How to calculcate heat loss correctly

Gas Safe news

How to make your brand work harder for you

Hydrogen Initiatives ramp up around the UK

Heat pumps

Will you be getting on board?

Win: A £400 holiday gift card from Salamander Pumps

Gas Safe news

How to make your brand work harder for you

Hydrogen Initiatives ramp up around the UK

Heat pumps

Will you be getting on board?

Win: A £400 holiday gift card from Salamander Pumps

12 News focus

We round up of some of the latest initiatives and plans to position hydrogen as a serious contender in the UK’s race to net zero

The

27 Focus: heat pumps

Are you getting on board the heat pump train? Momentum is building behind the technology in the UK’s homes; The importance of quality installation; Ignore them at your peril; Driving a low-carbon future

from Baxi, Continal, Navien and Spirotech 19

Being

inspector in Northern Ireland is a wide-ranging role that takes in everything from inspection to supporting HSENI to working with environmental health officers, says Chris White-Overton

Inside this issue, we’re delving deeper into the world of heat pumps. Considering the magazine’s title, you might wonder why one of our focus topics is a heating technology that has nothing to do with gas.

It’s because it’s becoming clearer that heat pumps are not going to just go away. The number of installers who are qualified now to fit them is a fraction of where it needs to be to achieve the government’s hugely – many would say overly – ambitious target of 600,000 installations a year in just five years’ time.

So, on top of stumping up for the existing Boiler Upgrade Scheme grant for homeowners and extending its longevity, the government is starting to address the skills gap by raiding the Treasury’s piggy bank for cash for a Heat Training Grant. Those of you who want to become qualified to fit heat pumps will be able to get £500 off the cost and many organisations are adding their own additional discounts and offers too.

Our major reader survey earlier this year showed that 7 in 10 gas engineers are considering training to work with the technology this year, which means that it’s a topic that’s becoming increasingly relevant in your world. We will continue to make sure you have the essential gas safety information you need to work safely and legally in your customers’ homes – and we’ll also make sure that you have the knowledge you might need as your work changes.

Nicki Shearer, editorGas Safe Register, PO Box 631, DARLINGTON, DL1 9GD

Email: enquiries@gassaferegister.co.uk, register@gassaferegister.co.uk or technical@gassaferegister.co.uk

Managing editor: Sue Harker sue.harker@gassaferegister.co.uk

Editor: Nicki Shearer editorial@registeredgasengineer.co.uk

News: Jennie Ward news@registeredgasengineer.co.uk

Publisher: Peter McCreary publisher@registeredgasengineer.co.uk

Technical consultants: Carl Banister, Stephen Gallagher, Jonathan Palmer, Rob Walkerdine

Production: Mark Turpin

Advertising enquiries only: Ian Carter ian@rgemagazine.co.uk

Additional print subscriptions £25 per year

email: wgardiner@circdata.com, Tel 01635 869 868

The views expressed in this magazine are not necessarily those of Gas Safe Register. The publishers will accept an advertisement or other inserted material only on the condition that the advertiser warrants that such advertisement does not in any way infringe copyright or contravene the provisions of the Trade Descriptions Act. All copy is subject to the approval of the publisher, who reserves the right to refuse, amend, withdraw or otherwise deal with advertisements submitted to it at its absolute discretion and without explanation. All advertisements must comply with the British Code of Advertising Practice. ABC membership approved 19 March, 2009.

Registered Gas Engineer is written, designed and published by The Team on behalf of Gas Safe Register. 30 Park Street, London, SE1 9EQ

Since 2009, Gas Safe Register has been your brand, with its bold yellow triangle signalling to your customers that you’re qualified and competent to work on their gas appliances. It helps you to stand out and enhance your own reputation. And it’s important to make sure that it’s used correctly so that it’s immediately recognisable as a sign of trust.

As a registered business, you are encouraged to make use of the logo and other free marketing materials that are available to you as part of your Gas Safe registration. When you log into your online account, you’ll find guidelines on how to use the brand – and how not to – as well as a host of downloadable logos, banners,

leaflets, stationery and more.

The brand is easy to use, with a simple but effective design that encourages people to ‘look for the sign of a registered gas engineer’. But it’s important to make sure that it’s represented in the right way, as using it incorrectly may cause confusion. And it’s important not to try to recreate the logo yourself: there are multiple formats available free that you can use in different marketing materials.

Did you know that, as a registered business you should only use the logo that shows the triangle on its black background? There are different versions in both colour and black and white. It’s a good idea to include your registration number underneath the logo so that your customers can find and check you on the Register.

Don’t use the yellow triangle with no background: this is for Gas Safe Register’s corporate use only.

The Gas Safe brand can only be used alongside the trading title that is on the Register. The details in your ads and any other promotional materials should be the same as the information held by the Register –for example, your business address.

The logo should be positioned in the bottom right corner wherever possible and Gas Safe strongly recommends that you include your registration number in your ads, either in the panel underneath the logo or in plain text, as shown in the images at the top of the opposite page.

123456

123456

You can use these logos: remember that including your registration number makes it easier for your customers to confirm your details on the Register.

Q: Should I use the logo in my promotional material?

A: We would encourage you to use the logo in any promotional materials such as stationery, website, leaflets and advertising to signal your competence and promote your business.

Q: Do I have to include my Gas Safe Register registration number?

A: We strongly recommend that you include your registration number in advertising as this allows potential customers to confirm that you are registered. We would recommend that you use your registration number on all your stationery and vans and clothing where practical.

Don’t do this

Please do not stretch, adjust or distort the logo, and never remove the word ‘Register’ or replace it with other words.

Gas Safe Register will protect its brand and the gas engineers who work hard to maintain their competence and registration and who are entitled to use it. It will take action against those who use the brand and logo illegally or inappropriately.

Misuse of the brand is when the brand or logo is shown by a person or business that is not registered but gives the impression that they are, whether that’s online, on stationery, vehicles or on workwear.

Businesses and contractors many not use the registration number of another company as their own. It’s a common misconception that those who sub-contract gas work to

engineers may use the trademarks: however, this is not correct. The trademarks can only be used by the Gas Safe registered business. The company sub-contracting the work should use the wording “we sub-contract to Gas Safe engineers” (also see page 8).

Registered businesses that continuously misuse the logo or do not adhere to the Register’s brand enforcement policy can be sanctioned, which could lead to suspension from the Register.

The penalties for misuse of the Gas Safe brand vary depending on how the rules have been breached. Gas Safe Register will work with the relevant authorities, including Trading Standards, to

prosecute offenders under the Consumer Protection from Unfair Trading Regulations 2008. Sentences for successful prosecution vary from a fine to community service, awarding of court costs and victim surcharges.

If illegal gas work has been carried out by someone falsely claiming to be registered by using the brand, courts can impose a prison or suspended sentence, electronic tagging or a curfew. Offenders may be disqualified from being a company director as well as being fined, and ordered to pay court costs and a victim surcharge. HSE may also impose a Penalty Notice or Prohibition Notice.

Q: I create my own stationery and marketing materials. Can I get electronic versions of the logo to use for this?

A: Electronic versions of the logos, plus instructions on their use, can be downloaded from the marketing toolkit in your online account at: www.GasSafeRegister. co.uk/sign-in

You can give these logos and guidelines to printers if they are designing and printing stationery for you.

Q: Where can I get Gas Safe branded forms and labels?

A: There are a number of suppliers that are specially licensed to create and produce Gas Safe Register branded items. You’ll find a list of these when you log into your online account.

Gas Safety Week will take place on 11-17 September 2023. As in previous years, the industry will be coming together to highlight the importance of gas safety to its own audiences, sharing messages far and wide. You can pledge your own support now and in return you’ll

receive a free toolkit full of materials so that you can join in easily. The toolkit will include logos and images, social media updates, web banners, articles and factsheets and a press release template. You’ll also be able to order free leaflets and posters.

We’ll be updating you with more information about Gas Safety Week in forthcoming editions of this magazine, along with some ideas about how you can get involved and the benefits of supporting. You can pledge your support at www.GasSafetyWeek.co.uk

“As a Gas Safe registered business, you can promote the logo to show that you are on the official list of Gas Safe engineers. Because it’s a badge to be proud of, and something consumers are encouraged to look at, we want to make sure it’s always displayed correctly.”

Rachel Craggs, Brand Marketing Manager Gas Safe Register

Gas Safe Register sets out your responsibilities for gas work and gas safety management when you use a sub-contractor.

• You must ensure that all sub-contractors who undertake gas work are suitably competent and registered

• Sub-contractors must use their own registration details on customer-facing documentation

• Your business can be held responsible for rectification of gas safety defects attributable to the sub-contractors that you use

Asub-contractor is anyone you get in to work for you who is not your employee. Using sub-contractors for maintenance, repairs, installation and other work may be routine in your business: however, there are several points to consider before you engage them to carry out gas work on behalf of your business.

The law

Under the Gas Safety (Installation and Use) Regulations 1998, all gas engineering businesses –including self-employed gas engineers – must be Gas Safe registered, whether they carry out such work as their main or part-time activity. In addition, anyone who undertakes work on a gas fitting must be competent to do so.

• You need to understand the law

• You have a legal responsibility towards your sub-contractor. They have a duty to work safely and owe a responsibility to you

• Communication and co-operation are needed on both sides, and this requires active management.

The duty to ensure that gas engineers are competent extends to other employers and selfemployed persons with control over the work concerned, ie, a main contractor, and those requiring work to be done in a workplace under their control.

As such, it is a requirement that your business should make reasonable efforts to obtain evidence that any person you intend to perform gas installation work on your behalf is suitably competent and Gas Safe registered. This may mean that the sub-contract engineer is subject to the same or equivalent quality management process that your business has in place for directly employed engineers.

The Health and Safety at Work etc Act 1974 applies to ALL work activities. It requires employers to ensure, so far as is reasonably practicable, the health and safety of their employees, as well as any contractors working on their behalf. Employers with more than five employees must also have a written, up-to-date health and safety policy.

Registered businesses are responsible for all gas work carried out by their employees in the name of the business, whether they are employed directly or indirectly, ie, sub-

• In cases of dispute where the main contractor and the sub-contractor are both Gas Safe registered, both business may be subject to defect resolution and/or sanctions, as appropriate

• Responsibility for work that is notifiable under Building Regulations should be agreed at the outset as part of the contract agreement. Where this is not agreed, the responsibility will be held with the main contractor if it is Gas Safe registered.

contracted. They must be appropriately qualified and Gas Safe registered.

Registered businesses must ensure that the engineers under their control, whether employed directly or indirectly, have the legal right to work in the UK, Isle of Man, Guernsey or Jersey, and are certified as competent in the appropriate work categories for the gas work they carry out.

Registered businesses/ engineers carrying out gas work as a sub-contractor to another registered business must use their own registration details on any customer-facing documentation. The registration details of the main contractor under whose name the work is done must also be shown on supporting documentation.

For example, where a registered business carries out work on behalf of another

registered business (contractor) on a sub-contracting basis and is not listed as an engineer against the contractor’s registration, then all documentation issued on behalf of the contractor business must also include as a minimum the registration numbers of both the contractor and sub-contracting businesses as well as the licence number of the engineer who carried out the work.

By registering with Gas Safe, your business is agreeing to comply with the Rules of Registration and all other supporting policies and guidance. Failure to comply with the rules may result in sanctions being applied to the registration, in accordance with the rules and/or policy.

You can find more information about Gas Safe Register’s policies at: www.GasSafeRegister.co. uk/about-us/our-policies ■

Viessmann Group is to combine its Climate Solutions business area with US Carrier Global Corporation to form a new transatlantic climate and energy solution partnership.

Both companies see the climate goals in North America and Europe as a once-in-acentury opportunity to make a positive impact, by actively shaping sustainable climate and energy solutions.

Viessmann Group chairman Martin Viessmann says: “Carrier is a strong partner for our Climate Solutions business. By joining forces, we will be able to uplift our impact on the decarbonisation of the building sector to the next level with more reach and scale.”

Viessmann Group activities outside the Climate Solutions business are not affected. The group will remain an independent business fully owned by the Viessmann family.

Kevin Lowe is HHIC’s new technical manager, who will instigate and manage positive change in the drive towards the successful implementation of heat pump technology.

HHIC says it is committed to supporting innovation by encouraging action on the energy crisis, decarbonisation and the future of the UK’s heating mix. Kevin has a wealth of industry experience and his role will focus on the drive towards reducing carbon emissions, delivering cost-effective energy solutions that benefit consumers.

Kevin says: “It is fantastic to be back at the heart of the industry, driving forward renewable heating progress and supporting organisations and professionals with decarbonisation.”

The Heating Installer Awards has announced its 2023 regional winners and finalists in the Rising Star and Most Sustainable Installer categories.

The shortlists have been decided by a panel of experts including representatives from the awards’ partners CIPHE, Danfoss, LG, Stelrad and Polypipe Building Products. They scored all the entries on technical expertise,

problem-solving, product knowledge and outstanding work.

The panel was also joined by the 2022 Heating Installer Awards national winner, John Cruickshank, from Cruickshank Plumbing and Heating.

Now in its eighth year, the Heating Installer Awards recognises the achievements and raises the credibility of plumbers and heating installers across the country for

delivering excellent work every day. They awards encourage plumbers and installers to nominate a project of which they’re particularly proud and which demonstrates high technicality, outstanding professionalism, and exceptional service – all resulting in a happy customer.

The regional winners and category finalists have gone through to the next stage of the awards, which involves a technical challenge and a public vote, with prizes up for grabs for the winners.

Now it’s your turn to get behind them and vote for the National Winner, Rising Star or the Most Sustainable installer. You can cast your vote at: heatinginstallerawards.co.uk/ vote

The public vote will make up one-quarter of the overall scores, alongside the judges’ scores and the scores from a technical challenge.

The winners will be announced on 28 June 2023.

The government must clamp down on the ‘swarm’ of noncompliant central heating pumps being imported into the UK, according to pump leaders.

The appeal is driven by increasing concerns that Far East exporters have penetrated the traditional merchant distribution channels to target the UK, with more than 100,000 non-compliant pumps being sold in the UK every year.

Steve Schofield, chief executive of the British Pump Manufacturers Association (BPMA), says: “We estimate that circa 10 per cent of the 1 million central heating pumps, technically known as circulators, being brought into the UK are non-compliant.

"It is a swarm, it is blatant and it is now over-the-counter. Once fitted, they are costing consumers

hundreds of pounds every year on their heating bills."

Lee Tebbatt, managing director at Wilo UK, says the key problem is in the stand-alone pump replacement market. “The stand-alone market, where a non-condensing boiler is being used with a hot water cylinder and header tank, is the target for non-compliant pumps.”

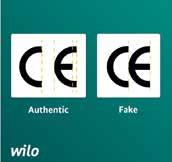

Non-compliant pumps that Wilo experts have seen are being

manufactured to look like genuine OEM pumps, sometimes even equipped with fake CE markings that stand for China Export.

Steve says the government needs to clamp down. “We have been very lax in the UK in terms of policing the market and eradicating non-compliant pumps.

“It is the legal responsibility of the importer to ensure that only compliant pumps are brought into the UK. However, legal responsibility does not stop there. It is the distributor’s responsibility to only sell CE-marked pumps and it is the installer’s responsibility to ensure that what they are fitting is compliant.

"We need the government to step in, empower the market surveillance authorities and clamp down to protect consumers and its own climate change targets.”

Worcester Bosch’s Savvy Series supports heating engineers to guide homeowners through the different options and advantages of green and future home heating technologies.

The Savvy Series is fronted by TV presenter and consumer champion Angellica Bell, with videos that provide tips on how to save money in the face of skyrocketing household bills or gain a better understanding of greener heating options for the home.

It delivers impactful energy-

saving tips to help reduce household spend and energy usage. The series simplifies greener home heating, giving the viewer a better understanding of the future technology that may be available to them and includes hydrogen, heat pumps and hybrid systems.

Martyn Bridges, director of Technical Services, says: “We’re delighted to have Angellica as the face of our Savvy Series. Her involvement will help us reach more homeowners with both energy-saving tips and the right

Intergas Diagnostic Software (IDS) gives heating engineers and their customers a new way to save energy. IDS provides instant access to the burner control units of all Intergas boilers so that the engineer can get insights on the boiler’s performance and fault history. They can also commission a boiler, produce and send detailed information on the boiler settings to landlords and build a reliable picture of its operation.

The statistical information is also available via the Intergas Dashboard’s remote management facility, but not all users are

comfortable with the level of intrusion involved in remote management, says the company.

They’ll be able to see a display of how many operational hours were spent in central heating and domestic hot water modes, for example, along with gas and water volumes used for central heating and for showers/baths/basins.

With this information, installers can advise their customers on suitable controls and relevant upgrades, including low-flow taps and showerheads to reduce water use, to improve efficiency and lower bills. All that’s needed is a

guidance to help them transition to the greener heating future.”

Cannock installer Richard Lloyd says: “Future home heating solutions – what they are, and how they can help – is something customers often ask us about. The landscape is complex for those unfamiliar with the various options, and it can be quite scary to get your head around.

“This series will really support the industry in communicating to customers in new, engaging and simplistic terms not only what the different types of technologies

are, but how customers can benefit from each one.”

www.worcester-bosch.co.uk/ savvy-series

Intergas runs a bespoke training day for IDS which covers installation and set-up, data access and storage through to advanced commissioning and evidencing. Installers who are registered with MiREG+ are eligible.

Screwfix has paid £3 million to acquire Connect Distribution Services, a retailer of appliance spares, accessories and consumables to tradespeople and consumers. The retailer was in administration but Screwfix will continue to operate it as a going concern, acquiring its e-commerce platforms, stock, intellectual property and product data. More than 400 Connect Distribution Services employees are transferring to Kingfisher.

Connect Distribution Services’ online trading brands, which include well-known sites such as eSpares, BuySpares, 4OurHouse

and the Connect Trade Portal, will continue to operate as normal.

John Mewett, Screwfix CEO, says: “I’m very pleased to be able to secure the future of the business of Connect Distribution Services and its brands for its customers, engineers and colleagues. The business’s popular ecommerce platforms have significant growth potential and they play an important role in helping tradespeople and consumers keep products in use for longer, supporting our sustainability agenda.

“As an entrepreneurial and customer-focused family business

with a 50-year history, [Connect’s] culture is a great fit for Screwfix and we look forward to welcoming our new colleagues.”

Mark Depper, COO, Connect Distribution Services ,says: “I’m delighted that Screwfix and Kingfisher have recognised the strengths of the brands and will continue to run this amazing business that my father started 50 years ago. I’m confident that this new ownership will realise the full potential of the brands.”

Screwfix is part of Kingfisher plc, an international home improvement company with more than 1,500 stores.

Rinnai has added a comprehensive 12-year warranty on all its continuous-flow hot water heaters. The heater can be fitted as stand-alone gas heaters or as a hybrid hot water system supporting solar thermal or heat pumps.

The company’s Chris Goggin says: “The introduction of our 12-year warranties are specifically designed to give all heating engineers, contractors, consultants and end-users a solution that is practical, technically and economically viable, [with] the ability to lower on-site carbon when [hydrogen] blending commences.

“When these continuous-flow water heaters approach end of life, it is expected within policy documents that 100 per cent hydrogen could well be entering the grid system and we shall be ready to ease this transition.”

In 2022, Rinnai announced its 100 per cent hydrogen combustion for continuous-flow hot water heating units and systems for domestic and commercial applications. This development complements its range of water heaters, which are all hydrogen blend-ready now.

when

£ 20 Bag cash giveaway!

We all need a bit of joy in our lives, now more than ever! So, pick up a promotional pack of JG Speedfit 15mm Equal Elbows to enter our 20 Grand Giveaway – plus more monthly prizes to be won. What would you spend it on? speedfit-giveaway.co.uk

The government is backing hydrogen production projects to further its ambitions for the UK to have up to 10gW of lowcarbon hydrogen production capacity by 2030: potentially that’s enough to power London for a year. It’s bringing forward hydrogen transport and storage infrastructure business models and aims to introduce legislative powers to support these new business models by 2025.

It’s signalled its ongoing commitment by announcing funding awards for new hydrogen projects from the £240 million Net Zero Hydrogen Fund. The Department for Energy Security and Net Zero (DESNZ) aims to replace the UK’s energy supply with cheaper, cleaner, domestic sources including hydrogen, wind and solar, power with carbon capture, usage and storage (CCUS) and new nuclear plants.

The industry is also preparing to increase its focus on designing and testing hydrogen heating appliances.

Cadent and Northern Gas Networks have each submitted design proposals for a hydrogen heating village trial to Ofgem and DESNZ. These apply for funding to convert a large village’s existing gas network infrastructure from natural gas ready for 100 per cent hydrogen. DESNZ will choose the successful village trial location this year, with a view to it being operational by 2025. The village trial is expected to last a minimum of two years and the results will help make further decisions on the potential role of hydrogen in the UK’s future heat strategy.

The Energy Networks Association (ENA), alongside Northern Ireland’s Mutual Energy, has launched new report “A hydrogen vision for the UK”, committing to a vision of how hydrogen can support decarbonisation.

The report includes detailed maps of what the rollout of the

UK’s hydrogen infrastructure could look like in the years ahead, expanding to an integrated network serving industry, homes, businesses, power generation and some transport applications by 2050.

is given the right tools and mandate to deliver its part in the hydrogen vision.

James Earl, director of Gas at ENA, says: “Gas network operators are ready to invest, innovate and deliver this vision for

Do you know your definitions? With hydrogen expected to become part of the UK’s decarbonised energy mix, the Industrial and Commercial Heating Equipment Association (ICOM) wants to make it easier to understand the different levels of hydrogen-readiness of boilers and other combustion products.

The report asks the government to show the same commitment to hydrogen network infrastructure development that it has shown to hydrogen production, expedite the development of critical business models for transport and storage, make key policy decisions around blending and hydrogen-ready boilers, and ensure that the planned Future System Operator

hydrogen’s role in the UK energy system, but we need certainty from government to let them plan with confidence. Our gas network members pledge to work collaboratively with government, the regulator, businesses and the communities they serve to explore and deliver the significant benefits that hydrogen can have to the energy system, industry, consumers and the UK economy.”

ICOM has created three types of label to signify different hydrogen products: hydrogenblend, hydrogen-ready, and 100 per cent hydrogen. The labels will help heating engineers familiarise themselves with these terms ahead of the government’s decision on grid blending, which is expected later this year.

Director Steve McConnell says: “Use of hydrogen as an alternative to natural gas is a vital step in ensuring we can decarbonise heat in the UK. As a result, there are a growing number of products entering the

“Use of hydrogen as an alternative to natural gas is a vital step in ensuring we can decarbonise heat in the UK.”

market which can use hydrogen to a lesser or greater degree. These are labelled in different ways, so it’s important that [people] understand the different levels of hydrogenpreparedness.”

Hydrogen-blend products can run on natural gas with up to 20 per cent hydrogen added. Hydrogen-ready products can use up to 20 per cent blends now and, crucially, can be converted quickly and cheaply to 100 per cent hydrogen in the future. Products considered 100 per cent hydrogen will be able to run on a full hydrogen gas network without any need for conversion.

ICOM has also produced the ICOM Hydrogen Ready Appliances Statement to establish the definition of hydrogen-ready non-domestic appliances that would be supplied with 100 per cent hydrogen, including boilers, water heaters, air and radiant heaters and burners.

100 per cent hydrogen boiler demonstration

Baxi is supplying its 100 per cent hydrogen boilers for the H100 Fife Project, a hydrogen-to-homes demonstration delivered through a partnership between SGN and Fife Council, in cooperation with Ofgem.

The H100 Fife project will see households in the Buckhaven and Denbeath areas of Methil, on the south Fife coast, able to opt in to be supplied with hydrogen through a new network due to go live in 2024.

Construction has now begun on the H100 Fife hydrogen homes demonstration facility, which is due to open to the public in the summer. There will be two show homes, where visitors will be able to try out domestic hydrogen appliances.

The scheme has already signed up more than 300 householders who want to be part of the world’s first 100 per cent green hydrogen-to-homes

Teesside University is helping a Tees Valley company bring a new hydrogen production process to market. Stockton-based Torvex Energy has developed a way to use hybrid electrolysis to generate green hydrogen from seawater.

Unlike conventional electrolysis, oxygen is not a by-product, so there is a significant reduction in energy consumption per kg of hydrogen produced. Using existing electrolysis technology, producing hydrogen required an electrical energy consumption of around 55-60kW/h per kg of hydrogen. Torvex says its method is almost twice as efficient, consuming around 25kW/h.

The Tees Valley Hydrogen Innovation Project at Teesside University helped Torvex Energy to understand the electrochemistry of its process and to verify its specific energy consumption and the amount of hydrogen it would produce.

zero-carbon network. Green hydrogen will be supplied via a dedicated ORE Catapult 7MW wind turbine connected to an on-site electrolyser and storage facility. Modelling suggests the turbine could provide the energy to produce enough hydrogen for up to 900 homes a year.

Plans accelerated

SGN is stepping up its hydrogen plans by accelerating work to develop and connect key hydrogen production and storage sites.

Over the next 12 months, the gas distribution company will undertake three studies in Scotland and southern England to determine the route and design of hydrogen transmission infrastructure to support its wider ambition to decarbonise heat in homes.

The work will also explore how existing networks can support the development of the Scottish and Solent clusters, as well as the

likely cost and timescales of any new infrastructure required.

All three projects will connect to the national transmission system operated by National Gas Transmission (NGT). They will work alongside Project Union, NGT’s project to create a UK hydrogen backbone, transporting 100 per cent hydrogen, and connecting production and storage facilities with end users.

This involves repurposing up to 2,000km of existing pipeline in phases and represents onequarter of the UK’s current transmission network, meaning that minimal new infrastructure will be needed by the early 2030s.

H2 Caledonia combines two projects in Scotland’s Central Belt and Fife’s East Coast, while H2 Connect will develop a design to connect a hydrogen network in central/southern England. This project will focus on the future expansion of hydrogen production, storage and imports in the Solent region. ■

From the 1st April - 30th September 2023, Excelerate members like Jamie here will be able to receive up to £500 of Amazon.co.uk Gift Cards, when registering more Greenstar boilers compared to the same period in 2022†.

▶ Fit 1 more = Receive a £50 Amazon.co.uk Gift Card

▶ Fit 3 more = Receive an additional £150 Amazon.co.uk Gift Card

▶ Fit 6 more = Receive an additional £300 Amazon.co.uk Gift Card

Sign up to Excelerate by visiting worcester-bosch.co.uk/excelerate-signup

500£

*Restrictions apply, see amazon.co.uk/gc-legal †Terms and conditions apply. Visit your Excelerate portal for full details.

April’s edition featured an article on the Flue Safe plug, a plumber’s brilliant idea. We had Condensate Pro before that, Flue Snug, Nerrad tools and even the good old magnetic filter. What do they all have in common? They’ve all been designed by plumbers and gas engineers.

These days it seems to me they’re the only ones innovating. Manufacturers, institutions and government, with their huge power and resources, don’t seem to be coming up with anything new. Instead, they’re all bogged down with heat pumps, hydrogen, hybrid systems, an extra 0.5 per cent efficiency, yet better controls and insulating

DHW pipework. Hardly groundbreaking for most of them. Heat pumps have been around for decades.

There’s so much more to this industry than heat pumps and Boiler Plus.

We’re supposed to have the installation manual at hand when working on a gas appliance. How often do we really have it when carrying out a landlord’s gas safety record on a cooker or fire? Have you tried getting the manual? It’s the law, yet some manuals are still very hard to find. Why not force all manufacturers to submit a copy of their manuals to Gas Safe for members to access? A central and complete repository, rather

than the myriad places offering boiler manuals of the most popular brands only.

Why do we still have to pay to access British Standards? That’s not a very encouraging way to disseminate them.

Is there a good reason why manufacturers are still producing boiler flues made of metal externally, which often end up corroded? Why not plastic? The inner flue is already in plastic.

Why are manufacturers still placing the PCB in combi boilers at the bottom, where water will collect in the event of a leak? Why not move it anywhere else except there?

Newer controls are coming out all the time. Has any

Reading this month’s Registered Gas Engineer, it fills me with a deep sense of sadness at the lost opportunity the industry has had in educating homeowners about weather compensation.

I read that a great deal of back-slapping is under way for succeeding in educating homeowners about flow temperatures and for persuading them to lower their flow temperatures in order to save fuel. Apparently, on average, £112 has been saved by lowering one’s flow

temperatures, which equates to about a 10 per cent improvement, I would have said.

That’s great. However, the part that has been totally missed is to educate the homeowner as to the next stage and tell them about an automatic system that will lower the flow temperature even further, as low as 35°C in some cases, giving even more saving and preparing people for the way that heat pumps work so that their introduction can be as smooth as possible.

I’m talking about weather

compensation: a system that should be fitted to all new combi boilers from 2018 but which is sadly not due to the ignorance of customers and fitters alike.

It would be magnificent to see a follow-on [consumer] campaign where the benefits of having an automatic system to vary your flow temperatures in line with the outside temperature is the next step towards saving fuel, CO2 and money for the customer.

Richard Weir, Boiler Beemanufacturer still not thought of a USB plug-and-play connection? Let eBus, OpenTherm and EasyControl sort themselves out behind the scenes.

Why is the government not creating a deposit service for tradespeople and customers, akin to the tenancy deposit scheme – which has proved its worth? The money for building work would be held in escrow until the job is complete. In one strike, that would get rid of cowboy builders who disappear with the deposit money and customers who don’t want to pay after a job is completed.

Henry GI just would like to add my thoughts to the article in April’s magazine, Don’t compromise on safety.

I have used refurbished fans a few times as bearings can wear out and they can be replaced.

However, there are companies advertising refurbished parts that are nothing more than untested and unchecked used parts.

As you rightly point out, every time an engineer makes a repair, its their reputation on the line, so a new part may well be the best value for money in the long run. Thanks for such a timely article.

Nigel MooreRegistered Gas Engineer wants to see your pictures – whether you’ve come across some horrors or instances of really good work. Please email your stories and pictures to editorial@registeredgasengineer.co.uk or via Twitter to @RGEMag

We may share some of your pictures on social media, so remember to include your contact details so we can tag you (or let us know if you’d rather we didn’t).

Andy Gatenby discovered that this appliance with a twin-wall flue had been adapted so that it was taking its combustion air from the room and dispersing flue gases out via the twin wall terminating on the roof. The appliance had been serviced for the past 18 years. It was isolated and made safe.

Dan Corkin found a gas escape when he was carrying out a tightness test: a section of gas pipe had corroded. It had been caused by condense dripping on to it because the customer had cut the condense pipe when it kept freezing. The condense pipe has been upgraded and terminated correctly.

Patryk Sekula came across these chimney/flue terminals installed in an external enclosed space with insufficient clearances. The installation was made safe.

Russell Scott identified low working pressure at the boiler, then went the meter, which was in a semiconcealed box. The meter box was almost completely submerged in mud which had also affected its regulator. The meter and regulator have been replaced.

John Jones was asked to service an old fire and back boiler unit. Sadly, after a full stripdown, it could not be rescued and John made it safe.

There’s a prize for the best photo sent in (in our opinion). Please remember to take your pictures at high resolution and email them to: editorial@registeredgasengineer.co.uk

This month iHeat is giving away a 25-piece Wera Kompact tool set with tools and bits from Wera’s top 20 for plumbing and heating systems.

iHeat is one of the fastest-growing and most trusted boiler installation companies in the UK, seeing major success due to its forward-thinking approaches, as well as the convenience it provides for its engineers.

iHeat operates with a network of more than 300 self-employed installers all over the country, each having the freedom to manage their own workload at the touch of a button via the straightforward iHeat app.

The simplicity of iHeat’s strategy means engineers never have to worry about working out of their local area or working into the evening. iHeat takes care of all the logistics, invoicing, materials and customer communication for any job, freeing up installers to work as much or as little as they’d like.

Some installation companies carry out disruptive and delaying location assessments, whereas iHeat provides time-saving online quotes in as little as 60 seconds.

iHeat covers all types of boiler installation, including upgrades, conversions, servicing and back-boiler removals. Installing highly efficient and eco-conscious boilers from the most well-known and celebrated manufacturers in Europe, iHeat fuses simplicity with innovation, representing the future of the domestic heating industry. www.iheat.co.uk

This month’s winner is Russell Scott from Southsea. Congratulations!

Rated ‘Excellent’ on

At Continal, we have the UK’s widest range of underfloor heating systems. Combine this with our expert sales advisers, and you can see why Continal always provides the best solutions.

We design all our systems to work with any heat source, floor construction and covering. Whatever your project we have the solution.

0333 800 1750

www.continal.co.uk

“I’ve used many UFH companies and Continal are the best by far!”

Being an inspector in Northern Ireland comes with a role and responsibilities that take in everything from inspecting registered businesses to supporting HSENI to working with environmental health officers. Registered Gas Engineer caught up with Chris White-Overton to find out what’s involved.

I’m a Jack of all trades over here,” says Chris. The inspector, who has been with the Register for four years, deals with small businesses, large businesses, and illegal investigations, as well as working with HSENI on RIDDORs, complaints relating to gas and providing the Executive with technical help on site when needed.

He and his inspector colleague Shaun Smyth look after Northern Ireland and its 892 Gas Safe registered businesses between them. But that’s not all of it: the two of them also cover the Isle of Man, Guernsey and Jersey.

All that means a fair bit of travel and a lot of organisation. On top of his own wide patch around the greater Belfast area, Chris goes to the Isle of Man for a week at a time four times a year, as well as seeing registered businesses in Guernsey and Jersey regularly.

Mains (its local term over here) natural gas came later in Northern Ireland than to the mainland; the network started in 1996 and is still expanding. It also has a slightly higher calorific value. “That doesn’t affect combustion but we use a slightly different value for gasrating calculations,” says Chris.

“In England, it’s generally 10.76 but here it varies between 11.1 and 11.4. The heat input figure on the data badge is generally worked out using 10.76, but we use the adjusted figure and it can appear that the appliance is overgassed – but it’s not, it’s just that we use the higher figure.

“The other main difference is that our network is predominantly medium-pressure supply as opposed to lower pressure, so we use a different process and procedure for tightness testing*.

“Currently around one-third of the homes in Northern Ireland are on the natural gas network. The others are mostly on oil, with some LPG in more rural locations, and there’s certainly a lot more LPG

than on the mainland.”

The gas may be slightly different but gas engineers need to achieve the same competences and go through the same training and ACS as their colleagues on the mainland. And when it comes to being inspected, they have the same worries. “There can be a certain fear, which is something I try and help them overcome,” says Chris.

“No one looks forward to it but afterwards many feel better and they’re glad it’s happened. There can be a misconception that we’re trying to trip you up but that’s obviously not the case.”

He knows that nerves can sometimes be apparent too. “When I see that, I say that nerves aren’t a bad thing because it means you care. A huge majority of gas engineers do work safely.”

Chris and Shaun work closely with HSENI too, supporting the Executive with RIDDORs and complaints and providing technical assistance on site.

“We also work closely with environmental health officers (EHOs): right now we’re checking on restaurants, making sure appliances have been serviced and they have gas safety records.

We’ve carried out training with EHOs on how to rate a gas safety record and ensure appliances are recorded, what to look out for, alarm bells, how to check an operative on the Register and that they have the required ACS.”

Right place, right time Chris knows how engineers feel about being inspected. He used to be a gas engineer himself, and was at a major boiler company for 11 years before he joined. “I was a service engineer in the renewables team but I was actually doing commercial, domestic and renewables as well as helping with system design and commissioning.

“But the Register was something I’d been interested in since day dot, especially the role it plays in the industry. Gas safety was something that I always took seriously. A friend sent me the job ad as a bit of a joke but it was right up my street. So I put my CV in, got an interview, was offered the job and the rest is history. I was in the right place at the right time.”

Inspectors have to hold many ACS qualifications and renew them in the same way as gas engineers. And although Chris was

892

already highly qualified, he had to do a whole lot more. “I had a few of the commercial ACS but not all of them, and not all the domestic ones either. I had to do warm air heating, which had been common in England many years ago, but it’s never been here; we’ve never seen or heard of it, so I didn’t have it.”

He has it now, along with many other qualifications. “As part of our training and induction, we have to go through 80-90 training packages and assessments over three months. It was quite interesting to learn something new.

“Training is a massive part of any inspector’s duty, as well as the importance of keeping up to date with regulations and requirements. Some training has to be renewed annually and some every two years. And we have to do our ACS every five years too.”

With such a varied role, it’s hard to imagine that Chris has much downtime, but he does manage to fit in the occasional round of golf and fishing in the summer around his home in County Down – only when he’s not spending time with his two young daughters. ■ * See also, Tightness testing in Northern Ireland, overleaf.

“No one looks forward to inspection but many engineers feel better afterwards.”

The Northern Ireland gas network in the street is generally at 75 mbar to 4 bar. Although medium pressure on the mainland is usually up to 2 bar pressure, in Northern Ireland it reaches up to 4 bar feeding the regulators at the primary domestic meter installation and is then reduced to a low-pressure supply of 21 mbar (+/-2) for the gas installation.

For tightness testing and purging downstream of the meter, we recommend following the guidance in IGEM/UP/1B Edition 3 1; for meter installations up to 6m3/h, you should reference BS 6400-2:2018 2

Medium-pressure meter boxes must be installed to BS 64002:2018: if they are installed inappropriately or damaged, there is an increased risk of gas entering the cavity/property. Therefore, the location of the box and vent from the relief valve must conform to the separation distances guidance given in section 6 of that standard. Further guidance can be found in TB004 and TB100 from Gas Safe Register.

You should be aware that a medium-pressure meter installation is slightly different from a low-pressure type, with a regulator that has been selected to be suitable for the mediumpressure supply. It may be a single or two-stage regulator incorporating several safety features like a slam-shut device, UPSO, excess flow valve and relief valve.

The tightness test procedure that follows is guidance in relation to natural gas (NG) domestic installations commonly found in Northern Ireland and some other parts of the UK. Most of the procedure is already commonly used for low-pressure gas installations but an additional procedure is required to test the safe working of the regulator with a medium-pressure supply with

low pressure downstream.

New installations will have a meter isolation valve (MIV) fitted between the regulator outlet and the meter; this is in addition to the Emergency Control Valve (ECV) fitted at the end of the service pipe before the meter installation.

These types of meter installation have a reset lever at the regulator to enable pressure to be released/equalised as part of the testing procedure. Depending on the regulator type, this lever is used to reset the UPSO or excess flow/slam-shut device.

Tightness test procedure of a domestic individual dwelling with a medium pressure service (where an MIV is fitted):

• With the ECV shut, ensure there are no open ends that will permit the escape of gas, and that all appliance isolation valves (AIV) are open and the MIV is closed. Attach your manometer to the test point after the MIV.

• Slowly open the ECV to pressurise the pipe up to the regulator, then open the UPSO reset lever on the regulator to pressurise up to the MIV. With the ECV open, slowly open the MIV until the manometer reads between 7 mbar and 10 mbar. When you have a suitable pressure reading, start your 60-second let-by test.

• If there is no perceptible movement of the manometer reading, the MIV has passed a let-by test. If it fails by giving a readable movement, then the MIV should be tested with leak detection fluid (LDF). Disconnect the outlet of the MIV and use a small amount of LDF on the closed ball of the valve to determine the passing of gas. If it is confirmed as a faulty valve, inform the local emergency service provider (ESP), which will attend the fault.

• A tightness test can only proceed following a successful let-by test.

Natural gas was first introduced in Northern Ireland in 1996 via a gas pipeline from Scotland. Initially, it was available to homes in Greater Belfast, the immediate surrounding area and Larne, where the gas distribution network was been developed by Phoenix Natural Gas. By last year, nearly a quarter-of-a-million customers had been connected.

In the following years, the network was extended to the North-west and Ballymena, Antrim, Banbridge, Craigavon, Portadown, Armagh and Newry, connecting a further 64,000 customers.

More recently, the Gas to the West project, completed in 2019, has brought natural gas to Dungannon, Coalisland, Cookstown, Magherafelt, Omagh, Enniskillen, Derrylin and Strabane and is expected to serve around 40,000 households and businesses. Similarly, Gas to East Down is providing new infrastructure to 13 towns and the majority of pipelines are now laid.

To do this, slowly open the MIV and raise the pressure to between 20 mbar and 21 mbar, closing the MIV once the correct pressure is reached.

• The temperature and pressure must now be allowed to stabilise for 60 seconds (stabilisation period). Adjustment to between 20 mbar to 21 mbar is allowed but you should wait until a stable reading is obtained.

• When you are satisfied that the gas is stable, the 120-second tightness test can begin. It is expected that for new installations a successful test/ pass will only be when there is no readable movement.

• For an installation with existing appliances connected and no smell of gas (with a installation volume (IV) not exceeding 0.035m3), the maximum permissible drops detailed in the table below are deemed as acceptable.

Tightness test procedure of a domestic individual dwelling with a medium-pressure service (where an MIV is NOT fitted):

• With the ECV shut, ensure there are no open ends that will permit the escape of gas, and that all appliance isolation valves (AIV) are open. Attach your manometer to the test point on the meter.

• Slowly open the ECV: this will pressurise the pipe up to the regulator, close the ECV. Open the reset lever to pressurise the whole installation and keep open: at this point, adjust the pressure to between 7 mbar and 10 mbar. You do this by allowing more pressure by slowly opening and closing the ECV, or purging gas from a purge valve to a safe area. When you have a suitable pressure reading between 7mbar and 10 mbar, start your

60-second let-by test. Keeping the reset lever open ensures you are testing from the ECV through the whole installation, however this can be difficult on some regulators. Alternatively, you can operate the reset lever and record the pressure reading

determine the passing of gas. If it is confirmed as a faulty valve, inform the local emergency service provider (ESP), which will attend the fault.

• A tightness test can only proceed following a successful let-by test: to do this, slowly

must now be allowed to stabilise for 60 seconds (stabilisation period). Adjustment to between 18 mbar and 19 mbar is allowed but wait until a stable reading is obtained.

• When you are satisfied that the gas is stable, the 120-second tightness test can begin. The pass criteria of the test is the same as that for an installation with an MIV fitted.

2) BS 6400-2:2018 Specification for installation, exchange, relocation, maintenance and removal of gas meters with a maximum capacity not exceeding 6m3/h. Medium pressure (2nd family gases)

Technical Bulletin 004: Managing risks from inappropriately installed medium-pressure-fed domestic-sized meter installations located in built-in or surface-mounted boxes

Technical Bulletin 100: Dealing with damaged pre-fabricated built-in domestic sized gas meter boxes.

at the start of the test, then operate it again at the end of the test (60 seconds). Record and compare the two readings to confirm no perceivable movement.

• If there is no perceptible movement of the manometer reading, the ECV has passed a let-by test. If it fails by giving a readable movement, then the ECV should be tested with leak detection fluid (LDF). Disconnect the anaconda from the ECV and use a small amount of LDF on the closed ball of the valve to

open the ECV, and raise the pressure to between 18 mbar and 19 mbar and close the ECV.

• If you have exceeded 19 mbar but not 21 mbar, you can drop this back to between 18 mbar and 19 mbar from a purge valve to a safe area. If you exceeded 21 mbar, then to ensure there has been no lock-up of the regulator you must drop to between 7 mbar and 10 mbar and raise the pressure slowly again.

• The temperature and pressure

Note: When carrying out a let-by on an ECV (where no MIV is fitted), you can operate the reset lever and record the pressure reading at the start of the test, then operate it again at the end of the test (60 seconds). Record and compare the two readings to confirm no perceivable movement. The other option is to hold the rest lever open throughout the 60-second test, but this will be difficult on some models of regulator. ■

Bibliography

1) IGEM/UP/1B Edition 3 (with Amendments October 2012): Tightness testing and direct purging of small Liquid Petroleum Gas/Air, Natural Gas and Liquid Petroleum Gas installations

You can find additional guidance in Technical Bulletin 004 (meter installations) and Technical Bulletin 100 (damaged meter boxes). These can be read and downloaded by logging into your Gas Safe Register online account at www.GasSafeRegister. co.uk/sign-in

For further guidance please contact the technical team by phone on 0800 408 5577 or email at: technical@ gassaferegister.co.uk

“The tightness test procedure is guidance in relation to natural gas domestic installations commonly found in Northern Ireland.”

Understanding how to calculate heat loss is a crucial part of designing and installing efficient heating systems, especially given the rise of boiler alternatives. Here, Ian Trott, training manager at Baxi, looks at how heat-loss calculations help to determine the appropriate size of equipment needed to maintain a comfortable temperature in a building while minimising energy costs, whatever the heat source.

Over the past several years, and especially over the previous 12 months, it has become overwhelmingly clear that energy efficiency needs to be a major priority. This goes for governments and industries as much as in our homes. Heating installers have a crucial role to play not only in installing a heat pump or boiler but in being heating experts.

It’s important to understand this evolving role in the race to net zero and that, no matter the appliance being installed, you can promote efficiency at every opportunity. It’s time to rethink your role as a professional who fits boilers as someone who is also a heating and energy consultant, recommending efficient solutions based on the household’s requirements and scientific principles.

When advising consumers on how to improve their home’s energy efficiency, you need a firm grasp on heat-loss calculations and be ready to discuss them with your customers.

generally use more energy to heat up and so produce more than is needed for the space. Along with the cost of the energy output, bigger units are more expensive to install and maintain. If a large unit is installed in a building that only needs a relatively small boiler, the oversized appliance will not be able to run at a peak performance, which means that more maintenance will be needed, further adding to costs.

By making heat-loss calculations part of every heating installation – as required by Part L of the Building Regulations – it will be possible to recommend a heating solution that strikes the right balance between being powerful enough to meet peak demand for heat and being efficient enough to keep costs and emissions down.

Part of the calculation process involves understanding and anticipating your customer’s heating needs, so talking to

Heat-loss calculations balance the amount of energy needed to overcome the heat lost though the fabric of the building. Although some might expect a larger heating system to provide the extra assurance that output will always meet peak demand, a heating system that is too big for the building can be counterproductive.

An oversized heating system is less efficient because it will

them is an important part of the process. Ask about their current heat use, and whether they expect it to change so that you can make an accurate estimate. Questions about changes to the property, such as plans to have double-glazing installed, or to convert the loft into a home office, can give a clearer picture of what the heating system will be required to do.

Changes to the residents can be relevant, too. Will children or older people also live there in the

future? The heating requirements for an older person can be different from someone in their 20s or 30s, so anticipating these changes makes it more likely that the proposed heating solution will

meet the household’s needs.

The next stage is to assess the building. This includes measuring its overall size as well as the size of each individual room. Measuring every room in the

“Part of the heat-loss calculation involves understanding and anticipating your customer’s heating needs, so talking to them is an important part of the process.”

property means that a more accurate heat-loss calculation can be completed and therefore you can make a better heating appliance recommendation.

The type and thickness of

insulation needs to be considered, as well as which parts of the building are insulated. Doors and windows must be taken into account, including how many there are, their size, and

whether they are single, double or triple-glazed.

Once the necessary information has been gathered, it’s time to do the calculations. Thankfully, there are tools to make this step simpler. Downloadable Microsoft Excel documents are freely available through the MCS website: simply add the relevant information to the document, which will then perform the calculation and provide answers. You can make well-founded recommendations based upon these calculations as to whether to upgrade elements of the heating system, and which ones.

Crucially, heat-loss calculations will help you provide the most effective and efficient heating solution for your customers, saving them money and boosting your reputation as a skilled and knowledgeable professional.

With the aid of online tools, the calculations shouldn’t be too tricky. Problems are most likely to be caused if you overlook certain parts of the process or don’t ask the right questions of the homeowner. It is important to consider the heating environment as a whole, so weather conditions at different times of year will come into play, as will the direction the

windows face and how much sun hits those windows.

Making the effort to understand heat-loss calculations and becoming competent at doing them will ensure that you are ready to recommend solutions that are the right fit for your customers: this may be a gas boiler, a heat pump, a hybrid system or another heating appliance. With accurate heat-loss calculations, you can help your customers save money and energy – which makes you an invaluable ally.

The number of factors involved in heat-loss calculations can seem intimidating at first, but support is available and good manufacturers provide a full range of specialist training courses on this and related topics. You can help your customers understand the financial and environmental benefits of this process and why it is an important part of any heating installation.

You’ll be able to take advantage of the rewarding opportunities that comprehensive heating consultation can provide by keeping up to date with changes to relevant laws, training opportunities, and assistance. ■

• Find out more about Baxi’s training courses at: baxi.co.uk

• Downloadable MCS calculation spreadsheets are at: www.mcscertified.com

“Problems are most likely to be caused if you overlook certain parts of the process or don’t ask the right questions of the homeowner.”

NICEIC Certification has issued an important amendment to its Liquefied Petroleum Gas Safety On Site Guide. Gas engineers who undertook NICEIC’s LPG boat training course or bought the Liquefied Petroleum Gas Safety Guide before May 2022 should be aware of the following addendum, published by NICEIC, in response to an error in Section 13: Boats: Table 13.1. Pipe sizing table.

Table 13.1 is reproduced from Table A.1, Annex A of BS EN ISO 10239 Small craft – Liquefied petroleum gas (LPG) systems

Prior to May 2022, the first column of Table 13.1 had the heading “Inside diameter of hose/ outside diameter of copper pipework (mm)”, which reflected the 2008 edition of BS EN ISO 10239, but which was subsequently amended in 2014, and remains unchanged in the latest 2017 edition of BS EN ISO 10239, to read “Inside diameter of hose/pipe”.

The remainder of the table, including the important pressure drop values, has not changed over the years and is correctly reflected within Table 13.1 of the Guide.

The current version of NICEIC Certification’s LPG Guide (Version 7 dated May 2022, ISBN: 978-1-83863-036-2), contains the correctly labelled table, as shown on the right.

Gas engineers are reminded when sizing gas pipework, particularly when a given size is close to its theoretical pressure

* Inside diameter of hose or pipe

Note

Note

loss limit, to use the pipe/hose manufacturer’s data, which will take account of the pipe wall thickness when specifying the correct pipe size to use. ■

FACT: 80% saving in gas consumption when paired with any Intergas boiler.

FACT: Can be retrofitted to any Intergas (ErP) boiler.

FACT: Commissioning in under 10 minutes with QR code on control unit.

FACT: Disruption minimal, as there’s no need to resize radiators.

FACT: 5kW split air source heat pump is a compact 69cm x 97cm x 37cm.

On all three days at InstallerSHOW we’ll be demonstrating how Xtend works and why it’s going to revolutionise the heat pump industry.

Come and see us on Stand D120 at the NEC, 27-29th June.

When it comes to the benefits of Xtend, the new hybrid heating system from Intergas, there are no grey areas:

Xtend for effective, economical and sustainable heating and hot water.

What’s the latest as momentum starts to build on fitting heat pumps in the UK’s homes? Registered Gas Engineer looks at some recent developments.

Whether you’re already fitting heat pumps or not, there will need to be a lot more of them in our homes if the UK is to hit its net-zero targets.

The government has already set out its ambition: by 2028 it wants to see 600,000 fitted every year. And it’s put some money where its mouth is with the launch last year of the £450 million Boiler Upgrade Scheme (BUS), a grant in England and Wales that gives homeowners £5,000-£6,000 to replace their gas, oil or other fossil fuel boilers with a heat pump, or, in a few very specific instances, a biomass boiler.

Launched in May 2022, the BUS was due to run for three years before being extended until 2028 as part of the government’s ‘powering up’ strategy. But uptake has been slow. With a first-year target of 30,000 installations, by the end of March 2023 nearly 16,000 applications had been received in total, with just under 14,000 vouchers

issued, 10,300 of which had been redeemed. It’s believed that unspent money at the end of the first year will be returned to the Treasury.

The average cost of fitting an air source heat pump under the Boiler Upgrade Scheme is more than £13,000, according to the government’s own BUS statistics, so it can hardly come as a surprise that consumers are not champing at the bit to replace their trusty boilers.

There has also been criticism that the BUS favours those who are more able to bear the higher cost of a heat pump anyway and doesn’t help the millions who are struggling to make ends

meet in the cost-of-living crisis.

Cost hasn’t been the only barrier: the government has said it will ramp up marketing to increase consumer awareness and take-up, but perhaps the biggest issue is a huge skills shortage. Hitting the government’s installation targets in just five years’ time will need a trained and qualified workforce of around 30,000: currently, there are reckoned to be 3,000 heating engineers who are competent and qualified to fit heat pumps.

This means that even if consumers want to fit a heat pump, they may be struggling to find someone to do it for them.

But the tide could be turning. Gas engineers are increasingly thinking about adding installing heat pumps to their skills. Our own reader survey earlier this year found that although just 19 per cent of you are working with renewable technologies right now, 7 in 10 say you are considering training to work with heat pumps this year.

Vaillant has also carried out a major survey among its Advance loyalty scheme members recently. Its findings are very similar: 18 per cent currently fit heat pumps but a whopping 87 per cent are or may be interested in training.

Age is a factor: the older the engineer, the less likely they are to be considering training, says Vaillant in its report, Aspiring to a Green Future: “We can conclude that 36 per cent of installers surveyed are close to retirement age in the next 15 years, with some choosing not to retrain and

“Our reader survey found that although 19 per cent of you are working with renewables now, 7 in 10 are considering training to work with heat pumps this year.”

transition to heat pumps as they will not be working when we need to meet the 2050 net-zero target.

“The largest interest in heat pump training comes from younger installers with fewer years of experience. The lesser interested are those aged over 60 and those who have more than 30 years’ experience.”

Vaillant’s survey also asked heating engineers what they think the government’s role should be in scaling up heat pump training. More than 70 per cent said the government needs to do more to support them to upskill to be able to offer the technology; 60 per cent said it needs to make it easier to diversify and 65 per cent believe the government should support them financially to do so.

The government seems to be listening. It’s putting up £5 million for a Heat Training Grant to support 10,000 plumbing and heating engineers in England become accredited to install heat pumps over the next two years. An announcement is also expected on low-carbon apprenticeships later in the year.

Training providers and manufacturers offering the Heat Training Grant will be able to

6 days

provide trainees with a discount or rebate of up to £500, and some are adding their own additional discounts and offers to entice trainees.

Baxi says it will match the grant with £500 worth of Baxi Works loyalty points for heating engineers who use the voucher to train and achieve its BPECaccredited qualification. When the first installation has been completed and registered, points can be used for a range of rewards including gadgets, vouchers, tools and workwear. “We welcome the government’s focus on skills and its commitment to the installer community,” says Jeff House, Baxi’s External Affairs and Policy director.

And Mark Wilkins, Vaillant’s Technologies and Training director, says: “The Heat Training Grant is a significant step towards making heat pump training more accessible for the installer community, wherever they are in their career.

“Vaillant is supporting this scheme, and we are working diligently with our training partners and internal teams to enhance our current heat pump training offer to ensure it simplifies the process for installers, providing them with cost-effective and accessible training to gain the relevant qualifications to take a heat pump installation through from the design stage all the way to commissioning.”

Its new Aspire programme consists of a personalised learning pathway to upskill heating engineers to correctly design and install heat pumps. It blends online and practical training and supports heating engineers to put in place the necessary processes so that they can join a Competent Persons Scheme or become MCSregistered (see page 37).

Martyn Bridges, director of

Germany is taking the renewables bull by the horns and has proposed banning the installation of most gas and oil heating systems with effect from next year. New and replacement heating systems will need to run on 65 per cent renewable energy, it’s been reported, either from heat pumps or district heating, electric or solar thermal systems.

The contentious Bill is due before the German Parliament this month (June).

Stiebel Eltron UK managing director Mark McManus says: “Germany’s decision to ban fossil fuel boilers from January next year is a bold statement in pushing the market towards the use of renewable heating systems.

“If the government is serious about starting a heat pump revolution, it should follow Germany’s example and implement measures that will galvanise the market and really inspire a shift towards renewable heating systems.”

Technical Services at Worcester Bosch, adds: “A Level 3 heat pump qualification takes up to three days of training. Therefore that’s an expense the installer not only presently has to fund, but also means they miss out on three days of potential earnings. This grant will help upskill the labour market and the course will be offered at all our training centres as soon as it becomes available.’’

Daikin says it has the capacity to train more than 7,000 people on air source heat pumps every year and aims to arm 30 per cent of the UK’s heating engineers with the right skills. But its heating and renewables commercial manager Iain Bevan says: “Reaching the UK’s net-zero target won’t happen without collaboration and partnership between specialists up and down the country.”

It’s all going to take time but progress is being made. Consumers are certainly more conscious about trying to live more sustainably, and some are already planning ahead and asking their gas engineers about heat pumps.

Gas boilers are here for the foreseeable future, especially when it comes down to a distress purchase caused by a broken-

down appliance, a cold home and no hot water.

But heat pumps will ramp up, particularly because gas boilers cannot be fitted in new-build homes after 2025. With around 200,000 new homes built every year, that’s a lot of new lowcarbon technology going in.

Heat pumps on their own won’t get us all the way to net zero. But at Vaillant’s recent Parliamentary launch of its research, Lord Callanan, Under Secretary for Energy Efficiency and Green Finance, said: “They are the paving stone on the journey to decarbonised heating.”

Labour’s shadow minister Dr Alan Whitehead also acknowledged how important they will be, but added that they can only get us so far and would probably account for 60-70 per cent of home heating by 2050. Other technologies will be needed for off-grid and ‘hard to heat’ properties, and district heating is likely to play a bigger role.

With well-known players already active in the consumer space, particularly British Gas and Octopus, fitting heat pumps under the Boiler Upgrade Scheme from as little as £3,000, that’s yet another step to ‘normalising’ them in the eyes of consumers. ■

Average time a heating engineer needs to diversify into heat pumps

As more and more homeowners choose air source heat pumps, now is the time to invest in your business and partner with Mitsubishi Electric for success.

We need to accelerate momentum and demand for heat pumps to reduce our reliance on imported fossil fuels and achieve our net-zero targets, says Martin Passingham, product and training manager at Daikin UK.

Putting government targets

aside for a moment, it’s vital that homeowners have a good experience during the installation process, and confidence in their heat pump solution in the weeks, months and years that follow. Early adopters who opt for a heat pump in the short term will effectively become ambassadors for the technology and can encourage others to make the move as well.

For installers, ensuring that the installation is carried out to a high standard will reduce the need for follow-up visits to resolve issues, increasing word-of-mouth recommendations and maximising the time available to take on more new jobs.

What a successful install looks like

Heat pumps are very different from gas-powered heating systems. But as long as you know what to look out for, there’s no reason why you can’t future-proof your businesses by entering the world of renewables.

There are five key considerations when fitting an air source heat pump.

Outdoor unit minimum clearances: It’s important to get the location of the outdoor unit right. If there’s not enough space for air to flow across the heat exchanger, the system’s capacity and efficiency throughout its lifetime can be compromised.

Hydraulic connections: Setting up the hydraulic components properly is critical to ensure the optimum flow rate in the system, so that it can effectively and consistently meet the household’s heating and hot water needs.

The use of automatic bypass values helps to maintain a constant minimum flow rate, and hydraulic separators are recommended in larger properties with multiple zones to service, or

where there is a combination of solutions with different flow rates, such as radiators and underfloor heating.

Directing the heating load: Three-way valves are key to ensuring the energy transfer from the heat pump is directed to either the heating system or the hot water cylinder, depending on where the heating load is needed. Misaligned valves are one of the most common issues – but it’s really easy to avoid.

Prevent the system from freezing: Glycol is widely used to protect water circuits from freezing but anti-freeze vales (AFVs) are an effective alternative. AFVs mean you don’t need to handle glycol and the associated loss of system efficiency. They are preassembled and calibrated to drain water from the system when the water temperature reaches 3°±1°C – a condition that should only occur during a power or pump failure. This system draining prevents freezing and the risk of subsequent mechanical damage. If the AFVs have been activated, all that’s required is a simple refilling after the power/ pump failure has been rectified. Two AFVs are recommended at the lowest points on the outside flow and return water pipes.

A thorough handover: The handover process at the end of the install is key to getting homeowners off on the right foot. Take time to go through the user manuals and controls with your customer to help them get the very best out of their new heat pump system from day one.

While upskilling heating installers on heat pumps is crucial, there is a huge opportunity at college level that is currently being missed as heating and plumbing courses focus only on gas – but not for long.