Chalk

vases & bowls

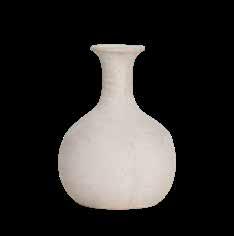

CHALK VASE JALOR

BSST00110 20x20x27cm

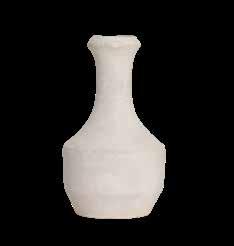

CHALK VASE RAYARO

BSST00113

12x12x20,5cm

CHALK VASE MALANI

BSST00116

7x7x13cm

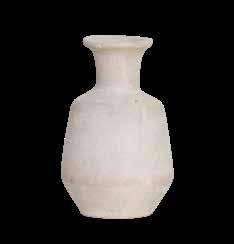

CHALK VASE CHOTAN

BSST00111 15x15x17cm

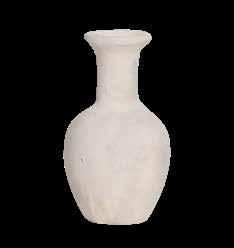

CHALK VASE OSIAN

BSST00114 15x15x24cm

CHALK VASE FALNA

BSST00117 9,5x9,5x16cm

CHALK VASE SAYALA

BSST00112 20x20x33cm

CHALK VASE BALESAR

BSST00115 15x15x24cm

CHALK VASE NAGAUR

BSST00118 20x20x35cm

CHALK VASE KOLAYAT

BSST00119 17x17x30cm

CHALK VASE DAUSA

BSST00121 12x12x23,5cm

CHALK JUG ALWAR

BSST00131

16,5x14x18cm

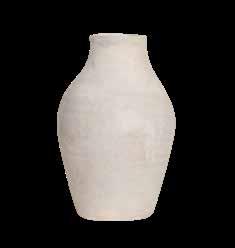

CHALK VASE CHARAN

BSST00120 21x21x20cm

CHALK VASE CHIRA

BSST00122 18x18x32cm

CHALK PLATE CHARKI L

BSST00132

20,5x20,5x2,5cm

CHALK BOWL CHANDRAPUR

BSST00134

25x25x8,5cm

CHALK VASE MANDORE M

BSST00135

22x22x31cm

CHALK PLATE CHARKI M

BSST00133

15x15x3cm

CHALK BOWL PANO

BSST00130

27x27x10,5cm

CHALK VASE MANDORE L

BSST00136

27,5x27,5x35cm

LIST00001 15x15x17,5cm

LIST00003 15x15x21,5cm

LIST00002 15x15x20,5cm

LIST00004 17x17x23,5cm

CHALK LAMP SUKKUR

CHALK LAMP MORO

CHALK LAMP KANOI

CHALK LAMP PUGAL

lighting | Paper mache |

This vases from this collection are made from a mix of paper mache and chalkpowder. Materials

The vases are made from an eco mix which consists of old newspapers, chalkpowder & glue in different percentages.

The process of how the base material is made:

1. Old newspapers are first soaked in water

2. The wet newspapers go through a machine and smashed into pulp

3. The pulp is mixed with crushed powdered chalk or lime-stone

4. Natural tree resin functions as the adhesive.

5. Resin crystals are melted in warm water and the liquid substance is added in the mix

6. Pulp, chalk & resin are mixed and pushed through an avegar

7. We then have the right substance and consistency, our base material.

From base material to final design:

1. Blocks of clay are pounded with a wooden mallet into sheets

2. The clay sheet is laid into a mould and pressed into the sides

3. Two half moulds are closed together, wrapped with a plastic band

4. From the inside extra clay is pushed into the connecting joints

5. The mould is left for 1-2 days drying in the air

6. The mould is opened and excess clay is cut off & small holes are filled by hand

7. The model is naw further left to dry for another 3-5 days in the open air

8. Finally it is sprayed with a sealer so no colour comes off when handling

The full process consists of only 2 important items: the use of natural materials & skilled labour, exactly the 2 things Raw Materials loves the most! Any new design is firstly made in plaster of Paris. This goes into a black of gips. This is cut in half and these are the 2 moulds.

Gips moulds can only be used 10 to 12 times.

Maintenance

Apart from dusting with a dry cloth, no maintenance is needed.

Extra information

Please note that the items from this collection are not waterproof.