Teacher

Script and Handouts for the

FANUC

CRX - 5iA Collaborative Robot (COBOT)

Spring 2025

Nathan King (RCU)

Morgan Fisher (NEMCC)

Carver Middleton (AIM UP)

Mary Med eros (MGCCC)

Note: In the week prior to the arrival of the collaborative robot, it is suggested self-guided block coding tutorial found on the Blockly.games website. See how far they are able to make it through each of the sections titled: Puzzle, Tutor, Pond. If enrichment is needed to fill the time allotted for your class, then students can complete the Blockly modules that are not provided on Canvas course. This script provides a structured students how to program and interact with the CRX-5iA FENCELESS Collaborative Robot, ensuring they understand both the technical aspects and protocols involved.

Introduction

Today, we're diving into the exciting world of collaborative robotics with the robot, also known as “COBOT. This robot is designed to work safely alongside industries to assist with tasks such as assembly, packaging, and material handling. educational settings like ours.” This unit focuses on the fundamentals of programming robots, commonly referred to as COBOTs Throughout this four-hour session, experience in programming COBOTs to perform simple tasks effectively.

Required Materials

• Access to collaborative robots (COBOTs) for hands-on training.

• Safety handout printed and visible before operating the COBOT. Access to this file is on Canvas course.

By the end of this workshop, students will be able to:

• Understand the basic concepts of collaborative robotics.

• Identify various types of COBOTs and their applications in industry.

• Program COBOTs to complete straightforward tasks.

• Troubleshoot common issues encountered during programming.

• Demonstrate safe practices while working with COBOTs.

Unit 1: Introduction to COBOTs

Overview of Collaborative Robots

• You will learn about the definition and characteristics of COBOTs, how they differ from industrial robots, and their applications in different industries including assembly, packaging, and material handling.

• A Mississippi State AIM UP instructor that conducts COBOT trainings for teachers, Carver Middleton, stated that, “it’s not the robot that makes it collaborative, it’s the application of the robot that makes it collaborative.”

• This quote emphasizes that the term "collaborative robot" (or "COBOT") isn't just about the robot itself, but about how it's used.

• For example, a robot, by itself, is just a tool or a machine. What makes it "collaborative" is not its physical design alone, but the way it is integrated into tasks and environments specifically, how it works alongside humans. A robot becomes "collaborative" when it is used in a way that allows it to interact safely and effectively with people, sharing tasks, spaces, or responsibilities. In terms of a human-centered focus, the focus is on the relationship between humans and robots. The same robot could be used in a non-collaborative way (working alone, separated from people) or in a collaborative way (directly assisting or cooperating with people).

• For example, If a robot is placed in a factory and works in a cage, away from humans, it’s not collaborative even if it has features that could allow for collaboration. If that same robot is set up to work side-by-side with a human, handing them tools or assisting in assembly, it’s the way it’s being used the application that makes it collaborative.

• Why Does This Matter? Understanding this distinction helps educators and students think creatively about how to use technology in ways that enhance teamwork and productivity, rather than just focusing on the machine itself. In industry, businesses must design workflows and environments that take advantage of collaborative possibilities, not just buy "collaborative robots" and expect results.

What is a COBOT and what makes them unique?

• Definition: Collaborative robot - is a compact, easy-to-program, and safely designed for humanrobot interaction in industrial settings

• The importance of safety when working with COBOTs will be emphasized, along with an overview of safety standards and protocols. A demonstration of safe interaction with COBOTs will be provided.

• Characteristics:

• General Characteristics: This is a robot that is used in collaborative mode allowing the operator to work in close proximity of the robot safely. If the robot were to bump the operator, it would stop itself immediately with no injury to the operator.

• Safety Features: They have built-in sensors to detect human presence and adjust their movements accordingly. It includes sensitive contact detection, ensuring safe collaboration with human workers. It complies with ISO 10218-1 safety standards, allowing for safe operation without safety fences. Additional safety features include contact stop, push-toescape, and retract functions.

• Collaborative Mode: They do not require fencing and safeguards when used in collaborative modes. They can detect opposing forces and stop their operation before injury can occur.

• Sensors: Additional Sensors can be added to these robots, which can allow them to transition between collaborative and normal industrial robot modes.

• Varying Speeds: When in collaborative mode the robot moves slower, at a set speed limit, and has a set impact force limit.

• Ease of Use: Programming is user-friendly, often through intuitive interfaces or teach pendants. They can be hand guided into positions.

• Payload and Reach: This particular model has a payload capacity of 11 lbs and a reach of 39 inches, making it suitable for various industrial and manufacturing tasks.

• Programming Interface: The robot features a simplified programming interface for users with limited robotic experience which includes drag-and-drop technology on a touchscreen.

Programming interface:

• Block style: Block functions are picked from a library and placed on a timeline. Each block contains sub menus with options and wizards to configure the function. Each block is executed in the order they are placed in the timeline.

• Maintenance: The robot has 8 years of zero maintenance, reflecting industrial reliability.

• Versatility: The robot can be used in various industries due to its adaptability, with options for different end-of-arm tooling (EOAT) like grippers and cameras, and it supports integration with third-party components.

• Environmental Resistance: It has an IP67 rating (e.g., completely protected against dust and can withstand water immersion up to 1 meter deep for 30 minutes) for the upper and lower arm, providing protection against dust and oil leaks, which is crucial for industrial environments.

What are Industrial Robots

• Industrial Robots are programmed to complete a specific task autonomously without interactions with humans. They are mounted in a stationary fashion.

• Definition: Industrial Robots – robots programmed to complete a specific task autonomously without interactions with humans.

• Characteristics:

• General Characteristics: They are typically programmed via a “teach pendant” and require some technical knowledge of programming languages.

• Safety Features: They are typically fenced off, as it is not safe to be around them while in operation. Unless proper safety protocols are used, such as lock out tag out and hand-held “dead man” switches.

• Possible Unsafe Situations: They are unable to detect objects in their path. They will execute the programmed path and inflict injury or harm to anything in their way. This is why they require fencing and safe entry sensors.

• Safe Area: When the operator is in the safe area and the “Light Curtain” is not triggered. Robot can operate as normal.

• Light

Curtain: If the Operator has broken the light curtain by standing in the entry way of the fenced area and the robot has been placed in an emergency stop (E-STOP) state.

The robot cannot return to regular operation until the operator exits the red zone. Then the operator must give a signal via buttons to the robot for it to return working.

• Lock out Tag out: Operators should never enter the robot cell. This can only be performed by trained individuals along with safety protocols and procedures in place, such as Lock out Tag out.

The major differences between industrial robots and collaborative robots (COBOTs)

• Open the Canvas Course and have students work on the Edpuzzle Assignment: Industrial Robots vs. Collaborative Robots | A Clear Winner? (4 min )

• Design and Safety: Collaborative robots are designed to work safely alongside humans without the need for safety barriers like fences. They feature rounded designs, internalized wires and motors, and advanced sensors to detect human presence and adjust their actions for safety. Industrial robots, on the other hand, are typically larger, more rigid, and require safety barriers to protect human workers due to their high speed and force capabilities.

• Programming: COBOTs are known for their ease of programming, often allowing non-technical personnel to set up tasks through intuitive interfaces or by physically guiding the robot arm. Industrial robots require specialized programming knowledge, making their setup and operation more complex.

• Flexibility and Adaptability: COBOTs are highly flexible, capable of performing multiple tasks within a company, and can be easily moved or reprogrammed for different applications. Industrial robots are designed for high-volume, repetitive tasks with less adaptability to part variations or changes in production processes.

• Cost: COBOTs generally have lower upfront costs, lower maintenance costs, and a faster return on investment (ROI) due to their ease of integration and operation. Industrial robots, while potentially less expensive initially, require significant resources for setup, programming, and maintenance.

• Applications: Industrial robots excel in applications requiring high speed, precision, and heavy lifting, such as assembly lines, welding, or painting. COBOTs are suited for tasks that require human-robot collaboration, like pick-and-place operations, machine tending, and quality control,

Light Curtain Safety Sensor

Light Curtain Safety Sensor

and safety are paramount. COBOTs also allow for flexibility with proper safety sensors.

• Size and Relocation: COBOTs are compact and can be easily relocated within a production floor, making them ideal for small and medium enterprises. Industrial robots are larger, often fixed in place, and require substantial floor space.

• Performance: Industrial robots offer unmatched technical specifications in terms of speed, accuracy, and power, making them ideal for high-volume manufacturing processes. COBOTs, while improving in performance, are designed for tasks that don't require the same level of precision or speed.

• Work Settings: COBOTs can operate in shared workspaces with humans, saving space and facilitating worker movement. Industrial robots typically require dedicated, enclosed work cells for safety reasons.

• Sensors: With the addition of an area scanner safety sensor, if the operator is in the green zone, the collaborative robot can operate at highspeed with no set impact force limit. When the operator advances to the yellow zone, the robot will switch back to collaborative mode and the speed limit and impact force limit are activated.

• Safety: Collaborative robots are safer for humans to interact with than industrial robots.

• Ease of use: COBOTs are easy and intuitive to program

Applications in Industry

Collaborative robots (cobots) are increasingly being adopted across diverse industrial sectors, performing a wide range of tasks that enhance productivity, safety, and flexibility. Below is a descriptive list of real-world and emerging applications of cobots in industry, with examples drawn from recent deployments and case studies: Assembly

• Assisting with repetitive assembly tasks such as screwing, gluing, and fitting components on production lines.

• Gearbox manufacturer SEAT Componentes integrated 10 cobots from Universal Robots to streamline assembly operations using only internal resources. (video and article – in Spanish, gives a great visual use of collaborative robots)

• Harmon, a leading facade company, uses UR20 cobot arms from Raise Robotics to improve consistency and safety in facade assembly. (video and article)

Packaging and Palletizing

• Automating end-of-line packaging and palletizing, including picking and placing items into boxes or containers. (video/article)

• AIM Processing utilizes cobots from Universal Robots for stacking trays, picking parts off conveyors, and tending machines, increasing throughput and reliability.

• Packaging and palletizing are common cobot applications in almost all production facilities, enabling scalable and modular automation (video and article and another video/article).

Material Handling

Area Scanner Safety Sensor

• Moving materials, parts, or products within a facility, including tote handling, sorting, and transferring items between workstations.

• DENSO automated tote handling for automotive painting using cobots and CapSen technology, improving efficiency and reducing manual labor. (video/article)

• Texas Children’s Hospital employs an ABB YuMi cobot to safely transfer fruit flies for research, demonstrating precision in delicate material handling tasks. (video/article)

Machine Tending

• Loading and unloading CNC machines, presses, and other equipment to reduce human exposure to repetitive or hazardous tasks.

• Cobots are frequently used to tend machines, including in fabrication, welding, and machining environments, leading to higher productivity and reduced lead times.

Welding and Fabrication

• Performing welding operations, especially in high- mix, low-volume production environments where flexibility is crucial. (video)

• A Florida manufacturer of exhaust parts increased weld speed tenfold and improved quality by integrating a cobot into its welding processes. (video/article)

• Skilled welders often welcome cobot assistance for repetitive, lower-value welding work, freeing up time for more complex tasks. (article)

Surface Finishing, Polishing, and Quality Inspection

• Conducting tasks such as sanding, polishing, material removal, edge breaking, and quality inspection. (blog article, and website)

• Standard collaborative cells are used for polishing and material removal, enhancing consistency and reducing ergonomic risks for workers. (website with videos)

• 3D and stereo cameras are increasingly attached to cobots for automated inspection and quality control, particularly in automotive and electronics sectors.

Automotive Industry

• Cobots are widely deployed for assembly, painting, inspection, and material handling in automotive manufacturing, with rapid growth projected in this sector. (video/article)

• Automated tote handling and machine tending are notable examples in automotive painting and component production. (article, second article)

Electronics and Semiconductor Manufacturing

• Precision tasks such as chip handling, assembly, and inspection are performed by cobots equipped with advanced sensors and vision systems. (article and another article)

• Lam Research uses the Dextro robot system to deliver precision and repeatability for improving chipmakers’ yields. (video/article, second video/article)

Healthcare and Laboratory Automation

• Handling delicate biological samples, such as the ABB YuMi cobot transferring fruit flies at Texas Children’s Hospital, showcasing cobots’ ability to work safely alongside humans in sensitive environments. (article/video, second article)

• Medical Device and Healthcare Applications (article)

• Facade construction, high-precision industrial applications, and flexible manufacturing cells for small batch runs and rework in machine shops. (video)

• Universal Robots’ UR+ ecosystem features over 30 cobot-powered systems for a variety of industry-specific applications, demonstrating the technology’s adaptability. (video/article)

Safety and Best Practices

• Safety First! Here's how to interact safely with the collaborative robot:

• Safety Interaction

• Keep a safe distance: Never stand directly in the path of the robot's movement.

• Emergency Stop (E-Stop): Know where the emergency stop button is located.

Answers for Safety Test:

• It is acceptable to operate the COBOT only when the teacher is present and gives permission

• Do not put hand/fingers in gripper

• Do not put hands between table and robot tool/gripper

• If the COBOT moves erratically, FIRST press E-stop and notify the instructor.

• Industrial Robots are programmed to complete a specific task autonomously without interactions with humans.

• They are typically programmed via a teach pendant and require some technical knowledge of programming languages.

• They are typically fenced off, as it is not safe to be around them while in operation. Unless proper safety protocols are used, such as lock out tag out and hand-held “dead man” switches.

• They are unable to detect objects or humans in their path. They will execute the programmed path and inflict injury or harm to anything in their way.

• When an operator brakes the light curtain or initiates the emergency stop (E-stop) the robot will be placed in an emergency stop state The robot cannot return to regular operation until the operator exits the red zone. Then the operator must give a signal via buttons to the robot for it to return working.

• Collaborative Robots are programmed to complete a specific task autonomously and allow for interactions with humans. They are also mounted in a stationary fashion.

• They do not require fencing and safeguards when used in collaborative modes. They can detect opposing forces and stop their operation and enter safety stop.

• Additional Sensors can be added to these robots, which can allow them to transition between collaborative and normal industrial robot modes. COBOTs are generally considered safer than industrial robots because they incorporate force/torque sensor to detect human or inanimate object contact.

• Collaborative robot is being used in collaborative mode.

• This allows the operator to work in close proximity of the robot safely. If the robot were to bump the operator, it would stop itself immediately in the direction of the contact with no injury to the operator.

• When in collaborative mode the robot moves slower, at a set speed limit, and has a set impact force limit.

• Collaborative Robots use touch screen tablet style teach pendants.

• They operate in a collaborative space which is a designated area for humans to work alongside robots.

• They can be hand guided into positions

• They are typically programmed via a teach pendant and require some technical knowledge of programming languages.

• They are typically fenced off, as it is not safe to be around them while in operation. Unless proper safety protocols are used, such as lock out tag out and hand-held “dead man” switches.

• They are unable to detect objects or humans in their path. They will execute the programmed path and inflict injury or harm to anything in their way.

PRINT THIS PAGE OFF AND TAPE IT TO THE TABLE THAT THE COBOT IS CONNECTED TO. STUDENTS SHOULD UNDERSTAND THE POSSIBLE DANGERS ASSOCIATED WITH NOT BEING CAUTIOUS WHILE RUNNING THEIR PROGRAMS.

DO NOT PUT YOUR HAND IN OR UNDER THE GRIPPER ARMS. STAND AWAY FROM THE COBOT ARM WHILE IT IS IN MOTION. GENTLY PUSH THE ARM OUT OF THE WAY BEFORE MANIPULATING THE AREA THAT YOU ARE WORKING WITH.

IT IS ACCEPTABLE TO OPERATE THE COBOT ONLY WHEN THE TEACHER IS PRESENT AND GIVES PERMISSION

DO NOT PUT HAND/FINGERS IN GRIPPER

DO NOT PUT HANDS BETWEEN TABLE AND ROBOT TOOL/GRIPPER IF THE COBOT MOVES ERRATICALLY, FIRST PRESS E-STOP AND NOTIFY THE INSTRUCTOR.

Research COBOT - Discussion Guide

Questions to gauge understanding Overview of Collaborative Robots

1. Explain the difference between a traditional industrial robot and collaborative robot (COBOT)?

2. Can you name three industries where COBOTs are commonly used, and explain how they benefit these industries?

3. List some key characteristics that make COBOTs suitable for collaborative work environments?

Safety and Best Practices

4. Why is safety critical when working with COBOTs, and what are some safety standards or protocols we should follow?

5. What would you do if you noticed a COBOT behaving unexpectedly or if there was an emergency situation?

6. How does the design of COBOTs ensure they can safely interact with humans?

7. What are some potential hazards when working with COBOTs, and how can they be mitigated?

8. Can you describe a scenario where a COBOT's safety features would be particularly beneficial?

9. What are the implications of not following safety protocols when working with COBOTs?

safety features of COBOTs change or evolve in the future to new technologies or work environments?

Unit 2: Introduction to COBOT Operation

Complete the Edpuzzle assignment on the Canvas course titled “Right Hand Rule.”

COBOT Movement – Manual Guided Teaching

Introduction: In this session, you will program COBOTs to move freely by hand to any position necessary. This is useful when initially teaching your COBOT the endpoints of any program. Each of the corresponding four movement modes: Free, Translation, Rotation, and Custom have their own settings either enabling or limiting the freedom of manually guided movement within specified parameters. The following section demonstrates how to enable and utilize each of the four movements. Later, we will determine how to precisely position your COBOT endpoints for accurate repeatability.

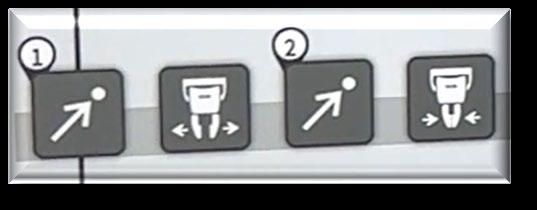

Robot Operation: Manual Guided Teaching – “Free” Movement

This setting does not limit the freedom of movement for the COBOT.

3. Now, locate the “Free” icon and slide the toggle for “Teaching weight” to 50%.

4. Then, enable “Free Hand Teaching” mode.

Robot Operation: Manual Guided Teaching – “Translation” Movement

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Manual guided teaching” midway on the left hand of the tablet screen.

This setting limits the COBOT to only a side-to-side “linear” direction along the X, Y, and Z axes without rotation.

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Manual guided teaching” midway on the left hand of the tablet screen.

3. Now, locate the “Translation ” icon and slide the toggle for “Teaching weight” to 50%.

4. Then, enable “Free Hand Teaching” mode.

Robot Operation: Manual Guided Teaching – “Rotation” Movement

This setting limits the COBOT to only circular “rotational” direction at each of the six joints.

3. Now, locate the “Rotation” icon and slide the toggle for “Teaching weight” to 50%.

4. Then, enable “Free Hand Teaching” mode.

Robot Operation: Manual Guided Teaching – “Custom” Movement

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Manual guided teaching” midway on the left hand of the tablet screen.

This setting customizes or allows you to limit the movement in one or more axes. It also allows you to disable the rotational movement in any of the three axes: X, Y, and Z. (See information “Right Hand Rule” above to gain a better understanding of how this limitation allows for greater accuracy when positioning the COBOT manually).

COBOT Movement – Jog

Robot Operation - Jog – Jog Mode: “Joint” Movement

This setting allows you to move each of the COBOT’s six joints individually.

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Manual guided teaching” midway on the left hand of the tablet screen.

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Jog” on the middle bar of the tablet screen next to Manual guided teaching.

3. Select Jog Mode “Joint ”

3. Now, locate the “Custom” icon and slide the toggle for “Teaching weight ” to 50%.

4. Then, enable “Free Hand Teaching” mode.

Robot Operation -Jog – Jog Mode “S/CART” (Cartesian) Movement

This setting customizes or allows you to limit the movement in one or more axes. It also allows you to disable the rotational movement in any of the three axes: X, Y, and Z. (See information “Right Hand Rule” above to gain a better understanding of how this limitation allows for greater accuracy when positioning the COBOT manually).

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Jog” on the middle bar of the tablet screen next to Manual guided teaching.

3. Select Jog Mode “S/CART” and click “Apply”

4. Notice on the picture that the “Y” axis toggle button is in the UP (Y+) position. Try that and see how the COBOT responds. Do you see a correlation to the “Right Hand Rule?”

Robot Operation –“Manual Handle” Movement.

This setting allows you to finely tune the movement of each of the six COBOT joints through the use of a scroll wheel. Try moving each of the six joints: J1, J2,..., J6 by selecting the scaling factors: x50, x10, x5, and x1, in that order.

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Manual Handle” on the middle bar of the tablet screen next to Jog and Align.

3. Select “Joint” in the Jog Mode menu and click “Apply”

4. Select “J1” in the Motion Dir/joint section

5. Select “x50” on the Scaling Factor section.

6. Turn the scroll wheel with the “FANUC” logo to the left and to the right to see how Joint 1 moves. Note where each joint is located. Review the Canvas course Edpuzzle assignment titled “What is a 6-Axis Robot?” if you wish.

7. Scroll the wheel at the following speeds: x50, x10, x5, and x1, in that order.

8. Now repeat step 7 for each of the joints: J1, J2, J3, J4, J5, and J6.

Robot Operation –“Manual Handle” Movement. This setting allows you to finely tune the movement of each of the six COBOT joints through the use of a scroll wheel. Try moving each of the six joints: J1, J2,..., J6 by selecting the scaling factors: x50, x10, x5, and x1, in that order.

1. Select “Robot Operation” at the bottom right hand of the tablet screen.

2. Select “Manual Handle” on the middle bar of the tablet screen next to Jog and Align.

3. Select “CART” in the Jog Mode menu and click “Apply”

4. Select “J1” in the Motion Dir/joint section

5. Select “x50” on the Scaling Factor section.

6. Turn the scroll wheel with the “FANUC” logo to the left and to the right to see how Joint 1 moves. Note where each joint is located. Review the Canvas course Edpuzzle assignment titled “What is a 6-Axis Robot?” if you wish.

7. Scroll the wheel at the following speeds: x50, x10, x5, and x1, in that order.

8. Now repeat step 4-7 for each of the joints: J1, J2, J3, J4, J5, and J6. You will change to a different joint (i.e., “J2”) in step 4. Change to each of the scaling factors (i.e., “x10”) as you go. Take note of the differences in action for your COBOT.

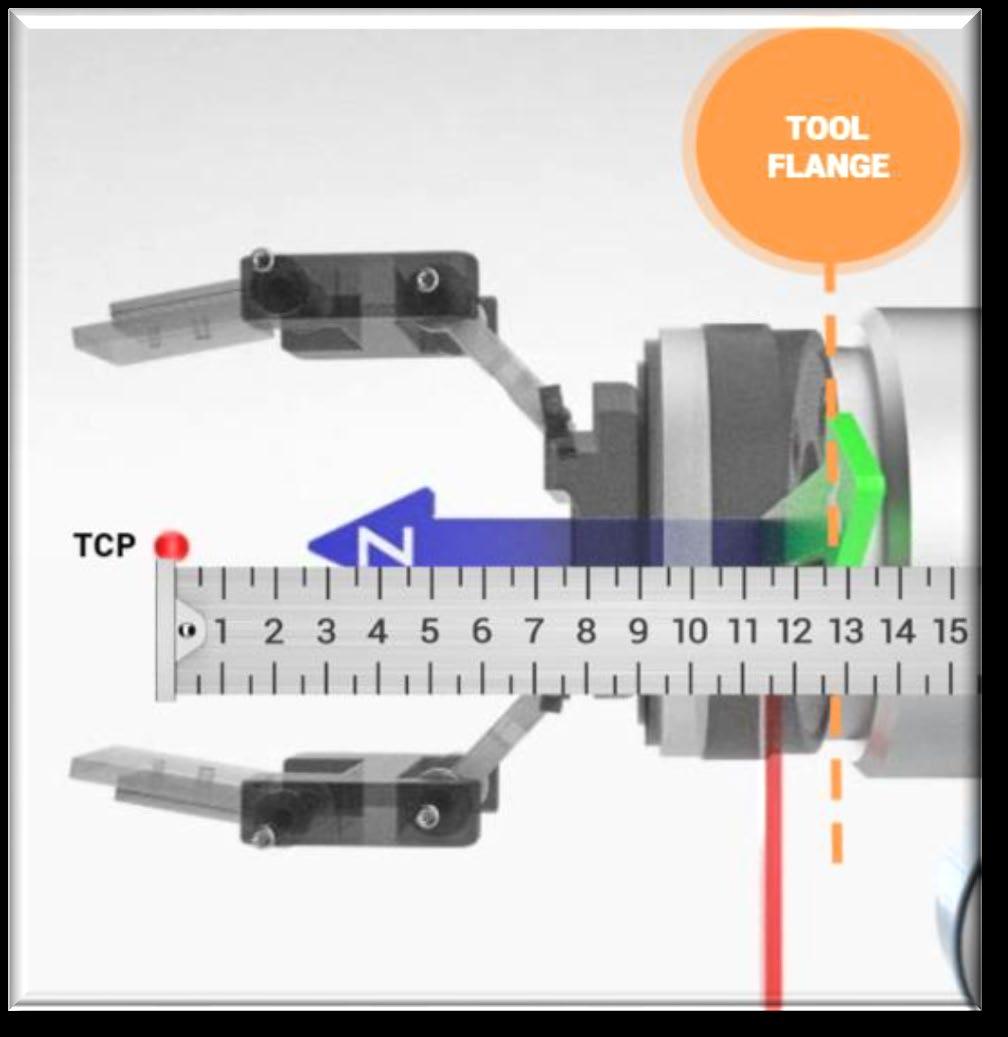

Tool Center Point (TCP): Overview.

• Tool Center Point (TCP): The Tool Center Point is the characteristic point of the tool which will be in contact with the workpiece (see red dot in the picture below). It’s this point that defines where waypoints are set in the program. The robot also touches the TCP to each waypoint defined in a program, paths are created between waypoints, and the TCP “travels” along these paths. Tool Center Point (TCP), Payload, and Center of Gravity (CoG) are necessary parts of robot setup The TCP is typically measured by the distance from the point of contact on the workpiece to the tool flange located depicted in the picture below.

• The robot uses:

o TCP to tell where to go and how to interact with the environment

o Payload to compensate against gravity

o CoG to assist with movement calculations

Unit 3: Introduction to COBOT Programming

Basic Programming

Helpful Tutorial Video

Set up a free FANUC account to view the following video tutorial: CRX Manual Guided Teaching

Introduction: You will receive an overview of common programming methods and gain familiarity with the user interface of the COBOT programming software..“Now, we will cover an overview of the methods used in the FANUC COBOT programming ”

Programming Environment

• You will engage in a hands-on session with the available COBOT to learn basic programming commands. This includes step-by-step guidance on setting up a programming environment and an using the motion programming that you learned in Unit 2 to teach the COBOT to move through defined paths.

• Pick up the tablet and use the touchscreen programming interface to begin

• To program the robot you will need to select the tool that you want, press and hold onto the icon, then drag it up to the “Program Timeline” section on your screen.

• All programming icons can be found in the “Programming ALL” section on your touch screen.

Basic Commands:

• “Motion” Tab: (Under the All tab)

To locate a particular programming command that moves the robot to a specific position you will need to select the “Motion” tab on the touchpad.

• Joint Move: (“J” icon)

The robot will move to a specific position by taking the easiest path. See photo to learn how to apply the joint move operation.

• Linear Move: (“L” icon)

The robot will move to a specific position in a straight line.

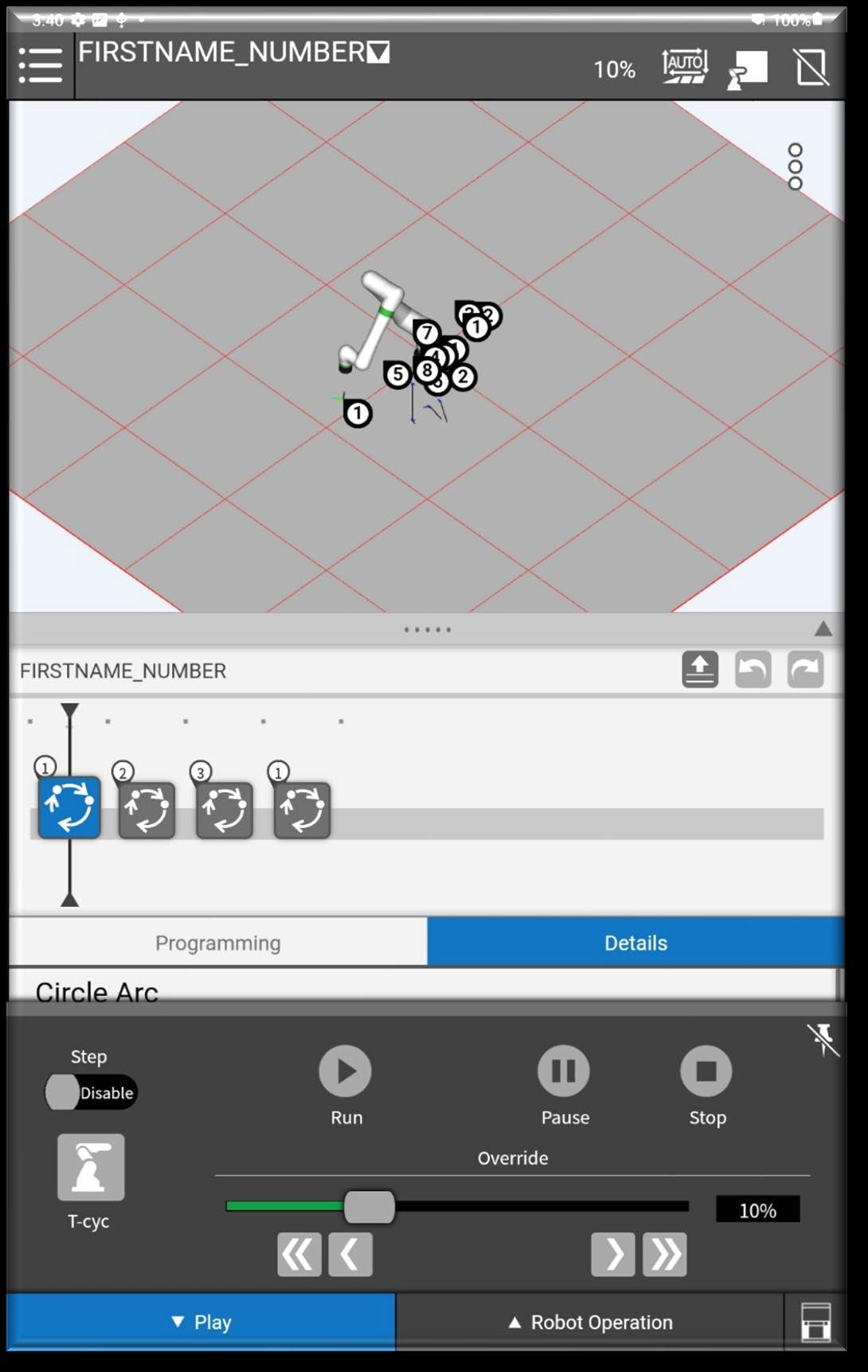

• Circle Arc Move: (“Circular” icon)

The robot will move to a specific position in a circular or arched path.

• Open Gripper: (“Open” icon) To open the gripper arm attachment

• Close Gripper: (“Close” icon) To close the gripper arm attachment.

Jog Tab

Hands-On Programming Session

1. Power On: Press the power button on the robot's controller. (Video 2 – watch second half)

2. Open the Programming Software: Navigate to the "Program" tab.

3. Create a New Program: Select the “Hamburger” or “MENU” icon, select ‘Select Program” Click on "New" and name it “New”: Select the New Button

Hand Teaching”

4. Type in "[YourFirstName]_number" (i.e., Barry_20). See the example in the picture above. (No spaces in program name) then select “OK”

5. Select “Robot Operations” at the bottom of your screen, then in the left side panel select “Motion ”. This should contain all of the movements that you will need to get your COBOT working.

Note: Later on if your students need more enrichment, then you can select “All” and discover the other things that this robot is capable of.

6. Teach Points: Use the teach pendant to manually move the robot to desired positions your COBOT must be in “Free Hand Teaching” enable mode to move from one position to another by hand.

7. “Free Hand Teaching” enable mode: Disable the TP, click “Reset” if there is an error, deselect “Robot Operation” at the bottom right of the tablet screen (make sure this tab is out of the way), then select “Manual guided teaching” tab at the left of the screen, press enable “Disable/Enable” button to the right of “Free

Note: With this setting, you can move the robot without much effort. Remember to set the Teaching weight to “light” or “100%”

8. Teach Pendant: When programming a position, they can be hand guided by the operator or by the touch screen controls on the teach pendant. Make sure that you follow step step 7 above.

9. Jog: Use the jog buttons to move the robot.

10. You can jog each one of the six servo motors on the robot “J1, J2, J3, J4, J5, and J6”. Select the Jog tab in the “Robot Operation” at the bottom right of the tablet. For practice, move the sliders for any of the J1-J6 joints to move them from one position to another.

11. In the “Align” tab, you can record the position by pressing the "Record Pose" button to save the current position.

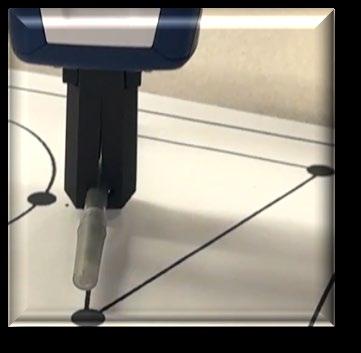

Step-by-Step Programming: Pick and Place: (Small Object)

1. Menu: Use the menu button in the top right and navigate to Teaching/Select Program (Video 2 – watch second half)

2. “New”: Select the New Button

3. Name Program: Name your program your first name underscore the activity number. It is important to not have any blank spaces in the name of your program (i.e., “Barry_20”)

4. Deselect “Robot Operations” (make sure this tab is out of the way), then select “Programming” tab and “Motion” on the left side of the tablet screen.

5. In the icon pallet, find the instruction titled “L” which stands for Linear Move.

6. Drag and drop the “L” icon onto the program line.

7. If at anytime through this process you see an error message at the top of the screen with a “Reset” button. Make sure that you always select “Reset” to clear the error message.

8. Select “Robot Operation”, “Manual guided teaching”, “Free”, and enable “Free Hand Teaching”. See picture below for example.

9. Move the COBOT arm to the position that you would like to start with.

10. Deselect “Robot Operation ” to move that out of the way.

11. Select the Linear Move that you placed on the program line (this will highlight it blue). This is called “Position 1.”

12. Select “Touch Up” icon on the left side of the tablet screen and select “OK”

13. Select the Open icon pallet, find the instruction titled “OPEN” which will open the gripper end of arm tool (EOAT).

14. If you need to manually open the gripper while you are setting up your program, then you can click on the Open icon in the program line and an option displays “Test Gripper”. You can select Open and the gripper will open manually. You can also Close the gripper if necessary, but remember to KEEP YOUR HAND OUT OF THE GRIPPER while it is closing.

15. Now ensure that “Free Hand Teaching” is enabled and move the COBOT arm until the gripper surrounds the small object that you intend to automatically pick up when your program is complete.

16. Now, drag and drop second Linear Move “L” icon onto the program line.

17. Then, drag and drop second “CLOSE” icon onto the program line. When the

program is running, this will close the gripper on the small object that you wish to pick up and place somewhere on the work space.

18. If you select the “CLOSE ” icon in the program line, then you can manually close the gripper to pick up the item as you complete the rest of the program.

19. Now, move a third Linear Move “L” icon onto the program line. We want to have this position move back to “Position 1” so, click the down arrow next to the “3 ” as seen in the picture and then select the number “1” to change its position.

20. Now, move the COBOT arm to the position on the workspace where you would like to place the object for its final destination. The small object should still be closed in the gripper. (Make sure “Free Hand Teaching” is enabled). You can see how the object has been moved manually in the picture here.

21. Now, move a third Linear Move “L” icon onto the program line. We want to call this new position “Position 3” as seen in the picture and then select “Touch Up” icon on the left side of the tablet screen and select “OK”. This will make sure that the position has been modified correctly.

22. Now, select the Open icon pallet. Drag and drop the “OPEN” icon onto the program line.

23. Now, move a fourth Linear Move “L” icon onto the program line. We want to have this position move back to “Position 1” so, click the down arrow next to the “4” as seen in the picture and then select the number “1” to change its position.

24. Manually open the gripper by clicking on the second “OPEN ” icon that is already in the program line and select “OPEN” in the “Test Gripper” option as you did previously You can select Open and the gripper will open manually. This will allow you to move the small object that you are picking and placing back to its original position.

25. Now, move the COBOT arm out of the way, preferably anywhere that is higher than “Position 1” on your workspace.

26. Select “Play”, Shift the “Override” slider over to “50%”, then select “Run” and your program should begin and follow the steps that you specified.

Programming Screen Layout

Virtual View

Joint Move:

Robot will move to this point taking the easiest path

Linear Move:

Robot will move to this point in a straight line

Open Gripper:

Robot will open gripper

Close Gripper:

Robot will close gripper

Circle Arc Move:

Robot will move to this point taking an arched path. Three of these moves are required to move in a circle. With the first move being repeated after the third

Teaching Robot Positions

1. Enable the Teach Pendant

2. Drag a function to the timeline

3. Then jog robot to the desired position.

4. Use the Touch Up button to save the current robot position for the highlighted function

Jogging the Robot

• Use the “Robot Operation Tab” at the bottom of the screen to open the set of options that you will need to jog the robot.

• “Jog Tab”: control for speed of robot and each direction or joint

• “Manual guided teaching TAB”:

• “MPG Tab”:– for fine adjustments in each direction or joint

Jog Tab

Running a Program

1. Disable the Teach Pendant

2. Use the Play tab at the bottom of the screen

3. Press the Run button

Play Tab

Practical Application

Introduction: In this session, you will program COBOTs to perform simple assembly tasks. You will participate in a group activity to design a task that a COBOT can assist with and program the COBOT to package items, such as assembling boxes.

Programming Simple Tasks

• Powering off: Cold Restarting your COBOT (Video 1)

o Select the “Hamburger” button or “MENU” icon at the top left of the screen.

o Select “Utility” then “Cycle Power” then “Cold”

o Make sure that Robot Operations tab is collapsed

o Select “Next Step”

o On the Power box connected to your COBOT turn the power switch to OFF. (Twist the handle counter-clockwise until the COBOT “powers off”)

• Powering the COBOT on.

o Turn the Power box connected to your COBOT turn the power switch to ON. (Twist the handle clockwise until the COBOT “powers on”)

o Your tablet will tell you wait a moment

o A “Payload Confirmation” pop up will ask to enter a number. You should type in the default code “1111”. (Video 2 – watch first half)

o Select “OK”, ‘Yes”, “OK” again, and then select the “Hamburger” button or “MENU” icon

Teachers: For in-depth video on these steps visit the Fanuc training website and register for a free account, then follow the steps in the first 5 videos: You will not be able to view the videos without an account.

1. Overview and Features

2. Unboxing and Setup

3. Programming Part 1: Initial Settings

4. Programming Part 2: Manual Operation

5. Teaching the CRX

***The following section is not necessary if your COBOT is set up already***

Initial Setup: (Powering Up the COBOT): Program the robot to pick up a part from one location and place it in another:

1. If tablet is off, turn tablet on by pressing and holding on the button on the top right side of the tablet.

2. Swipe up from the bottom of the screen and open the “Tablet TP” icon

3. Turn the breaker on the power box to the “ON” position.

4. Press “Next Step” as you answer the setup questions

5. Select “Continue with Guidance” and “Next Step”

6. Select “Americas” and “Next Step”

7. Select “CST Central Standard” and “Next Step”

8. Set the correct time and date and “Next Step”

9. On “Network Access” screen select “No Network Access” and “Next Step”

10. On “ Editor Type” screen select “Touch Panel Editor (recommended)” and “Next Step”

11. If all information is correct, then select “Finish”

12. In the “Payload Confirmation” pop-up, type “1111” and press “OK”

(If you cancelled this pop-up box and you see an error at the top of the screen stating “Need to confirm payload” you can bring it back by selecting the “RESET” button and then type in the code on step #12,

If your tablet is already set up

• Use the information on the previous page s to help with understanding the locations of specific icons or wording on the touchpad. Press the “Robot Operation” tab at the bottom of the screen

• Press the “Manual guided teaching” tab (ensure that your program has been named without spaces, see above)

1. Use the teach pendant to manually move the robot to desired positions your COBOT must be in “Free Hand Teaching” enable mode to move from one position to another by hand.

2. “Free Hand Teaching” enable mode: Disable the TP, click “Reset” if there is an error, select “Robot Operation” at the bottom right of the tablet screen, select “Manual guided teaching” tab at the left of the screen, press enable “Disable/Enable” button to the right of “Free Hand Teaching ”

3. To manually guide your robot you must press the switch on the back of the touchscreen halfway down to “2nd position” (see photo)

4. Now, manually guide your robot with one hand by using any of three options: “Free”, “Translation”, and “Rotation ” . Note the differences between the three options.

• Jog Mode

1. Press the “Teach Pendant ” button to enable it.

2. If the TP enable alarm is present, then press the “RESET” button to clear it.

3. Press the “Jog ” tab

4. We will need to put the robot in Cartesian Jog mode, to do this select the “Jog mode” drop down menu and select “Cart”

5. Move or “Jog” the robot along the X axis by moving the “Position” slider up or down (i.e., +X orX)

1. Select “Hamburger” or “MENU ” icon

2. Tap on “Select Program ”

3. Move to Pick Up: Open the program that you created previously. Select “Open” on the right hand of the tablet screen to open the program

4. Select Gripper Open: Under “Programming ” select “Open” Command and drag it onto the timeline. This will open the gripper when we run the program later on. After running the program make certain that the object your COBOT is picking up is placed back in the original location.

5. Move the robot to the placement location.

6. Gripper Close: “Close” command closes the gripper to hold the part.

7. Right Hand Rule: Now, on the Canvas course under Unit 2, you will see an Edpuzzle assignment titled, “Right Hand Rule.” Complete and practice the information found in that video before moving on to the next section.

8. Move Back: Return to the starting position.

Testing

and Iteration

• Run the Program:

• Execute your program by pressing the "Run" button on the teach pendant:

• Run Button

• Observe and Adjust: Watch the robot's movements. If there are issues:

• Troubleshoot: Check for incorrect movements or safety stops. Here are common issues:

• Incorrect Path: Adjust the taught points.

• Safety Stops: Ensure no obstructions or human presence in the robot's path.

Testing and Iteration (“Repetition”)

Students will execute their programs on the COBOTs to observe performance and troubleshoot common issues like incorrect movements and safety stops. They will work on iterating (‘repeating”) their programs to improve efficiency and effectiveness.

Have your students work through the Hands on Programming Activities: Activity 1 and 2 below as they demonstrate their ability to program the COBOT.

Hands on Programming Activities: Activity 1

Square:

• Use four move functions (move j or move l) to move the robot to each corner of the square.

Circle:

• Use three circle arc moves to move the robot to each of the three points on the circle.

Hands on Programming Activities: Activity 2

Obstacle Course:

• Use a series of motion functions to pick up a block at the START box and move to the mappedout boxes. Do not release the block until you have placed it on the END box. Avoid knocking over the obstacle blocks that are standing up in the STAND 3 boxes. You should not drag your block across the template.

Programming: Pick and Place (Small Object)

• Students will create their own program accomplishing a task that interests them and could be useful in an industrial setting (e.g., pulling a box out of a slot, stacking boxes in an orderly fashion on a pallet, etc.)

Final Project Presentation

• Students will create their own program accomplishing a task that interests them and could be useful in an industrial setting (e.g., pulling a box out of a slot, stacking boxes in an orderly fashion on a pallet, etc.)

Conclusion and Next Steps

• (NEED AN EXAMPLE or OUTLINE in terms of a cobot program) You could use the engineering design method to create their programs in an effective way.

Students could define a problem within an industrial setting, brainstorm their ideas – in other words “generate concepts” (no idea is a bad one), then develop a solution to the problem, construct the program and test it out, evaluate the effectiveness of the program, and then present their solution to the rest of the class.

• Each group will present their programmed task and the results of their execution. Feedback from peers and instructors on performance and programming techniques will be provided.

• Present Your Work: Each group will demonstrate their programmed task:

• Show the Program: Explain the steps you took to program the task.

• Run the Robot: Execute the program live for the class.

• Use the Collaborative Robot Programming Project Presentation Rubric below as a formative assessment for the student’s program presentation.

• An overview of further resources and learning opportunities in COBOT programming will be provided, along with a discussion of certifications and career paths in robotics and automation.

• Further Learning: Here are resources for those interested in robotics:

• Certifications: Look into FANUC CERT programs for further education.

• Career Paths: Robotics and automation offer numerous career opportunities.

Collaborative Robot Programming Project Presentation Rubric

Note to Instructor: Evaluate student groups holistically, considering their collaborative effort and technical growth throughout the project.

Program

Complexity and Design

Technical Explanation

Live Robot Execution

Peer Interaction and Feedback

Professional Communication

Extremely sophisticated robot programming with multiple complex tasks and innovative problem-solving approach

Comprehensive, detailed explanation of programming steps with advanced technical vocabulary; demonstrates deep understanding

Advanced programming with clear logic and multiple integrated functions

Clear and thorough explanation of programming process with technical accuracy

Flawless robot performance demonstrating precision, efficiency, and complete task completion Robot performs task with minor, negligible errors

Exceptionally engaging presentation; responds to peer questions with depth and technical expertise

Highly professional, clear, and confident presentation with exceptional visual aids and communication

Scoring Guide:

Total Possible Points: 25

• 22-25 Points: Exceptional (A)

• 18-21 Points: Proficient (B)

Strong presentation with thoughtful and constructive peer interactions

Professional presentation with clear communication and good supporting materials

Functional programming with moderate complexity and clear objectives

Adequate explanation of programming steps with some technical details

Robot completes most of the programmed task with some inconsistencies

Satisfactory presentation with basic peer engagement

Adequate presentation with basic communication skills

Basic programming with limited functionality

Limited explanation with minimal technical depth

Significant performance issues during robot execution

Limited peer interaction and shallow responses

Somewhat disorganized presentation with limited clarity

Minimal programming effort with significant gaps

Vague or incomplete explanation of programming process

Robot fails to complete basic programmed tasks

Minimal or no meaningful peer engagement

Poorly organized and ineffective communication

• 14-17 Points: Developing (C)

• 10-13 Points: Emerging (D)

• 0-9 Points: Beginning

Unit 4: Enrichment Activities and Real-World Industrial COBOT Use Cases

Review:

This workshop provides a foundational understanding of COBOT programming and its applications, equipping you with the skills needed to engage in the rapidly evolving field of robotics. Through hands-on experience and collaborative learning, you will leave the workshop with practical knowledge and with the confidence to further explore the world of robotics.

Enrichment Activity: Case Studies in Industry

• You will discuss real-world applications of COBOTs in manufacturing and logistics, along with exploring the future of collaborative robotics and potential advancements in technology.

• Collaborative robots are transforming manufacturing and logistics by enhancing efficiency, safety, and adaptability. With advancements in AI, machine learning, and mobility, COBOTs are poised to revolutionize industries further, making automation accessible to businesses of all sizes. As their capabilities expand, COBOTs will play a critical role in shaping the future of industrial automation.

• Students can access online resources such as CobotTrends.com to research new and innovative ways that COBOTs are utilized in industry or real world settings.

• Discussion: Share examples of COBOTs in real-world settings:

• Have students spend time researching and collaborating ideas found in COBOT related resources such as the following:

• Manufacturing:

• Discuss how COBOTs are used in assembly lines, such as the Fiat 500 production line, and how they address labor shortages and optimize production cycles.

• Fiat 500 Production Line: Collaborative robots assist with assembly processes and quality control, addressing labor shortages and optimizing production cycles

• Welding Applications: Raymath, a metal fabricator, uses Universal Robots for TIG and MIG welding, resulting in a 200% increase in production efficiency

• Automated Bin Picking: New England Union Company deployed UR10e cobot arms with ActiNav systems to operate untended overnight, reducing lead times and freeing workers for higher-value tasks

• Logistics:

• Explore how COBOTs are used in warehouses for order fulfillment optimization and how they reduce unnecessary walking and increase productivity.

• Order Fulfillment Optimization: Collaborative mobile robots guide warehouse associates through picking activities, reducing unnecessary walking and increasing productivity by up to 3x

• Autonomous Mobile Robots (AMRs): Companies like TBSI use MiR200 robots to save up to 16 hours of human labor daily, reallocating workers to more valuable tasks

• Error Reduction: AI-powered cobots minimize human error during order fulfillment by optimizing picking routes and guiding associates through tasks

• Future of Collaborative Robotics

• Technological Advancements

• AI and Machine Learning:

• Discuss how future COBOTs will leverage machine learning for one-shot learning and predictive algorithms to enhance safety and compliance.

• Enhanced Mobility:

• Explore how COBOTs are expected to become more mobile, enabling seamless collaboration across different workspace sections.

• True Collaboration:

• Advanced COBOTs will sense human behavior within larger projects and adjust their actions dynamically to maximize productivity.

• Expanded Applications

• Healthcare:

• Discuss the increasing adoption of COBOTs for surgery assistance, rehabilitation, and patient care tasks.

• Agriculture and Retail:

• Explore emerging applications in precision-based tasks such as food processing and inventory management.

• COBOTs in industry

• ABB

• Ultra Accuracy GoFa Cobots: ABB has introduced new COBOTs with enhanced accuracy, suitable for applications like D printing and welding. These COBOTs offer a path accuracy of mm and are versatile for various industrial tasks. ABB's COBOTs are used in electronics, automotive, aerospace, and metal fabrication, leveraging their precision and flexibility.

• Global Presence: ABB operates across North America, South America, Asia Pacific, Europe, and the Middle East and Africa, offering a range of collaborative robots including YuMi, GoFa, and SWIFTI series.

• KUKA AG

• Cobot Innovations: KUKA developed the world’s first collaborative robot in and continues to innovate with user-friendly and cost-effective solutions. Their COBOTs are ideal for small and medium-sized companies entering automation. KUKA COBOTs are used in manufacturing, logistics, and healthcare, offering advantages like easy programming and safety features.

• Medical Applications: KUKA will showcase COBOTs for medical applications at AAOS , focusing on reducing worker injuries and speeding up medical device development.

• FANUC CORPORATION

• CR and CRX Series: FANUC offers collaborative robots with features like hand guidance for easy programming and compatibility with FANUC's intelligence features. FANUC's COBOTs are used in automotive, packaging, distribution, metalworking, and other industries, providing reliability and accuracy.

• Packaging and Processing: FANUC showcases its cobot solutions for packaging and processing at events like Pack Expo Chicago, highlighting food-grade and versatile robots.

• Kawasaki Heavy Industries Ltd

• CL Series Cobots: Kawasaki recently introduced the CL series of collaborative robots, which combine safety with high speed and precision, suitable for tasks requiring both human collaboration and industrial robot capabilities. Although specific resources are limited, Kawasaki's COBOTs are likely used in manufacturing and logistics, similar to other major players in the market.

• Additional Resources

• Market Reports: Grand View Research and MarketsandMarkets provide comprehensive market analyses, including growth projections and key players in the collaborative robot market. Events like Pack Expo and AAOS showcase the latest innovations and applications of collaborative robots from major companies.

Enrichment Activity: Block Coding Practice

• iRobot Education: iRobot Education website

Students who are not working with the COBOT can access the iRobot Education block coding site to use logic and enhance their critical thinking skills. Have them begin with “Level 1 Coding Basics”. Once they have successfully completed this section they can move on to select any of the following challenge: Mini-Golf, Code a Letter, Avoid the Obstacle, Collect the Coins, Draw a Shape, Bumper Bot, and/or Level 1 Advanced Coding Puzzles.

• This can be utilized as a formative assessment, if you so choose.