February 2018 // Railway Track & Structures 1 rtands.com ALSO: T TC OPERATED BY ENSCO NRC CHAIRMAN’S MESSAGE CYBERSECURITY TRACK GEOMETRY FASTENING SYSTEMS ROLLING CONTACT FATIGUE ROOT CAUSES AND MITIGATION MAY 2024 | WWW.RTANDS.COM

A clear cut represents a good start

Plasser American offers a wide range of shoulder cleaning machines for purchase and for contracting services. With the FRM802 and the FRM85F , the Plasser portfolio contains self-propelled shoulder cleaning machines for individual demands. The auto-levelling function of the shaker box creates a high return rate even in steep-graded curves. In combination with the modern excavation unit, the machines need just one single pass to pick up the designated shoulder area. The modern design allows a clear cutting depth, which is essential for the drainage function of the ballast shoulder. Unbeatable quality leads to cost savings by extending maintenance cycles.

”Plasser & Theurer“, ”Plasser“ and ”P&T“ are internationally registered trademarks plasseramerican.com HIGH CAPACITY I PRECISION I RELIABILITY

May 2024 // Railway Track & Structures 1 rtands.com CONTENTS FEATURES Follow Us On Social Media @RTSMag 10 Rolling Contact Fatigue Root Causes and Mitigation 16 Vendor-Product Spotlight Track Geometry and Inspections 21 Vendor-Product Spotlight Fastening Systems 24 Vendor-Product Spotlight Cybersecurity May 2024 21 DEPARTMENTS COLUMNS 4 8 Editor’s Notebook Information Technology on the Railroad From the Board Larry R. Parsons by Gary Wolf, RT&S Board Member 3 32 Cover Story: Root Causes and Mitigation of Rolling Contact Fatigue For story, see p. 10 TTC Operated by ENSCO Building and Maintaining Robust Software Systems in Rail Technology NRC Chairman’s Column Mentors Can Make All the Di erence in Building a Successful Career AREMA Message from the President 27 32

PRESENTING

PRESENTING

The Educational Railroading Conference Leader Since 1994

29th ANNUAL WHEEL RAIL INTERACTION CONFERENCE

COMING TO CHICAGO,

The Rail Transit Seminar is devoted to examining wheel/rail, vehicle/track interaction on rail transit systems. This cross-disciplinary seminar includes presentations from experts in vehicle/ track dynamics, noise and vibration, vehicle/track design and maintenance, friction management, and State of Good Repair. Join a unique group of transit professionals, researchers and suppliers at this seminar to examine recent developments in research and technology, to participate in lively discussion and gain a better understanding of the complex interaction at the rail transit wheel/ rail interface. Sample topics include:

• Rail Grinding/Rail Milling

• Wheel/Rail interface Studies for Vehicle Procurement

• Practical Implementation of Friction Management Systems

IL • MAY 21 - 24, 2024

The Principles of Wheel/ Rail Interaction Course is an intensive, full-day course that provides fundamental coverage of the primary aspects of wheel/rail, vehicle/track interaction. Drawing from both theory and practical application, the course covers contact mechanics, track geometry, vehicle suspension systems, vehicle/track dynamics, wheel/rail profile design, friction management, measurement technologies and more—all the elements that are required to promote a more complete understanding of vehicle/track dynamics and wheel/rail interaction. Typical topics include:

• Wheel-Rail Contact Mechanics

• Track Structures, Components & Geometry

• Vehicle Types, Suspensions & Components

• Vehicle-Track Measurement Technologies

The Heavy Haul Seminar is devoted to examining wheel/rail, vehicle/ track interaction on rail freight and shared-track passenger systems. The Seminar brings together track and mechanical users, researchers and suppliers in a positive, educational setting like no other in the industry. Information on where and how the latest technology is being used to improve wheel/ rail interaction and overall performance on freight and passenger railways is presented. Information is presented through a combination of seminar sessionss, dedicated Q&A periods and “InfoZone” sessions. Topics include:

• Lessons Learned from Derailment Investigations

• Reducing Rail Surface Defects through Rail Grinding

• Managing Longitudinal Forces Transmitted into the Rail

• Validating Effective Friction Management in Heavy Haul

The

concentrates on the “Big Picture” of where the wheel and rail meet.

Register at www.wheel-rail-seminars.com

Questions? Contact Brandon Koenig, Director of Operations 847-808-1818 or email at brandon@wheel-rail-seminars.com

Wheel Rail Seminars is pleased to introduce our 2024 InfoZone Partners:

Produced by Wheel Rail Seminars

InfoZone is an interactive learning environment that is designed to augment the information presented at the annual Heavy Haul Seminar. The InfoBreaks are short interactive small-group sessions hosted by our partnering company representatives. The format is educational and the information presented

RAIL TRANSIT

SPONSOR FOR

FOR HEAVY HAUL

SPONSOR

Vol. 120, No. 5

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189

Telephone (470) 865-0933 Website www.rtands.com

DAVID C. LESTER Editor-in-Chief dlester@sbpub.com

JENNIFER M c LAWHORN Managing Editor jmclawhorn@sbpub.com

EDITORIAL BOARD

David Clarke, University of Tennessee

Brad Kerchof, formerly Norfolk Southern William Riehl, Genesee & Wyoming/AREMA

Scott Sandoval, Genesee & Wyoming

Robert Tuzik, Talus Associates

Gary Wolf, Wolf Railway Consulting

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102

Telephone (212) 620-7200 Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 847-559-7372

Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001

212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

Information Technology on the Railroad

An Old Term, Long History, and Changing Every Day

Anyone who works on the railroad today knows that computer so ware and hardware play an increasingly signi cant role in how work gets done. It’s a rare area of our industry that has not been touched by this change, which has been under way for decades. Today, though, soware and hardware capabilities are developing at a faster and more furious pace, and you’ll see increasing coverage of them in Railway Track and Structures in the coming months and years.

For example, in our March issue, the folks at TTC Operated by ENSCO prepared a good overview of what’s called “arti cial intelligence” that’s touching many aspects of our lives and impacting work on the railroad. is month, Matthew Dick at TTC Operated by ENSCO has penned a wonderful discussion of how so ware is designed, built, tested, and implemented. “Implemented” is another term for “going live” and it’s not until a new or upgraded system has been live for some period before one can declare that it’s working as designed and there are no bugs or defects to deal with.

In addition to Matthew’s piece, we have added cybersecurity to our topics for Vendor-Product Spotlights. Our rst entry on that topic appears in this issue and will be in the regular rotation with our other VPS features.

Now, please don’t think we’re going overboard on cyber issues. We will continue our strong coverage of other rail infrastructure and maintenance of way topics, such as the pieces on rolling contact fatigue, track geometry, and fastening systems found in this issue. Nevertheless, cyber issues, in terms of new so ware, hardware, capabilities, applications, and regulations are likely changing faster than most, if not all other, aspects of rail infrastructure and maintenance of way. It’s important for RT&S to keep up with these changes and provide useful and insightful information to readers.

You’ll read in the TTC report, as you

read in my “Systems Management” editorial in the November 2023 issue, that so ware problems that shut down a system and the railroad along with it, are scary as hell. And many immediately think “cyberattack!” which may be possible. However, chances are that the problem resulted from a soware bug or defect that was introduced to the system through a code upgrade or some le changes. Managing complex so ware can be nerve-wracking and the folks who do it are very skilled and professional, but the consequences of a failure are always at the top of their minds. Can you imagine the cold wave of terror that engulfs your body when you realize that a code problem that you unknowingly entered into the system and through no fault of your own has shut down the railroad? I have personal and similar insight into this, as I worked for a well-known healthcare so ware company for 12 years and saw a few folks do things exactly by the book, but a code defect they could not have foreseen almost shut down the hospital, forcing them to go to paper charts for recordkeeping until the problem was resolved.

ere may come a day when coding procedures and so ware development will trend toward being foolproof, but we’re not there yet. is is not to say that our systems are weak and poorly operated. Most of the time, our systems work well and do amazingly complex things in a short amount of time. If they weren’t solid and reliable, no company would implement them. Hopefully, though, one day we’ll be able to rely on computers with the rock solid con dence with which we used to rely on the old landline telephone – connect it and use if for 50 years or more without a glitch.

DAVID C. LESTER Editor-in-Chief

DAVID C. LESTER Editor-in-Chief

EDITOR’S NOTEBOOK May 2024 // Railway Track & Structures 3 Railway Track & Structures (Print ISSN 0033-9016, Digital ISSN 2160-2514), (USPS 860-560), (Canada Post Cust. #7204564; Agreement #40612608; IMEX P.O. Box 25542, London, ON N6C 6B2, Canada) is published monthly by Simmons-Boardman Publ. Corp, 1809 Capitol Avenue, Omaha, NE 68102. Printed in the U.S.A. Periodicals postage paid at Omaha, NE, and additional mailing offices. Pricing: Qualified individual and railroad employees may request a free subscription. Printed and/or digital version: 1 year Railroad Employees (US/Canada/Mexico) $16.00; all others $46.00; foreign $80.00; foreign, air mail $180.00. 2 years Railroad Employees US/Canada/Mexico $30.00; all others $85.00; foreign $140.00; foreign, air mail $340.00. Single Copies are $10.00 ea. Subscriptions must be paid for in U.S. funds only. COPYRIGHT © Simmons-Boardman Publishing Corporation 2024. All rights reserved. Contents may not be reproduced without permission. For reprint information contact: PARS International Corp., 102 W 38th St., 6th Floor, New York, N.Y. 10018 Phone (212) 221-9595 Fax (212) 221-9195. For subscriptions and address changes, Please call 847-559-7372, Fax +1 (847) 291-4816, e-mail rtands@omeda.com or write to: Railway Track & Structures, Simmons-Boardman Publ. Corp, PO Box 239, Lincolnshire IL 60069-0239 USA. POSTMASTER: Send address changes to Railway Track & Structures PO Box 239, Lincolnshire IL 60069-0239 USA.

Building and Maintaining Robust Software Systems in Rail Technology

Software Resiliency Through Quality Controls

Matthew Dick, P.E., Chief of Strategy & Development, ENSCO, Inc., Pueblo, CO

Software has become such a massive part of the rail industry, permeating nearly all activities and operations. While cybersecurity is crucial for protecting software systems from external threats, ensuring software quality controls is equally vital to safeguard against internal issues. A recent example illustrating this occurred on August 28, 2023, when a Norfolk Southern network service interruption, attributed to a PTC outage caused by a software defect, disrupted operations.[1]. The software update was made to one system and then automatically copied to the other system allowing the defect to spread.[2] These types of incidents are not limited to the rail industry. Similarly, the January 11, 2023, FAA system outage, resulting from a mistake during a software update, grounded all departure flights in the United States.[3] These incidents underscore the importance of robust software development and quality control measures within the rail industry.

Software Development

Software development encompasses a wide range of approaches, from individual efforts to large teams of software engineers operating within a structured framework. As projects scale, they necessitate increased process and organization to maintain coherence. An effective analogy is viewing software development as akin to multiple individuals writing different sections of a very large document, aiming for seamless integration, error-free content, and accurate conveyance of the authors’ intent.

Common frameworks such as ISO 9001 – Quality Management Systems, along with the ISO 25000 family of standards, also

SOFTWARE HAS BECOME SUCH A MASSIVE PART OF THE RAIL INDUSTRY, PERMEATING NEARLY ALL ACTIVITIES AND OPERATIONS. WHILE CYBERSECURITY IS CRUCIAL FOR PROTECTING SOFTWARE SYSTEMS FROM EXTERNAL THREATS, ENSURING SOFTWARE QUALITY CONTROLS IS EQUALLY VITAL TO SAFEGUARD AGAINST INTERNAL ISSUES.

known as “System and So ware Quality Requirements and Evaluation”, focus speci cally on so ware quality assurance from the top-to-bottom. Additionally, IEEE 730 “Standard for So ware Quality Assurance Processes,” is commonly used in the rail industry and provide a similar framework. Both standards provide essential structures for organizing large soware development teams.

There are two major philosophies for the management of software development. The first is called Waterfall. This method is linear and sequential, ideally suited for projects where requirements are well-defined and unlikely to change. In Waterfall, software development follows a rigid path of requirements gathering, design, implementation, verification, and maintenance. Often a specification is written at the beginning with a customer, subject matter expert, and software architect inputs and is used as the governing design throughout the implementation. Waterfall offers predictability that the end-product will be what the architect intended. However, this method has its drawbacks, notably its challenges with changing requirements or unexpected hurdles appearing during development.

Contrasting sharply with Waterfall, Agile development emphasizing speed, flexibility, and iterative progress through short development cycles called “sprints” often organized by a manger referred to as a “Scrum Master.” Sprints may be as short as two weeks and result in completed software code at each cycle. Requirements are often defined throughout the

development, as opposed to the Waterfall approach where it is all defined at the beginning. This model allows for continuous revision of a project’s direction, which is crucial for adapting to the fast-evolving scenarios. Additionally Agile provides a structured methodology to keep progressing development. However, Agile can have drawbacks where it can be so fast and flexible, there is a risk that the end-product doesn’t meet the customer’s expectations if the customer wasn’t intimately involved in the sprints. Many times, a hybrid of Waterfall and Agile is used. This provides the best-of-both worlds with an overall vision capable of flexibility and speed.

After software code is written, another common practice to improve quality is code reviews. This is where the developer and their senior manager review the code together. By having multiple eyes on the software code, it improves the ability to identify bugs and implement high quality coding methods. This process is not much different than a student and teacher sitting side-by-side reviewing an essay assignment, sentence-by-sentence.

It is important that software code be kept organized and tracked, so software repositories are considered standard practice. One of the most common software repository systems used is called Git. Software code must be compiled and deployed to be usable by customers. Historically this process was labor intensive for software teams, but over the last several years, automation server tools, such as Jenkins, have become commonplace to automatically compile and deploy software from its code. This

4 Railway Track & Structures // May 2024 rtands.com TTC OPERATED BY ENSCO

automation has been critical to the ability to have short deployment cycles needed by the Agile process.

Ensuring software quality extends beyond the application code to encompass all supporting elements, such as configuration settings, databases, and server environments, requiring meticulous management and control.

Software Testing

Software testing is an essential phase in the development process, akin to proofreading a manuscript to ensure it’s free of typos. Just as editors are meticulous in their review to guarantee the clarity and accuracy of the text, software testing aims to verify that the code performs as intended. This process involves a variety of methodologies, including both manual and automated testing.

Automated testing is particularly effective for repetitive tasks where the steps are well-defined and can be scripted. This method excels in environments where precision and repeatability are key, and the expected outcomes are wellunderstood. For example, automated tests can be run to verify that business logic algorithms calculate as intended, based on predetermined scenarios. These tests are fast, reliable, and can be executed at any time. Automated testing is also essential to the Agile sprint cycles where rapid and numerous deployments are needed.

On the other hand, manual testing is invaluable when the source of potential bugs is unclear, or when the test scenario requires human insight, such as testing for user experience issues. Manual testers can explore the software as an end-user would, providing insights that are difficult to predict. For instance, while testing a new feature, a manual tester might uncover usability issues that were not anticipated during the design phase. Often, both manual and automated testing are employed in tandem to leverage the strengths of each method and achieve a more comprehensive examination of the software.

Testing also distinguishes between functional and non-functional requirements. Functional testing focuses on verifying that the software operates

according to its specified functions. This typically involves comparing the software’s behavior against the requirements outlined in the functional specification document. For instance, if a software application is supposed to calculate monthly expenses, functional testing will check precisely that feature to ensure it operates correctly under various conditions.

Conversely, non-functional testing assesses aspects of the software that do not pertain directly to specific functions but are crucial to the overall user experience, such as performance, scalability, security, and reliability. For example, performance testing might simulate multiple users accessing the software

simultaneously to ensure that it can handle the expected load without significant slowdowns or crashes.

In the realm of software testing, both Unit testing and End-to-End (E2E) testing play critical roles. Unit testing involves checking individual components of the software in isolation, which helps in identifying errors in the codebase at an early stage. Each unit is tested separately before integrating them into larger systems. This is akin to checking the components of a machine before assembling it to ensure each part individually works correctly.

E2E testing, however, evaluates the soware’s overall functionality and its interaction with other systems, ensuring all

May 2024 // Railway Track & Structures 5 rtands.com TTC OPERATED BY ENSCO

Before heading to the field when trouble occurs, check to see if the problem may lie in software!

parts work together seamlessly. is type of testing is crucial for verifying complex work ows in applications that involve multiple subsystems and external interfaces.

Regression testing is another vital aspect of the software testing lifecycle, particularly when minor changes or updates are made to the code. It ensures that recent changes have not adversely affected existing functionality. This is crucial because even small tweaks in the code can create new bugs in areas that were previously stable.

Finally, User Acceptance Testing (UAT) serves as the final validation before the software is released into production. During UAT, the software is tested in an environment that mimics the production setting as closely as possible. This step is crucial to catch any remaining defects that could impact users after release. It involves real-world scenarios and aims to ensure that the software meets all business requirements and is ready for deployment.

All these aspects of software testing

aim to achieve bug-free production deployments. Over the years, these methodologies have proven to be helpful, providing a structured approach to achieve quality assurance.

Production Environment

Transitioning a software system to the Production Environment, or “going live,” is a significant phase where the system begins operation in the real world. This stage is critical because the Production Environment is designed to be a stable and reliable setting, unlike testing or development environments where experimentation is common. In this context, any software modifications are rigorously tested in a User Acceptance Testing (UAT) environment prior to their deployment in Production. This ensures that only thoroughly vetted changes make their way to the live environment, minimizing risks and potential disruptions to ongoing operations. e deployment process in the Production Environment involves a series of

meticulously planned and executed steps. Much like the detailed process of disassembling a house and reassembling it at a new location, so ware deployment requires reassembling certain components at a new location. is analogy highlights the complexity and precision required in this process. Historically, as explored in previously discussed case studies, challenges managing this transition can lead to failures, underlining the importance of careful planning and execution.

To mitigate such risks, the deployment process includes written procedures to be strictly followed, supplemented by automated scripts to standardize, and streamline tasks. This structured approach helps prevent human error and ensures consistency across deployments. Practicing the deployment process in the UAT environment is a common strategy. This rehearsal allows teams to refine their procedures, address any potential issues in advance, and increase the likelihood of a smooth transition when deploying to the Production Environment.

K1270 II RAIL SAW

6 Railway Track & Structures // May 2024 rtands.com TTC OPERATED BY ENSCO

- Easy Starting - Straight Cuts - Low Vibration - 16” Blade - Weighs 46 lbs - Active Air Filtration 866-245-3745 www.trak-star.com Hydraulic & Gas Rail Drills • Hydraulic & Gas Rail Saws Twister Bits ™ • Gas Impacts • Rail Accessories Hou-759 RTS-K1270.indd 1 1/24/23 2:23 PM

Once the software is operational in Production, continuous monitoring of its performance becomes paramount. This includes the implementation of automated logging systems and performance monitoring tools that help detect and diagnose operational issues quickly. Modern advancements in cloud computing significantly enhance this aspect by offering solutions like hardware redundancy and load balancing. These technologies are essential for maintaining system availability and performance, especially under varying load conditions. Hardware redundancy ensures that backup components are readily available and can take over without interruption in case of hardware failure, while load balancing efficiently distributes incoming network traffic across multiple servers.

These proactive measures are crucial to ensuring that the software can handle unexpected demands without degradation of service, upholding the expected standards of users and stakeholders. This rigorous approach fosters trust and reliability in the software system, delivering consistent, high-quality operation.

Conclusion

e rail industry, like modern so ware development, prioritizes resilience to prevent failures. Diligent so ware quality assurance practices are essential as so ware complexity grows. At the Transportation Technology Center (TTC), a commitment to safety and resilience is evident in e orts to simulate and test infrastructure and so ware in protected environments before deployment, ensuring uninterrupted operations.

For further reading on software quality assurance, “Release It!: Design and Deploy Production-Ready Software” by Michael Nygard is recommended for its clear, practical insights.

References

1. https://apnews.com/article/norfolk-southern-railroadoutage-653b107758e66225ee640c7494e8a063

2. https://apnews.com/article/norfolk-southerncomputer-problem-railroad-outage-37c5938c0796ed60b1b22a3f7cf5d416

3. https://www.nbcnews.com/news/us-news/ us-flights-grounded-faa-outage-rcna65243

rtands.com

JOE DALOISIO Chairman, National Railroad Construction and Maintenance Association (NRC)

JOE DALOISIO Chairman, National Railroad Construction and Maintenance Association (NRC)

Mentors Can Make All the Di erence in Building a Successful Career

Have you ever looked back on your life and asked yourself, “How did I get here?” If you have, I’m willing to bet you can attribute your success to at least one person who taught, guided, influenced or encouraged you. In an industry that is all about people, where would any of us be without these mentors?

Mentors are invaluable role models who will share insights and advice they’ve learned along their career path. Oftentimes more experienced and successful, mentors will walk alongside you and provide advice, guidance, encouragement and even a kick in the pants to help you succeed in your professional or personal life.

and more senior professionals miss the benefits of connecting in the workplace and the potential long-term advantages.

WITH SO MUCH REMOTE WORKING TODAY, I FEAR THAT BOTH YOUNG AND MORE SENIOR PROFESSIONALS MISS THE BENEFIT OF CONNECTING IN THE WORKPLACE.

As a third-generation railroader, I have been blessed to have many indispensable mentors and role models in the family business and throughout my life. My grandfather, Joe Sr., built track as a track gang foreman on the Erie Railroad and later established Railroad Construction Co. My father, Joe Jr., and my aunts, uncles, and cousins all followed along the same track.

I started working in the family business during high school and, over the years, have held nearly every job. Although Joe Sr. died 30 years before I was born, he influenced me by his strong work ethic and the culture he established. Joe Jr. built on that foundation and passed on the practice of learning the business from the ground up. Both men led by example, but Joe Jr. wasn’t shy about offering direction too. He was always willing to answer questions and include me in discussions about the proper way of doing business, serving customers, and how to cultivate capable and loyal employees.

On-the-job interactions with my father, our field supers and foremen, and other managers inspired me and gave me a head start. The benefits of watching, listening to, and interacting with senior leaders in the workplace are irreplaceable. Likewise, making an effort every day to lead by example and mentor those around us will leave each day better than when we started it. With so much remote working today, I fear that both young

Our industry is ready-made for these mentor-mentee relationships. And the NRC, an association of aspiring and leading industry professionals, provides fertile ground for both finding and being a mentor. It all starts with attending NRC events, from the annual conference to the railroad equipment auction and Railroad Day on Capitol Hill. These events are structured to encourage connections. There’s no doubt about it, there is plenty of business conducted at these events, but there is also valuable relationship-building with discussions about networking and teaming, and methods and strategies.

My exposure to both formal and informal mentors expanded when I made the smart decision to take my involvement in the NRC to the next level. I became an NRC Board member and joined with other like-minded professionals from across our industry. It has been invigorating to work together, to brainstorm, and to pool our capabilities in efforts that strengthen our industry.

My work on the Board and on many committees gave me the opportunity to learn from the great people around me, but also to be a mentor and share my knowledge and experience. Board members and prior board presidents, including but not limited to Mike Choat, Jim Hansen, and Steve Bolte, have been incredible mentors to me. The give and take of interacting with mentors and mentees has made my personal and professional life infinitely more successful and satisfying.

If you’re looking for a way to learn from seasoned professionals, give back, and boost your career, look to the NRC. Please reach out to me, other NRC Board members or the NRC staff for advice on how to get involved. But just get involved!

“We aren’t just in this industry. We are this industry!”

8 Railway Track & Structures // May 2024 rtands.com NRC CHAIRMAN’S COLUMN

MITIGATING ROLLING CONTACT FATIGUE: An Overview for 2023

By Je Tuzik

Rolling contact fatigue (RCF) a ects railroads and transit systems globally. e e ects of RCF damage range from poor ride quality and excessive noise, to shelling and spalling so deep and widespread that rail sections must be replaced. Over time, the railroad and transit industries have developed tools to detect and measure RCF and a suite of techniques to mitigate it.

Whether on wheel or rail, RCF appears similarly. Light cracking, progressing to intermediate cracking, to heavy cracking and incipient shelling, and nally signicant shelling. Another manifestation of RCF is gage corner collapse and deep-seated shells. ese occur when there is signicant loading on the gage corner, especially

on the high rail, leading to a collapse of the corner and large pieces of rail breaking (or shelling) out. In some cases of gage corner collapse (sometimes before the rail material has sloughed o ), the shell can meet an internal aw and lead to a transverse defect and a broken rail, Eric Magel, Principal Consultant with EM-WRI Consulting Inc. and project consultant with Advanced Rail Management/Global Rail Group, told participants at the 2023 Wheel/Rail Interaction Heavy Haul Conference.

RCF can also manifest as squats or studs (squat type defects). ese have become more common in North America in the past 20 years, but they represent a fairly universal problem. As studs progress, they can shell or break out of the rail, leaving

defects that are typically 2mm to 4mm deep, Magel said. Crushed heads, a defect similar in appearance to squats and studs, have historically been a problem on some freight railroads. ese start as cracks that develop toward the gage, typically in older, so er steels, propagate towards the crown of the rail, lead to a depression in the rail head which is then battered by nearly every passing wheel, in some cases causing the head of the rail to collapse.

RCF, especially in its early stages, can be di cult to detect. Historically, and still today, much of this detection is done visually on freight railroads by track inspectors from a hi-rail vehicle moving at speeds below 25 mph. Depending on the severity, the inspector can also feel and hear RCF

10 Railway Track & Structures // May 2024 rtands.com

ROLLING CONTACT FATIGUE

Principal Consultant with EM-WRI Consulting Inc. and project consultant with Advanced Rail Management/Global Rail Group.

while traveling over it.

Within the past 15 years, electromagnetic measurement devices have begun to emerge; before then, there was no objective way to measure or quantify RCF. A number of walking-stick systems are now available to the North American rail industry including: the Rohmann Draisine and Goldschmidt Trackscan Mira which use eddy current, the MRX rail surface condition monitoring system that uses magnetic ux and the Athena RAGA which uses electromagnetic eld imaging. Some of these have been adapted to be towed behind a hi-rail vehicle, enabling larger scale data collection on a regular basis, Magel said. ese devices typically display data as a strip chart indicating the number of cracks and maximum crack depth in a given

May 2024 // Railway Track & Structures 11 rtands.com

ROLLING CONTACT FATIGUE

Figure 1. Gage corner collapse can occur under many conditions. In the worst-case scenario, cracking can co-occur with an internal flaw and create a transverse defect

Figure 2. A sample strip chart from the MRX RSCMS indicating (RCF) crack depth and location on the rail.

Figure 3. An example of a proposed universal surface quality index used to assess RCF conditions.

ERIC MAGEL,

Photo: Mike Yuhas

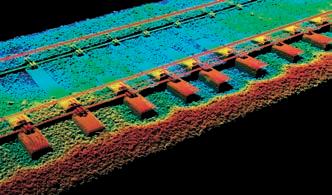

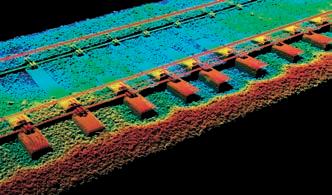

location. e MRX system can also produce a contour chart which indicates both the severity and position of the RCF damage. Machine vision is a relatively new entrant in RCF detection; these include the ENSCO Rail Surface Inspection System, the Loram Rail Inspection Vehicle, and Plasser & eurer’s machine vision system. “ ese [machine vision] systems are pretty good at detecting cracks and RCF, but the trick is to quantify that somehow, based on severity,” he said.

“How can we take that data and put it in a useful form?” Magel asked. He cited Dan Hampton, the Director of Contract Services at CSX Transportation, who has championed the development of a common scoring approach to RCF — a shared surface quality index. e idea is to divide the rail into distinct bands and apply a common severity scale that can be informed by and compared to data coming from any type of RCF measurement device. An SQI like this would make it easier to turn data into actionable information, Magel said.

Magel identi ed three primary root causes of RCF. e rst is overstressing the steel. e combination of excessive contact stress and shearing traction at the wheel/rail contact patch causes plastic ow; the material workhardens and continues to strain until it exhausts its ductility and cracks. e crack forms along the line of the deformed layers in the rail. Depending on the conditions, these cracks may wear away. If they don’t wear fast enough, they can propagate up to the point of shelling (see gure 4).

e second root cause is overstressing of the gage corner, which can lead to gagecorner collapse. Many conditions can lead to excessive loading on the gage corner.

ese include pro le shape, plastic ow, and outward rotation of the rail (also called dynamic gage widening). “Even under perfect lubrication, you can collapse the gage corner,” Magel said.

e third mechanism relates to martensite, a thermally-transformed layer that forms under very high creepages and contact stresses between the wheel and rail. Martensite can form on the rail due to wheel-slip events, for example, but it can take other forms, too. On transit systems, martensite can appear as a thin layer scattered throughout the system; this occurs due to generally high and repetitive creepage force at the contact patch due to propulsion systems and operations seeking higher tractive e orts. is layer may wear away without incident, but it can also initiate cracks that propagate via classical RCF mechanics, Magel said.

12 Railway Track & Structures // May 2024 rtands.com ROLLING CONTACT FATIGUE

Figure 4. Multiple studs that have broken out of the rail during grinding.

Figure 5. Example shakedown charts used to assess the likelihood of RCF development.

Figure 6. A shakedown chart showing the improved performance of the WRISA2 wheel (lavender).

Defects initiated in this way can manifest as squat-type defects (studs), and by the time they are visible, the depth of damage can be 3mm deep and many centimeters long.

With the root causes of RCF in mind, the following conditions are known to promote RCF development:

• Mismatched wheel/rail transverse pro les

• High dynamic loads

• Track irregularities (increased dynamic loading and creepage)

• Low material strength (so er steels are more prone to RCF)

• Misaligned wheelsets (high angle of attack and creepage)

• Excessive friction

• Excessive creepage

Magel pointed out that the likelihood of RCF developing at a given location can be illustrated by a shakedown diagram (see gure 5). e Y-axis is the ratio of the contact stress (P0) at a particular wheel/rail contact point to the strength of the material in shear (the value in K ). e X-axis is the traction coe cient, which is the ratio of the shearing forces divided by the normal forces at the wheel/rail contact. Any contact condition that falls in the red-highlighted area will contribute to RCF development. Moving from the red area to the green area requires either increasing material strength, lowering contact stress, or reducing traction coefcient (or some combination of the three), he said. From a practical standpoint, there are many ways to approach this.

Improved wheel pro les can help manage RCF. In the early 1990s, the Quebec Cartier Mining railway (QCM) struggled with wheels that failed due to shelling very early in their service life — in the 10-to-20-thousand-mile range. A study indicated that their

LOCOMOTIVE UGMS

The most economical loaded track measurement per mile

May 2024 // Railway Track & Structures 13 rtands.com ROLLING CONTACT FATIGUE

Figure 7. Contact stresses (that exceed the shakedown limit) modeled on di erent rail profiles and at di erent steel hardnesses.

Figure 8. A chart showing the e ect of rail grinding on hypothetical projected crack growth.

wheel pro le was a poor match for their rail pro le, resulting in excessive creepage and contact stress. Magel, working with Joe Kalousek, at the National Research Council of Canada (NRCC), developed a customized wheel pro le, which upon implementation, increased wheel life by 60%.

On the basis of that success, Magel and Kalousek and the NRC developed a wheel pro le (the NRC-ASW) for the Canadian National and Canadian Paci c railroads that yielded an 18% increase in wheel life.

e WRISA2/P12 wheel is another example. A er Network Rail (then Railtrack) experienced a broken rail derailment at Hat eld in 2000, they undertook a number of wheel/ rail improvement projects. One of these was the development of an “anti-RCF” wheel. e shakedown plot shown in gure 6 illustrates how the new wheel population (shown in lavender) shi ed down and to the le (into the “green area” show in gure 5) relative to the former wheel (unworn in blue, worn in red). e three lines on the chart represent three di erent rail strength limits.

Improved rail pro les can also help reduce RCF. Figure 7 shows the results of a

The Symbol of Innovation in Maintenance of Way Equipment

14 Railway Track & Structures // May 2024 rtands.com ROLLING CONTACT FATIGUE

Figure 9. Excerpt from an Amtrak study on the e ects of TOR and lubrication on L/Vs.

Visit us at racinerailroad.com Follow us on LinkedIn: linkedin.com/company/racine-railroad-products See our machines and operator controlled screens at youtube.com/@racinerailroad1986 Contact us on how we can assist you with your MOW needs (262) 637-9681 Racine Railroad Products, Inc. 1955 Norwood Court, Racine, WI 53403

Racine Railroad Products’ cutting edge operator control interface and computerized automation not only increases production, it also improves safety while making our machines easier to operate and maintain the equipment. We offer a wide-range of innovative powered portable hand tools.

quasi-static pummeling simulation where only contacts exceeding the shakedown limit are accumulated. e accumulated damage for three di erent rail pro les having three di erent hardness are plotted. e CPR-H pro le shows a signi cant reduction in these forces. “Just by changing the rail pro le you can reduce the amplitude of the contact stress and the probability of rolling contact fatigue,” Magel said. e gure also shows how improved pro les are synergistic with harder rail steels; the best combination is the CPR-H at 390 HB.

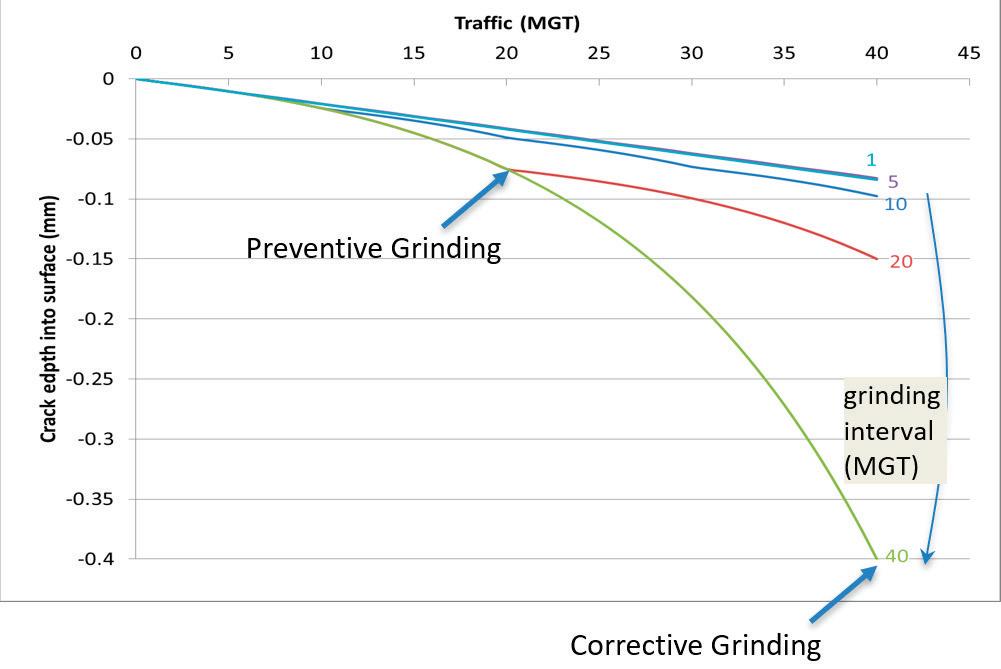

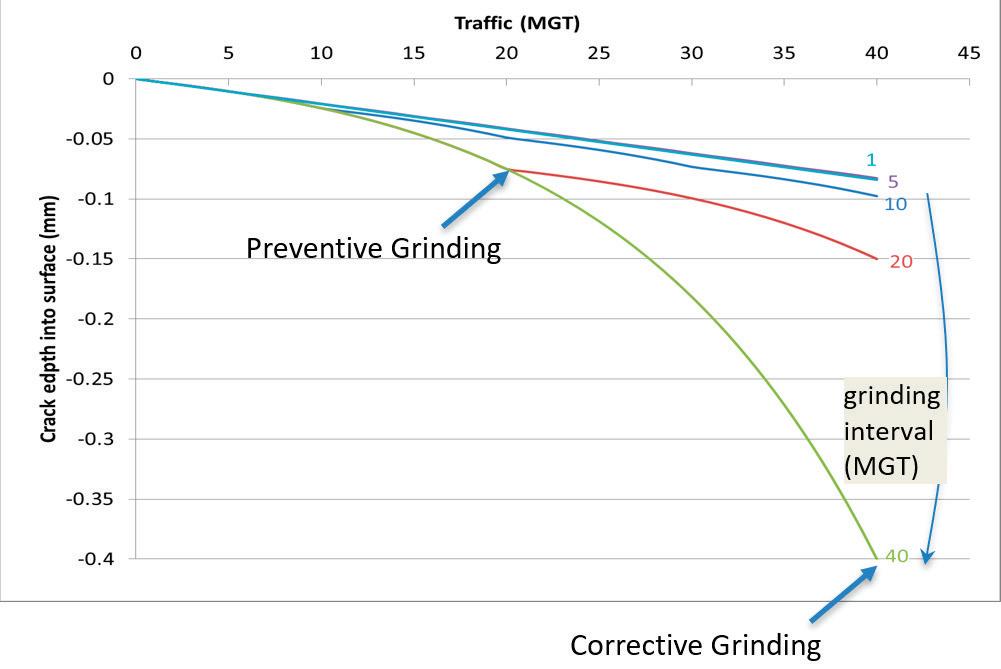

Rail grinding also plays an important role in managing RCF. In addition to being the means by which new rail pro les are implemented, regular preventive grinding is an e ective way to arrest the exponential growth of RCF cracks. “10 or 20 MGTs is typically the ideal time to grind,” Magel said, in terms of balancing metal removal and RCF management. Grinding like this e ectively resets the crack growth curve (see gure 8).

ere are also less-invasive ways to help mitigate RCF. Top-of-rail (TOR) friction management shi s the population on the shakedown graph by limiting surface

traction and reducing lateral forces. is is also synergistic with improved wheel/rail pro les and harder steels, Magel said. Figure 9 shows an Amtrak study showing the e ects of gage-face lubrication and TOR on lateral over vertical forces (L/Vs). “Laboratory and eld testing has shown that TOR, whether combined with lubrication or not, gives a dramatic reduction in L/Vs,” Magel said. is in turn leads to less shakedown exceedance.

Truck suspension also synergizes with improved wheel and rail pro les. A exible suspension, combined with the improved steering of matched wheel/rail pro les reduces the yaw angle and wheel angle of attack, which reduces creepage, which reduces the likelihood of RCF, Magel said.

e M-976 truck, adopted in 2003 by the AAR, has shown to improve wheel life by 18 % to 24% versus standard three-piece trucks. Finally, wheel and rail metallurgy play an important role in mitigating RCF in addition to the add-on e ect of their synergy with other wheel/rail conditions. e K in the shakedown chart is the shear strength of the metal; an increase in hardness translates to an increase in RCF resistance.

TheRailwayEducationalBureau

TrackSafetyStandards Subparts A-F

TrackSafetyStandards, containstheTrackSafety Standards,SubpartsA-F,forClassesoftrack1-5.The standardscovergeneralinformation,Roadbed,Track Geometry,TrackStructure,TrackAppliancesand Track-RelatedDevices,andInspection.IncludesDefectCodes. Updated December28,2023.

BKTSSAF TrackSafetyStandards,SubpartsA-F $11.95 Only$10.75forordersof50ormore!

BridgeSafetyStandards

FRAPart237establishesFederalsafetyrequirements forrailroadbridges.Thisrulerequirestrackownersto implementbridgemanagementprograms,whichinclude annualinspectionsofrailroadbridges,andtoauditthe programs. Part237 alsorequirestrackownerstoknow thesafeloadcapacityofbridgesandtoconductspecialinspectionsif theweatherorotherconditionswarrantsuchinspections. Updated December28,2023.

BKBRIDGE BridgeSafetyStandards $8.95 Only$8.00forordersof50ormore!

And RCF doesn’t just a ect rail. e wheel experiences the same contact stress, and the same type of RCF damage. e interventions that mitigate RCF on the rail also bene t the wheel. ” ey’re part of the same system,” Magel said. Although there are more measurement devices available to detect and quantify RCF in rail, several companies are currently developing machine vision and electromagnetic systems that are wheel-speci c.

Last, but not least, e ectively mitigating RCF requires a systemic approach. Strategies that work well alone work better in concert with each other. As the ability to quantify RCF continues to improve, so does the ability to intervene earlier and more cost-e ectively. ese mitigation techniques have proven their e ectiveness on heavy-haul and transit systems around the world. As these techniques are optimized, so too is the wheel/rail interface.

Je Tuzik is Managing Editor of Interface Journal https://interfacejournal.com/ is article is based on a presentation made at the WRI 2023 Heavy Haul conference https://wheel-rail-seminars.com/

WorkplaceSafety

ThisreprintincludestheFRA's RailroadWorkplaceSafety Standards addressingroadwayworkersandtheirwork environments.Theselawscoversuchthingsas:personal protectiveequipment,fallprotection,andscaffoldingfor bridgeworkers;andtrainingissues.Alsoincludessafetystandardsfor on-trackroadwayvehicles. UpdatedDecember28,2023.

BKWRK RailroadWorkplaceSafety $11.50 Only$10.35forordersof50ormore!

TrackCalculator

The TrackSafetyStandardsCalculator isamustfor anyonewhoworksontrack.Thisslideruletype calculatorcontainsmanyofthedetailsforClassesof track1-5.Deviationfromuniformprofileandfromzero crosslevel.Differenceincrosslevel.Compliantwithpart213.

U.S.A.CAN

AddShipping&Handlingifyourmerchandisesubtotalis: Ordersover$75,callfor shipping.Canadaplease calltoplaceorders.

May 2024 // Railway Track & Structures 15 rtands.com ROLLING CONTACT FATIGUE

1809CapitolAve.,OmahaNE,68102 800-228-9670 www.RailwayEducationalBureau.com

UPTO$10.00 $6.40 $11.70 10.01-25.00 11.0019.55 25.01-50.00 15.0025.50 50.01-75.00 16.8531.85

FederalRegulations

BKTCAL TrackCalculator $11.50

Only$10.75forordersof50ormore!

UpdatesfromtheFederalRegistermaybesuppliedin supplementform.

Rhomberg Sersa’s survey teams use track survey trolleys to capture and monitor the geometry of the track throughout the construction phase.

INSPECTION GADGETS

When inspecting track geometry, there lies a multitude of products and services on the market. To sort through some of these, RT&S has shone a spotlight on o erings from nine companies.

ENSCO Rail features a robust system for track geometry and inspection with its Zero Speed Track Geometry and Rail Pro le Measurement System (Z-TGMS). is compact solution, featuring optional full rail pro le measurement, strengthens railway safety by integrating all functionalities into a single beam. Designed for both manned and autonomous operation, this system is distinguished by its ability

to mount directly to the car body of highspeed train bodies, eliminating the need for truck modi cations and simplifying installation and maintenance while ensuring high measurement accuracy. A pivotal advancement of this technology is its “Zero Speed” measurement capability, enabling accurate measurements from standstill to high speeds without any data loss. Unlike traditional systems, which can fail to measure alignment and pro le accurately at low speeds, ENSCO Rail’s Z-TGMS is especially bene cial in areas where trains decelerate or halt, providing comprehensive data coverage that is crucial for stations and slow-moving sections.

Integrated with ENSCO’s broad suite of inspection technologies, the Z-TGMS allows for the correlation of geometry data with other measurements, enhancing maintenance planning and operational safety. e inclusion of ride quality and machine vision imagery data o ers a holistic view of track conditions, facilitating precise maintenance decisions. In Florida, Brightline has successfully integrated ENSCO Rail’s Zero Speed Single-Beam TGMS into its high-speed rail operations, enabling multiple daily track assessments at speeds of up to 125 mph. is system ensures maximum passenger comfort and safety by providing automatically gathered

16 Railway Track & Structures // May 2024 rtands.com

TRACK GEOMETRY & INSPECTIONS

Photo Credit: Rhomberg Sersa

Key factors contributing to track geometry maintenance include ballast and drainage conditions. Analyzing the vertical pro le geometry channel over successive inspections enables evaluation of track ballast and drainage conditions.

Loram Technologies has developed “heat plot” that represents geometry roughness using a color scale, with cooler colors indicating smoother geometry and hotter colors indicating rougher geometry. is visualization aids in studying time, distance, and roughness in a 2D view.

A broad look at analyzing and maintaining proper track geometry

By Jennifer McLawhorn, Managing Editor

data in near real-time through ENSCO’s Track IT platform, empowering maintenance teams with instant access to crucial information for optimal track care.

e primary indicator of track condition is its geometry, o en evidenced by poorly performing track geometry prompting the need for quality improvement. Track geometry encompasses the lines, curves, and angles de ning the track’s position within the right-of-way. Data collected from Track Geometry Measurement Vehicles (TGMVs) o ers an objective assessment of track roughness. By comparing track geometry data over time, one can quantify track performance and deterioration rates.

Loram Technologies provides Ground Penetrating Radar (GPR) and Lidar measuring services, along with data analysis for condition assessment. Their proprietary analysis tool, “Rail Doctor,” integrates GPR/Lidar data with TGMV data, offering insights into the root causes of track performance issues. GPR data continuously measures track substructure conditions, including ballast fouling, subsurface moisture, and layer thickness and configuration. Integrating information from track geometry, GPR, Lidar, and right-ofway scanning provides a comprehensive view of line health. This integrated data, presented intuitively, is valuable for track maintenance management and renewal planning. The Rail Doctor output guides railways in understanding maintenance needs, planning activities, and budgeting. Loram Technologies’ analysis recommends areas for tamper application, ballast maintenance, drainage improvements, and other necessary actions for a healthier track. In the new generation of substructure maintenance management approach, Loram Technologies will offer a suite of advanced technologies for rail infrastructure management, including remote controlled autonomous data collection, remote QC and QA, enhanced positioning, tools tailored for large-scale data collection projects, and AI-based GPR data analytics integrated into Rail Doctor.

Humatics Focus , a new player in the automatic track inspection market, is currently deployed with New Jersey Transit. It uses revenue service vehicles for non-disruptive automated track scans, transforming inertial sensor data into actionable insights. is allows transit and rail customers to focus on xing issues rather than nding them. e system uses AI and machine learning to detect and classify vehicle dynamics into track

geometry defects and insights. Advanced pre-processing algorithms lter out noise and other impacts, allowing the system to be installed in a protected location within the car body. is reduces maintenance and installation costs and extends service life signi cantly. Advanced positioning algorithms enable complex determinations like track discrimination in real time without post processing or manual data entry, aiding in positional alignment to minimize false positives due to positional errors. is process traditionally took weeks o ine. is combination of powerful defect detection and advanced positioning is highly attractive to customers. Brendan Kaplan, Head of Innovation at NJ Transit said, “ is solution contributes towards continuous monitoring of track condition . . . and is part of our e orts to enable visibility into track conditions and predictive maintenance through digital transformation.” Since May 2023, Humatics Focus has been monitoring over 65 miles of light rail track on four revenue service vehicles with New Jersey Transit.

Within the construction process, Rhomberg Sersa’s survey teams use track survey trolleys to capture and monitor the geometry of the track throughout the construction phase. e digitized information which includes LiDAR is used to generate a geospatial referenced absolute track model that can be used to verify quality of construction and supports handover into ongoing maintenance activities. During construction the digitization of the alignment is used in combination with specialized in-house developed equipment namely RhoTAS and RhoSAS track alignment technology and processes for plain track and turnouts, as well as the company’s semi-automated track installation machine RhoMAT, that enables it to build track e ciently and repeatedly within design tolerances. For machine maintenance, its patented PALAS absolute track geometry technology ‘works hand in glove’ with the absolute track model that enables on-track maintenance of way machines, including tampers, to e ciently maintain track geometry and alignment to within the original design limits. Ongoing track geometry inspection and measurement of the track is performed through the company’s own in-house, rail bound, track geometry measurement systems or through third-party solutions.

NxGen Rail Services provides a variety of track and rail geometry

May 2024 // Railway Track & Structures 17 rtands.com

TRACK GEOMETRY & INSPECTIONS

inspection systems services, including installation and maintenance of manned or autonomous track and rail geometry measuring systems in partnership with DMA of Italy. DMA is a premium manufacturer of high accuracy measurement systems for high speed and conventional rail networks, based in Turin, Italy. Autonomous Turnout Inspection Systems provide dynamically loaded inspection of turnouts. These systems use a combination of geometry measurements and AI driven machine vision instruments to put together a complete suite of data for every turnout. This replaces manual inspections which are time consuming and which do not provide a true dynamic reading of a turnout´s performance under load. NxGen can also use its own NxTrack™ rail

bound rail and track geometry inspection vehicle, certified to operate at line speed on the back of passenger trains. This system is integrated with machine vision systems and ground penetrating radar. It can also be used for independent acceptance testing of new track infrastructure, or as a development platform for other measurement systems for third parties. All the systems are linked to maintenance planning and statistical evaluation software and can produce outputs that can be integrated into a clients own planning and analysis systems.

Holland’s Argus™ technology powers geometry inspections in a variety of applications from TrackSTAR® track strength testing to portable inspection to locomotive UGMS (Unattended Geometry

Measurement Systems). With its portable Track Inspector system, Holland o ers four so ware applications that provide real-time gage measurement or full track geometry, as well as rail pro le. e full track geometry so ware applications can run autonomously, attended, or “heads up” with real-time defect noti cations, depending on the experience of the operator. e Argus Track Inspector includes a non-contact encoder and a foldable GPS antenna - a plug-and-play track measurement technology deployed from a conventional tow hitch receiver. is feature eliminates the necessity of a dedicated hi-rail platform and can be stored without disassembly and return to track without calibration. Argus UGMS allows track measurement at track speed under an operational load environment without any interruption to revenue service.

Railmetrics’ LRAIL track inspection system combines 3D laser, inertial measurement, and AI to perform track geometry measurements and track component inspection simultaneously. LRAIL installation is highly exible, allowing for mounting on almost any high-rail or railbound platform and measurements can be performed under dynamic load conditions. e LRAIL is also capable of unattended (autonomous) operations and can inspect at speeds up to 75 mph. One of the key advantages of LRAIL technology is that it is multi-functional; the same sensors are used to capture geometry and inspect track components, removing the challenge of aligning inspection data from multiple separate inspection systems. A more full and robust interpretation of traditional track geometry results is achieved by combining traditional geometry outputs with inspection of components such as joint bars, frogs, switches, ties and transitions of tie or fastener types. is information on component condition leads to a better understanding of the underlying issues that may be causing any geometry anomalies, empowering railroads to take a more proactive approach to planning maintenance to address areas of concern.

RailWorks Maintenance of Way latest addition to its Track Geometry eet includes an all-in-one Portable Laser Pro ler System for measuring track geometry and rail pro le on any hitched mounted hi-rail vehicle. e unique assembly includes wireless connection and requires no permanent changes or installation on a hi-rail vehicle. RailWorks

18 Railway Track & Structures // May 2024 rtands.com TRACK GEOMETRY & INSPECTIONS

Holland’s Argus™ Technology powers geometry inspections in a variety of applications.

Photo Credit: Holland

footprint and vast equipment eet across the United States and Canada allow them to quickly respond to customers’ needs by providing a Portable Laser Pro ler System that can be quickly deployed on any vehicle platform and provide real- time track geometry results. Operating this system allows users the exibility to inspect track in limited track windows and in short notice while providing pinpoint GPS and accurate data on track conditions. RailWorks customized inspection service and the ability to provide immediate feedback on track conditions utilizing its Track Geometry hi-rail eet or operating a Portable Laser Pro le System allows them to respond to all market demands.

Tamping, a crucial maintenance task for correcting railroad track geometry, traditionally relies on the empirical knowledge and experience of operators in the United States. Railroads have learned that improper tamping parameters impact ballast stability and cause quick track geometry deterioration. In the quest to de ne the perfect tamping process, Plasser American and Penn State joined forces for a research project that will have a long-lasting impact on the value of this essential maintenance practice. e goal was to identify the correct tamping parameters based on the boundary conditions and automate this process to support the operators for consistent high tamping quality. To gather the data needed, the testing team utilized a Plasser American ‘Smart Tamper’ on a Class I mainline in combination with a ‘Smart-Rock’ wireless sensor. e ‘Smart-Tamper,’ equipped with pressure sensors and angle encoders, recorded tamping tool behavior, while the ‘Smart-Rock’ wireless sensor, embedded in the tamping zone, monitored ballast particle motion, and contact stresses. When testing concluded and the ndings were analyzed and reviewed, a number of insights stood out. e study found that clean ballast responds more sensitively to tamping parameters compared to fouled ballast. e study shows that the correct squeezing time signi cantly in uences the resulting work quality. e study also reveals that the energy imparted to the ballast by the tamper is a key factor in determining post-tamping ballast stability. e use of ‘Smart-Tamper’ and ‘Smart-Rock’ technology is proven e ective in enhancing the understanding of the tamping process and optimizing tamping e ciency and quality.

e Smart Tamping sensor set can be mounted on di erent tamping machines and should support inexperienced operators in the future in choosing the right tamping settings. By implementing this knowledge and selecting the optimal tamping parameters for real-time conditions, future operators will see improvements in e ciency and consistency. is will ensure safe and economic track maintenance to ensure long lasting track geometry conditions that will be consistent and reliable which, in turn, provides railroads with the most economical track maintenance strategies.

Plasser American asserts that ballast cleaning has been proven to extend the intervals between tamping maintenance cycles, resulting in cost savings and increased track availability. Plasser American has a versatile eet of undercutters, including the wellknown RM80 and RM80-800. e RM802 is designed for highcapacity ballast undercutting/cleaning on track with or without pre-dumped ballast, achieving production rates more than 2,000 feet per hour. ese machines are just one piece of the maintenance of way puzzle, working with its eet of specialized machines to improve e ciencies on the tracks. e GRM4000, the latest model in the GRM series of tamping machines, o ers a modi ed design with a two-tie tamping unit to signi cantly increase the production rate and improved weight distribution. e GRM4000

May 2024 // Railway Track & Structures 19 rtands.com

has the ability to switch automatically to single-tie tamping if tie spacing is insufcient for two-tie tamping mode. is

allows the machine to be used in a multitude of applications which leverages the machines high production capabilities.

e GRM4000 remains easily transported by truck keeping the same modular design as its predecessor, the GRM3000T, which remains in Plasser American’s portfolio. e addition of the Autonomous Remote Stabilizer Upgrade Kit “links” the Plasser Dynamic Track Stabilizer PTS90C increases e ciency while reducing costs. Once installed, the stabilizer can be fully controlled by the lead machine operator and requires no additional operator. is remote upgrade keeps headcount low and performance high, while radar safety solutions ensure the safe operation on track. Similarly, the 09-2X DYNACAT, a heavyduty, high-speed, and continuous action two-tie switch and production track-tamping machine, is equipped with its own integral dynamic track stabilizer and a perfect tool to face challenges of low headcount and increased output. While the satellite tamps and indexes two ties at a time during the actual work process, the machine’s main frame, with stabilizer system, moves smoothly and continuously at a speed determined by the operator.

20 Railway Track & Structures // May 2024 rtands.com TRACK GEOMETRY & INSPECTIONS

Railmetrics’ LRAIL track inspection system combines 3D laser, inertial measurement, and AI to perform track geometry measurements and track component inspection simultaneously.

Photo Credit: Railmetrics

Progress Rail o ers an e-Style clip, resilient Loadmaster DF for timber ties, and the ADFF55 high attentuation direct fixation fastener.

FASTEN IT

Fastening systems have continued to be a major track safety component

By Jennifer McLawhorn, Managing Editor

Away of securely attaching ties to rails, fasteners serve as a fundamental component of track infrastructure. As the focus of this Vendor Product Spotlight, an array of fastener systems is described in detail along with how they have been implemented in various projects across North America.

voestalpine Railway Systems Nortrak (“Nortrak”) has grown its lineup of rail xation systems for freight and transit customers by focusing on the intersection of solving customer challenges and leveraging Nortrak’s design capabilities and manufacturing assets. e result has been the development of a portfolio of

concrete ties, rubber vulcanized direct xation fasteners, and resilient fastener components for special trackwork and mainline applications. In 2023, Nortrak expanded its vertically integrated system solutions by adding a new rubber vulcanization production line at its Pueblo, Colo. facility. is expansion enables the company to manufacture all components for rubberbonded direct xation fasteners, including ductile iron components from its Decatur, Ill. foundry. According to John Stout, SVP of Fixation Strategy and Development, “Having in-house production and tooling capabilities allows us to control production pace, ensure quality consistency, manage

costs, and foster innovation.” Over the past ve years, more than thirty direct xation fastener designs were developed, including a new series tailored for special trackwork with high attenuation properties. is addition gives the company three series of special trackwork DF fasteners, with stiness ranging from 58-140k pounds per inch, catering to various transit operating environments, including those necessitating ground-borne noise and vibration mitigation.

LA Metro recently installed Nortrak’s High Attenuation Direct Fixation Fasteners on the 5.1-mile underground D Line Extension Project spanning Beverly Hills,

May 2024 // Railway Track & Structures 21 rtands.com

Photo Credit: Progress Rail

FASTENING SYSTEMS

time with less material handling and fewer personnel required for the same work. e DF Block System improves life expectancy of DF units, reduces maintenance, and provides a signi cant initial installation savings as compared to the 30+ year-old top-down construction technique. With manufacturing facilities located strategically around the globe, Progress Rail produces fastener and trackwork solutions to the highest standards. For comprehensive information, Progress Rail encourages readers to visit its website. From rail anchors and all styles of clips to DF and ballast mats to turnouts, li frogs and crossovers for transit, commuter and HAL applications, Progress Rail provides a full range of fastening and special trackwork solutions.

Century City, and Westwood. While supplying various special trackwork assemblies for the design-build project, Nortrak faced a unique challenge at the Wilshire/La Brea Station area. e installation of the #10 DXO required an integrated system design approach between the turnouts and the xation system to provide for operational safety, with special geometry to t the tunnel section and provide vibration damping to minimize the impact on the surrounding buildings and structures in an area. In addition, it had to ensure operational safety amidst challenging subsoil conditions, high seismic activity, and dense urban surroundings. is marked the second DXO installation in Los Angeles utilizing Nortrak’s higher attenuation special trackwork DF fasteners, following the initial installation as part of the Regional Connector Project in 2021using the Medium Attenuation Series of fasteners to meet the 75-100k pound sti ness range targeted by the project engineers. Nortrak emphasized the adaptability of its fastening systems to match surrounding conditions, providing operational and

maintenance exibility while maintaining a consistent footprint. Recent projects in Seattle, Phoenix, Baltimore, Salt Lake City, and Los Angeles showcase its commitment in special trackwork direct xation fasteners.

Progress Rail, a Caterpillar company, supplies a full line of fastening systems for heavy haul and transit railways, o ering one of the broadest fastening product portfolios in the world. By delivering innovative options, such as the e-Style Clip, the resilient Loadmaster DF for timber ties, and the ADFF55 high attenuation direct xation fastener, Progress Rail supports its customers’ e orts to improve e ciency, service quality and cost. For example, the DF Block System drastically improves the quality of direct xation fastener installations for both standard and high attenuation units. e product eliminates the risk of irregular support surface conditions, honeycombs in the concrete, and improper elevation setting of the concrete embedded insert. On the Los Angeles Westside Purple Line Section 1, the DF Block system has reduced installation

In view of rising rail temperatures due to extreme temperature uctuations, lateral track stability is becoming even more important. To avoid speed restrictions or even track closures, infrastructure components that are “more forgiving” are becoming real problem-solvers for operators. Vossloh o ers the key to long-term higher track availability with its physically optimized M-Generation tension clamps. eir innovative geometry with the outwardly curved spring arms o ers both contact points that are further apart on the rail base and a greater robustness against external in uences, such as vibrations due to rail irregularities or higher rail temperatures. Depending on the components used within the rail fastening assembly (e.g. elastic or sti rail pad), the natural frequency of the M-Generation clamps is always signi cantly higher compared to the well-proven W-tension clamps and other fastening systems, making them more resistant to high-frequency loads and enabling more elastic system solutions in parallel. In addition, the M-Generation clamps lead to a multiplication of the torsional resistance and thus signi cantly improve the lateral track stability of the concrete tie ballasted track structure without having to disturb the ballast. erefore, more and more national railways around the world are considering de ning the M-Generation as standard. e stability of the track can be further increased in areas of particular buckling risk if the M-Generation tension clamp is combined with the HTR angled guide plate. With the increased safety that comes with improved lateral track stability, railroads are better equipped to con dently operate at track speed even in extreme weather conditions.

22 Railway Track & Structures // May 2024 rtands.com FASTENING SYSTEMS

Vossloh o ers the key to long-term higher track availability with its physically optimized M-Generation tension clamps.

Photo Credit: Vossloh

Having been in business for over 100 years, Lewis Bolt track fasteners cover all sections of track starting with screw spikes, frog bolts for turnouts, bridge hardware and drive-on rail anchors. At its facilities in La Junta, CO, Lewis Bolt produces a variety of Screw Spikes, including the latest G2™ Evergrip and Permagrip Spikes. Other items produced are the Recessed Head Timber Screws and Drive Spikes for grade crossings. Lewis bolt produces a variety of hardware for rail bridge construction such as the Sealtite Hook Bolt and the innovative & patented Quick-Set Hook Bolt System. Lastly, Lewis bolt produces Drive-On Rail Anchors for a variety of sizes of rail. Its latest innovation is the Patented Viper-1® drive-on anchor.

George Apostolou, VP, Sales told RT&S that the Viper-1® has been adopted by a Class I, and that the “Viper-1® exceeds American Railway Engineering and Maintenance-of-Way Association (AREMA) Chapter 5, Section 7.1.4 requirements and has a minimum holding power of 9,000 pounds versus 6,000 pounds (AREMA 7.1.4, Part B).” Additionally, the Viper-1® has a

much higher re-application rate than any current anchors on the market. e anchor can be removed and reapplied multiple times because of improved sti ness in the design of the anchor jaw. Another key bene t of the Viper-1® is the larger bearing surface against the tie. e Viper-1® boasts 75% more bearing surface than standard drive-on anchors. is results in increased tie life preventing movement and damage to the tie surface. In addition, Viper-1® o ers an increased life cycle that is designed to last the life of the rail. With two dedicated stand-alone facilities that manufacture a variety of anchors domestically, Apostolou says “Lewis Bolt continues to work on incremental product improvements for customers and has been looking internally to make its manufacturing process more e cient.”

L.B. Foster Company has designed, tested, and quali ed over 60 unique direct xation fastener assemblies to meet its customer’s speci cation and installation requirements across the majority of transit authorities in North America. ese fastener designs incorporate varying design and performance characteristics including

rail seat height, anchor locations, lateral adjustment, cant requirement, sti ness and resiliency, noise and vibration mitigation, improved electrical isolation, as well as performance coatings. In the past year, it supplied the Model F25 fastener, a 1:40 cant fastener which accommodates a 6” rail base, through Graham Commuter Rail Solutions to the Davenport Diamond project in Toronto. L.B. Foster supplied the Model F51, a resilient plate/plate replacement for wood tie applications, to the Maryland Transit Administration for the Purple Line project. It supplied special trackwork direct xation fasteners coated with a porcelain performance coating which o ers superior corrosion resistance in areas of track that experience water intrusion. rough collaborative e orts between its Pittsburgh R&D and Atlanta Transit Products Engineering and Laboratory teams, it leverages advanced technologies such as nite element analysis and state-of-the-art test equipment. By combining these resources with its extensive industry knowledge, L.B. Foster continuously strives to introduce new additions to its product lines.

May 2024 // Railway Track & Structures 23 rtands.com FASTENING SYSTEMS

VIPER-1® The next generation Drive-On Rail Anchor For more information contact us at sales@lewisbolt.com www.lewisbolt.com | (800) 328-3480 | Domestic manufacturers of railroad fasteners since 1927

CYBERSECURITY IN RAIL

Protecting rail infrastructure from all angles

By Jennifer McLawhorn, Managing Editor

An emerging area of infrastructure maintenance, RT&S is focusing on cybersecurity as it relates to the rail industry. For the first vendor product spotlight in this arena, what follows is a grouping of emerging technologies in the cybersecurity sector.

Like many industries, the rail industry is innovating. New technology can help improve operational efficiency and

reduce costs, but these digital initiatives also can expose rail networks to new risks and vulnerabilities. Critical infrastructure like railways are increasingly a prime target for cyberattacks. In addition to defending against new threats, rail operators also must adhere to industry-specific regulatory requirements and be able to integrate new technologies with their existing operational processes. Conventional operational

technology security solutions often fail to address the unique challenges of the rail industry, which operates within a specialized ecosystem. Without the visibility, operating, and safety factors the rail industry requires, operators can be exposed to disrupted rail operations, unplanned downtime, and serious financial and safety impacts. Recognizing the unique risks to the rail industry, Cylus and Fortinet have joined forces

24 Railway Track & Structures // May 2024 rtands.com

Photo Credit: Shutterstock/ Yurchanka Siarhei

CYBERSECURITY & INFRASTRUCTURE

to provide a comprehensive cybersecurity solution tailored to the rail industry and all its operational environments. With the solution, rail operators can proactively manage evolving cyber risks, helping ensure safety, reliability, and uninterrupted service.

e operational rail tech cybersecurity solution combines the Cylus rail tech security platform, CylusOne, with Fortinet FortiGate Next-Generation Firewalls

(NGFWs), FortiSIEM security information and event management, and FortiManager, which provides centralized management of Fortinet devices from a single console. CylusOne protects the entire operational rail tech environment using a combination of the CylusOneprobes and CylusOne platform. e CylusOne probes monitor networks for rolling stock, signaling, and all other operational rail system deployments. e CylusOne platform receives data from CylusOneprobes across the entire rail operational environment and provides analysis of network communication, threat detection capabilities, live asset inventory, and SIEM integration. e CylusOne-FortiGate integration passively and virtually segments the network and divides railway network assets into security zones. With the CylusOne-FortiManager integration, rail operators can oversee network security using FortiManager centralized management and automation features. And the CylusOne-FortiSIEM integration provides security alerts, customized rail incident response playbooks, and access to rich rail asset and network context.

Recently, a leading rail-based transportation supplier with approximately 20,000 route miles wanted to enhance the e ciency of its security operations

center by expediting threat identi cation and response. e company had already replaced existing rewalls with FortiGate NGFWs at its corporate locations and looked to replace its existing network and application monitoring solution with advanced threat detection, threat investigation, and application and network performance monitoring. A er a successful proof of concept, the company seamlessly integrated Fortinet security products integrated with CylusOne to improve visibility and simplify management, making it easier for analysts to perform their tasks. Cylus told RT&S that it encourages readers to “visit Cylus.com or Fortinet.com/transportation.”

As the transportation industry undergoes a digital transformation, the need for robust cybersecurity measures is apparent. The integration of smart technologies, digital operations, and interconnected systems has undoubtedly brought forth new efficiencies and safety protocols yet is has also laid bare the sector to unprecedented cyber risks. Security solutions are provided by the Center for Critical Infrastructure Protection (CCIP), an ally in safeguarding transportation infrastructure. Through ENSCO ’s collaboration with the Transportation Technology Center

May 2024 // Railway Track & Structures 25 rtands.com

Photo Credit: Shift5 CYBERSECURITY & INFRASTRUCTURE

The Shift5 GPS Integrity Module provides sophisticated, multi-faceted detection and alerting for GPS spoofing attempts. While this example covers aviation, the same functionality works with rail.

(TTC) in Pueblo, Colorado, CCIP safeguards critical infrastructure across diverse sectors, including freight, railroads, passenger transit, railway suppliers, manufacturers, and more. ENSCO’s team specializes in cyber and physical security training, assessment, testing and modeling, and protection, delivering tailored services to enhance defenses against a myriad of threat actors. By identifying and mitigating vulnerabilities in personnel, processes, and technologies, CCIP ensures comprehensive protection against all potential attack vectors.