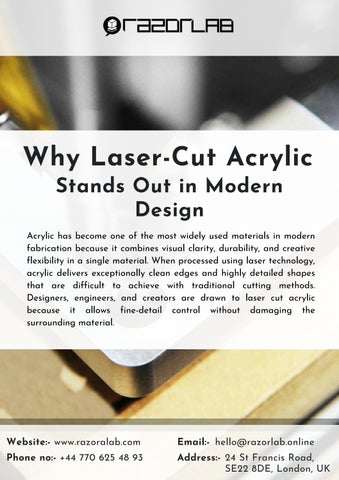

Why Laser-Cut Acrylic

Stands Out in Modern Design

Acrylic has become one of the most widely used materials in modern fabrication because it combines visual clarity, durability, and creative flexibility in a single material. When processed using laser technology, acrylic delivers exceptionally clean edges and highly detailed shapes that are difficult to achieve with traditional cutting methods. Designers, engineers, and creators are drawn to laser cut acrylic because it allows fine-detail control without damaging the surrounding material.

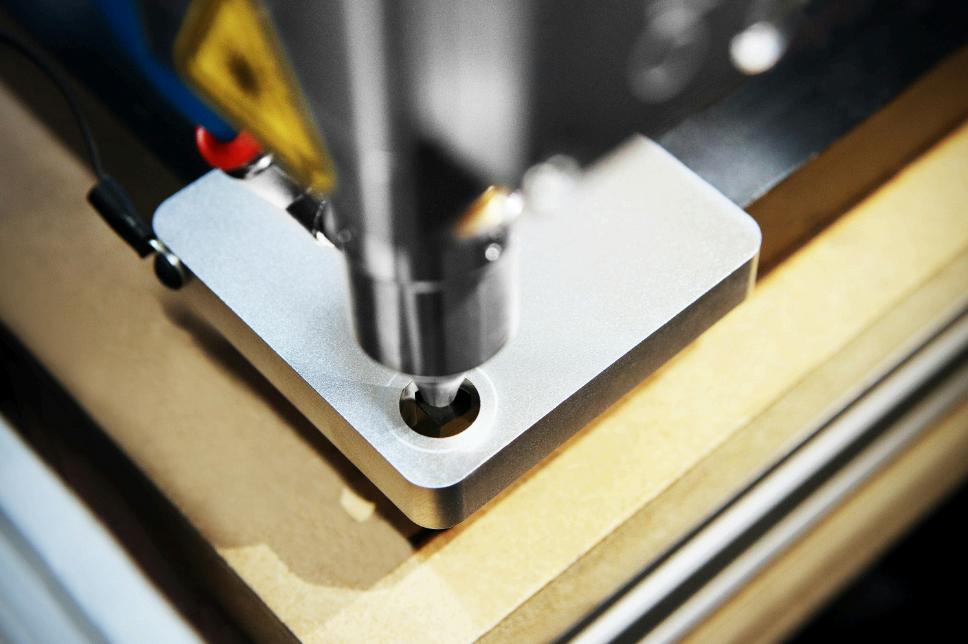

Despite its advantages, acrylic requires careful handling during the laser cutting process. One of the most frequent challenges is overheating, which leads to burn marks, melted edges, or unwanted discolouration. These issues often arise when power settings are too aggressive or the cutting speed is too slow. Cracking is another common concern, particularly when excessive heat builds up in a concentrated area, creating internal stress that causes the sheet to fracture. Poor-quality file preparation also contributes significantly to cutting errors. When vector paths overlap or contain excessive detail, the laser may perform double cuts or leave rough finishes. Inconsistent results are often linked to material selection, as not all acrylic is manufactured equally. Cast acrylic generally performs far better than extruded sheets for both cutting and engraving applications.

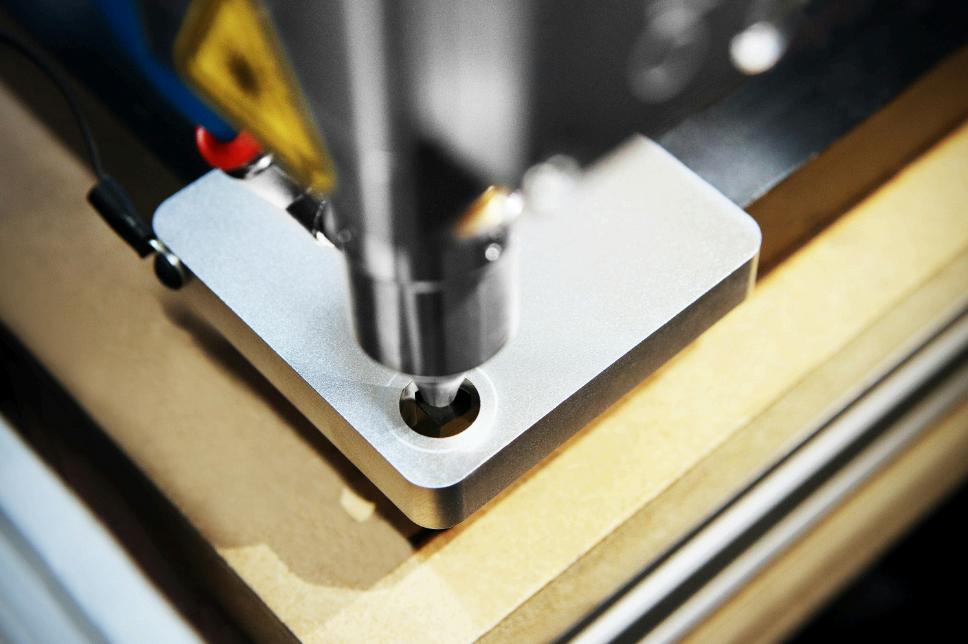

Achieving flawless laser-cut acrylic outcomes depends on a combination of equipment calibration, material preparation, and proper workflow. Maintaining the correct balance between laser power and cutting speed ensures smooth edges without burning. Keeping the protective film intact during cutting helps reduce surface damage and prevents micro-cracking caused by thermal stress. Using air assist systems and proper ventilation improves edge clarity and reduces smoke residue. File preparation plays a major role in the final look, as simplified vector paths allow the laser to move cleanly and accurately. Testing cutting small sections before full production allows creators to fine-tune settings and avoid costly mistakes. Clean working conditions and properly maintained lenses also contribute significantly to consistent, professional-quality finishes.

There are many situations where working with professional laser cutting services becomes the most efficient choice. Complex projects that require precise tolerances, bulk production runs, or intricate detailing often exceed the limits of entry-level equipment. Professional services provide access to advanced laser systems, refined calibration techniques, and experienced operators who understand material behavior deeply. For businesses producing signage, retail displays, architectural elements, or branded merchandise, outsourcing eliminates the learning curve and minimizes wasted material. Professional services also allow designers to focus on creativity rather than technical troubleshooting. Outsourced production ensures consistency across batches and delivers superior finishing techniques that are difficult to achieve without industrialgrade equipment.