 5440-1:2008 states: “The chimney outlet shall not be obstructed. Any obstructions such as TV ariels, small wind turbines mounted on the chimney stack or nearby and above the chimney outlet and trees shall be removed or the chimney outlet sited elsewhere.”

The main function of the chimney for both room-sealed, and non room-sealed appliances is to remove the products of

combustion and effectively discharge them to the outside air under all weather conditions. This is achieved by choosing the correct terminal and location.

The openings in these terminals are sized so as to prevent the ingress of foreign matter that could seriously impair the flue performance. Under certain conditions, pluming can occur at the flue outlet and so its installation in an area where this could cause a nuisance should be avoided.

When surveying a site for a

potential new installation or when working on an existing installation, look for issues that could be problematic now or in the future. These could include lightwells, car ports, property boundaries and vertical flue installations that may end up close to windows. Don’t forget about Velux windows: if the proposed chimney/flue route is vertical, it would be good practice to discuss the possibility of future Velux windows with the property owner, as a later alteration could prove costly.

It’s best to avoid light wells as a location for a new chimney/flue and to find an alternative location. However, if you cannot find an alternative, refer to BS 54401:2008 for guidance on installation in a lightwell. Please remember that this location must also be permitted by and in accordance with the manufacturer’s installation instructions.

Chimney outlets shall be sited so as not to discharge within the curtilage or confines of any basement area, light well or external space formed by a retaining wall or passage unless provision is made to ensure the safe disposal of the flue gases, as follows:

• Chimney outlets from roomsealed appliances and fanneddraught non room-sealed appliances may be sited in such areas provided that they are not sited more than 1m below the top level of the basement area, light well or retaining wall.

• Chimney outlets from roomsealed appliances and fanneddraught non room-sealed appliances may be sited in a basement area or light well where this is formed by a single retaining wall that creates an uncovered passageway at least 1.5m wide. This shall only be done if the passageway allows free air circulation beyond and around the ends of the structure and the retaining wall, if the passageway terminates above or at ground level, and if unobstructed air movement can take place at the open ends of the passageway.

Some appliance manufacturers do not permit the termination of a condensing boiler chimney/flue within a car port. Others do but specify that the guidance in BS 5440-1:2008 must be followed.

This guidance sets out that when a terminal is to be sited in a

car port or building extension, the following additional recommendations apply:

• The car port or add-on extension must have at least two open and unobstructed sides.

• The distance measured vertically above the terminal to the underside of the balcony or car port roof should be at least 600mm for natural-draught balanced flue, and 200mm for a fanned-draught room-sealed flue.

• If there are any openings under the car port that communicate with the inside of the property, such as opening doors, windows, or air bricks, the distance from these should be no less than 1200mm.

• If the roof is made from a plastic material, the installation should be treated with great care due to there being no simple method of protecting the roof against potential heat damage.

The chimney/flue is not sealed to the wall or has been sealed with incorrect materials

The appliance chimney/flue must be sealed to the building fabric internally and externally in accordance with the manufacturer’s instructions. Any material other than mortar used for this purpose must be confirmed as acceptable by the appliance and sealant manufacturer. Refer to Technical Bulletin 152

The horizontal flue pipe protruding from the wall has not been cut to the specified length

This issue is encountered almost every day. Only the boiler manufacturer can confirm whether the method of termination is acceptable or not. There will generally be more specific guidance in the MIs about whether the installation is acceptable.

The flue is incorrectly supported or not screwed when required

The appliance chimney/flue must be assembled and installed in accordance with the boiler installation manual. If it is not supported correctly or screwed when required, complete a risk assessment to determine the relevant risk classification to apply. In some instances, it may be deemed to be “Not in Accordance with MIs”.

The appliance chimney/flue must be assembled and installed in accordance with the boiler installation manual. This should contain the information you need to ensure that the flue termination is safe.

Where the flue termination is positioned diagonally from an opening door, window or air vent and the required distance is not specified in the manufacturer’s instructions or BS 5440-1:2008, you must contact the appliance manufacturer for guidance, preferably in writing.

For a vertical flue termination positioned where there is an opening window or door located on an adjacent wall and the required distance is not specified in the manufacturer’s instructions or BS 5440-1:2008, contact the

However, if this information is not in the manual, you should contact the manufacturer’s technical helpline. If they can’t help, they may recommend referencing BS 5440-1: 2008. This advises that a minimum distance of 300mm should be applied from re-entry points such as opening windows and doors. A distance of 300mm is required from a boundary line adjacent to the chimney/flue termination or 600mm from a boundary opposite the terminal.

The standard also recommends not to terminate directly across a boundary line, regardless of how far away from the boundary it is. This should prevent nuisance pluming on to neighbouring patios, etc (see previous page).

appliance manufacturer for guidance, preferably in writing.

You can send the manufacturer’s response to Gas Safe Register to save to your business notes for future reference.

All vertical flue installations must be completed in

accordance with the appliance manufacturer’s installation instructions. The system must be adequately supported throughout its entire length at the distances specified by the manufacturer and using manufacturer-specified support brackets. ■

“Many existing chimney/flues do not comply with current standards and regulations, which means that the current location is not suitable for a new boiler installation.”

When deciding where a chimney/flue and its terminal should be installed, you must consult the following guidance and comply with regulations:

Gas Safety (Installation and Use) Regulations 1998 (GSIUR)

These regulations are the law and must be adhered to. Regulation 27(5) states: “No person shall install a flue other than in a safe position.”

Guidance Note 258 of the Approved Code of Practice and Guidance to the GSIUR then states: “A flue (including any terminal) should be installed in a position which ensures it will operate effectively and the products of combustion will safely disperse and not present a hazard to any person, whether in the premises in which the associated appliance is installed (eg, by being located a safe distance from openings in the property such as air vents, openable windows, and doors), or in adjoining/ neighbouring premises. The location decided needs to take in to account any possible developments in neighbouring property, eg, building extensions.”

Important: A plume management kit may not be used to circumvent the requirement to locate the flue correctly in the first instance. However, it may be an option to safely overcome a problem if the boiler manufacturer gives their permission for this. Plume management kits must be installed strictly in accordance with the appliance

manufacturer’s instructions. Installing the flue in a high position or a vertical termination is generally the best option to avoid nuisance pluming.

The chimney/flue installation must always be in accordance with the MIs. Any diversion from these must be confirmed in writing by the appliance manufacturer as being acceptable because this will provide a written record. You can find and complete a Request for Concession to the Manufacturer’s Instructions by logging into your Gas Safe Register online account and choosing the Resource Hub at: www.GasSafeRegister. co.uk/sign-in

You can also find guidance on requesting a concession to the manufacturer’s instructions in Technical Bulletin (TB) 158.

These regulations are the law and must be adhered to: in some instances, the appliance instructions will refer you to these regulations. You can download the Approved Document and its guidance free from www.gov.uk

This standard gives guidance on how to comply with the relevant regulations. You should use it where there are no manufacturer’s instructions if you’re working on an appliance or installing a previously used appliance.

Technical Bulletins cover various aspects of flueing. You can read and download them by logging into your online account at: www.GasSafeRegister.co.uk/sign-in

• TB 007: Room sealed (natural/fanned draught) and open flue (fanned draught) appliance flues terminating within covered passageways (Ginnels). Published 01/07/2015.

• TB 008 Edition 3: Existing concealed room-sealed fan draught boiler chimney/flue systems. Published 15/07/2015.

• TB 016: Room-sealed flue/chimney terminations – Possible nuisance from fumes and the use of plume management kits. Published 02/08/2017.

• TB 139: Room-sealed fanned-draught vertical condensing flexible flues concealed within voids. Published 01/03/2012.

• TB 147: Clarification between “manufactured” and “connection” chimney/flue joints Edition 2. Published 19/04/2022.

• TB 152: Securing and sealing horizontal chimney terminations. Published 02/01/2018.

Bibliography

BS 5440-1:2008: Flueing and ventilation for gas appliances of rated input not exceeding 70kW net (1st, 2nd and 3rd family gases) Part 1: Specification for installation of gas appliances to chimneys and for maintenance of chimneys

Martyn Bridges, director of Technical Services at Worcester Bosch, looks at the implications of the updates to Part L of the Building Regulations.

Part L of Building Regulations, which came into effect last year, is a significant piece of legislation that guides the industry towards the more extensive changes that will come into play in 2025. For gas engineers, it particularly affects replacing boilers and heating systems in non-domestic buildings.

The terminology has changed too: no longer are there separate documents for new-build and existing properties, and nondomestic. Instead a single document covers new and existing properties, as well as buildings other than dwellings.

Weather compensation is recommended, building on the requirements for control of heating systems and zones. There is also

more coherence on the required interlocks between room control, boilers and pumps – an area that had been overlooked previously.

The long view of Part L prepares us to meet the requirements of 2025 and beyond. That means giving consideration to technologies that may not be so prevalent now, such as district heating and heat pumps. It looks unlikely that we will see boilers being installed in new properties built to these regulations.

In existing properties, the replacement of boilers is also touched upon, with increased emphasis on cleansing and flushing and the installation on system filters.

It is an additional legal requirement for installers to provide

information, within five days of the work being completed, on how to use installed building services so that they can be operated efficiently. Information on the correct use of heating and hot water controls is an obvious part of this requirement, to help occupants understand the best way to use the controls to maintain comfort and minimise their energy use.