FLAT ROOF INSULATION

outstanding local service

CONTENTS

Quantum Insulation Ltd (QI)

Standard Inverted Roof Insulation

Experts in Insulation

Radmat Quantum PLUS+

Ravatherm XPS X 300 SL Ultra

Ravatherm XPS X 300 SL

Ravago XPS Upstand

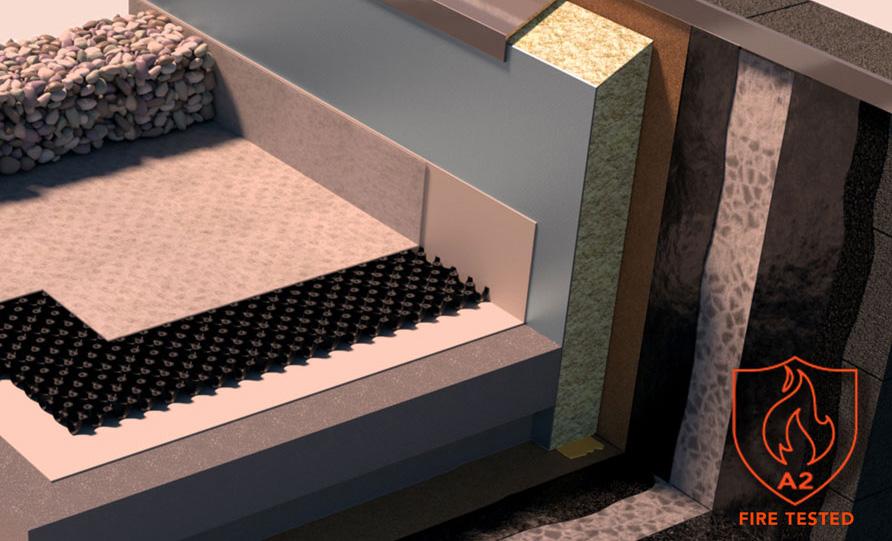

Non-Combustible Inverted

Roof Insulation

FOAMGLAS® INVATHERMTM

Radmat RockFace A2 Upstand Board

Radmat RockFace A2 SL Soffit Board

Non-Combustible Warm

Roof Insulation

FOAMGLAS® F

4 - 5 6 - 9 10 - 11 12 - 13 14 - 17 18 - 19 20 - 23 24 - 27 28 - 29

EXPERTS IN INSULATION

Roofbase has partnered with Quantum Insulation (QI) bringing together over 100 years of flat roof insulation expertise to aid roofing contractors in achieving regulatory and standards compliance by specifying the right product for each individual application: supporting this process with thermal and tapered design services.

QI offers innovative insulation solutions, particularly for inverted waterproofing systems. With the only VIP solution designed specifically for inverted roofs, the thinnest XPS offer in the market and a fire tested Upstand Board, they have accredited products to support any inverted waterproofing specification.

RADMAT QUANTUM PLUS+

Radmat Quantum PLUS+ Inverted Roof Insulation system is a rigid Vacuum Insulation Panel (VIP). The VIP panel consists of a compressed fumed silica sand microporous core which is evacuated of air and moisture before being encased and sealed in a special thin, gas-tight, hybrid aluminium foil envelope, encapsulated in a solvent free polyurethane waterproof coating. The coating is a factory applied solvent free two component elastomeric polyurethane waterproofing membrane. The resulting panel gives outstanding thermal conductivity, with the thinnest possible insulation solution.

GENERAL INFORMATION:

The waterproofing system must be approved for inverted roof applications

The waterproofing system must be installed correctly, watertight and clean

The surface of the waterproofing should be clean, dry, level and free from projections

Where required the roof waterproofing should be inspected for guarantee purposes prior to the installation of the Radmat Quantum PLUS+ Pure Inverted Roof Insulation system or Radmat Quantum PLUS+ Hybrid Inverted Roof Insulation system

Radmat Quantum PLUS+ Inverted Roof Insulation systems should not be used in association with solvent-based adhesive systems, or be exposed to naked flames or excessive heat

Radmat Quantum PLUS+ cannot be cut or punctured. Every project is designed to use XPS insulation at penetrations and outlets, and as infill where required.

PRODUCT DESCRIPTION:

top side Anthracite

Fumed Silica Sand

bottom side Anthracite

DECLARED PERFORMANCE:

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

7 www.roofbase.com

Appearance

Core

Appearance

Essential CharacteristicsPerformance UnitEN CodeStandard Ozone Depletion Potential Zero Global Warming Potential < 5 Density 180-210 kg/m³BS EN 1602: 1997 Tensile Strength 60kPaBS EN 1607: 1997 Dimensions and Tolerances - Thickness - Width - Length 22, 27, 32, 37, 42, 47, 52, 57, 62, 67, 72, 77, 82, 87, 92, 97, 102 302, 402, 502, 602 302, 402, 502, 602, 702, 802, 902, 1002, 1102, 1202 mm mm mm-BS EN 823 BS EN 822 BS EN 822 Thermal Conductivity (aged designvalue allowingforedge effect) 0.007 W/mK - EN 12667: 2001 Thermal Resistance (R-Value) Declared value (1) 20mm 25mm 30mm 40mm 3.333 4.167 5.000 6.667 m²K/W m²K/W m²K/W m²K/W-Mechanical Properties - Compressive strength at10% deformation 160kPaBS EN 826: 1996 Linear Thermal Expansion Coefficient Longitudinal Transverse 0.08 0.06 mm/ m.K mm/ m.K-mm/m.K Surface Temperature -40 to +80 oC-Surface Anthracite coloured polyurethane waterproofing membrane Edge Profile Butt

DECLARED PERFORMANCE:

Weight Unit EN Code Standard Length x width Weight 1202 x 602mm 2.78 3.48 4.18 5.57 6.97 kg -1202 x 402mm 1.85 2.32 2.78 3.72 4.65 kg -1202 x 302mm 1.39 1.74 2.09 2.79 3.48 kg -1002 x 602mm 2.33 2.92 3.5 4.67 5.84 kg -1002 x 302mm 1.17 1.46 1.76 2.34 2.93 kg -1002 x 402mm 1.56 1.95 2.34 3.12 3.90 kg -602 x 602mm 1.39 1.74 2.09 2.79 3.48 kg -602 x 402mm 0.93 1.16 1.39 1.86 2.32 kg -402 x 302mm 0.46 0.58 0.7 0.93 1.16 kg -302 x 302mm 0.35 0.44 0.52 0.7 0.87 kg -Coverage Unit EN Code Standard Length x width Weight 1202 x 602mm 0.724 m2 -1202 x 402mm 0.483 m² -1202 x 302mm 0.363 m² -1002 x 302mm 0.302 m² -1002 x 402mm 0.402 m² -1002 x 602mm 0.603 m² -602 x 602mm 0.362 m² -602 x 402mm 0.242 m² -402 x 302mm 0.121 m² -302 x 302mm 0.091 m² - -

RAVATHERM XPS X 300 SL ULTRA

RAVATHERM XPS X 300 SL ULTRA Inverted Roof Insulation is a unique rigid, closed cell type extruded polystyrene board with integral high density skin.

GENERAL INFORMATION:

RAVATHERM XPS X 300 SL ULTRA Inverted Roof Insulation utilises infra-red blocking particles to scatter and reflect heat radiation

RAVATHERM XPS X 300 SL ULTRA Inverted Roof Insulation has a Zero Ozone Depletion Potential (ODP), a Global Warming Potential (GWP) of less than 5

Use with RAVATHERM XPS X MK Water Flow Reducing Layer prior to the installation of paving, ballast and green roof

For use with appropriate Waterproofing Systems

PRODUCT DESCRIPTION:

Appearance top side Grey Skin Core Grey color, HFC free, Extruded polystyrene foam XPS (EN13164) Appearance bottom side Grey Skin

DECLARED PERFORMANCE:

Hygrometric Properties

- Long term water absorption by immersion (28 days)

- Long term water absorption by diffusion

- dN ≥50 mm to <80 mm

- dN ≥80 mm

- Water vapour diffusion resistance factor (μ), typical

- Freeze/thaw, after 300 cycles

- Dimensional stability under specified temperature and humidity conditions

- Deformation under specified compressive load and temperature conditions

(1) Declared thermal conductivityD according to BS EN 13164 (§ 4.2.1; Annex A; Annex C.2 and C.4.1) EN designation code T1-CS(10\Y)300-CC(2/1,5/50)110-WL(T)0,7-WD(V)3-FT2-DS(TH)-DLT(2)5

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

11 www.roofbase.com

Essential CharacteristicsPerformance UnitEN CodeStandard Ozone Depletion Potential Zero Global Warming Potential < 5 Density (aim, foam only)34 kg/m³ - BS EN 1602 Dimensions and Tolerances - Thickness - Width - Length 70, 80, 105, 130, 145, 175, 205 600 1250 mm mm mm-BS EN 823 BS EN 822 BS EN 822 Thermal Conductivity Declared value (1) - Thickness 80 - 205 mm Design value (1) - Thickness 80 - 205 mm 0.027 0.028 W/mK W/mK T1 D D BS EN 13164 BS EN 13164 E-Modulus (typical)12 - 20 MPa CC(2/1.5/50) oc Mechanical Properties - Compressive

at 10% deformation - Design load 2% max. deflection (50 years) 300 110 kPa kN/m² CS(10\Y) CC(2/1.5/50) oc BS EN 826 BS EN 1606

strength

< 0.7 ≤ 2 ≤ 1 150 < 1 ≤ 5 ≤ 5 vol % vol % vol % vol % vol % vol % % %WD(V) WD(V)FTCD DS(70,90) DLT(2)5 BS EN 12087 BS EN 12088 BS EN 12088 BS EN 12088 BS EN 10456 BS EN 12091 BS EN 1604 BS EN 1605 Reaction to Fire Class E- Euroclass BS EN 13501-1 2016 Linear Thermal Expansion Coefficient 0.07mm/m.K Maximum Service Temperature -50/+75°C-Capillarity 0 Surface Skin Edge Profile Shiplap

RAVATHERM XPS X 300 SL

RAVATHERM XPS X 300 SL Inverted Roof

Insulation is a unique rigid, closed cell type extruded polystyrene board with integral high density skin. RAVATHERM XPS X 300 SL utilises infra-red blocking particles to scatter and reflect heat radiation.

PACK AND SUPERCUBE UNIT SIZES

RAVATHERM XPS X 300 SL has a Zero Ozone Depletion Potential (ODP), a Global Warming Potential (GWP) of less than 5 and a Green Guide to Specification A+ rating.

Use with RAVATHERM XPS X MK Water Flow Reducing Layer prior to the installation of paving, ballast, a green roof or timber

For use with appropriate Waterproofing Systems decking.

Board Thickness (mm) Board Sizes (mm) Board per pack Packs per supercube 50 600 x 1250 8 48 80 600 x 1250 5 48 100 600 x 1250 4 48 120 600 x 1250 3 52 130 600 x 1250 3 56 140 600 x 1250 3 48 160 600 x 1250 2 64 180 600 x 1250 2 56 200 600 x 1250 2 48 205 600 x 1250 2 48

GENERAL INFORMATION:

top side Grey Skin Core Grey color, HFC free, Extruded polystyrene foam XPS (EN13164).

bottom side Grey Skin

DECLARED PERFORMANCE:

Hygrometric properties

- Long term water absorption by immersion (28 days)

- Long term water absorption by diffusion - Water vapour diffusion resistance factor (μ), typical

13 www.roofbase.com

Appearance

Appearance

PRODUCT DESCRIPTION:

Essential CharacteristicsPerformance UnitEN CodeStandard Ozone Depletion Potential Zero Global Warming Potential < 5 Density (aim, foam only)34 kg/m³ - BS EN 1602 Dimensions and Tolerances - Thickness - Width - Length 50, 80, 100, 120, 130, 140, 160, 180, 200, 205 600 1250 mm mm mm T1BS EN 823 BS EN 822 BS EN 822 Thermal Conductivity Declared value (1) - Thickness 40 - 50 mm - Thickness 80 - 220 mm 0.030 0.031 W/mK W/mK D D BS EN 13164 BS EN 13164 Mechanical properties Declared value (1) - Compressive strength at 10% deformation - Design load 2% max. deflection (50 years) 300 110 MPa kN/m² CS(10\Y)300 CC(2/1.5/50)oc Mechanical Properties - Compressive strength at 10% deformation - Design load 2% max. deflection (50 years) 300 110 kPa kN/m² CS(10\Y) CC(2/1.5/50)oc BS EN 826 BS EN 1606 RD values - 50mm - 80mm - 100mm - 120mm - 130mm - 140mm - 160mm - 180mm - 200mm - 205mm 1.60 2.50 3.15 3.75 3.82 4.35 5.00 5.60 6.25 6.20 m².K/W-Reaction to Fire Class E- Euroclass BS EN 13501-1 2016

- Freeze/thaw, after 300 cycles <0.7 <3 80-200 <1 vol %-FTi BS EN 12087 BS EN 12088 BS EN 12086 BS EN 12091 Linear Thermal Expansion Coefficient 0.07mm/m.K Maximum Service Temperature -50/+75°C-Capillarity 0 Surface Skin Edge Profile Shiplap (1) Declared thermal conductivityD according to BS EN 13164 (§ 4.2.1; Annex A; Annex C.2 and C.4.1)

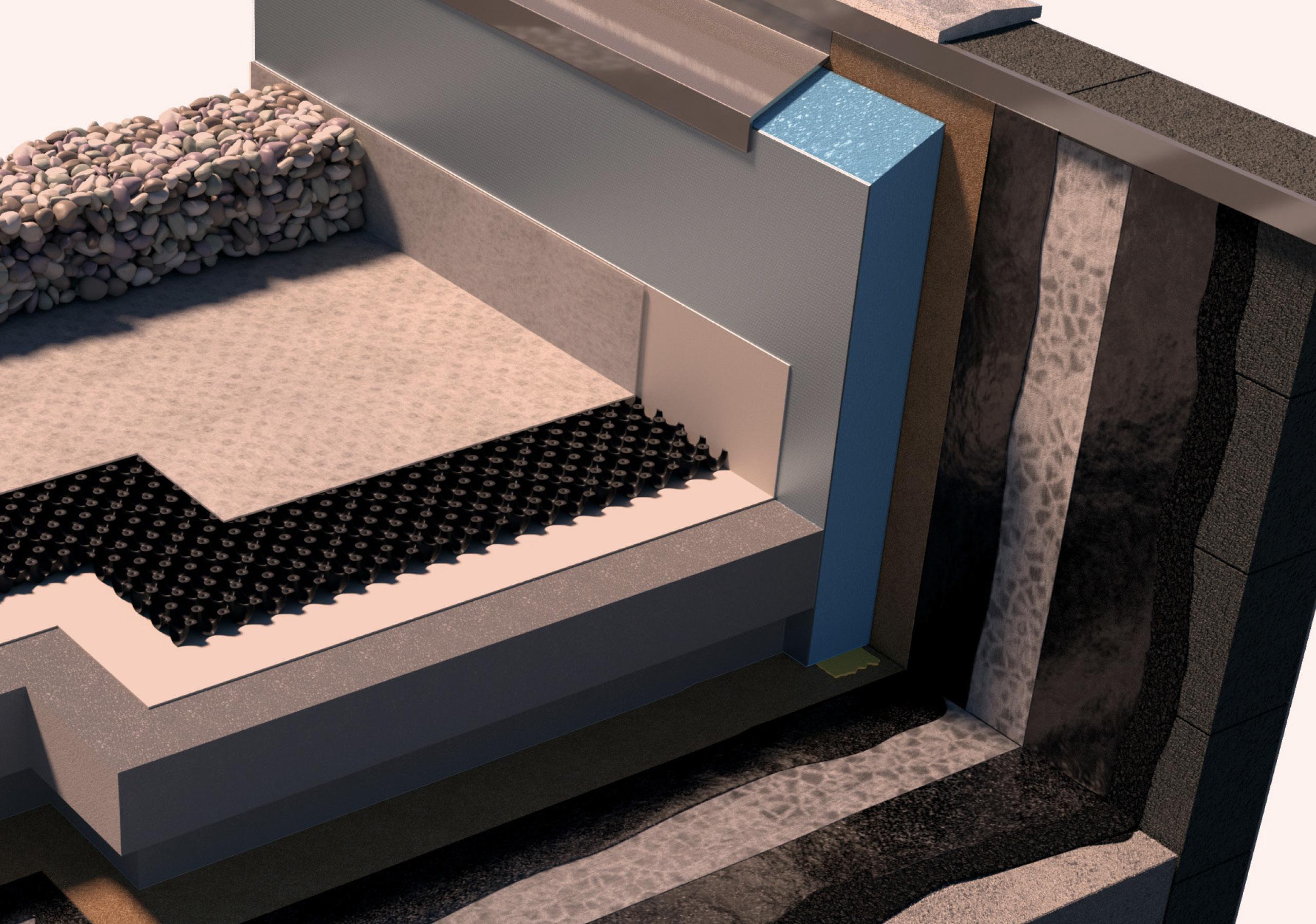

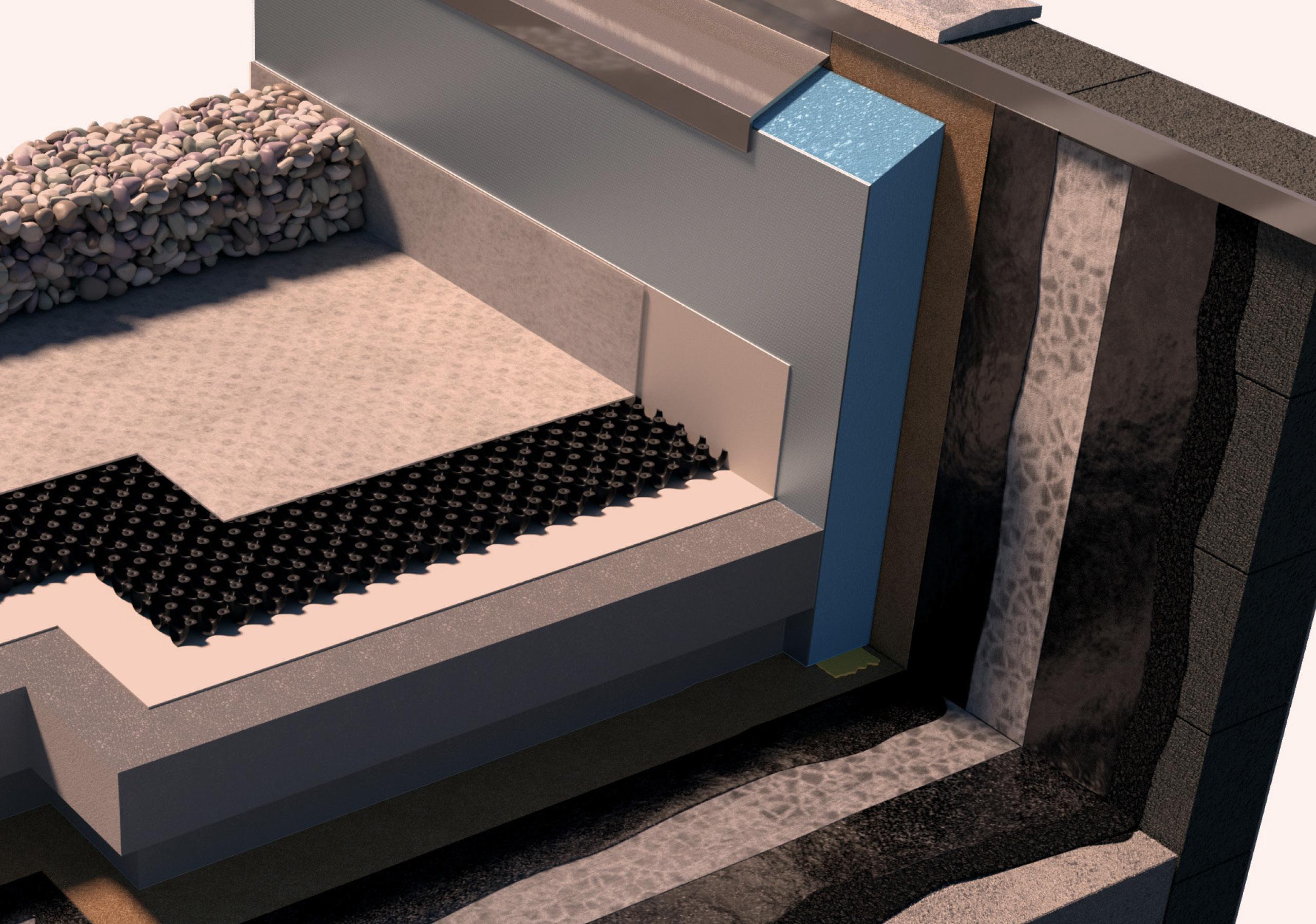

RAVAGO XPS UPSTAND

XPS Upstand Insulation Board is used to thermally insulate and protect upstand walls. Manufactured from a CO² blown extruded polystyrene foam factory laminated to a 6mm thick weather resistant high impact facing board. Available in a range of thicknesses, see declared performance table for available thickness.

XPS Upstand Insulation Board has a Zero Ozone Depletion Potential (ODP), a Global Warming Potential (GWP) of less than 5 and an A rating in accordance with the Green Guide to Specification.

For use with Inverted Roofing Waterproofing Systems.

PRODUCT DESCRIPTION:

Appearance top side Grey cementitious

Extruded polystyrene

bottom side Blue Foam

DECLARED PERFORMANCE:

FACING: high performance, heavy duty, exterior grade fibre-cement sheet

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

15 www.roofbase.com

Material

Appearance

Essential CharacteristicsPerformance UnitEN CodeStandard Ozone Depletion Potential Zero Global Warming Potential < 5 BRE Green Guide Rating A Sheet size - Length - Width 2400 1200 mm mmBS EN 822 BS EN 822 Tolerances ±2 Tolerances Square--Weight (board / m²) SD20 SD40 SD50 SD60 SD80 SD100 SD120 SD150 24.9 / 8.65 26.8 / 9.31 27.8 / 9.64 28.7 / 9.97 30.6 / 10.63 32.5 / 11.29 34.4 / 11.95 37.3 / 12.94 kg

Colour Grey Thickness – nominal 6mm Density 1320kg/m³ Thermal Conductivity 0.30W/mK Flexural Strength (average Parallel and Transverse) 18MPa

DECLARED PERFORMANCE:

INSULATION: Styrofoam LB A Extruded Polystyrene (XPS)

Essential Characteristics Performance Unit EN Code Standard

Colour Blue - -Thickness 20, 40, 50, 60, 80, 100, 120, 150 mm -Tolerance - Thickness - Width - Length ±0.5 ±5 ±10 mm mm mmBS EN 823 BS EN 822 BS EN 822 Compressive Strength 300 kPa - BS EN 826 Thermal Conductivity - <80mm - 81 - 120mm - >120mm 0.035 0.036 0.038 W/mK W/mK W/mK D BS EN 13164 Nominal Density (foam only) 33 kg/m³ - BS EN 1602 Water Absorption by Immersion 0.07 % - BS EN 12087 Fire Performance Class E - - BS EN 13501-1 Coefficient of linear thermal expansion 0.07 mm/mK - -

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

17 www.roofbase.com

FOAMGLAS® INVATHERM TM

FOAMGLAS® INVATHERMTM has been engineered to meet the demand for a class A1* inverted roof insulation board for use on roofs, roof terraces and balconies. Suitable for use with any inverted roof waterproofing membrane including hot melt, liquid applied, reinforced bitumen membrane or single ply membrane.

Consisting of cellular glass with a pre-applied inorganic coating# on the topside both the core material FOAMGLAS® INVATHERMTM is manufactured from specially graded recycled glass (≥ 60%) and natural raw materials which are available in abundant supply (sand, dolomite, lime). Totally inorganic FOAMGLAS® INVATHERMTM contains no ozone depleting propellants, flame resistant additives or binders, VOC or other volatile substances.

* Class A1 to BS EN 135011, sometimes referred to as ‘non-combustible’¯

# As product is made from natural materials the colour cannot be guaranteed and can vary in batches.

Other dimensions and thicknesses are available on request.

FORM OF DELIVERY (CONTENT PER PACKAGE) Length mm 600 600 600 600 600 600 600 600 600 600 600 Width mm 450 450 450 450 450 450 450 450 450 450 450 Thickness mm 100 110 120 130 140 150 160 170 180 190 200 Units 48 40 40 36 32 32 28 28 24 24 24 Square metre [m2] 12.96 10.8 10.8 9.72 8.64 8.64 7.56 7.56 6.48 6.48 6.48

DECLARED PERFORMANCE: DESIGN VALUE U OR COR ≤ 0.043 W/(M·K)

1) CE-marking ensures conformitywith the mandatory essential requirements of CPD as mentioned in EN 13167; within the CEN Keymark certification all mentioned characteristics are certified by an empowered, notified and accredited 3rd party.

* As product is made from natural materials the colour cannot be guaranteed and can vary in batches.

** ≥ 60% recycled glass consists of highly selected postconsumer glass and highly selected production scrap/co-products

19 www.roofbase.com

Essential CharacteristicsPerformance UnitStandard Density (± 15%) 100kg/m3EN 1602 Thickness ± 2 mm from 100 up to 200 mmEN 823 Length ± 2 mm 600 ± 3mmEN 822 Width ± 2 mm 450 ± 3 mmEN 822 Thermal conductivity D ≤ 0.043W/(m·K)EN ISO 10456 Reaction to fire Euroclass A1 -EN 13501-1 Point load PL ≤ 1.5 mm EN 12430 Point load top PL ≤ 1.5 (≤ 0.5) kPaEN 826 annexe A Compressive strength CS ≥ 400 kPaEN 826 annexe A Bending strength BS ≥ 400 kPa EN 12089 Tensile strength TR ≥ 100 kPaEN 1607 Water absorption on short term WS ≤ 0.5 kg/m2Water vapour transmission ∞-Freeze/Thaw resistant Service temperature limits -265°C to +430°CISO 14025 and EN 15804 Water vapour resistance ∞μEN ISO 10456 Hygroscopicity zero Capillarity zero Melting point >1000°Ccf DIN 4102-17 Thermal expansion coefficient 9 x 10-6 K-1 -EN 13471 Specific heat 1000 J/(kg·K)EN ISO 10456 PRODUCT

Colour Grey* Material Specially graded recycled glass** and natural raw materials

DESCRIPTION:

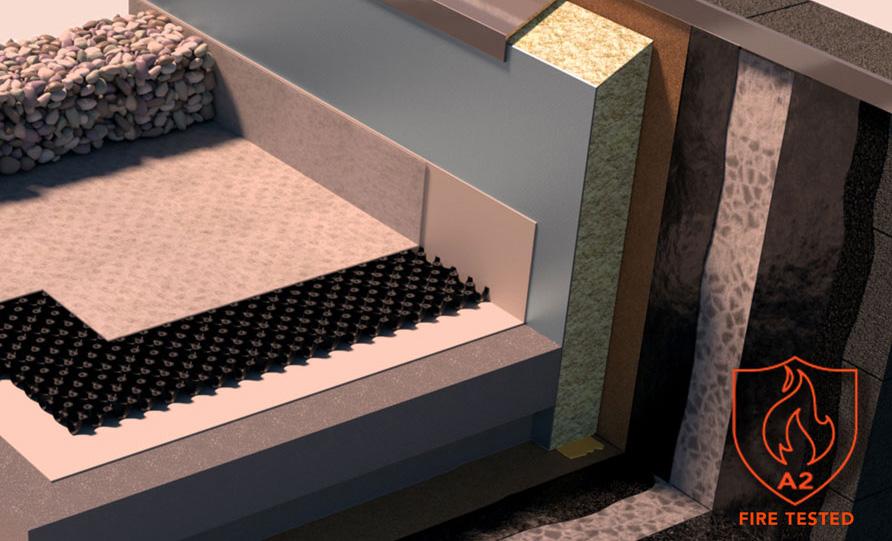

RADMAT ROCKFACE A2 UPSTAND BOARD

RockFace A2 is a Non-Combustible Upstand Insulation Board used to thermally insulate and protect upstand walls in inverted flat roof systems. Classified Euroclass A2-s1,d0 to BS EN13501-1:2108 by Warrington Fire under classification report no. 19808F dated 10 10 2019. Building Regulation

Approved Document B volume 1 – dwellings and volume 2 - non-dwellings compliant solution for buildings over 18m high in England. Technical Handbook – domestic Annex 2.C and Technical Handbook – non-domestic Annex 2.F compliant solution for buildings over 11m high in Scotland.

Manufactured with non-combustible stonewool it will not develop smoke or promote flame spread, even when directly exposed to fire. It also repels and drains water away from the product, and will completely dry out while maintaining its original physical properties. Stonewool and factory laminated to a 6mm thick weather resistant high impact facing board. Available in a range of thicknesses, see declared performance table for available thickness.

RockFace A2 has a Zero Ozone Depletion Potential (ODP), a Global Warming Potential (GWP). For use with appropriate waterproofing systems.

FACING: high performance, heavy duty, exterior grade fibre-cement sheet

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

21 www.roofbase.com

PRODUCT DESCRIPTION: Appearance top side Grey cementitious Core Stonewool Insulation DECLARED PERFORMANCE: Essential CharacteristicsPerformance UnitEN CodeStandard Fire Performance RockFace A2 (product rating)A2-s1,d0--BS EN 13501-1 Ozone Depletion Potential Zero Global Warming Potential < 5 BRE Green Guide Rating A Sheet size - Length - Width - Thickness overall 2000 1.2 56, 116, 142 mm m mm-BS EN 822 Tolerances ±2 -CC(2/1.5/50)oc Tolerances Square--Weight (board / m²) RF56 RF116 RF142 35.9 48.12\ 56 kg kg kg--Colour Grey Thickness - Nominal 6mm Density 1320kg/m³ Thermal Conductivity 0.30W/mK Flexural Strength (average Parallel and Transverse) 18MPa Fire Performance (component ratings) A1 --BS EN 13501-1

DECLARED PERFORMANCE:

Stonewool

• A2 = limited combustibility

• s1 (smoke) quantity/speed of emission = absent or weak

• d0 = no dripping

Essential Characteristics Performance Unit EN Code Standard Colour Pale Green - -Thickness (allowing for 6mm facing board) 50, 110, 136 mm -Tolerance - Thickness - Width - Length 2 ±5 ±10 mm mm mmBS EN 823 BS EN 822 BS EN 822 Compressive Strength 30 @ 10% Compression kPa - BS EN 826 Thermal Conductivity 0.038 W/mK D BS EN 13162 Nominal Density (Stonewool only) 110 kg/m³ - BS EN 1602 Water Absorption by Immersion Water Repellent - - ASTM E136 Fire Performance (component ratings) A1 - - BS EN 13501-1 Delamination Strength 13 kPa - ASTM C356 INSULATION:

Fire Performance Classified Euroclass A2-s1,d0 to BS EN13501-1:2108 by Warrington Fire under classification report no. 19808F dated 10 10 12019.

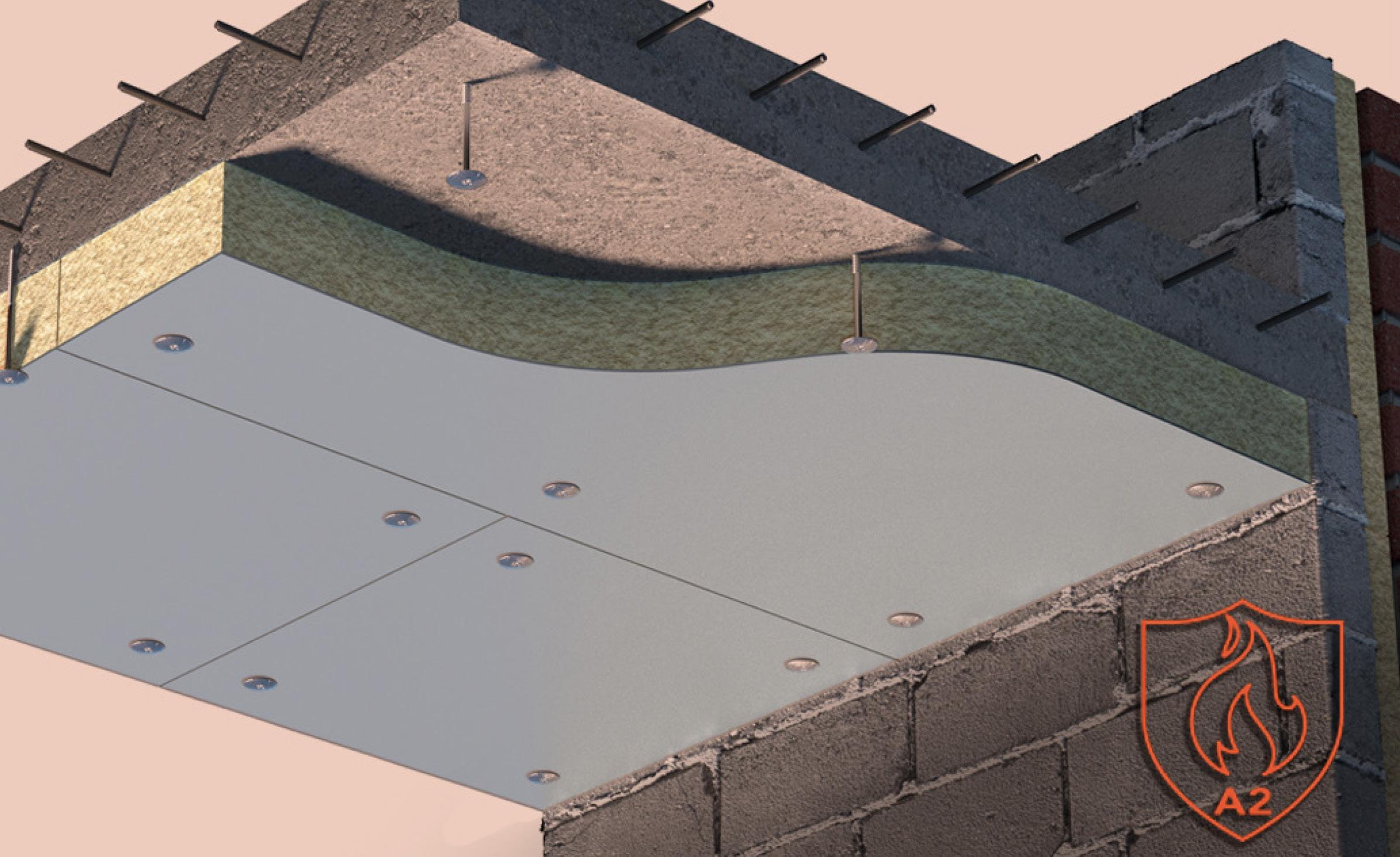

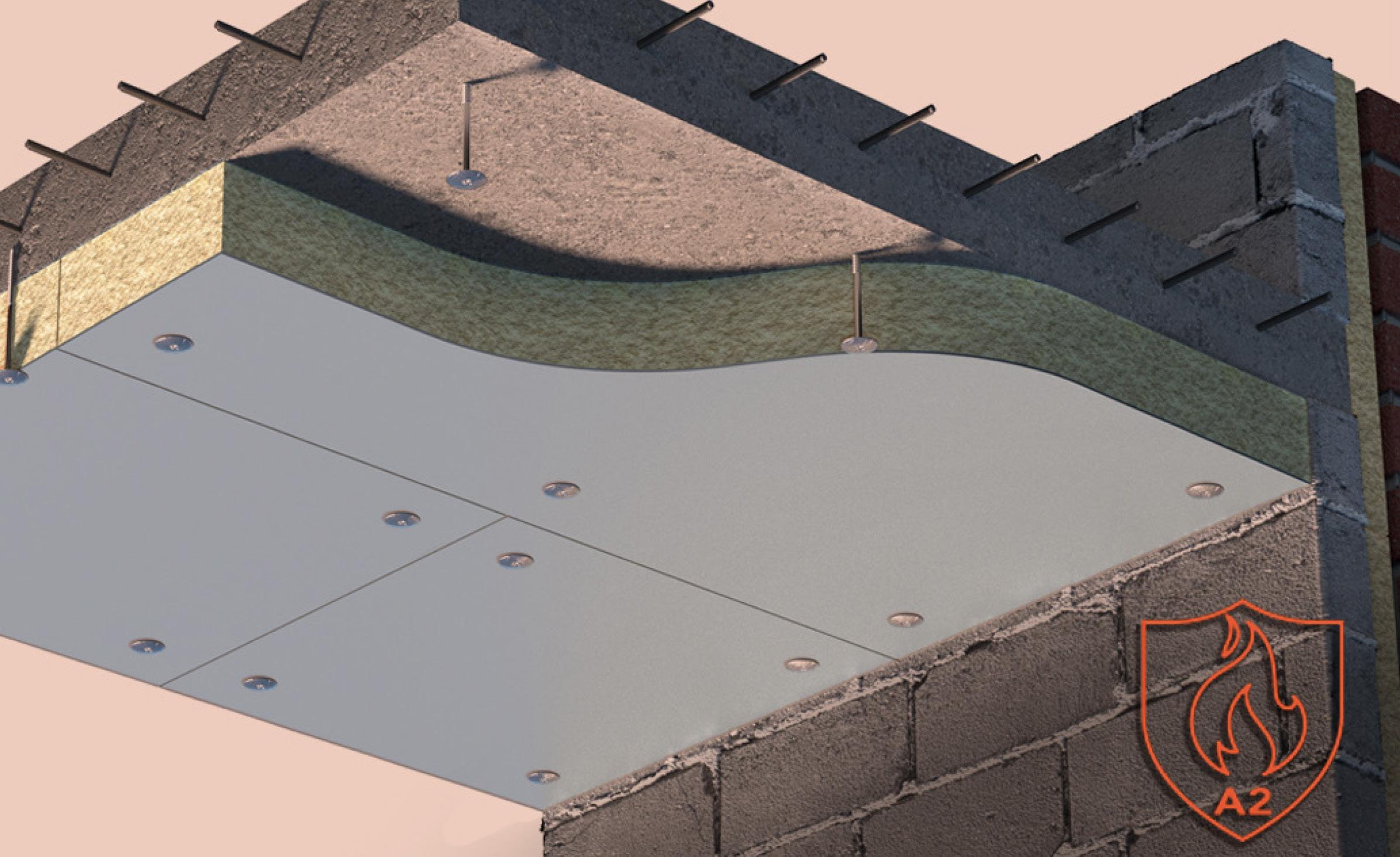

RADMAT ROCKFACE A2 SL SOFFIT BOARD

QI RockFace A2 SL is a Non-Combustible Soffit Insulation Board designed to insulate semi exposed concrete soffits. Classified Euroclass A2-s1,d0 to BS EN13501-1:2108 by Warrington Fire under classification report no. 19808F dated 10 10 2019. Manufactured with non-combustible Stonewool it will not develop smoke or promote flame spread, even when directly exposed to fire.The stonewool is factory laminated to a 6mm thick weather resistant high impact facing board. As an example of thermal performance 0.025W/m2K can be achieved

if a 136mm (O/A) panel is fixed to a 150mm dense concrete slab in a semi-exposed application. Available in a range of thicknesses, see declared performance table for available thickness. RockFace A2 SL has a Zero Ozone Depletion Potential (ODP), a Global Warming Potential (GWP). Certificates ISO 9001@2008 Quality Management System, ISO 14001 :2004 Environmental Management System, EPD as per ISO 14025 and EN 15804.

FACING: high performance, heavy duty, exterior grade fibre-cement sheet

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

25 www.roofbase.com

PRODUCT DESCRIPTION: Appearance top side Grey Skin Core Stonewool Insulation DECLARED PERFORMANCE: Essential CharacteristicsPerformance UnitEN CodeStandard Fire Performance RockFace A2 (product rating)A2-s1,d)--BS EN 13501-1 Ozone Depletion Potential Zero Global Warming Potential < 5 BRE Green Guide Rating A Sheet size - Length - Width - Thickness overall 2000 600 56, 116, 136 mm- BS EN 822 Tolerances ±2 EN 12089 Tolerances Square-- EN 1607 Weight (board / m²) RF56 RF116 RF142 18 26.5\ 29.5 kg Colour Grey Thickness - Nominal 6mm Density 1320kg/m³ Thermal Conductivity 0.30W/mK Flexural Strength (average Parallel and Transverse) 18MPa Fire Performance (component ratings) A1 --BS EN 13501-1

DECLARED PERFORMANCE:

INSULATION: Stonewool

Performance

Classified Euroclass A2-s1,d0 to BS EN13501-1:2108 by Warrington Fire under classification report no. 19808F dated 10 10 2019.

• A2 = limited combustibility

• s1 (smoke) quantity/speed of emission = absent or weak

• d0 = no dripping

Essential Characteristics Performance Unit EN Code Standard Colour Pale Green - -Thickness (allowing for 6mm facing board) 50, 110, 130 mm -Tolerance - Thickness - Width - Length ±10 ±5 2 mm - BS EN 823 Compressive Strength 30 @ 10% Compression kPa - BS EN 826 Thermal Conductivity 0.038 W/mK D BS EN 13162 Nominal Density (Stonewool only) 110 kg/m³ - BS EN 1602 Water Absorption by Immersion Water Repellent - - ASTM E136 Fire Performance (component ratings) A1 - - BS EN 13501-1 Delamination Strength 13 kPa - ASTM C356 Fire

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

27 www.roofbase.com

FOAMGLAS® F

FOAMGLAS® F is a warm roof insulation board manufactured from specially graded recycled glass (≥ 60%) and natural raw materials which are available in abundant supply (sand, dolomite & lime). The insulation is totally inorganic, contains no ozone depleting propellants, flame resistant additives or binders.

Offering the highest compressive strength of any FOAMGLAS® product, FOAMGLAS® F is used above or beneath floor slabs, and upon roofs where the compressive loads are high.

For use with approved waterproofing systems.

DELIVERY (CONTENT

Length mm 600 600 600 600 600 600 600 600 600 600 600 600 600 600 600 Width mm 450 450 450 450 450 450 450 450 450 450 450 450 450 450 450 Thickness mm 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 RD [m²K/W] 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.20 2.40 2.60 2.80 3.00 3.20 3.40 3.60 Units 12 10 8 7 6 6 5 5 4 4 4 3 3 3 3 Square metre [m2] 3.24 2.70 2.16 1.89 1.62 1.62 1.35 1.35 1.08 1.08 1.08 0.81 0.81 0.81 0.81 Other dimensions and thicknesses are available on request.

FORM OF

PER PACKAGE)

DECLARED PERFORMANCE:

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

29 www.roofbase.com

Essential CharacteristicsPerformance UnitStandard Density (± 10%) 1653kg/m3 EN 1602 Thickness ± 2 mm from 40 to 180 ± 2 mm mmEN 823 Length ± 2 mm 600mmEN 822 Width ± 2 mm 450 mmEN 822 Thermal conductivity D ≤ 0.050W/(m·K)EN ISO 10456 Reaction to fire Euroclass A1 -EN 13501-1 Point load PL ≤ 1.0 mm mm EN 12430 Compressive strength CS ≥ 1600 kPaEN 826 annexe A Bending strength BS ≥ 550 kPa kPa EN 12089 Tensile strength TR ≥ 200 kPa kPaEN 1607 Thermal diffusivity at 0°C 3.5 x 107 m2/secFlexural modulus of elasticity 1500MN/m2BRE Green Guide Rating A Certificate natureplus 0406-1101-101-1-Reaction to fire (EN 13501-1) Material complying with Euroclass A1, non-combustible, no toxic fumes Service temperature limits from -265°C to +430°C Water vapour resistance (EN ISO 10456) μ = ∞ Hygroscopicity zero Capillarity zero Melting point (cf DIN 4102-17) >1000 °C Thermal expansion coefficient (EN 13471) 9 x 10-6 K-1 Specific heat (EN ISO 10456) 1000 J/(kg·K) according to EN 13167

outstanding local service