Vol. 119, No. 1 Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189 Telephone (470) 865-0933 Website www.rtands.com

DAVID C. LESTER Editor-in-Chief dlester@sbpub.com

KYRA SENESE Managing Editor ksenese@sbpub.com

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102 Telephone (212) 620-7200 Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher MARY CONYERS Production Director NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director MICHELLE ZOLKOS Conference Director

JONATHAN CHALON Publisher MARY CONYERS Production Director NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 402-346-4740

Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

One of the dilemmas of modern media is the coverage of news stories. By “modern media” I‘m referring to the model most magazines and newspapers use – a website with a daily news feed and a print publication. The dilemma is to what extent does it make sense to print news stories in the magazine when they were on the website news feed a month earlier? No one wants to read news that’s a month old. Unless, however, they haven’t seen it at all.

There are arguments for both sides. Some folks prefer to get their news from printed material. Others prefer web news. Those preferring print media may not have had time to read all the stories on the web feed, and the print magazine provides an opportunity for them to catch up. On the other hand, many people look to websites for news stories while looking to print for longer, in-depth feature stories. The likely reality is that most readers take a hybrid approach – i.e., looking to both the web and print for news stories.

Some publications offer robust web news along with strong print news. In most cases, the same stories appear in both, and it’s up to the reader to decide

which source they want to read. Other publications put most of their news on the web and offer only a smattering of stories in print. Then, other publications put all news on the web and none in print. For the past several years, RT&S has been in the last category.

That approach is changing with this issue, but not in the way you may think. We will continue to feature our daily news feed on the web, posting four to six stories per day and more if events warrant. As I mentioned in this space last month, we’re adding coverage of railroad structures and communication and signals to our web story lineup. Our aim is to give readers the best coverage of rail infrastructure and maintenanceof-way issues you’ll find anywhere.

The print edition, though, has a new section called “NewsWatch.” Each month, NewsWatch will provide a photograph and short briefing on several stories we believe you should watch throughout the year, just as we are. These stories are evolving over the medium to long run, and updates about them will appear in our website news feed as warranted. These updates will be regular news stories and will not be marked in any way to indicate they’re among our “top” stories. And there will be a new set of stories in NewsWatch each month.

When you’re inundated with hundreds of news stories from various sources every day, even those just on RT&S, NewsWatch will provide a handy guide to the top stories we’re covering and build value during the year, enhancing the value of your subscription. We hope you find it helpful.

DAVID C. LESTER Editor-in-ChiefMatthew Dick, P.E., Chief of Strategy & Development, ENSCO, Inc., Pueblo, CO

Jeffrey Baca, Sr. Staff Cyber Systems Engineer, ENSCO, Inc., Pueblo, CO

Erin Plemons, Staff Cybersecurity Engineer, ENSCO, Inc., Pueblo, CO

Cybersecurity has become one of the top terms enveloping our daily lives over the past several years. We have all heard about the data breaches involving stolen credit card numbers and personal information associated with parts of our economy that don’t seem to have much connection to the rail industry, such as the 2013 Target Corporation cyberattack or the 2017 Equifax data breach. However, cybersecurity hit close to home with the 2021 Colonial Pipeline ransomware attack which left one of the largest pipeline operators in the United States forced to suspend operations for five days causing cascading issues of gas shortages in the southeastern portion of the U.S. and a presidential state of emergency declaration. It is still difficult to wrap our minds around the faceless attackers behind these incidents and because of that, it’s still difficult for us as an industry to perceive how a cyberattack can happen in the rail sector. But let’s pull back the curtain to have a better look at the players behind cyberattacks.

What we find is that there is a wide range of threat actors all with varying capabilities, funding and motivation. On the low end of the scale are the “Script Kiddies,” these are individuals who have gained enough experience to cause damage but have very little funding to execute their reckless pursuit of hacking for

fun. An example of this was the 2008 Trams in Łódź, Poland.(1) Łódź is a city with approximately 700,000 people with a tram network of 124 kilometers (77 miles). A local fourteen-year-old boy had monitored his city’s tram switches enough to devise a remote to allow him to control the switches at his whim. His cyber joy ride resulted in a tram derailing at a switch, causing it to collide into another passing tram. The Łódź tram switches were operated by the tram driver using an infrared (IR) light signal from the tram to the receiver at the switch, directing which way to line the switch. This enables the tram driver to choose their direction, instead of a dispatch operations center. This inquisitive young boy observed the IR light coming from the trams in his city and then focused his time on modifying a television remote to use its IR emitter to mimic the same signals coming from the trams. It is unknown how long the Łódź IR switch control system had been in place before this Script Kiddie discovered its vulnerability. But it’s now evident that the obscurity that kept the system safe for years, was eventually exposed.

Moving up the threat actor list, we find Cyber Criminals and Organized Crime. These two groups have more capabilities and funding to back their ultimate pursuit of financial gain. Ransomware is one of the largest cybersecurity threats right now in that it is powerful and compelling to convince its victims to hand over

money. Ransomware is malware that works similar to a virus or worm that, once it enters a computer network, it infects and then encrypts the victim’s files with a key only known to the attackers. The computer network lockdown may be as severe as what Colonial Pipeline experienced that preempted their operations for five days. The victim is presented a no-win situation on a computer screen message giving them instructions on where to send the money (typically in bitcoin), when to have it delivered by, and the repercussions if they don’t send the money, including release of the company’s sensitive data to the dark web or public sites, or in some instances, complete deletion of the data. The cybercriminal organization behind the Colonial Pipeline attack was an Eastern European group named DarkSide. In the end, Colonial Pipeline paid the ransom, totaling $5 million U.S. Dollars. To this day, the criminals behind the attack have not been brought to justice and the members of the DarkSide organization claim to have disbanded, but it is easy to believe that they have only slipped back into the shadows to plan their next payday.

If cybercriminals looking for money isn’t enough, there are additionally Hacktivists and Terrorist Groups that are motivated purely for political or ideological purposes. An example hacktivist organization that has made the international news goes by the name Anonymous. Members of Anonymous are easily identified by the Guy Fawkes masks they wear with a distinctive mistletoe moustache

Cybersecurity is a challenge for all industries, including railroads

and spear goatee popularized by the graphic novel, V for Vendetta written by Britain’s Alan Moore. A real-life example of hacktivism was in January 2022 with a Belarusian Hacktivist group named Cyber-Partisans which crippled the Belarusian state railway using ransomware to negotiate the release of fifty political prisoners and prevent the movement of Belarusian and Russian troops to the Ukraine border.(2) Lastly, at the top of the threat actor food chain are, Nation States which have extremely advanced capabilities and a seemingly endless amount of funding to meet their mission of geopolitical gains through cyber destruction. It is well documented that the U.S. and its allies are routinely targeted from Nation State attacks associated with Russia, Iran, China, and North Korea. In June 2022, the state railway of Lithuania and in April 2022, the state railway of Romania, were both attacked with Distributed Denialof-Service (DDoS) attacks of Russian origin for the purpose of crippling their operations in retaliation for their nations’ support of Ukraine.(3) DDoS is a brute-force cyber tactic where countless bot programs are used to overwhelm an organization’s network by issuing excessive communication requests or similar transactions causing the network to fail and cease to operate. The events mentioned are obtained via open-source information. It is believed that the number of attacks on rail transportation infrastructure

globally is much higher, but the events remain restricted or classified by national government agencies for security reasons.

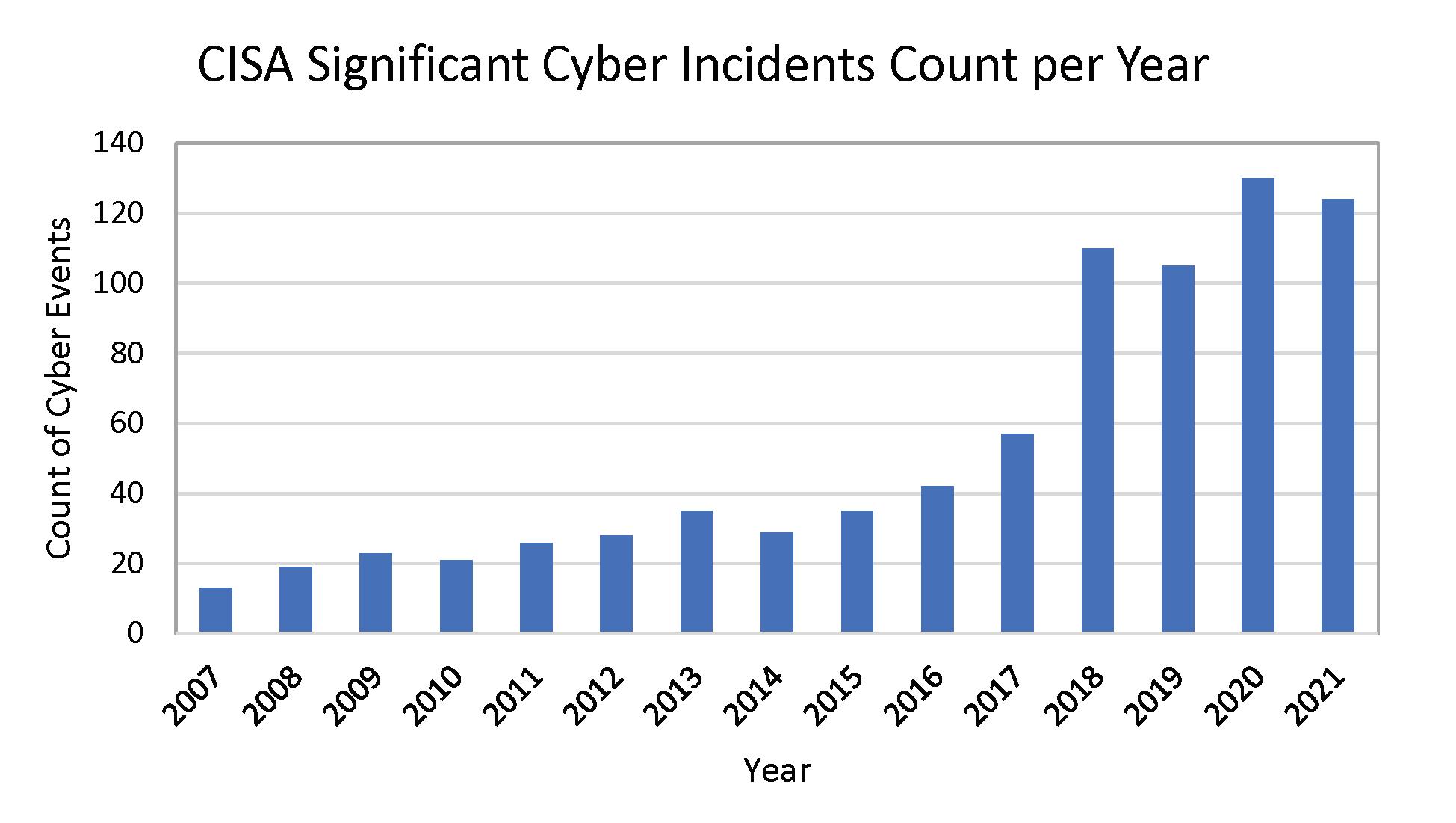

In response to the worldwide growing cyber threats, the U.S. government formed the Cybersecurity and Infrastructure Security Agency (CISA). CISA is an agency within the Department of Homeland Security (DHS) that serves many functions including monitoring cyberattacks on critical infrastructure in the U.S. and abroad. Figure 1 depicts data available from the CISA website where they record cyber incidents on critical infrastructure exceeding $1 million U.S. Dollars in damages. (3) Clearly, as shown in the chart, cyberattacks are becoming more prevalent. The most recent cyberattack on a railway occurred on November 3rd, 2022, at Danske Statsbaner (DSB) also known as the Danish State Railways.(4) DSB is the largest railway operator in Denmark with approximately 220,000 passengers per day. A subcontractor of DSB that provided a critical element of their train control system inside the cab, stated that their server testing environment had become compromised by criminal hackers prompting the subcontractor having to shut down their production servers causing the DSB train operations to come to a standstill. The investigation is still ongoing. It is clear that train control and signaling systems are susceptible, but what about track

and structures? We don’t like to surmise about possible vulnerabilities publicly, but I ask you to do this thought experiment: Please think of how much of your daily responsibilities are dependent on computers. Include your staff, your equipment, or support organizations, your suppliers, everything. Now imagine those computers suddenly not working. What is the operational impact? What is the cost? Computers have enabled a safety and efficiency level that propelled the rail industry into what it is today. The conclusion is: it needs to be protected.

At this point, it may seem that the current state of cybersecurity is an unconquerable mountain to climb. It can certainly seem overwhelming, but we can protect ourselves and continue to obtain continued economic and safety growths. The realization we must all come to is that cyberthreats are as ubiquitous as rain falling from the sky. We protect our infrastructure against rain with a risk-based approach. We assess the risk and apply controls to mitigate that risk. Both water control practices and cybersecurity controls are a needed part of railway business operations. You may be surprised to learn that the Transportation Security Administration (TSA) isn’t only in airport security lines. They are throughout the U.S. transportation industry ensuring security of railways pipelines. In response to the growing cyber threats to railways, the TSA has recently released two

Security Directives and an Advance Notice of Proposed Rulemaking (ANPRM). Security Directive 1580-21-01 released on December 31, 2021, was focused on laying the basics for railways to report cybersecurity incidents to CISA and to coordinate with the TSA. Security Directive 1880/82-2022-01 was released October 24, 2022 and is focused on railways providing their Cybersecurity Implementation Plan (CIP) which details their cybersecurity protection level. Additionally, on November 30th, 2022, the TSA released the ANPRM in Federal Register Vol. 87 No. 229. In the ANPRM, the TSA has a series of questions to railways to ensure a better understanding of the status of cybersecurity in the rail sector. The increased focus of the TSA is also on other transportation modes including the pipeline industry and corresponding the rise of cyber incidents shown in Figure 1 and the national impact that they have as shown following the Colonial Pipeline ransomware attack.

So how does the Transportation Technology Center fit into cybersecurity? ENSCO, as the operator of the Federal Railroad Administration’s TTC, also serves as cybersecurity experts for the Department of Defense (DoD) aiding in various areas including providing subject matter expertise in the rapidly–changing cybersecurity landscape that includes satellite networks in space under the Air Force and the newly formed Space Force. ENSCO has leveraged our expertise

supporting DoD’s critical space infrastructure and systems and opened the door for us to also aid organizations responsible for critical infrastructure in both government and the private sector. In 2022, ENSCO’s cyber experts trained over 1,000 students ranging from hands-on courses at the Transportation Technology Center to in-depth, concentrated courses for executives. To continue to serve organizations responsible for railway cybersecurity, the TTC is in the process of launching the Center for Critical Infrastructure Protection (CCIP) located at the TTC. The CCIP’s purpose is to aid organizations in their mission for cybersecurity through training, assessments, testing and modeling, and protection. A unique capability of the CCIP is our ability to do penetration testing (pen testing) with railway Operating Technology (OT). OT is the operational counterpart of Informational Technology (IT). Where IT includes servers and laptops, OT includes signaling systems, locomotives, tampers, etc. Penetration testing is designed to identify gaps in cybersecurity before the threat actors do, using tactics, techniques and procedures that if done in an operational environment may impact the confidentiality, integrity or availability of the system. Losing operational capability in the revenue generating environment is something no railway wants to have happen; not to mention the reputational cost if things go badly. That is where the TTC aids the industry by providing a separate operating environment for OT such that it can be fully pen tested without

interfering with a railway’s revenue service. The CCIP will take advantage of the existing Positive Train Control test bed, fiber optics track network, and upcoming two test beds that will support testing of the rail industry SCADA and Control systems at the TTC. More information about the CCIP will be coming out in 2023 so stay tuned.

Cyber threats are growing, but the railway industry can learn from other industries that have already been living with this reality for years. To reduce risk and ensure continuity of operations, the railway sector must prepare for the inevitability of cyberthreats through training and adopting best practices. By understanding vulnerabilities and preparing responses, the railway sector can take steps to safeguard its critically important role in their nation’s infrastructure.

1. https://www.theregister.com/2008/01/11/ tram_hack/

2. h ttps://www.zdnet.com/article/ belarusian-activists-launch-cyberattack-against-railway-in-protest-of-dictatorship-russian-troop-surge/

3. https://csis-website-prod.s3.amazonaws. com/s3fs-public/221212_Significant_ Cyber_Events.pdf?5RVe0CglJK0dJqGjblIJ eHORD95oJ_QW

4. https://www.reuters.com/technology/ danish-train-standstill-saturday-causedby-cyber-attack-2022-11-03/

Culvert and Storm Drain Inspection

Part 1: February 22 | 2:00 - 4:00 PM ET

Part 2: February 23 | 2:00 - 4:00 PM ET

4.0 PDH | Presenters: Matthew C. Richie & Shawn R. Coombs, PE

This two-part course presents methodology for rapid condition evaluation of culverts and buried bridges that establishes a rating system to prevent failure/ washout. The system also provides a framework for managing assets, reducing risk, and prioritizing maintenance and rehabilitation.

To REGISTER or for more information, visit www.arema.org

WARMING have all been put forward as reasons why the southern California Coast has eroded for several years. Impacting infrastructure, homes, highways, and rail lines, this challenge has played havoc with railroads trying to maintain normal schedules along this line.

The amount of line involved is about 350 miles between San Diego, Los Angeles, and San Luis Obispo. Bloomberg reported in October that three key areas are under serious threat from the erosion – the Del Mar section, on which RT&S has reported

extensively, an area near Santa Barbara, along with one near San Clemente. Bloomberg also reported that Amtrak and Metrolink service through most of this area has been suspended until short-term solutions can be implemented. This issue also impacts BNSF freight service in the area, which provides a critical rail links to the Camp Pendleton Marine Base and the San Diego Naval Base.

Earlier this year, Tropical Storm Kay battered the Southern California coast, and Bloomberg reported that “geotechnical sensors detected that the fragile landscape

MANY U.S. COMMUTER RAIL AND TRANSIT SYSTEMS have worked diligently to make heavy repairs to their infrastructure over the past two years, leveraging the pandemic’ reduced service and low ridership to create extended maintenance-of-way windows that allowed repairs to be made more quickly than usual. For example, during the past year, several transit systems have either closed early each day or closed for several days to complete

of sand and rock underneath the tracks near San Clemente was moving as much as nearly half an inch per day.”

Several short-term and long-term engineering projects are either under way or being considered to address the issue, including one initiated by the San Diego Association of Governments (SANDAG) to move the line inland and route it to an underground tunnel near San Clemente.

Railway Track & Structures will continue to follow and report on this story as new developments occur.

infrastructure projects. This allowed crews to make repairs within several days when they would ordinarily require years to complete.

Even though the pandemic has eased, and ridership is approaching pre-pandemic levels, watch for more work being done during extended m/w windows. Passengers are somewhat inconvenienced as agencies provide other arrangements, but the time required for the work is slashed dramatically.

AMTRAK IS IN BETTER FINANCIAL POSITION because of the federal government’s stimulus spending initiated by the Biden Administration. There are two key items to watch. First, how will Amtrak spend its money? Second, will the concerns expressed in Amtrak’s Office of Inspector General report earlier this year come to fruition?

Amtrak-owned Northeast Corridor infrastructure needs significant repair and replacement. This can be accomplished if Amtrak spends its money wisely. In March of last year, the company’s internal Office of Inspector General (OIG) warned that it wouldn’t be easy for Amtrak to handle the amount of money coming its way. For example, the OIG stressed that transparency and accountability, applying rigor to the capital planning process, and protecting the money from fraud, waste, and abuse is paramount. While these may seem to be common sense guidelines, Amtrak has not received this much federal support at one time since it was formed on May 1, 1971. Therefore, accounting, planning, and monitoring tools must be put in place to ensure the money will not be lost to careless spending and even malfeasance.

The OIG reported in December, for example, that some Amtrak employees have been selling high-security keys (physical keys) that could pose a risk to Amtrak from bad actors. Roll Call reported that “Amtrak employees have tried to sell ‘high-security keys’ used to operate rail switches and other critical sensitive infrastructure,’” posing security risks to passengers and crews, according to the OIG and court documents.

In a report released Dec. 14, the OIG faulted Amtrak’s lack of centralized guidance and security systems for the keys, saying it has “limited controls governing the distribution, management, tracking and retrieval of its high-security keys.” While this is not a misuse of stimulus money, it is an example of what the OIG sees as a general lack of controls at the agency.

THE FUTURE OF TRUE HIGH-SPEED RAIL (HSR), which is generally defined as 200+ m.p.h., is uncertain in North America, particularly in the U.S. A lot of time, money, and effort has been expended on the Los Angeles-San Francisco California High-Speed Rail project, yet the logic of the construction sequence has caused some to question the plan’s wisdom. Moreover, the Texas Central project is, for the moment, at least, dead in the water.

HSR projects have been planned for and discussed for years, but we don’t have much to show for it except a few “higher-speed” (up to 110 m.p.h. on routes shared with freight) services and Amtrak’s Washington-New York-Boston Northeast Corridor (NEC),

which is not true HSR as it also hosts conventional intercity and commuter trains, and some freight. Dedicated systems are very expensive, and while most Americans seem to support the concept of HSR, it’s not certain they will support the staggering costs—unlike Europe and Asia, which have invested hundreds of billions in HSR since the mid-1960s.

RT&S will closely follow HSR developments and continue reporting on them. The fastest train to ply North American rails will likely remain for at least the immediate future is Amtrak’s NEC Acela service, with new Alstom TGV-based equipment debuting in 2023.

The NRC honored exceptional railway contractors and suppliers in early January at its 2023 annual conference in Boca Raton, Florida. Congratulations to the top performers in these categories.

Projects of the Year - Walsh Construction Co. II, LLC (Walsh) won the NRC’s Large Project of the Year award (greater than $10 million) for its work on the Terminal Railroad Association of St Louis’ (TRRA) Merchants’ Bridge Reconstruction project. The complex, innovative project replaced three existing twin-track trusses spanning the Mississippi River dating back to 1890.

Walsh constructed four, 80-foot-tall cofferdams into the riverbed to create seismically improved foundations and encase the existing masonry pier structures in concrete. The bridge spans were replaced individually during seven-day track outages using a unique gantry lifting system.

TRRA Chief Engineer Eric Fields praised Walsh’s exceptional performance for skillfully managing a complex major project that required extensive coordination to deliver under budget and ahead of schedule.

Bottom Line Co. won the NRC’s Small Project of the Year (less than $10 million) for its work to upgrade 26 railroad bridges on three subdivisions of Watco’s South Kansas & Oklahoma Railroad (SKOL). Funded in part with a Consolidated Rail Infrastructure and Safety Improvements (CRISI) program grant, the project modernized and revitalized the regional railroad.

Watco commended Bottom Line by noting it “delivered on time, under budget, and with extremely high quality and safety.” Watco also referenced the contractor’s expertise in planning, coordination, communication, project oversight, and material delivery. Bottom Line did an “outstanding job,” affirmed Watco, “we can’t say enough about the work quality.”

Field Employee of the Year - The NRC honored Hamilton Construction Project Manager Chad Hummel for his service to railroad clients in the Pacific Northwest. Chad has a well-established reputation for dedication and excellence in the field, as

noted by two clients.

“Having Chad as the project manager is a blessing because I know I’m in good hands. He is second to none when it comes to safety. Chad leads by example and his people respect him,” reports Daniel Ramirez, BNSF project engineer.

“Chad is all-business. He will drop everything he’s doing to address all quality and safety issues, (Chad) is someone everyone can count on … His customer service skills are top notch,” says Steven Chase, resident engineer with HNTB.

Innovation in Technology - FTS Tools LLC. is the first-place winner of the NRC’s new award recognizing ways member companies are using technology to enhance safety and operations in our industry. In response to requests by Class I railroads for safer and greener high-performance tools, FTS Tools successfully developed battery-operated tools with comparable productivity, durability, and power as hydraulic options.

Throughout the development process, FTS Tools collaborated with railroad and contractor clients to secure input and to test new tools. The results are earning praise from trackworkers for eliminating hoses, hazards, injuries, and excessive set-up time, while enhancing safety with lightweight, purposeful designs.

The NRC honored Harsco Rail with the second-place award for its TX16 production/switch tamper. After two years of field operation, the tamper is delivering significant reductions in set-up and shutdown time along with more than a 30-percent increase in tamping productivity.

The tamper features a range of other innovations that are producing safety and operating advantages, including improved operator visibility and safety, greater efficiency in switches, expanded productivity windows, and automated, highly accurate technology.

Check out more details about these award winners as well as our Safe Contractors of the Year and Hall of Fame inductees on the NRC’s website at www.nrcma.org.

A manifest freight from Laurel, Mont., to Pasco, Wash., crosses the NP-built bridge on August 14, 2022, when the new bridge was nearing structural completion. Steel piers with concrete caps were installed beneath both ends of the existing bridge during 2008-09.

are rolling on BNSF’s new bridge near Sandpoint, Idaho

An Exciting Endeavor

BNSF’s Assistant Vice President of Engineering Services & Structures, Craig Rasmussen, speaks with pride and enthusiasm about the new bridge over Lake Pend Oreille in the northernmost section of Idaho. The new bridge parallels an existing bridge that has been in service since 1904 and will help eliminate a single-track bottleneck that has become increasingly detrimental to traffic flow on BNSF’s Northern Corridor. Rasmussen told RT&S, “I get excited about these kinds of projects. This is a major efficiency play for BNSF that people have been thinking about for a long time.” As the chief engineer on this project, he oversaw every phase of the bridge’s planning, construction, and opening.

The original bridge construction reflects the methods of the time (1905), including masonry piers that rest on driven timber pile foundations. The spans are typically 50 ft. riveted deck plate girders. In the modern era, for the new bridge, the foundations are comprised of steel pipe where six pipe piles form each bent (pier) with a concrete cap. Also, each span for the new bridge is nominally 100 ft. long using precast concrete members. BNSF selected the 100-ft. length because it was a multiple of the existing 50-ft. spans and will keep the pier alignment consistent across the lake for the benefit of boaters.

BNSF started with initial civil work in August 2019 with site prep and grading. The bridge work began in Mary 2020 and opened in November 2022 (vs. the initial schedule of July 2023.)

The railroad hired a firm to conduct ultrasonic sonar testing to measure the pipe pile’s bearing capacity. Rasmussen said the “design depth proved correct for most of the piles, but a few needed adjustments because the lake bed is sandy instead of rock.” One of the neat things about the construction is that the pipes used for the piles are, of course, hollow and fill with sand as they are driven into the lakebed. This minimizes the displacement of the lakebed and provides a strong foundation for the bridge.

Monitoring equipment attached to the existing bridge looked at three dimensions to ensure no movement occurred during the construction of the new bridge. BNSF continually monitored the bridge in three dimensions so it wouldn’t have any rotation of the piers or any settlement. There was not enough movement in the old bridge to be concerned about, and it wouldn’t have even been noticeable without monitoring equipment. At some point, the company will

replace parts of the existing bridge, but not anything with the substructure because all the tests and monitoring indicated that the substructure is in good shape, and it will only need to replace the spans. The railroad will complete work on the existing bridge in July, and the railroad will be able to take advantage of the new alignment.

Railroad journalist and Railway Age Contributor Bruce Kelly told RT&S, “Some might say that BNSF’s second bridge across Lake Pend Oreille and the double track extension to Sandpoint Junction have been a halfcentury in the making. Following the 1970 merger that formed Burlington Northern, various route segments from the Midwest to the Pacific Coast deemed redundant were either sold off, leased (in the case of Montana Rail Link (MRL), or abandoned. Between Spokane and Sandpoint, BN phased out the use of the former Great Northern main line as a through route, leaving portions of it in place only for branch line service. In 1972, BN completed major bridge and track projects in Spokane and Sandpoint that channeled all through traffic from either direction onto one line between those two cities: the former Northern Pacific, which earned the nickname ‘The Funnel.’”

Rasmussen adds, “a single bridge over Lake Pend Oreille created challenges, and you’d often have trains stopped at both ends of the bridge waiting to get across.” The existing bridge required regular maintenance, including replacing both ends of the bridge. Traffic over the route was heavy, so finding maintenance windows to work on the existing bridge was challenging.

When asked about the significant milestones of the project, Rasmussen said, “well, the first milestone is to conclude that building the new bridge is the right thing to do. This was a major investment, a major outlay of capital, and a ‘forever’ type of decision. Next, getting permit approvals took years.” Rasmussen added, “Surprisingly, there were adversaries of the project for reasons that didn’t have anything to do with the bridge itself.” Fortunately, there were a lot of supporters of the project, too. Permitting is a process where BNSF, or any railroad, must bear down and stick with it.

The next step was to choose the construction method, then bid it out to a contractor. BNSF selected Ames Construction, then mobilized all the equipment needed for the project. Significant milestones included setting the last piece of the foundation and installing the last span. Throughout most of the project, the

railroad was in “production mode” because the construction work consisted mainly of adding spans.

Reflections on Sandpoint from Bruce E. Kelly, Railway Age Contributing Editor BNSF’s opening of its second bridge over Lake Pend Oreille coincides with the 50th anniversary of predecessor Burlington Northern’s “Funnel” between Spokane, Wash., and Sandpoint, Idaho. This route was so named because it channeled the traffic of multiple BN predecessor routes onto a mostly single-tracked main line, all in the name of economizing and network rationalization.

A byproduct of the BN merger of 1970, The Funnel came into being in 1972 after BN built new bridges and track structure in Spokane to consolidate its former Great Northern; Northern Pacific; and Spokane, Portland & Seattle lines together onto the NP’s doubletracked, elevated corridor through the heart of the city. Also in 1972, BN built a connecting track in Sandpoint – complete with a new bridge over Sand Creek – to join its former GN and NP lines, with all trains getting funneled onto the former NP from there to Spokane.

The ex-GN main line between Spokane and Sandpoint saw several miles of track removed near its midsection. What remained of the GN north of Spokane became a BN (now BNSF) branch line, while the ex-GN

track west of Sandpoint spent several years as a BN branch before the majority of it was handed over to short line Pend Oreille Valley Railroad (POVA).

The first real effort to widen The Funnel came in 1982, when BN expanded a siding at Algoma, Idaho, into a nearly 7-mile stretch of dual main line. During 1997-98, successor BNSF extended the Algoma double track to 9 miles and linked up other sidings on The Funnel to create two additional double track segments, both approximately 15 miles long. Another 11 miles of second main was added in 2017, followed by 2.5 miles in 2019. This left The Funnel with only two segments of single-track main line: approximately 4 miles between Irvin and Otis Orchards, Wash., and roughly 2 miles between East Algoma and Sandpoint Junction.

For the last half-century, Sandpoint Junction has been The Funnel’s often-congested choke point where trains off the former GN and NP main lines from the east converge.

In recent years, it’s been a place where coal, grain, oil, or manifest trains coming west via Montana Rail Link often wait while BNSF trains between the Pacific Northwest and the Midwest traverse the existing single-track bridge over Lake Pend Oreille. Not that the distance between East Algoma and Sandpoint Junction is significant, but the authorized speed of only 25 mph over the ex-NP

bridge for loaded freight and intermodal trains, and 35 mph for empty trains and passenger trains, can produce a long wait for any trains that are holding on either side of the bridge for their turn to cross.

Completing BNSF’s second bridge over Lake Pend Oreille is a significant step toward uncorking some clogging that has troubled traffic flow through Sandpoint Junction. The new bridge will bear the burden of The Funnel’s business during much of 2023 while the older NP-built bridge undergoes much-needed renovations, some of which were completed during 2008-09.

During 2023, BNSF will also remove the existing platform at Sandpoint’s historic, former NP depot – which supports Amtrak’s Empire Builder – to make room for a second main track between Sandpoint Junction and the two Lake Pend Oreille bridges. Amtrak riders will ultimately use a new platform that will be constructed on either end of the depot, which has served as Amtrak’s only scheduled passenger stop in all of Idaho since the annulment of The Pioneer in 1997.

Having two main tracks in service from Sandpoint Junction clear to Otis Orchards will indicate that The Funnel, as we’ve known it, is coming to an end. Only four miles of single track will remain on Spokane’s outskirts, and the railroad will add a second main in the future.

Wabtec/Nordco

Wabtec/Nordco

When holding a short section of rail in your hand or working on the installation of welded rail, you may ask yourself how can something this heavy and this hard break in two like a matchstick. The answer is the forces from heavy and fast trains are so powerful that even the most robust rail can develop problems and break. Of course, this usually takes some time after rail installation, but the weak points are numerous on both jointed and welded rail.

First, the rail could be weak in spots because of a manufacturing error. While

quality control is essential for top-drawer rail manufacturers, errors can occur. Second, proper attention to inspection and maintenance is required to identify issues such as rolling contact fatigue, spike and tie weaknesses, and narrowing or widening of standard gauge. Both visible and invisible to the naked eye, surface wear can develop into a transverse fissure. This almost guarantees a derailment if the fissure eludes detection before the next train comes along.

Weld quality is a critical aspect of rail condition that railroads must inspect frequently. Workers must weld long sections to form continuous welded rail

when installing this type of rail. Over time, inspectors may find the weld is not holding up properly due to poor quality materials or improper welding technique. If a bad weld doesn’t receive immediate attention, it can fail and cause a major accident.

Jointed rail requires more time and effort to inspect properly. In addition to the issues that need monitoring on welded rail, jointed rail has joint bars and bolts that need careful inspection. Failure of either can create a gap between the rail sections or failure of the joint altogether if a hardware issue is allowed to fester.

Rail flaws have been around since societies built railroads. There were

numerous reports of rail breaks in the “modern” era of rail science, starting around the first half of the 20th Century. Elmer Sperry, the founder of today’s Sperry Rail Service, developed a track recorder car outfitted with gyroscopes in the 1920s that provided railroads with a much better

method of track inspection than simple visual assessment. However, it was not until he developed induction systems to find internal rail defects that the science of track inspection took off. Sperry developed ultrasonic testing in the 1950s, and the latest breakthrough in rail inspection is

using eddy current on the surface of the rail. Eddy current looks for cracks in the rail surface that could lead to a transverse fissure, and the results help determine the details of rail grinding programs.

Sperry is just one company that offers rail flaw detection services. For example, Wabtec’s Nordco division has expanded its use of ultrasonic systems in the global market, where high-speed internal flaw detection is a relatively new concept. Like most providers, they offer railbound and hi-rail vehicles and portable systems equipped with defect detection technology. The company recently announced its development of a Guided Wave based system designed to augment and eventually surpass traditional bulk wave ultrasonic inspection. This new technology will be able to inspect at significantly faster speeds over longer distances with full rail coverage. Dave Stanton, Vice President and General Manager of Nordco Inspection Technologies, told RT&S that “We can’t wait to demonstrate the future of rail flaw detection and show how [our] rail industry guided wave technology will [improve the

science of rail inspection].”

Over time, rail detection service providers have migrated much of their work from railbound vehicles, such as the Sperry Rail Car, to Hi-Rail trucks that carry tremendous technology for track inspection on a convenient truck that can access the railroad at any railhighway crossing. While railbound cars remain in use for some inspection services, the Hi-Rail truck has become the dominant platform.

One company that uses Hi-Rail trucks is Ensco. Its system is the Ultrasonic Rail Flaw System (URFS) and is compatible with either Hi-Rail or railbound vehicles. Ensco told RT&S that URFS combines several technologies, including machine vision, rail profile measurement, and zerospeed track geometry measurement. The company also has a patented Rail Surface Imaging System and Joint Bar Imaging System that provides a robust assessment of overall rail integrity. The rail industry has introduced continuous testing, and the market has shifted toward technologies facilitating higher-speed, continuous

testing. Nevertheless, traditional stopand-verify methods remain the preferred method in the market for many railroads.

When people hear the name Herzog, they may think of ballast and ballast trains, as this is a significant business for the company. However, it offers rail flaw detection services as well. One offering is the company’s turnkey Continuous Testing (CT) services. This system provides comprehensive data collection/ analysis, and Herzog’s Hi-Rail testing vehicles service every track environment. The company uses multiple inspection technologies on a single vehicle, allowing it to tailor inspections to each client to meet their unique needs.

Herzog’s CT equipment and data processing include:

• SmartProbe technology – Detection instrumentation inside the wheel probe accelerates processing time. Fourteen transducers per rail provide [strong] signalto-noise ratio and comprehensive coverage with 24 UT channels;

• Geometry system (add-on feature)

– Assesses measurements along the track,

including gauge, alignment, curvature, surface, cross-level, super-elevation, warp, and twist;

• Joint bar inspection (add-on feature)

– High-definition line scan cameras integrate detailed images of both the gauge and field side of the rail joint bar into the UT software data stream to quickly identify missing bolts, broken fasteners, or cracks in the fishplate;

• Historical record – Each indication is tracked across survey runs as a Repeat Marked Object and prioritized based on its expected severity. Analysts can refer back to previous inspection scans and photo imagery to monitor growth;

• Pattern recognition – UT data is analyzed using machine learning algorithms that automatically identify and classify various types of anomalies or defects that may be present in the rail.

Troy Elbert, Herzog’s Senior Vice President of Quality Assurance and Rail Flaw Detection told RT&S that “Herzog has invested significant resources in advancing monitoring and inspection solutions.”

Keeping the railroad clear of vegetation on, around, and above the tracks is an ongoing maintenance challenge. Today, more than ever, railroads and vendors are working on ways to keep roads vegetation-free in the most environmentally responsible way possible.

As suppliers continue to aim for increasingly efficient and cost-effective vegetation management strategies, RT&S reports on the industry’s latest offerings in mulchers, aerial equipment, and herbicidal vegetation-related tools.

Starting from the top The Asplundh Railroad Division, known for its on-track mechanical and herbicide vegetation management services, offers

core railroad services, including on- and off-track spraying, tree and brush cutting, and emergency storm response. Asplundh’s specialized equipment resources—from Hi-Rail aerial lifts, canopy cutters, and chippers to high-capacity spray trains— are designed to maximize efficiency, lower budget spend, and reduce track time for MOW activities.

Asplundh Brush Control is prepared to handle tasks from large-scale erosion control projects to installing gateways and culverts. Asplundh Engineering Services provides engineering design, support of land use permitting, Federal Transit Administration state-of-good-repair assessment, traction and signal infrastructure design, renewable energy infrastructure

installation, and more.

The company’s ArborMetrics solution offers environmental assessments for new and existing rail lines. The Rotor Blade offering uses helicopters for aerial tree removal and trimming, line inspection, and emergency storm response, including wildfire response.

Asplundh’s employees are trained, certified, and up to date on environmental best practices.

“No matter the task, Asplundh company strives to complete every job without injury and in compliance with government and industry regulations and standards,” Asplundh told RT&S.

The company adds that it understands railroads’ challenges, from vegetation

75HRT mounts on a Hi-Rail equipped 58,000 lb. GVW commercial truck chassis. The trimmer boasts an independent airconditioned cab with joystick controls that operate the chassis and the trimmer while on rail. The HRT can propel down the track in a matter of minutes to clear limbs and overgrown brush and then legally selftransport on public highways to the next job site, negating the need for trailer transport, Progress Rail said.

Progress Rail’s Kershaw® Model 60 is a multi-purpose machine platform that workers can transform from a heavy-duty snow fighter into a ballast regulator for roadway ballast profiling or heavy-duty on-track brush cutting. For adaptability and controlling vegetation, the Model 60 is available with different styles of cutter heads to tackle multiple jobs as required.

Progress Rail, a Caterpillar company, told RT&S it manufactures heavy-duty Kershaw® equipment for vegetation management. Kershaw machines enable railroads to perform brush clearing, tree trimming, and general vegetation control so crews can access track or rights-of-way quickly and easily.

Fecon BH40EXC Bull Hog Mulchers feature a 36-inch wide working width and 18 cutting tools which shred vegetation up to 10 inches in diameter, making them ideally suited for clearing vegetation along railroads.

products are sold internationally through equipment dealers and distributors.

Industry-Railway Suppliers, founded in 1966, is the distribution representative of Supertrak machines and a North American distributor of American Railway Engineering and Maintenance-of-Way Association (AREMA) track tools, abrasives, heavy railroad equipment, work equipment wear parts and mechanical shop tools.

Supertrak is a 30-year CAT- authorized OEM building custom machines for vegetation management, heavy-duty trenchers, custom utility trucks, cable retrieval equipment, and monorail work tractors. Supertrak specializes in small-footprint, yet high-performance, upfitted machines, Industry-Railway Suppliers told RT&S.

The Supertrak SK170RR Hi-Rail Excavator has a CAT313 Hi-Rail platform. It has a single 170-horsepower engine, dedicated high flow with reversing fans, and multifunctionality. The Hi-Rail has four-wheel drive and four-wheel brakes.

Industry-Railway Suppliers told RT&S, “The SK170RR maintains huge power in a small package with zero permit required for transportation due to its compact size, making it well suited for land clearing and vegetation management in remote places.”

maintenance projects to new infrastructure construction, and has the resources to do the job.

When tree trimming becomes a needed step in vegetation management, Progress Rail told RT&S that it has several SkyTrim tools to tackle the job. The SkyTrim 75G3 Hi-Rail for specialized vegetation control, the SkyTrim 75 HRT for rail applications, the Klearway 500HD Industrial Brush Cutter for overgrowth and the Model 60 On-Track Brush Cutter are among the tools in its arsenal.

Explicitly developed for railroad applications, the Kershaw SkyTrim 75HRT is an insulated telescopic tree trimmer featuring a hydraulic-driven 24” rotary saw blade with a 75-foot reach. The SkyTrim

Fecon’s forestry mulchers weigh in at 3,200 pounds and can withstand the harshest conditions and remote operations, the company said. Fecon describes its mulchers as versatile enough to handle the wide variety of vegetation typically encountered along railways, including standing and felled trees, heavy brush, vines, limbs, thickets, and more.

A variable displacement motor provides ample torque to keep the mulcher working when others bog down. The motor can power 15 to 45-ton excavators, with 30-75 gpm of hydraulic flow available, Fecon told RT&S. Rugged carbide teeth provide hundreds of hours of maintenance-free service, and other tool options are available. Fecon’s BH40EXC mulchers are routinely paired with Hi-Rail excavators, Hi-Rail Gradall carriers, and more.

Established in 1992 near Cincinnati, Fecon manufactures the Bull Hog® as well as tracked carriers and tractors, a full range of attachments, and other equipment for vegetation management. The company’s

When Industry-Railway Suppliers’ SK170RR is upfitted with the heavy-duty hydraulic-powered Bull Hog mulcher, it can quickly clear large trees and heavy brush along railways or in preparation for new track. The low-maintenance design of the mulcher supports tool durability with optional knives or carbide teeth, the company said. The SK170RR also offers a custom variable displacement motor and three rotor choices to match application needs.

Chemical agents for good Corteva Agriscience offers two compatible tank-mix partners that work together to improve the efficiency of railroad vegetation management programs and mitigate the associated costs: TerraVue® herbicide and Piper® EZ herbicide.

In the past, applications featuring TerraVue herbicide effectively controlled more than 140 broadleaf weeds and brush species to keep tracks clear of plants that threaten the integrity of railway infrastructure, Corteva Agriscience told RT&S.

Vegetation managers can broaden the weed-control spectrum by mixing TerraVue herbicide with Piper EZ herbicide. As a suspension concentrate containing

Keeping the Right-ofWay Vegetation-Free with Environmental Responsibility

flumioxazin and pyroxasulfone, Piper EZ enhances pre- and early postemergence control of annual weeds and grasses that threaten the integrity of railway infrastructure, including marestail, hairy fleabane, kochia, and glyphosate-resistant

Italian ryegrass.

Considered essential components of total vegetation control programs, TerraVue herbicide and Piper EZ herbicide work in tandem to address problematic species and prevent the emergence of germinating

seedlings throughout the growing season, Corteva Agriscience told RT&S. By strengthening postemergence control after targeted species emerge early in the year, railroad vegetation managers can achieve bare ground results that improve everything from railway mechanics and visibility to drainage, slippage prevention and more.

As an added benefit, this residual control can minimize retreatment requirements and associated costs, resulting in significant savings that benefit annual resource management.

Corteva Agriscience has also announced a three-year partnership with the habitat conservation group Pheasants Forever and Quail Forever to enhance habitat within various non-crop areas and help improve plant and wildlife biodiversity throughout the U.S. The partnership aims to strengthen the Rights-of-Way & Energy (ROWE) Habitat Program, which Pheasants Forever and Quail Forever launched to assess and improve habitat, biodiversity, and conservation on transportation, railway, oil and gas, electric and solar corridors across

Track Safety Standards, contains the Track Safety Standards, Subparts A-F, for Classes of track 1-5. The standards cover general information, Roadbed, Track Geometry, Track Structure, Track Appliances and Track-Related Devices, and Inspection. Includes Defect Codes. Updated March 21, 2022.

BKTSSAF Track Safety Standards, Subparts A-F $11.95 Only $10.75 for orders of 50 or more!

FRA Part 237 establishes Federal safety requirements for railroad bridges. This rule requires track owners to implement bridge management programs, which include annual inspections of railroad bridges, and to audit the programs. Part 237 also requires track owners to know the safe load capacity of bridges and to conduct special inspections if the weather or other conditions warrant such inspections. Updated March 21, 2022.

BKBRIDGE Bridge Safety Standards $8.95 Only $8.00 for orders of 50 or more!

Railway Educational Bureau 1809 Capitol Ave., Omaha NE, 68102 www.RailwayEducationalBureau.com

This reprint includes the FRA's Railroad Workplace Safety Standards addressing roadway workers and their work environments. These laws cover such things as: personal protective equipment, fall protection, and scaffolding for bridgeworkers; and training issues. Also includes safety standards for on-track roadway vehicles. Updated March 21, 2022

BKWRK

Railroad Workplace Safety $11.50 Only $10.35 for orders of 50 or more!

The Track Safety Standards Calculator is a must for anyone who works on track. This slide rule type calculator contains many of the details for Classes of track 1- 5. Deviation from uniform profile and from zero cross level. Difference in cross level. Compliant with part 213.

BKTCAL

Track Calculator $11.50 Only $10.75 for orders of 50 or more!

Updates from the Federal Register may be supplied in supplement form.

U.S.A. CAN

UP TO $10.00 $6.10 $11.00 10.01 - 25.00 10.50 18.25 25.01 - 50.00 14.30 23.85 50.01 - 75.00 16.05 29.75

the country.

“Corteva Agriscience shares common goals with Pheasants Forever and Quail Forever,” said Damon Palmer, marketing leader of U.S. Specialties for Corteva Agriscience. “We want to improve land stewardship to create healthier, diverse ecosystems that connect fragmented landscapes for significant habitat benefits. Together, we’ll work to help industry professionals enhance everything from biodiversity and conservation efforts to cost efficiency, community engagement, and ESG actions.”

The partnership expects to help industry practitioners create sustainable habitat management plans with the potential to improve up to five million acres of the estimated 35 million acres of rights-of-way and energy corridors in the U.S. This would be a 14% improvement in total rights-of-way and energy acres nationwide.

“There are plenty of reasons for focusing on rights-of-way and energy as an untapped habitat resource, but this incredible opportunity also resonates deeply for partner

Happy New Year! I trust you enjoyed the holidays and are well on your way of achieving your New Year’s resolutions. If you are looking for a way to “pay it forward” as one of your resolutions, I suggest considering a contribution to the AREMA Educational Foundation. Your contribution will help provide scholarships to engineering students who demonstrate a strong interest in railway engineering. You can find the details on the AREMA homepage by selecting the DONATE tab in the top ribbon.

This past November, for the first time, I attended the 24th Annual Railroad Environmental Conference (RREC) hosted by the Rail Transportation and Engineering Center (RailTEC) at the University of Illinois Urbana-Champaign. For many years I have heard from my environmental engineering peers about this popular conference. The RailTEC team did a terrific job. There were over 430 registered attendees, over 45 program presentations, nearly 50 exhibitors, and 21 sponsors. Topics included regulatory compliance, environmental permitting and planning, remediation, environmental management systems, wastewater management, and incident management. The annual Association of American Railroads (AAR) Environmental Excellence Award, the highest honor for environmental professionals in the railroad industry, was presented during the luncheon on the first day. Congratulations to this year’s winner James Taylor, Asst. Director Advanced Energy Innovation, with BNSF Railway.

In recent years RailTEC and the RREC

Planning Committee has placed a new focus on sustainability and resilience and its evolving importance to the rail industry. Over the two-day conference there were 15 presentations on sustainability and resilience. One panel discussion included most of the Class 1s, the AAR, the Federal Railroad Administration (FRA), and Amtrak who each summarized their respective sustainability programs and then responded to questions. This abundance of involvement says something about not only where our industry is going but also the demand for knowledge in this technical space.

On the first evening AREMA Committee 13 – Environmental hosted their annual dinner to recognize the committee membership’s role in supporting the RREC. The keynote speaker was Alissa Yakali, Sustainability and Supplier Relations Manager with Honda Development & Manufacturing of America. She spoke on Honda’s collaborative work with suppliers to improve their sustainability. They invite their suppliers to voluntarily work with them to find win-win approaches to progress their goals. Honda’s approach could serve as a great model for the railway industry. If you would like to learn about any of the environmental engineering fields or need to better understand how sustainability relates to your role, I recommend attending the 2023 conference on November 14-15 at the iHotel Illinois Conference Center in Champaign, Illinois. The RREC organizers would like to encourage more participation from the passenger rail (commuter and transit) and rail supply sectors so that their perspectives and expertise can be shared.

I was fortunate to meet Dr. Chris Barkan who leads the conference and is the director of RailTEC. Dr. Barkan made it clear that the conference will continue to be responsive to new railroad interests, direction, and issues - especially sustainability and related concepts. The conference has seen many changes – with significant attendance growth, an expanded program, changes in the principal topics reflecting the evolving priorities of the railroad environmental community, and a substantial expansion in the number of sponsors and exhibitors. Another objective of the conference is to strengthen the bonds within

the railroad environmental community, which I can say I witnessed while attending. High quality program/presentations and the networking opportunities among railroad professionals are the two most common compliments received from past attendees – I left the conference with the same opinion.

The RREC organizers see sustainability as a critical focus for the rail industry and will be seeking to support this effort in the coming years. Dr. Barkan believes virtually all areas covered by the AREMA Technical Committees have an impact on the railroad’s collective sustainability efforts. In talking with the railroads, he has learned to interpret sustainability more broadly than just the environment and to include their customers, supplier processes, community relations, employees, and shareholders. Ongoing discussions are envisioned with AAR Environment & Climate Committee (E&CC) and AREMA Committee 13 about how RREC can best serve the evolving sustainability objectives of the industry.

RailTEC has the largest rail engineering curriculum and most extensive academic rail research program of any university in North America, with roots dating back to the latter 19th Century. The RailTEC students help with RREC and doing so gives them developmental opportunities and provides them with contacts in the industry. This year, Kari Harris, the AREMA Committee 13 Chair promoted student engagement at the Committee dinner, which the conference organizers hope to expand upon in the future. I congratulate Dr. Barkan and his team on the excellent rail program they have developed. Many highly trained and motivated graduates of this program are working for the rail industry – including several who work on my team at BNSF.

AREMA is a supporter of RREC and Committee 13 helps support the annual conference planning. This has been a strong and beneficial relationship for AREMA, one we wish to continue to build upon in the coming years. I hope to see you at the 25th Annual RREC in 2023.

Enjoy your journey until next month.

TRENT M. HUDAK AREMA President

Only a few short weeks until the AREMA Railway Roadbed & Ballast Symposium, February 6-8, in Kansas City, MO. To check the latest information about hotel reservations, speakers, presentations, registration, and more, visit www.arema.org.

Did you know we have a wide variety of On Demand education for learning on your time? Browse our most popular webinars, seminars, and Annual Conferences to earn your PDH credits on the go. Visit www.arema.org to start your On Demand learning today.

Don’t miss out on the conversation happening in AREMA’s Member Forum. The Member Forum connects you with other Members allowing you to send

messages, start conversations, and more. See what everyone is talking about today: https://community.arema.org/home.

If you’re looking for a podcast to binge, listen to AREMA’s Platform Chats. It features guests from every aspect of the railway industry. Come ‘roll with AREMA’ available on all of your favorite listening services.

Do you want to generate leads, promote your company and reach a target audience? Sign up for sponsorship at the AREMA 2023 Annual Conference to be held October 1-4 in Indianapolis, IN. Please visit www.arema.org or contact lmcnicholas@arema.org for more information on sponsorship investment opportunities.

Order the NEW, 2022 edition of the Portfolio of Trackwork Plans . This edition features new plans and specifications that relate to the design, details, materials and workmanship for switches, frogs, turnouts & crossovers, crossings, rails and other special trackwork. Order online now at www.arema.org or contact publications@arema.org for more details.

NOT AN AREMA MEMBER?

JOIN TODAY AT WWW.AREMA.ORG

CONNECT WITH AREMA ON SOCIAL MEDIA:

JAN. 19

Committee 16Economics of Railway Engineering & Operations Virtual Meeting

FEBRUARY 9 - 10

Commitee 1Roadway & Ballast Kansas City, MO

MARCH 19 - 21

Committee 11Commuter & Intercity Rail Systems Los Angeles, CA

JAN. 19-20

Committee 8Concrete Structures & Foundations Orlando, Fla.

FEB. 22-23

Committee 7Timber Structures Russellville, Ariz.

MAY 15 - 17

Committee 5 - Track Dallas, TX

JAN. 31-FEB. 1

Committee 15Steel Structures Atlanta, Ga.

FEB. 22-23

Committee 9Seismic Design for Railway Structures Las Vegas, Nev.

MAY 16 - 17

Committee 15 - Steel Structures Pueblo, CO

FEBRUARY 9

Committee 9 - Seismic Design for Railway Structures Las Vegas, NV

MARCH 19

Committee 17 - High Speed Rail Systems Los Angeles, CA

JUNE 15-16

Committee 8Concrete Structures & Foundations Washington, D.C.

Joining a technical committee is the starting point for involvement in the Association and an opportunity for lifelong growth in the industry. AREMA has 30 technical committees covering a broad spectrum of railway engineering specialties. Build your network of contacts, sharpen your leadership skills, learn from other members and maximize your membership investment. If you’re interested in joining a technical committee or sitting in on a meeting as a guest, please contact Alayne Bell at abell@arema.org.

For a complete list of all committee meetings, visit www.arema.org.

hands-on maintenance-of-way experience. As I continued to attend my student chapter’s speaker events and field trips, I became interested in the design side of the industry, which led me to pursue an internship and then postgraduate track design position at Gannett Fleming.

AREMA: In 2019, you were the recipient of the Committee 1 - Roadway & Ballast Scholarship and in 2020 you received the Committee 5 - Track Scholarship. How did this impact you while you were at IIT?

hike when I can on the weekends.

AREMA: If you could tell your younger self one thing, what would it be?

Over the years, the AREMA Educational Foundation through the generosity of its donors has provided hundreds of thousands of dollars in scholarships funds to students interested in a career in railway engineering. Over the next few months, we’ll be checking in with a few of these recipients to see how these funds have helped them and where they are in their careers now.

This month we’ll be checking in with Daniel Rappoport.

AREMA: Daniel, you started your rail career as a student at the Illinois Institute of Technology (IIT). You were also the President of the Student Chapter at IIT and one of its founding members. What made you want to create a Student Chapter at your university?

DANIEL: My main motivation for starting the AREMA Student Chapter at the Illinois Institute of Technology was that there was interest in railroad engineering in the student body and even in faculty, but no structured organization to connect them with each other and to the industry. The AREMA Student Chapter became that link, helping bring railroad companies on campus via speaker events and students onto railroad property via field trips, and foster mentoring relationships between students and faculty with railroad experience.

AREMA: How did participating in a Student Chapter guide you to your career goals?

DANIEL: I got my first college internship directly through AREMA, landing an interview with Union Pacific at the 2018 AREMA Conference & Expo that led to an incredible summer of riding freight and commuter trains and gaining

DANIEL: Being a recipient of the Committee 1 - Roadway & Ballast Scholarship and the Committee 5 - Track Scholarship eased the financial burden of my student loans, helping me get through school with less worry and letting me focus my time on my classes, career, and AREMA Student Chapter. It also helped me feel welcome to begin a career in the railroad industry, showing that we are an industry that takes care of its own - even our newest members.

AREMA: What is your biggest accomplishment during your career at Gannet Fleming?

DANIEL: My favorite part of being a railway track designer is getting to work on multidisciplinary teams where I get to represent track design in a project with many other components, such as signals, structures, and traction power infrastructure. An example of this was being tasked to coordinate the assembly of interdisciplinary typical sections through a complex Northeast Corridor facility - combining my group’s track design with the drawings of every other discipline, and then working to identify, communicate, and resolve space proofing conflicts that arose from all the overlaid layers. This task was a big learning opportunity for me on how to balance advocating for the design decisions of my group with the need to keep the best interests of the overall project as the main priority.

AREMA: Outside of your career, what do you do with your spare time?

DANIEL: Outside of my career, I love to cook and bartend in my spare time because it’s a fun way to destress after work away from a screen and makes life more colorful. I also weightlift to help manage my stress levels, and

DANIEL: I would encourage my younger self to seek understanding of why people come with perspectives and opinions they have. Breaking out of my hometown bubble to attend university in Chicago and now working with teams across North America at Gannett Fleming has taught me a lot about how to collaborate with people from many different backgrounds, and I wish I had gotten this exposure earlier in life after being raised that one way of life is absolutely correct and others are not.

AREMA: What advice would you give to students interested in starting a Student Chapter at their university? Or contemplating a career in the rail industry, in general?

DANIEL: The advice I would give a student who wants there to be an AREMA Student Chapter at their university is that you are qualified to start it! As a freshman, getting involved in a railroad-focused student organization was just a pipe dream for me until an upperclassman with student org leadership experience talked some sense into me - getting over the imposter syndrome was a bigger hurdle than the actual logistics and paperwork of getting it moving. I made plenty of mistakes throughout the years of running the chapter, but the only reason I even got a chance to make them and most importantly, learn from them, was because I was pushed to start the process.

My advice to a student contemplating a career in the railroad industry is that relationships are everything. While landing your first internship or job with zero prior railroad experience may seem daunting, you can start chipping away at your goal by getting to know the industry’s professionals, who are often eager to share knowledge and create opportunities for you, especially when you approach them with a desire to learn as opposed to transactionally as “I am going to use you to get a job”. Use all of AREMA’s resources to make these connections! Beyond attending the events of a student chapter, there are lots of opportunities such as signing up for the mentorship program, utilizing the membership directory, and attending conferences and seminars.

railroad track and transit experiences from New York City and Honolulu, provided invaluable knowledge and contacts. This experience will support my future development in the rail industry as the City and County of Honolulu Department of Transportation Services’ Track Compliance Officer at the Honolulu Driverless Metro. I obtained new ideas on how to improve customer experiences from a holistic approach found in Singapore going from design to maintenance, in order to run a safe, reliable, and resilient rail system.”

The AREMA Educational Foundation has been instrumental in introducing college students to the opportunities and rewards of working in our industry, but in 2014, the Foundation created a learning opportunity for railroad and transit employees new to the industry and that are also members of an AREMA committee. Called the “Watford Fellowship,” the program provides a monetary award to attend the annual Watford Conference for Design Professionals covering the conference registration fee and incidental travel expenses. The 2022 Fellow, Yifeng Mao, P.E., Track Compliance Officer at Honolulu’s DTS, attended the 54th Conference in Singapore. AREMA’s connection to the Watford Group began in 1994 when all members of Committee 6, Railroad Facilities, Utilities and Buildings, were invited into the US Watford Group delegation and became eligible to attend Watford Conferences. Currently, participation is open to any AREMA member.

Hosted by the Singapore Land Transport Authority (LTA), the agency responsible for the design, construction and ownership of the railway network, the conference featured 25 presentations from railroads, infrastructure management companies, and consultants from three continents. Presentations looked at large station redevelopments, systems integration, innovation, and problem solving in a variety of contexts that embraced both facilities and rolling stock. The program also included technical tours to several intermodal hubs and a pre-opening visit to the newest phase of the Thompson East Coast Line’s Napier Station. Yifeng remarked, “The opportunity to converse with other rail designers from around the world, and to be able to share my own

The Watford Group was created in 1963 by British Railways to encourage the exchange of ideas and promote design excellence among its operating regions; other countries were invited to join and subsequently, over twenty nations are now eligible to send delegates to the annual Watford Conference. The meetings mostly occur in Europe, but have been hosted in Japan and the United States and integrate all aspects of rail transportation. Yifeng further noted, “I am excited to bring back some of the experiences in Singapore, especially lessons learned from meeting with LTA’s Track SME team. This will enhance my involvement in AREMA Committee 4 Rail and in my Committee 5 role as vice chairman of the Special Track Work Design subcommittee. I am better prepared to continue to improve America’s rail industry and legacy through ‘built on tradition, and thriving on innovation’ along with Watford’s motto, ‘good design is good business’.”

The 2023 Watford Fellowship program will be valued at approximately US$1500.00. The three-day conference is scheduled for Fall 2023 in England and will feature presentations and field trips addressing all aspects of railway planning, design, and construction with an emphasis on buildings, bridge and tunnel structures, and operational maintenance. The selected person must also make a technical presentation at the conference. The Watford Conference fellowship grant includes the conference registration fee, four nights of hotel, and incidental travel expenses during the conference not included in the registration fee. Most of the conference travel and meals are included in the registration fee. The only added cost to a North American would be air travel (could be done using airline rewards) and incidental expenses before and after the conference. Eligibility

is limited to AREMA committee members that have less than 15 years of rail industry experience and are direct employees of a railroad, transportation agency, or employed as a consultant assigned on a near full-time basis to a single railroad or transportation agency. The AREMA Educational Foundation will post the rules and applications for 2023 on its website in February with applications due in April. For additional information about the Watford Group, contact Thomas Cornillie, Chairman of the US Watford Group Delegation, at publications@ThomasCornillie.com.

AREMA is focused on your education and helping you advance in the railway industry. AREMA’s webinars provide Professional Development Hours (PDH) to serve your educational needs.

Culvert and Storm Drain Inspection Webinar

Date: Wednesday, February 22Thursday, February 23

Time: 2:00-4:00 PM ET Each Day

PDH Hours: 4

AREMA also offers On Demand education available to watch at any time at your convenience. Find courses like the newly released AREMA 2022 Annual Conference, the Bridge Inspection Webinar series, and even FREE Webinars for Members.

These courses are comprised of recommended practices and relevant accumulated knowledge from subject matter experts in the railroad industry. They are not intended as a regulatory qualification.

To register for these webinars and our other On Demand education, please visit www.arema.org.

marketing@arema.org

Reber.Acacia@ensco.com victor.soucy@epiqmachinery.com amcclain@hrsi.com bbrundige@sb-reb.com

JONATHAN CHALON

Publisher (212) 620-7224 jchalon@sbpub.com AL, KY, TN, CHINA JONATHAN CHALON (212) 620-7224 jchalon@sbpub.com

CT, DE, DC, FL, GA, ME,MD, MA, NH, NJ, NY, NC, OH, PA,RI, SC, VT, VA, WV, CANADA: QUEBEC AND EAST, ONTARIO JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

AMERICAS, EUROPE, ASIA, AFRICA, AUSTRAL ASIA NORTH AMERICA - CT, DE, DC, FL, GA, ME, MD, MA, NH, NJ, NY, NC, OH, PA, RI, SC, VT, VA, WV, AND EASTERN CANADA. EUROPE EXCEPT GERMANY, AUSTRIA, GERMAN SPEAKING SWITZERLAND, EASTERN EUROPE, ITALY, AND ITALIAN-SPEAKING SWITZERLAND. ASIA EXCEPT JAPAN AND CHINA.

ITALY, ITALIAN-SPEAKING SWITZERLAND

DR. FABIO POTESTA

Media Point & Communications SRL Corte Lambruschini

AR, AK, AZ, CA, CO, IA, ID, IL, IN, KS, LA, MI, MN, MO, MS, MT, NE, NM, ND, NV, OK, OR, SD, TX, UT, WA, WI, WY, CANADA: ALBERTA, BRITISH COLUMBIA, MANITOBA, SASKATCHEWAN HEATHER DISABATO(CHICAGO OFFICE) (312) 683-5026 hdisabato@sbpub.com

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

GERMANY, AUSTRIA, GERMAN-SPEAKING SWITZERLAND, LATVIA, LITHUANIA, ESTONIA, POLAND, CZECH REPUBLIC, SLOVAKIA, HUNGARY, SLOVENIA, CROATIA AND SERBIA Simone and Simon Fahr Breitenbergstr. 17 Füssen 87629 Germany Tel: +49 8362 5074996 sfahr@railjournal.com

Corso Buenos Aires 8 V Piano, Genoa, Italy 16129 +39-10-570-4948 Fax: +39-10-553-0088 info@mediapointsrl.it

JAPAN KATSUHIRO ISHII

Ace Media Service, Inc. 12-6 4-Chome, Nishiiko, Adachi-Ku Tokyo 121-0824 Japan +81-3-5691-3335 Fax: +81-3-5691-3336 amkatsu@dream.com

IRJ PRO AND CLASSIFIED ADVERTISING SALES

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

This section has been created solely for the convenience of our readers to facilitate immediate contact with the RAILWAY TRACK & STRUCTURES advertisers in this issue.

The Advertisers Index is an editorial feature maintained for the convenience of readers. It is not part of the advertiser contract and RTS assumes no responsibility for the correctness.

Readers may have noticed that the title of this news/opinion column changed from “Last Stop” to “From the Dome” in the Dec. 2022 issue. There are two reasons for this. First, I think it’s a neat header. Second, it has sentimental value for me and, perhaps, a subset of our readers. I hope you will allow me some personal reflections on this change.

Many of you may be familiar with the magazine Passenger Train Journal. This magazine began publication in 1968 when it became clear that America’s rail passenger system was facing significant changes, resulting in the formation of Amtrak, which began operation on May 1, 1971. During the 1970s, the private American passenger train was struggling, and the nation’s Class I railroads weren’t doing too well either. Tough economic regulation by the Interstate Commerce Commission kept freight rates so low that roads couldn’t earn their cost of capital. Several went bankrupt, and most of the ones that didn’t were barely hanging on. The resolutions to these problems were, as most know, the development of Amtrak in 1971, which removed the burden of running passenger trains from the Class

Is, and the passage of the Staggers Act in 1980, which changed the landscape for how railroads do business and was the key milestone leading to the financial success and “rebirth” of the private freight rail industry.

Three companies published Passenger Train Journal until 1996, when it ceased