PORTFOLI

Raye Liu

Intern Architect, Alberta Association of Architects

Masters of Architecture (‘22), School of Architecture, Planning and Landscape, University of Calgary

Intern Architect, Alberta Association of Architects

Masters of Architecture (‘22), School of Architecture, Planning and Landscape, University of Calgary

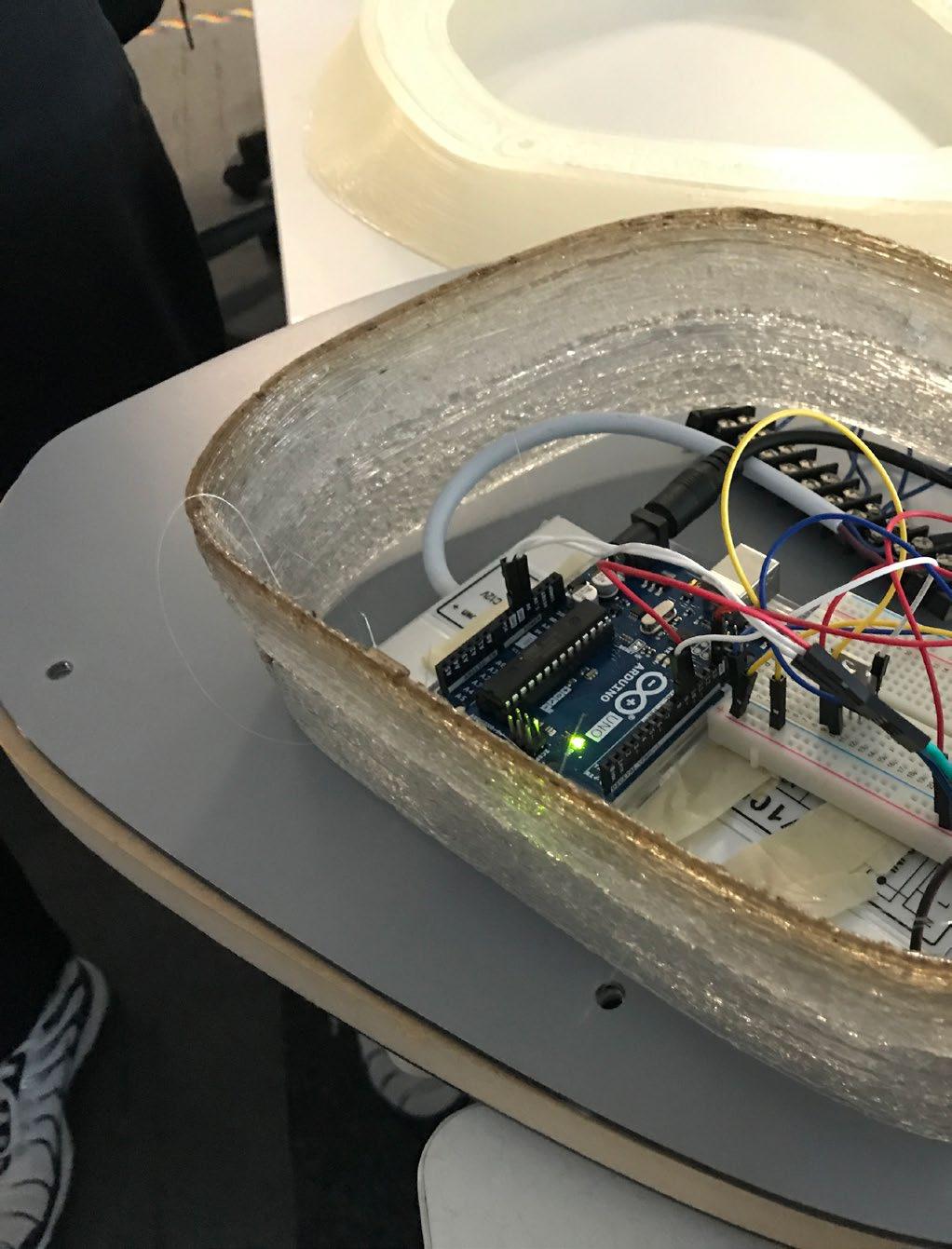

Built Installation 2020

Team project

Team members and roles:

Team Lead: Assistant Professor Mauricio Soto-Rubio

Lighting design (assembly system) and prototype (3D printing script and form design): Raye Liu

LED coding and installation: Shelby Christensen

Structure: Ji Song Sun, Jonathan Monfries

Digital Fabrication Specialist: Guy Gardner

Software: Rhino, Grasshopper, Photoshop, Illustrator

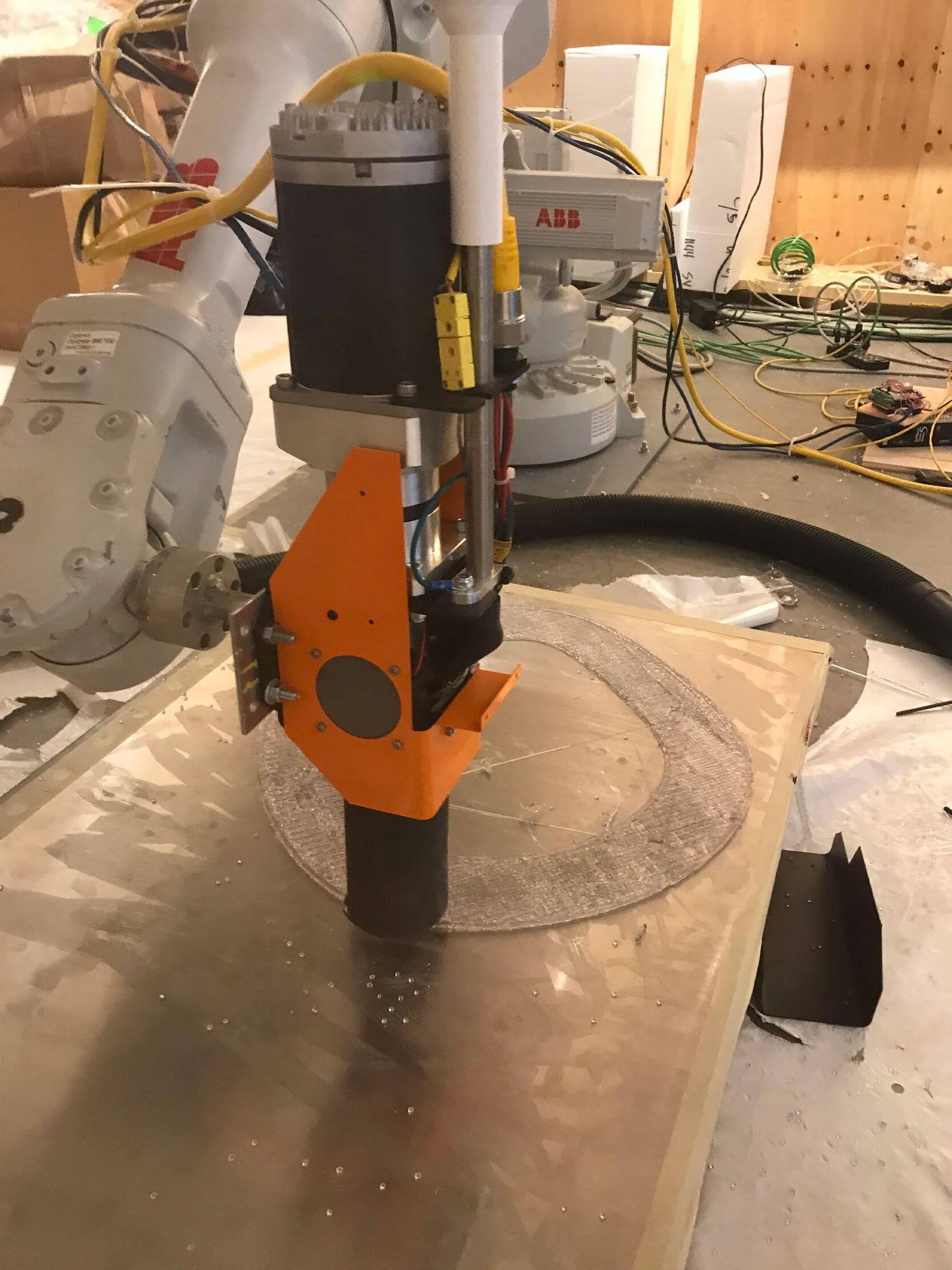

Tools and Equipment: Robotic arm 3D printing, CNC machine

Initiated and commissioned by the City of Calgary, SAPL was selected as a collaborator to introduce a quick pilot solution in the nine blocks that surround City Hall. The main objective of this project is to improve vibrancy and sense of safety in this important area in downtown through a relatively low-cost but impactful design solutions.

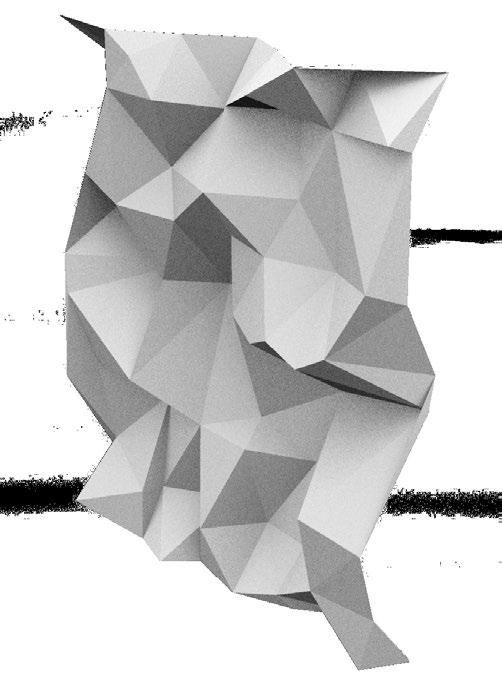

Situated on Macleod Trail and 7th Avenue SE, Calgary, the 9 block canopy project consists of an undulating plywood slat design that contains curvatures to provide a dynamic effect as pedestrians and vehicles pass through the site.

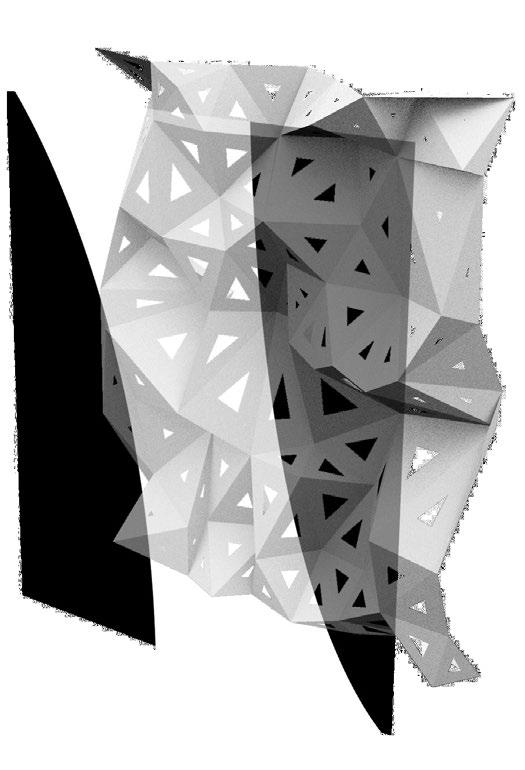

16 lights in total for the whole canopy; the shapes vary depending on the undulation of the near slats, a design approach achieved through algorithm scripted in Grasshopper

Section

The light fixtures have been 3D printed at the SAPL’s City Building Design Lab using recycled plastic and contain sensors. So during night time, they will illuminate the sidewalk through the “infinity mirror“ and the linear LED strips underneath each layer of “shell“ when the sensors detect pedestrian’s movement below. This ensures people feel safe waiting for the bus at night. During the day when the LED’s are not on, the “infinity mirror“ turns into a one-way mirror, so pedestrians will see their own reflections in the mirrors.

One-way mirror effect during day time Photo credit: Shelby Christensen Infinity mirror effect at night timeNuts Nuts

Top Cover

Top Cover

Water-resistant MDF

Outer Shell and Housing

Outer Shell and Housing Space for Electronics (Arduino board, transformers etc.)

LED Strand

LED Strand Attached unto the Edge

Electronics

Electronics

Acrylic Mirror (one-way)

CNC Milled MDF Spacer

Acrylic Mirror Spacer

LED Strand

LED Strand along the Edge

Plexiglas with Two Way Mirror Film

Plexiglass with Two Way Mirrow Film (function as two-way mirror)

PIR Sensor

PIR Sensor

Inner Shell

The electronics and transformer, programmed

LED Strand

LED Strand Attached along the Edge

Customized plastic Grasshopper

Threaded Rods

Nuts

Inner Shell Rods

Nuts

Light 14 (Large)

Light assembly axo

electronics compartment houses power cord transformer, and an arduino board that can be programmed through wifi connection to change colors of the LED strips in each lamp

Customized robotic arm using granulized recycled plastic to 3D print the light parts directly through Grasshopper scriptting and Rhino 3D model

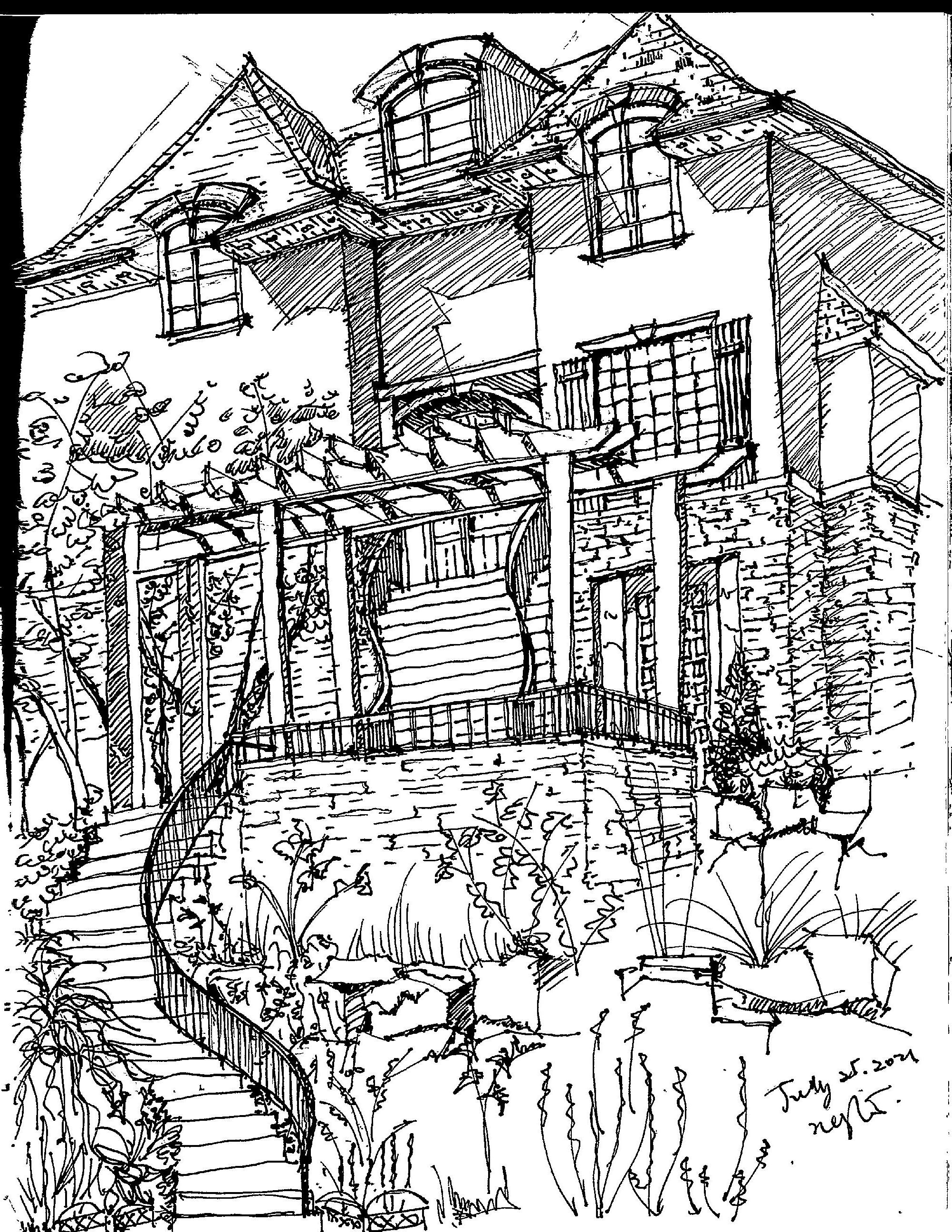

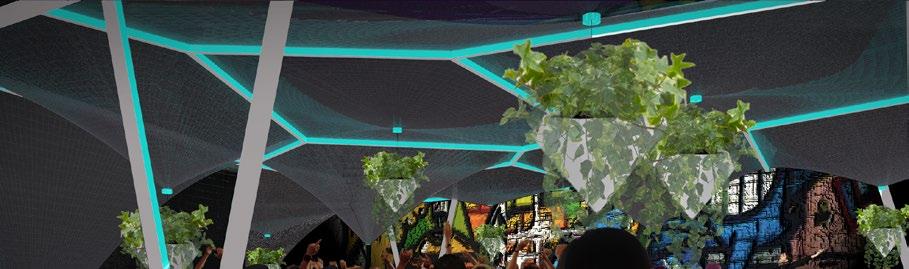

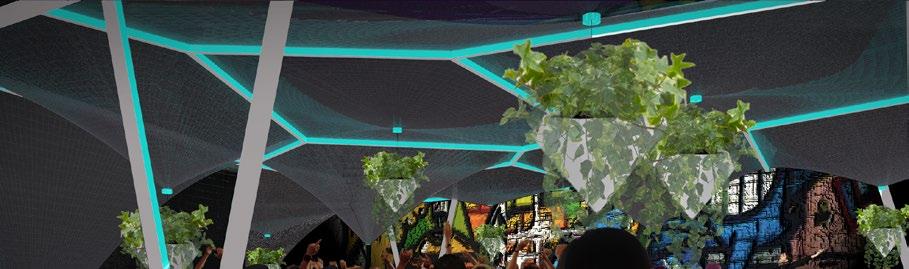

Built installation, exhibited on PARK(ing) Day 2019, Calgary

Dimension: 2.4 m (L) x 6 m (W) x 2 m (H) (two parking stalls)

Materials: tires, paint, yarns, colored films, two-way mirror films, wood dowel pins, 2"x12" wood planks, metal hardware, LED lights, ivy planters

Team project

Team members and roles:

Team Lead: Raye Liu

Design Assistance: Judy Liu

Technical Support: Ji Yong Chyung

Graphics: Jason Park

Finance and Fundraising: Ryan Spring

Software: Rhino, Photoshop, Illustrator

Tools and Equipment: CNC machining and power tools during pre-fabrication, hand tools during installation insitu

"Re-Tire" is a public-space intervention designed and built by a student team of five. It won the exhibition opportunity for PARK(ing) Day (September 20, 2019) in Calgary, Alberta, Canada, after the evaluation of the submissions conducted by the Alberta Association of Landscape Architects (AALA). Our team is one of the only two grant-winners among all the participants of the year. The installation of "Re-Tire" received media coverage before and after the event by the City of Calgary, the Avenue Calgary Magazine, University of Calgary and AALA.

"Re-Tire" advocates environmental sustainability by upcycling used car tires and curates a space to interact with people of all ages. There is a pathway within the installation for visitors to walk through and enjoy the different visuals each tire has to provide. The whole structure is pre-fabricated off-site, and transported by truck on the installation day. The assemblies are put together sequentially according to how they are numbered.

The internal pathway within the installation Friends and families appreciating the fun interaction "Re-Tire" creates and taking photos of each other

The top and bottom plates are manufactured through CNC using 3D models created in Rhino directly; double plates are bolted together for stability and depth to secure the vertical dowels

ASSEMBLY 6

ASSEMBLY 5

Experiments with weaving through half tires and their shadow effects. Those half tires were design to be installed as the "roof" of the stallation, which was not realized on the installation day

ASSEMBLY 4

ASSEMBLY 3

ASSEMBLY 2

ASSEMBLY 1

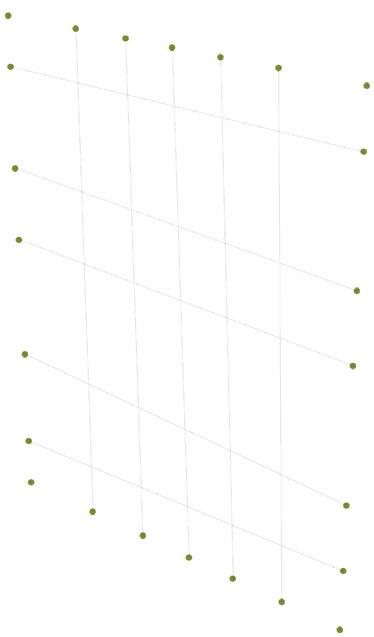

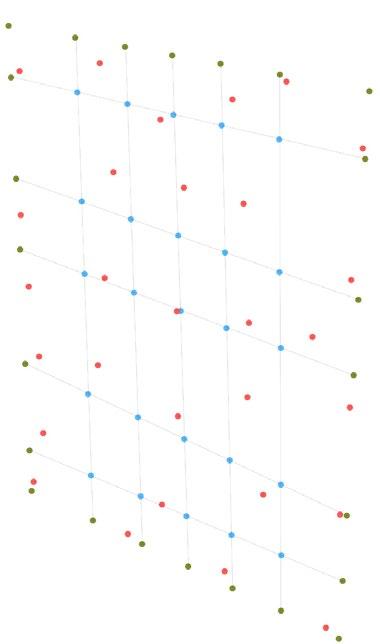

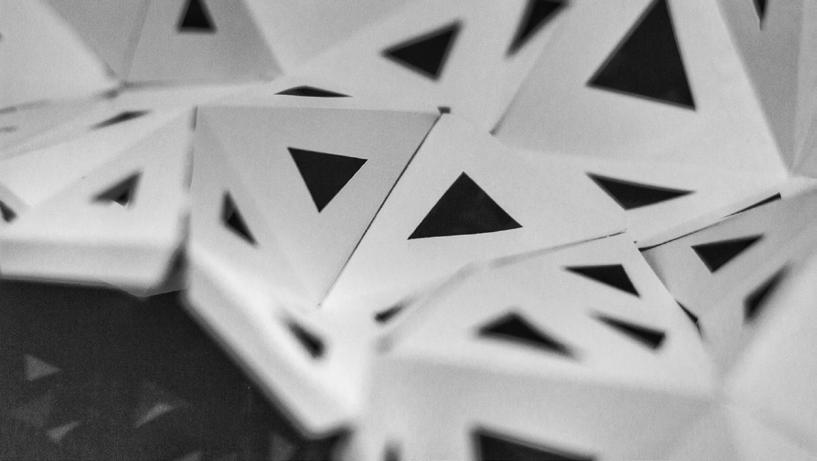

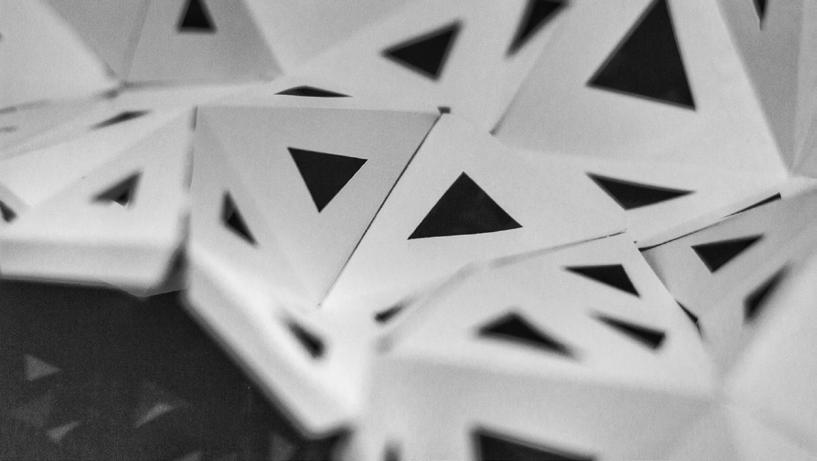

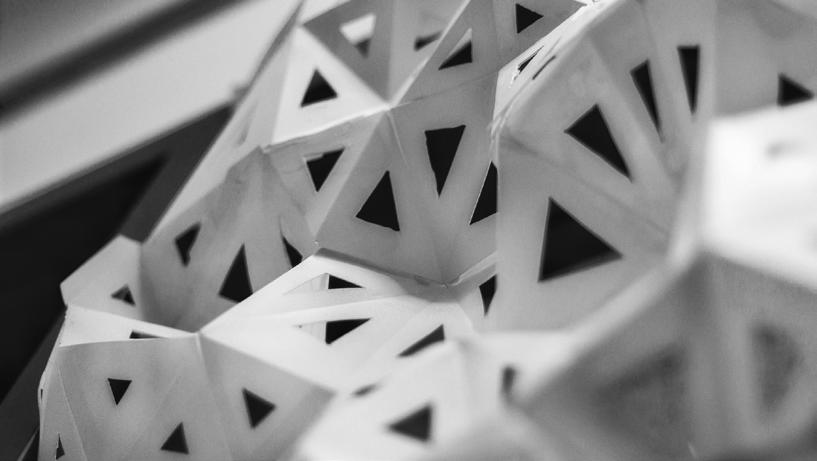

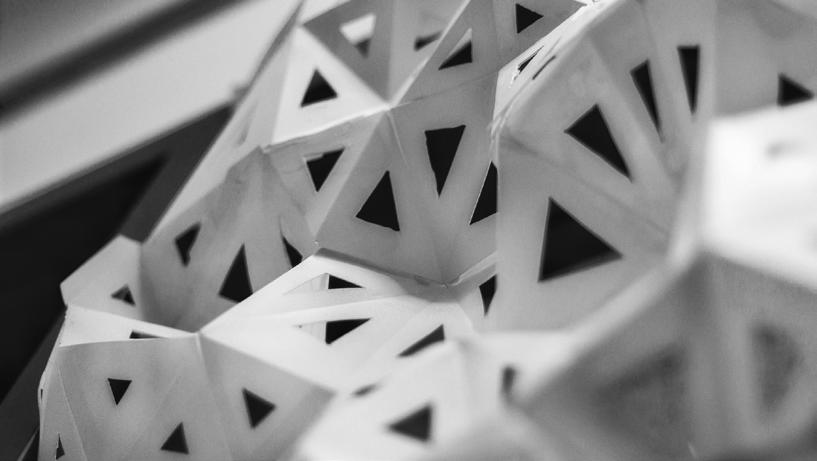

1. Points on grid

2. Locate points at curves' intersections; add randomized points

Tool: Rhino, Grasshopper

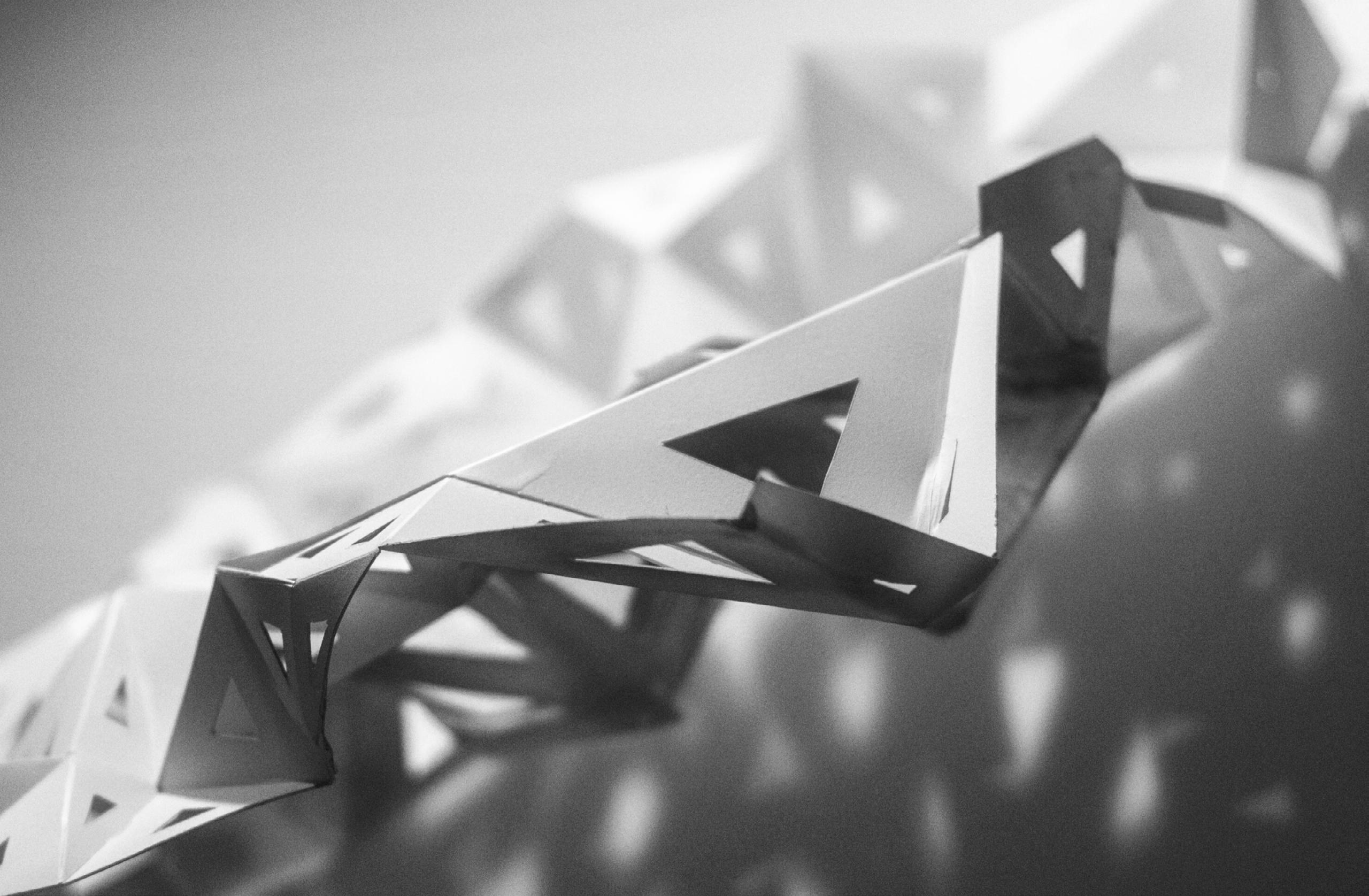

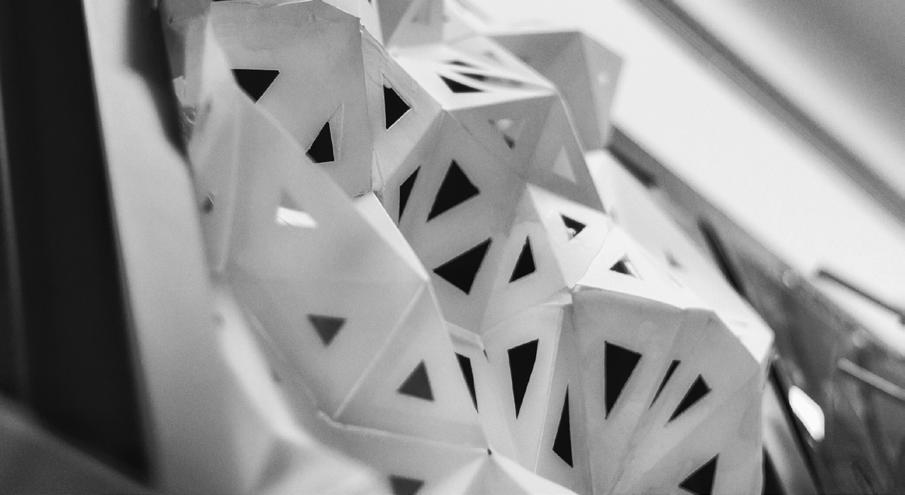

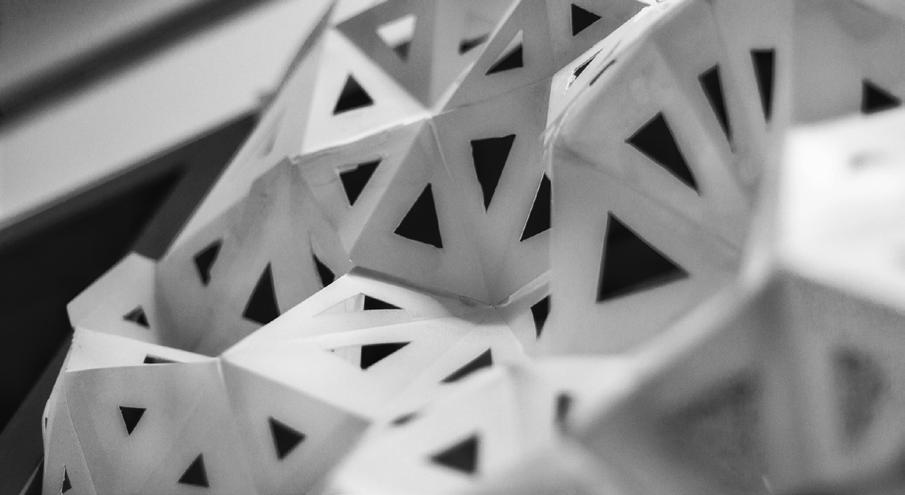

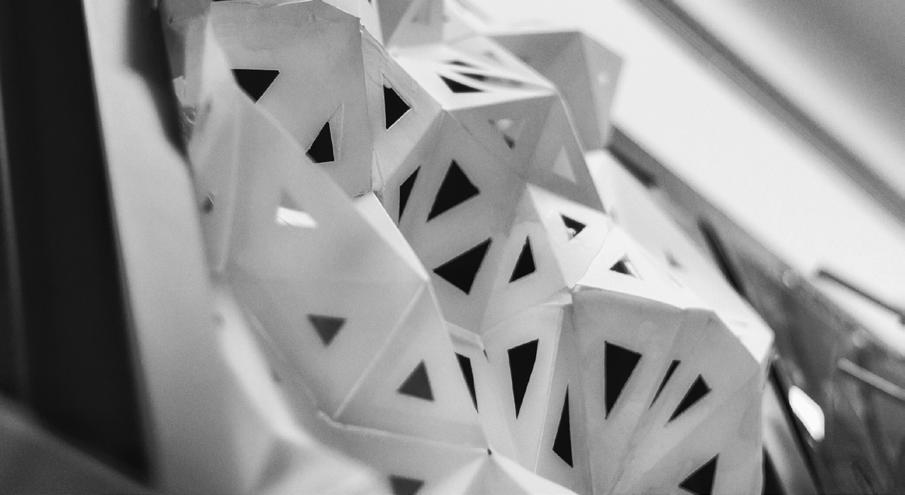

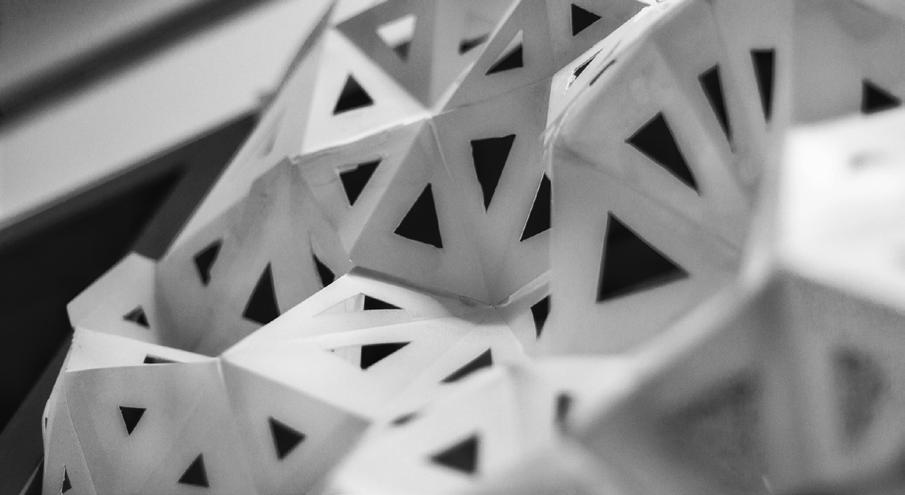

Team Project: John Rivera, Raye Liu, Zhengshi Lu, Rajbir Dhaliwal, Eric Sloan

Personal Contribution: conceptualization, coding, drafting, physical production

G2

3. Merge all points and randomiz on Y-axis within 0 - 100 mm domain range to create depth

4. All points are connected through the Delaunay mesh component in Grasshopper to create a mesh

Render

5. Scale of triangle becomes larger and triangles rotate to maximum 10 degrees in the white zone

Scale of triangle becomes smaller and triangles do not rotate in the black zone

RENDERING 2 CLOSE-UP VIEW G3

The screen is composed of 12 unrolled pieces, colorcoded as above.

Typical detail

Academic (2020)

Individual project

Conceptual Design

Project Area: 1,567 m2

Function: Cultural , Recreational

Software: Rhino, Grasshopper, Photoshop

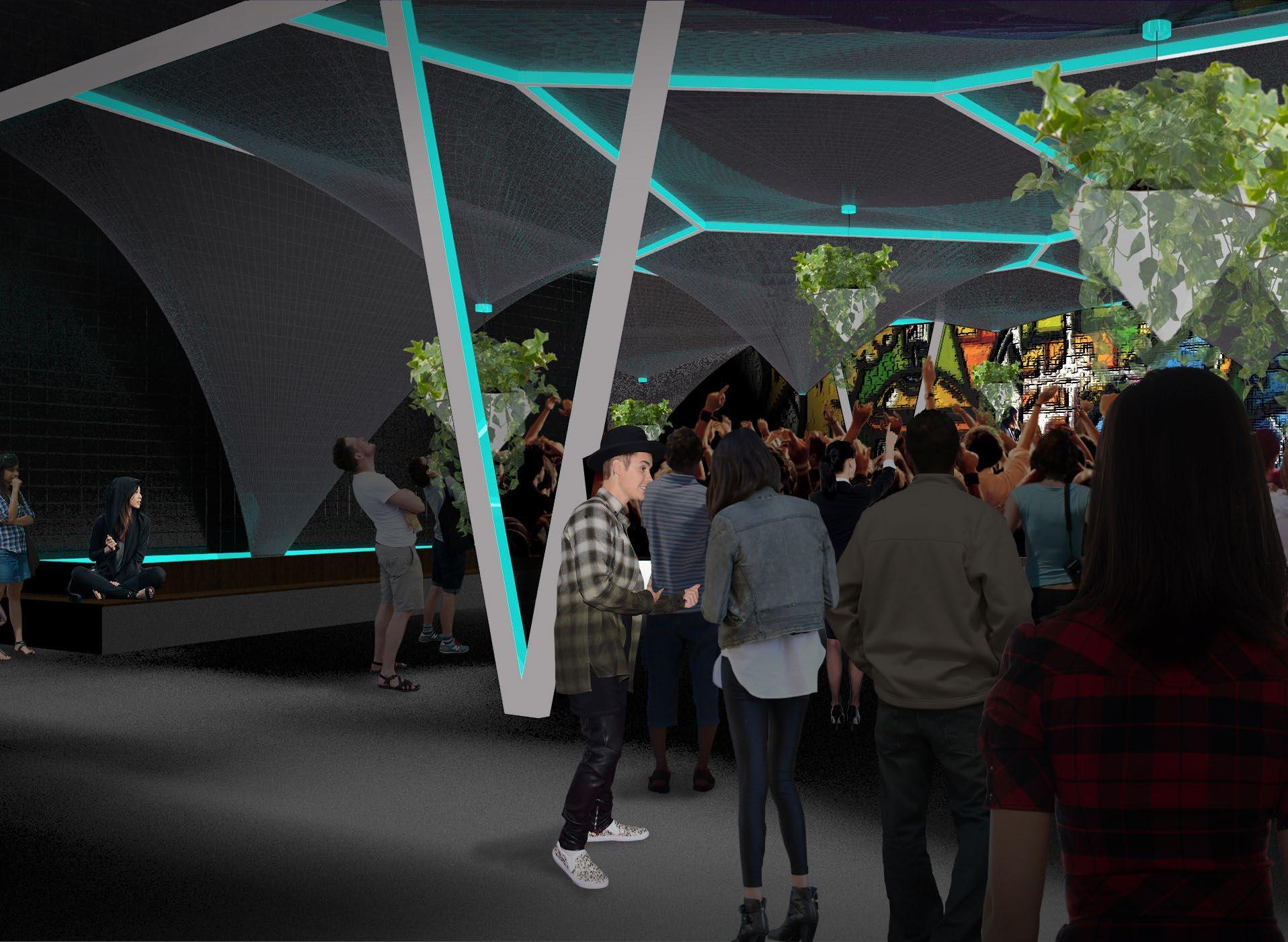

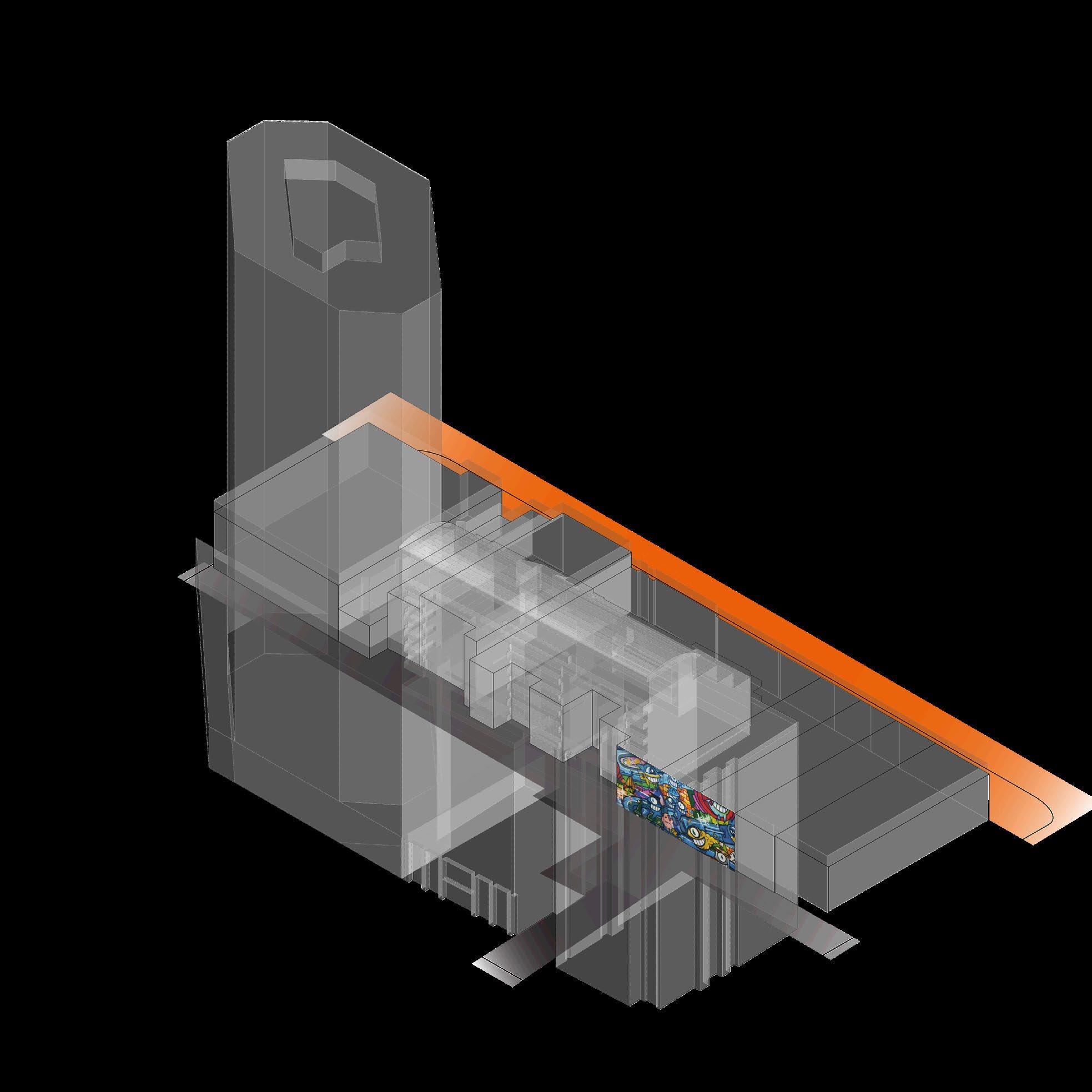

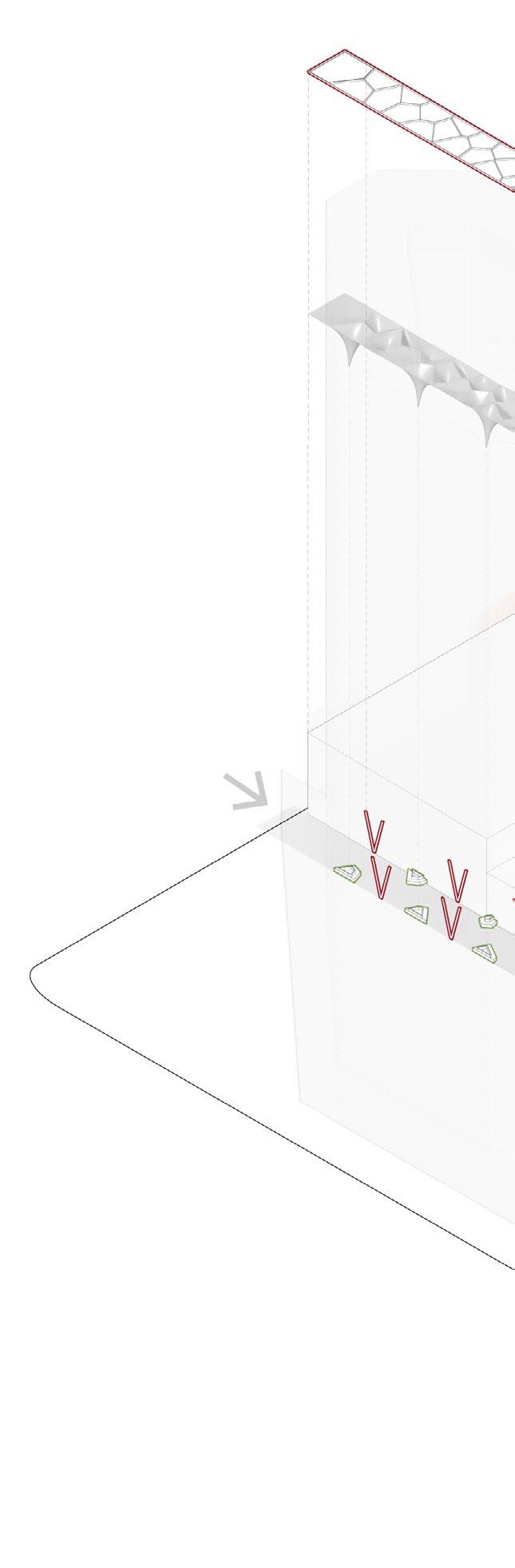

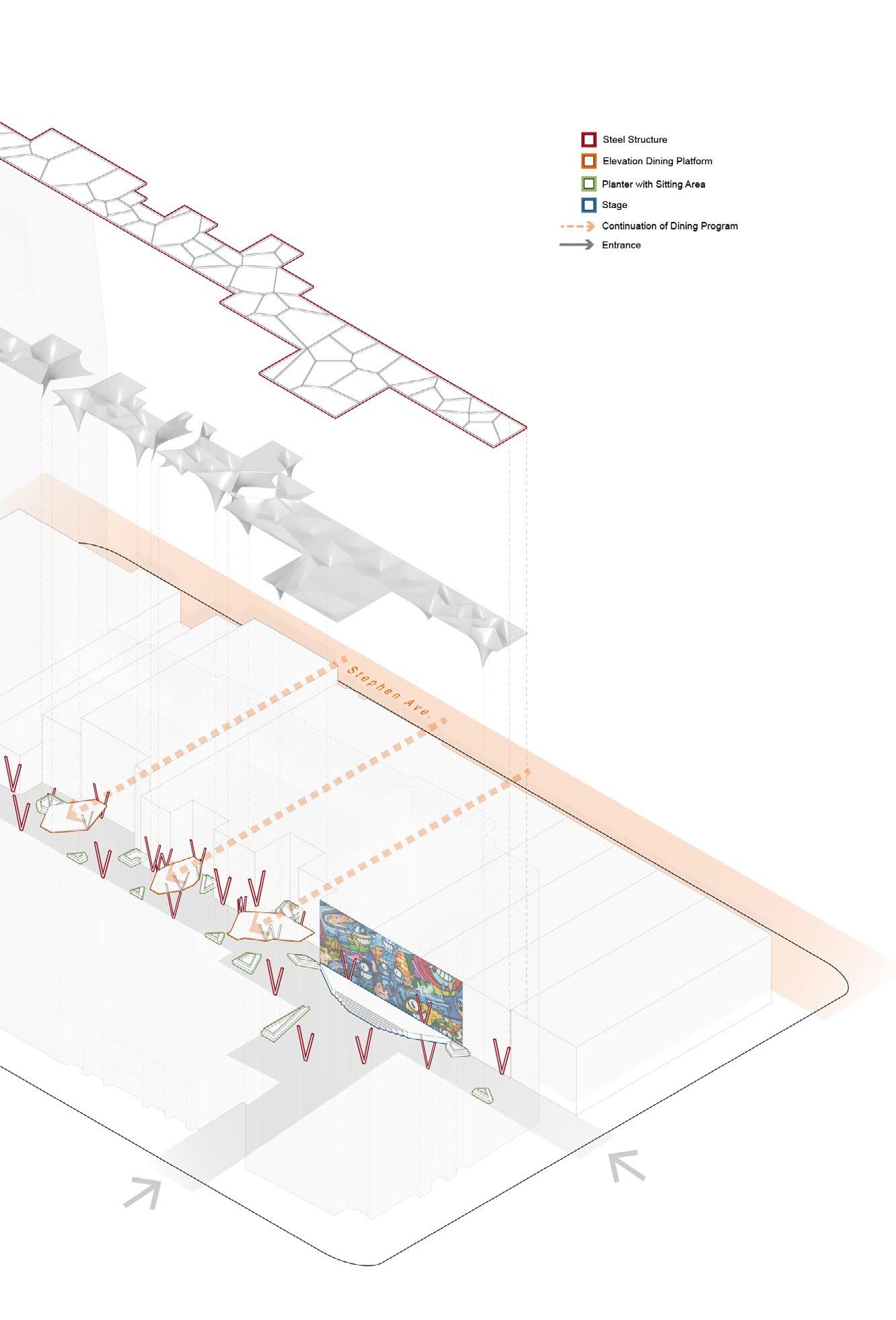

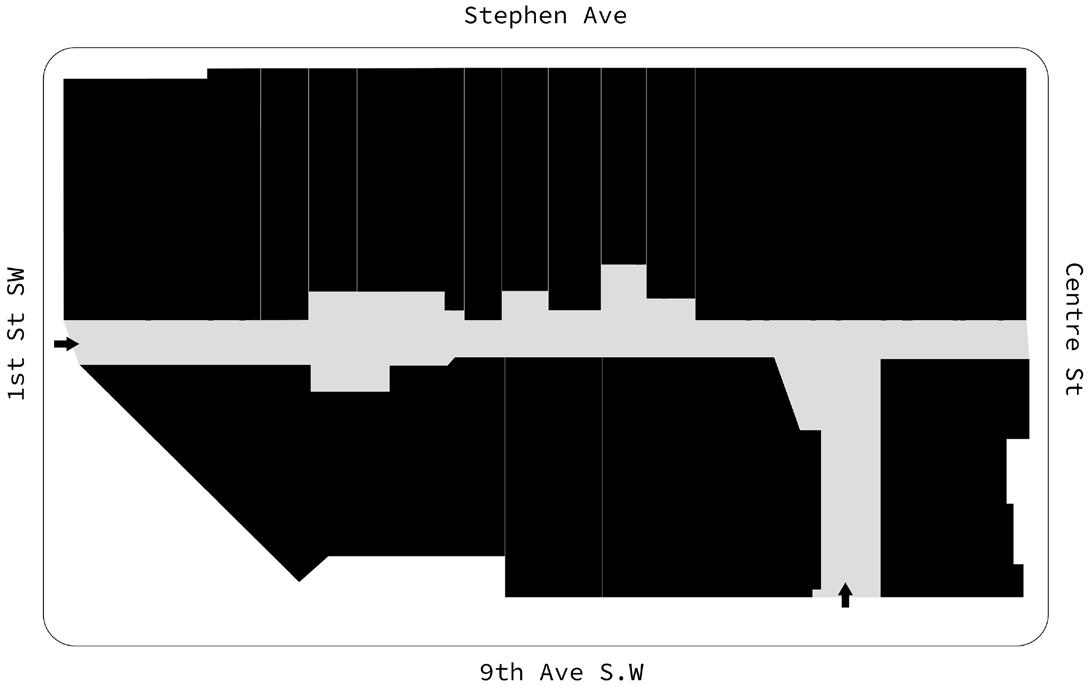

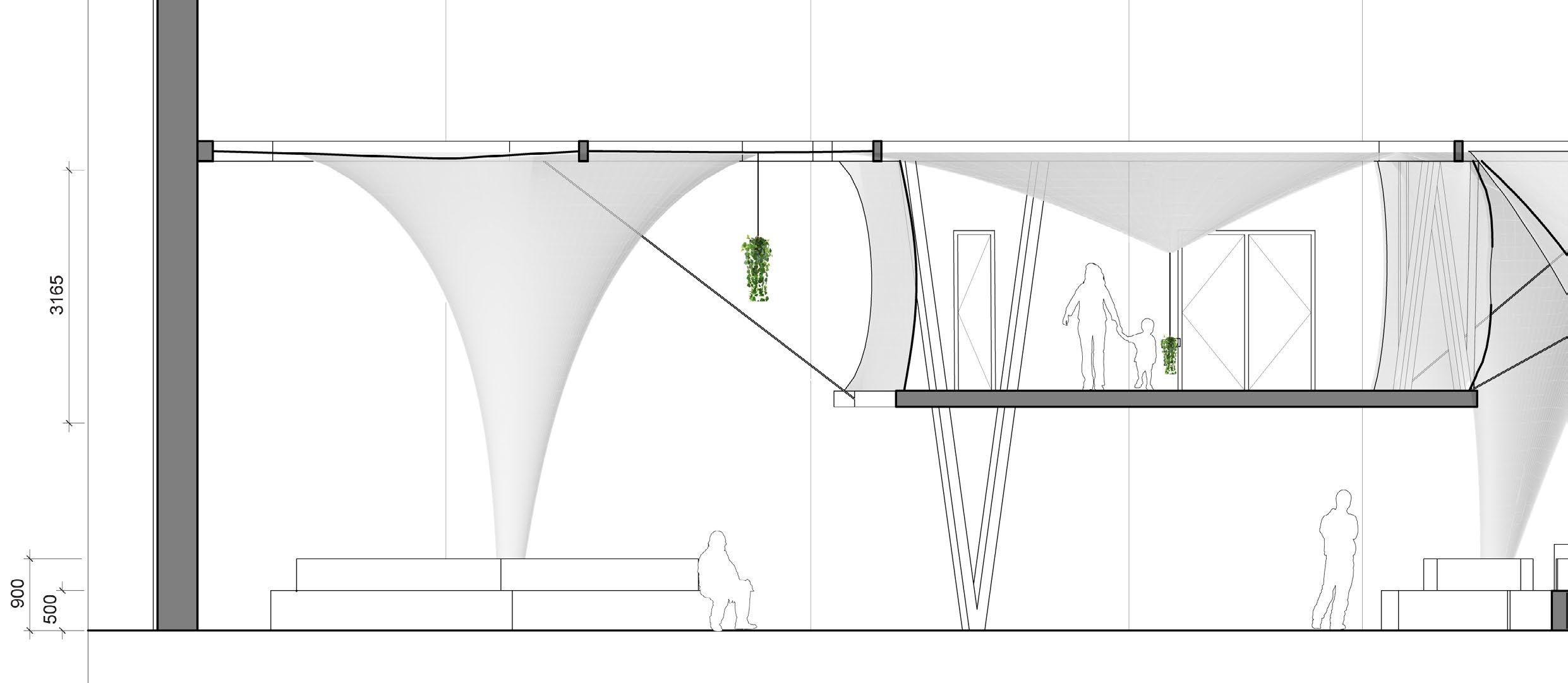

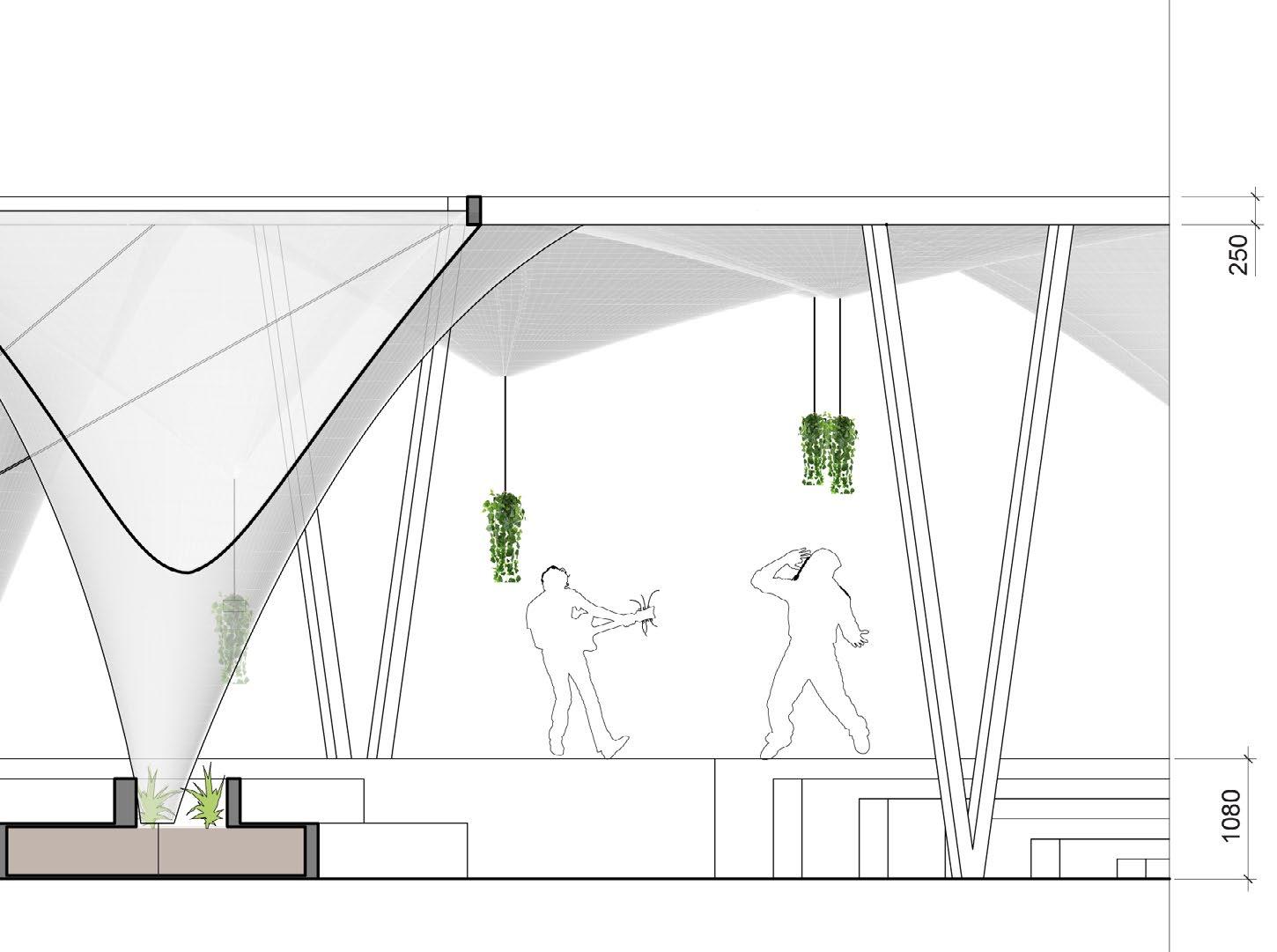

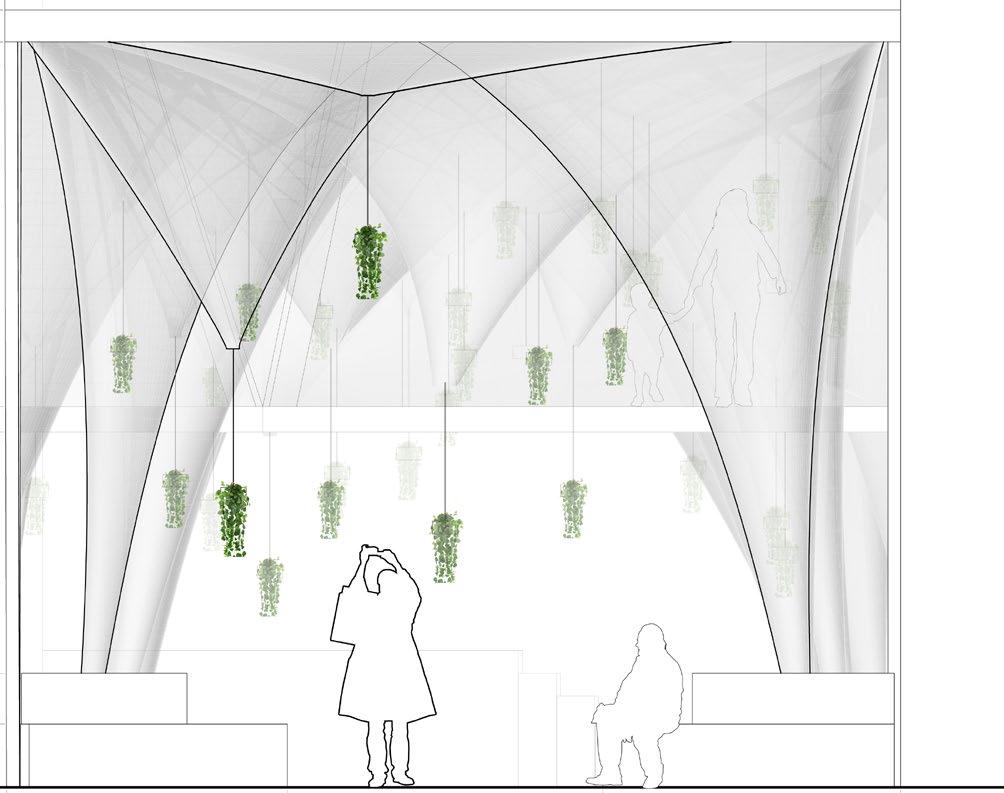

The project “Pounce“ is a tensile fabric structure to activate the back alley between buildings sitting along 8 Ave (Stephen Ave) and 9 Ave, Calgary.

Considering the currently dominant dining program along 8 Ave, the project intends to let the dining services overflow into the back alley, to serve the nine-tofive office workers and hotel dwellers along 9 Ave within a minimized walk distance.

While dining on those elevated platforms, people also have the opportunity to enjoy the landscape along the alley.

Another intention is to maximize the landscape influence the current graffiti wall can exert at the south entrance. Functioning as a beacon for fun and vibrancy during both daytime and night, the graffiti wall now works as a backdrop for the semi-outdoor stage. Hopefully, through a re-arrangement of programs and refinement of landscape details, the project will be an attraction point, especially for the younger generation.

The existing condition: the back alley has three entrances - two at each end and the third is a crossthrough on the ground level under a high-rise, which also expose the graffiti wall when people passby on the main road

Steel Edge Beams

INDEX

Site Analysis

Zoning Program Details

Tensil Fabric

Intention:

INDEX

Site Analysis

Zoning Program

Details

• Dining & entertainment

• Increase greenery area

• Night life

Elevated Dining Platforms on 2nd Floor

Steel Frame Hanging Elevated Platform

Dining

Graffiti Wall

Island Planter Seat

Entertainment

Greenery

Graffiti Mural

Intention:

• Dining & entertainment

• Increase greenery area

• Night life

Dining Entertainment

Dining Entertainment

Greenery

Green Spaces

Graffiti Backdrop

Graffiti Mural

Proposal: extend the dinning program in the storefronts on Stephen Avenue all the way to the back alley. Use the back alley as an outdoor dining environment. Build a stage using the graffiti wall as the backdrop, creating an amphitheatre for entertainment events. Island planters on the ground level function also as anchors for the tensil membrane structrue that provides a certain degree of protection from the environment.

2nd Level Floor Plan

Inner Clamping Ring

Turnbuckle

PRODUCED BY AN

Detail: Hanging Planter System and Low-Point Ring

Outer Clamping Ring

Cage Holding Planters

Roof Plan

PRODUCED BY AN AUTODESK STUDENT VERSION

Self-tapping Screw Clamping Plate

Wrapped Kedar Inside Fabric

Detail: Rigid Edge

Clamping Plate Self-tapping Screw

Fabric Kedar

Edge Beam Pin Connection

Sectional Detail: Rigid Edge Beam

Detail: V-Frame Footing & Connection

Academic (2020)

Individual project

Conceptual Design

Project Area: 6,156 m2

Function: Cultural , Recreational

Software: Rhino, Enscape, Photoshop

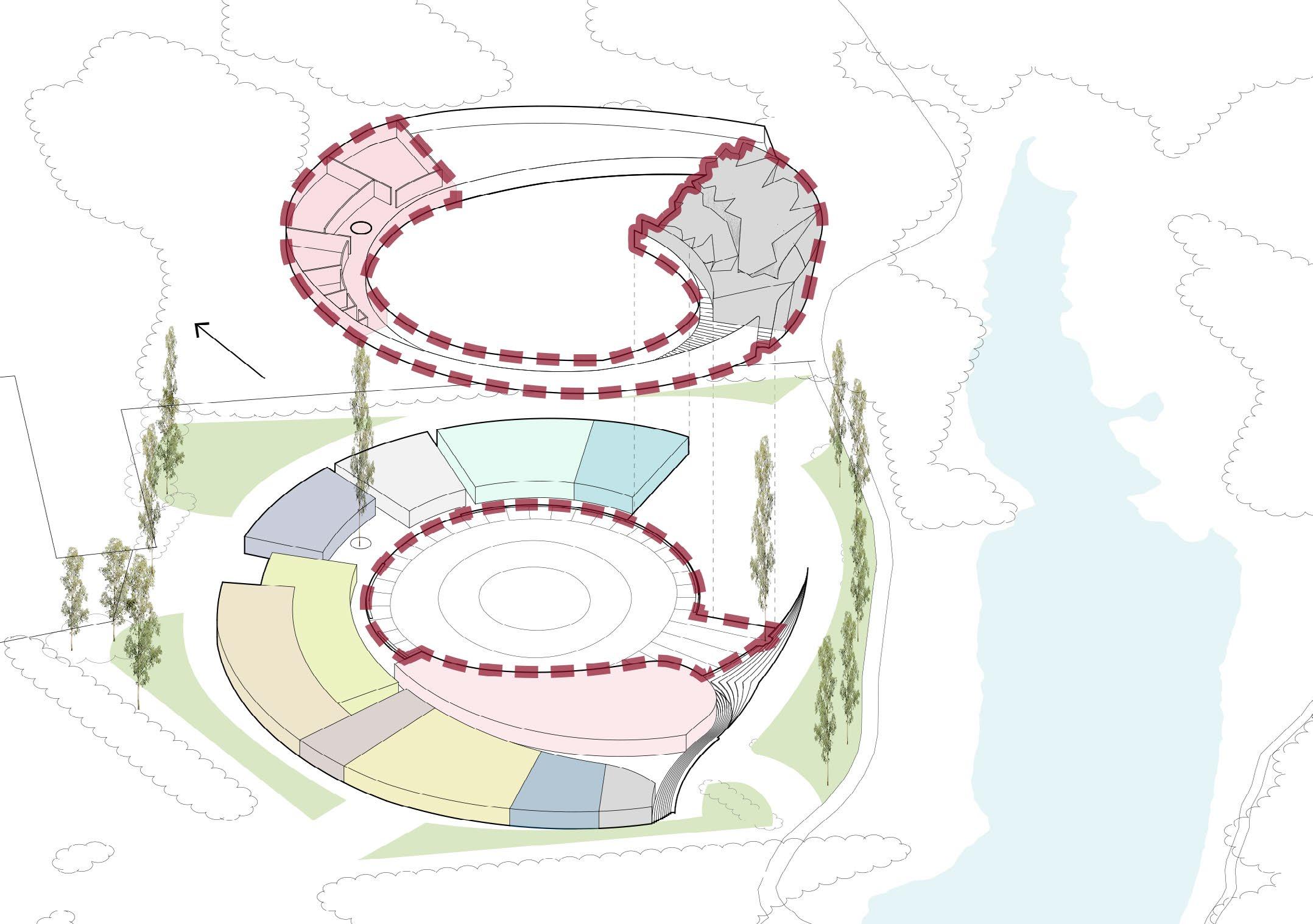

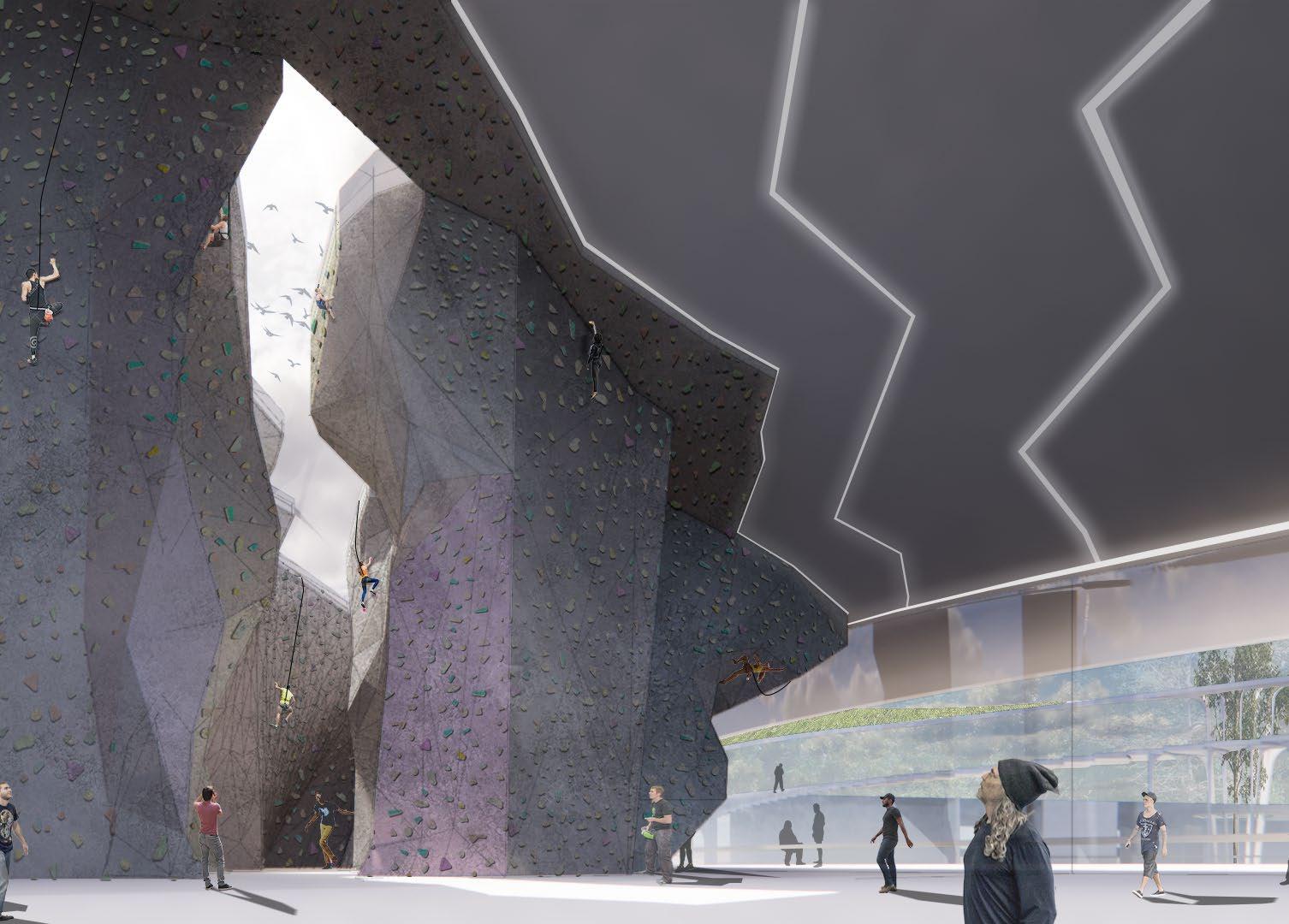

The site is the breath-taking Inglewood Bird Sanctuary situated along the Bow River in Calgary, Alberta. The curated bird-watching journey is a loop that starts and ends at the existing parking lot. To correspond with the curated linear journey, the architecture naturally is designed as a “loop within a loop“.

By the time of this design exercise, it was in the middle of the heated discussion about mental health issues that are brought about by COVID situation. Thus this project is also a review about how architecture can contribute to the mental health of the users. Based on the belief that a multi-modal program is beneficial to activate the different areas of the human brain, Collide is a recreational project that incorporated all different modalities and supra-modalities - as a collision of programs through various spatial heights and elevations, visual connections and adjacency to biophilia.

1. CAFE

2. BOOKSTORE

3. COUNSELLING

4. BREAKOUT ROOMS

5. PERFORMANCE ART

6. EXHIBITION

7. ART EDUCATION / MAKERS’ SPACE

8. ART & DESIGN STUDIO

9. MUSIC STUDIO

10. MIND-BODY WORKOUT

11. BOXING

12. SUNKEN GARDEN

13. ROCK CLIMBING

14. MEDITATION / PRAYER ROOMS

+6 M

GROUND

-1.5 M

OPEN CAFE & CASUAL SEATING NEAR EXIT

TRAIL & PUBLIC ENTRANCE

MEDITATION SPACE

ROCK CLIMBING

OPEN STAGE

BOH ENTRANCE FROM 9 AVE

ENTRANCE TO THE BUILDING

ART EDUCATION CLASSROOM

COUNSELLING CENTRE MEETING ROOM

COUNSELLOR OFFICE

THEATRE PERFORMANCE ART STUDIO KICK BOXING STUDIO ENTRANCE TO GARDEN

ALUMINUM CLADDING WHITE FINISH

100 MM RIGID INSULATION

WATER / VAPOUR BARRIER TO WRAP AROUND EXT. GRADE DRYWALL

EXT. GRADE DRYWALL

HAT CHANNEL SCREWED ONTO HSS

HSS - SEE STRUCTURAL DWGS

SLOPE DOWN TO GUTTER 3%

GUTTER BEYOND

SLOPE DOWN TO PIPE 2% MIN.

100 MM STEEL STUD

150 MM STEEL STUD

150 MM RIGID INSULATION

PIPE TO RAINWATER LEADER

OPEN TO PLANTER BELOW

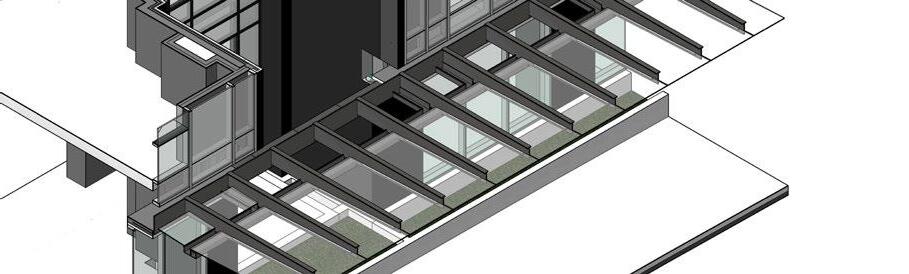

Building Canopy Detailing 1: Exterior Condition

CRole:

Coordinate engineering disciplines during Design Development phase;

Produce construction documents set, including envelop detailing;

Assist in the communication and clarification with the City during permitting process

Attend and write meeting minutes during consultant meetings

Location: Vancouver, BC

Construction documentation phase (2023present)

Project Type: New Construction

Gross Floor Area: 369,148 SF

No. of Stories: 28

Budget: CAD$60,000,000

Occupancy: Residential, Office, Healthcare

Software: Revit

LEVEL 02

LEVEL 01

North Elevation

LEVEL 02

38 MM RIGID INSULATION

GLASS SPANDREL PANEL

150 MM RIGID INSULATION

150 MM STEEL STUD

PREFABRICATED METAL FLASHING

EXT. GRADE DRYWALL

EXTERIOR

WATER / VAPOUR BARRIER TO WRAP AROUND EXT. GRADE DRYWALL

ALUMINUM CLADDING WHITE FINISH

100 MM RIGID INSULATION

HSS - SEE STRUCTURAL DWGS

GUTTER BEYOND

SLOPE DOWN TO PIPE 2% MIN.

150 MM STEEL STUD

PIPE TO RAINWATER LEADER

TRANSLUCENT TEMPERED GLASS PANE

SLPOE DOWN TO GUTTER - 3%

HSS SECTION - STR. DWGS

MEMBRANE LINED 150 MM X 150 MM STEEL GUTTER

OPEN TO PLANTER BELOW

Building Canopy Detailing 2: Interface with Interior Conditioned Space B

LEVEL 02

LEVEL 01

South Elevation

Storefront Option 1: 12 CRU's all at different elevations allows for smooth continuation of accessible path of travel in front of all CRU’s; disadvantage is that it is harder for CRU’s to be combined in the future, which will require to introduce internal ramp (s) within combined CRU’s

South Elevation

Storefront Option 2: 10 CRU's, with every two CRU's at the same elevation allows for every two CRU's to be easily combined in the future without building internal ramps; requries the accessible path of travel in front of the CRU's to go round the steps

There is a total of 4 feet grade change east-west wise along the south storefront of the building. Different options of how to design the elevation change of the CRU Units and the plaza in front of them are explored,

considering 1) the possibility of combining CRU’s in the future, 2) the accessibility of path of travel both outside of the stores, as well as inside the stores, including the scenarios where some of them are combined.

Role:

Explore design options during Design Development phase, e.g. planter and parapet wall conditions, and building canopy design;

Material research;

Building Code and by-laws research; Coordinate with engineering disciplines;

produce drawing set for Building Permit application, e.g. stair and core drawings, and window schedules;

Attend and write meeting minutes during consultant meetings

Location: Burnaby, BC

Design Development phase (2023), Construction Documentation phase (2023-present)

Project Type: New Construction

Gross Floor Area: 326,250 SF

No. of Stories: 43

Budget: CAD$48,500,000

Occupancy: Residential, Retail, Office

Software: Revit

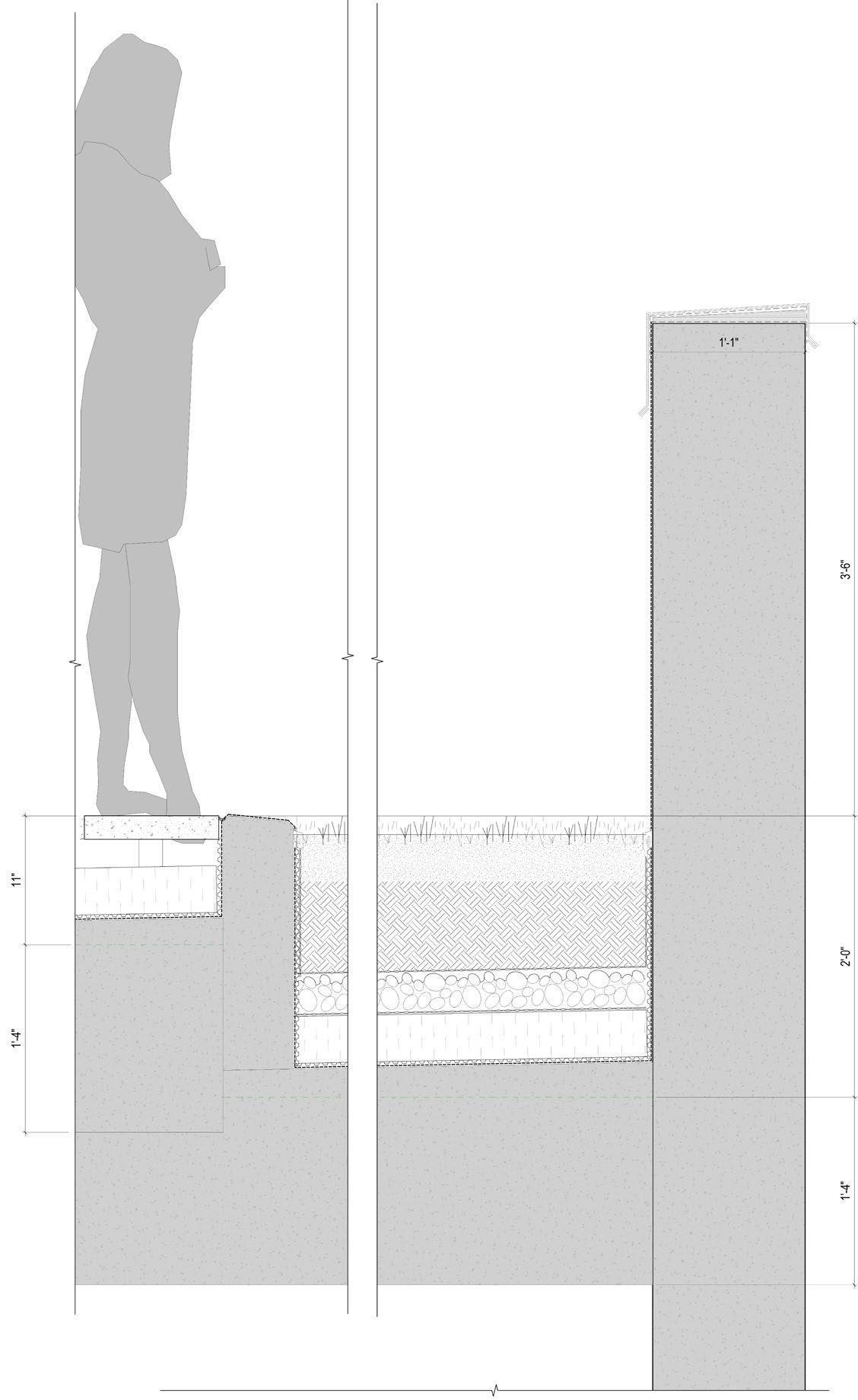

Bassano is a mix-used high rise. On the third level in the podium, there is this luxurious residential unit that has a vast terrace, and the task was to explore different options of the height of the planter v.s. the parapet wall, considering various factors, such as to continue the luxurious design style for the tenant, aesthetics, privacy, cost, and structural design.

PAVERS

OVERFLOW SCUPPER IN WALL PAVERS

5% SLOPE DOWN 10% MIN.

EXTEND ROOFING MEMB. UP THE UPSTAND

MEMBRANE TERMINATION BAR

TOP OF PLANTER WALL

SEE LANDSCAPE BUILDUP

METAL FLASHING ON PEEL AND STICK MEMB. ON TREATED PLYWOOD

2% SLOPE

16" CONC. SLAB (SEE STR.) CONC. WALL (SEE STR.)

GUMLIP FLASHING TO PROTECT LEADING EDGE OF ROOF MEMBRANE AND DRAINAGE MAT TYP.

PAVERS

OVERFLOW SCUPPER IN WALL PAVERS

10% MIN.

EXTEND ROOFING MEMB. UP

MEMBRANE TERMINATION

TOP OF PLANTER

SEE LANDSCAPE BUILDUP

2%

16" CONC. (SEE

EXIT BELOW EXIT

Option 1

Higher parapet wall because of the required 3’ 6” nonclimbable height starting from the soil surface

lower

Tall (3’ 6”) planter; sight line may or branches of plants;ROOFING THE UPSTAND

MEMBRANE TERMINATION BAR

PLANTER WALL

LANDSCAPE

SLOPE

CONC. SLAB STR.)

EXIT BELOW

5% SLOPE DOWN

CONC. WALL (SEE STR.)

METAL FLASHING ON PEEL AND STICK MEMB. ON TREATED PLYWOOD

GUMLIP FLASHING TO PROTECT LEADING EDGE OF ROOF MEMBRANE AND DRAINAGE MAT TYP.

10% MIN.

PAVERS

OVERFLOW SCUPPER IN WALL PAVERS

EXTEND ROOFING MEMB. UP THE UPSTAND

MEMBRANE TERMINATION BAR

TOP OF PLANTER WALL

SEE LANDSCAPE BUILDUP

5% SLOPE DOWN

Option 2

may only land on trunck

lower parapet allows visual connection

16" CONC. SLAB (SEE STR.)

2% SLOPE TO PLANTER DRAIN

16" CONC. SLAB (SEE STR.)

CONC. WALL (SEE STR.)

METAL FLASHING ON PEEL AND STICK MEMB. ON TREATED PLYWOOD

EXIT BELOW

Option 3

direct interaction with the planting area; special drainage and structural design requried for the inset planter; low parapet wall allows for visual connection

GUMLIP FLASHING TO PROTECT LEADING EDGE OF ROOF MEMBRANE AND DRAINAGE MAT TYP.