STAGE 1

TYPES OF WOOD AND GOODS USED

Main wood -Teak

Jackfruit wood and rosewood are used in designing the interiors

Other goods and woods used are : Venteak, Venga, Kari Marad, Vaga, Coconut, Coir Cattles, Salt, Grains.

SPECIALITY OF BEYPORE URUS

Beypore urus are purely made of wood, without using any modern techniques, and traditional methods are used to launch this ship into the water. The carpenters manually join each piece of wood to build the large boat.

TOOLS USED

Uru is made completely of wood, using indigenous tools like country saw, chisel and wooden hammer.

STAGE 2

-

long irkon nails

STAGE 4

Launching of an Uru is a festive ceremony witnessed by a huge crowd. Mappila Khalasis or dockyard workers, renowned for their amazing weight shifting skills, employ the traditional pulley-wheel mechanism to roll the boat on a bed of logs to float it out into the water.

STEP 8 Finishing the deck and ‘aruthi’ are the final stages. The basic framework of the deck will be made using steel or iron structure and the exterior part will be fined with wood.

STAGE 3

Hammer and chisel Saw Plane Adze

Country Saw Blow drills Caulking mallet and iron

TIME AND COST OF CRAFTING ONE URU

The time taken for completion of a project is nearly 2 to 3 years. Barring some frames and important structures constructed of steel, the Urus are mostly made of wood.

An average 100 ft dhow

- Weight = 1000 tonne

- Cost = Around 8cr to build the hull at beypore

An equivalent amount is required at Dubai for outfitting and upholstery. If these activities are done at Beypore, each Uru could fetch Rs.16 crore in foreign currency. Urus could be promoted as luxury yachts to rich, seafaring countries such as UAE, Brunei, Singapore, South Africa, Australia, New Zealand and Europe. A large number of handicraft shops sell miniatures of uru. This is a major small scale industry in Beypore. Intricate miniatures and painstakingly assembled miniature ships in bottles are the main attractions here.

LAUNCHING OF URU

The Launching of an Uru is a festive ceremony witnessed by a huge crowd. Mappila Khalasis or dockyard workers, renowned for their amazing weight shifting skills, employ the traditional pulley-wheel mechanism to roll the boat on a bed of logs to float it out into the water. The effort is quite physical, using steel ropes, wooden rollers, rounded logs, wooden pulleys and winches. They also recite some poetic shlokas (Arabic verses), Hindi verses and regional dialectic shlokas while they perform this important procedure. Examples for such native songs are

“Hele maali ….. yaa Allah

bala maale …. aisaa amaram thattikkodu … aisaa randu koodi thttikkodu … aisaa

porattangane … aisaa

O’ thinabe … aisaa

aalaath thangale … aisaa othorume pidikkeda … aisaa.

2) Allahu Rabbee … ya Allah

Ya Rabbi swallee … yaa Allass

Swallee swalathee … yaa Allass

Moosa bhayee … yaa Allass

Aalath lingaru … yaa Allass hele maalee … yaa Allass

Aalee maalee … yaa Allass

3) Jorse … yaa Allaah

Jallaa … jorsee Jallaa jorse… maalee jorsee..”

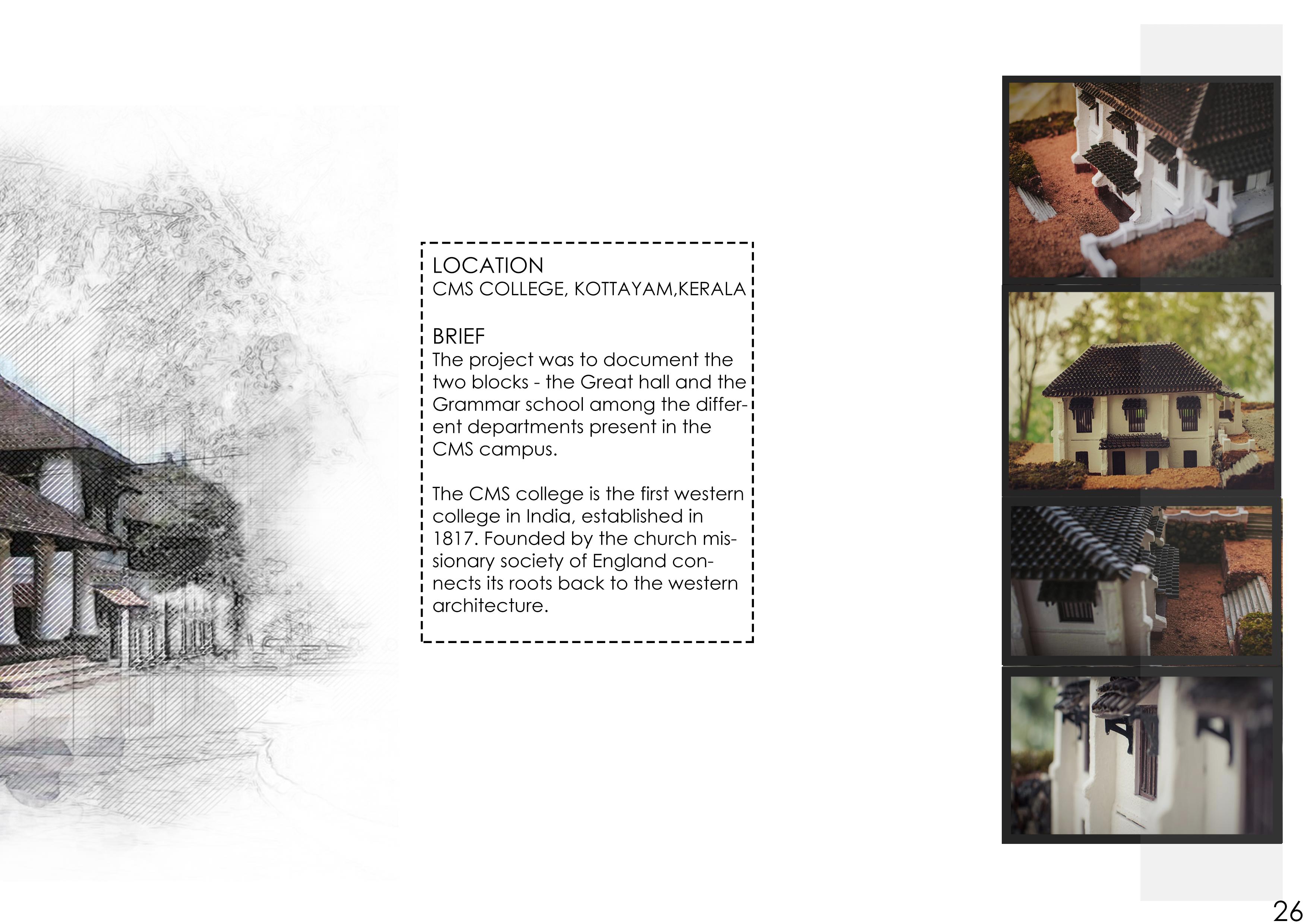

AIM

The main intent of this topic topic is to study how architecture influences in the rejuvenation of heritage of Uru community

OBJECTIVE

The attempt is to study the spatial cultural characteristics related to uru or Dhow wooden ships and its community, in the ancient port city of kerala by getting knowledge on possibilities for restoring and reviving of traditional uru crafting village and providing sustainable and innovative architectural solutions.

SCOPE

To understand the relevance of Uru in the past, present and gain oppurtunity to do this project for its future

LIMITATION

First of its kind

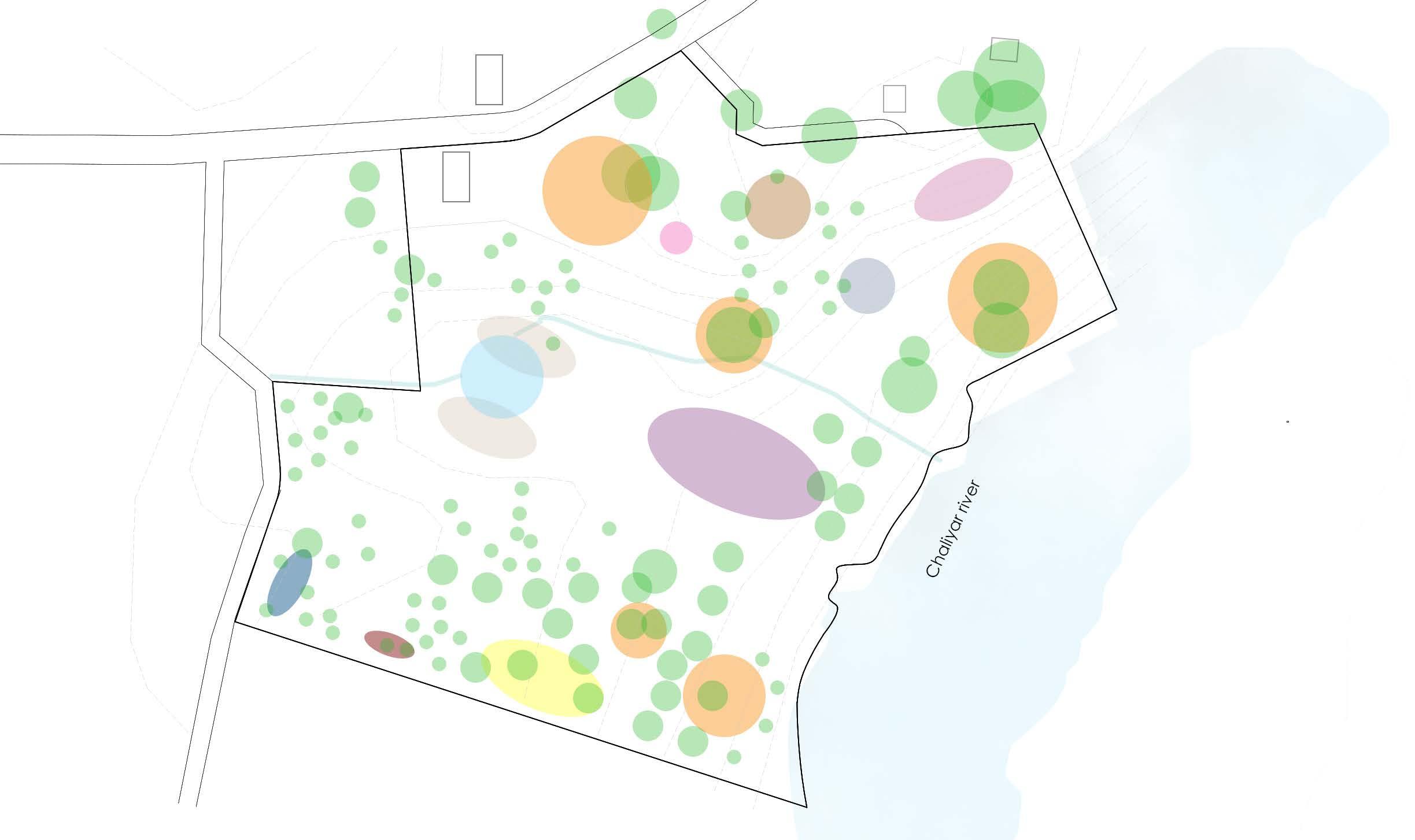

The line of connectivity - The building are oriented towrds the main view ie., the Chaliyar river and in a way where the users can get a point of view towrds whats happening in the site form the entry point followed by pedestrian pathway.

The use of natural features of the site the is the natural drainage towards the sea, views, water body existing trees etch for various active purposes.

Seating spaces under the main trees are provided as a depiction where people used to sit under babyan trees for communication and story telling. Vaikom Muhammad Basheer known as Beypore sultan used to sit under these types of tree seating and used to tell stories.

10m walking distance - at each 10 m a space various active spaces or art elements in the form of seating, play spaces etc are provided where people can sit rest and enjoy each time.

ZONING AND ORIENTATION - GRID PATTERN

Beypore Cheruvannur main road

Service entries

Zones of old large trees and wateracting as the centre point from each entry points positioned with central plazza and seating space.

Natural drainage

1. Central plazzas - Active zones - These are provided sourrounding the main vegetion area in the form of seatings under the tree where people can sit and enjoy story telling, communicate, playspace etc.

2. The Ticket counter and auditorium block is placed in close proximitry with the main entry points

3. Library block is placed close to 1rst service entry, ticket counter, cafeteria for the easiness of access from all direction and adjacent to the dhow yard and musuem block.

4. Guest cottages is placed adjacent to cafetreia, service and 1 and in the N-E position where it is away from noice from ship building.

5. Cafeteria is zoned in a position which can be accessed frrely from the library, guest cottages, play ar eas.

6. Dhow Yard is placed near the chaliyar river and in the central line contour i.e., @7m above sea level as it is sloping towards the sea and for the easiness of launching the ship

7. The museum blocks are dived into two with the water body as the centre courtyard. It is placed at the back of Dhow yard with terraced roof that can be accessed for various events such as leisure activi ties, shilp building veiwing and during the launching function of dhow festival.

8. Saw mill is placed away from all the actve and public zones to buffer form the noices and also in close proximity to service entry 2

9. Workers quaters is placed close to the saw mill and adjacent to the Dhow yard

10. The academy,hostel and canteen block is placed adjacent to Dhow yard for the students to access workshops.

- Towards a new life for a better tomorrow.”The rib framework of Dhow-Uru ship is used as an abstract feature in the form of columns

Total Built up area : 13029.8 sq.m

F.A.R : 0.21

Max. permissible : 21%

Total Built up area : 13029.8 sq.m

F.A.R : 0.21

Max. permissible : 21%

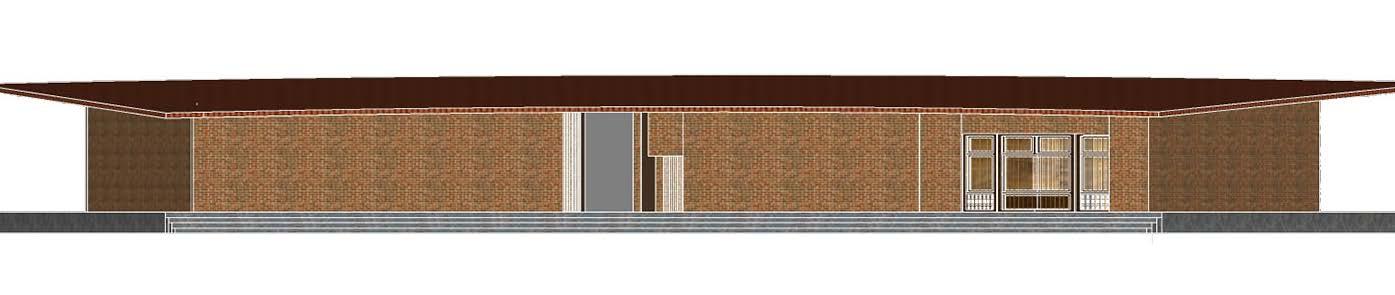

DHOW YARD

Dhow yard is placed @7m above sea level which is the centre of the site. The orientation(SW-NE) is done in such a way for the easiness of launching the Uru/Dhow to the sea. This building serves as centre and highest of all buildings located at the site.

The building consist of ground floor accomodating :

Ship Yard : 924 x 2 sq.m

Slipway

Carpentry room : 73 sq.m

Machinery room : 73 sq.m

Timber storage area : 109.25 sq.m

Semi open discussion room : 99.96 sq.m

Courtyrad(Leisure space) : 71.4 sq.m

Office : 20.25

Total floor area : 2531.8 sq.m

DETAIL B - COLUMN BASE

DISCUSSION ROOM ADJACENT TO SEMI OPEN COURTYARD

DETAIL A - ROOF GUTTER

DETAIL B - COLUMN BASE

SECTION AA’

Pulley

S-W ELEVATION

Scale : 1:200

OPEN COURTYARD

Scale : 1:200

ROOF Detail A Detail B 09

The museum which is situated along the central line of site and dhow yard is designed in a way where the roof can be accessed as a terrace with looking toward the yard, which can be used for leisure activities and various events such as during the launching of uru.

WORKER’S QUARTERS