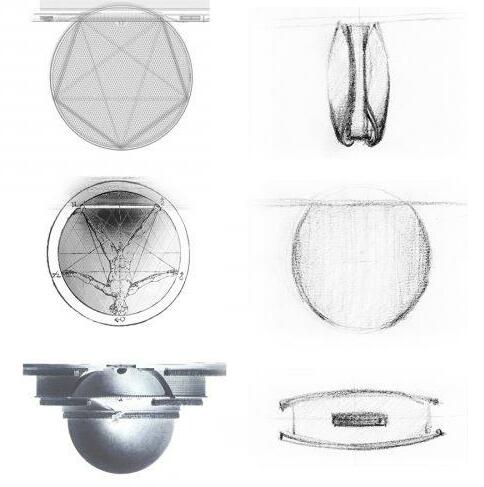

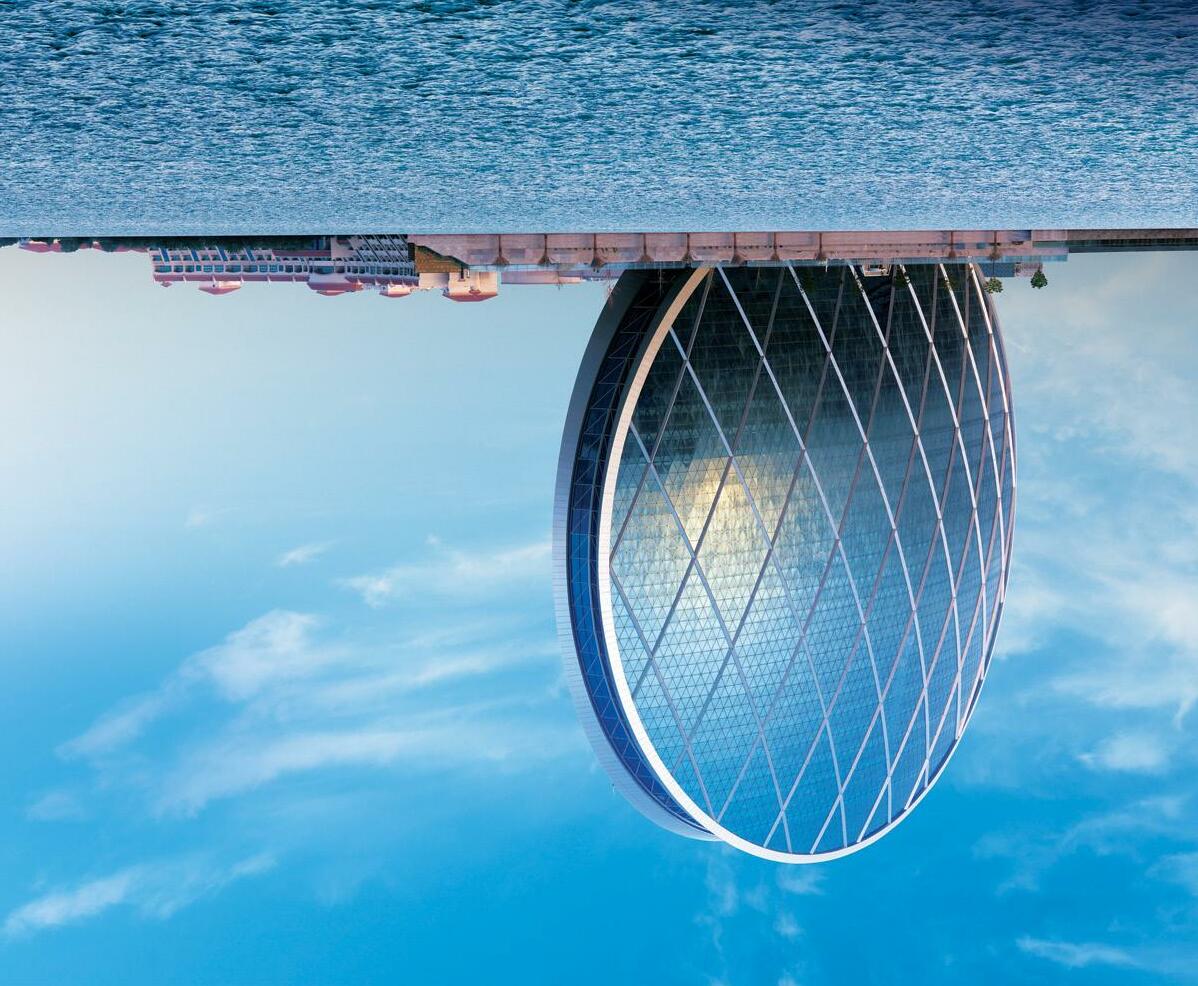

NAME OF THE BUILDING: ALDAR HEADQUATER BUILDING INSPIRED BY: SEA SHELL

LOCATION: AL RAHA BEACH ,ABU DUBAI

LOCATION: AL RAHA BEACH ,ABU DUBAI

CONCEPT Inspired by the clam shell that has a deep meaning for Abu Dhabi with its maritime heritage and the symbolism of the geometric round shape, the architect imagined two giant circular curved walls of glass that evoke an open shell. Tis thinking was born a pure, geometric but extremely ambitious: a skyscraper round with a curved glass skin

OUT PUT : LARGE CIRCULAR FLAT SHAPE BUILDING

ARCHITECT: MZ AND MARWAN ZAHEIB.

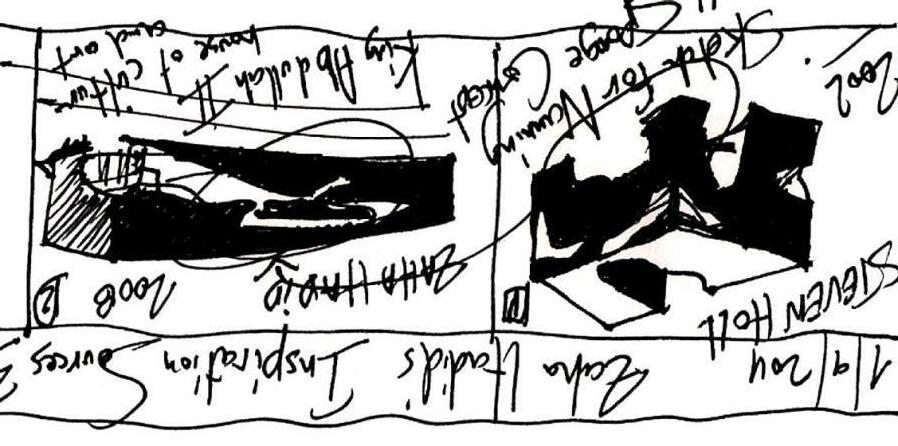

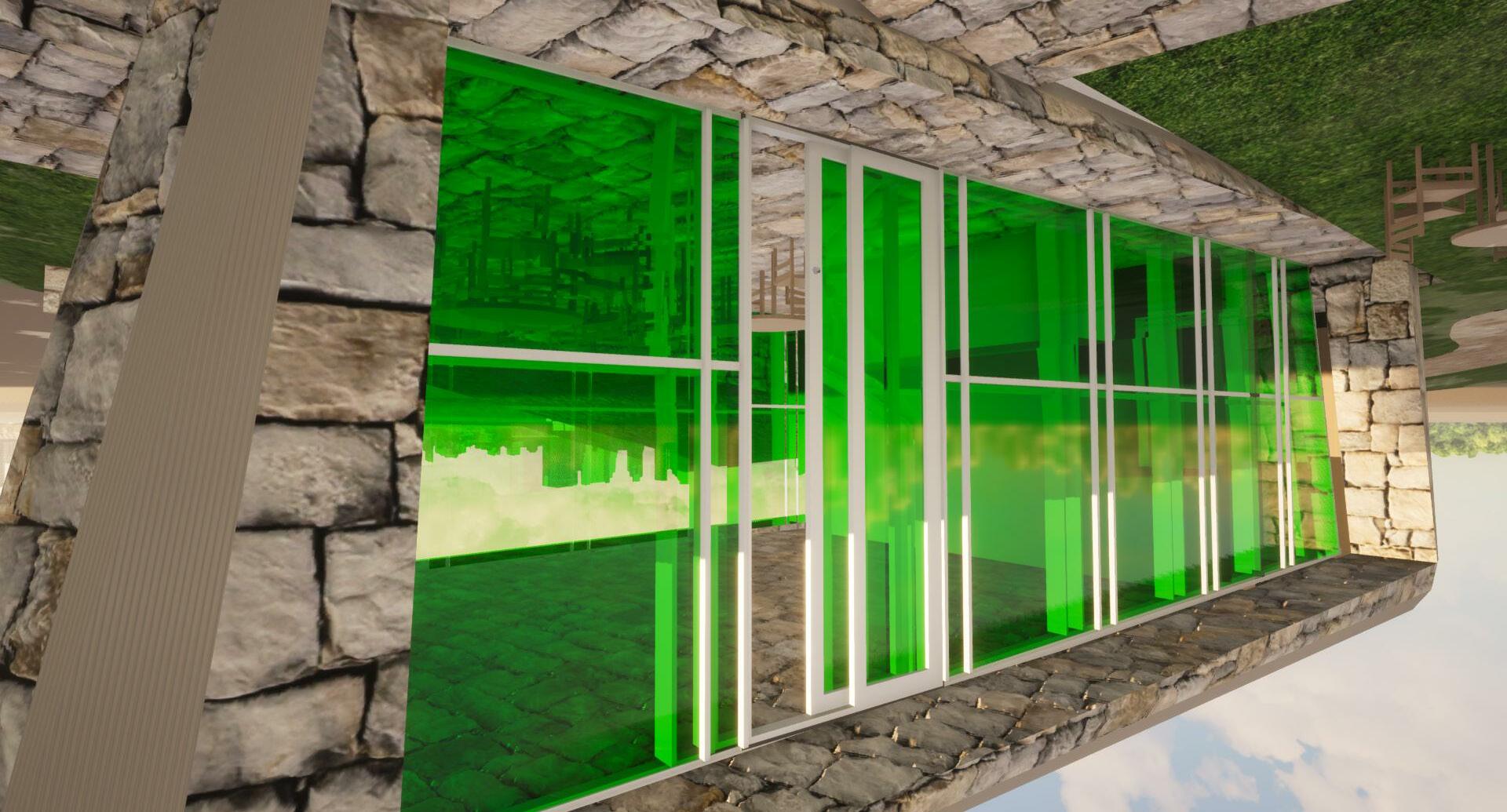

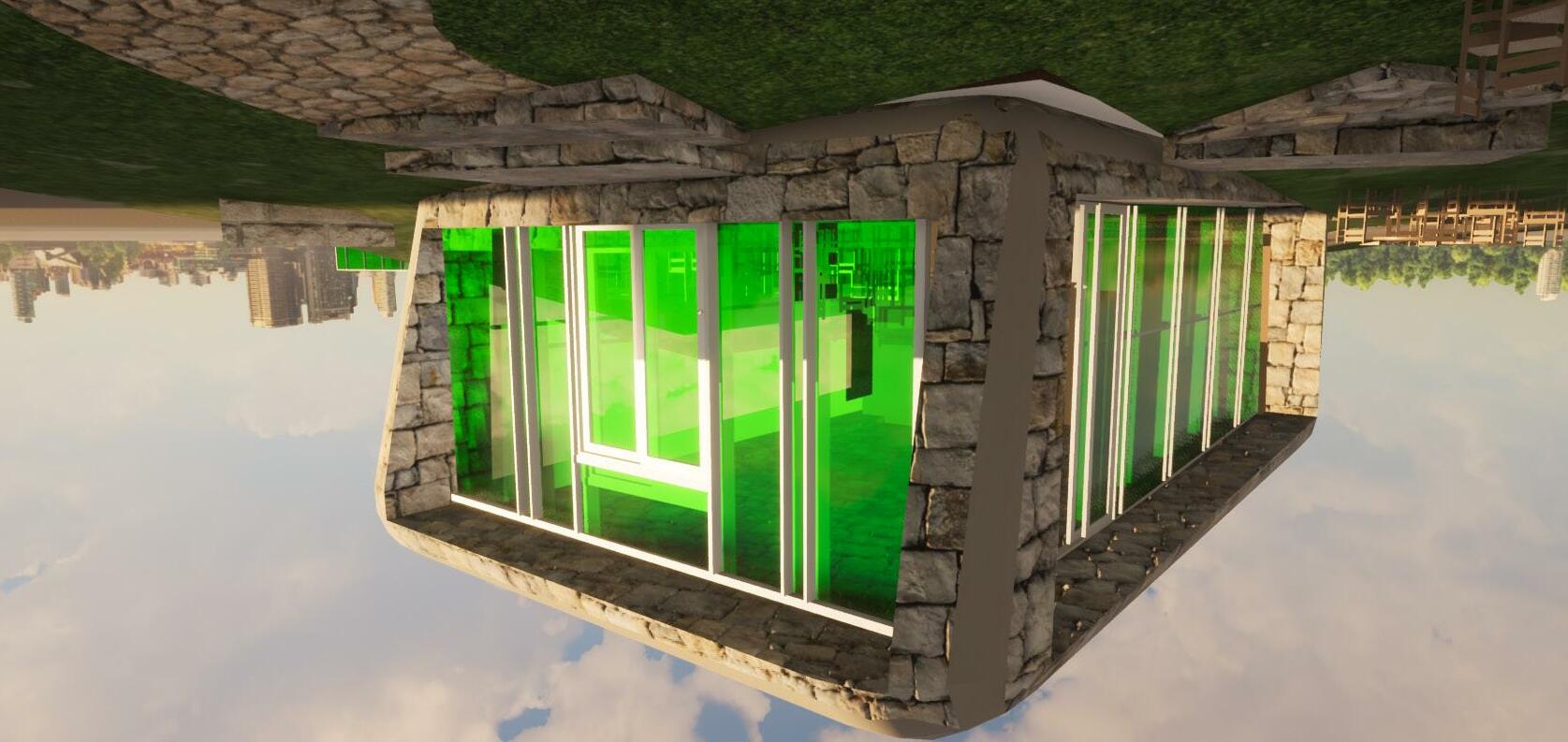

NAME OF THE BUILDING: ABDULLAH HOUSE OF CULTURE AND ART INSPIRED BY: MOUNTAIN FORMULATION

LOCATION: JORDANIAN CAPITAL OF AMMAN

CONCEPT : Te architectural expression for the new performing arts centre has been inspired by the magnifcent ancient city of Petra explains Zaha Hadid. “Petra is an astonishing example of the wonder ful interplay between architecture and nature, as well as the intricate complexity and elegance of natural forms – the rose-colored mountain walls have been eroded, carved and polished to reveal the astonish ing strata of sedimentation.

OUT PUT : Te interior public space is a continuous, multi-level space that cuts through the building.

ARCHITECT: ZAHA HADID

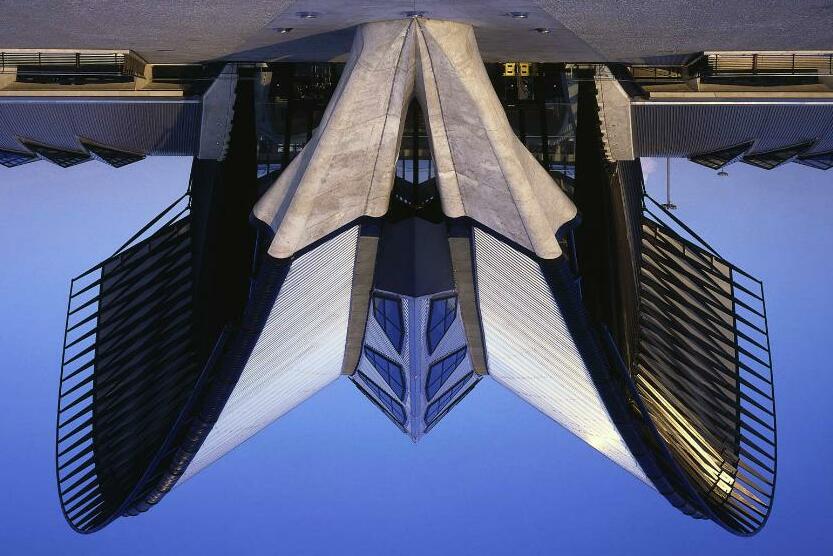

NAME OF THE BUILDING: Lyon-Satolas Airport Railway Station

INSPIRED BY: SHAPE OF THE BIRD LOCATION: TGV STATION LYON SAINT- FRANCE

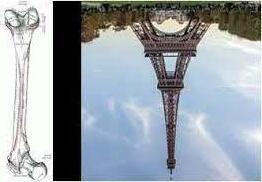

CONCEPT Te structure of almost forty meters high steel and concrete is the metaphor of a huge bird that stretches out its wings, covering or protecting the railway. As in other structures of the architect, the movement is present in the profle and arrangement of the elements of it, its shape also refers to many of the sculptures of Calatrava as “Bird”

OUT PUT : THE GLASS WALLS THAT FORM THE LOBBY ARCHITECT: SANTIGO CALATRAVA

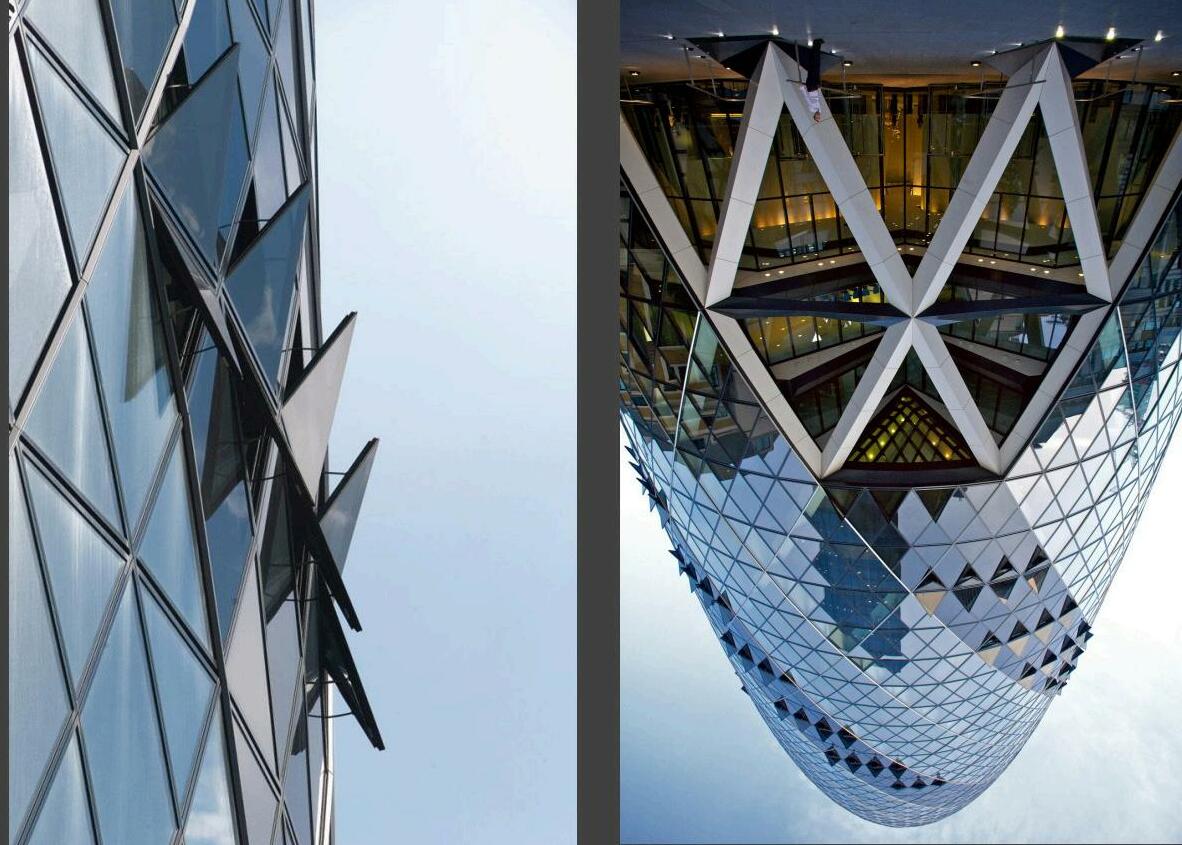

NAME OF THE BUILDING: 30 ST MARY AXE TOWER, LONDON

INSPIRED BY: PENGUIN BIRD LOCATION: LONDON

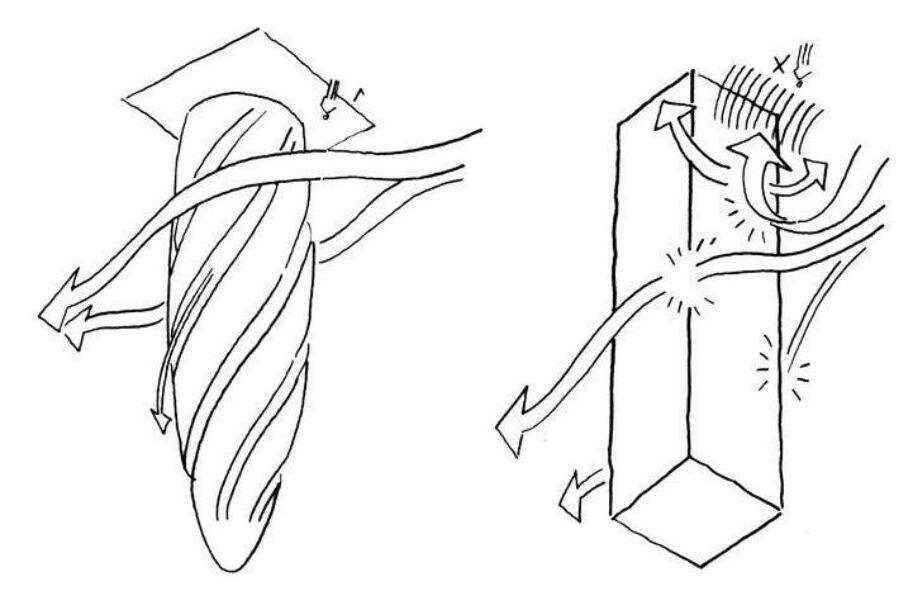

CONCEPT More air fows around the cylindrical structure than a traditional rectangular building.

Te smooth fow of wind around the building was one of the main considerations.

Te shape of the tower is infuenced by the physical environment of the city.

OUT PUT : Natural Ventilation Windows opened 40% of the year

Six light wells act as bufer zone to collect fresh air and control the speed and temperature as it fows through the building

ARCHITECT: FOSTER

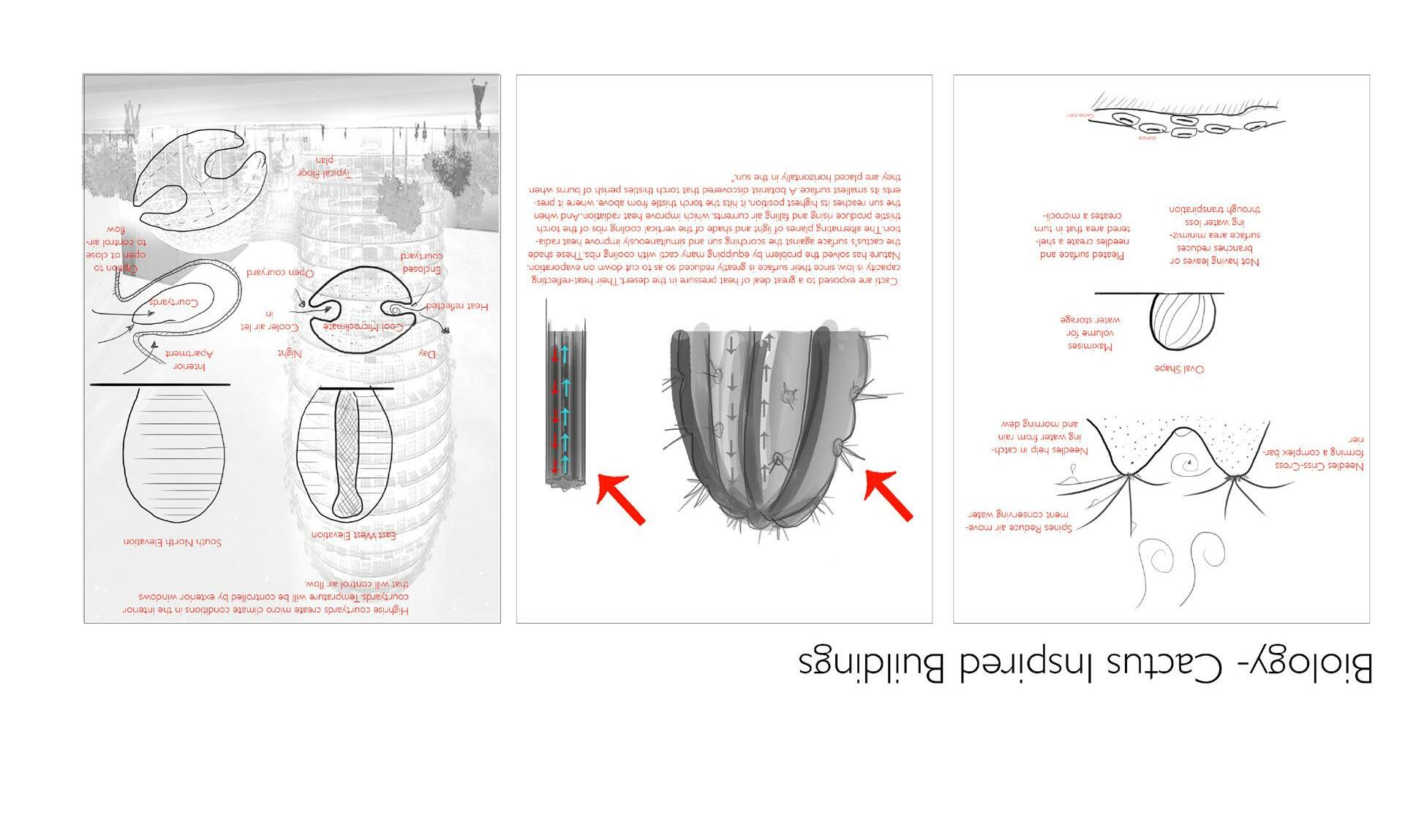

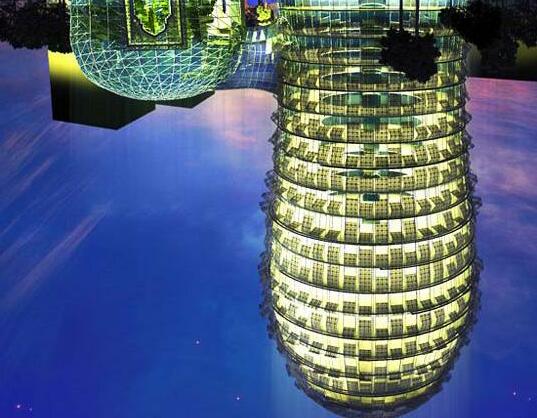

NAME OF THE BUILDING: MMAA BUILDING

INSPIRED BY: CACTUS PLANT LOCATION: DOHA, QATAR

CONCEPT Individual sunshade panels that open and close relative to the sun’s intensity, designed to mimic the appearance of a cactus in the desert, connecting botanical dome houses plants that could be used as a source of food or a way to clean wastewater OUT PUT : Te botanic dome at the base of the tower ARCHITECT: Bangkok frm Aesthetics Architecture

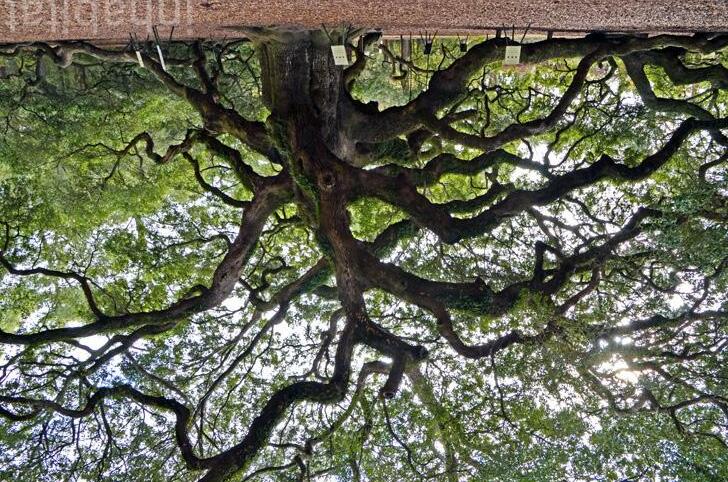

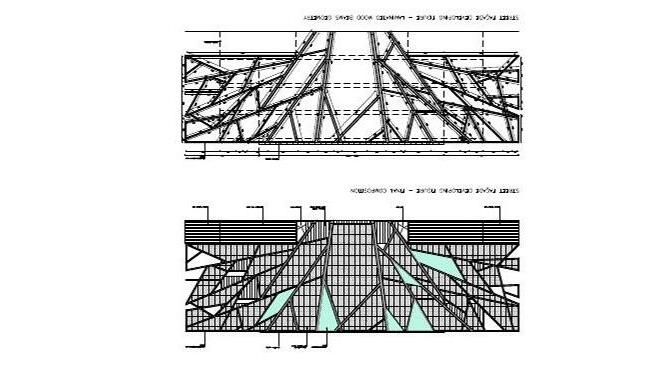

NAME OF THE BUILDING: GRAAFSCHAP COLLEGE

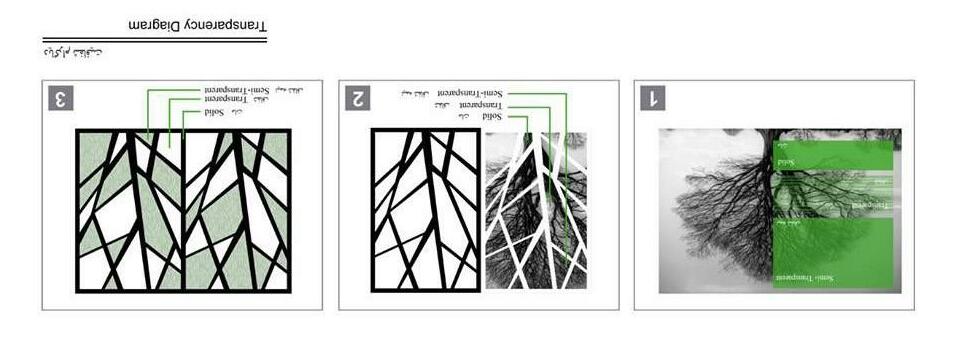

INSPIRED BY: OKA TREE LOCATION: Sportweg 3, Doetinchem, Netherlands

CONCEPT OKA TREE BRANCH FACADE OUT PUT : DECORATIVE FACADE ARCHITECT: Tibo Hoek

REMARKS NAME BASAVARAJ P KARAGAON

DATE 05/11/21

OF ARCHITECTURE

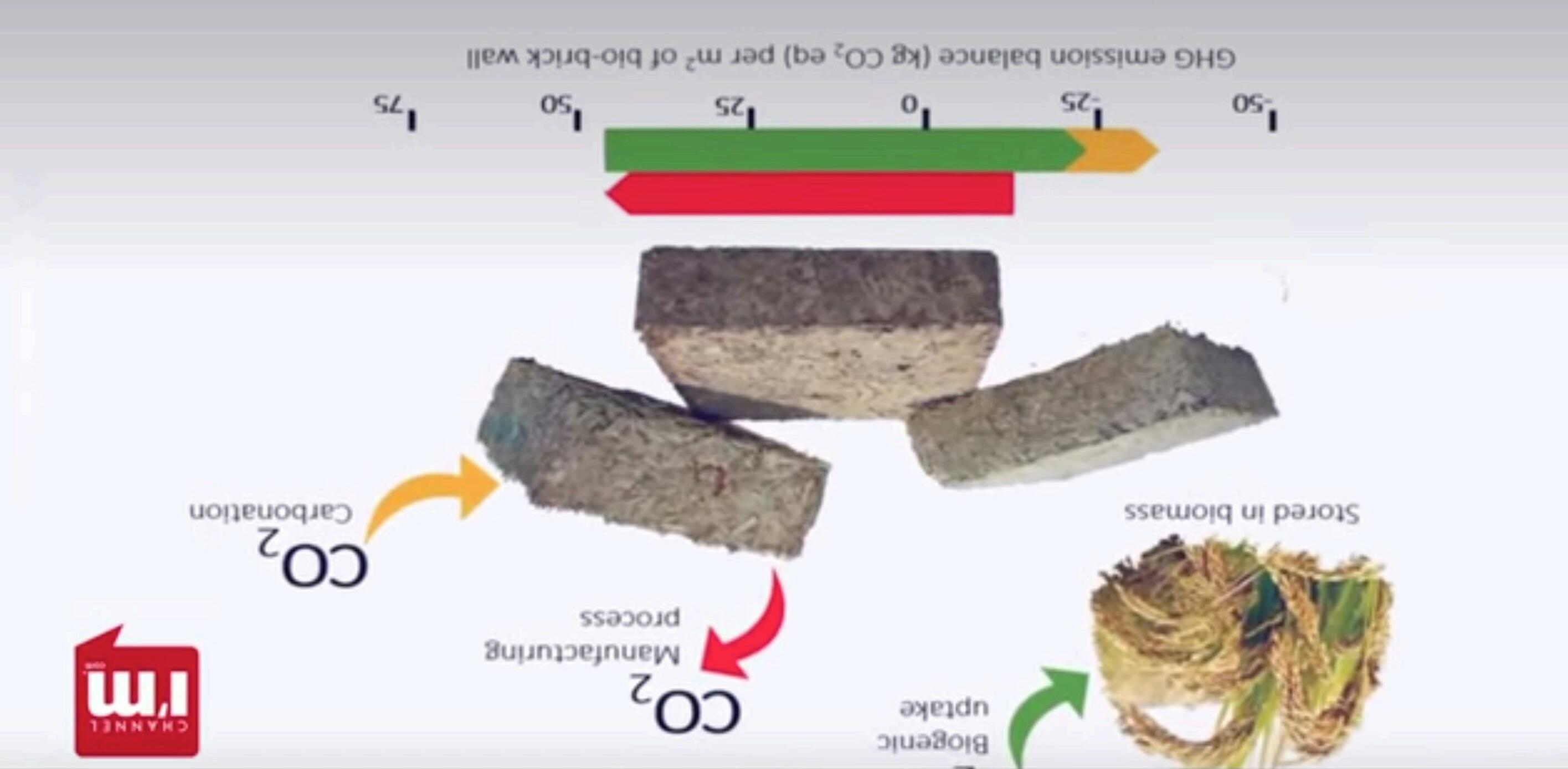

India’s frst building made of bio-bricks from agro-waste has been inaugurated at IIT Hyderabad. Te sample building is made up of bio-bricks supported by a metal framework. Te roof is also made of bio-bricks over PVC sheets to reduce heat. It is part of the Bold Unique Idea Lead Development (BUILD) project to demonstrate the strength and versatility of the material.

DESIGN BY Priyabrata Rautray CONSTRUCTION APRIL2021 LOCATION IIT HYDERABAD MATERIAL USED BIO BRICK

DESIGN BY Priyabrata Rautray CONSTRUCTION APRIL2021 LOCATION IIT HYDERABAD MATERIAL USED BIO BRICK

•This technology was developed to counter the air pollution caused by stubble burning.

•This material exhibits excellent thermal insulation and fre-retardant properties. When used in roof ing and wall panelling, it can efectively reduce heat gain by 5 - 6 degrees.

• Compared to burnt clay bricks, Bio-Bricks will cost about Rs.2 - Rs.3 when mass-produced.

• Bio-Bricks are found to be 1/8 and 1/10 of weight for similar volume compared to burnt clay bricks and concrete blocks, respectively.

• Bio-Bricks are quite economical, farmers can make this material at the site and further reduce the labour costs.

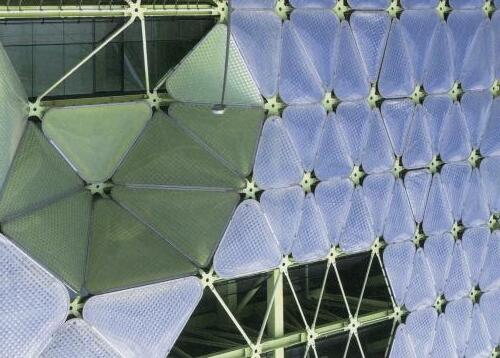

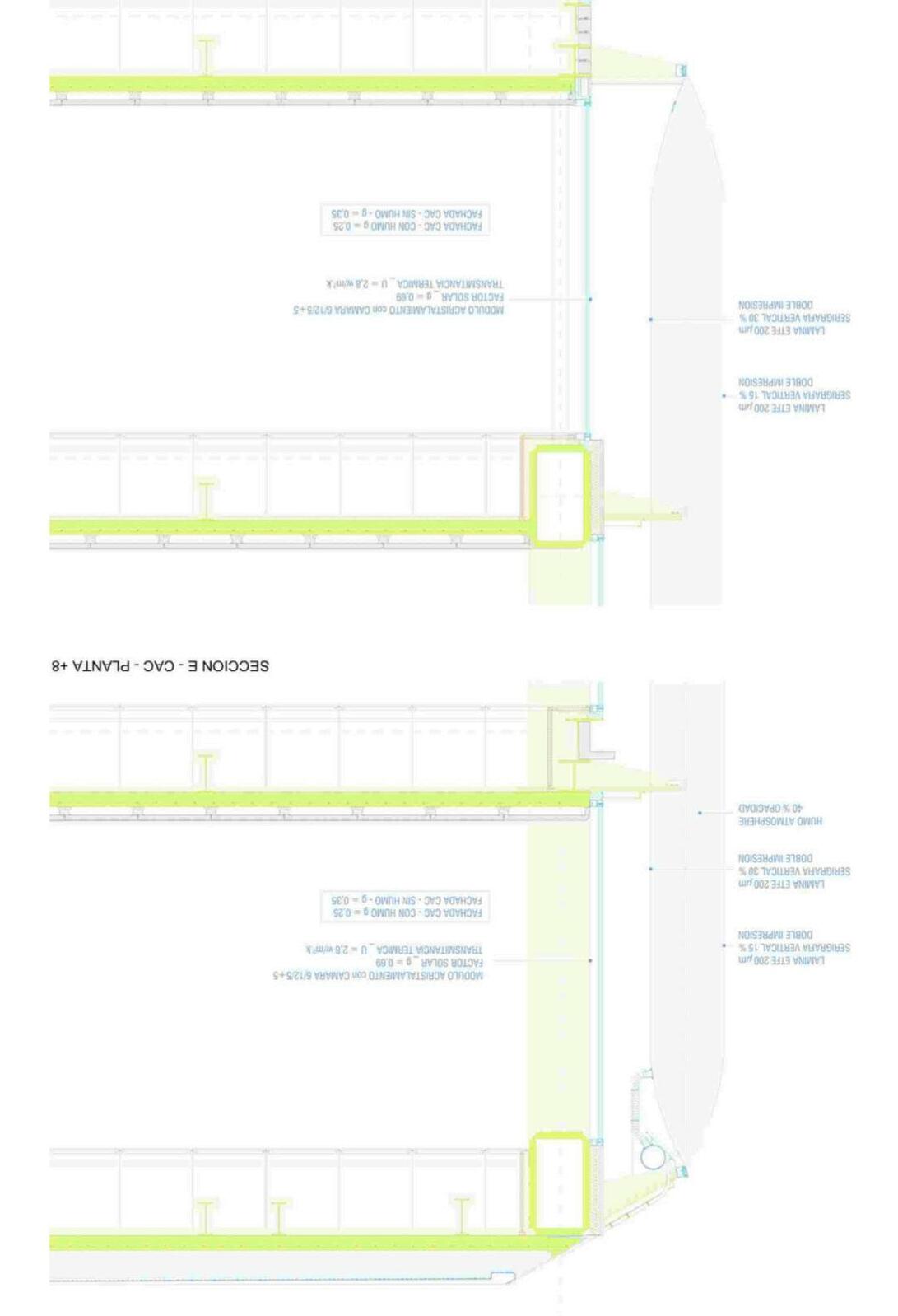

Solar Protection is necessary in order to achieve an eco-efcient building. Using 2,500m2 of ETFE cladding, the MEDIA-TIC building will enable energy savings of 20% and will score 42 points of the maximum 57 points envisaged by the decree on environmental criteria and energy eco-efciency for buildings.

ETFE is a hybrid material (Ethylene Tetra Fluoro Ethylene) with very special characteristics.

WE ACHIEVE A SOLAR FILTER AND A FAÇADE WITH A THICKNESS OF 200 μm .

RESULTS WITH VERY LITTLE MATERIAL

ULTRA VIOLET COEFFICIENT 85%

350 g/m2

MATERIAL . LIGHTNESS

FORM FINDING

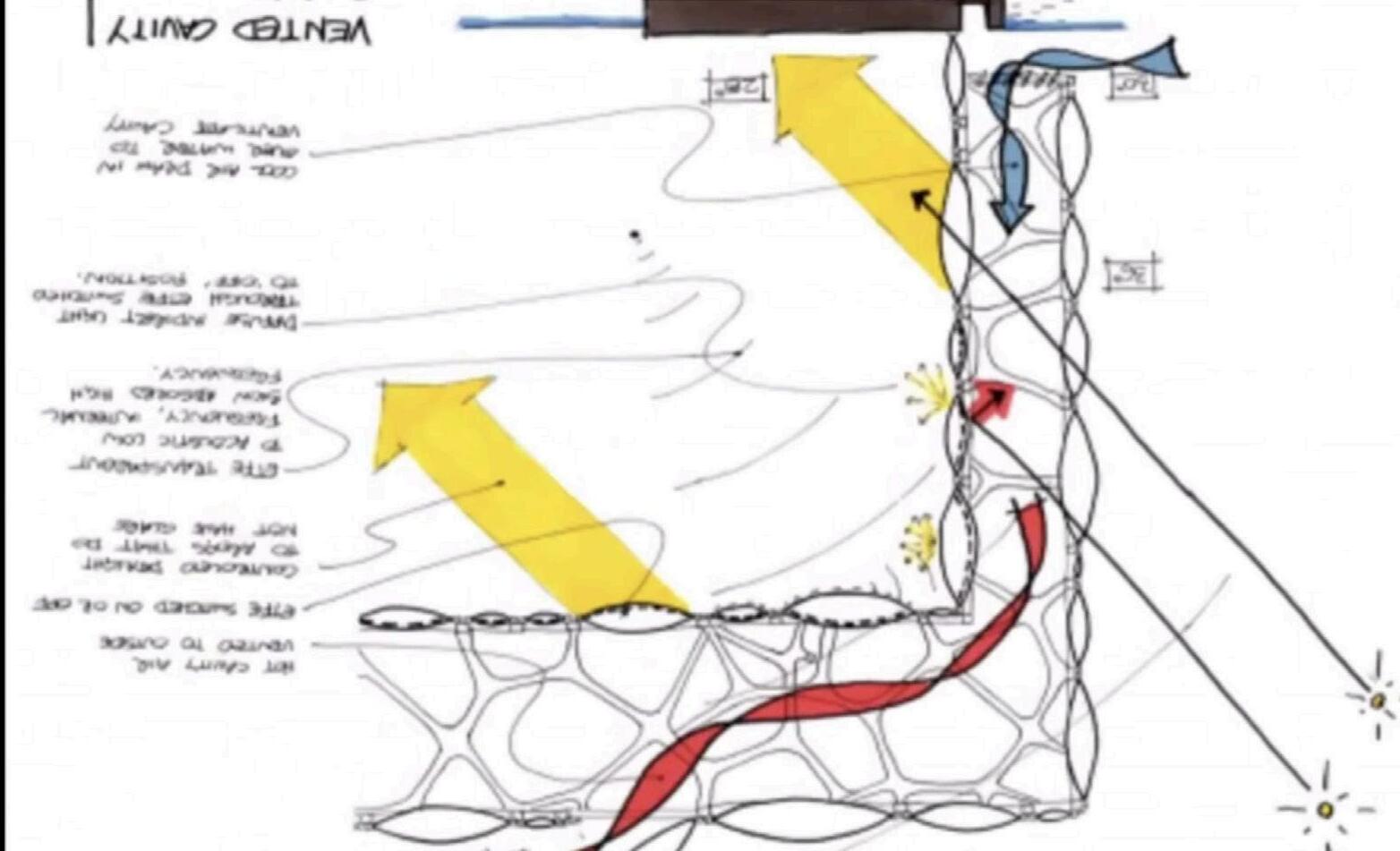

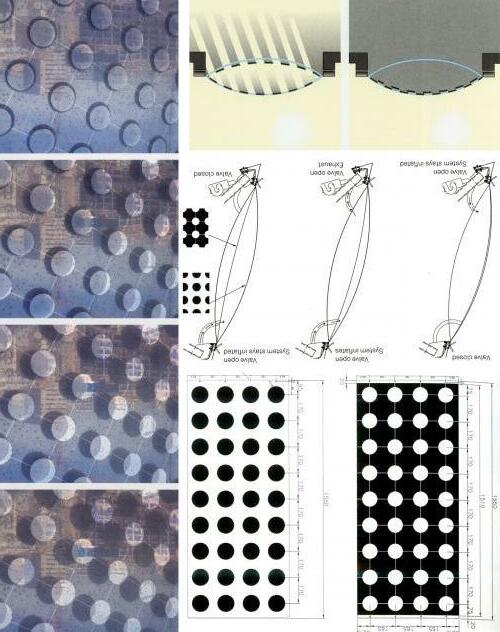

Tis façade also receives an average of 6 hours of sunshine a day. For this rea son, thanks to the powerful heat energy that enters, the suggested solution is the so-called LENTICULAR solution, based on 2 layers of ETFE, flled with nitrogen.

In this case, we use the air density of its particles in order to create a solar fl ter. Tis is a mechanism created following exhaustive research that represents a very low economic cost with respect to the project, accounting for 5% of the total.

We are in an area of ICT innovation, where energy manage- ment is the most important objective.

For this reason, the theme of the MEDIA-TIC building is how architecture creates a new balance with the digital use of energy.

Architect Enric Ruiz Geli Cloud 9

Designed in 2007 Floors 8

Floor Area 3,572 m2

Built-up Area 23,104 m2

CosT $20,791,486 €

Location Barcelona, Spain

MADE UP OF ETFE is a hybrid material (Ethylene Tetra Fluoro Ethylene)

“

One of the facades sistea has a tempera ture sensor which activates a vertical cloud of particles of nitrogen, with air gnereado the ETFE coating protects the building from solar radiation and cools.

Increasing the density of air cushions with ETFE nitrogen particles, the G fac tor of the building passes 0.35 to 0.19. Te system is activated automatically by a network of temperature sensors.

A vertical cloud that flters the solar radi ation.

Augmenting the air density of the ETFE cushins with nitrogen particles, the G fac tor of the building goes from 0,35 to 0,19. Te system activates itself automatically with a temperature sensor network.

An architecture that performs. At this point, it performs and regulates the solar energy with a flter in the façade, which combines a nitrogen particle sys tem with air from the ETFEs and creates a cloud that protects the building interior.

Te south facade of the Barcelona Media-Tic building has a very interesting solar protection. Tis is an outer layer separated from the curtain wall by the spatial metallic structure. It is composed of triangular elements, each one consisting of two layers of ETFE, which are kept separated and in fated by the pressure of the air inside. Between these two layers there is a third one, which can move manipulating the air pressure.

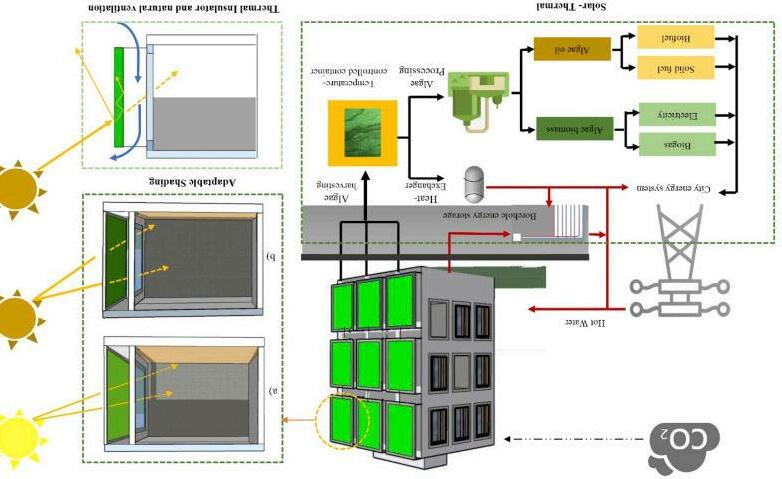

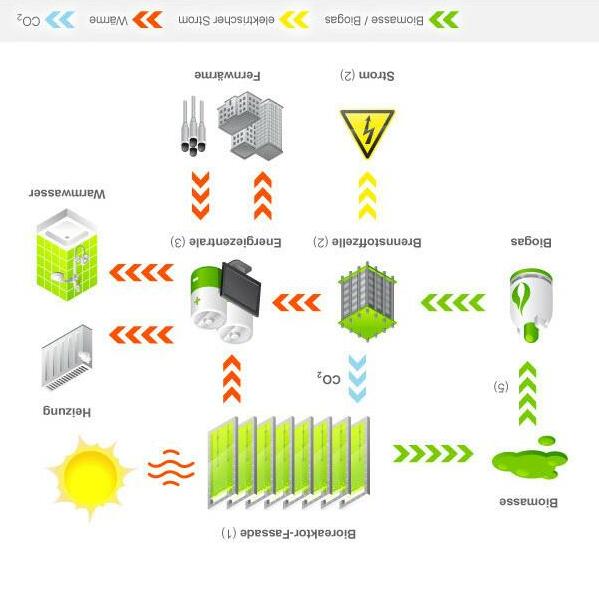

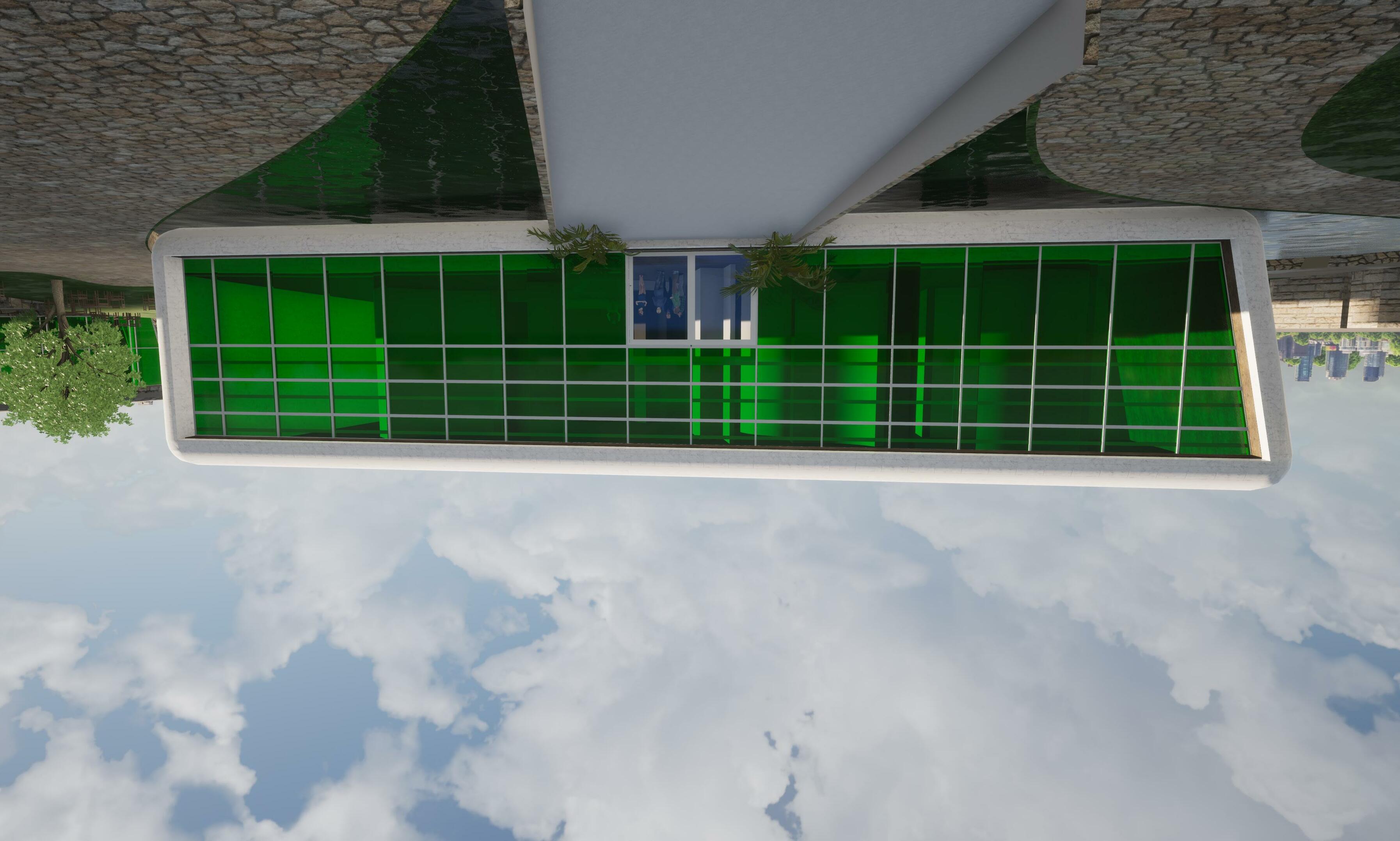

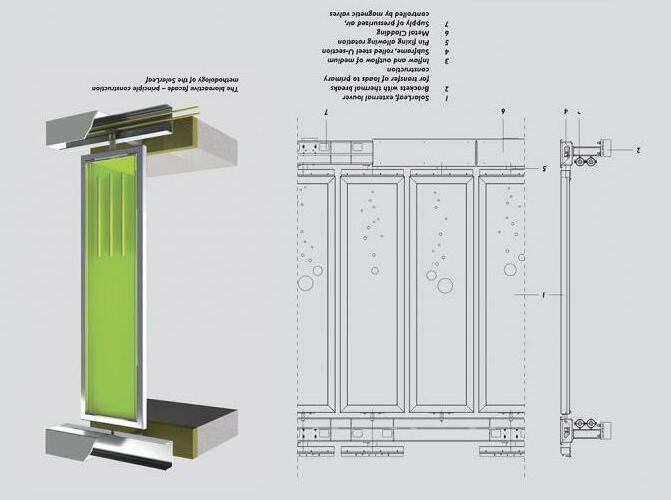

Te advantage of biomass is that it can be used fexibly for power and heat generation, and it can be stored with virtually no energy loss. Moreover, cultivating microalgae in fat panel PBRs requires no additional land-use and isn’t unduly afected by weather conditions.

In addition, the carbon required to feed the algae can be taken from any nearby combustion process (such as a boiler in a nearby building. Tis im plements a short carbon cycle and prevents carbon emissions entering the atmosphere and contributing to climate change.

Because microalgae absorb daylight, bioreactors can also be used as dy namic shading devices. Te cell density inside the bioreactors depends on available light and the harvesting regime. When there is more daylight available, more algae grows – providing more shading for the building.”

THE Algae House has made it possible to test a decentralised system that supplies a building with heat and power while producing high-quality bio mass energy. It also reduces the greenhousFDe gas CO2

Te BIQ Algae House. It is a pilot with which future microalgae can be cultivated on a large scale. Tey can be fed with waste gas es and use the containing CO2 for the development of biomass, which in turn serves as an energy supplier. Te “seaweed house”, world’s frst home with a bioreactor facade was presented at IBA. Tis facade spans microalgae that produce oxygen from the CO2 from exhaust gases, thereby producing biomass grow. By com bining the energizing algae facade with geothermal and solar thermal energy, the building produces more energy than its resi

The biomass and heat generated by the façade are transported by a closed loop system to the build ing’s energy management centre, where the biomass is harvest ed through foatation and the heat by a heat exchanger. Because the system is fully integrated with the building services, the ex cess heat from the photobioreactors (PBRs) can be used to help supply hot water or heat the building, or stored for later use.”