RED CEDAR STEEL—ERECTING THE FUTURE

THE COMPANY

Larry Hayes, a skilled ironworker, started Red Cedar Steel (Red Cedar) in Wisconsin in 1977. Larry was a one-man show –estimating to the hands-on work. Pete Hayes joined the family business straight out of high school as an ironworker. After 15 years in the field, Pete joined Larry in the office and helped continuing to grow the company.

In 1995, Red Cedar opened an office in the Milwaukee area to serve the southern region of Wisconsin. Then in 1998, Larry retired, with Pete taking over the leadership. Red Cedar expanded the geographical region, moving operations to Minnesota to focus on the St. Paul and Minneapolis regions.

In 2007, Red Cedar expanded again, opening an office in Phoenix, AZ, to serve the southwest. Pete's brother, Mike, joined in 2011, assuming responsibilities of managing the branch.

After 45 years of growth and expertise, Red Cedar is in the Top 10 of Structural Steel Erectors in the U.S. and highly respected for our capabilities and geographic reach to serve our diverse client base.

With over 300 employees and operational teams in four dynamic offices, Red Cedar is able to take on the largest building structures to small specialty projects. As a partner, we offer:

> A strong collaborative culture to mesh with your team

> Nationwide reach with experienced union field professionals

> Ability to assemble and manage large erection crews (100+ personnel)

> Superior financial and bonding capacity

> Talented and highly experienced operations staff

> The latest technology (3D planning and Total Station) for collaboration

> A strong, dedicated emphasis on safety and quality

> American Institute of Steel Construction (AISC) certification

OUR PURPOSE

We build our people, our future, and our world by erecting steel nationwide.

RED CEDAR IS AN EOS COMPANY - A HIGHLY DISCIPLINED BUSINESS MANAGEMENT SYSTEM OUR TALENT UTILIZES TO CONSISTENTLY MEET OUR CLIENTS' GOALS.

OUR 10-YEAR GOAL

Become a Top 3 Steel Erector in the United States capable of erecting any project, anywhere.

OUR CORE VALUES

INTEGRITY: Stated simply, we do the right thing.

SAFE: We prepare and stay aware.

WWW.EOSWORLDWIDE.COM

DRIVEN: We work proactively to ensure success.

OWN IT: We each take responsibility to find solutions.

PRODUCTION-FOCUSED: We constantly innovate to improve field production.

RESPECT: We value people to enhance our teamwork.

MANAGEMENT TEAM

PETE HAYES CHAIRMAN AND CEO

Pete Hayes has been with the company for nearly 40 years. He is in charge of developing the company’s long-term strategy and overseeing the business. Pete is head of business development and has been integral in our growth from a Wisconsin regional to a national steel erector.

MIKE HAYES PRESIDENT

Mike Hayes has been in the steel industry since 1996. He has been a leader in the company’s expansion in the Western part of the US and a key part in our nationwide growth. Mike earned a business management degree from Olivet Nazarene University.

TROY GARRETT CHIEF OPERATING OFFICER

Troy Garrett oversees our different business units. A 30-year veteran of the commercial construction industry, he has led operations for both large-scale construction management firms as well as engineering and specialty contracting firms with operations nationwide.

JEFF STOVERN CHIEF FINANCIAL OFFICER

Jeff is responsible for finance, risk management, insurance, banking, and oversees human resources and IT. Jeff assists the CEO and President in developing and management of the long-term strategic goals.

SCOTT FALK CHIEF ESTIMATOR

Scott Falk has 25 years of experience in the structural and miscellaneous steel industry within both fabrication and erection. His knowledge of pricing projects includes in seismic, commercial, arenas, industrial, automotive, healthcare, multi-story, tenant-improvement, and even retrofits.

CORY COOK OPERATIONS AND GENERAL MANAGER

Cory Cook serves the Midwest Division. He has more than 22 years of experience in commercial construction. He built his career through many roles ranging from an ironworker through company leadership.

WHAT WE DO

STEEL ERECTION

MISCELLANEOUS METALS

From new construction to remodels and additions, we’ll manage complex projects with precise attention to safety, including 100% tie-off over six feet, budgets, and aggressive schedules.

Structural & ornamental metal installation for commercial and industrial applications.

COMMERCIAL SOLAR

METAL DECK & SHEAR STUDS

Leading the industry in commercial solar system design, fabrication, and installation services since 2010.

Efficient and safe. We maintain 100% tie-off procedures during all metal deck installations.

SAFETY-DRIVEN CULTURE

We’ve redefined industry safety norms by achieving or surpassing the highest standards in the steel erection sector. Safety isn’t just a goal in our operations, it’s a requirement and core value of Red Cedar.

> Extensive safety plans starting from pre-construction phase

> Designated safety directors

> Morning Stretch & Flex and daily task-specific safety planning

> 100% tie-off policy

> Every employee accountable – from project managers to ironworkers

> Zero tolerance substance abuse policy

> E-verify compliant

> 10 & 30 hour OSHA training programs

> First aid & CPR training

A KEY PART OF YOUR PROJECT’S SUCCESS

Red Cedar’s nationwide ability allows us to be part of complex projects. Our highlytrained and experienced ironworkers are committed to safety, reliability, and excellence. In our 45 years of operation, Red Cedar has gained recognition as a top steel erection firm.

STEEL ERECTION

Red Cedar has earned a reputation as one of the nation’s top steel erectors and holds the AISC Certified Steel Erector credential. Each year, we complete thousands of projects across the U.S. ranging from engineered erection plans to building automotive and data manufacturing centers, corporate headquarters, schools, and more.

LARGE STEEL ERECTION

Budgeting and Estimating: We pride ourselves on providing an accurate early understanding of expected costs during schematic, design development, and early construction document phases. Our dedicated team of experienced estimating professionals can provide accurate budgets from concept to full buyout.

Red Cedar utilizes On-Screen Takeoff (OST) for 2D and SDS/2 for 3D projects. With these refined documents and models, our estimators complete full steel budgets including:

> Structural steel quantities

> Complete miscellaneous packages

> Full durations and accurate estimates

> Job-specific requirements

> Critical lift analysis

> Local market knowledge

Project Management: Upon project award, our estimating team conducts a formal turnover to the operations team to ensure a seamless transition, this includes project management and key field supervisors. Each project is reviewed through the plans, specifications, schedule, special conditions, and other parameters to determine the best approach. Once assigned to a Project Manager, that professional manages the project from beginning to closeout to enhance collaboration and clarity.

Red Cedar uses sophisticated IT and software systems to enhance communication and productivity including BlueBeam Revu, SDS/2 Erector, MS Project, OST ,and a host of other applications and systems to keep our projects on-track. Each field leader is equipped with specialized tablets for the ability to review all drawings, changes, RFI’s, models and other critical information in the field.

Logistics and Planning: Construction is a manufacturing process with a different “factory floor” on every project. To be highly productive and minimize the critical path, efficient logistics planning is necessary, especially for large components such as structural steel. Steel deliveries need to be scheduled at appropriate times to follow the erection sequence, be placed within reach of cranes moving other equipment and have clear swing areas or transport paths for safe erection.

Red Cedar’s operations team works closely with the General Contractor and steel fabricator to craft a well-planned and coordinated logistics plan to ensure the best productivity. Using PlanGrid or SDS/2 software to analyze sequencing and crane options, we graphically overlay our preferred locations for coordinating with the project team.

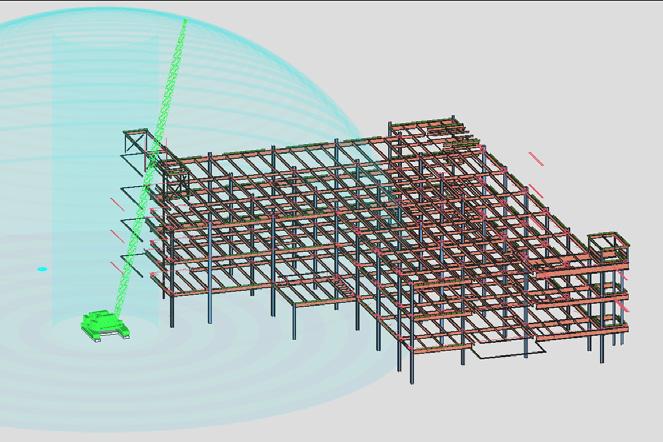

Crane and Critical Lift Analysis: Red Cedar uses 3D Lift Plan and SDS/2 software to optimize and choose the right hoisting equipment, including cranes based on the specific project parameters (e.g., logistics and staging, critical path sequencing, and general contractor preferences). Using 3D (e.g., IFC or BIM) files from the fabricator or Structural Engineer, Red Cedar can model the erection using different types of cranes based on availability, capacity, and cost. This software allows us to:

> Optimize crane placement during each sequencing phase

> Analyze maximum reach and lift based on placements

> Identify critical lifts of heavy pieces

> Quickly react to potential changes

Survey and Layout: From the layout of the anchor bolts to the elevation and plumb of structural members, proper benchmarking and dimension control is critical in structural steel erection. For precise site layout, Red Cedar has dedicated professionals using the latest Robotic Total Stations to analyze information from the documents and models to create accurate controls and reading.

In the earliest project stages, we utilize our LEICA iCR70 Robotic Total Stations to translate digital design information to on-theground control. We regularly work with the General Contractor’s survey team to confirm benchmarks, elevations, and offsets. This achieves accurate placement of anchors bolts, plates and other attachment items in the concrete to minimize discrepancies. Once the concrete is poured, Red Cedar runs an anchor bolt survey to quickly identify any issues that may affect the column placement. Geospatial field information is transferred to office and field crews (as-needed) for RFI’s or placement in as-built 3D models. During the steel erection, the total stations are used to confirm plumb and elevation for different members and identify anomalies that might need to be addressed.

Erection Sequencing: A solid sequencing plan is the key to project success for the fabricator, general contractor, and Red Cedar. The sequencing plan determines how the project will be erected based on the structural requirements, schedule, fabrication and delivery logistics, and the type of hoisting equipment used.

For every large project involving a crane, Red Cedar utilizes our SDS/2 software to visualize the project in 3D. Optimizing sequencing plans involves analyzing the structural members, the crane capabilities, critical lift requirements, site restrictions, and scope integration with others trade to determine the proper sequence. Since the model is interactive, Red Cedar can share and collaborate with the fabricator and general contractor to discuss and develop an appropriate plan. A good sequencing operation achieves productive use of the labor and equipment and keeps the project on schedule.

AISC CERTIFIED ERECTOR

Red Cedar is an American Institute of Steel (AISC) Certified Erector and possesses the AISC Quality Management Systems (QMS) Certification. This certification program is the GOLD STANDARD for the structural steel industry and is the most recognized national quality certification program. Engaging an AISC Certified Erector like Red Cedar assures Owner, designers and construction industry partners that certified participants have the personnel, organization, experience, documented procedures, knowledge, equipment, and commitment to quality to expertly perform structural steel erection. AISC focuses on the entire process of erection, to initiate quality at the start by focusing on error prevention rather than error correction.

Red Cedar follows a very strict quality control management program that includes training, regular quality verification and annual audit of our practices by AISC. Components of our comprehensive AISC Quality Assurance plan include:

> Management Responsibilities

> Erection Process

> Construction Document Review and Communication

> Document Control

> Quality Records Control

> Purchasing Procedures

> Material Identification

WELDING

BOLTING

COATINGS

MAINTENANCE

INSPECTION

CALIBRATION OF TEST EQUIPMENT

HANDLING, STORAGE, AND MATERIAL DELIVERY

TRAINING

INTERNAL AUDIT

Red Cedar is also an approved contractor for Avetta, ISN Net world, and Appruv. These organizations manage risk, safety , security, etc. for large companies and qualify contractors.

SPECIALTY PROJECTS AND INTRICATE WORK

Red Cedar's experience with specialized work outside of the typical industry process is tremendous. Renovation, conversion, or expansion projects using steel are complex and often involve intricate detailing and engineering to coordinate with existing structures.

Red Cedar provides turnkey services (e.g., design, engineering, fabrication (through partners), and installation) for complex installations and relieves the General Contractor and/or Client from that effort.

Engineering and Detailing: We have significant steel fabrication experience, which allows Red Cedar to offer specialized engineering and detailing as a turnkey package. Using both technology and on-site investigation, Red Cedar utilizes our SDS/2 software to create exact shop drawings that can be given to a fabricator. Using engineering partners, all requirements are completely detailed and stamped by a licensed, professional Structural Engineer prior to fabrication and coordinated with the Engineer of Record.

Factory Equipment Setting: Today’s manufacturing environments require complex and precise collaboration to properly set and stabilize equipment. From additive manufacturing systems to robotic assembly lines, Red Cedar works with all stakeholders including equipment manufacturers to assemble skilled teams of ironworkers, millwrights, electricians, and others for proper handling, placement and installation of critical equipment after the structure is complete.

Specialty Equipment Mounting: From hospitals with specialized ceiling mounted imaging systems to data centers with miles of electrical and cable management, numerous facilities require specialized “structure-hung” mounting designs for equipment. Red Cedar offers a turnkey process of engineering, design, fabrication and installation of these oftenoverlooked systems.

MISCELLANEOUS METALS

Because miscellaneous metals require more attention to detail as add-ons to existing structural environments, we work closely with your team to ensure our work meets your standards.

When appropriate, our team will visit the site to inspect and consider existing conditions prior to installation. We also evaluate and plan for the safest possible installation. You’ll be notified throughout the project of any hindrances or details that need attention and approval.

CAPABILITIES

> Awnings & Canopies

> Light Structures

> Architectural & Ornamental Metal

> Mechanical Support

> Stairs & Rails

> Ladders

> Custom Gates

> Specialty Products

MATERIALS

> Stainless Steel

> Aluminum

> Galvanized & Plain Steel

> Glass Rails

> Design Assist

Our vast knowledge and experience is the foundation of our design assist services, where we offer insights in creating the most cost effective solution for your solar structure needs.

> Structural Engineering

Our team will determine the capacity of your current framing elements, select the appropriate attachment system, and evaluate all aspects of structural requirements. To expedite the project, our pre-approved DSA structural design drawings make the process as streamlined as possible.

> Concrete Foundations

Red Cedar subcontracts some of the most reputable concrete subcontractors to offer foundation options (e.g., drilled concrete piers, wet set systems, rebar cage and anchor bolt systems, raised piers).

> Steel Fabrication/Erections

An AISC Certified Steel Erector providing structural options (e.g., roof mounted systems/racking, ground mount systems/racking, carport canopy structures, parking garage structures, and architecturally exposed custom structures).

> Module Installation

Full service solar module installation for a stress-free and simple turnkey solution.

Because miscellaneous metals require more attention to detail as add-ons to existing structural environments, we work closely with your team to ensure our work meets your standards.

When appropriate, our team will visit the site to inspect and consider existing conditions prior to installation. We also evaluate and plan for the safest possible installation. You’ll be notified throughout the project of any hindrances or details that need attention and approval.

SERVICES

> Metal Deck Installation

Red Cedar understands the importance of proper deck installation and building code compliance, allowing us to offer advanced knowledge, resources, and equipment to meet your specific needs.

ALL METAL DECK SPECIFICATIONS MEET THE STANDARDS OF THE STEEL DECK INSTITUTE.

> Shear Stud Installation

Correctly installing shear studs into steel decking is imperative to the overall integrity of the structure. Every weld is completed with maximum precision and attention to detail, ensuring safety and longlasting durability.

Stud work comes with inherent risks, and Red Cedar is dedicated to minimizing those risks for your company with strict stud weld testing and inspection. You can count on our team to provide dependable and consistent results with any application.

SAMPLE PROJECTS

UP NORTH PLASTICS | COTTAGE GROVE, MN

Red Cedar erected a new 450,000 SF warehouse with structural steel, including a five-story tower and link bridge. The miscellaneous metals package included multiple stair towers, guardrails, handrails, and checkered plate.).

TAIWAN SEMICONDUCTOR (TSMC) | PHOENIX, AZ

With a $40B investment, TSMC's new chip plant is the largest, most expensive construction project currently in the U.S. Red Cedar was awarded a $20M+ contract for extensive miscellaneous metals for FAB 1, FAB 2 and auxiliary buildings.

GOOGLE (MUSTANG STY 1A DATA CENTER) | MCCARREN, NV

Two data floors of heavy structural steel with wall pipe braced frame, with a floor load of W30 main carrying beams. Miscellaneous metals package included stairs, elevators, precast panels, doors, pipe support and bollards.

SAMPLE PROJECTS

NTT DATA GROUP CORPORATION (NTT) PHASES 2 & 3| MESA, AZ

Red Cedar, along with Clayco and SteelFab Texas, are erecting two 126,000 SF multi-story data centers including 36-megawatt critical IT load capacity, six 6 megawatt vaults and Class A office space.

NATIONWIDE INSURANCE | SCOTTSDALE, AZ

Two identical 5-story buildings including 5 individual, full-height, architecturally exposed stair structures and steel structures linked to the parking structure with a clear span pedestrian bridge.

CALIFORNIA MILITARY DEP. HEADQUARTERS COMPLEX | RANCHO CORDOVA, CA

Red Cedar was part of a collaborative design-build process to construct this 285,700 SF facility. One of the first large scale NET ZERO Energy projects implemented by the State of California.

AMAZON FULFILLMENT CENTER | FARGO, ND

The new 1,300,000 SF facility is the largest building in Fargo. Red Cedar erected 5,700 tons of structural steel in 10 weeks. The miscellaneous metals package included dock stairs, ships ladders, access ladders, railings, & bollards.

CALIFORNIA STATE UNIVERSITY, MONTEREY CSUMB STUDENT UNION | MARINA, CA

The erection used a large crawler crane to erect from one location. The miscellaneous metals package included stairs, architectural stair, and balcony handrail an AESS exposed pipe canopy.

PALOMAR REHABILITATION HOSPITAL | ESCONDIDO, CA

Red Cedar and Greywolf (Fabricator) provided and erected the structural steel and a sizeable miscellaneous package for this 52 bed facility focusing on customized rehabilitation.

SAFETY IS A CORE VALUE

WE PREPARE AND STAY AWARE

Red Cedar is proud to be an industry leader in maintaining safe and accident-free work sites and in ensuring our employees stay safe 100% of the time. Safety isn’t optional, it’s a requirement – and something we take very seriously.

We encourage every employee at Red Cedar to ensure the #1 focus of every project is maintaining a safe work environment from start to finish. We have one of the lowest EMRs in the industry thanks to exceptional teamwork, mentorship, and accountability. Mistakes aren’t met with punishment – but instead with a root-cause analysis of how to prevent the same mistake again. This is how we promote honesty, integrity, and safe job sites.

REQUIRED EMPLOYEE TRAININGS

> OSHA Subpart R

> Fall Protection for Construction

> OSHA 10 Hour Construction

> Qualified Rigger

> OSHA 30 Hour Construction

> Crane Signal Hands and Voice

> 1st Aid + CPR Red Cross

> Aerial and Scissor (MEQP) Lift Operator

> Global Harmonization Systems/ Safety Data Sheets

> Forklift Operator

OUR SAFETY ACCOUNTABILITY SYSTEM

Every member of our company is responsible for safety, and it begins with upper management. Our leadership has a strong commitment to a safety-first culture, which continues on at every level.

SAFETY MEETINGS & TRAININGS EQUIPMENT MAINTENANCE POLICIES & PROCEDURES

DETAILED PLANNING

PROPER PPE

SAFETY DIRECTOR OVERSIGHT

LEADERSHIP ACCOUNTABILITY

ONGOING CERTIFICATIONS

EVERY PERSON ACCOUNTABLE OPPORTUNITIES FOR IMPROVEMENT

Safety information and metrics available upon request.

REFERENCES (PARTNERS)

3M

AMAZON

AMERICAN EXPRESS

APPLE

ARIZONA STATE UNIVERSITY

AT&T

BAYER

BOEING

BOSTON SCIENTIFIC

CARGILL

COSTCO

DHL

DOLLAR GENERAL

FED EX

FLEET FARM

FORD

GRACO

HAMPTON INN

HOLIDAY INN

IN

KAISER PERMANENTE

LUCID

MAYO CLINIC

MENARDS

NATIONWIDE INSURANCE

PFIZER

POLARIS

PRUDENTIAL FINANCIAL

SHERWIN WILLIAMS

TARGET

TESLA

TORO

TSMC

UPS

USPS

US BANK

VERIZON

WALMART

WELLS FARGO

XCEL ENERGY

REFERENCES (CUSTOMERS)

ADOLFSON & PETERSON (A&P)

BEN HUR CONSTRUCTION

BIG D CONSTRUCTION

BOLDT COMPANY

COOPER STEEL

DOING STEEL

DORAN CONSTRUCTION

HOLDER CONSTRUCTION

JE DUNN CONSTRUCTION

JOHNSON WILSON CONSTRUCTOR

KNUTSON CONSTRUCTION

KRAUS ANDERSON

LEJEUNE STEEL

MCCOWN GORDON

MERRILL IRON

NEWKIRK NOVAK

RYAN COMPANIES

SCHUFF

SPAN CONSTRUCTION

STEELFAB

TRIAD STEEL

BAYER MONSANTO | REDWOOD FALLS, MN